Welding control method of diplonema MAG and welding source

A control method and technology of welding power source, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of incompatibility, inability to achieve arbitrary phase adjustment, application limitations, etc., to increase flexibility and improve arc stability The effect of wide performance and welding specification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

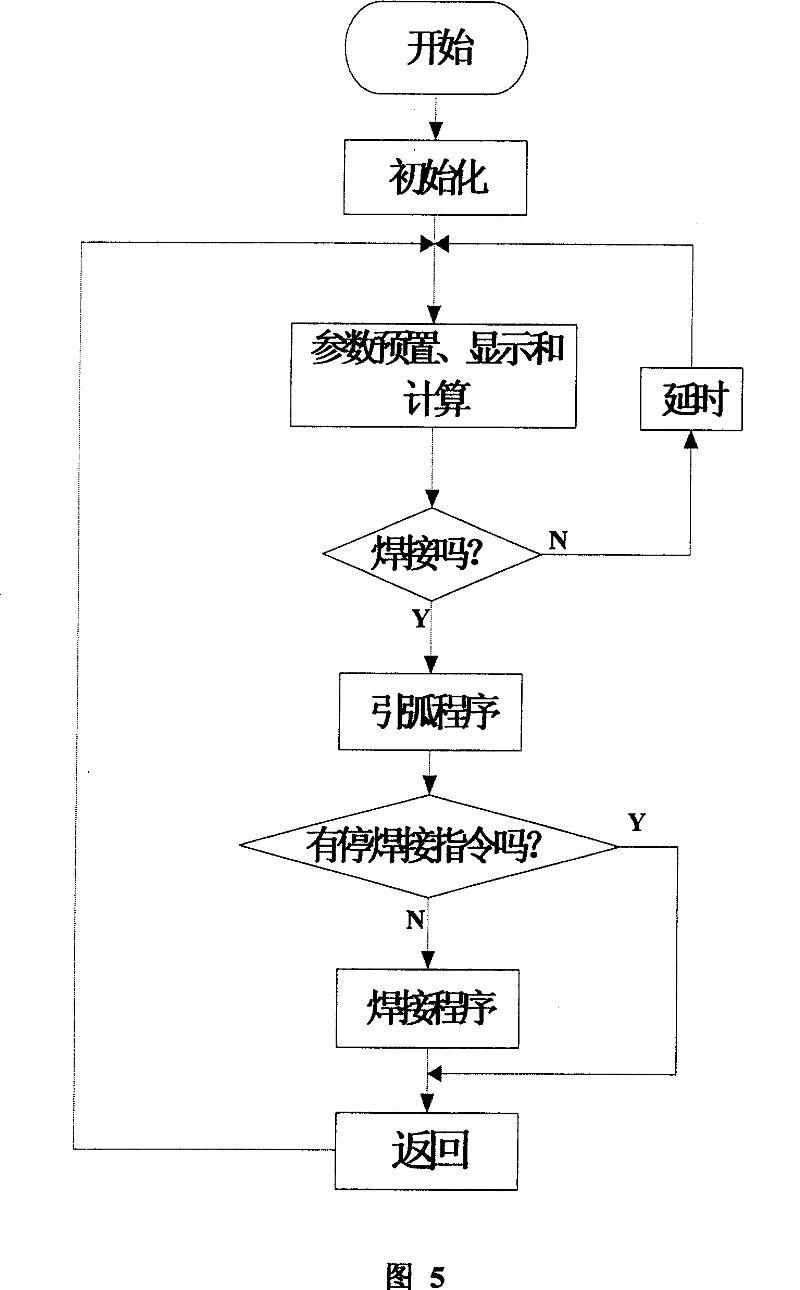

[0027] This example will now be described with reference to the accompanying drawings.

