Horizontal continuous light alloy casting process and apparatus with cooperation of power ultrasound wave and low frequency electromagnetic wave

A synergistic, light alloy technology, applied in the field of light alloy casting, can solve the problems of difficult to eliminate the coarse grain area and dendrite area of the ingot, unable to realize the full volume effect of the melt, coarse grains, etc., and achieve the size effect of microstructure solidification. Remarkable, excellent internal structure, coarse grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

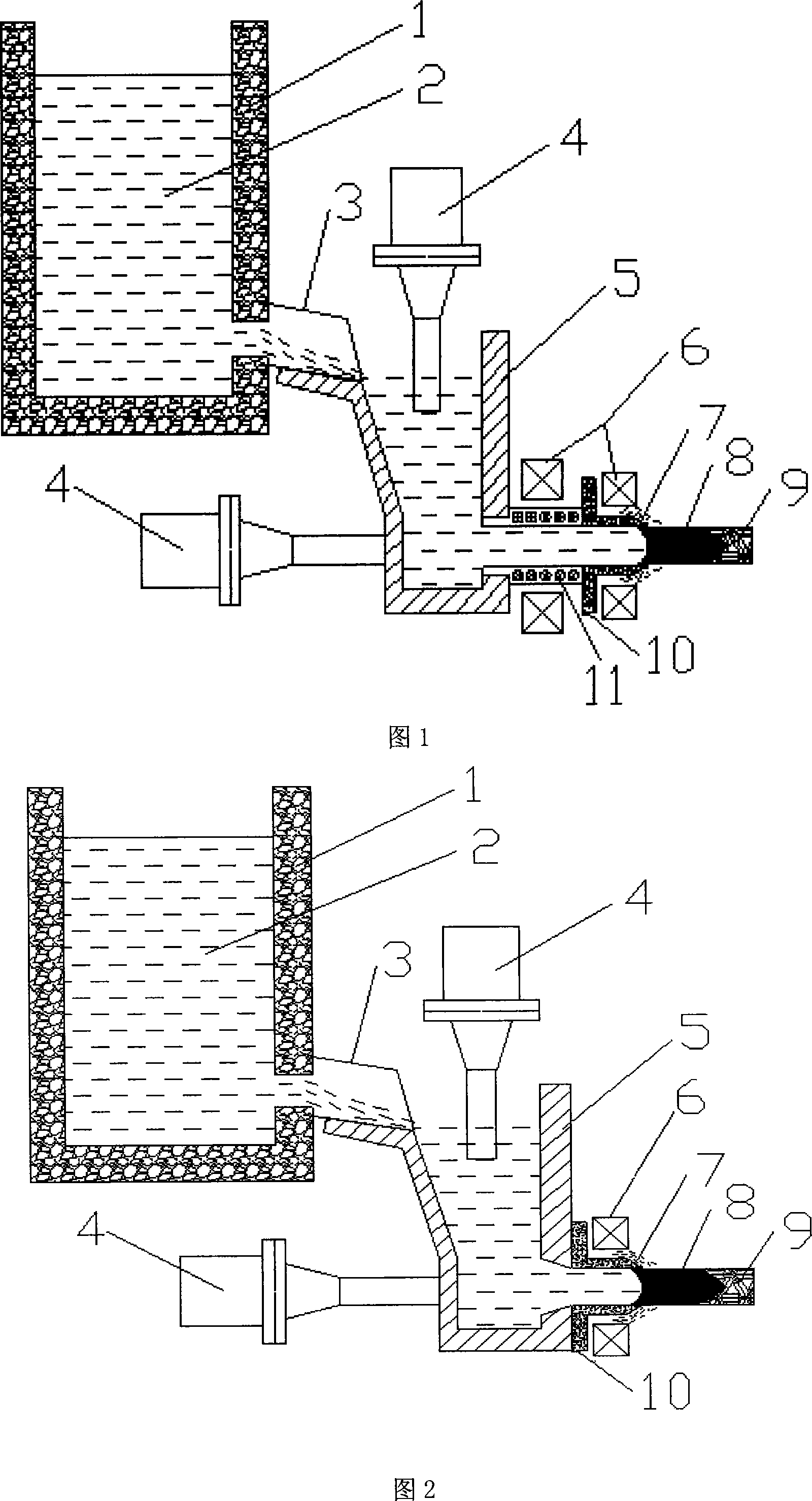

Method used

Image

Examples

Embodiment 1AZ91

[0024] Embodiment 1 AZ91 magnesium alloy Φ120mm ingot horizontal continuous casting

[0025] AZ91 magnesium alloy is smelted according to the ratio, and 2% Ca is added to achieve flame retardancy; the melt is not treated in the tundish with ultrasonic treatment, and the synergistic effect of power ultrasonic field and low-frequency electromagnetic field is applied in the crystallizer.

[0026] The casting process conditions are: the casting speed is 120mm / min; the Φ20mm ultrasonic horn is made of high-temperature cobalt-based alloy; the ultrasonic frequency is 20kHz, and the ultrasonic intensity is about 10W / cm 2 ;The melt temperature in the tundish is 680℃~690℃; the AC frequency is 25Hz, and the intensity is 5000AT.

