Agent of anti dirt of allylloxy polyether, and preparation method

An allyloxy polyether, allyloxy technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve pollution, poor performance, bacteria and algae red tide and other problems to achieve good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

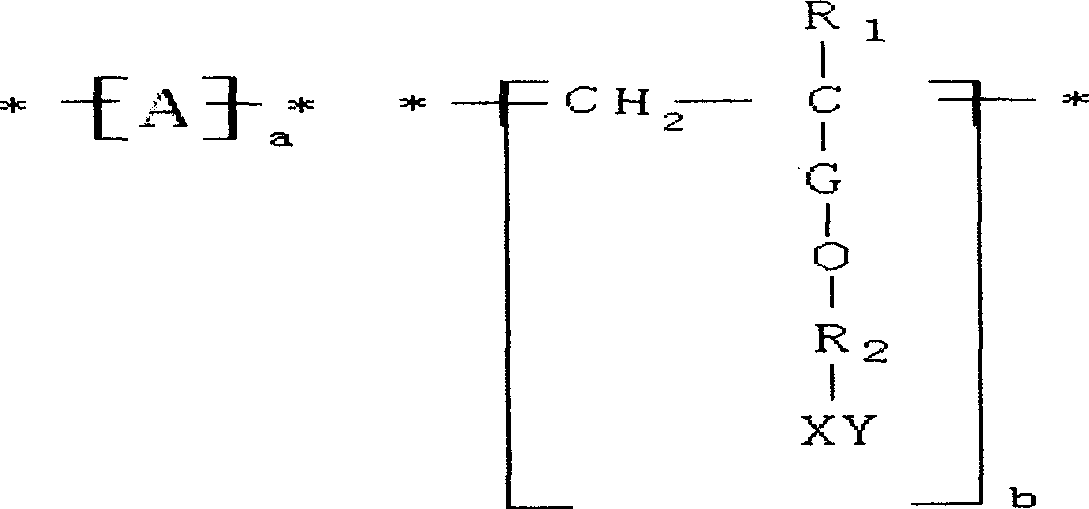

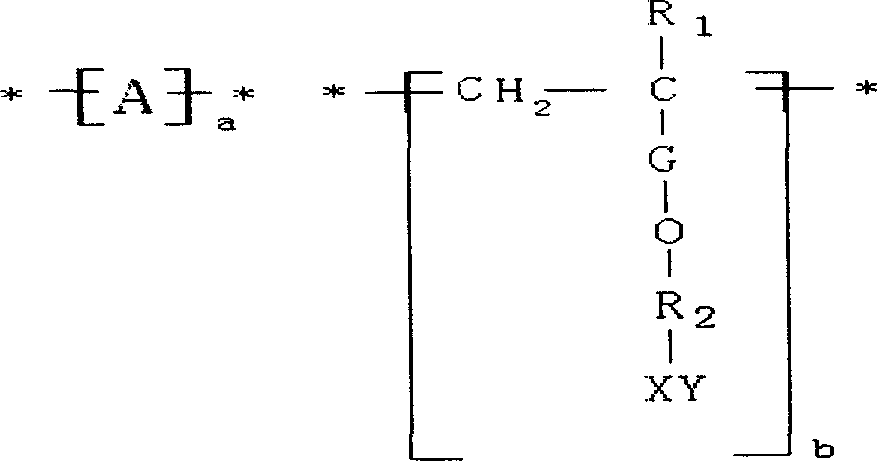

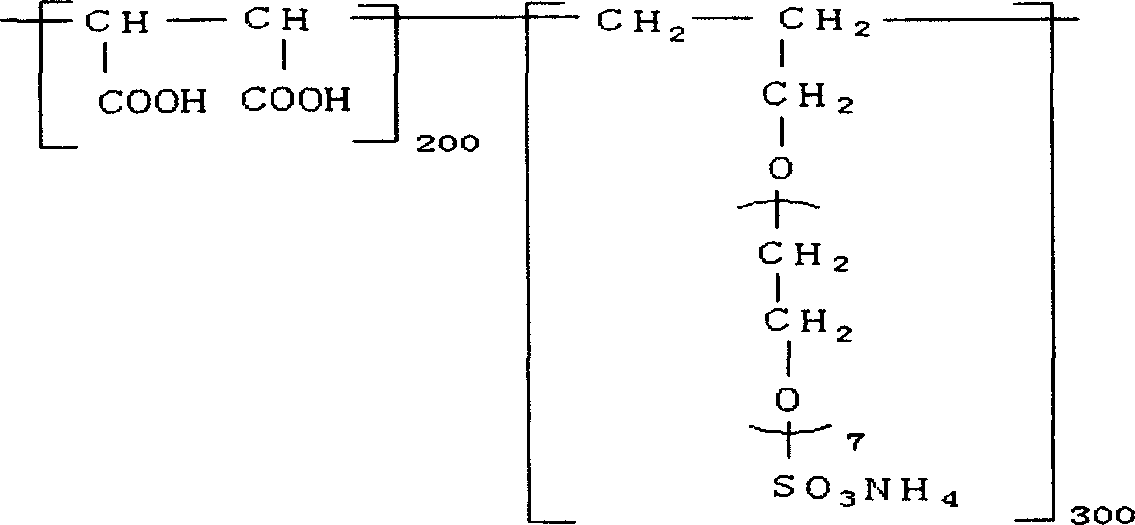

Method used

Image

Examples

example 1

[0037] Example 1: at N 2 Add 100g of allyloxy polyethoxy ether, 25g of sulfamic acid, and 1g of urea into the protected four-neck flask, and heat the reactants to 100-120°C for 4 hours to obtain allyloxypolyethoxysulfonium ammonium acid. in N 2 Under protection, mix 50g of allyloxy polyethoxy ammonium sulfonate (dissolved in 150g of distilled water) and 60g of maleic anhydride-acrylic acid copolymer and then heat up to 60°C, while adding 50g of 50% maleic anhydride dropwise Aqueous solution and 3g of benzoyl peroxide (dissolved in 50g of distilled water) were added dropwise at constant temperature for 1 hour. After the dropping, the temperature was raised to 70°C to continue the reaction for 1 hour, and then lowered to room temperature to obtain a dark yellow viscous transparent AOPE liquid.

[0038] The obtained AOPE scale inhibitor inhibits Ca 3 (PO 4 ) 2 The rate is 99.47%; CaCO 3 The rate is 97.97%.

example 2

[0039] Example 2: at N 2 Add 100g of allyloxy polyethoxy ether, 25g of sulfamic acid, and 1g of urea into the protected four-necked flask, and heat the reactant to 110-120°C for 4 hours to obtain allyloxypolyethoxysulfonium ammonium acid. in N 2 Under protection, mix 