Method for removing pyritic sulfur in gangue by microbe

A technology of microorganisms and coal gangue, applied in the field of microbial desulfurization, can solve problems such as air pollution, achieve the effects of eliminating spontaneous combustion, preventing water pollution and air pollution, and solving adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

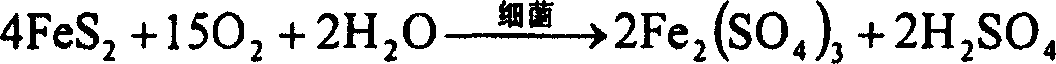

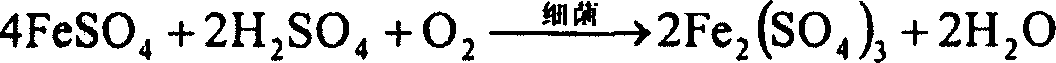

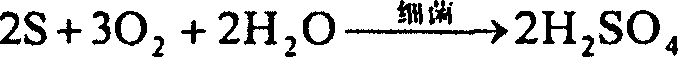

Method used

Image

Examples

Embodiment 1

[0024] The mass content of treated sulfur (as SO 3 %) is 2.73% coal gangue, crush the coal gangue into particles of about 0.1mm, take the granular coal gangue and put it into the cultivated culture medium M1 containing Thiobacillus ferrooxidans at a rate of 10g / L. The formula of M1 is:

[0025] (NH 4 ) 2 SO 4

[0026] The pH value of the culture medium M1 is 1.5, with H 2 SO 4 Adjustment; the concentration of Thiobacillus ferrooxidans in culture medium M1 reaches 10 7 The number of pieces / mL; leaching by stirring for 7 days, the desulfurization rate can reach 97.5%.

Embodiment 2

[0028] The coal gangue in Example 1 is crushed into particles of about 10 mm, and put into the ferrous oxide-containing Leptospira culture medium M2 that has been cultivated at 60 g / L. The formula for each liter of culture medium M2 is:

[0029] (NH 4 ) 2 SO 4

[0030] The pH value of the culture medium M2 is 2.5, with H 2 SO 4 Adjustment; the concentration of Leptospira ferrous oxide in the culture medium M2 reaches 10 8 The number of pieces / mL; the desulfurization rate can reach 97.0% by leaching for 10 days by aeration.

Embodiment 3

[0032] The coal gangue in Example 1 is crushed into particles of about 20 mm, and put into the cultivated Thiobacillus ferrooxidans-containing culture medium M1 at 100 g / L; the formula of every liter of culture medium M1 is:

[0033] (NH 4 ) 2 SO 4

[0034] The pH value of the culture medium M1 is 2.0, with H 2 SO 4 Adjustment; the concentration of Thiobacillus ferrooxidans in culture medium M1 reaches 10 9 The number of pieces / mL; leaching by stirring for 15 days, the desulfurization rate can reach 96.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com