Precipitation hardening stainless steel of surface laser alloy and its preparation process and application

A laser alloying and precipitation hardening technology, applied in metal material coating process, coating and other directions, can solve the problems of low surface hardness and poor erosion resistance, and achieve good surface quality, good forming and easy promotion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

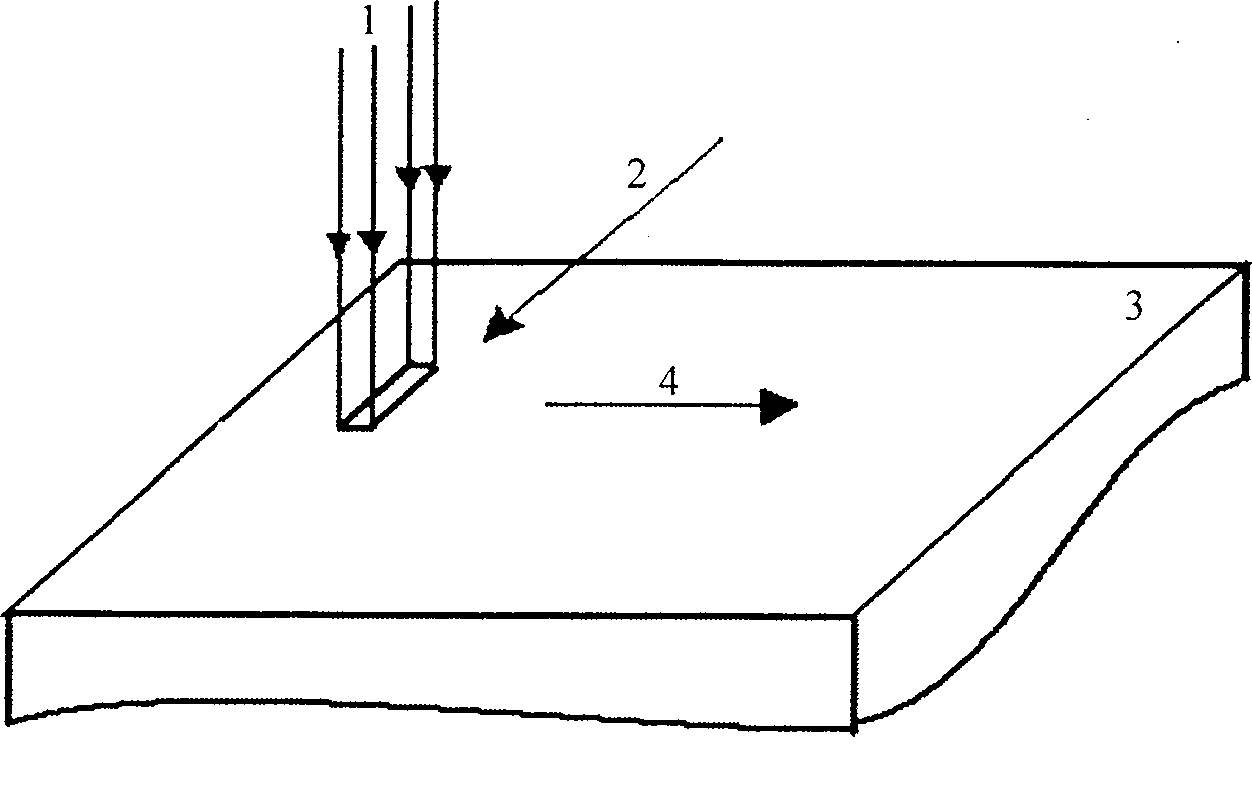

[0025] Combine below figure 1 A detailed description of the embodiment of the present invention: 1 is the laser beam, 2 is the shielding gas, 3 is the workpiece, and 4 is the moving direction of the laser beam. The workpiece material is 17-4PH stainless steel, which is a kind of precipitation hardening stainless steel with excellent comprehensive performance after solid solution (1020-1060°C) and aging (500-580°C) treatment. After the surface is cleaned twice with 98% acetone, a layer of alloy coating with a width of 16 mm and a thickness of 0.4 mm is pre-coated. The alloy coating contains W 52%, Co 18%, Cr 20%, Ni 8%, Fe 1%, Si 1%, after drying, carry out laser treatment.

[0026] The source of the laser beam is CO 2 Laser with a wavelength of 10.6 μm and a power density of 7.8×10 3 W / cm 2 , the laser is irradiated vertically on the workpiece surface. The size of the light spot is 16×2mm, and the defocus amount is 0. During processing, the workpiece remains still, the l...

Embodiment 2

[0030] In the material is 17-4PH, the original hardness is HV 0.2 The back arc side of the QD238 blade of 380 is cleaned and coated with an alloy coating with a width of 18mm and a thickness of 0.5mm. The alloy coating contains W 56%, Co 20%, Cr 15%, Ni 7%, Fe 0.8% , Si 1.2%. According to the blade profile programming, its laser treatment process parameters are power density 8.3×10 3 W / cm 2 , V=8mm / s, the spot size is 12×2mm; after laser treatment, take 5 points to obtain the hardness as HV 0.2 : 882, 898, 995, 876, 781, an alloyed layer with an alloyed layer depth of 60 μm. The blade treated by this method is installed and used, and the results show that its water cavitation resistance performance is obviously improved, and it is safe and reliable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com