Heating control system and method based on top separated control polycrystalline silicon ingot casting furnace

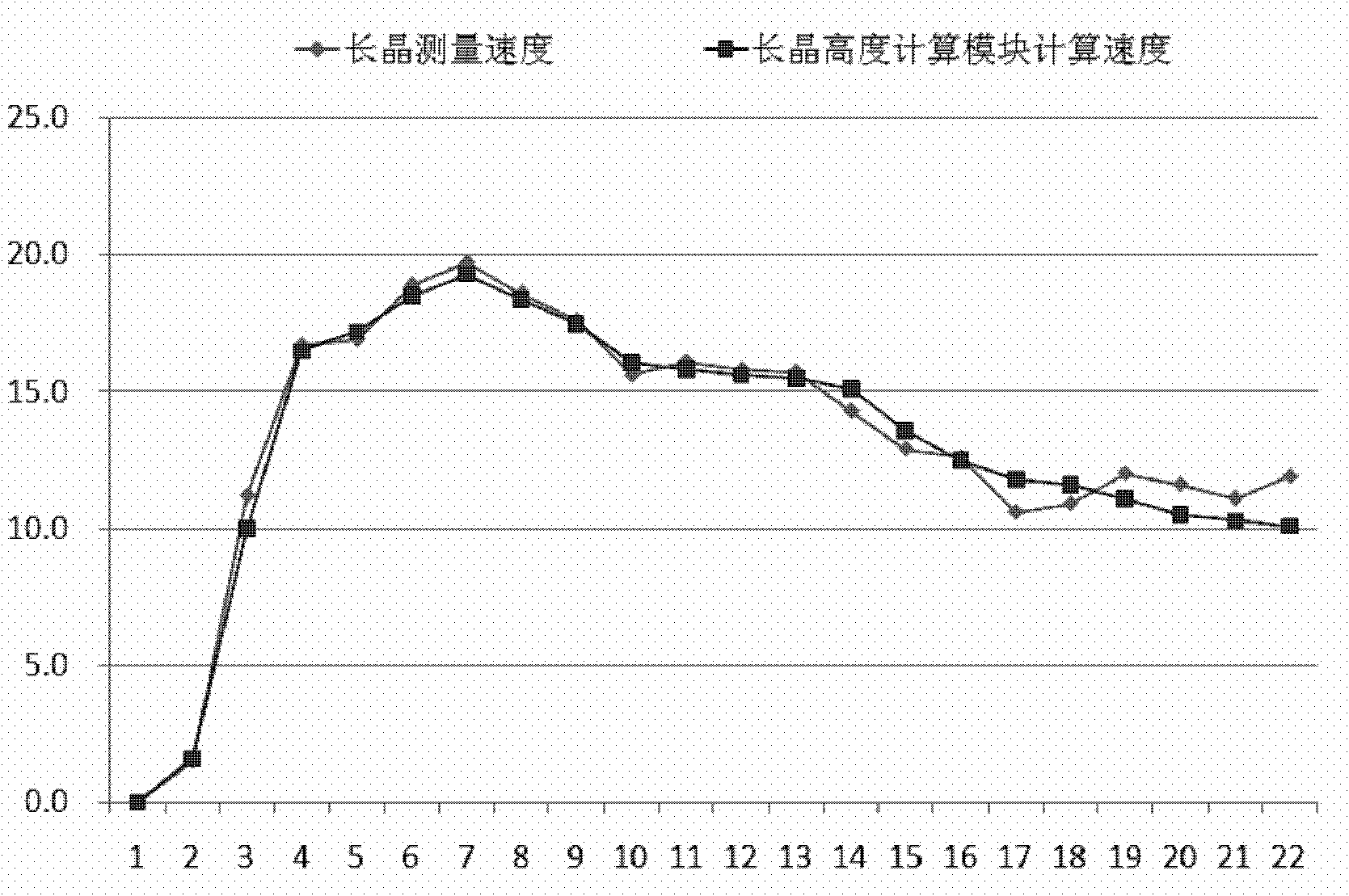

A polycrystalline silicon ingot furnace and heating control technology, which is applied to the growth of polycrystalline materials, chemical instruments and methods, and temperature control using electric methods, etc., can solve the problems of single heating effect change, weakened heat dissipation effect, and prolonged production time. , to achieve the effect of shortening the crystal growth time, improving the crystal quality and increasing the crystal growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

