PTFE/C composite powder for low temperature fuel cell electrode and its uses

A fuel cell electrode and composite powder technology, which is applied to battery electrodes, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. Advanced problems, to achieve the effect of high equipment requirements and complex preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of PTFE / C composite powder:

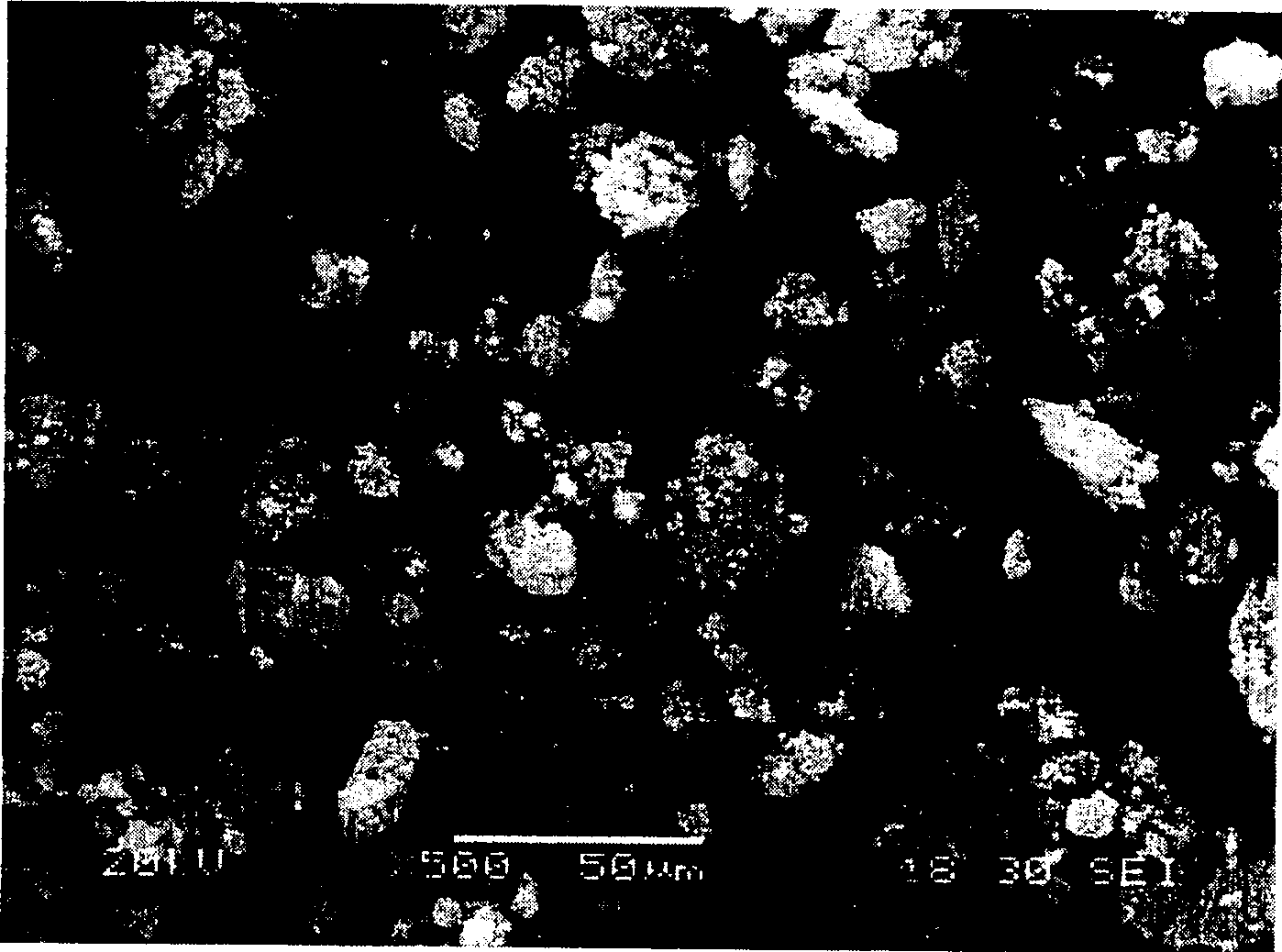

[0032] Take 5.0g VulcanXC-72 conductive carbon black, wet it with 10mL isopropanol solution, add 150mL deionized water, stir mechanically for 15min, and then perform ultrasonic treatment for 30min. Then, under mechanical stirring, 50g of 10wt% PTFE emulsion was slowly added dropwise, heated and dried under stirring to prepare a PTFE / C composite precursor with a PTFE content of 50wt%. Put this precursor into a microwave oven (LG WD700, 700W, 2450MHz), and perform a heating procedure of microwave heating for 5s and stopping for 20s four times to remove residual water in the sample. Subsequently, the heating procedure of heating for 20s and stopping for 60s was carried out twice, and after the temperature of the sample dropped to room temperature, it was weighed to obtain a PTFE / C composite powder with a PTFE content of 30wt%. Its SEM photo and EDX spectrogram are shown in accompanying drawing 1, from appendix Figure 1a It can be...

Embodiment 2

[0037] Preparation of PTFE / C composite powder:

[0038] Take 5.0g of acetylene black, wet it with 10mL of isopropanol solution, add 500mL of deionized water, stir mechanically for 15min, and then perform ultrasonic treatment for 30min. Then, under mechanical stirring, 0.51g of 10wt% PTFE emulsion was slowly added dropwise, and heated and dried under stirring to prepare a PTFE / C composite precursor with a PTFE content of 1wt%. Put this precursor into a microwave oven (LG WD700, 700W, 2450MHz), and perform a heating procedure of microwave heating for 5s and stopping for 20s four times to remove residual water in the sample. Subsequently, the heating procedure of heating for 20s and stopping for 60s was repeated to obtain a PTFE / C composite powder with a PTFE content of 0.5 wt%.

