Oxygen silicon base doped nitride film yellow green wave band LED and its preparing method

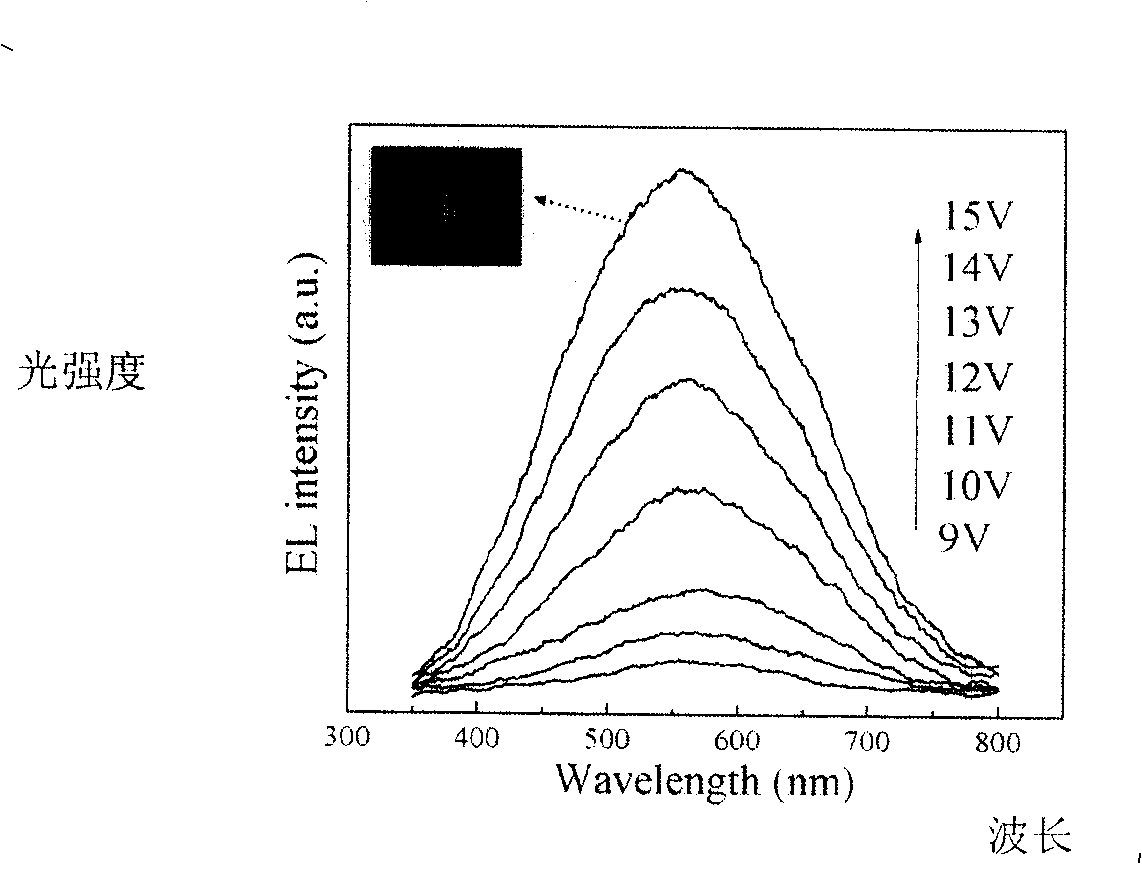

A technology of light-emitting diodes and nitrides, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of weak light emission and high working current density, achieve low turn-on voltage, increase the density of light-emitting centers, and improve the effect of light-emitting characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

