Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "The spacing can be adjusted arbitrarily" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

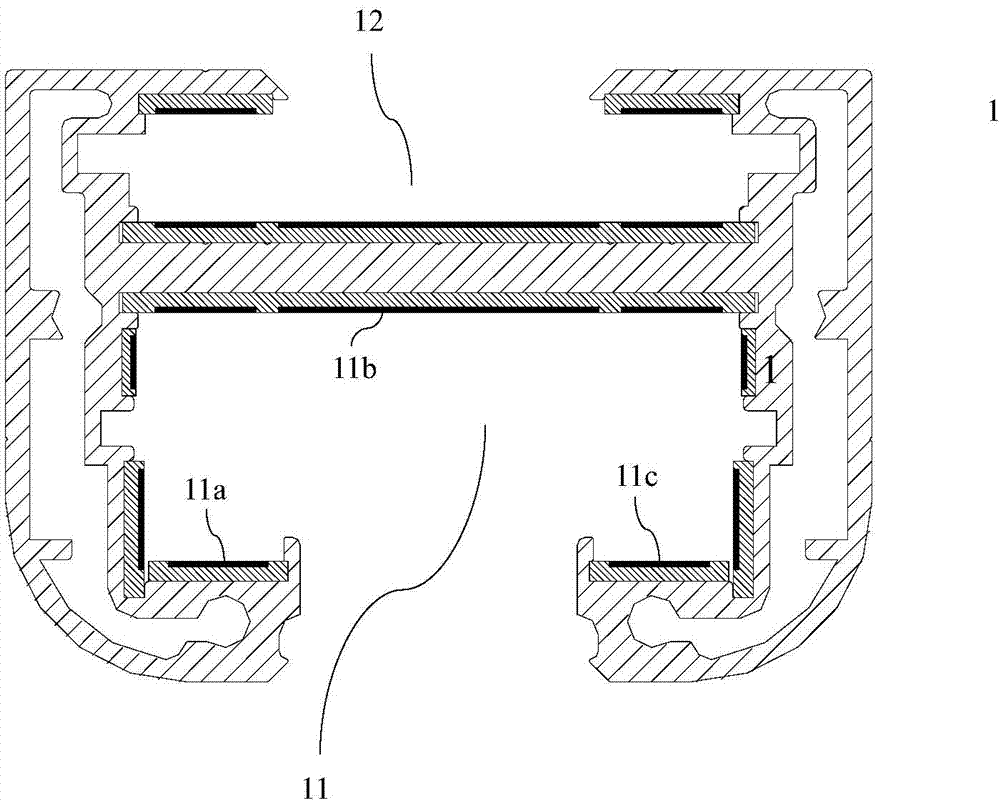

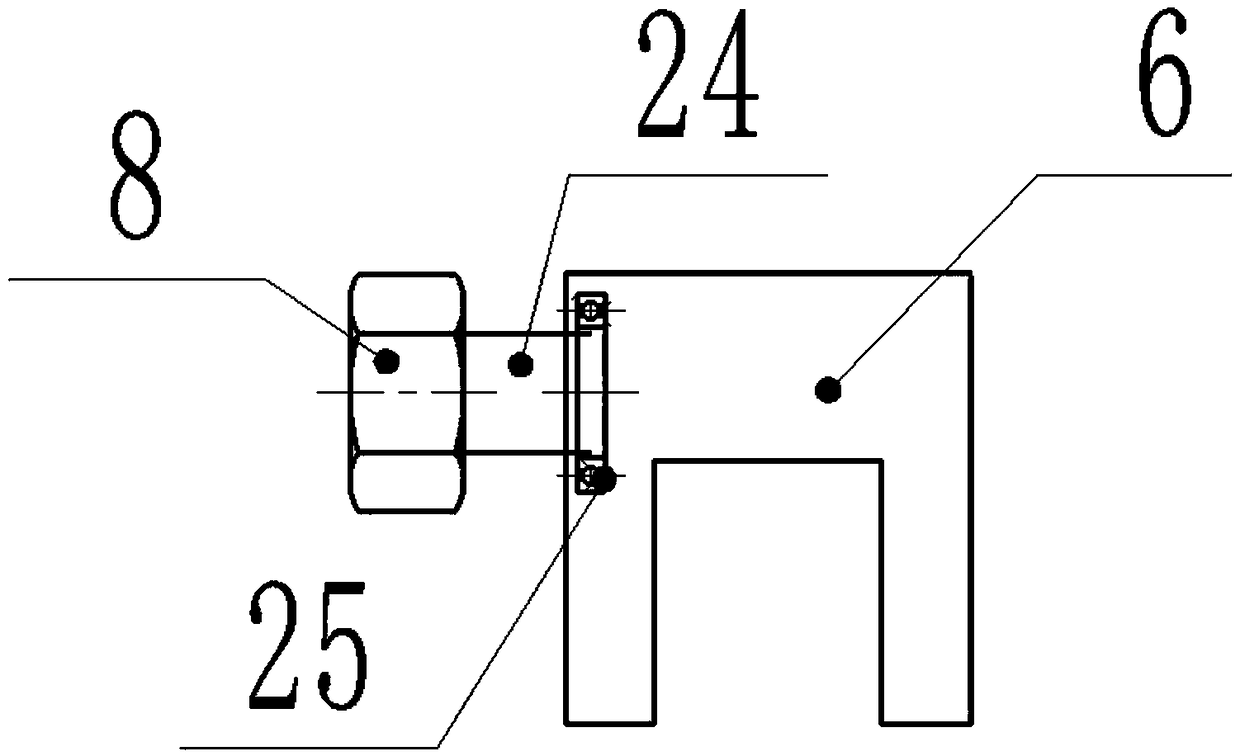

