Biotinylated pulullan polysaccharide nanometer grains and the preparation method

A pullulan polysaccharide and biotinylation technology, applied in the field of biotinylated pullulan polysaccharide nanoparticles and their preparation, can solve problems such as product toxicity, and achieve the effects of smooth surface, mild conditions and narrow particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

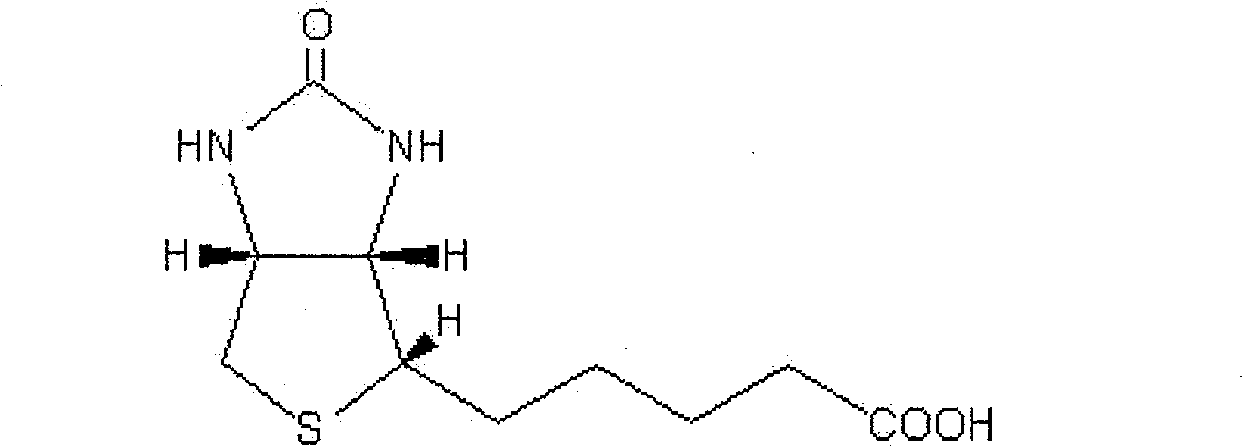

[0021] Take 2.44g of biotin, 2.06g of dicyclohexylcarbodiimide (DCC) and 611mg of 4-dimethylaminopyridine (DMAP) and add them into 50ml of anhydrous dimethyl sulfoxide (DMSO) to dissolve completely, and react for 1 hour . Subsequently, 244 mg of pullulan was added to the above reaction solution to react for 6 days, and the reaction was carried out under magnetic stirring. After the reaction was completed, the reaction solution was suction-filtered three times with a Buchner funnel to remove the precipitate DCU in the reaction solution. Put every 25ml of the filtrate into a dialysis bag, and then put the dialysis bag into 3L deionized water for dialysis for 6 days, changing the water every 30 minutes. After the dialysis, take out the white precipitate in the dialysis bag, use Buchner funnel to suction filter 3 times, collect the white solid on the funnel, wash 3 times with 200ml dichloromethane, then wash 3 times with deionized water, and dry , to obtain a white solid substan...

