Method of separating and purifying ursolic acid and oleanolic acid

A technology for separation and purification of oleanolic acid, which is applied in the fields of organic chemistry, steroids, sugar derivatives, etc., can solve the problems of low separation efficiency, complicated separation and purification technology, etc., achieves good chemical stability, and simplifies extraction steps. , The effect of chemical stability and antimicrobial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

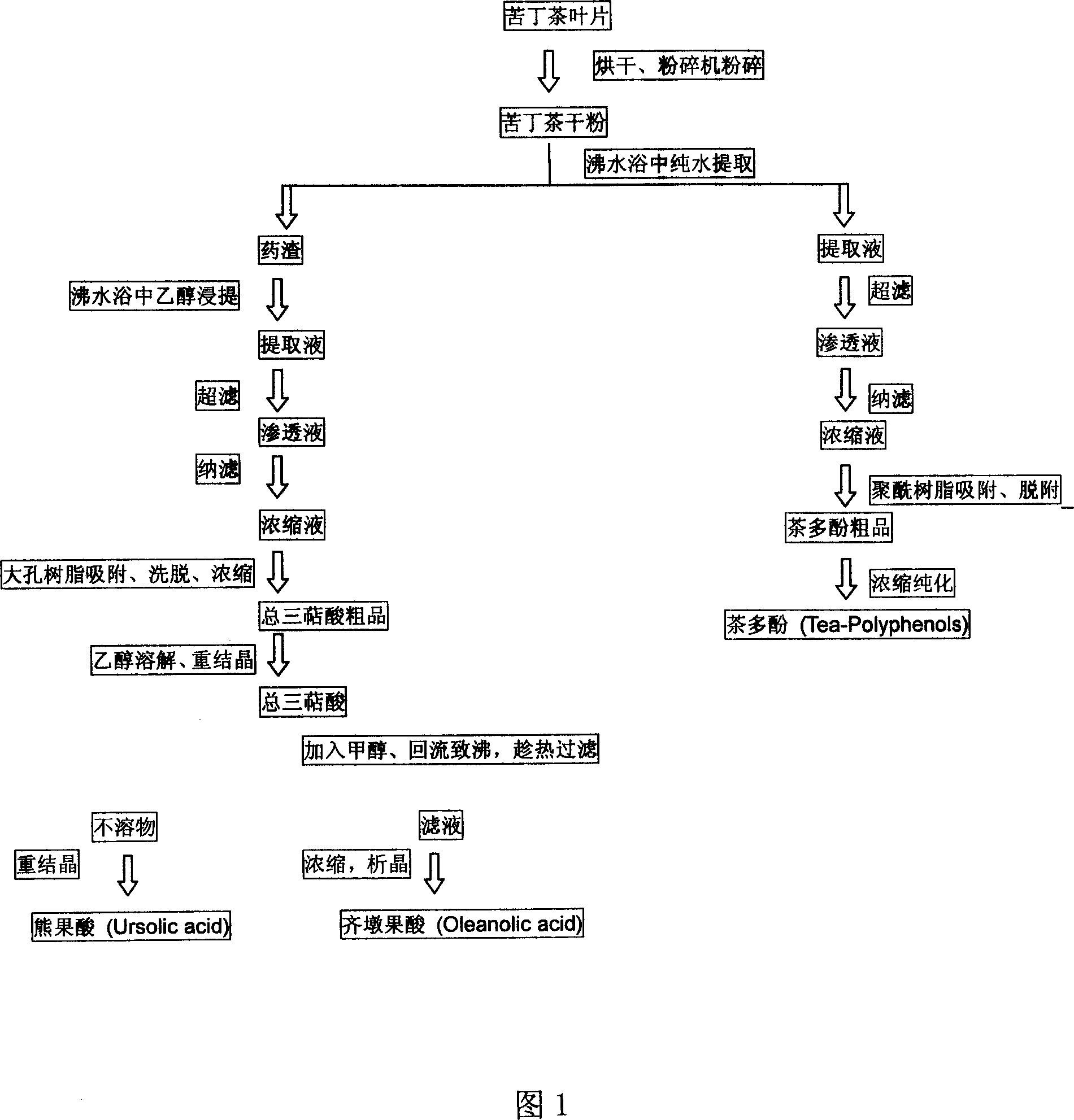

Image

Examples

experiment example 1

[0027] A) Get 5 grams of Kudingcha powder, add 100mL of pure water as the extract, extract in a boiling water bath for 1 hour, filter, and use 100mL of absolute ethanol solution as a solvent to extract the two residues obtained by filtering in a boiling water bath. Once, each time for 2 hours, the extract was filtered, and the filtrate was clarified with a 500nm ceramic membrane at an operating temperature of 40°C, a membrane surface flow rate of 3m / s and an operating pressure of 0.18MPa. The concentration of ursolic acid in the clarified liquid was detected to be 0.428mg / mL, the concentration of oleanolic acid is 0.149mg / mL, and the clarified solution is concentrated 10 times by a nanofiltration membrane with a molecular weight cut-off of 400 to obtain a concentration of ursolic acid of 3.878mg / mL in the concentrated solution, and a concentration of oleanolic acid of 1.246mg / mL;

[0028] B) The concentrated solution is injected into the macroporous adsorption resin chromato...

experiment example 2

[0031] A) Take 3 grams of Kudingcha powder, add 100mL of pure water as the extract, extract in a boiling water bath for 1 hour, filter, and use 100mL of absolute ethanol solution as a solvent to extract the filter residue obtained by reflux in a boiling water bath for three times , each time for 2 hours, the extract was filtered, and the filtrate was clarified with a 500nm ceramic membrane at an operating temperature of 40°C, a membrane surface flow rate of 2.5m / s and an operating pressure of 0.15MPa. The concentration of ursolic acid in the clarified liquid was detected to be 0.286mg / mL, the concentration of oleanolic acid is 0.101mg / mL, and the clarified solution is concentrated 10 times by a nanofiltration membrane with a molecular weight cut-off of 300 to obtain a concentration of ursolic acid of 2.437mg / mL in the concentrated solution, and a concentration of oleanolic acid of 0.923mg / mL;

[0032] B) The concentrated solution is injected into the macroporous adsorption r...

experiment example 3

[0035] A) Take 5 grams of Kudingcha powder, add 100mL of pure water as the extract, extract in a boiling water bath for 1 hour, filter, and use 100mL of absolute ethanol solution as a solvent to extract the filter residue obtained by reflux once in a boiling water bath , 2 hours each time, the extract was filtered, and the filtrate was clarified with a 500nm ceramic membrane at an operating temperature of 40°C, a membrane surface flow rate of 2m / s and an operating pressure of 0.1MPa. The concentration of ursolic acid in the clarified liquid was detected to be 0.147mg / mL, the concentration of oleanolic acid is 0.191mg / mL, and the clarified solution is concentrated 10 times by a nanofiltration membrane with a molecular weight cut-off of 500 to obtain a concentration of ursolic acid in the concentrated solution of 1.025mg / mL and a concentration of oleanolic acid of 1.306mg / mL. mL;

[0036] B) The concentrated solution is injected into the macroporous adsorption resin chromatogra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com