Controllable doping method for Si3N4 single-crystal low-dimension nano material

A low-dimensional nano- and single-crystal technology, applied in polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problems of limited doping amount of low-dimensional nanomaterials and inability to control doping amount, and achieve low cost , no pollution, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

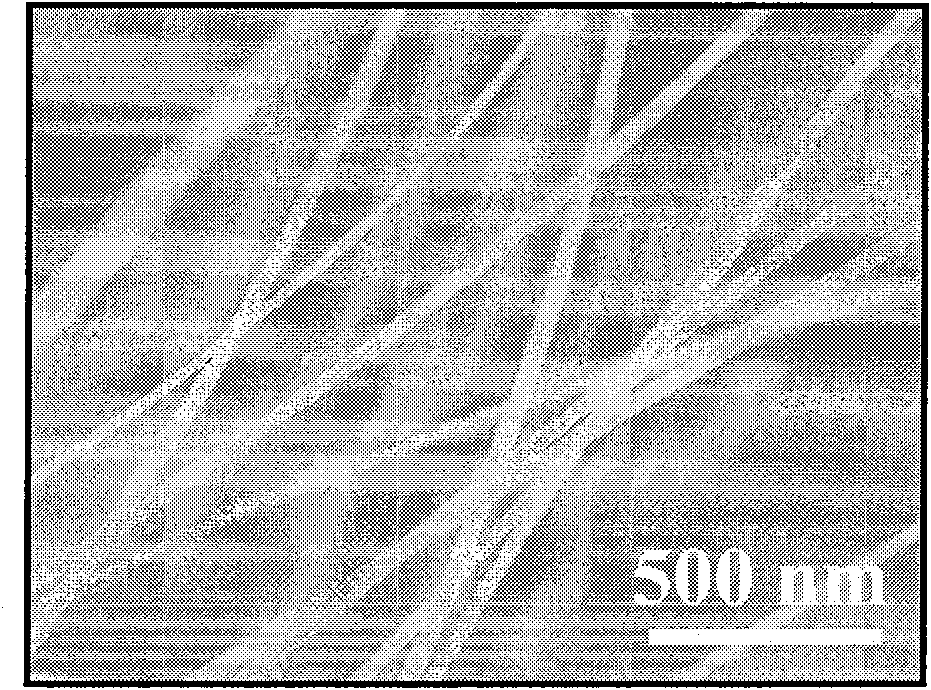

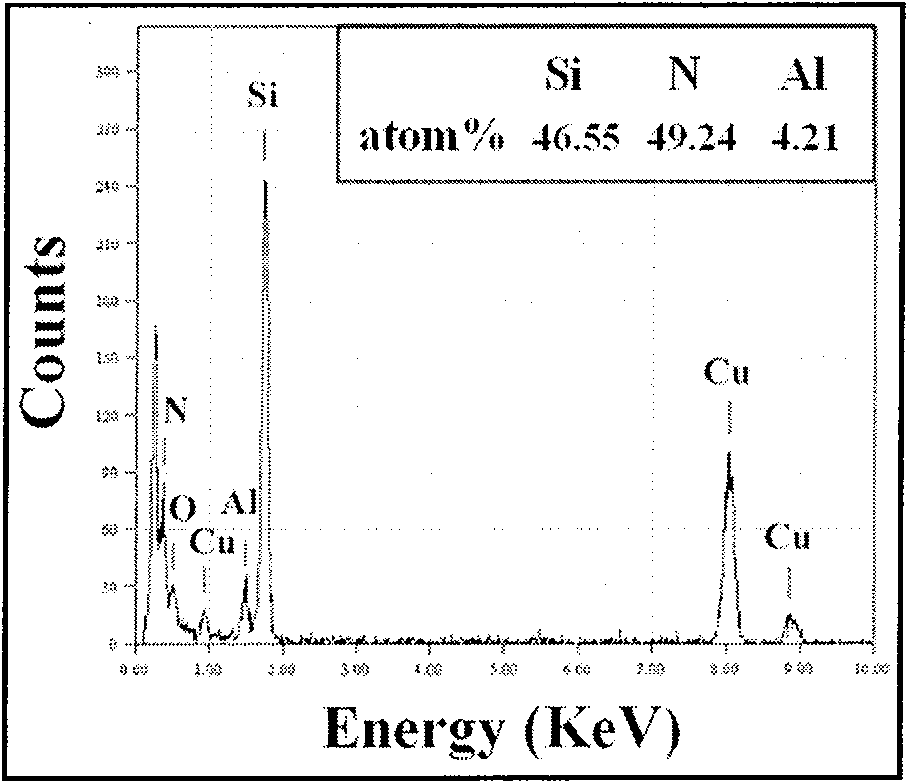

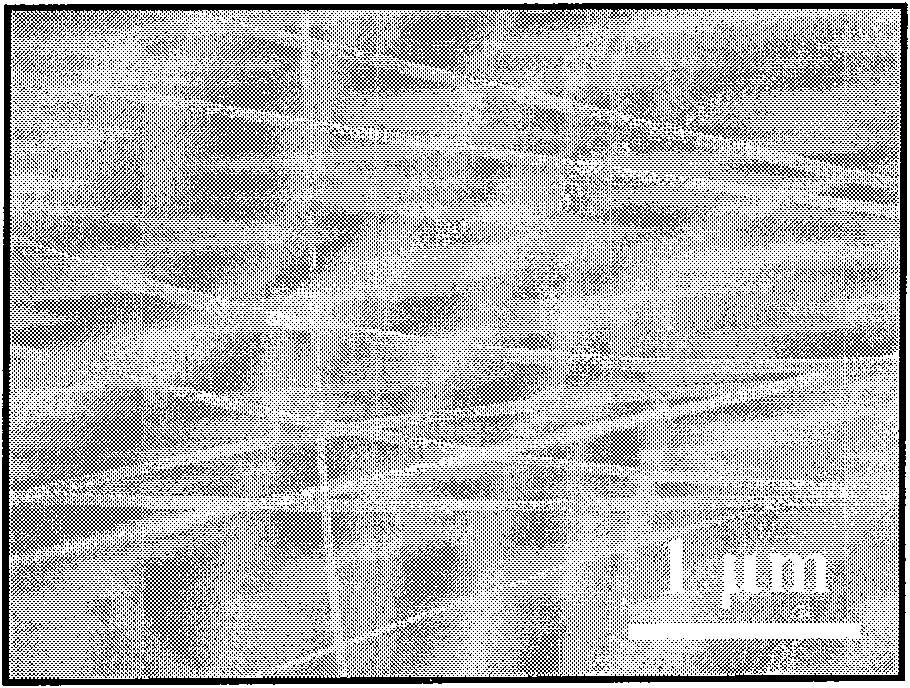

Embodiment 1

[0037] Weigh 10 g of the initial raw materials polysilazane and aluminum isopropoxide at a weight ratio of 4:1, put them into a nylon resin ball mill pot for planetary ball milling for 12 hours, and place them in a 99 alumina ceramic crucible after mixing evenly. N of MPa 2 Under the gas protection atmosphere, the temperature was raised from room temperature to 260°C at 10°C / min in a tubular sintering furnace, and kept for 0.5 hours for cross-linking and solidification to obtain an amorphous SiAlCN solid. Put the SiAlCN solid into a nylon resin ball mill jar, add 3wt% FeCl 2The powder is used as a catalyst in a high-energy ball mill for dry ball milling for 24 hours, and then the SiAlCN powder obtained after the high-energy ball milling is placed in a 99 alumina ceramic crucible, and the flow (200ml / min) of N at 0.1MPa 2 Under the protection of gas atmosphere, the temperature was increased from room temperature to 1300 °C in a tube furnace at 10 °C / min for high-temperature py...

Embodiment 2