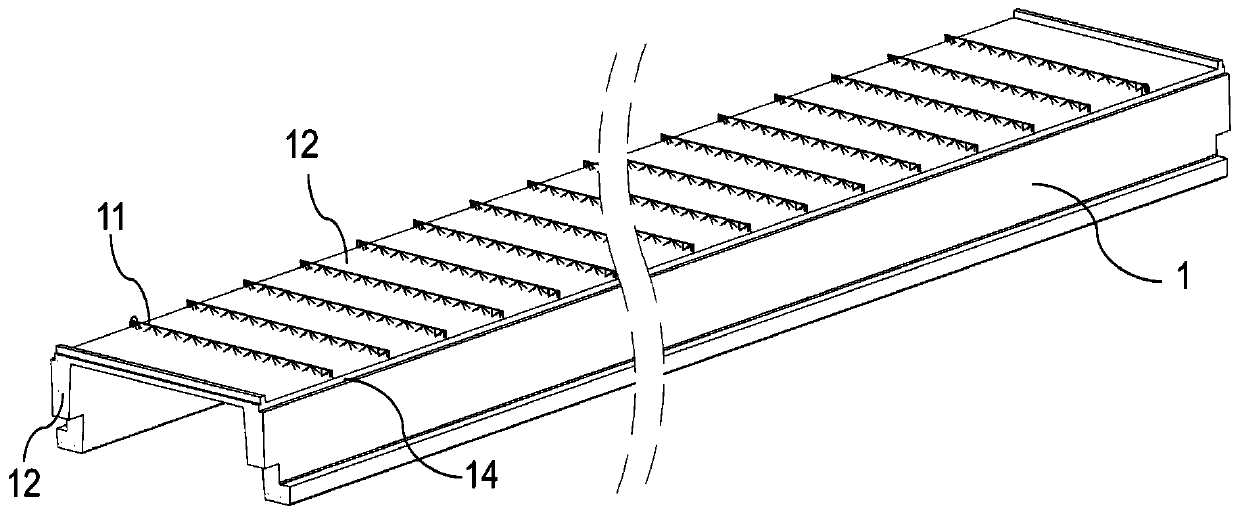

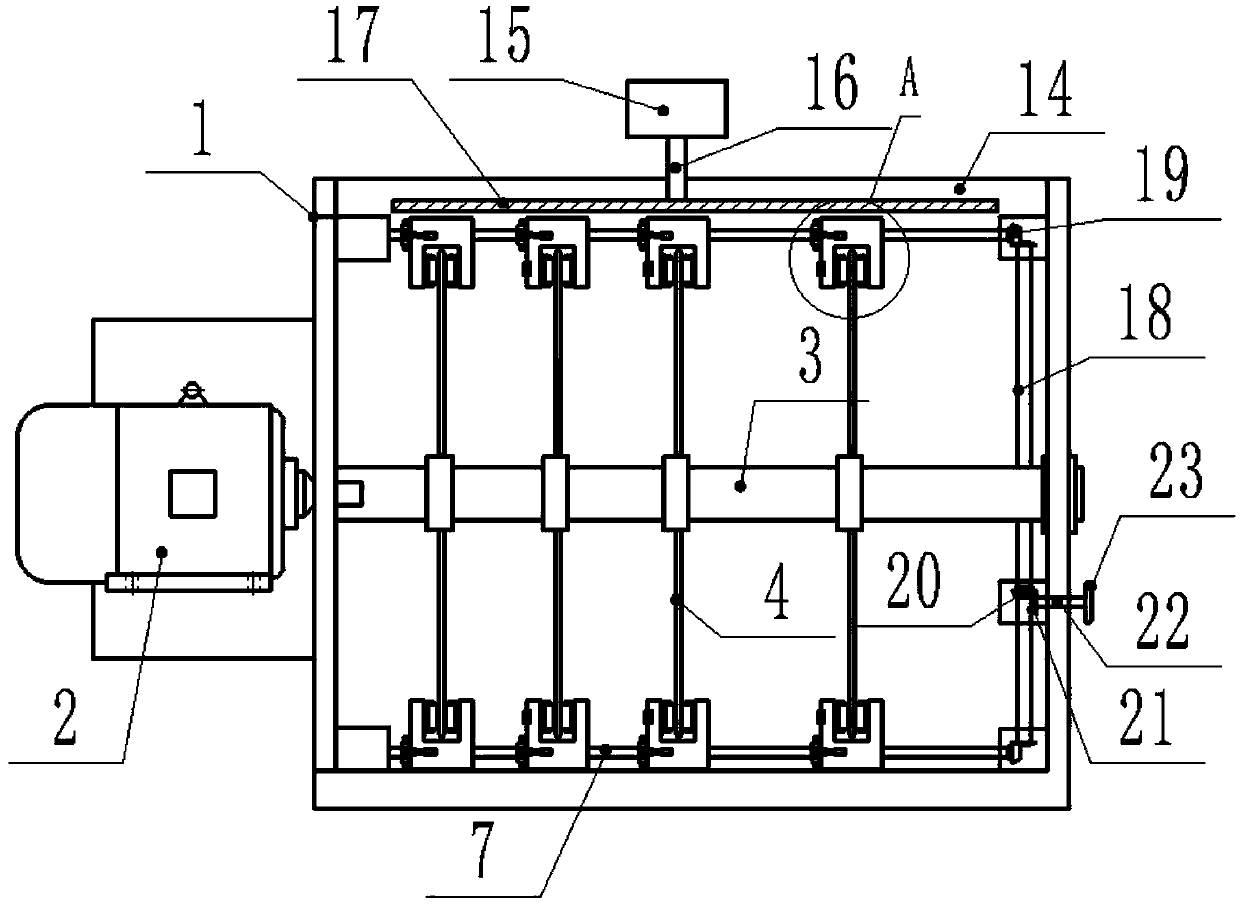

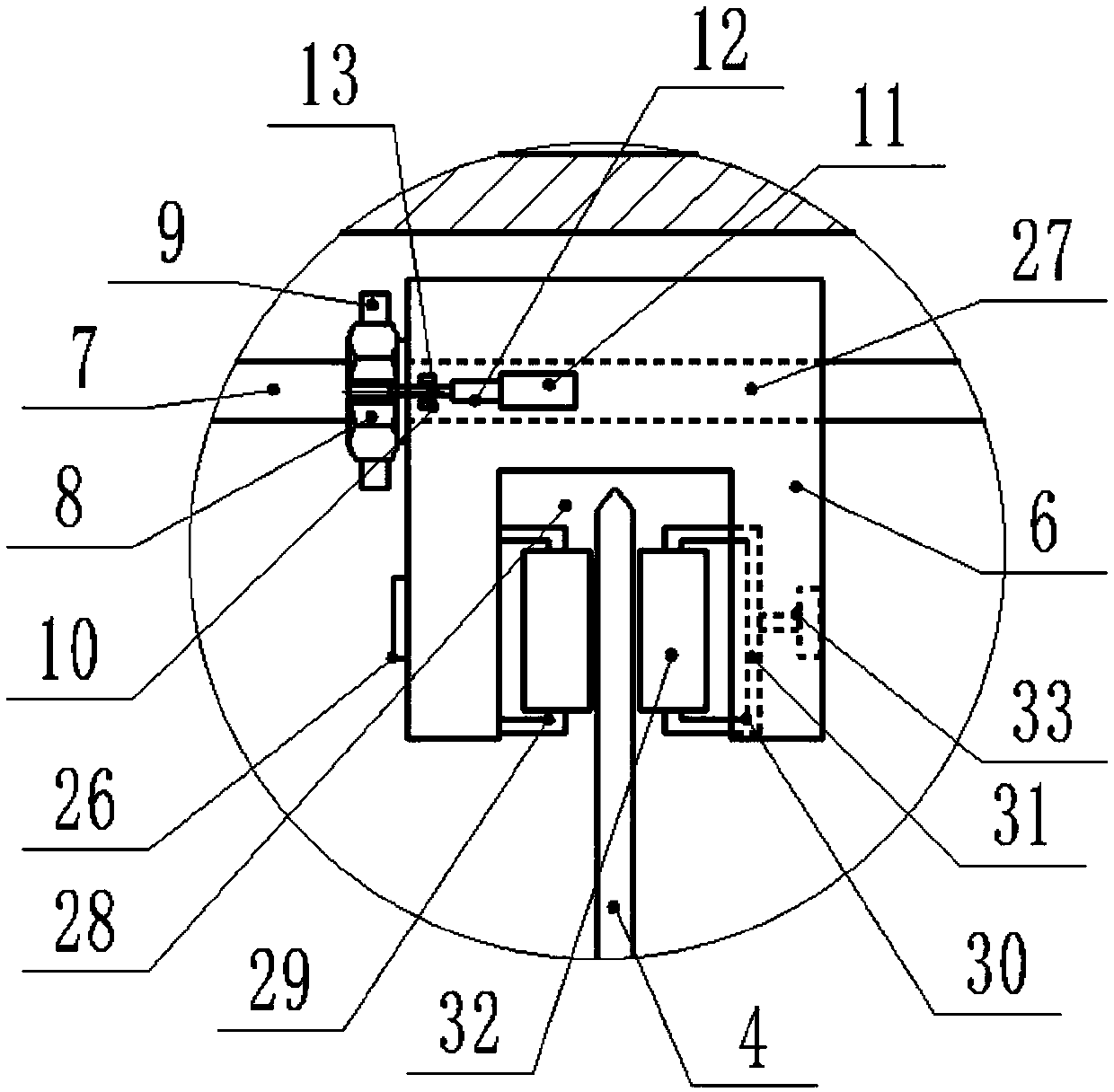

