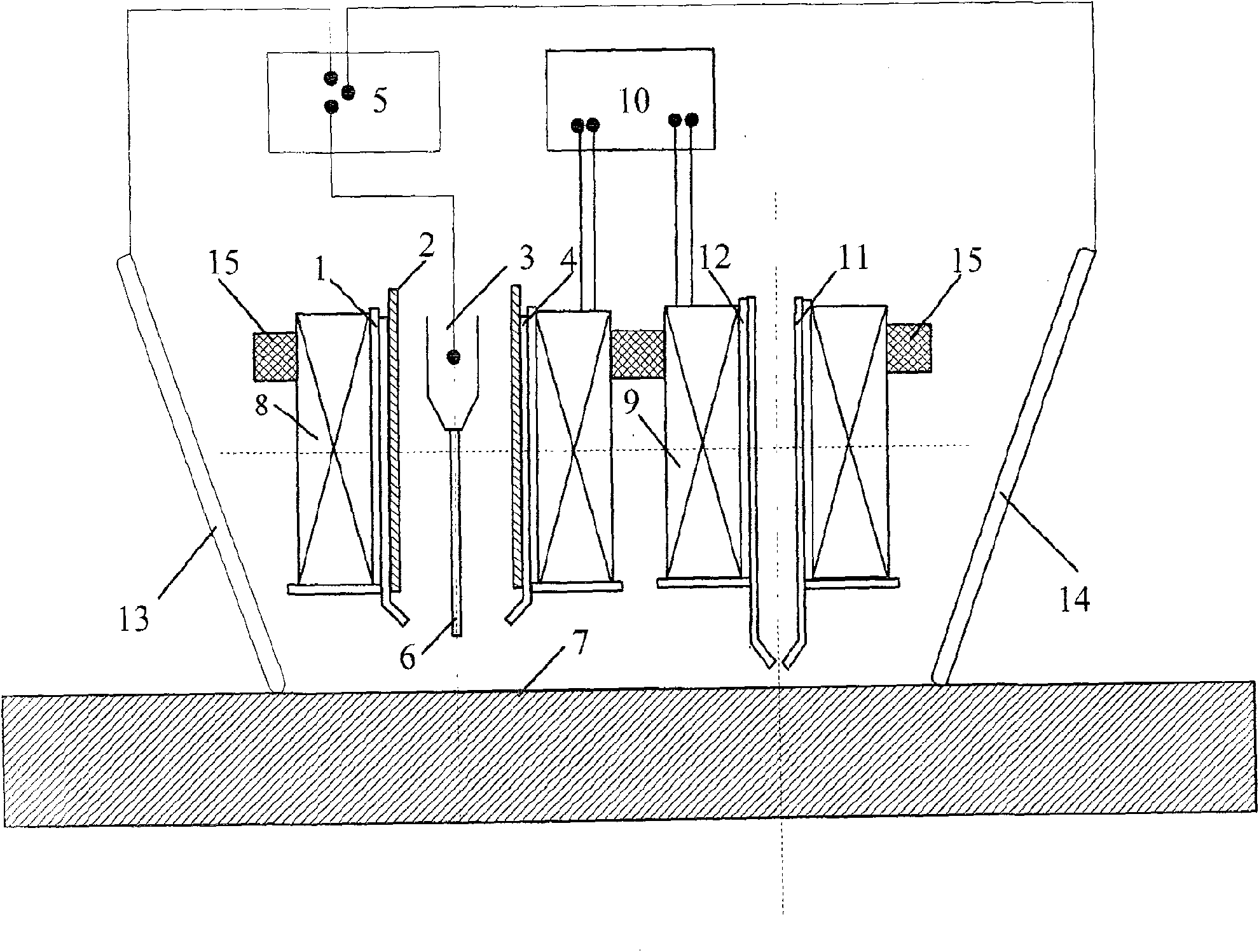

Consumable electrode surfacing method of electromagnetic complex field, and the device and extended application thereof

An electromagnetic composite, melting electrode technology, applied in non-electric welding equipment, arc welding equipment, resistance welding equipment and other directions, can solve the problems of difficult surfacing welding quality, low degree of automation, high labor intensity, etc., to reduce sensitivity and change solidification. process, the effect of changing the crystallization state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

