Novel dual metal composite pipes and preparation method

A bimetallic composite pipe and a manufacturing method are applied in the field of steel pipe manufacturing to achieve the effects of excellent corrosion resistance, excellent mechanical and mechanical properties, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

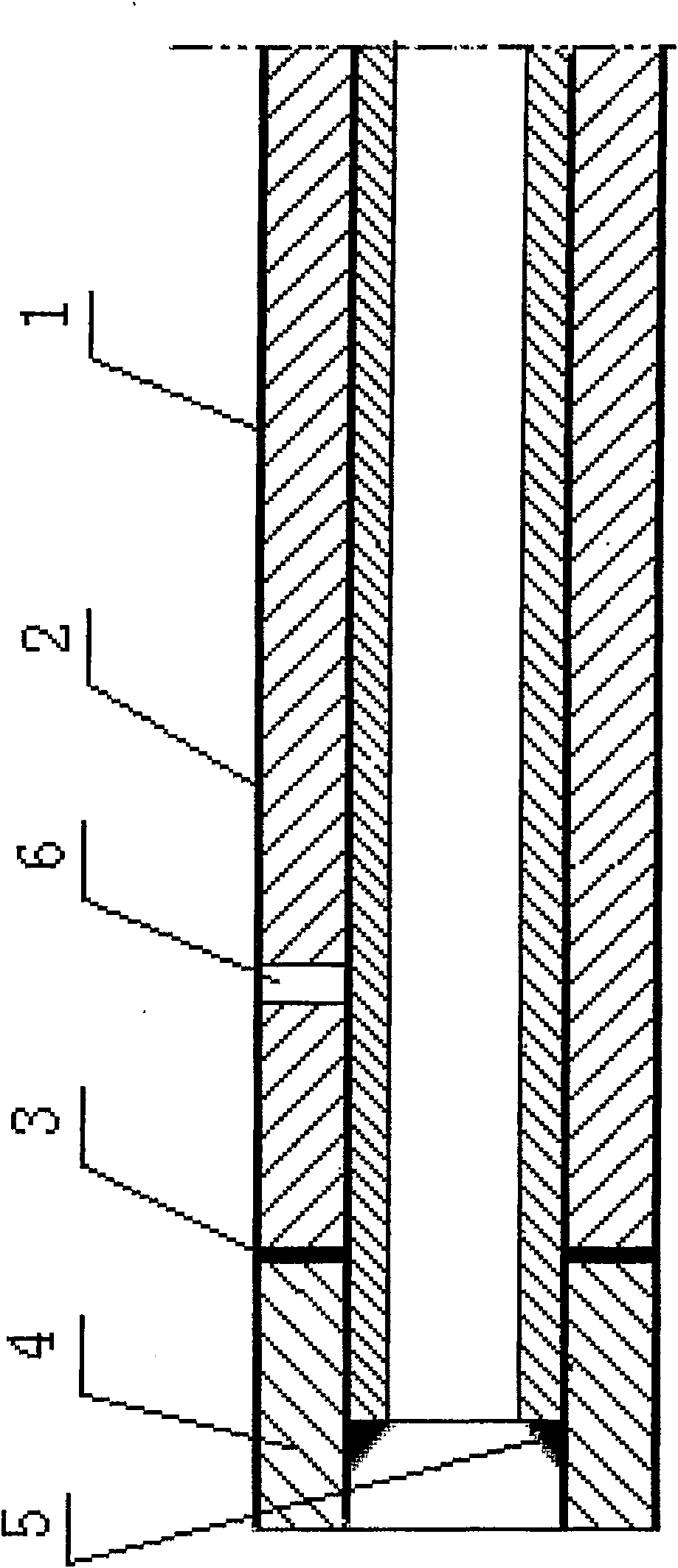

[0026] Embodiment 1: see attached figure 1 . The material of the outer wall pipe 1 is 16Mn low alloy steel, the inner diameter of the outer wall pipe 1 is 152.3 mm, the thickness is 8 mm, and the length is 12000 mm. The material of the lining pipe 2 is 316L stainless steel, the outer diameter of the lining pipe 2 is 150 mm, the thickness is 3 mm, and the length is 12060 mm. The short joint 4 is made of 316L corrosion-resistant stainless steel. The inner diameter of the short joint 4 is 152.3 mm, the thickness is 11 mm, and the length is 80 mm.

[0027] The outer wall pipe 1 is covered with an inner liner pipe 2 . Both ends of the outer wall pipe 1 are welded with short joints 4 , there is a weld 3 between the outer wall pipe 1 and the short joint 4 , and the two ends of the inner liner pipe 2 are welded on the inner wall of the short joint 4 . Drill 3 through holes 6 with a diameter of 5 mm on the outer wall pipe 1 wall. The through hole 6 drilled on the wall of the outer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com