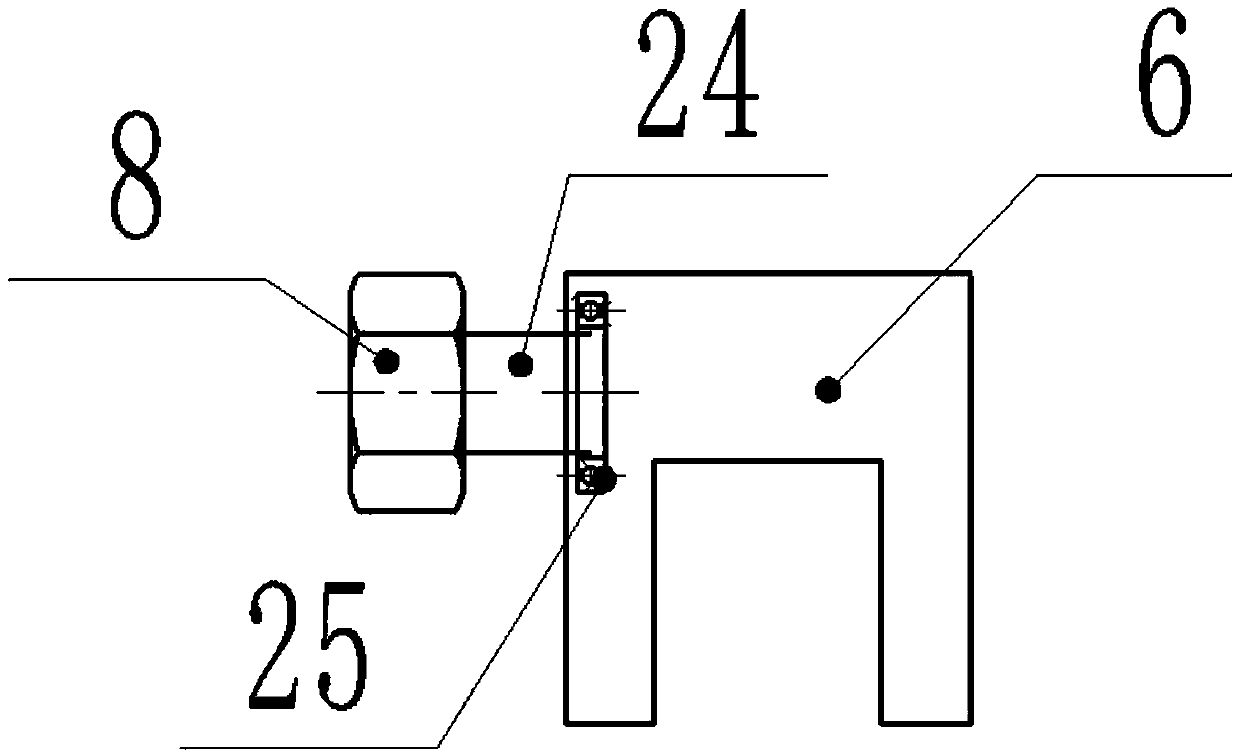

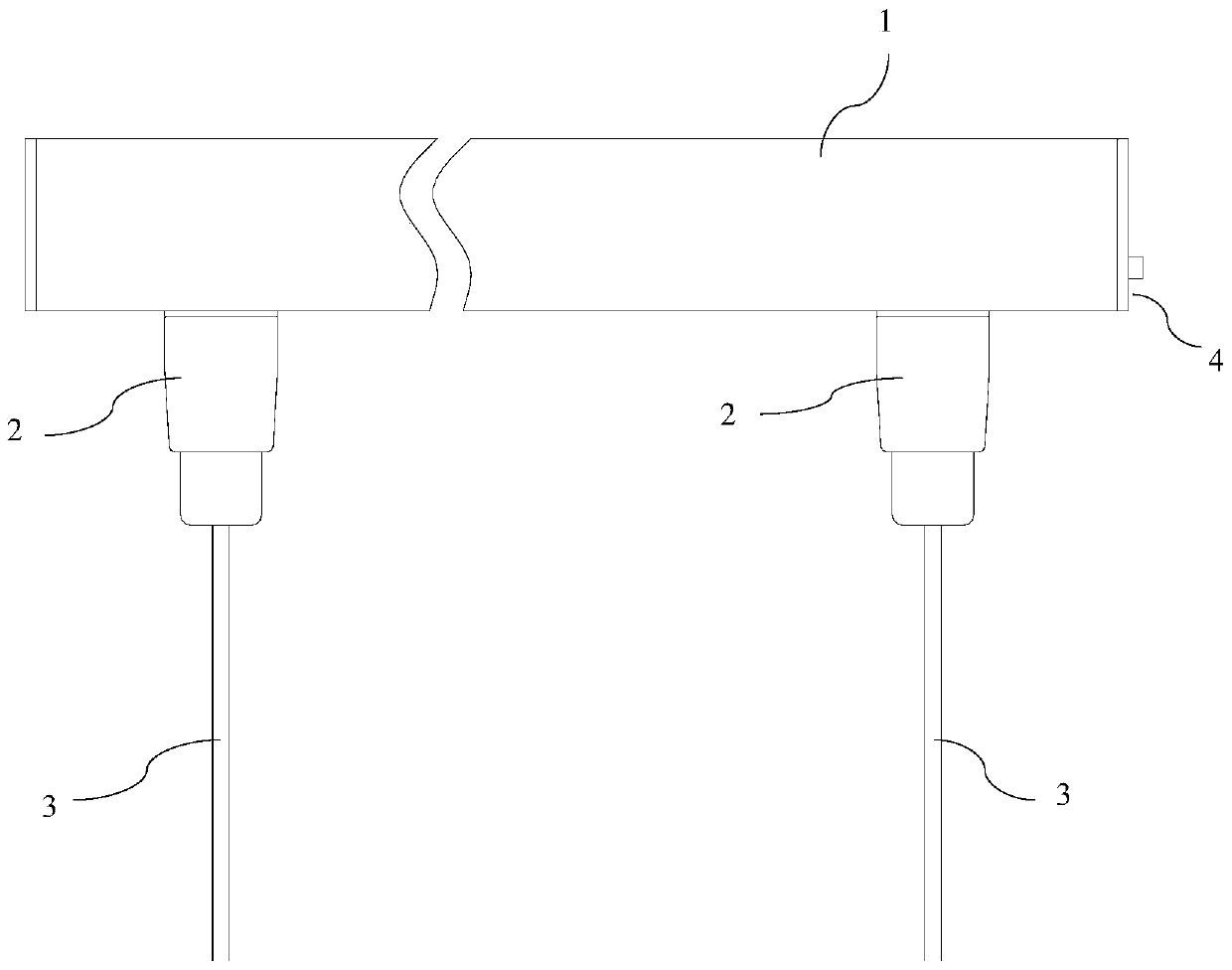

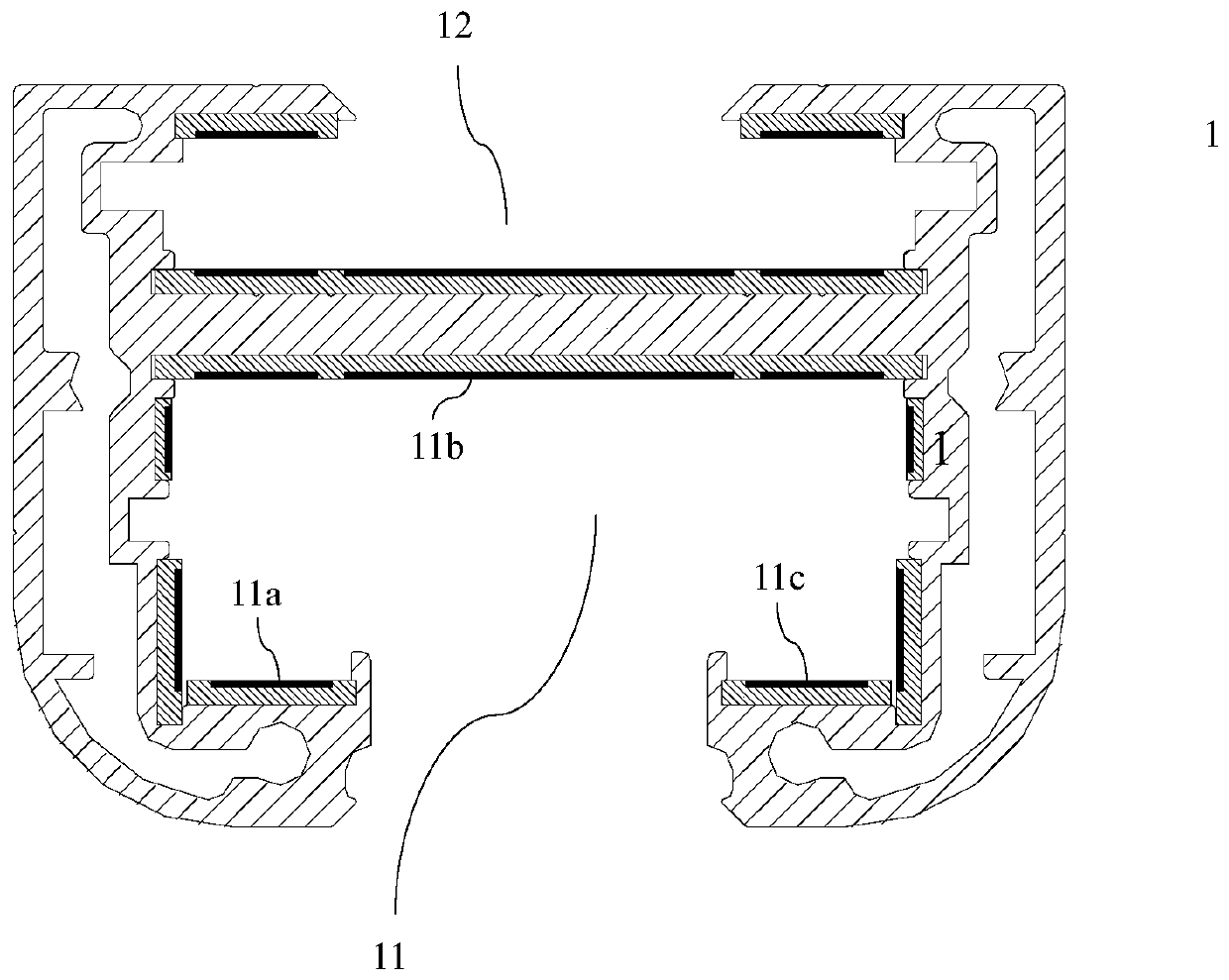

