Method for preparing diameter different monocrystal bismuth nanowire microarray by using uniform hole diameter alumina template

A kind of alumina template and bismuth nanotechnology, which is applied in chemical instruments and methods, single crystal growth, nanotechnology, etc., can solve the problems of difficulty in obtaining templates, difficulty in assembling high-quality nanowires, and difficulty in realizing bismuth nanowires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

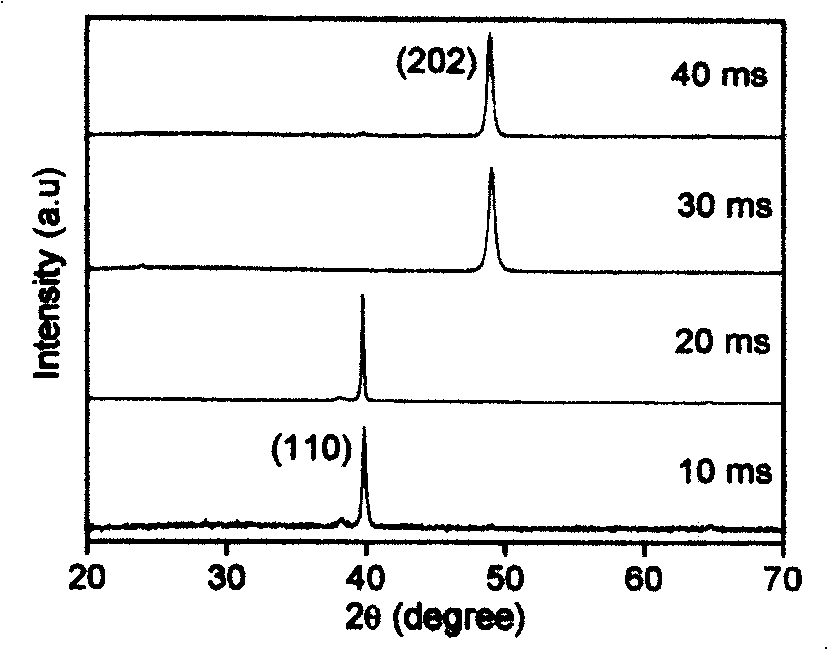

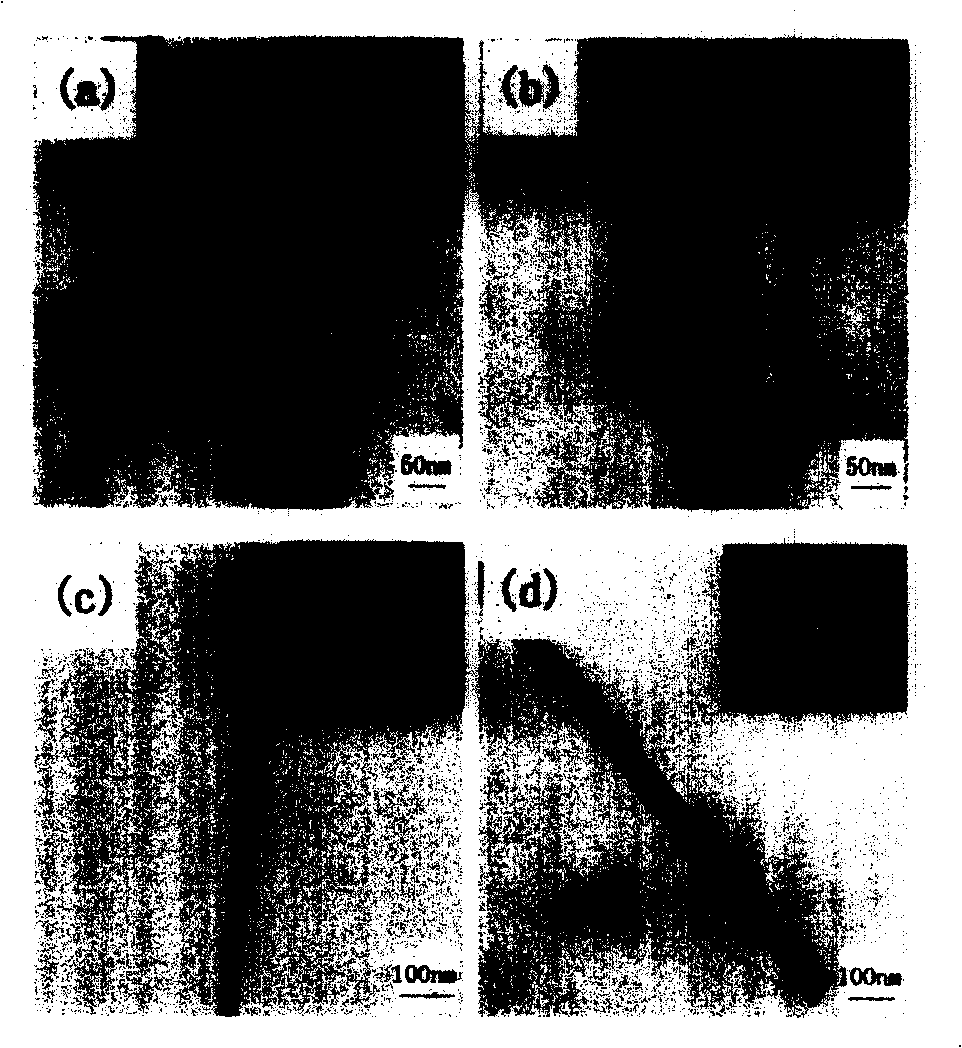

Embodiment 1

[0013] Example 1: First, one side of the prepared aluminum oxide ordered mesoporous double-pass template with a pore diameter of 98nm is sprayed with a gold foil with a thickness of 30nm by vacuum evaporation; Bismuth, tartaric acid, glycerol and sodium chloride are prepared in the pH value of 0.9 electrodeposition solution, wherein, bismuth trichloride is 5g / l, tartaric acid is 60g / l, glycerol is 85g / l, sodium chloride is 60g / l, the order of preparation of the electrodeposition solution is as follows: first mix sodium chloride and glycerin, then add tartaric acid and mix, finally add bismuth trichloride and mix; finally, use the gold foil on the template as the cathode , the graphite sheet in the electrodeposition solution is the anode, and a pulse delay voltage of 0 volts and a pulse deposition voltage of -1.1 volts are applied time-sharingly between the cathode and the anode, wherein the time of the pulse delay voltage is 60 ms, and the time of the pulse deposition voltage ...

Embodiment 2

