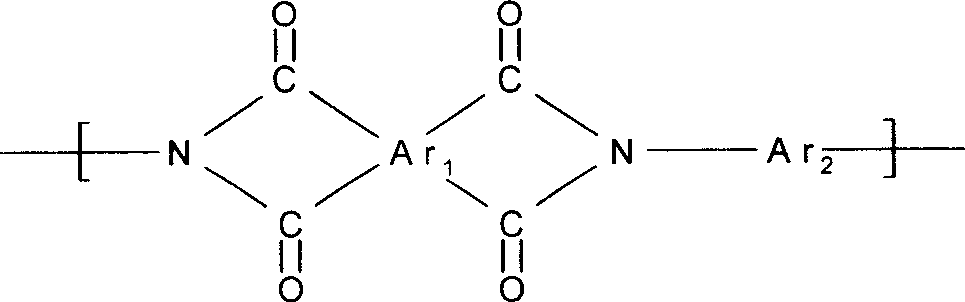

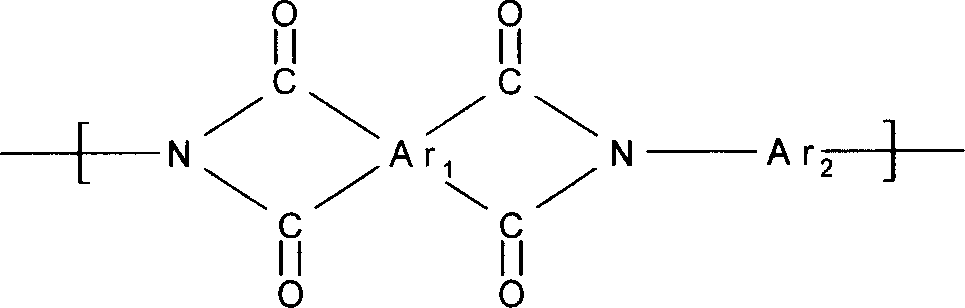

Lightening fire resistant polymer porous membrane laminated composite material and manufacturing method thereof

A technology of high temperature resistant polymers and composite materials, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc. The effect of good thermal insulation performance and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The carbon fiber braid is used as the reinforcing material, and the porous polyimide membrane is combined to prepare the porous membrane laminated composite material. The specific steps are as follows:

[0031] 1. Cut the carbon fiber braid into a 20×10cm sheet, clean it with acetone in an ultrasonic wave, and then dry it in an oven until the acetone is completely evaporated.

[0032] 2. the precursor polyamic acid of polyimide is dissolved in the polar organic solvent N, and in N-dimethylacetamide (DMAc) obtains the film-making liquid that mass concentration is 15%; The film-making liquid is filtered , After degassing, scrape a liquid film with a thickness of 100 microns on the stainless steel support; keep the liquid film in the air for a certain period of time and then immerse it in a coagulation bath at 20°C for 10 minutes; soak and clean the cured film with ethanol, and dry it A polyamic acid precursor film with a porous structure was obtained.

[0033] 3. Immerse t...

Embodiment 2

[0039] The glass fiber braid is used as the reinforcing material, and the porous polyimide membrane is compounded to prepare the porous membrane laminated composite material. The specific steps are as follows:

[0040] 1. Cut the glass fiber braid into a 20×10cm sheet, clean it with acetone in an ultrasonic wave, and then dry it in an oven until the acetone is completely evaporated.

[0041] 2. the precursor polyamic acid of polyimide is dissolved in the polar organic solvent N, and in N-dimethylacetamide (DMAc) obtains the film-making liquid that mass concentration is 20%; The film-making liquid is filtered, After degassing, scrape a liquid film with a thickness of 200 microns on the stainless steel support; keep the liquid film in the air for a certain period of time and then immerse it in a coagulation bath at 20°C for 30 minutes; soak and clean the cured film with ethanol, and dry it to obtain Polyamic acid precursor film with porous structure.

[0042] 3. Immerse the cle...

Embodiment 3

[0048] Copper wire mesh is used as a reinforcing material, and the porous polyimide membrane is composited to prepare a porous membrane laminated composite material. The specific steps are as follows:

[0049] 1. Cut the copper wire mesh into a 20×10cm sheet, clean it with acetone in an ultrasonic wave, and then dry it in an oven until the acetone is completely evaporated.

[0050] 2. The precursor polyamide ester of polyimide is dissolved in the polar organic solvent N,N-dimethylacetamide (DMAc) to obtain a film-making solution with a mass concentration of 30%; the film-making solution is filtered , After degassing, scrape a liquid film with a thickness of 400 microns on the stainless steel support body; soak the liquid film in the air for a certain period of time and then immerse it in a coagulation bath at 20°C for 30 minutes; soak and clean the cured film with ethanol or acetone, After drying, a polyamide ester precursor film with a porous structure was obtained.

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com