Process for producing 1,3-propylene glycol by microorganism aerobic fermentation

A technology of aerobic fermentation and propylene glycol, applied in the direction of fermentation, etc., can solve the problems of high investment and energy consumption, achieve the effect of increasing the final concentration, reducing investment and energy consumption, and reducing equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] (1) Bacteria: Klebsiella pneumoniae

[0018] (2) Medium:

[0019] (A) Solid medium (g / L)

[0020] LB medium: yeast extract powder 5, peptone 10, NaCl 5, agar 15, adjust pH 7.0. For short-term preservation and activation of Klebsiella pneumoniae strains.

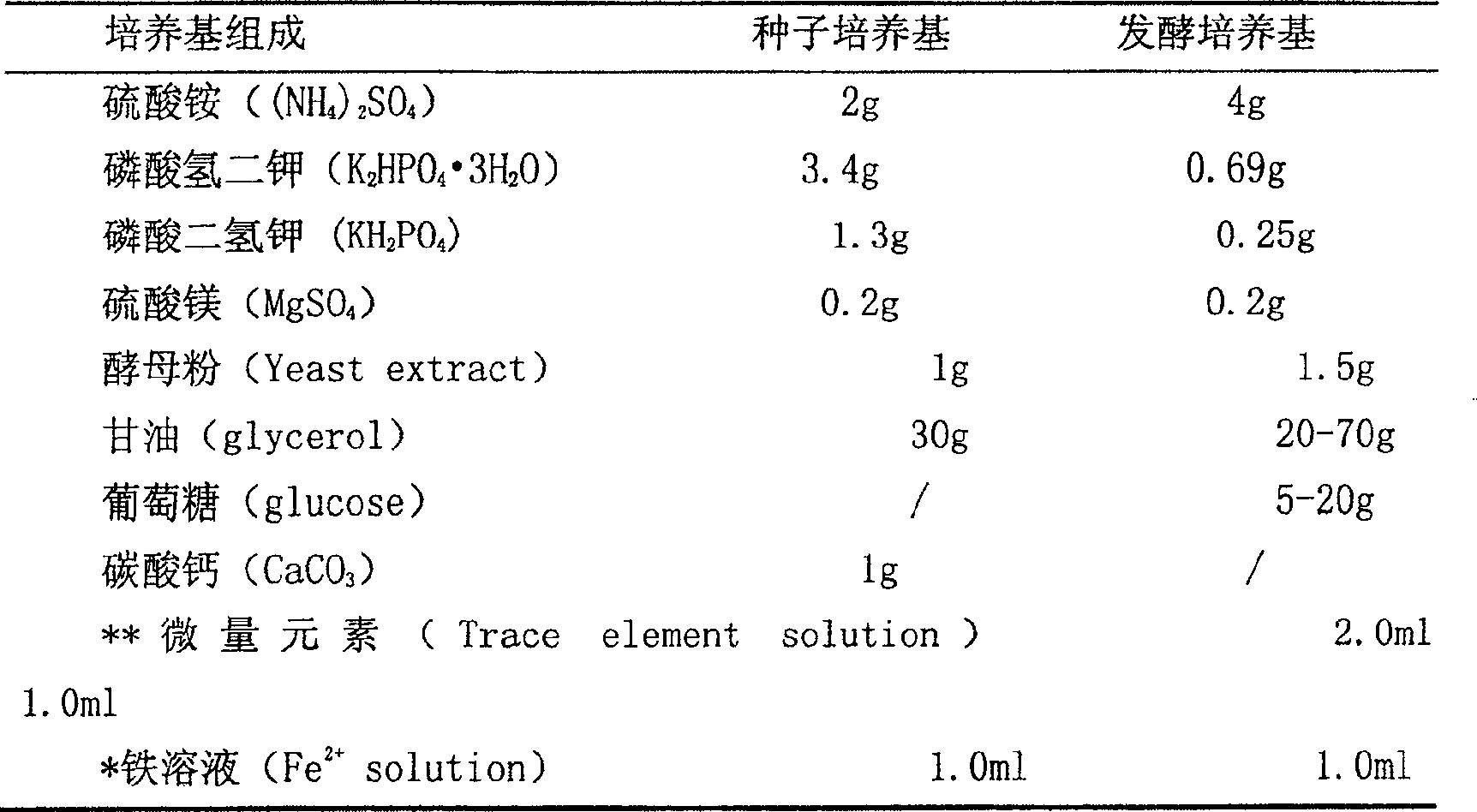

[0021] (B) Seed medium and fermentation medium

[0022]

[0023] *Preparation of iron solution: add FeSO per liter of water 4 ·H 2 O 5.0g, 37% concentrated hydrochloric acid 4ml.

