Steam and liquid separator for air conditioner and its producing method

The technology of a gas-liquid separator and manufacturing method is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., and can solve the problems of increasing the cost of the gas-liquid separator and increasing the manufacturing cost of the air conditioner, and achieves good airtightness and structure Reasonable, fine weld effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

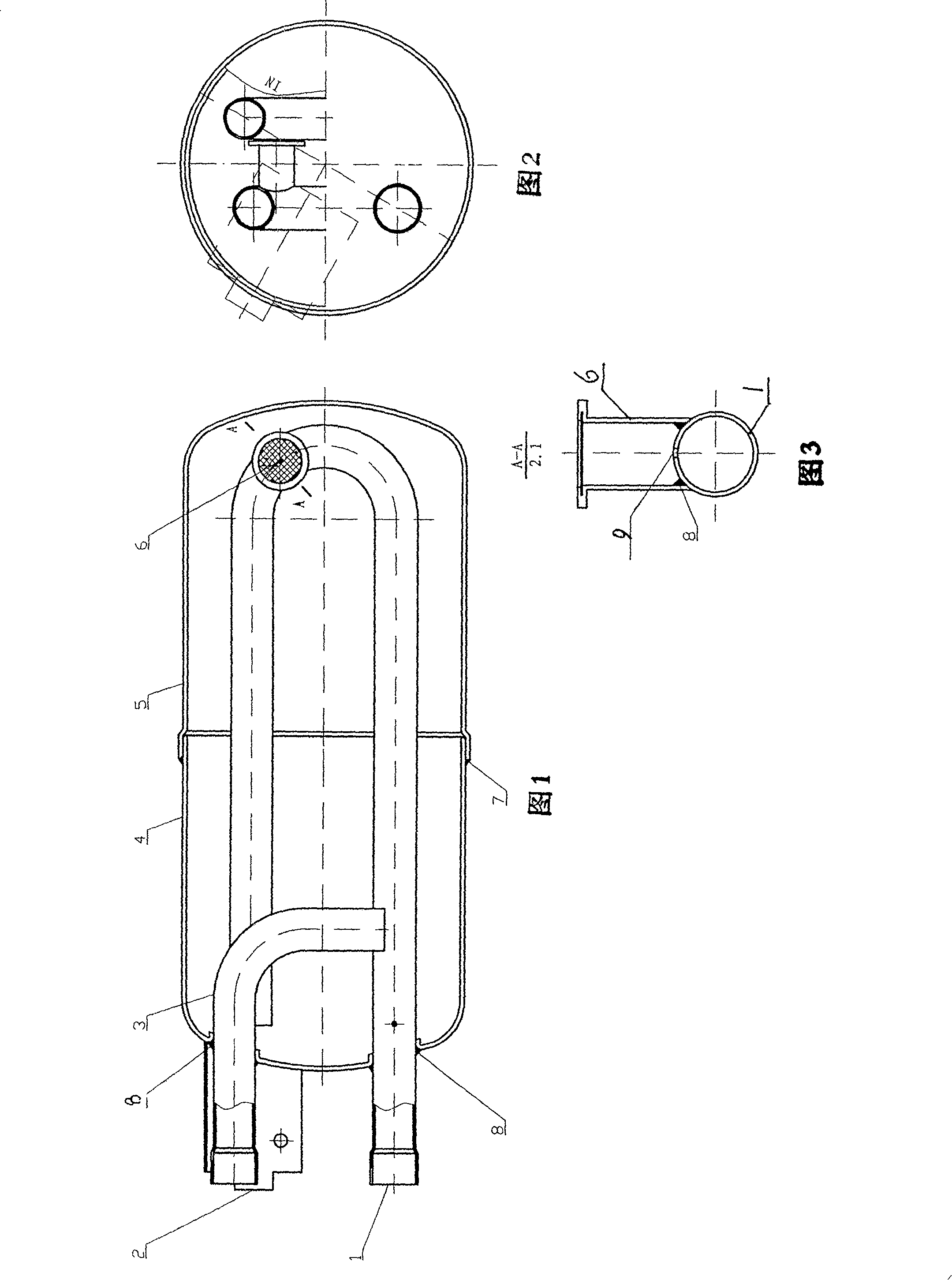

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing (embodiment):

[0014] 1-3, the present invention includes an exhaust pipe 1, a mounting plate 2, an air intake pipe 3, an upper cylinder 4, a lower cylinder 5, a filter 6, and the like. The exhaust pipe 1 and the intake pipe 3 are all made of iron pipes; they are installed in the upper cylinder body 4 for positioning, and are brazed and welded with red copper in the furnace to form solder joints 8 . CO is used between the upper cylinder 4 and the lower cylinder 5 2 Gas shielded welding to form solder joints 7 . The filter 6 is fixed on the exhaust pipe 1, and brazed with red copper in the furnace to form solder joints 8 between them. 9 is the oil return hole among Fig. 3.

[0015] In actual production, put the intake pipe 3 and the exhaust pipe 1 into the upper cylinder 4 for positioning, fix the filter 6 on the exhaust pipe 1, and braze with copper in a protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com