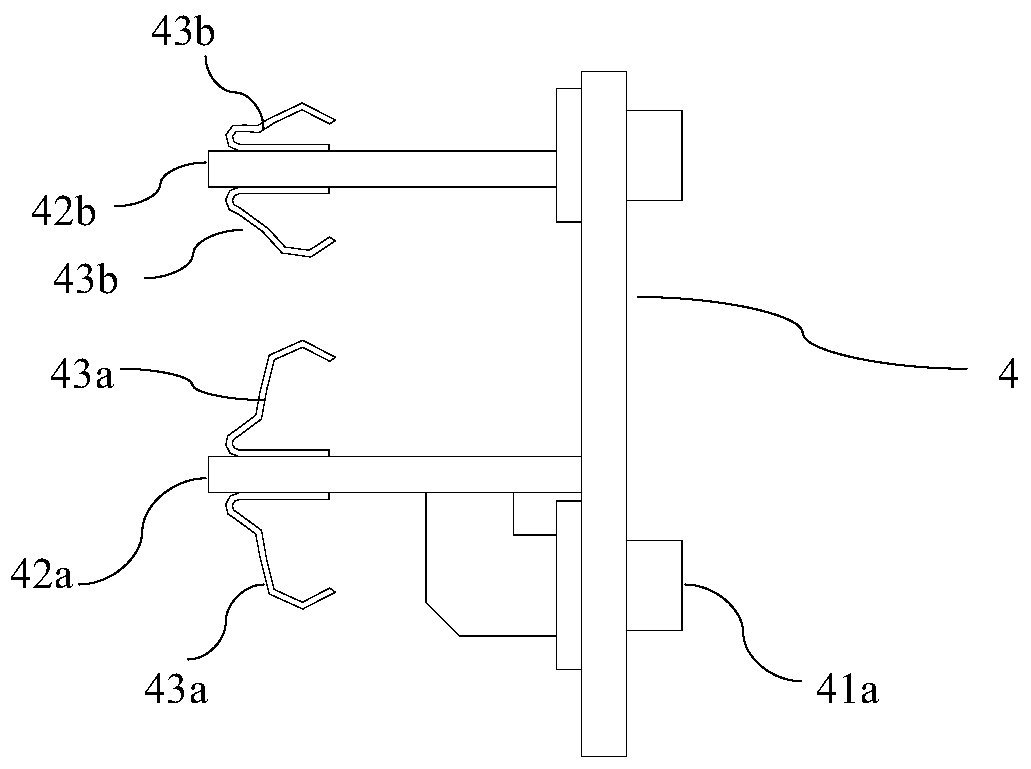

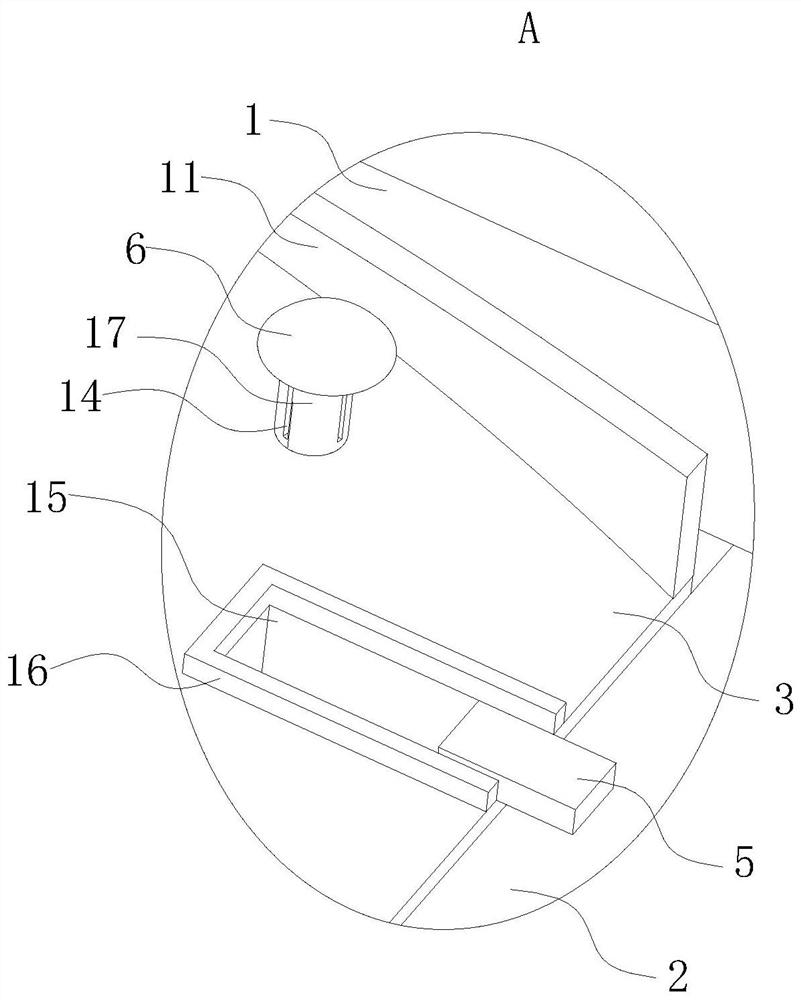

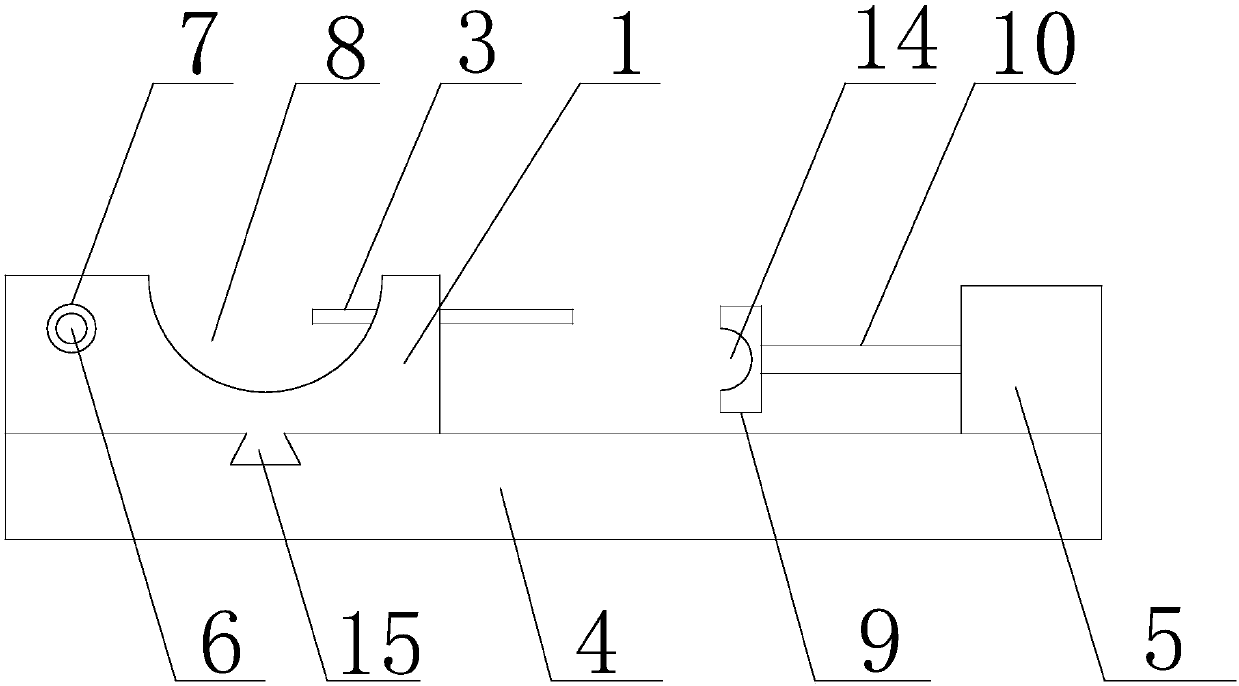

