Raw material alloy for R-T-B system sintered magnet, R-T-B system sintered magnet and production method thereof

A technology for sintered magnets and sintered bodies, which is used in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc. Effect of improving residual magnetic flux density and coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

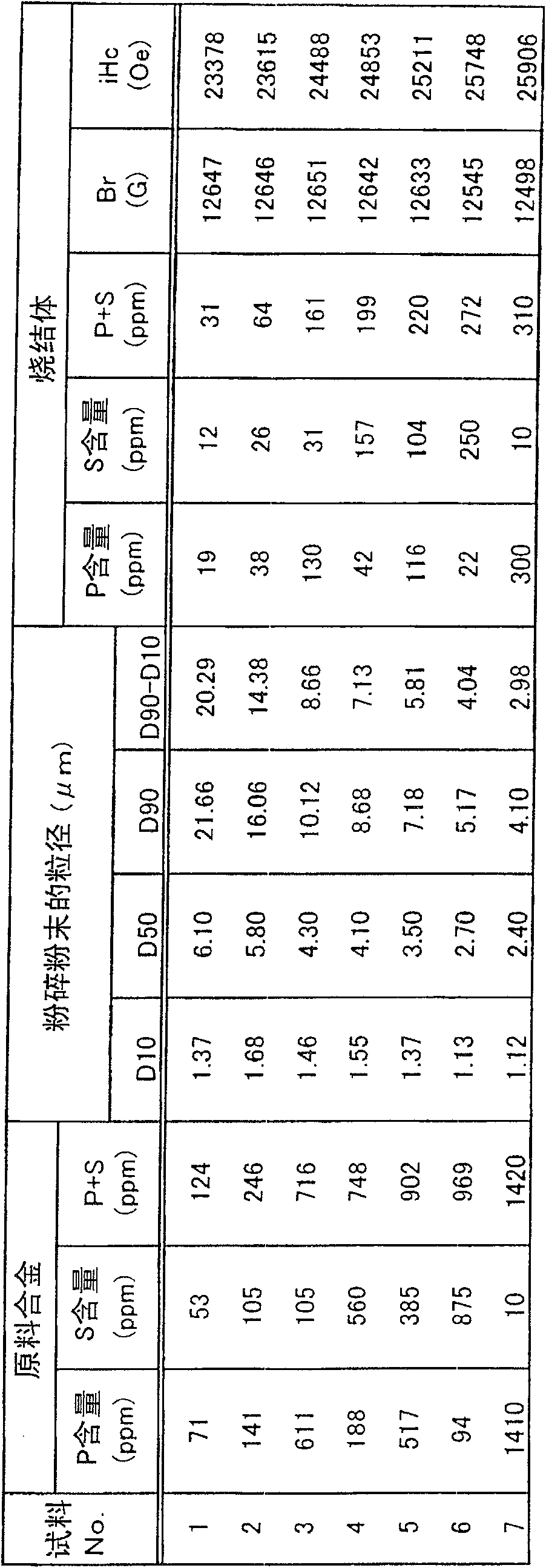

[0057] Prepare high-purity Fe raw materials. The raw material alloy is produced by the strip continuous casting method, and the raw material alloy has a composition of 26.5wt%Nd-5.9wt%Dy-0.25wt%Al-0.5wt%Co-0.07wt%Cu-1wt%B-the balance is Fe. At this time, P (phosphorus) and S (sulfur) are appropriately added to produce raw material alloys with different amounts of P and S.

[0058] Next, hydrogen is absorbed in the raw alloy at room temperature, and then dehydrogenation is performed at 600° C. for 1 hour in an argon atmosphere to perform a hydrogen pulverization treatment. In the alloy subjected to the hydrogen pulverization treatment, 0.05 to 0.1% by weight of lubricants that contribute to improving pulverization and orientation during molding are mixed. The mixing of the lubricant can be carried out for about 5 to 30 minutes using a Nauta-mixer or the like, for example. Then, it is finely pulverized under certain conditions to obtain finely pulverized powder with an average parti...

