Process for preparing ethylene, propylene and aromatic hydrocarbons by C4 alkene catalytic conversion

A technology for catalytic conversion and olefins, which is applied in chemical instruments and methods, hydrocarbon cracking to produce hydrocarbons, and bulk chemical production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

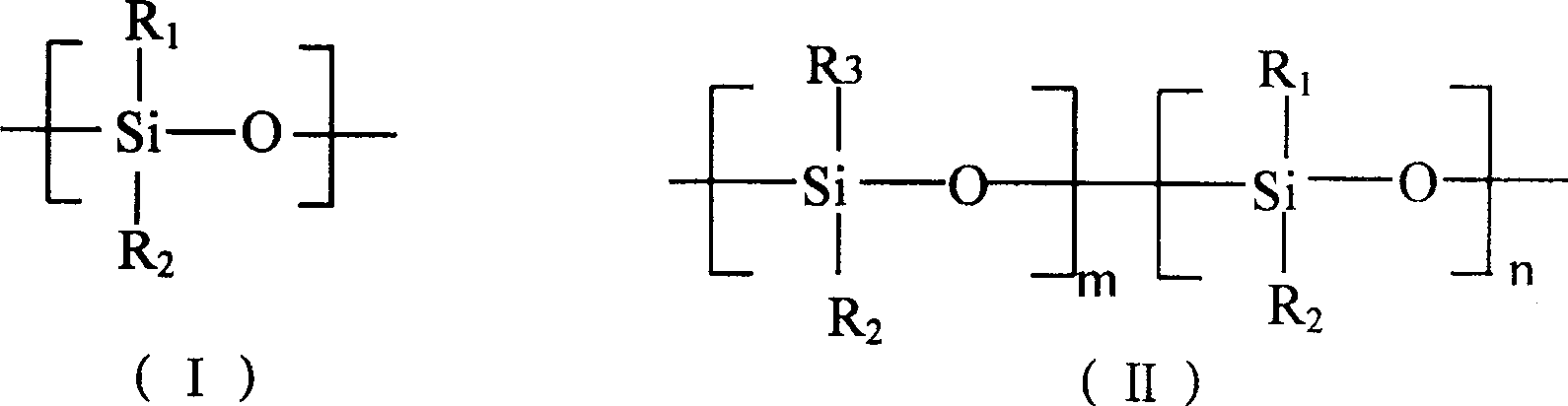

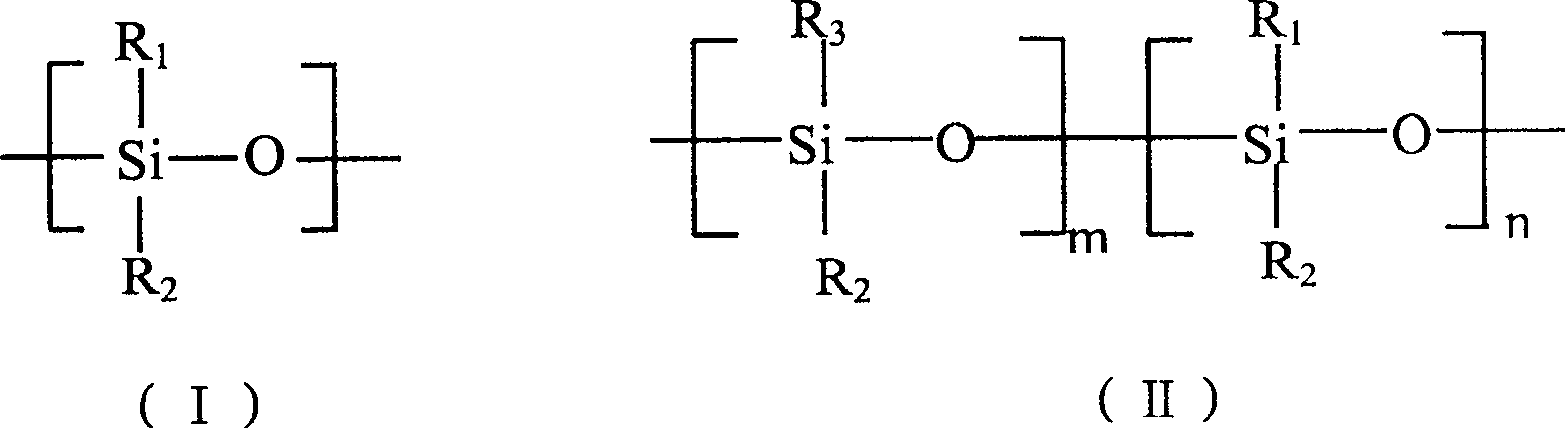

[0013] The preparation method of the catalyst of the present invention comprises mixing HZSM-5 and silicon dioxide uniformly at a mass ratio of 0.8 to 14:1, adding silica sol and kneading, molding, drying, and roasting to obtain the catalyst, and the catalyst is heated at 400 to 800 ° C. Carry out water vapor treatment, then impregnate the catalyst after water vapor treatment with polysiloxane or polysiloxane aqueous solution, dry and roast.

[0014] In the above method, when the catalyst is molded, the HZSM-5 and silicon dioxide are firstly mixed evenly, and preferably 1-3% of the total mass of the mixture is added to the extrusion aid Selina powder. Then add silica sol to the mixture and knead. The content of silicon dioxide in the silica sol is preferably 10-75% by mass. The kneaded material is extruded into strips, dried, pelletized, and calcined to obtain the catalyst. This catalyst is treated with water vapor, and the mass ratio of water vapor and catalyst passing throu...

example 1

[0025] Prepare the silicon-modified catalyst described in the present invention.