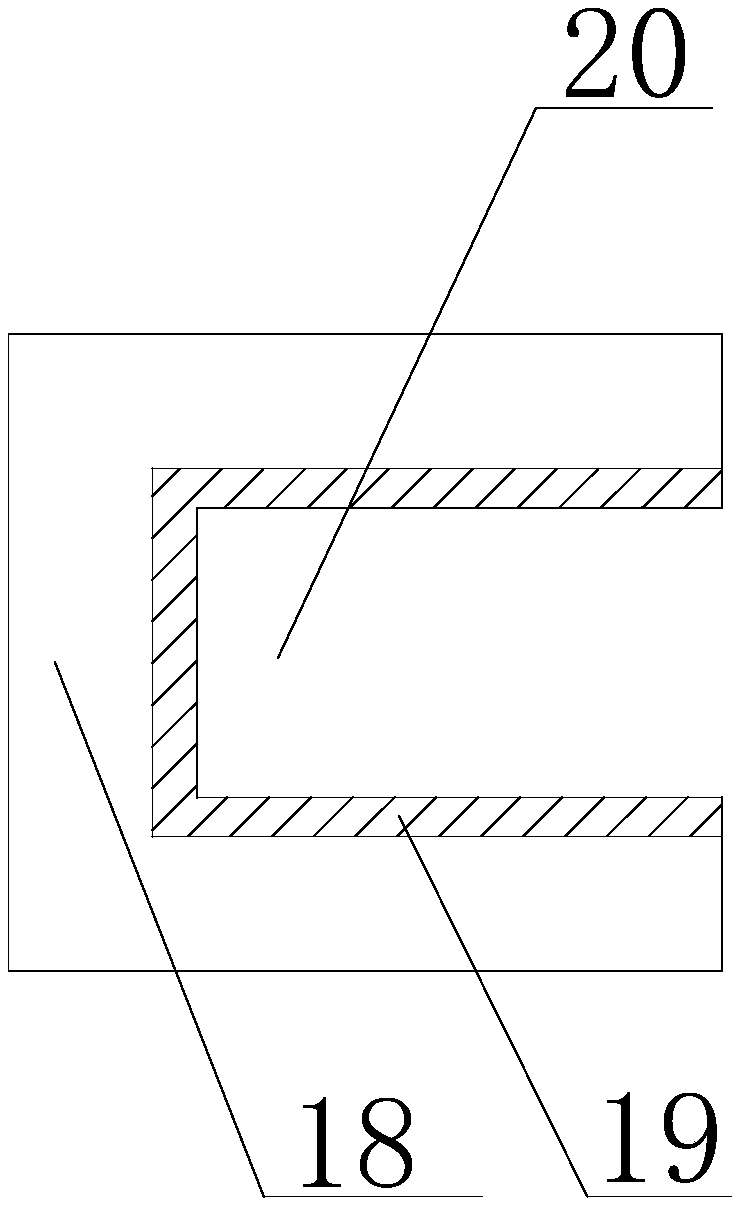

Electric conduction rail type mounting assembly

InactiveCN104848180AEasy to installLight structureLighting support devicesElectric circuit arrangementsPublic placeLow voltage

