Anti-fouling single-component room temperature sealing silicone sulfide glue and its production process

A vulcanized silicone and sealant technology, which is applied in chemical instruments and methods, adhesives, and other chemical processes, can solve the problems of easy discoloration, surface dust collection, and pollution of the sealant surface, and achieve good physical and mechanical properties and bonding Excellent performance and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

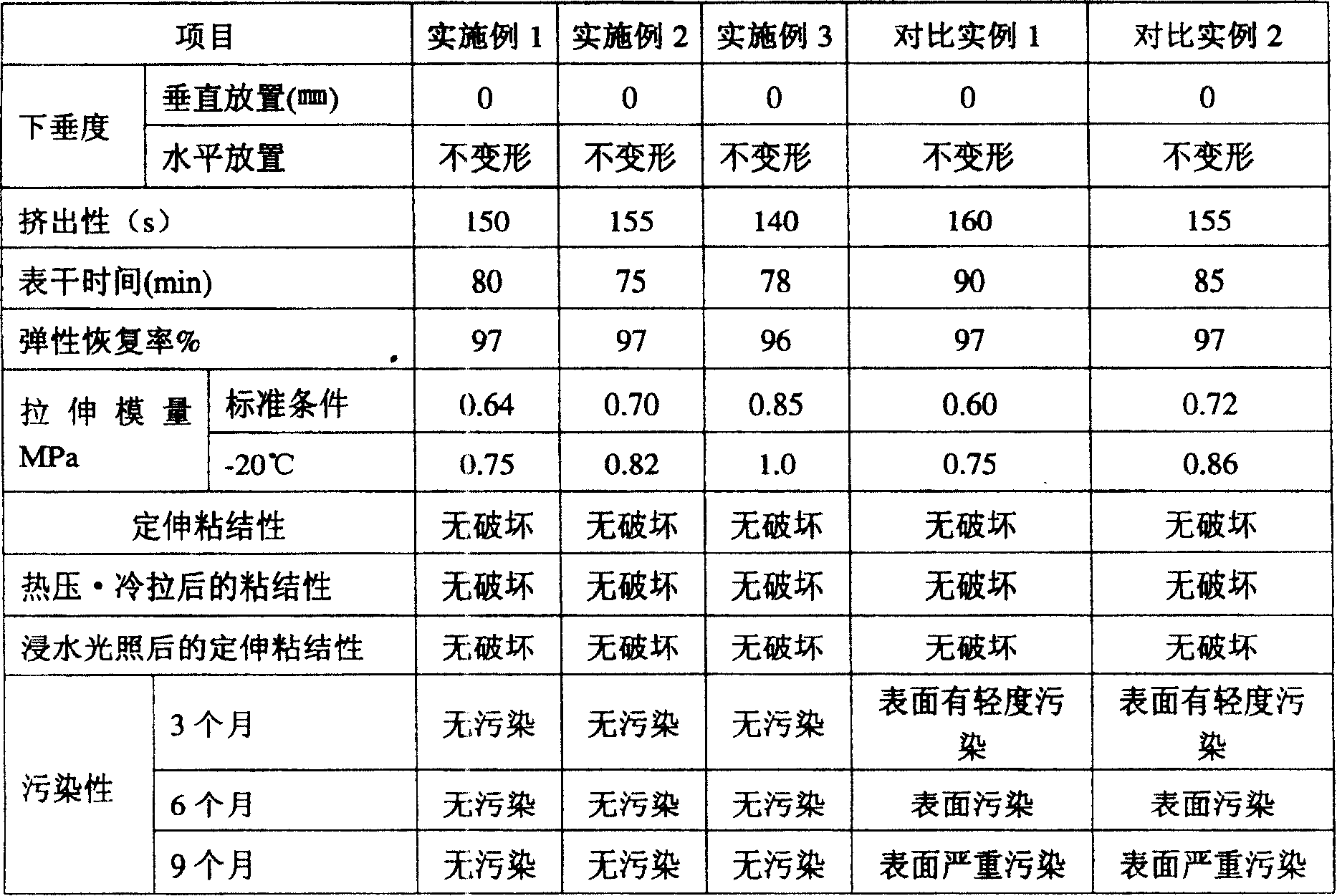

Examples

Embodiment 1

[0034] Example 1: Add 100 parts by weight of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 50 Pa·S at 25°C and 70 parts by weight of activated calcium carbonate into a vacuum mixer at a temperature of 130°C and a vacuum degree of 0.09MPa, dehydration and blending for 100 minutes, cooling to obtain base material. At room temperature, in a high-speed dispersion mixer equipped with the above-mentioned base material, add 5 parts by weight of antifouling agent I, 12 parts by weight of methyl ketoxime silane, and 0.5 parts by weight of γ-aminopropyl triethoxysilane , 1.2 parts by weight of dibutyl tin dilaurate, added into a high-speed dispersion mixer, stirred for 60 minutes at a vacuum degree of 0.09 MPa and a rotational speed of 600 rpm to prepare an anti-pollution one-component room temperature vulcanized silicone sealant.

Embodiment 2

[0035] Example 2: Add 100 parts by weight of α, ω-dihydroxypolysiloxane with a viscosity of 30 Pa·S at 25°C and 100 parts by weight of activated calcium carbonate into a vacuum mixer at a temperature of 120°C and a degree of vacuum of 0.085MPa. Dehydrate and blend for 120 minutes, and cool to obtain the base material. At room temperature, in a high-speed dispersing mixer equipped with the above-mentioned base material, mix antifouling agent I, 30 parts by weight, 7 parts by weight of methyl tributyrin, 2 parts by weight of vinyl tributyrin, γ -4 parts by weight of aminopropyltriethoxysilane and 0.7 parts by weight of dibutyltin dilaurate, add it into a high-speed dispersion mixer, stir for 60 minutes at a vacuum degree of 0.09MPa and a rotation speed of 600rpm to make a pollution-proof single-component room temperature Vulcanized silicone sealant.

Embodiment 3

[0036] Example 3: Add 100 parts by weight of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 10 Pa·S at 25°C and 130 parts by weight of activated calcium carbonate into a vacuum mixer at a temperature of 110°C and a vacuum degree of 0.080MPa, dehydration and blending for 150 minutes, cooling to obtain the base material. At room temperature, in a high-speed dispersion mixer equipped with the above-mentioned base material, add 20 parts by weight of antifouling agent II, 7 parts by weight of phenyl ketoxime silane, and γ-(2,3 glycidoxy)propyl 2 parts by weight of trimethoxysilane and 1 part by weight of dibutyltin diacetate are added into a high-speed dispersing mixer, and stirred for 60 minutes at a vacuum degree of 0.09 MPa and a rotational speed of 600 rpm to prepare an anti-pollution one-component room temperature vulcanized silicone sealant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com