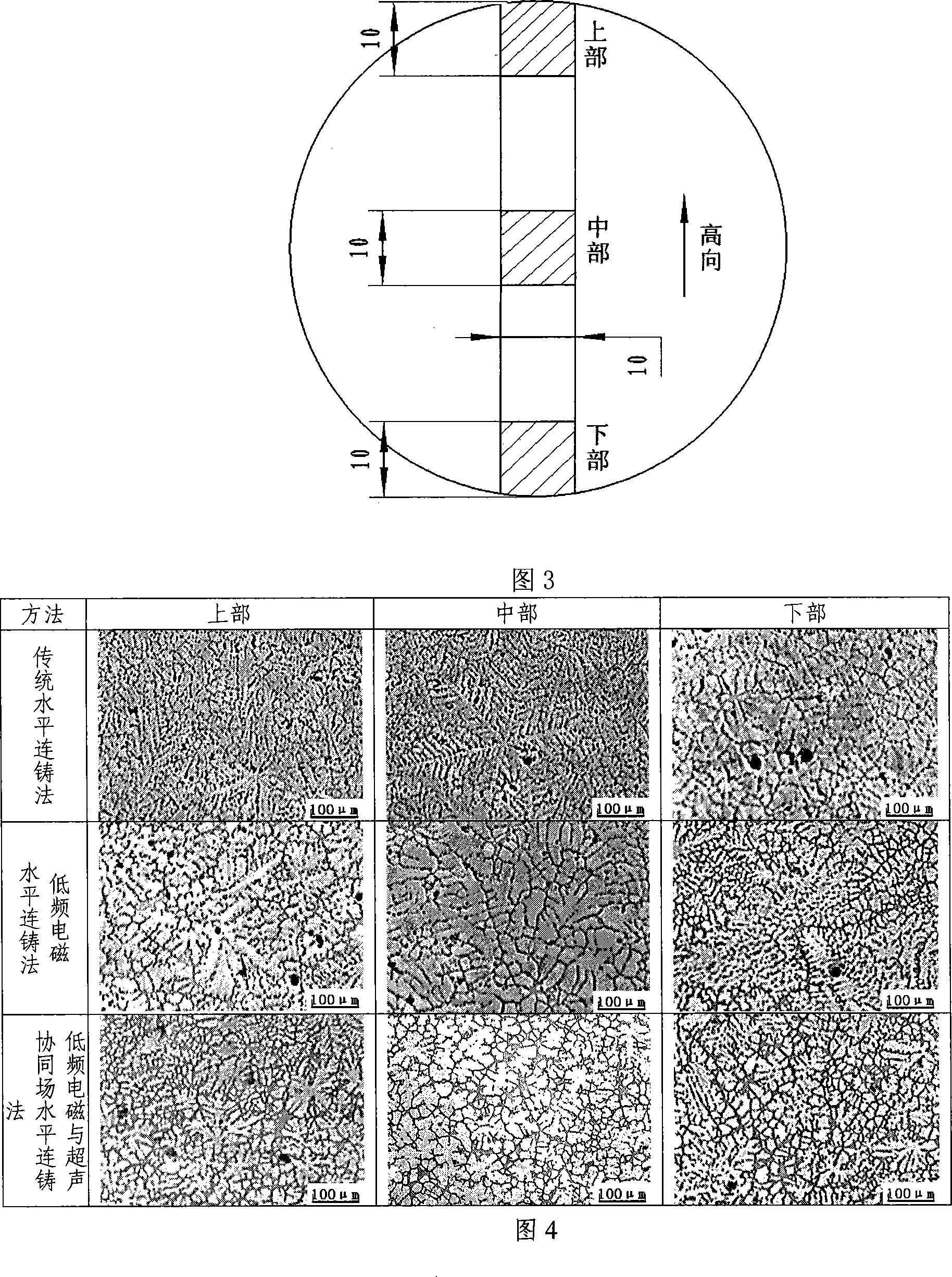

[0027]Fig. 4 is a comparison of microstructures of AZ91 magnesium alloy Φ120mm ingots obtained by traditional horizontal continuous casting, low-frequency electromagnetic horizontal continuous casting, and the present invention's method of low-frequency electrom...

Embodiment 2

[0029] Example 2: Horizontal continuous casting of ZK60 magnesium alloy Φ80mm billet

[0030] The ZK60 magnesium alloy is smelted according to the ratio, and 20ppm Be is added to achieve flame retardancy; the melt is not treated in the tundish with ultrasonic treatment, and the synergistic effect of power ultrasonic field and low-frequency electromagnetic oscillation field is applied in the crystallizer.

[0031] The casting process conditions are: the casting speed is 160mm / min; the ultrasonic frequency is 20kHz, and the ultrasonic intensity is about 10W / cm 2 The temperature of the melt in the tundish is 690°C to 700°C; the AC electromagnetic frequency is 30Hz, the intensity is 3200AT, and the DC electromagnetic field intensity is 3200AT.

