Air spring vibration insulating foundation with gas lubrication unit

A technology of gas lubrication and air spring, which is applied in the direction of non-rotational vibration suppression, can solve the problems of horizontal and vertical vibration isolation, etc., and achieve the effect of overcoming the poor bearing capacity and maintaining the inherent bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

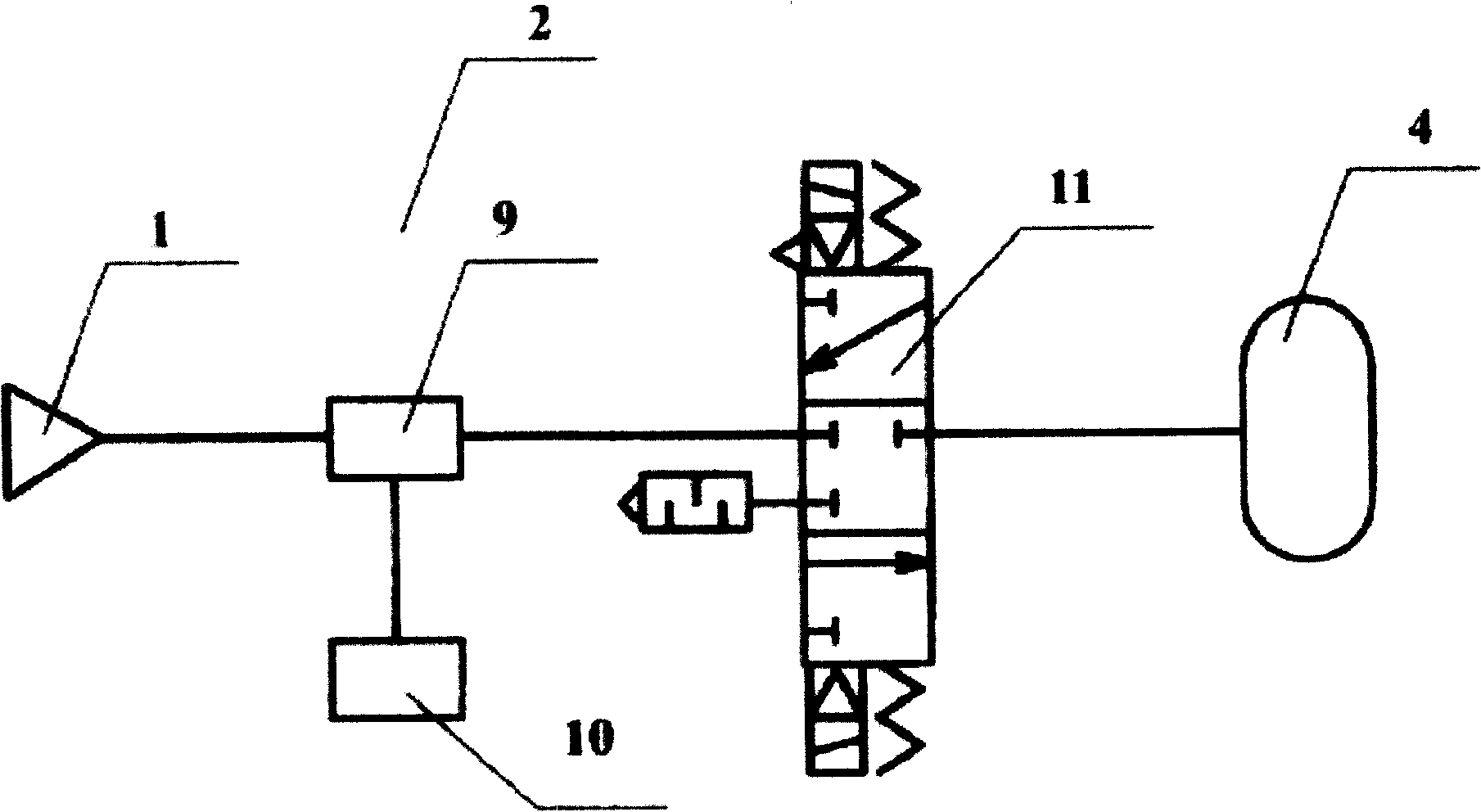

[0022] The system structure and working principle of an air spring vibration isolation foundation with a gas lubrication unit according to the present invention are described in detail in conjunction with the embodiments and accompanying drawings as follows:

