Prevention treatment method for fully mechanized coal mining face

A technology of fully mechanized mining face and treatment method, which is applied in the field of prevention and treatment of fully mechanized mining face, can solve the problems of not being able to avoid the hidden danger of roof fall and spontaneous combustion well, and achieve the effects of improving safety and improving the speed of advancement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

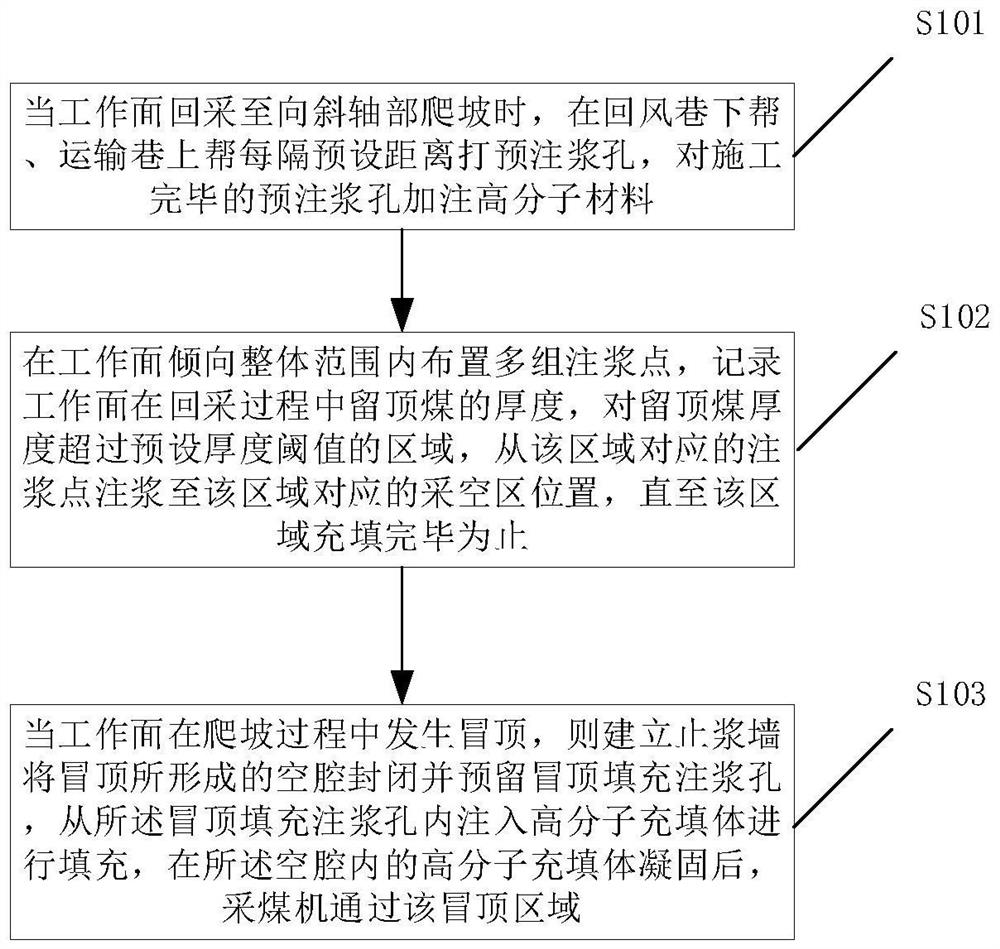

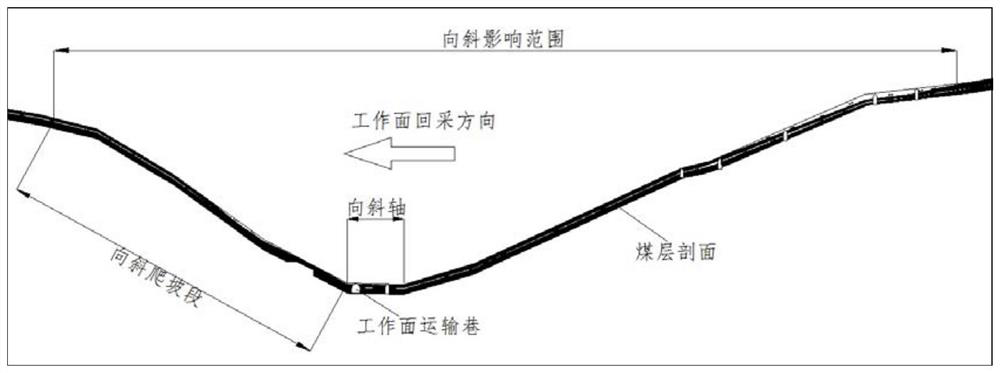

[0044] like figure 1 Shown is a working flow chart of a method for preventing and treating fully mechanized mining face of the present invention, including:

[0045] Step S101, when the working face is recovered to the syncline axis and climbs the slope, pre-grouting holes are made at preset distances in the lower side of the return air lane and the upper side of the transport lane, and polymer is injected into the pre-grouting holes that have been constructed. Material;

[0046] Step S102, arranging multiple groups of grouting points within the overall range of the working face inclination, recording the thickness of the top coal remaining in the mining process of the working face, and for the area where the thickness of the remaining top coal exceeds a preset thickness threshold, grouting from the corresponding area of the area Point grouting to the gob position corresponding to the area until the area is filled;