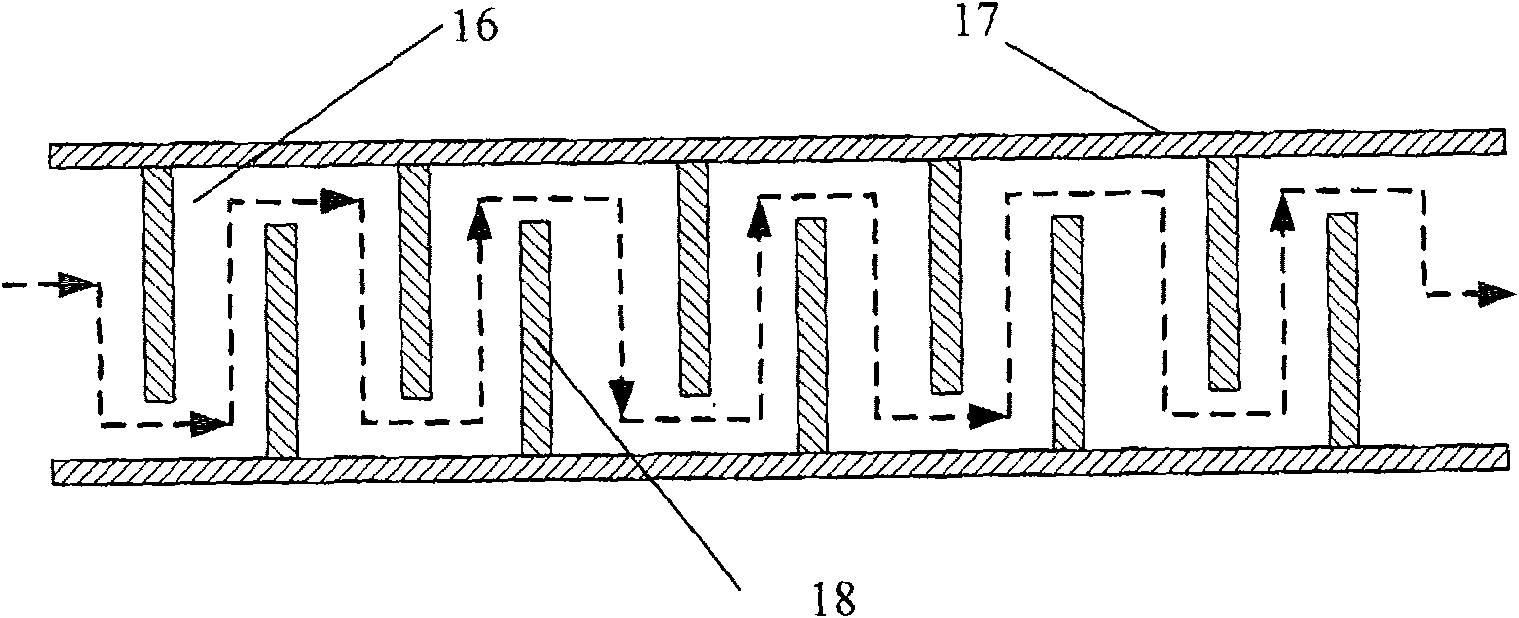

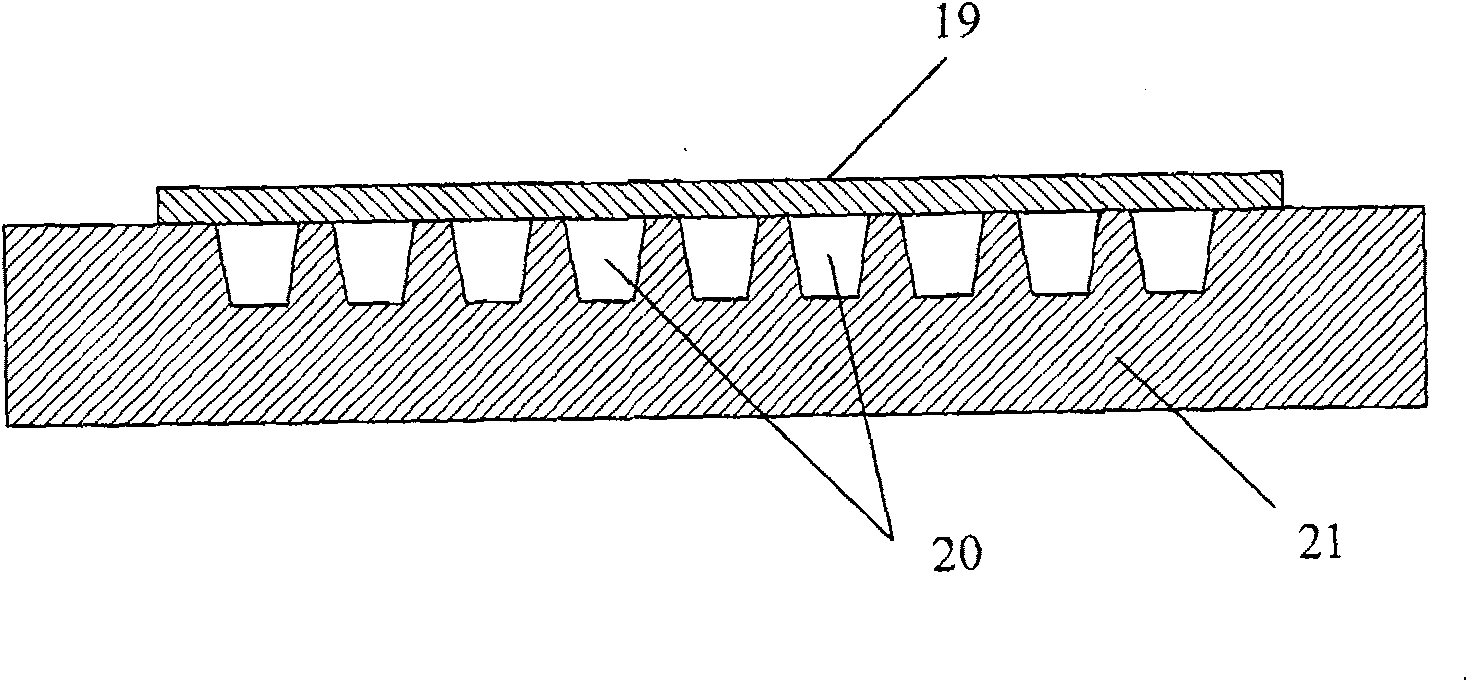

Method used

Image

Examples

example 1

[0124] Example 1: When applying intermittent alternating longitudinal magnetic field to control carbon dioxide surfacing welding flux-cored wire Fe-Cr-Mn-W-V series high-carbon high-chromium alloy, the surfacing process parameters are as follows to obtain a good surfacing welding function layer: the excitation current of the electromagnetic stirring magnetic field is 3~20A, electromagnetic stirring magnetic field frequency 1~6Hz, welding current 100~200A, welding speed 0.3~0.8m / min, 100% carbon dioxide shielding gas 5~20L / min, wire feeding speed 3.5~0.8m / min.

example 2

[0125] Example 2: When an external electromagnetic composite field is applied to control MAG surfacing welding of Cr-W-Co hard alloys, the surfacing process parameters are as follows to obtain a good surfacing welding functional layer: the welding current is 120-180A, and the electromagnetic stirring magnetic field frequency is 1- 4Hz, auxiliary electric field strength current 10A ~ 40A, welding speed 0.3 ~ 1m / min. The intensity of the electromagnetic heat treatment magnetic field is 0.01T-0.2T, the frequency of the electromagnetic heat treatment magnetic field is 1-20Hz, and the flow rate of the protective gas (100% pure argon) is 5-20L / min.

example 3

[0126] Example 3: When the high-efficiency MAG surfacing welding of Fe-Ni-Cr-B-Si alloy is controlled by an external electromagnetic compound field, the surfacing welding process parameters are as follows to obtain a good surfacing welding functional layer: welding current is 350-700A, electromagnetic stirring magnetic field excitation current 5-30A, electromagnetic stirring magnetic field frequency 1-8Hz, auxiliary electric field strength current 5A-30A, welding speed 0.8-4m / min. The excitation current of the magnetic field for electromagnetic heat treatment is 15-40A, the frequency of the magnetic field for electromagnetic heat treatment is 1-25Hz, and the flow rate of protective gas (100% pure argon) is 20-30L / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com