High-strength ship hull structural steel and production method of plate roll

A technology for structural steel and production methods, applied in the direction of furnace types, furnaces, rolling mill control devices, etc., can solve the problems of unstable heating temperature of slabs, uneven temperature distribution, and large occupation of working capital, so as to reduce working capital, Excellent flatness and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

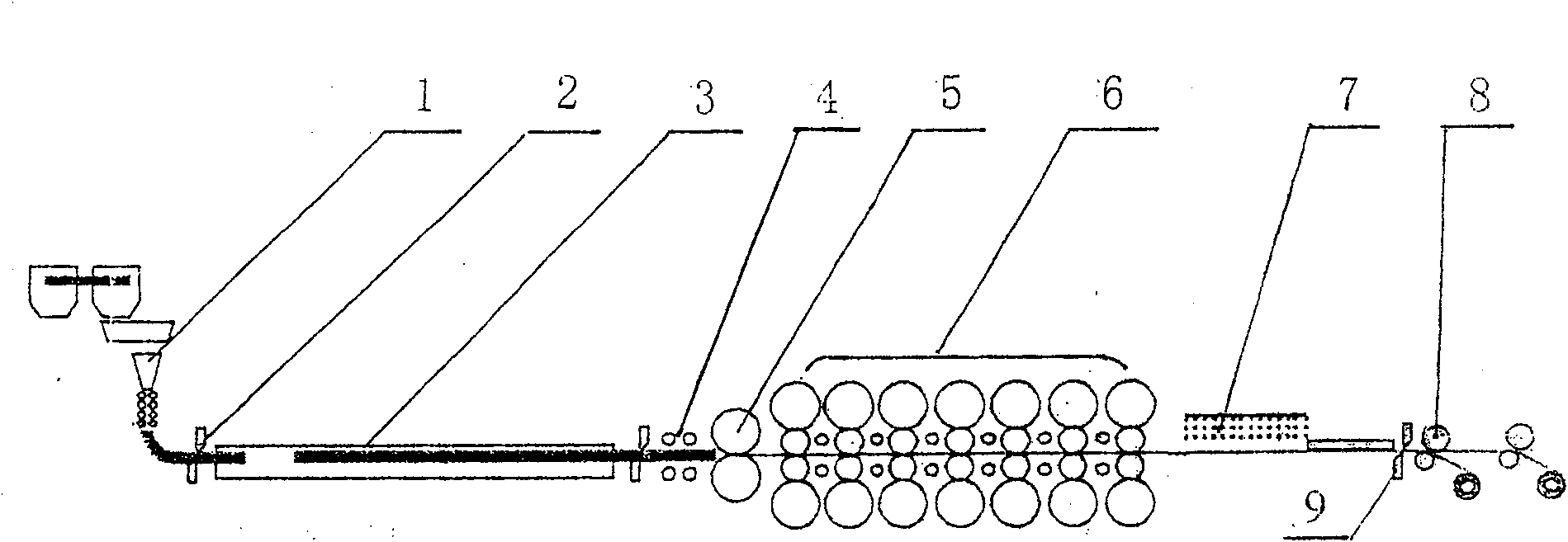

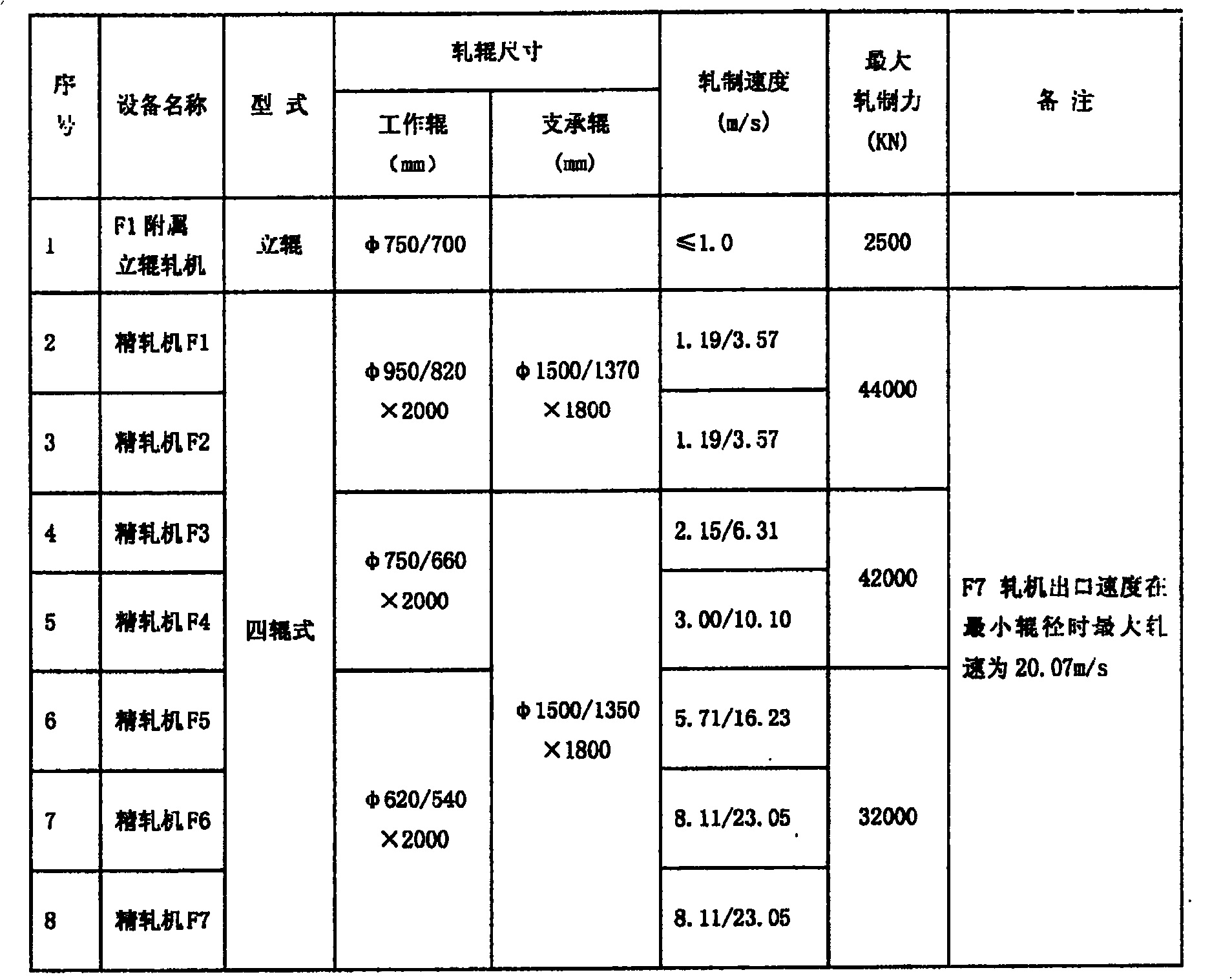

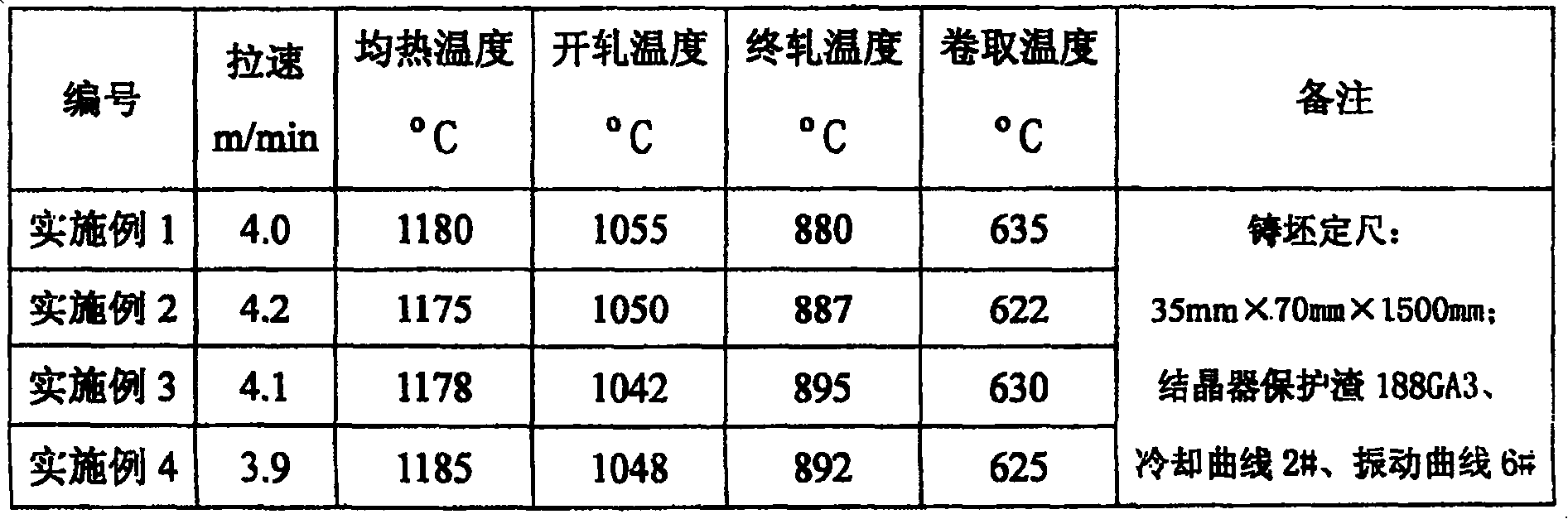

[0048]Example 1: Rolling 3.5mm ship plate, qualified molten steel, casting slabs at a casting speed of 4.0m / min through CSP continuous casting machine 1 (mold mold slag 188GA3, cooling curve 2#, vibration curve 6#), and then hydraulically Cut 2 into a fixed length (35m×70mm×1500mm), enter the soaking furnace 3 for heating, the soaking temperature is controlled at 1180±10°C, exit the soaking furnace, go through the high-pressure water descaling machine 4, and enter the vertical roller mill 5 After side pressing, it enters the seven-stand continuous rolling mill for 6 continuous rolling, the starting rolling temperature is 1050±10°C, and the final rolling temperature is 890±10°C. After exiting the last rolling mill, it passes through the laminar flow device 7 for controlled cooling at the rear stage, cuts the head through the flying shear 9, and is coiled into a hot-rolled coil by the coiler 8. The coiling temperature is 640°C, and then it is rolled off the production line. In T...

Embodiment 2

[0049] Embodiment 2: with the method for embodiment 1, roll the ship plate of 4.0mm, its steel plate composition is listed in table 1, and its performance test data is listed in table 2, and relevant process parameter is listed in table 3.

Embodiment 3

[0050] Embodiment 3: with the method for embodiment 1, roll the ship plate of 5.5mm, its steel plate composition is listed in table 1, and its performance test data is listed in table 2, and relevant process parameter is listed in table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com