Flattening active driving TFT matrix structure and method of manufacturing the same

A matrix structure, source-driven technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of easy oxidation or corrosion of the surface, disconnection of metal wires, poor thermal stability, etc. rate, reduce metal wire breakage, and reduce the effect of stress formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

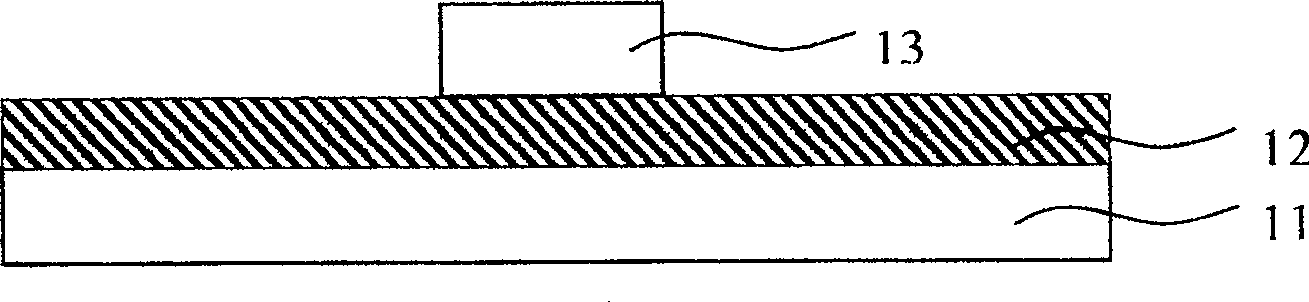

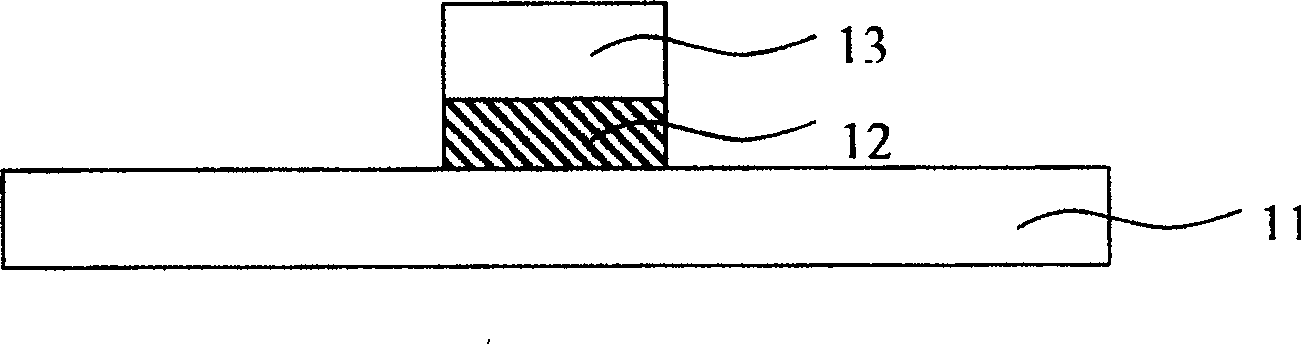

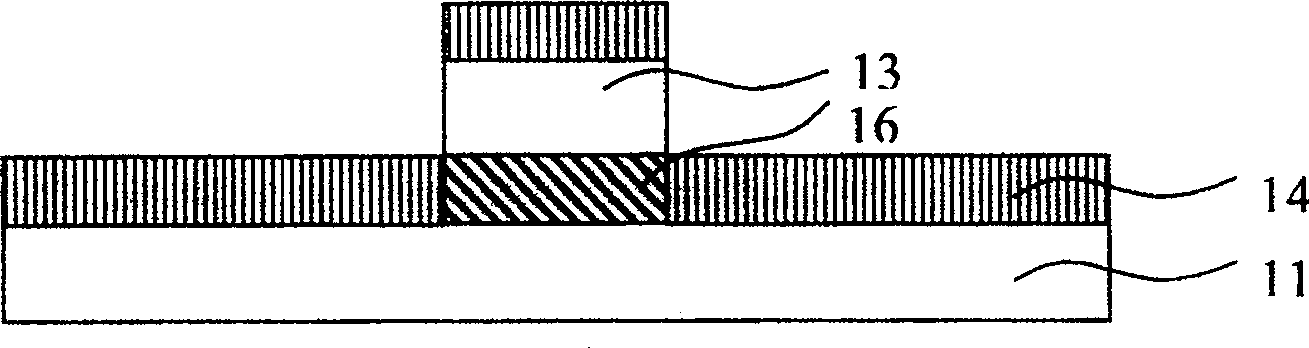

[0033] Figure 1A-Figure 1E The first process method for preparing a planarized TFT matrix structure proposed by the present invention is shown.

[0034] First, on a transparent glass substrate or quartz 11, use sputtering or thermal evaporation to deposit a thickness of about The gate metal layer 12. The gate metal layer can adopt a single-layer, double-layer or multi-layer structure, and the metal can be selected from Cr, W, Ti, Ta, Mo, Al, Cu and other metals or their alloys. After the gate metal layer is deposited, a photoresist 13 pattern is formed by a traditional photolithography process, wherein the photoresist adopts a positive photoresist, such as Figure 1A . Use wet or dry process to etch away the unnecessary gate metal layer to form gate lines and gate electrodes 16, and at the same time retain the photoresist 13 on the gate lines and gate electrodes 16, such as Figure 1B .

[0035] Secondly, on the transparent glass substrate or quartz 11, photoresist 13, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com