[0039] Membrane electrode preparation:

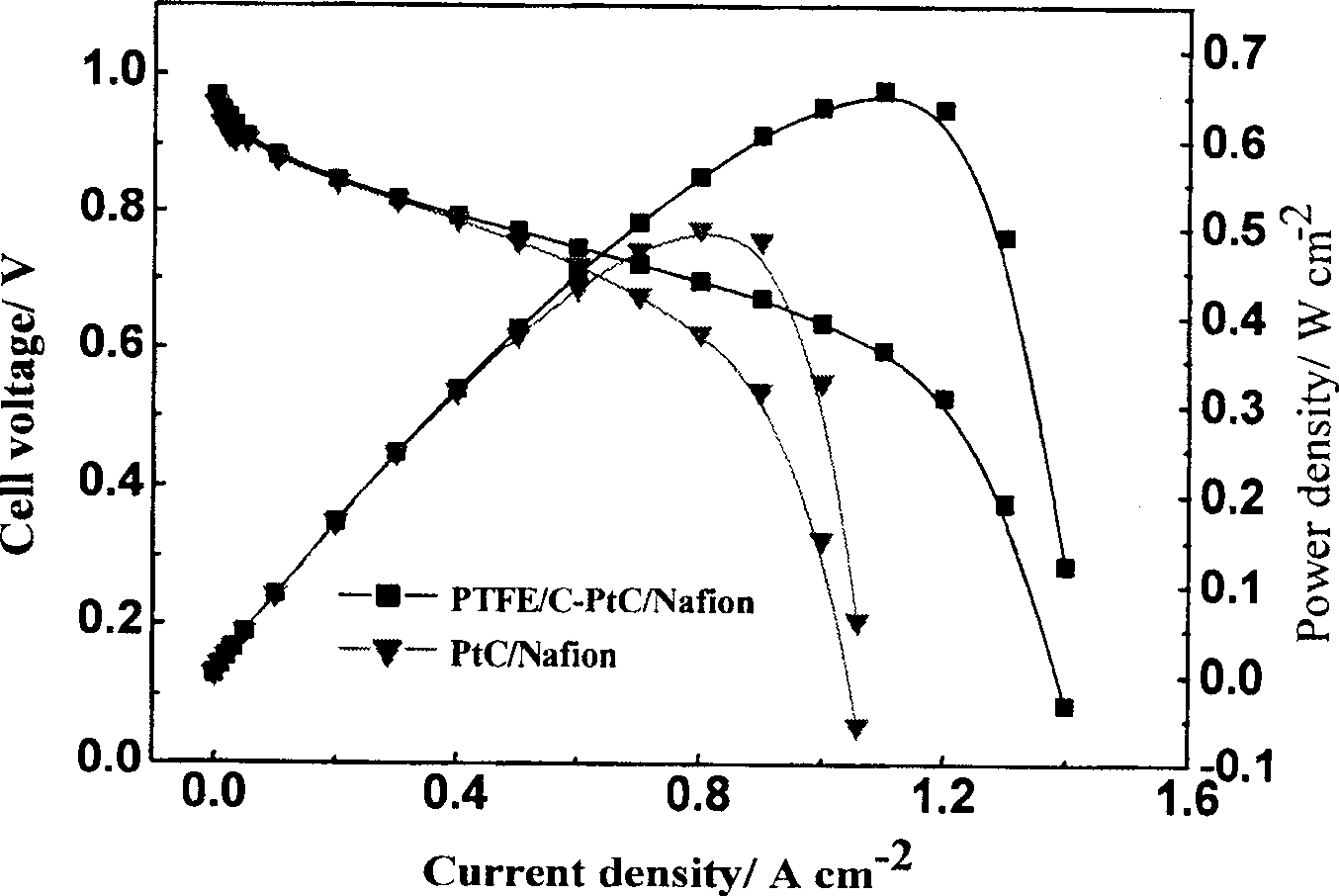

[0040] Get 20.0mg50wt%Pt / C catalyst (purchased from Tanaka Company, add 2mL isopropanol solution, after ultrasonic dispersion for 15min, add 70.6mg5wt%Nafion s...

Embodiment 3

[0042] Preparation of PTFE / C composite powder:

[0043] Take 5.0g of acetylene black, wet it with 10mL of isopropanol solution, add 500mL of deionized water, stir mechanically for 15min, and then perform ultrasonic treatment for 30min. Then, under mechanical stirring, 80g of 10wt% PTFE emulsion was slowly added dropwise, heated and dried under stirring to prepare a PTFE / C composite precursor with a PTFE content of 62wt%. Put this precursor into a microwave oven (LG WD700, 700W, 2450MHz), and repeat the heating procedure of microwave heating for 5s and stopping for 20s to remove the residual water in the sample. Subsequently, the heating procedure of heating for 20s and stopping for 60s was repeated to obtain a PTFE / C composite powder with a PTFE content of 50 wt%.

[0044] Membrane electrode preparation:

[0045] Get 20.0mg 50wt% Pt / C catalyst (purchased from Tanaka Company, add 2mL isopropanol solution, after ultrasonic dispersion for 15min, add 266.7mg5wt%Nafion solution (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com