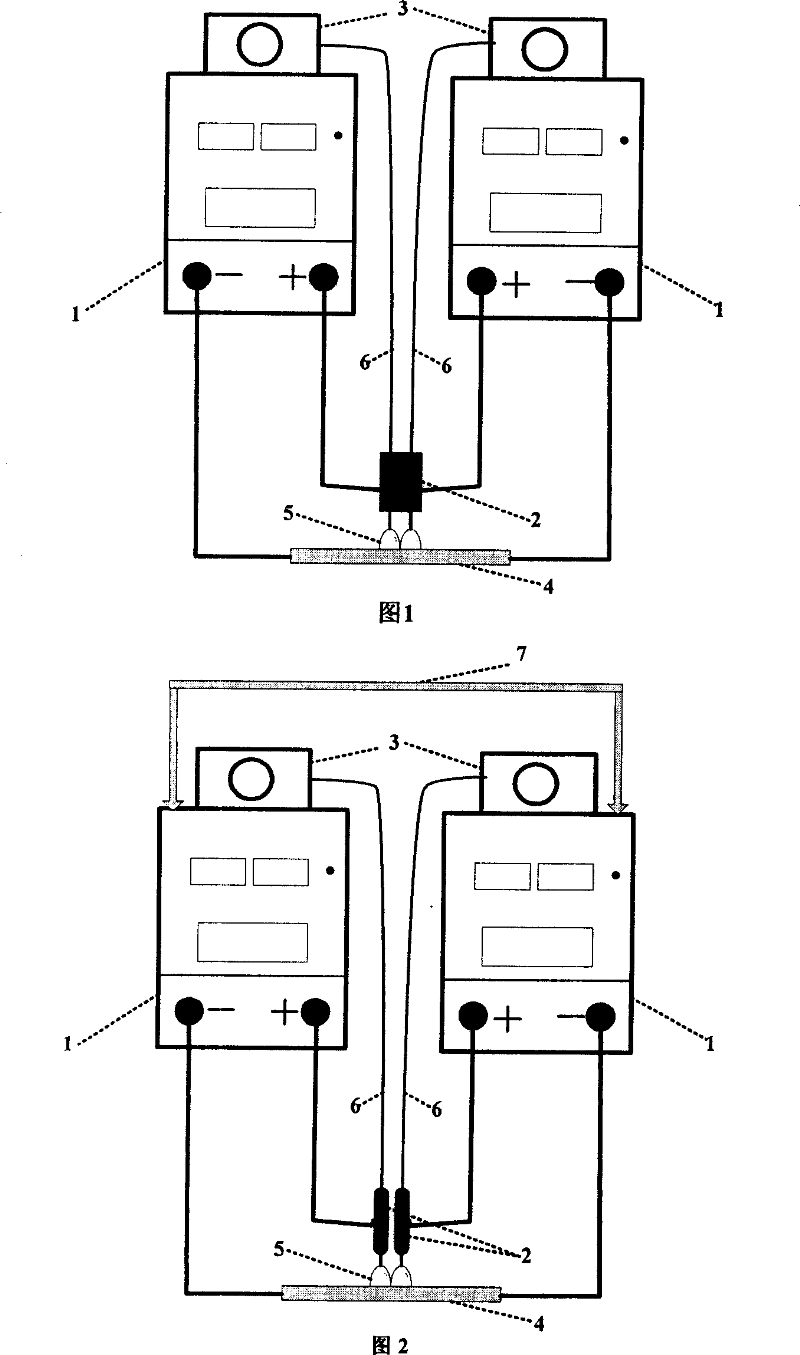

[0028] This example uses the schema shown in Figure 2.

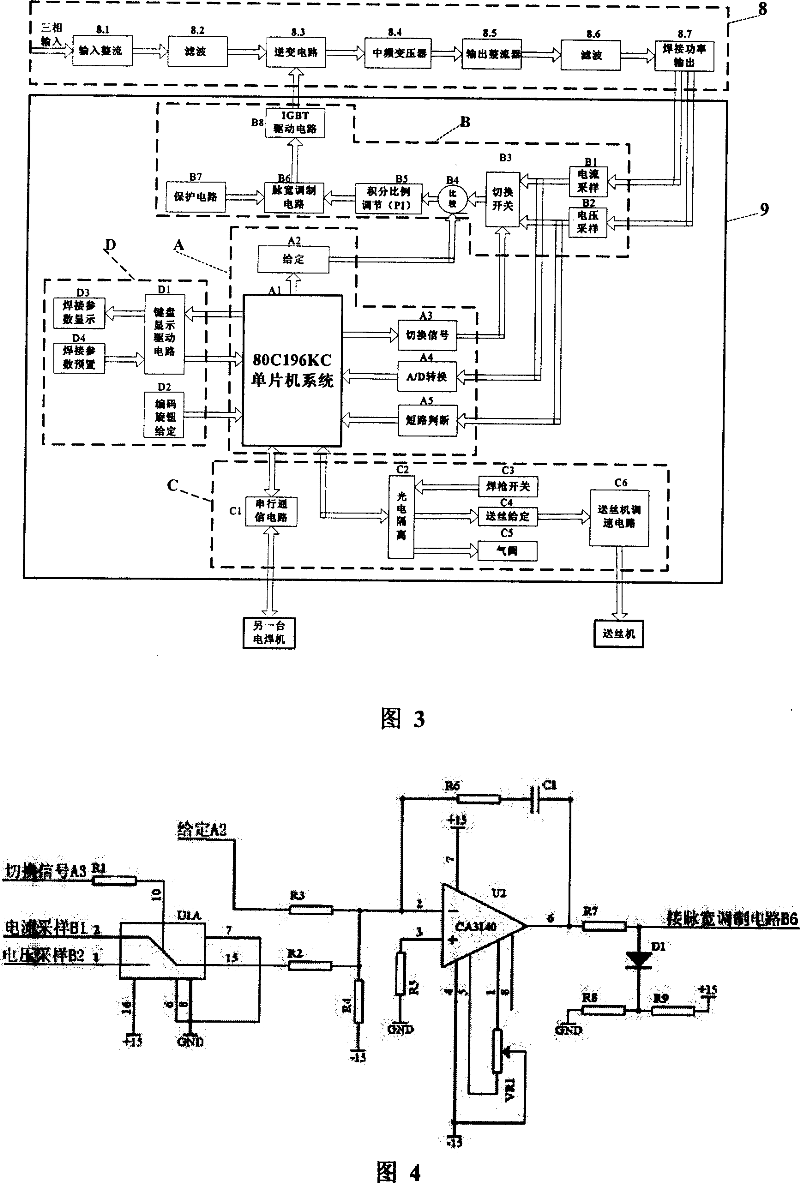

[0029] A concrete example of the present invention is shown in Fig. 3 as a structural diagram of a single welding machine, which generally includes two parts: the main circuit part 8 of the welding power supply and the control circuit part 9 with 80C196KC as the core. The input voltage of the main circuit is three-phase 380V; the input rectifier 8.1 is rectified by Fuji rectifier bridge, the model is FUJ6RI100G-160; The microcrystalline magnetic core has a transformation ratio of 15:2; the filter 8.6 uses a magnetic core saturated inductance, and the inductance is about 40μH; the control part adopts a control system based on 80C196KC single-chip microcomputer, which mainly completes the timing control and can realize the phase of the two welding machines The relationship varies from 0 to 180 degrees; the keyboard / display part adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com