Halogen-free expansion type retardant polyethylene contg. organic metal complex

A technology of flame retardant polyethylene and intumescent flame retardant, which is applied in the field of polyolefin flame retardant products, can solve the adverse effects of ammonium polyphosphate on the hygroscopic flame retardant performance, the droplet resistance needs to be improved, and the addition of flame retardants is large and other problems, to achieve the effect of reducing adverse effects, improving vertical combustion, and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14

[0024] (1) synthesis of pentaerythritol ester:

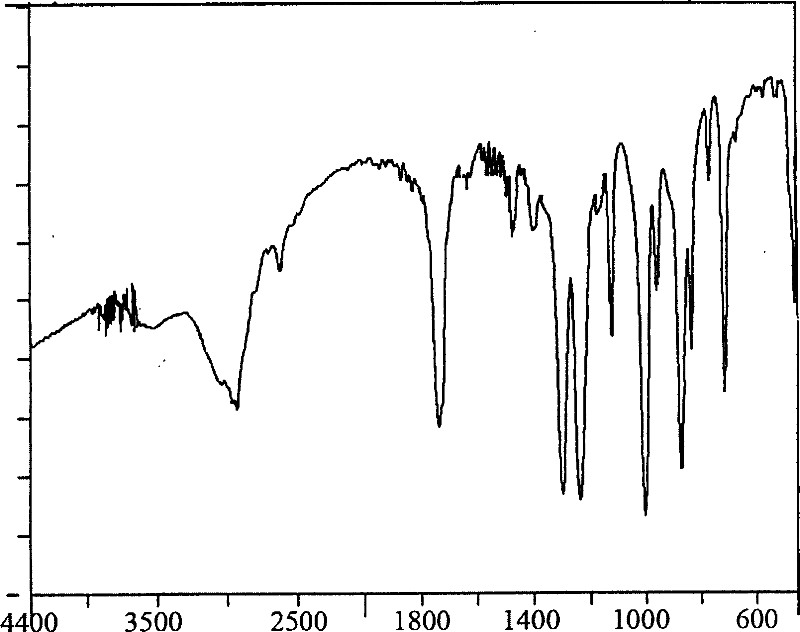

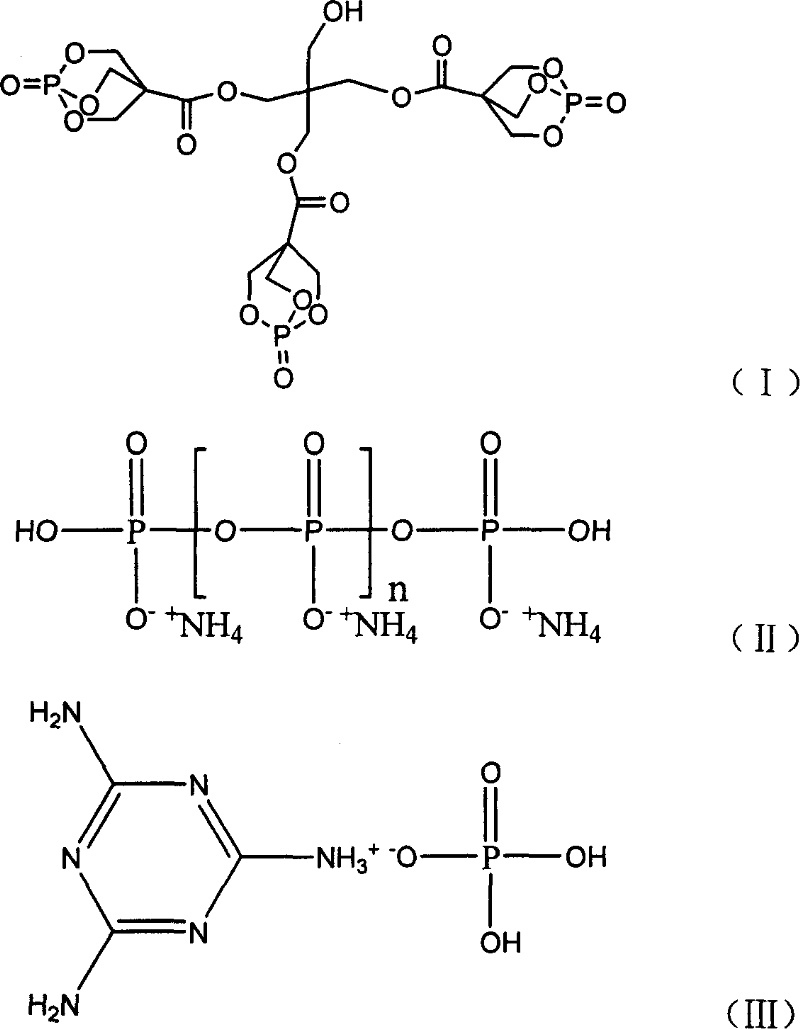

[0025] 2.72 grams of pentaerythritol, 12.72 grams of 1-oxo-4-hydroxymethyl-1-phospha-2,6,7-trioxabicyclo[2,2,2] octane (PEPA) acid chloride product was added Stir to dissolve in a three-necked flask with 100ml of dioxane, and add 0.15ml of pyridine dropwise; heat up to 95-105°C for reflux reaction for 6 hours; cool to room temperature, and then wash the product with dioxane and chloroform respectively 1-2 times to obtain a white solid product; finally dry it in a vacuum oven at 70°C for later use. The infrared spectrum of this pentaerythritol ester product obtained is as shown in the accompanying drawing, and its concrete structure is as follows: 3456cm -1 and 1121cm -1 For O-H; 2924cm -1 It is an aliphatic C-H structure; 1736cm -1 and 11234cm -1 For ester group; 1295cm -1 and 1001cm -1 Phosphate group; 873cm -1 and 835cm -1 It is a cage-like bicyclic phosphate structure.

[0026] (2) mechanical mixing polyethylene, pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com