Device and method for catalytic synthesis of acetyl tri-n-butyl citrate by fixed bed reactor

A technology of acetyl tri-n-butyl citrate and fixed bed reactor, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid esters, etc., and can solve problems such as catalyst separation and recovery, catalyst loss, and inconvenient operation , to achieve the effect of cheap and easy to obtain catalyst, easy regeneration and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

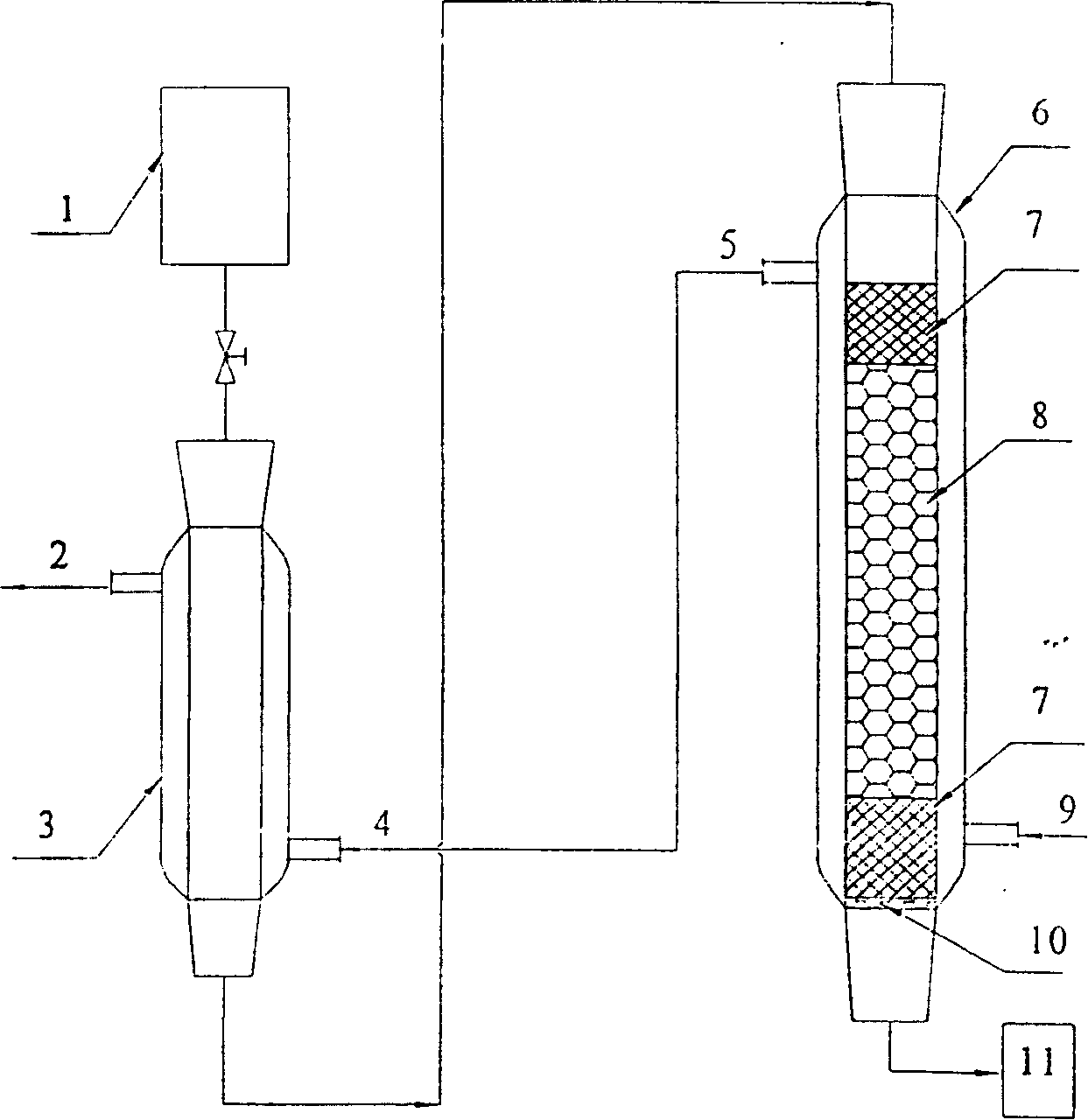

Embodiment 1

[0018] The inner diameter of the reaction tube of the fixed bed reactor 6 is φ8mm, the outer diameter is φ15mm, and the height is 700mm. The reaction tube is filled with packing section, catalyst section and packing section sequentially from the top to the bottom. 50mm, the catalyst section is filled with macroporous strong acidic cation exchange resin with a particle size ranging from 0.45mm to 1.25mm, the filling height is 540mm, and it operates under normal pressure.

[0019] According to the molar ratio of acetic anhydride to tri-n-butyl citrate as 2.0:1, the temperature of heating circulating water is 70°C, and the temperature is 5.0g.min -1 .cm -2 The flow rate of the reaction material of the above proportion is preheated through the serpentine tube and then passed through the bed to obtain the crude product of acetyl tributyl citrate. The yield is 99.7%, and there is no peak of tri-n-butyl citrate on the gas chromatogram. , indicating that tri-n-butyl citrate has been ...

Embodiment 2

[0021] Using the same fixed-bed reactor as above, the molar ratio of acetic anhydride to tri-n-butyl citrate is 1.6:1, the temperature of the heating circulating water is 70°C, and the temperature is 40.0g.min -1 .cm -2 The flow rate of the reaction material of the above proportion is preheated through the serpentine tube and then passed through the bed to obtain the crude product of acetyl tributyl citrate. The yield is 99.8%, and there is no peak of tri-n-butyl citrate on the gas chromatogram. , indicating that tri-n-butyl citrate has been completely converted. After the crude product obtained by the reaction is suction filtered to recover the catalyst, acetic anhydride and acetic acid are recovered by distillation under reduced pressure, and then washed with deionized water, 2% sodium carbonate aqueous solution, and then washed with water until the water phase is neutral, and the water is removed by distillation under reduced pressure , That is, tri-n-butyl acetyl citrate....

Embodiment 3

[0023] Using the same fixed-bed reactor as above, the molar ratio of acetic anhydride to tri-n-butyl citrate is 2.4:1, and the temperature of the heating circulating water is 40°C. -1 .cm -2 The flow rate of the reaction material of the above-mentioned proportion is passed through the bed layer after being preheated by a serpentine tube, and the crude product of acetyl tri-n-butyl citrate is obtained, and the yield is 99.0%, and there is no tri-n-butyl citrate on the gas chromatogram. peak, indicating that tri-n-butyl citrate has been completely converted. After the crude product obtained by the reaction is suction filtered to recover the catalyst, acetic anhydride and acetic acid are recovered by distillation under reduced pressure, and then washed with deionized water, 4% sodium carbonate aqueous solution, and then washed with water until the water phase is neutral, and the water is removed by distillation under reduced pressure , That is, tri-n-butyl acetyl citrate. Accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com