Method for producing sealing cushion for selenium-coated drum powdered ink

A sealing gasket and toner cartridge technology, applied to the equipment, chemical instruments and methods of the electric recording process using the charge pattern, and the electric recording process using the charge pattern, etc., can solve the change and influence of polytetrafluoroethylene and sponge size Problems such as product accuracy and mechanical properties, and the sealing function of the gasket are reduced, so as to achieve the effects of small elastic deformation, excellent and stable dimensional properties, and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

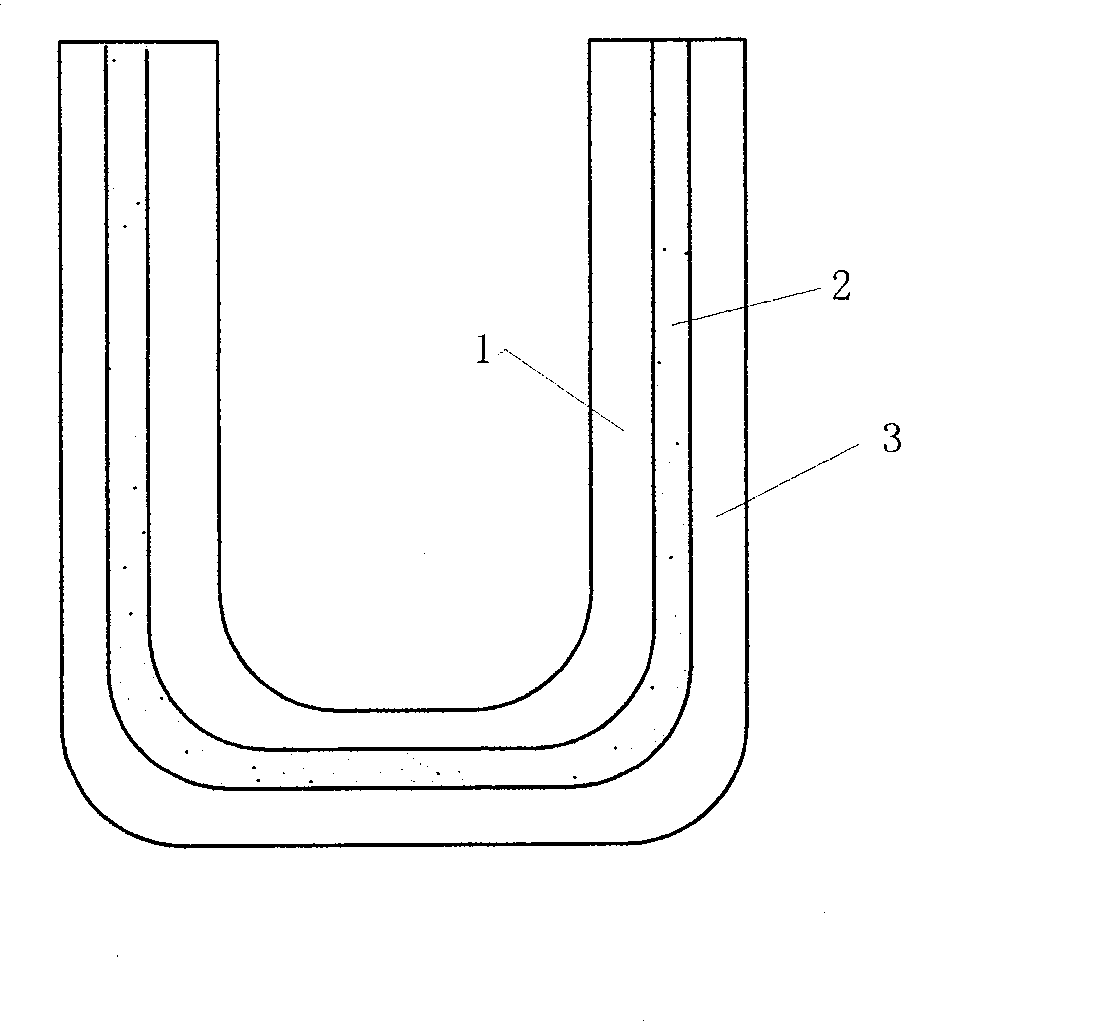

[0012] At room temperature, the sponge sheet is die-cut into a U-shaped sponge sheet of the size of a seal gasket for a toner cartridge using a processing device equipped with a U-shaped mold, and a commercially available PTFE needle-punched felt is die-cut into a The sponge sheet is the same size as the U-shaped sheet. Then the sponge sheet is pasted on the polytetrafluoroethylene felt sheet with a stronger adhesive. After removing excess adhesive, a sealing gasket for toner cartridges can be obtained.

[0013] The structure diagram of the product of this embodiment is shown in figure 1 . A sealing gasket for toner cartridges, consisting of three layers of materials, in order from the inside to the outside, are polytetrafluoroethylene felt 1, adhesive 2 and sponge 3, the adhesive 2 is mainly composed of polytetrafluoroethylene felt 1 The effect of bonding to the sponge 3.

[0014] In this embodiment, die-cut the sponge sheet to the specified size at room temperature, then...

Embodiment 2

[0016] At room temperature, the vulcanized silicone rubber sheet was die-cut into a silicone rubber sheet of the size of a seal gasket for a toner cartridge, and a commercially available polytetrafluoroethylene felt was die-cut into a sheet of the same size as the silicone rubber sheet. Then, the silicone rubber sheet is pasted on the polytetrafluoroethylene felt sheet with an adhesive with strong adhesive performance. The excess adhesive is removed to obtain a sealing gasket for the toner cartridge of the toner cartridge. The die-cutting apparatus of this embodiment is the same as that of Embodiment 1, and the structure of its product is the same as that of Embodiment 1.

[0017] Silicone rubber has excellent aging resistance, air tightness and high temperature resistance. The sealing pad of this embodiment adopts silicon rubber as one of the materials, which is beneficial to improve the aging resistance and high temperature resistance of the sealing pad, so that the printer...

Embodiment 3

[0019] Continuously expanded polystyrene sheets were die-cut at room temperature into styrofoam sheets the size of toner cartridge gaskets, and commercially available PTFE needle felt was die-cut to match the polystyrene foam. Styrofoam sheets are sheets of the same size. Then stick the foamed polystyrene sheet on the polytetrafluoroethylene felt sheet with a double-sided adhesive tape with strong adhesive performance, so as to obtain a sealing gasket for the toner cartridge of the toner cartridge. The die-cutting device and its product structure of this embodiment are the same as those of Embodiment 1.

[0020] Polystyrene foamed plastic has excellent shock resistance and good mechanical properties, so that the sealing gasket for the toner cartridge and toner cartridge using it as one of the materials has good sealing and shock resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com