[0047] Step S103, when the working face has a roof cavin...

Embodiment 2

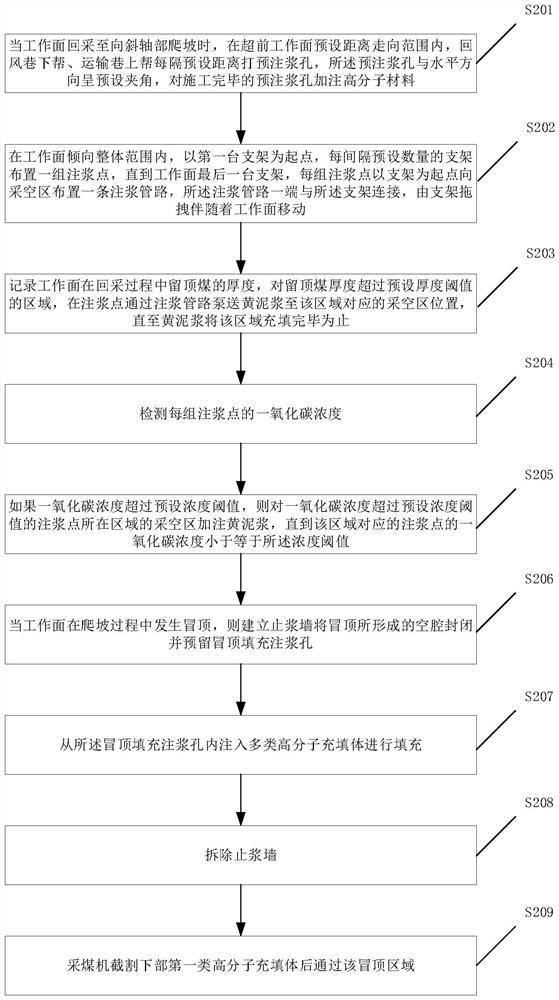

[0053] like figure 2 Shown is a working flow chart of a method for preventing and treating fully mechanized mining face in an embodiment of the present invention, including:

[0054] Step S201, when the working face is recovered to the syncline shaft and climbs the slope, within the range of the preset distance ahead of the working face, pre-grouting holes are made at preset distances for the lower side of the return air lane and the upper side of the transport lane. The pre-grouting hole is at a preset angle with the horizontal direction, and the pre-grouting hole after construction is filled with polymer material.

[0055] Step S202, within the overall range of the inclination of the working face, starting from the first bracket, arranging a group of grouting points at every preset number of brackets until the last bracket on the working face, each group of grouting points starting from the bracket A grouting pipeline is arranged to the goaf, one end of the grouting pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com