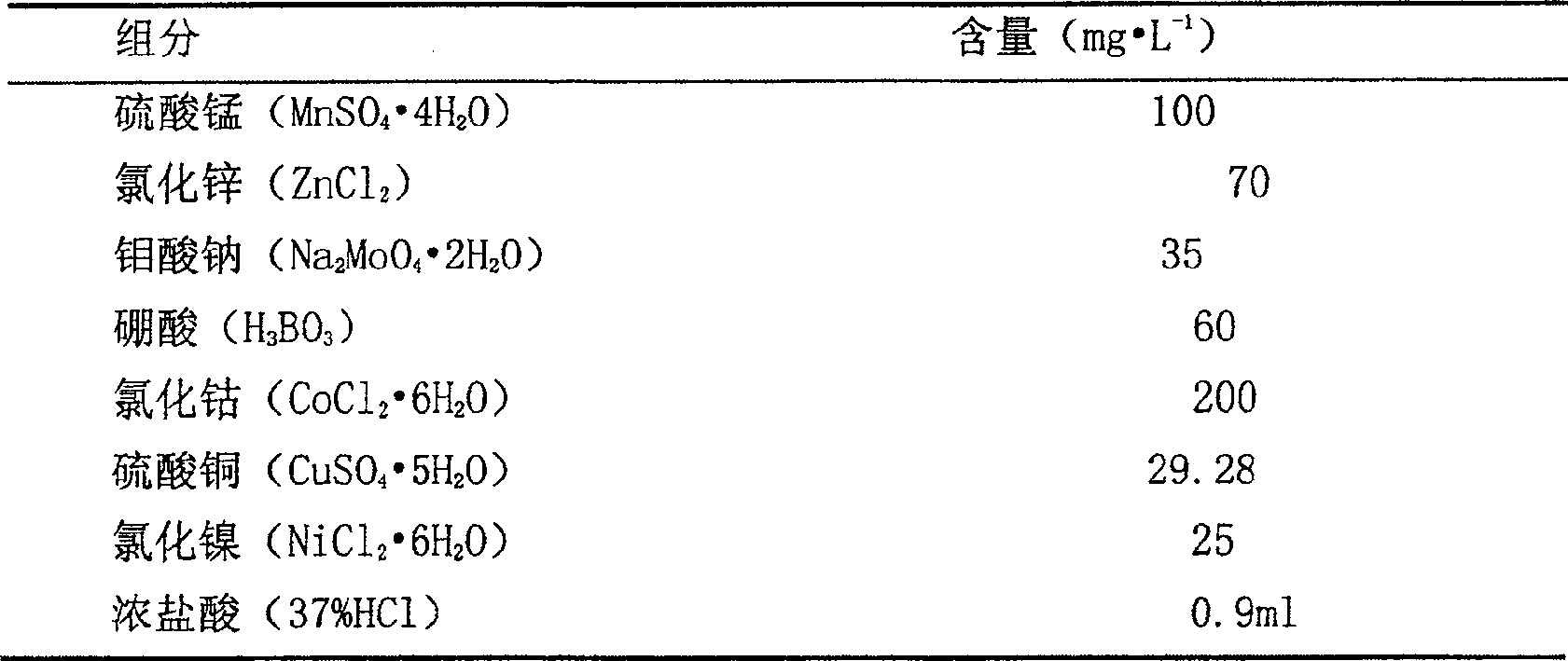

[0024] Composition of trace element solutions

[0025]

[0026] (3) Training method:

[0027] The strains preserved in glycerol tubes were transferred to LB slant and activated at 37°C for 12 hours. Seed culture adopts aerobic culture, using a 500ml Erlenmeyer flask with a liquid volume of 100ml. The culture temperature was 37° C., and the rotation speed of the shaker was 120 rpm.

[0028] The fermentation culture uses a 5L fermenter with a liquid volume of 4L, a culture temperature of 37°C, and a pH value of 6.8. During the...

example 2

[0032] (1) Bacteria: Klebsiella pneumoniae

[0033] (2) culture medium is the same as example 1

[0034] (3) The cultivation method is the same as in Example 1, but the fermentation temperature is 40°C.

[0035] (4) The fermentation result is as follows:

[0036] Ferment for 25 hours, the concentration of 1,3-propanediol is 35g / l, and the concentration of lactic acid is 10g / l. The production intensity of 1,3-propylene glycol is 1.4g / (lh). Ferment for 48 hours, 1,3-propanediol concentration 44g / l, lactic acid 23g / l. The production intensity of 1,3-propylene glycol is 0.92g / (lh).

example 3

[0038] (1) Bacteria: Klebsiella pneumoniae

[0039] (2) culture medium is the same as example 1

[0040] (3) The cultivation method is the same as in Example 1, but the stirring speed is 250 rpm.

[0041] (4) Fermentation result:

[0042] After 48 hours of fermentation, the concentration of 1,3-propanediol was 56.5g / l, 2,3-butanediol was 7.4g / l, lactic acid was 40.7g / l, and acetic acid was 1.8g / l. The production intensity of 1,3-propylene glycol is 1.2g / (lh). Ferment for 68 hours, 1,3-propanediol concentration 60.5g / l, 2,3-butanediol 7.7g / l, lactic acid 53.4g / l, acetic acid 2g / l. The production intensity of 1,3-propylene glycol is 0.89g / (lh).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com