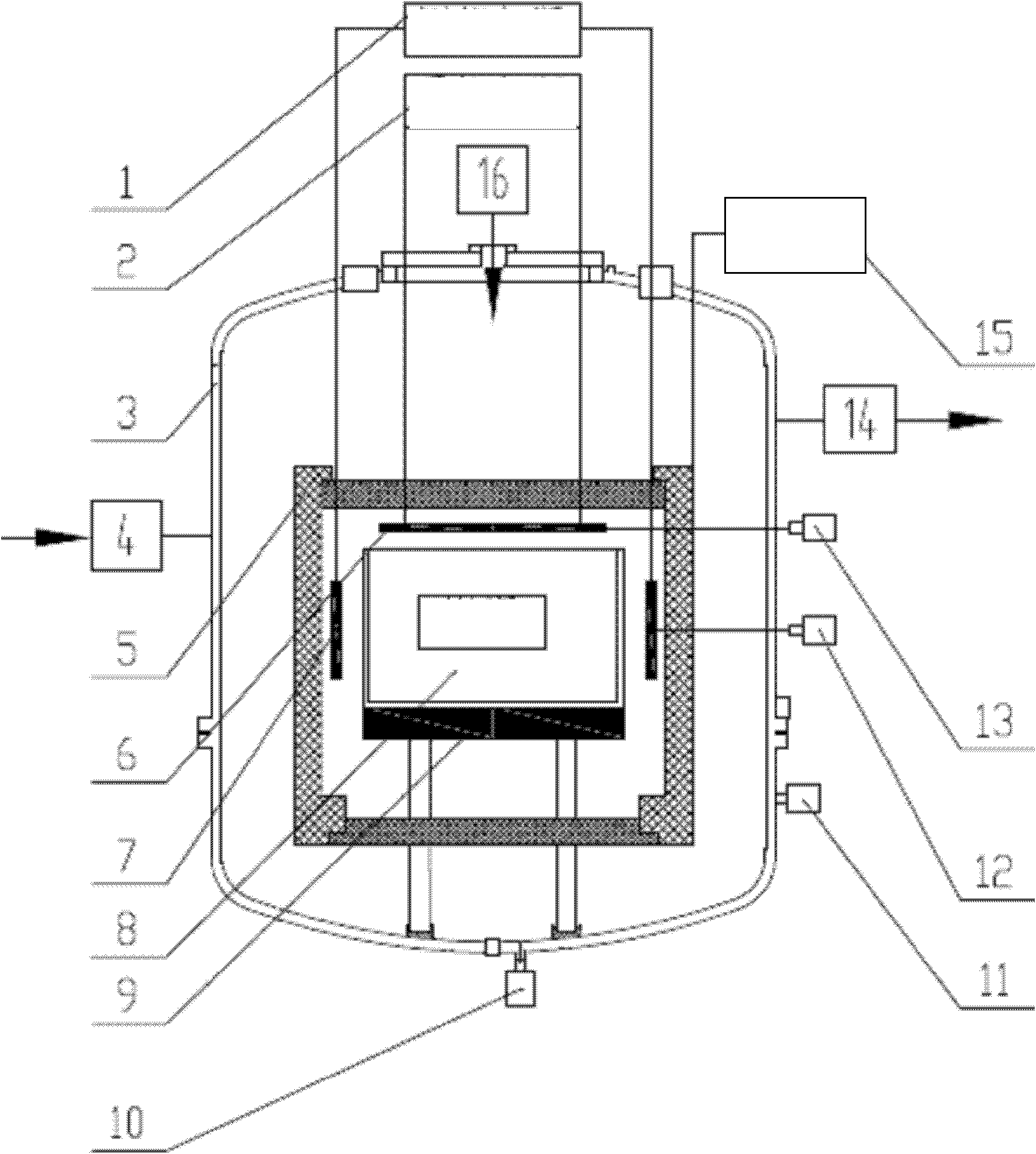

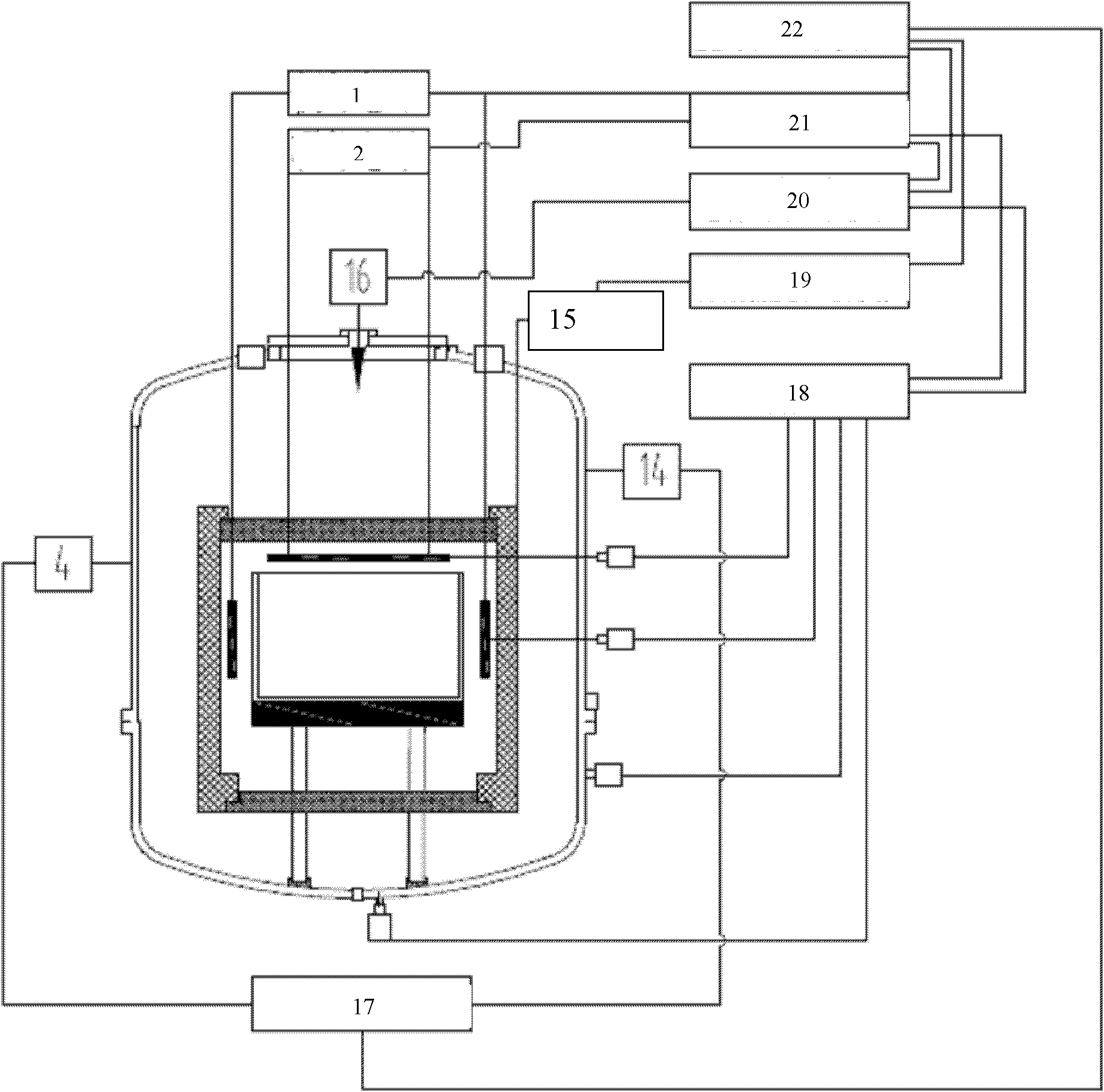

[0033] The heating control system based on separate control of the top and side of the polysilicon ingot casting furnace includes: a heat-insulating cage 5 placed in the furnace chamber 3, a crucible 8 and a heat exchange table 9 placed on the support column, and side heaters are arranged around the crucible 8 7 and side heater temperature sensor 12, the top is provided with top heater 6 and top heater temperature sensor 13, and the water cooling jacket of furnace chamber 3 is provided with lower water temperature flow sensor 10 and side water temperature flow sensor 11; Said side heater 7 Connected to the side power supply 1, the top heater 6 is connected to the top power supply 2, the side power supply 1 and the top power supply 2 are connected to the power distribution control module 21 through wires, and the power distribution control module 21 is respectively electrical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com