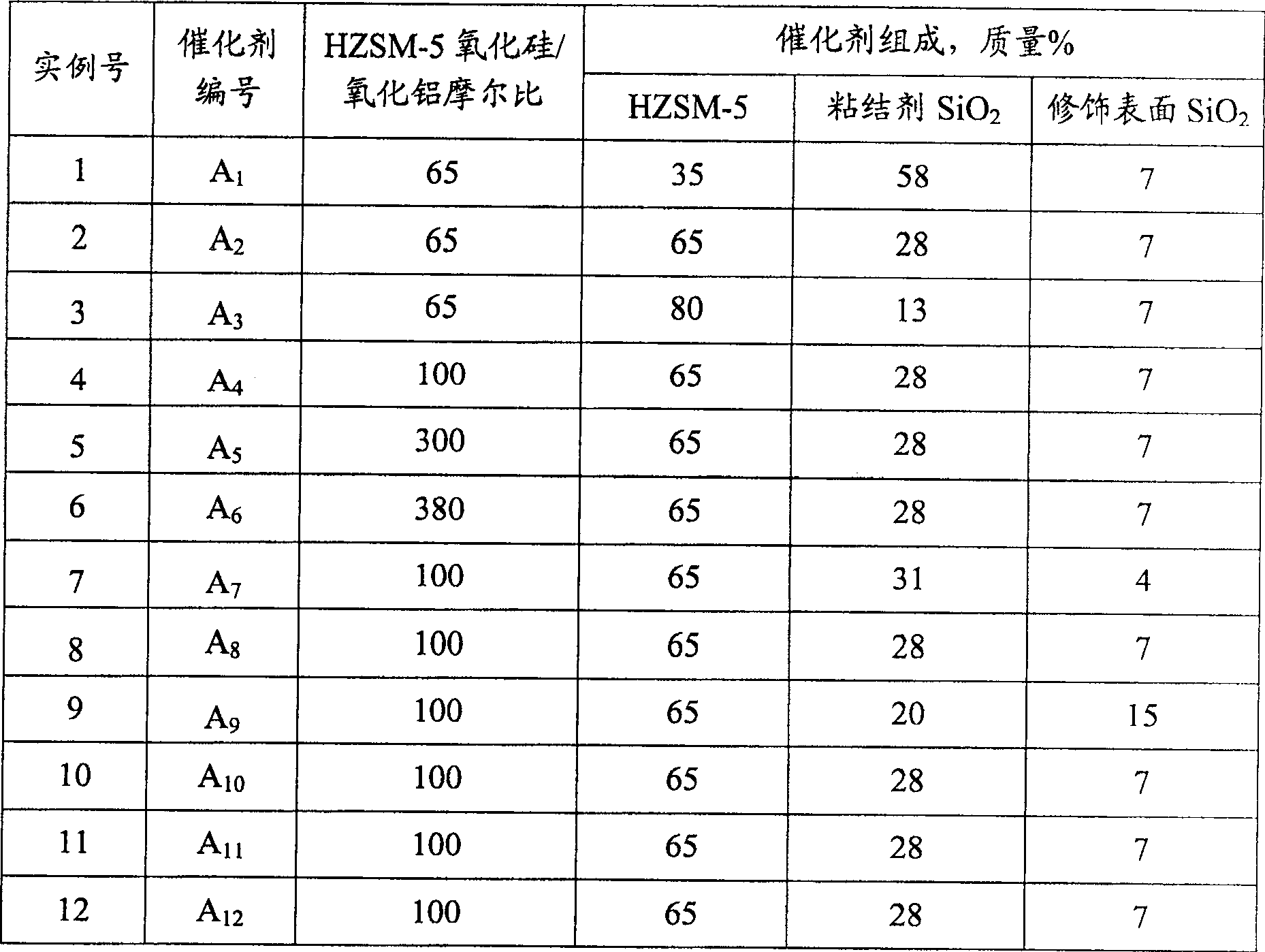

[0026] (1) Preparation of catalyst

[0027] Get 14.0 grams of HZSM-5 with a silica / alumina molar ratio of 65, 16.0 grams of silica powder and 0.8 gram of scallop powder and mix evenly, add 36.0 grams of silica sol with a silica content of 20% by mass (Fushun Petroleum Three Catalyst Factory) and kneaded, then extruded, dried at 120°C for 4 hours, pelletized, and calcined at 550°C for 3 hours to obtain the catalyst.

[0028] The catalyst was treated with water vapor at 600°C for 10 hours, and the mass space velocity of water vapor passing through the catalyst was 3.0 hours during the treatment -1 .

[0029] (2) Silicon modification treatment

[0030] The catalyst after the above-mentioned steam treatment was impregnated at 25°C for 4 hours with a polyaminopropylsiloxane (Shandong Luyang Chemical Factory) cyclohexane solution with a concentration of 10 mass%, and the liquid / solid volume ratio w...

example 2

[0032] Prepare silicon-modified catalyst by the method for example 1, difference is (1) the consumption of silica powder in the step is 5.0 grams, and silica sol add-on is 10.3 grams, and the content of silica in silica sol is 10 mass %, (2) The solid impregnated with the cyclohexane solution of polyaminopropylsiloxane was roasted at 550°C for 4 hours, and the prepared silicon-modified catalyst A 2 The composition is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com