Edge heating system for quasi-G7 ingot-casting thermal field

A technology of edge heating and ingot casting, which is applied in the growth of single crystal, polycrystalline material, crystal growth, etc. It can solve the problems of insufficient radiation on the heating surface, high impurity concentration at the edge, and low minority carrier lifetime, etc., so as to improve the crystal minority carrier. Longevity, reducing the generation of primary dislocations, reducing the effect of lateral temperature gradients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

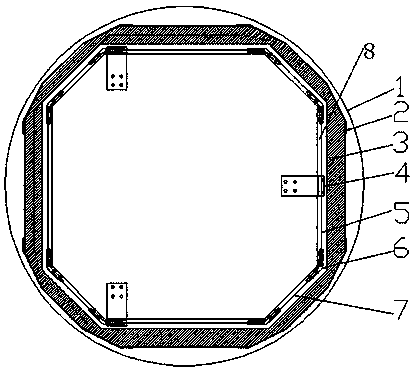

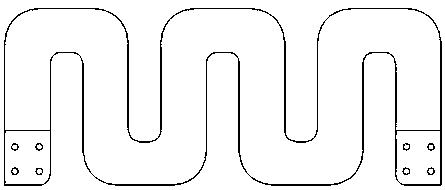

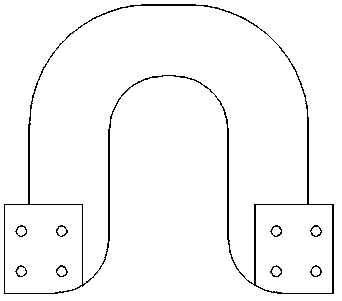

[0014] The system includes an ingot furnace 1 with an inner diameter of 1830mm, such as Figure 1-Figure 4 As shown, the ingot casting furnace 1 is provided with a heat-insulating steel cage 2, and a thermal field insulation device 3 made of a carbon felt material insulation board is installed on the heat-insulation steel cage 2, and a heating device is installed on the inside of the thermal field insulation device 3 8. The heating device 8 includes a plurality of side heaters 5 and side corner heaters 7, and the side heaters 5 and the side corner heaters 7 are connected in pairs by corner connecting pieces 6, and the heating device 8 is connected by The graphite boom heating plate 4 is connected to the electrode power supply.

[0015] Described side heater 5 and side angle heater 7 are 4 pieces, are connected to each other by corner connecting piece 6 between every side heater 5 and side angle heater 7, and corner connecting piece 6 is 8 pieces.

[0016] The 4 side heaters 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com