Floating type installation structure and method for offshore converter station

A technology for installing structures and converter stations, which is applied to floating buildings, ship safety, transportation and packaging, etc., and can solve problems such as equipment damage, excessive structural deformation, and low structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Referring to the drawings and specific embodiments of the present invention will be further described in detail.

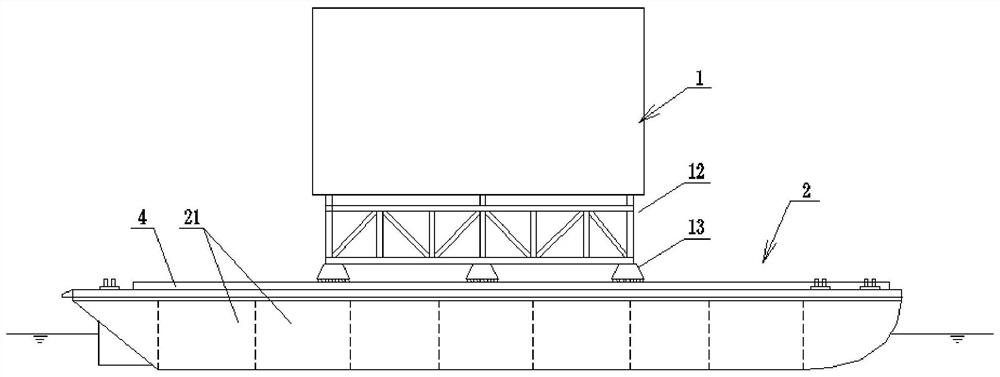

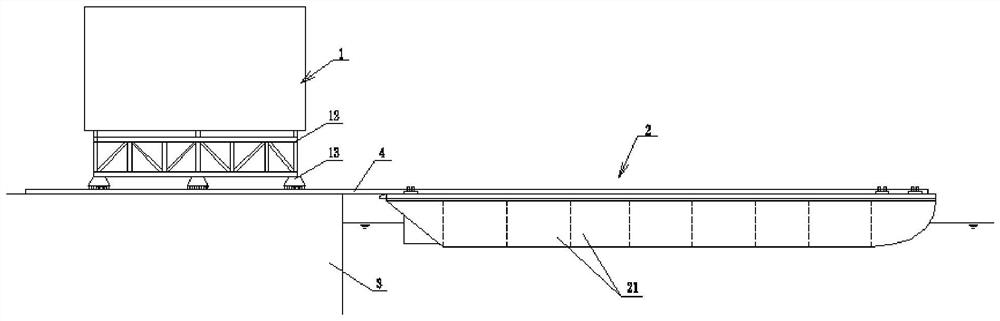

[0035] (1) such as Figure 1 ~ 3As shown in offshore topside converter station 1 and the floating vessel 2 Torr composition float system. Land 3 free start of construction, i.e., the upper block 1 and the support frame 12 by a shoe 13 located in the upper rail 4, and moved by the float-ship slide rail 4 after the completion of construction of the two. Bilaterally floating vessel holder 2, the anti-shake floating body 21 is provided by a fixed frame 22 fixed to both sides of the ship. Closed box structure 21 of the anti-shake with steel floating body is provided with internal reinforcing ribs and drainage, water injection system. Anti-shake floating body on the side of the ship and the ship's side connector 21, the fixed frame 22 is provided with an upper deck of the ship are connected. Before shipment, the anti-shake float 21 and the fixed frame 22 mounted on a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com