Embodiment 2

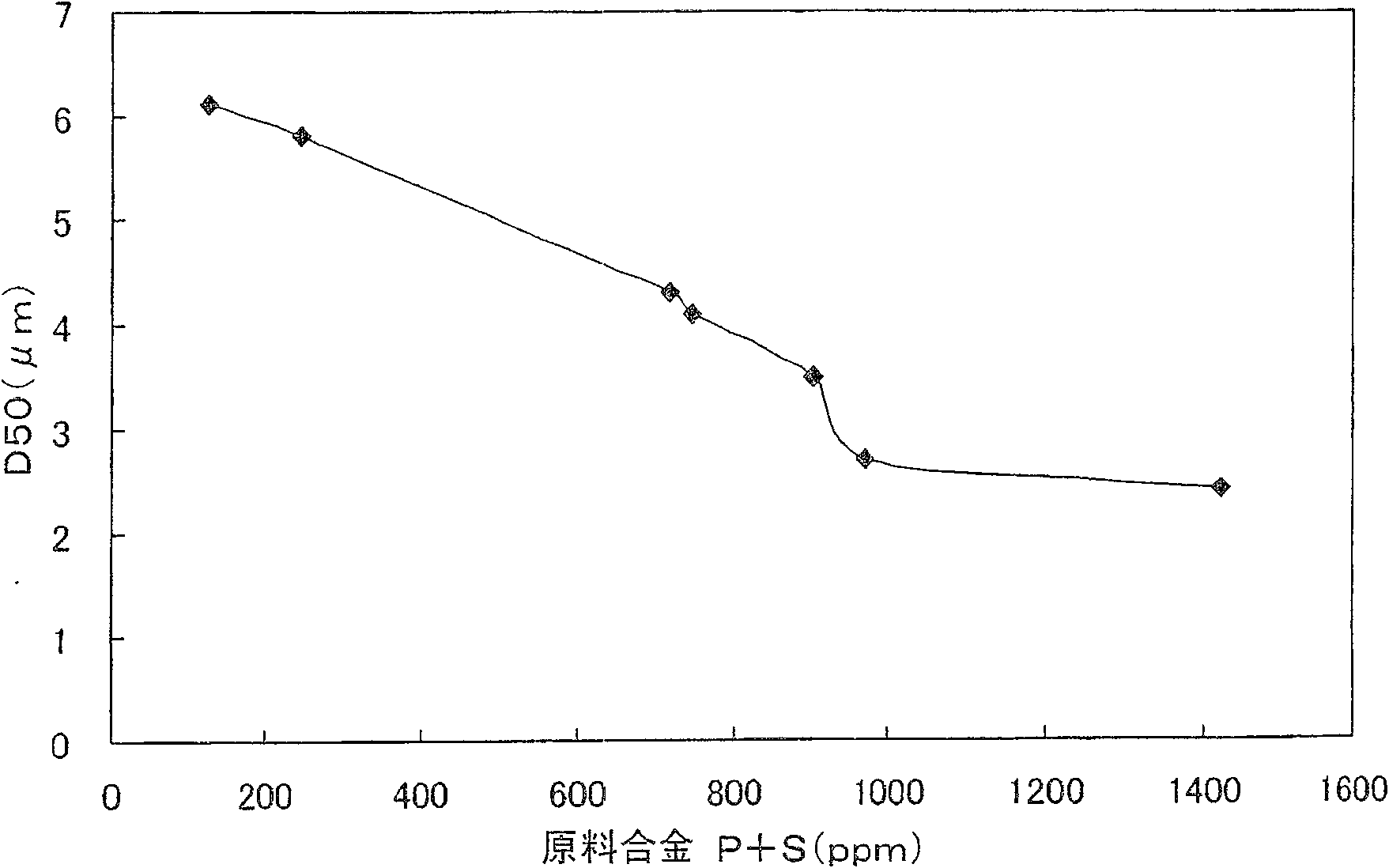

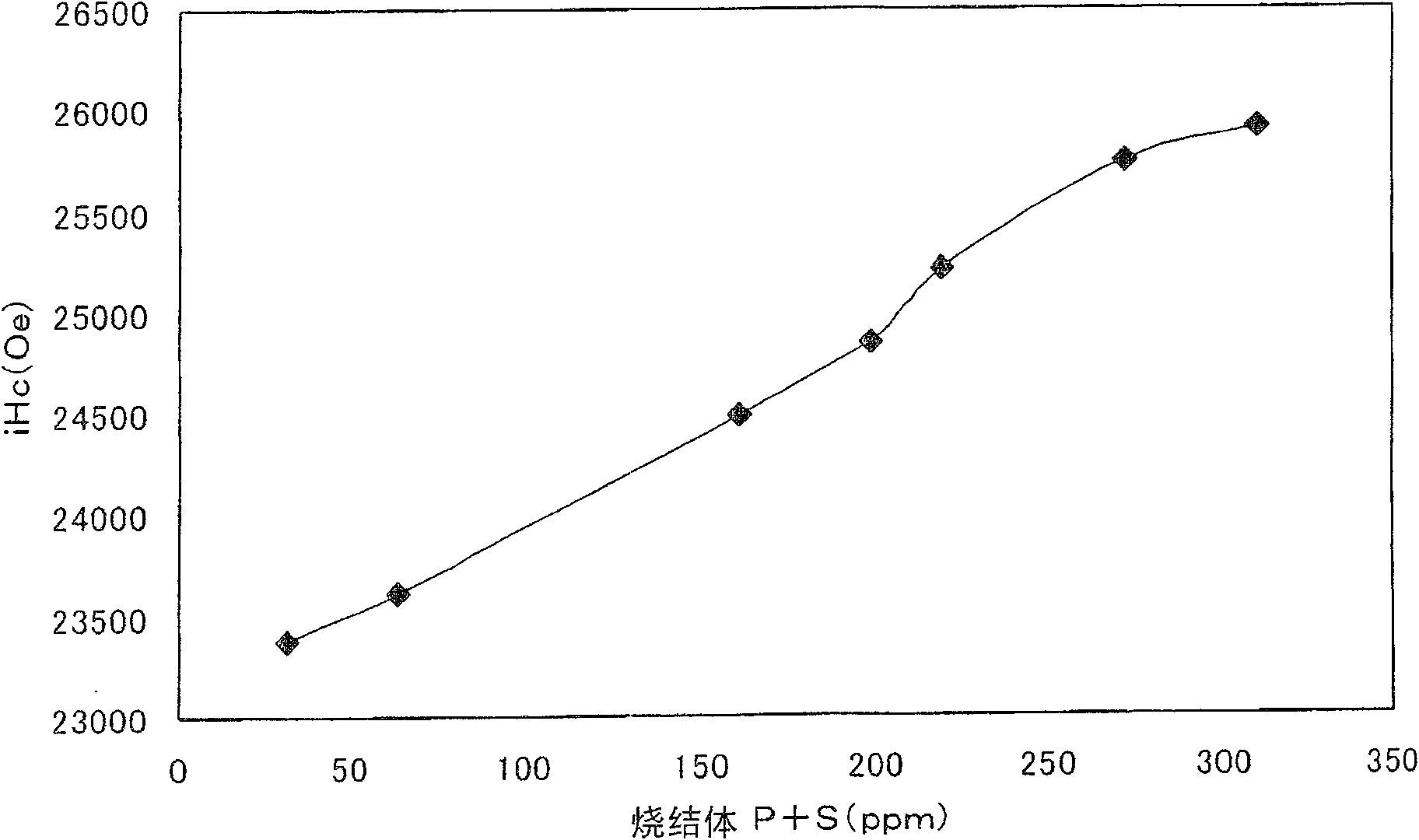

[0066] The alloy composition is set to 28.6wt%Nd-0.2wt%Dy-0.05wt%Al-0.2wt%Co-0.03wt%Cu-1wt%B-0.08wt%Zr-the balance is Fe; (Recovery after pulverization) In each step of sintering (putting into the sintering furnace), the atmosphere of each step is controlled to a level where the oxygen concentration is less than 100 ppm; and the sintering temperature is set to 1070°C. In addition, In the same manner as in Example 1, a sintered body was produced. In this step, the particle size of the finely pulverized powder was measured in the same manner as in Example 1. In addition, the obtained sintered body was measured in the same manner as in Example 1. The result is Figure 5 Shown. In addition, Figure 6 Shows the relationship between the content of P and S in the raw alloy and D50, Figure 7 It shows the relationship between the content of P and S in the sintered body and the coercivity (iHc), and Figure 8 It shows the relationship between the content of P and S in the sintered body and...

Embodiment 3

[0070] The alloy composition is set to 27.2wt%Nd-4.9wt%Pr-0.2wt%Dy-0.25wt%Al-4.0wt%Co-0.3wt%Cu-1.3wt%B-0.25wt%Zr-the balance is Fe ; Further, in each process from the pulverization process (recovery after the pulverization process) to sintering (input into the sintering furnace), the atmosphere of each process is controlled to a level where the oxygen concentration is less than 100 ppm; and the sintering temperature is set Except that the temperature was 1020°C, a sintered body was produced in the same manner as in Example 1. The obtained sintered body was measured in the same manner as in Example 1. The result is Picture 9 Shown. In addition, Picture 10 Shows the relationship between the content of P and S in the raw alloy and D50, Picture 11 It shows the relationship between the content of P and S in the sintered body and the coercivity (iHc), and Picture 12 It shows the relationship between the content of P and S in the sintered body and the residual magnetic flux density (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com