Pretreatment method for liquid-phase micro-extraction sample

A sample pretreatment and extraction technology, which is applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems of low stirring speed of the sample pool, unrealistic equilibrium, and limited extraction time, etc., to achieve improved sensitivity and extraction efficiency , high stability, and the effect of increasing the extraction volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

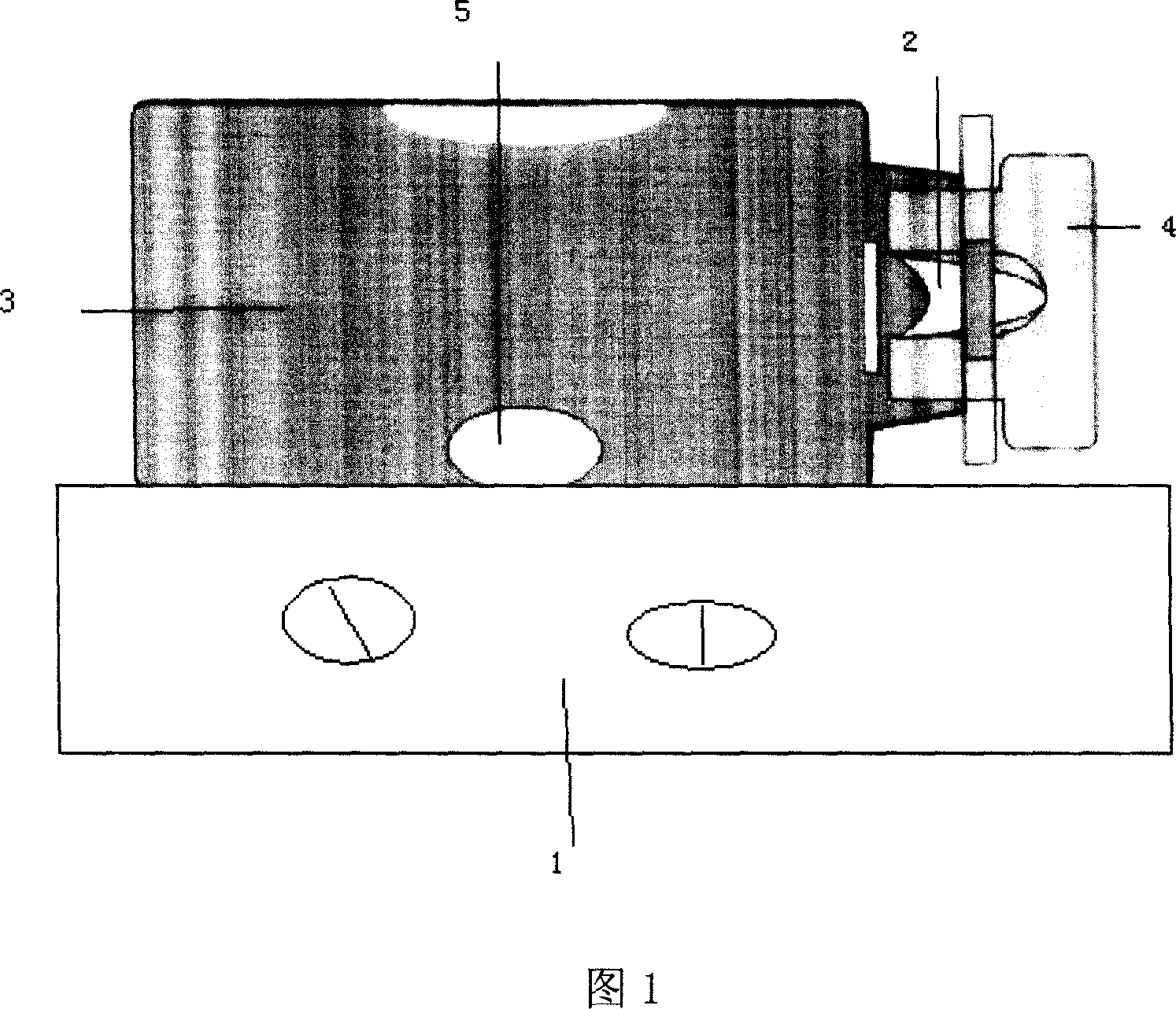

[0030] The example structure of this Fangming liquid phase microextraction method is as shown in Figure 1, and its device comprises a magnetic stirrer 1, a 0.2 milliliters of PCR tubes (cut off in advance) 2, a sample bottle 3, bottle stopper 4, magnetic stirring child 5. Fill the bottom of the PCR tube 2 with an appropriate amount of extraction solution, then seal it with an appropriate amount of sample solution, insert the PCR tube mouth upwards into the bottle stopper 4 of the sample bottle 3, and fill the sample containing the analyte solution (sample solution). A stirring magnet is placed in the bottle 3, the bottle stopper 4 equipped with the PCR tube is inserted into the sample bottle 3 containing the sample solution, and the sample bottle 3 is placed sideways on a magnetic stirrer for stirring and extraction.

[0031] Utilize the liquid-phase microextraction method of the present invention to measure the broad grass clear and two analogs thereof in the water sample:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com