50g of allyloxy polyethoxy ammonium sulfonate (dissolved in 150g of distilled water), 60g of maleic anhydride-acrylic acid copolymer and 100g of 50% maleic anhydride aqueous solution and then heat up to 60°C. Add 3g of benzoyl peroxide (dissolved in 50g of distilled water) dropwise, add dropwise at a constant temperature for 1 hour, after the dropping, raise the temperature to 70°C and continue the reaction for 2 hours, then cool down to room temperature to obtain a dark yellow viscous transparent AOPE liquid.

[0040] The obtained AOPE scale inhibitor inhibits Ca 3 (PO 4 ) 2 The rate is 94.92%; CaCO 3 The rate is 83.53%.

example 3

[0041] Example 3: at N 2 Add 100g of allyloxy polyethoxy ether, 25g of sulfamic acid, and 1g of urea into the protected four-necked flask, and heat the reactant to 110-120°C for 4 hours to obtain allyloxypolyethoxysulfonium ammonium acid. in N 2 Under protection, 50g of allyloxy polyethoxy ammonium sulfonate (dissolved in 200g of distilled water), 160g of maleic anhydride-acrylic acid copolymer were mixed and heated to 70°C, while 80g of maleic anhydride (dissolved in 150g of distilled water) and 5g of ammonium superphosphate (dissolved in 50g of distilled water), the temperature was kept at 70°C during the dropwise addition, and after the dropwise addition, the temperature was raised to 80°C and continued to insulate and stir the reaction for 3h, down to room temperature, and the obtained appearance was Dark yellow viscous transparent liquid.

[0042] The obtained AOPE scale inhibitor inhibits Ca 3 (PO 4 ) 2 The rate is 99.23%; CaCO 3 The rate is 80.78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com