Silicon containing 193nm negative photo resist and membrane forming resin

A film-forming resin, CH3 technology, applied in the direction of optics, optomechanical equipment, photosensitive materials for optomechanical equipment, etc., can solve the problems of wide range of positive photoresists, poor use, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

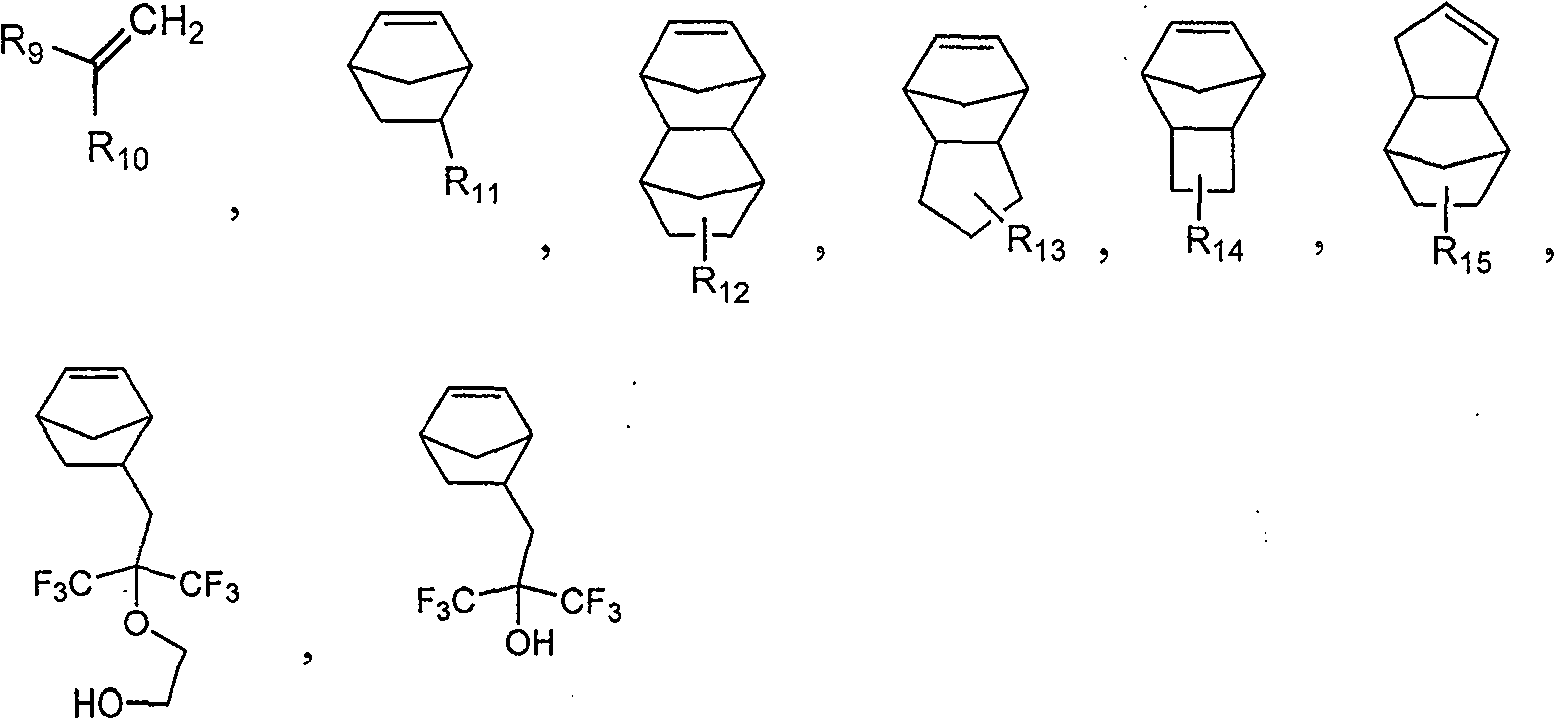

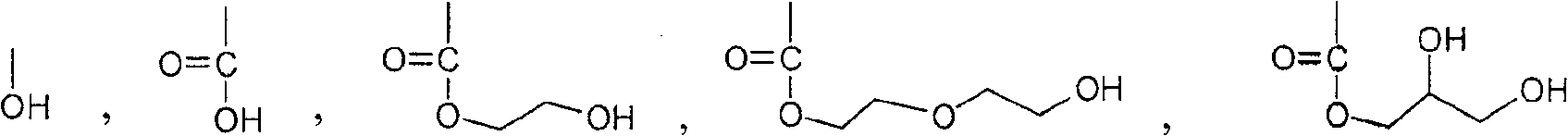

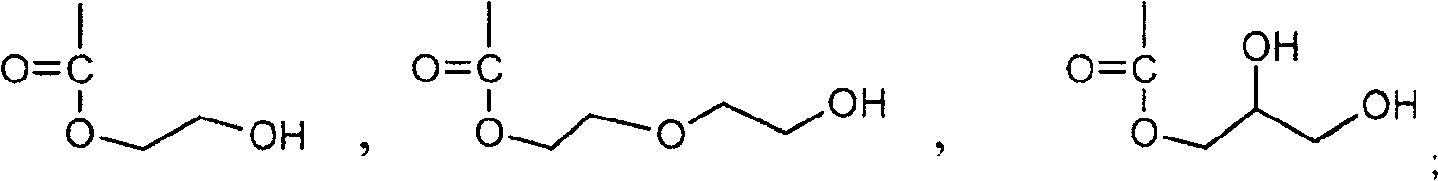

Method used

Image

Examples

Embodiment 1

[0143] A copolymer film-forming resin containing a silicon coupling agent is prepared from the following comonomers and their contents in the presence of a free radical initiator, and is prepared by heating for copolymerization. The chemical formula (not representing sequence structure) of copolymer film-forming resin is as follows:

[0144]

[0145] 2-hydroxyethoxyhexafluoroisobutyl-5-norbornene 98.2 grams;

[0146] Methacrylate - (5-norbornanyl-2-formyl) ester 33.5 grams;

[0147] Propyltrimethoxysilyl methacrylate 12.5 grams;

[0148] The preparation method is: in a 1000ml three-neck flask equipped with an electric stirrer, condenser, thermometer, temperature controller, heating mantle and nitrogen inlet, add 2-hydroxyethoxyhexafluoroisobutyl-5-norbornene 98.2 grams, 33.5 grams of methacrylic acid-(5-norbornanyl-2-formyl) ester, 12.5 grams of propyltrimethoxysilane methacrylate, 450 grams of tetrahydrofuran, nitrogen gas under stirring for 10 minutes, then heated to A...

Embodiment 2

[0150] A copolymer film-forming resin containing a silicon coupling agent is prepared from the following comonomers and their contents in the presence of a free radical initiator, and is prepared by heating for copolymerization. The chemical formula (not representing sequence structure) of copolymer film-forming resin is as follows:

[0151]

[0152] 5-norbornene-2,3-anhydride 24.6g

[0153] 5-norbornene-2-hydroxyethyl carboxylate 55.2g

[0154] Ethyldimethoxymethylsilyl methacrylate 9.5g

[0155] The preparation method is: in a 1000ml three-neck flask equipped with an electric stirrer, condenser, thermometer, temperature controller, heating mantle and nitrogen inlet, add 24.6 grams of 5-norbornene-2,3-acid anhydride, 5- 55.2 grams of hydroxyethyl norbornene-2-carboxylate, 9.5 grams of ethyl dimethoxymethylsilyl methacrylate, 400 grams of tetrahydrofuran, nitrogen for 10 minutes while stirring, then heated to 60-70 ° C, added A solution of 4.5 grams of azobisisobutyronit...

Embodiment 3

[0157] A copolymer film-forming resin containing a silicon coupling agent is prepared from the following comonomers and their contents in the presence of a free radical initiator, and is prepared by heating for copolymerization. The chemical formula (not representing sequence structure) of copolymer film-forming resin is as follows:

[0158]

[0159] 96.5 grams of methacrylate (5-norbornanyl-5-formic acid glycidyl) ester;

[0160] Methacrylic acid (tetracyclo[2,2,1,0 5,10 ] dodecyl-8-hydroxyl) ester 26.5 grams;

[0161] Propyldimethoxyethylsilyl methacrylate 12.5 grams;

[0162] The preparation method is: in a 1000ml three-neck flask equipped with an electric stirrer, condenser, thermometer, temperature controller, heating mantle and nitrogen inlet, add methacrylic acid (5-norbornanyl-5-glycidyl formate) ) ester 96.5 grams, methacrylic acid (tetracyclo[2,2,1,0 5,10 ] 26.5 grams of dodecyl-8-hydroxyl) ester, 12.5 grams of propyl dimethoxyethyl silyl methacrylate, 450 gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com