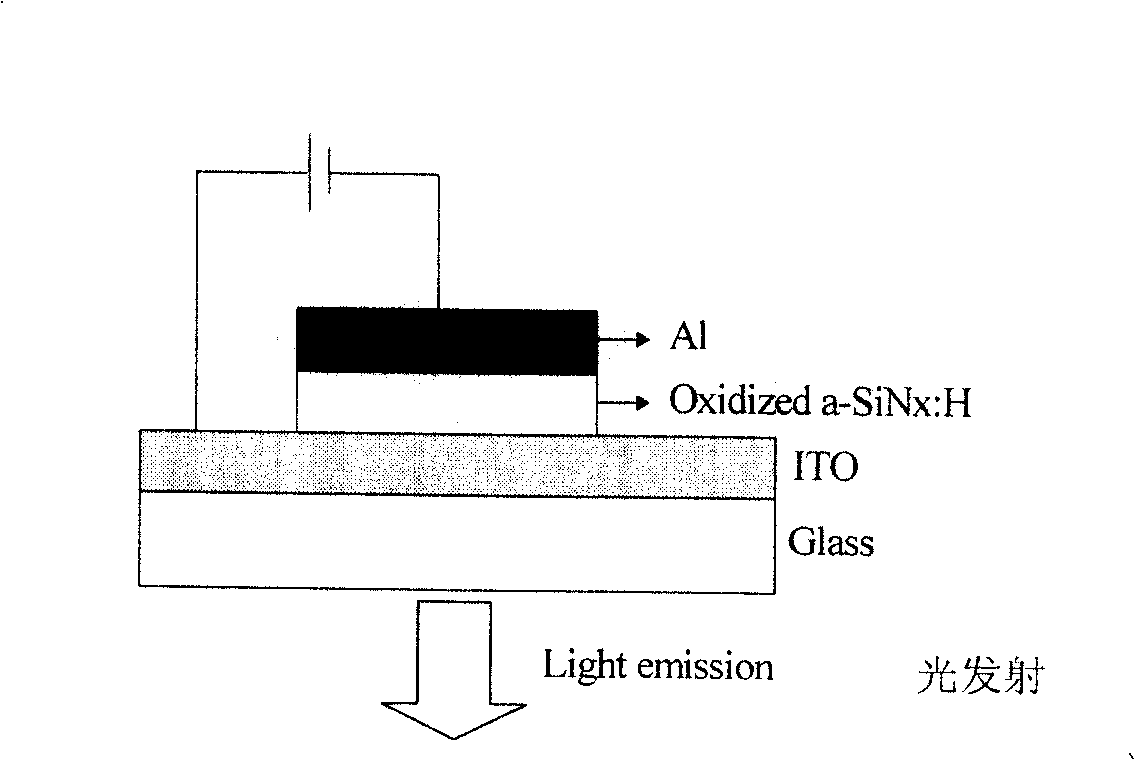

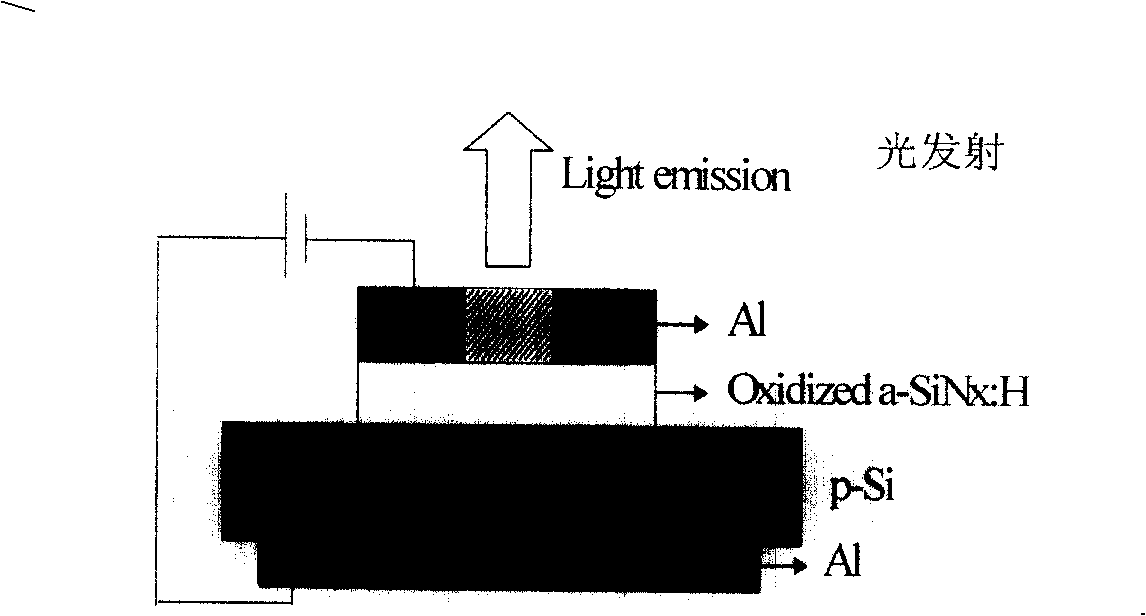

[0034] 1. Preparation of active layer of new silicon-based light-emitting devices

[0035] (1) Growth of amorphous silicon nitride (a-SiN) at room temperature x )film

[0036] Using plasma enhanced chemical vapor deposition (PECVD) technology, using silane (SiH 4 ) and ammonia (NH 3 ) as a reactant gas source, depositing a-SiNx film on a P-type single crystal silicon wafer with a resistivity of 4-20Ωcm and an ITO glass substrate. Concrete process conditions during preparation are as follows:

[0037] Power source frequency: 13.56MHz

[0038] Power density: 0.6W / cm 2

[0039] Reaction chamber pressure: 80Pa

[0040] Substrate temperature: 25°C

[0041] Depositing a-SiN x thin film, made of SiH 4 +NH 3 Formed by glow decomposition reaction, where SiH 4 The flow rate is 8sccm (standard cubic centimeters per minute), NH 3 The flow rate is 32sccm; the deposition time is 130s, and the film thickness is 80nm.

[0042] (2) Plasma oxidation of amorphous silicon nitride (a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com