Process for preparing polyester and copolyester

A technology of copolyester and polyester, which is applied in the field of catalyst preparation, can solve problems such as difficult dissolution, product quality fluctuation, and unevenness, and achieve the effects of improving catalytic activity and selectivity, improving quality, and reducing b value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

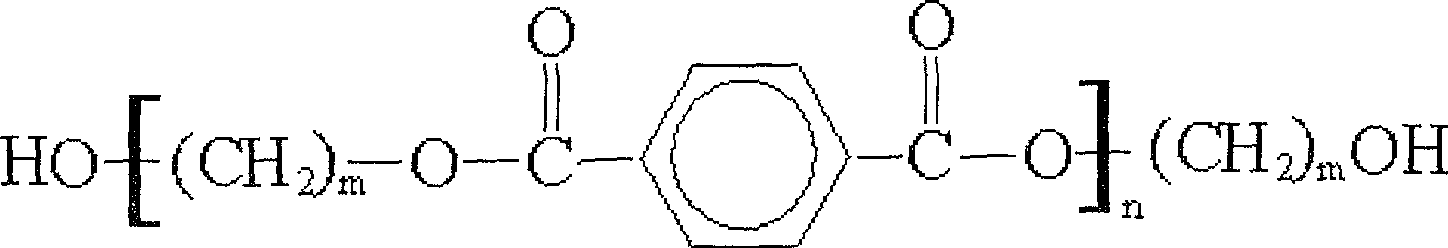

Image

Examples

Embodiment 1

[0027] Prepare titanium silicon catalyst according to the method disclosed in patent CN1415643A:

[0028] Dissolve 50 g of tetrabutyl titanate and 2 g of ethyl orthosilicate in 150 ml of absolute ethanol (solution A). 30 g of deionized water and 5 ml of phosphoric acid (15 mol / l) were dissolved in 150 ml of absolute ethanol (solution B). With uniform stirring, B was added dropwise to A to produce a white precipitate. The mixture was stirred for 3 hours, centrifuged, and the precipitate was washed with ethylene glycol to obtain a white slurry-like titanium-silicon catalyst containing ethylene glycol.

Embodiment 2

[0030] Add the titanium-silicon catalyst in the form of white slurry containing ethylene glycol obtained in Example 1 into 250ml of ethylene glycol, reflux at 190°C for 2 hours, the catalyst is completely dispersed and dissolved, and the catalyst solution A is obtained. The pH value of A is about 5.0, and the titanium The active ingredient content of the silicon catalyst is 1.0%. Placed in the air for 90 days, the solution is still clear without turbidity.

Embodiment 3

[0032] Heat 250ml of ethylene glycol to 170°C, add the white slurry-like titanium-silicon catalyst containing ethylene glycol obtained in Example 1, the catalyst gradually dissolves, and the dissolved catalyst solution is kept warm for 2 hours to obtain catalyst solution B, titanium-silicon The active ingredient content of the catalyst is 1.0%. B was placed in the air for 90 days, the solution was still clear and no precipitation occurred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com