Embodiment 2

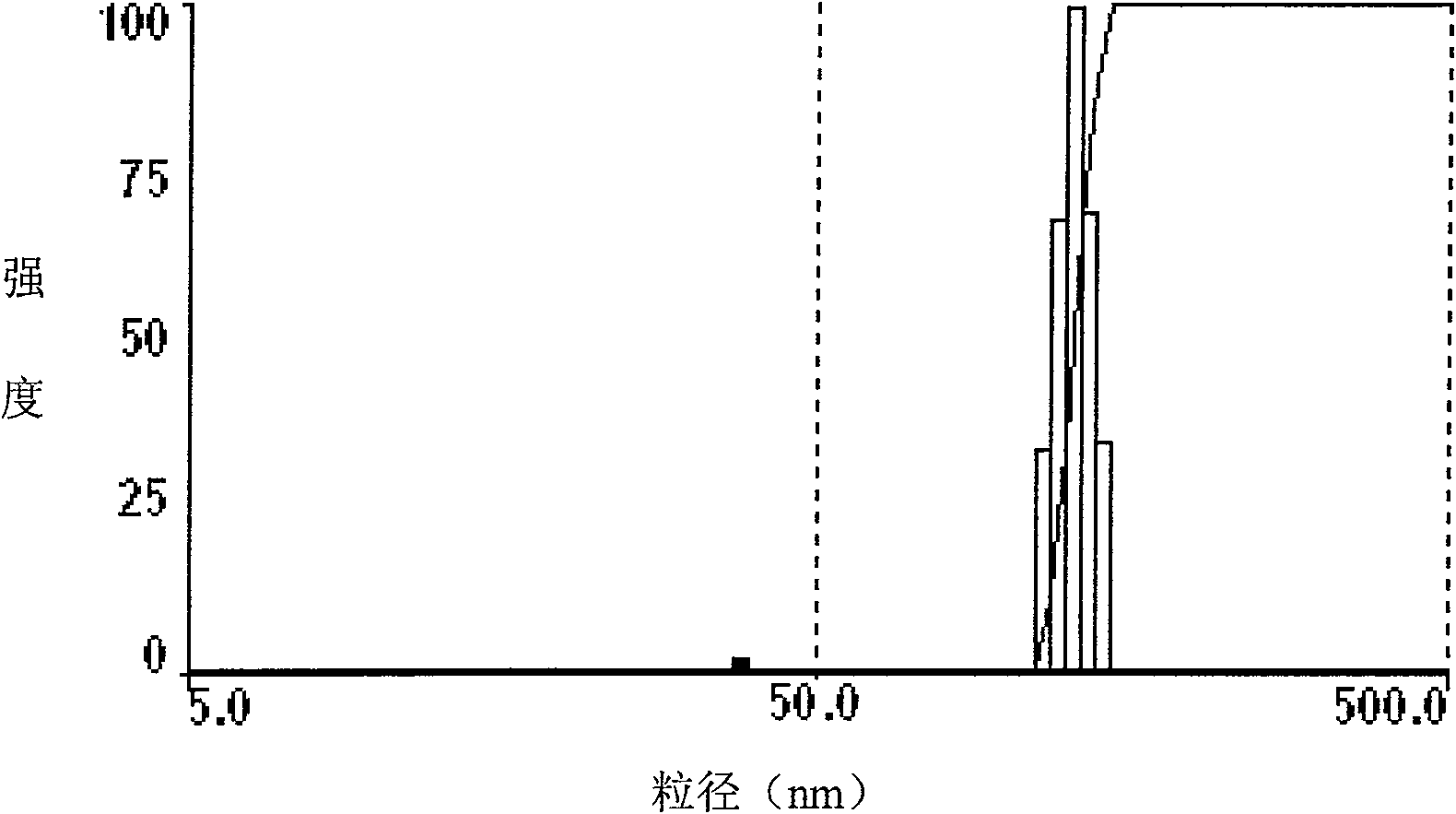

[0026] 10 mg of biotinylated pullulan prepared in Example 1 was completely dissolved in 2 ml of DMSO, and the 2 ml of DMSO solution was added to 4 ml of deionized water under stirring, and a nanosuspension with light blue opalescence was rapidly formed. Pour the nanosuspension into a dialysis bag (molecular weight cut off 8,000-14,000), and dialyze in 3L deionized water for 8 hours. The dialyzed nanosuspension was concentrated by ultrafiltration by centrifugation at 1200 rpm for 15 minutes using an ultrafiltration tube with a molecular weight cut off of 30,000. 5% mannitol was added to the ultrafiltrate and freeze-dried to obtain biotinylated pullulan nanoparticles in the form of white powder. Take a certain amount of white powder and redisperse it in a certain volume of deionized water, take the dispersed nano suspension and put it into the sample cell of the laser particle size analyzer for particle size analysis. The measured average particle diameter is 123.6±0.7 nm, and ...

Embodiment 3

[0028] Take 10 mg of biotinylated pullulan and completely dissolve it in 2 ml of DMSO, and add the 2 ml of DMSO solution dropwise to the water phase mixed with 5 ml of deionized water and 5 ml of ethanol under low-speed magnetic stirring, and quickly form a light blue opalescent Nanosuspension. Pour the nanosuspension into a dialysis bag (molecular weight cut off 8,000-14,000), and dialyze in 3L deionized water for 8 hours. The dialyzed nanosuspension was concentrated by ultrafiltration by centrifugation at 1200 rpm for 15 minutes using an ultrafiltration tube with a molecular weight cut off of 30,000. 5% mannitol was added to the ultrafiltrate and freeze-dried to obtain biotinylated pullulan nanoparticles in the form of white powder. The average particle size is 170.7±0.5 nanometers, and the dispersion coefficient is 0.065.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com