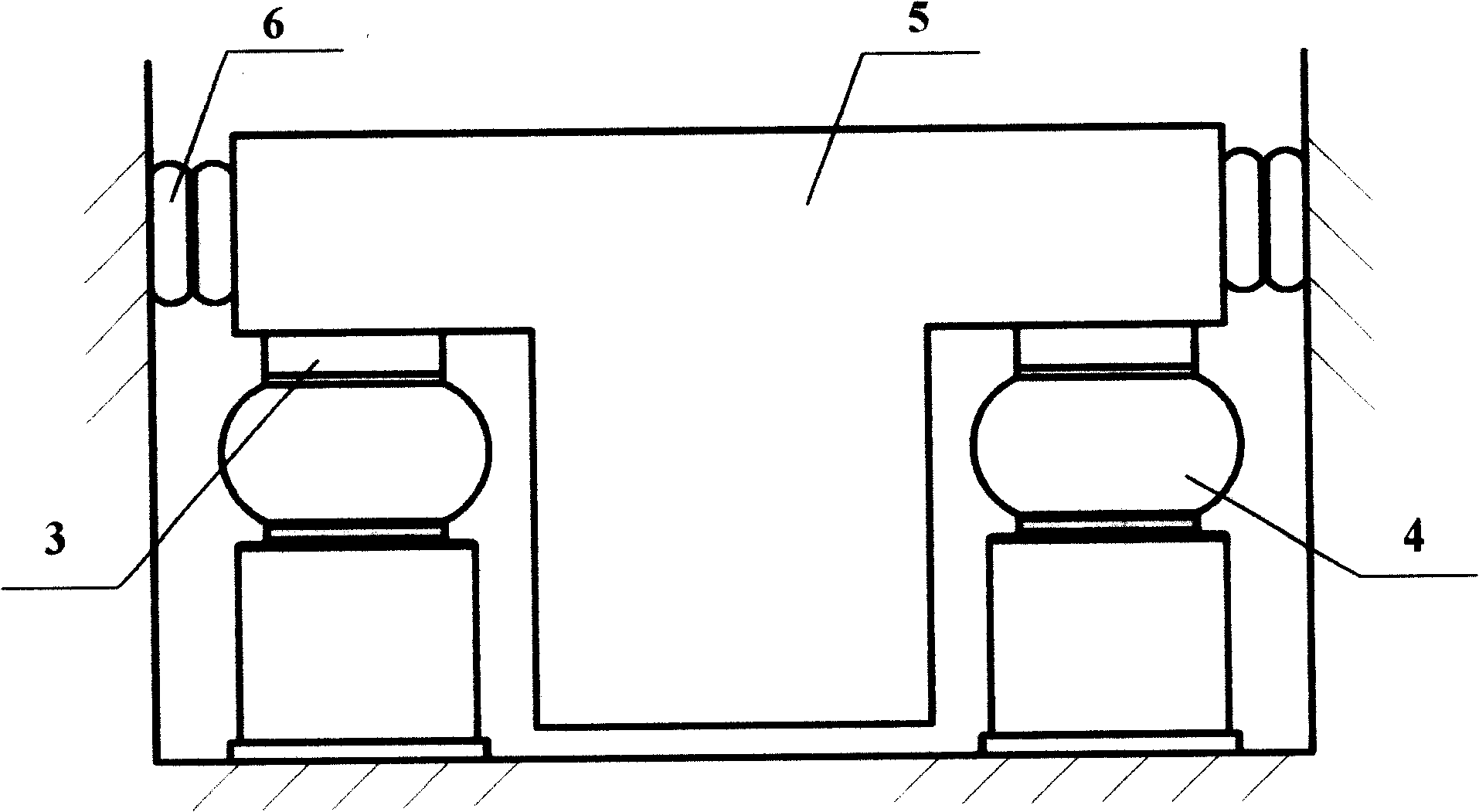

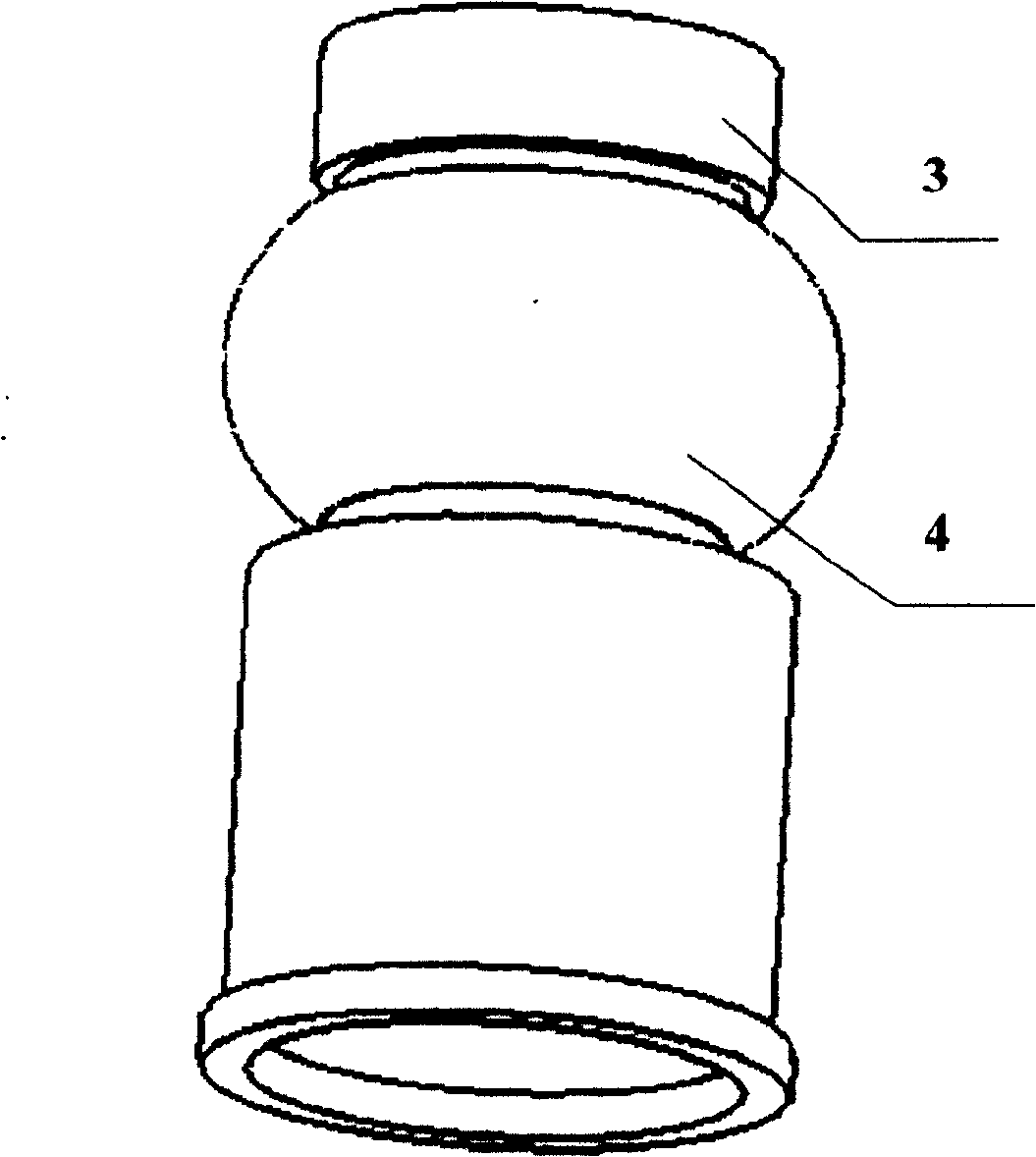

[0023] An embodiment of an air spring vibration isolation foundation with a gas lubrication unit of the present invention, the structure is as follows figure 1 As shown, it includes: base body 5, multiple air springs 4, multiple gas lubricating units 3, the series structure composed of gas lubricating units 3 and air springs 4 supports the base body 5, and the side of the base body 5 is arranged with a low-stiffness centralizing device 6.

[0024] Since the lateral friction of the gas lubrication unit 3 approaches zero, its equivalent lateral stiffness in series with the air spring 4 is zero, and the equivalent longitudinal stiffness is:

[0025] k = k ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com