Clean production method for rice-wheat straw pulp capable of poaching by acetic acid method

A technology of clean production and acetic acid method, which is applied in the direction of pulping with organic solvents, pulping of cellulose raw materials, washing/replacing pulp treatment liquid, etc., can solve the problems of difficult operation, difficult scale removal, complicated process, etc., and achieve The process is simple and easy, preventing the lignin condensation reaction and accelerating the effect of delignification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 industrialized production test

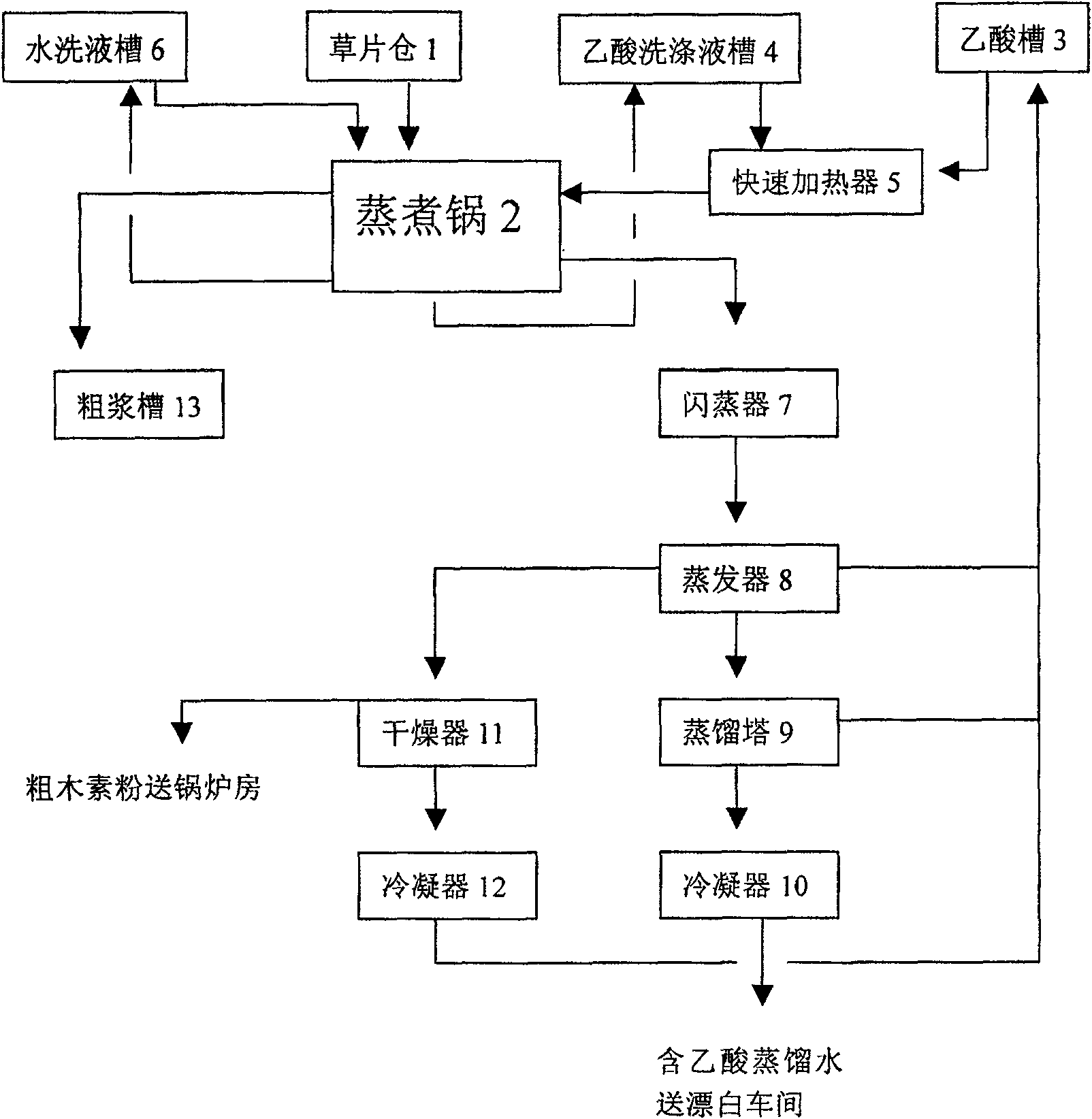

[0042] A clean production method of rice-wheat straw bleachable pulp by acetic acid method, characterized in that the process steps are as follows:

[0043] A. Add the chopped, screened and purified grass slices from the grass slice warehouse 1 to the cooking pot 2, use a vacuum pump to remove the air in the pot until the vacuum degree reaches 360-260 mm Hg, and then add the dried grass slices per kilogram. 4-12 liters of acetic acid solution is pumped into the cooking pot 2 from the acetic acid tank 3 through the fast heater 5, and the temperature in the cooking pot 2 is maintained at 110-135°C for 45-140 minutes. The pressure hydraulically pumps the spent acid into the flasher 7 .

[0044] The lower part of the cooking pot 2 is provided with a screen with an aperture of 1-8mm.

[0045] Catalyst (CaCl 2 +HCl) and additive NaCl, wherein the concentration of acetic acid is 55-95%, containing CaCl in every liter of acetic a...

Embodiment 2

[0051] Embodiment 2 laboratory test

[0052] Take 66 grams of air-dried straw with a moisture content of 12% and place it in a flask, add 600ml of acetic acid with a concentration of 849.5 grams per liter, and 1 liter of acetic acid contains 3.33 grams of CaCl 2 , 1.44 gram HCl, 1.94 gram NaCl, reflux heating 3 hours, pour out the waste liquid, wash 2 times with the acetic acid of 842 grams per liter with the concentration of 550ml, fully wash the paper pulp with clear water at last. Obtain 37.2 grams of fine pulp, 0.3 g of undistilled fraction, 64.1% yield of fine pulp, K value 18.

Embodiment 3

[0053] Embodiment 3 laboratory tests

[0054] Take by weighing 66 grams of air-dried wheat straw pulp (moisture content 12%) in the flask, add 600ml concentration and be the acetic acid of 918 grams / liter, contain 3.33 grams of CaCl in 1 liter of acetic acid 2 , 1.23 gram HCl, 1.94 gram NaCl, reflux heating 3 hours, pour out waste liquid, be that the acetic acid washing 3 times of 918 grams per liter with 600ml concentration, fully wash paper pulp with clear water at last. 38.7 grams of fine pulp were obtained, the undistilled score was 0, the yield of fine pulp was 65.1%, and the K value was 20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com