[0039] Weigh 10 g of the initial raw materials polysilazane and aluminum isopropoxide at a weight ratio of 8:1, put them into a nylon resin ball mill jar for planetary ball milling for 12 hours, mix them uniformly and place them in a 99 alumina ceramic crucible, and place them in a 0.1 N of MPa 2 Under the gas protection atmosphere, the temperature was raised from room temperature to 260°C at 10°C / min in a tubular sintering furnace, and kept for 0.5 hours for cross-linking and solidification to obtain an amorphous SiAlCN solid. Put the SiAlCN solid into a nylon resin ball mill jar, add 3wt% FeCl 2 The powder is used as a catalyst in a high-energy ball mill for dry ball milling for 24 hours, and then the SiAlCN powder obtained after the high-energy ball milling is placed in a 99 alumina ceramic crucible, and the flow (200ml / min) of N at 0.1MPa 2 Under the protection of gas atmosphere, the temperature was increased from room temperature to 1300 °C in a tube furnace at 10 °C / min...

Embodiment 3

[0041] Weigh 10 g of the initial raw materials polysilazane and aluminum isopropoxide at a weight ratio of 16:1, put them into a nylon resin ball mill pot for planetary ball milling for 12 hours, mix them uniformly and place them in a 99 alumina ceramic crucible, and place them in a 0.1 N of MPa 2 Under the gas protection atmosphere, the temperature was raised from room temperature to 260°C at 10°C / min in a tubular sintering furnace, and kept for 0.5 hours for cross-linking and solidification to obtain an amorphous SiAlCN solid. Put the SiAlCN solid into a nylon resin ball mill jar, add 3wt% FeCl 2 The powder is used as a catalyst in a high-energy ball mill for dry ball milling for 24 hours, and then the SiAlCN powder obtained after the high-energy ball milling is placed in a 99 alumina ceramic crucible, and the flow (200ml / min) of N at 0.1MPa 2 Under the protection of gas atmosphere, the temperature was increased from room temperature to 1300 °C in a tube furnace at 10 °C / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com