A kind of high-strength tarpaulin and its manufacturing method

A production method and high-strength technology, applied in the field of tarpaulin, can solve the problems of unstable overall performance of composite materials, no high flame retardancy, wear resistance, and inconvenience in the waterproof layer, and achieve excellent waterproofness, light weight and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

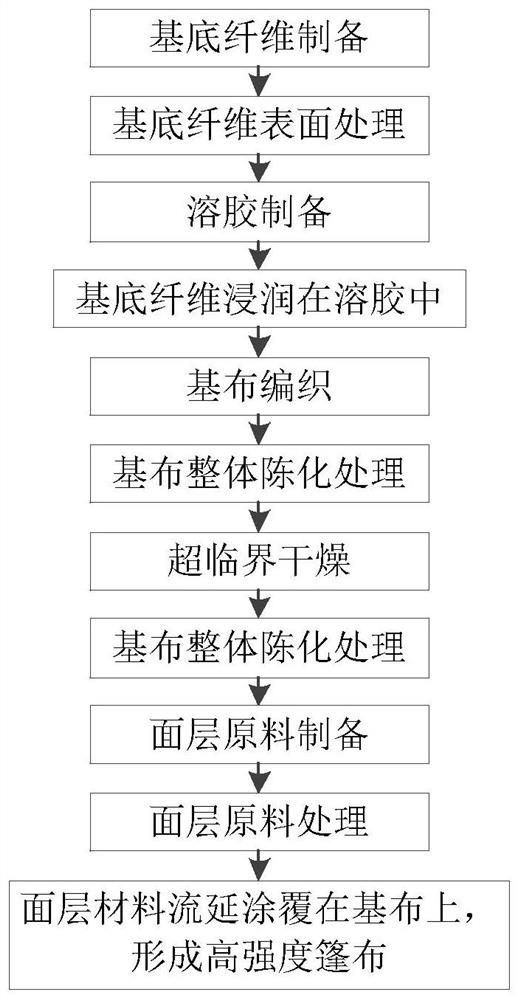

[0032] A method for making a high-strength tarpaulin, comprising the following steps:

[0033] S1: Base fiber preparation: using N-methylpyrrolidone and n-hexane as solvents, using p-phenylenediamine and terephthaloyl chloride as reaction monomers, using nitrogen as protective gas, at a temperature of -20°C , carry out the solution polycondensation reaction, and finally obtain the base fiber; specifically, the specific process of preparing the base fiber is as follows: first, configure 50 parts by weight of chloride and N-methylpyrrolidone mixed solution, wherein the chloride content is 7%, cooling Then add 3 parts by weight of pyridine and 25 parts by weight of terephthaloyl dichloride; then: use p-phenylenediamine and terephthaloyl dichloride as reaction monomers, at a temperature of -20°C, use nitrogen as a protective gas, The solution polycondensation reaction, centrifugation, drying and spinning are carried out to finally obtain the base fiber.

[0034] S2: Surface treat...

Embodiment 2

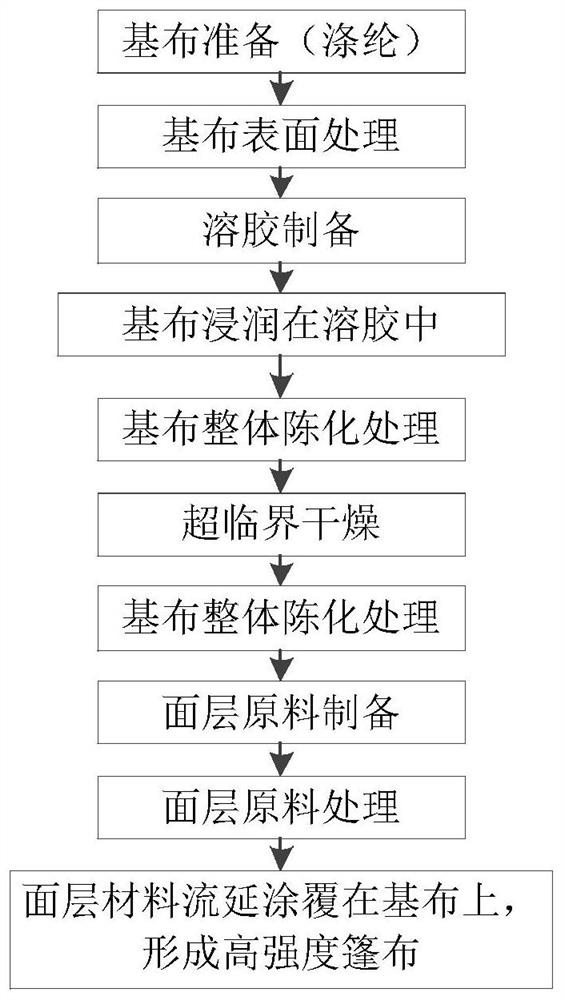

[0045] On the basis of the method described in embodiment 1, change relevant parameters, concrete steps are as follows:

[0046] S1: Base fiber preparation: using N-methylpyrrolidone and n-hexane as solvents, using p-phenylenediamine and terephthaloyl chloride as reaction monomers, using nitrogen as protective gas, at a temperature of -20°C , carry out the solution polycondensation reaction, and finally obtain the base fiber; specifically, the specific process of preparing the base fiber is as follows: first, configure 50 parts by weight of chloride and N-methylpyrrolidone mixed solution, wherein the chloride content is 7%, cooling Then add 3 parts by weight of pyridine and 25 parts by weight of terephthaloyl dichloride; then: use p-phenylenediamine and terephthaloyl dichloride as reaction monomers, at a temperature of -20°C, use nitrogen as a protective gas, The solution polycondensation reaction, centrifugation, drying and spinning are carried out to finally obtain the base ...

Embodiment 3

[0057] On the basis of Example 1, a flame retardant layer is compounded on the surface layer. The flame retardant layer is made of phenolic fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com