[0014] Example 2: First, one side of the prepared aluminum oxide ordered mesoporous double-pass template with a pore diameter of 98nm is sprayed with a gold foil with a thickness of 30nm by vacuum evaporation; Bismuth, tartaric acid, glycerin and sodium chloride are prepared in the pH value of 1 electrodeposition solution, wherein, bismuth trichloride is 8g / l, tartaric acid is 55g / l, glycerin is 90g / l, sodium chloride is 55g / l, the order of preparation of the electrodeposition solution is as follows: first mix sodium chloride and glycerin, then add tartaric acid and mix, finally add bismuth trichloride and mix; finally, use the gold foil on the template as the cathode , the graphite sheet in the electrodeposition solution is the anode, and a pulse delay voltage of 0 volts and a pulse deposition voltage of -1.2 volts are applied time-sharingly between the cathode and the anode, wherein the time of the pulse delay voltage is 55 ms, and the time of the pulse deposition voltage fo...

Embodiment 3

[0015] Example 3: First, one side of the prepared aluminum oxide ordered mesoporous double-pass template with a pore diameter of 98nm is sprayed with a gold foil with a thickness of 30nm by vacuum evaporation; Bismuth, tartaric acid, glycerin and sodium chloride are prepared in the pH value of 1.1 electrodeposition solution, wherein, bismuth trichloride is 10g / l, tartaric acid is 50g / l, glycerin is 95g / l, sodium chloride is 50g / l, the order of preparation of the electrodeposition solution is as follows: first mix sodium chloride and glycerin, then add tartaric acid and mix, finally add bismuth trichloride and mix; finally, use the gold foil on the template as the cathode , the graphite sheet in the electrodeposition solution is an anode, and a pulse delay voltage of 0 volts and a pulse deposition voltage of -1.4 volts are applied time-sharingly between the cathode and the anode, wherein the time of the pulse delay voltage is 50 ms, and the time of the pulse deposition voltage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com