Process and device for preparing orthoformate by using byproduct hydrocyanic acid from acrylonitrile production

An orthoformate and hydrocyanic acid technology, applied in ether preparation, organic chemistry and other directions, can solve the problems of low added value and waste of resources, and achieve the effects of reducing reaction by-products, improving product quality and stable reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

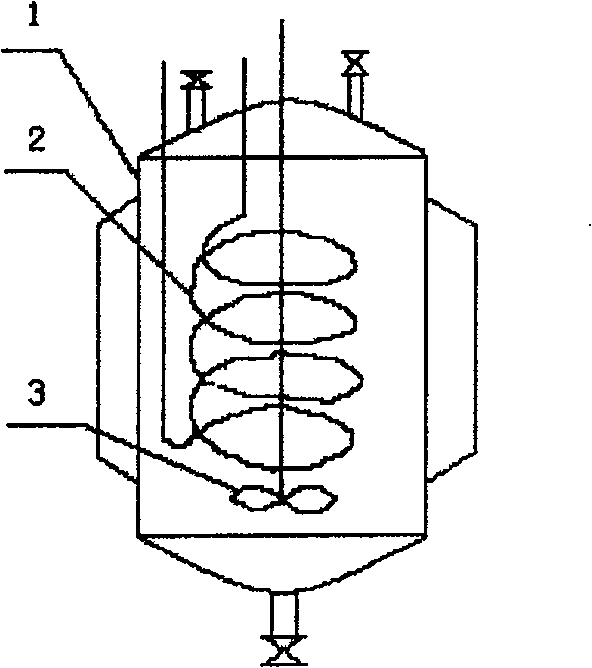

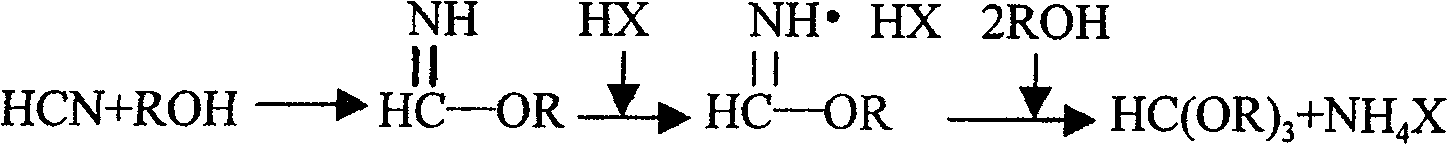

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: the molar ratio of reaction material is hydrocyanic acid: ethanol: hydrogen bromide=1: 3.5: 1.30.

[0020] Add 231.82kg of hydrocyanic acid (content 99%, pure 229.50kg, 8.5kmol), the first ethanol 432.26kg (content 99.5%, pure 430kg, 9.35kmol), inert solvent 2000kg, into the built-in plastic tube bundle coil In the halogenation reaction kettle of the heat exchanger, the temperature is lowered to -20°C, and 894.0kg of hydrogen bromide is uniformly introduced, and the reaction temperature is maintained at -20 to 10°C. , add the second portion of ethanol 943.12kg (content 99.5%, pure 938.4kg, 20.40kmol), adjust the pH of the reaction solution=3-4.0, keep the temperature at 50-60°C, and the total reaction time is 24 hours. After the alcoholysis, the ammonium bromide was removed by filtration, and after the solvent was evaporated, 1072.90 kg of triethyl orthoformate was obtained by rectification, with a content of 99.8%, 1070.75 kg of pure, and a yield of 85%. ...

Embodiment 2

[0021] Embodiment 2: the molar ratio of reaction material is hydrocyanic acid: ethanol: hydrogen chloride=1: 4.0: 1.20.

[0022] Add 231.82kg of hydrocyanic acid (content 99%, pure 229.50kg, 8.5kmol), the first ethanol 510.85kg (content 99.5%, pure 508.3kg, 11.05kmol), inert solvent 2000kg, into the built-in metal coil In the halogenation reaction kettle of the heat exchanger, the temperature was lowered to -15°C, and 372.3kg of hydrogen chloride was evenly introduced, and the reaction temperature was maintained at -18 to 10°C. After completion, the temperature was maintained at 10-50°C to form a salt. The second part of ethanol is 1061.0kg (content 99.5%, pure 1055.7kg, 22.95kmol), adjust the pH of the reaction solution to 2-2.5, keep the temperature at 50-60°C, and the total reaction time is 15 hours. After the alcoholysis, the ammonium chloride was removed by filtration, and after the solvent was evaporated, 1049.75 kg of triethyl orthoformate was obtained by rectification,...

Embodiment 3

[0023] Embodiment 3: the molar ratio of reaction material is hydrocyanic acid: methanol: hydrogen bromide=1: 3.5: 1.10.

[0024] Add 230.19kg of hydrocyanic acid (99.7% content, 229.50kg pure, 8.5kmol), the first methanol 300.70kg (99.5%, 299.2kg pure, 9.35kmol), and 2000kg inert solvent into the built-in plastic tube bundle In the halogenation reaction kettle of the tube heat exchanger, cool down to -18°C, evenly feed 756.4kg of hydrogen bromide, maintain the reaction temperature at -18 to 10°C, and keep the temperature at 10-40°C to form a salt, and the imide salt is precipitated Finally, add the second portion of methanol 656.08kg (content 99.5%, pure 652.8kg, 20.40kmol), adjust the pH of the reaction solution=1-2.0, keep the temperature at 50-60°C, and the total reaction time is 10 hours. After the alcoholysis, the ammonium bromide was removed by filtration, and after the solvent was evaporated, 768.34kg of trimethyl orthoformate was obtained by rectification, with a conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com