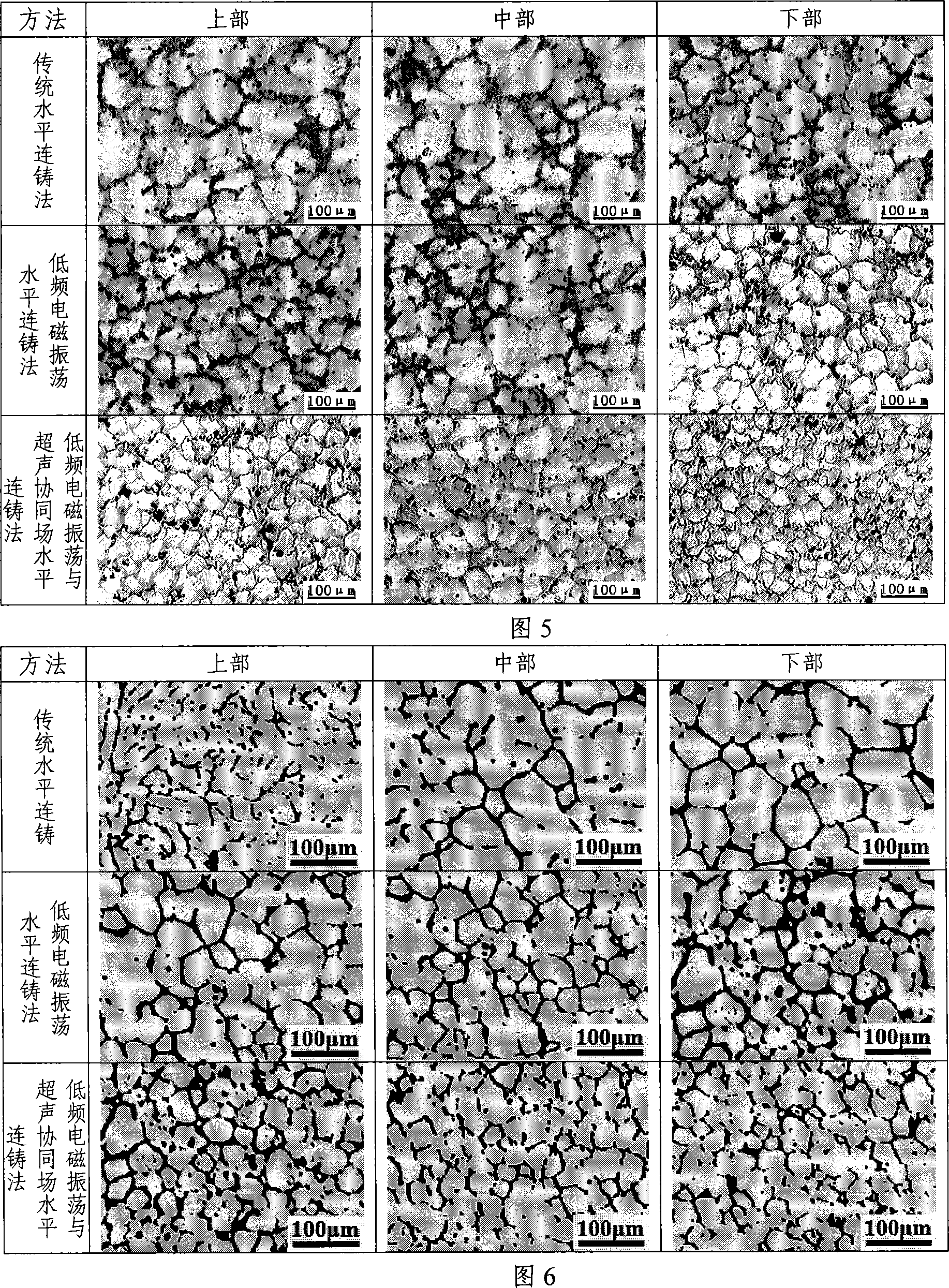

[0032] Fig. 5 is a comparison of microstructures of ZK60 magnesium alloy Φ80mm ingots obtained by three methods of traditional horizontal continuous casting, low-frequency electromagnetic oscillation horizontal continuous casting and the p...

Embodiment 3

[0034] Example 3: Horizontal continuous casting of a 7XXX aluminum alloy Φ150mm billet

[0035] A 7XXX aluminum alloy is smelted according to the ratio, and undergoes degassing and purification operations; the melt has no ultrasonic treatment in the tundish, and the synergistic effect of power ultrasonic field and low-frequency electromagnetic oscillation field is applied in the crystallizer.

[0036] The casting process conditions are: the casting speed is 110mm / min; the ultrasonic frequency is 20kHz, and the ultrasonic intensity is about 10W / cm 2 ;The melt temperature in the tundish is 700℃~710℃; the AC frequency is 25Hz, and the intensity is 12000AT.

[0037] Fig. 6 is a comparison of the structure of the 7XXX aluminum alloy Φ150mm ingot obtained by the three methods of traditional horizontal continuous casting, low-frequency electromagnetic oscillation horizontal continuous casting and the present invention's horizontal continuous casting of low-frequency electromagnetic o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com