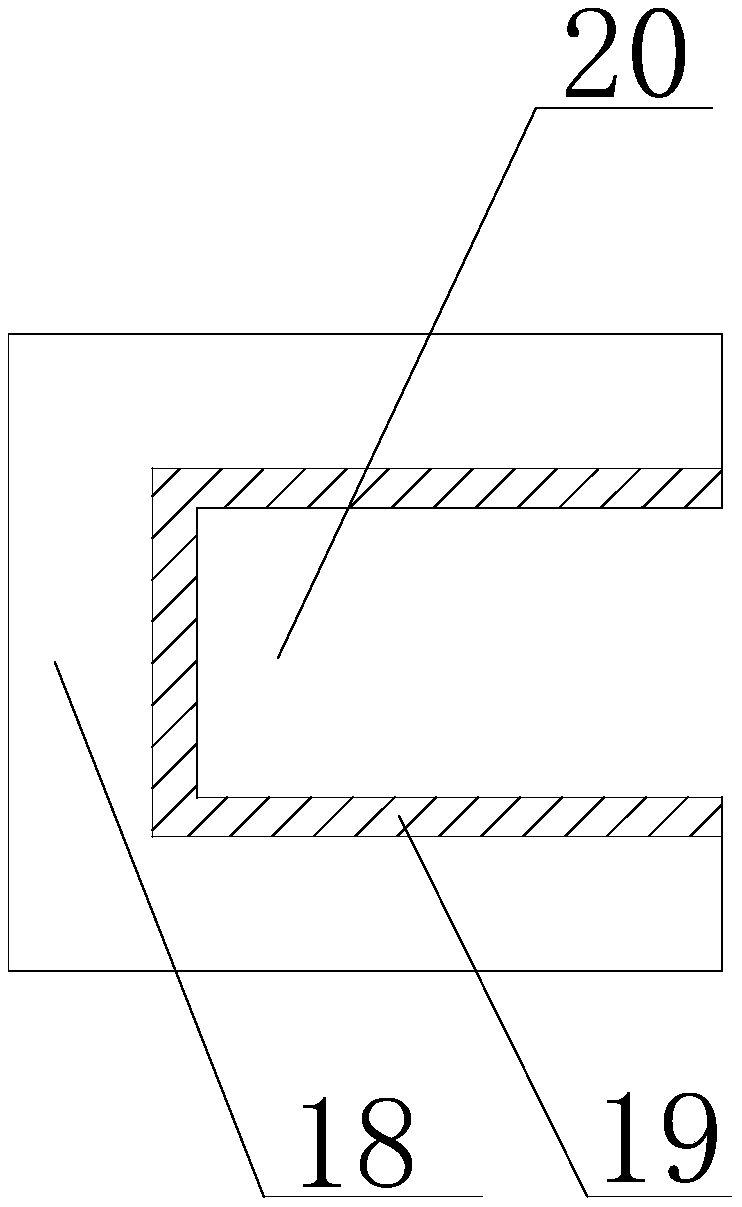

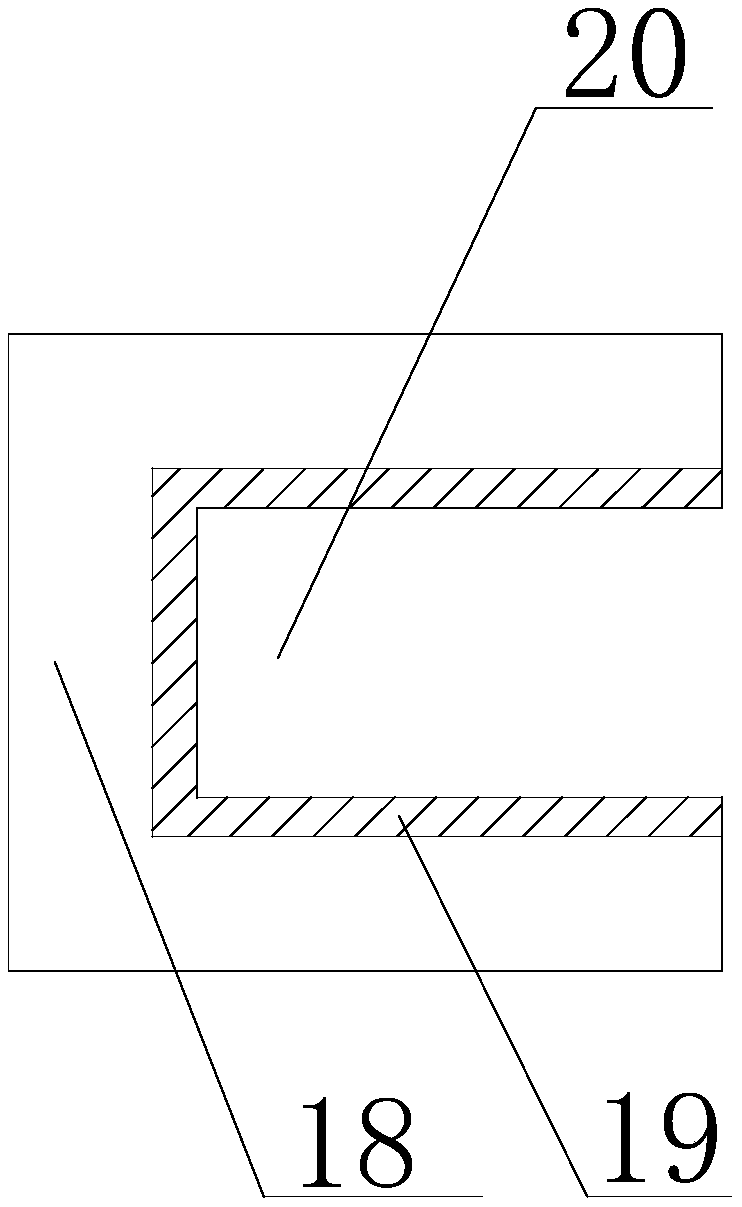

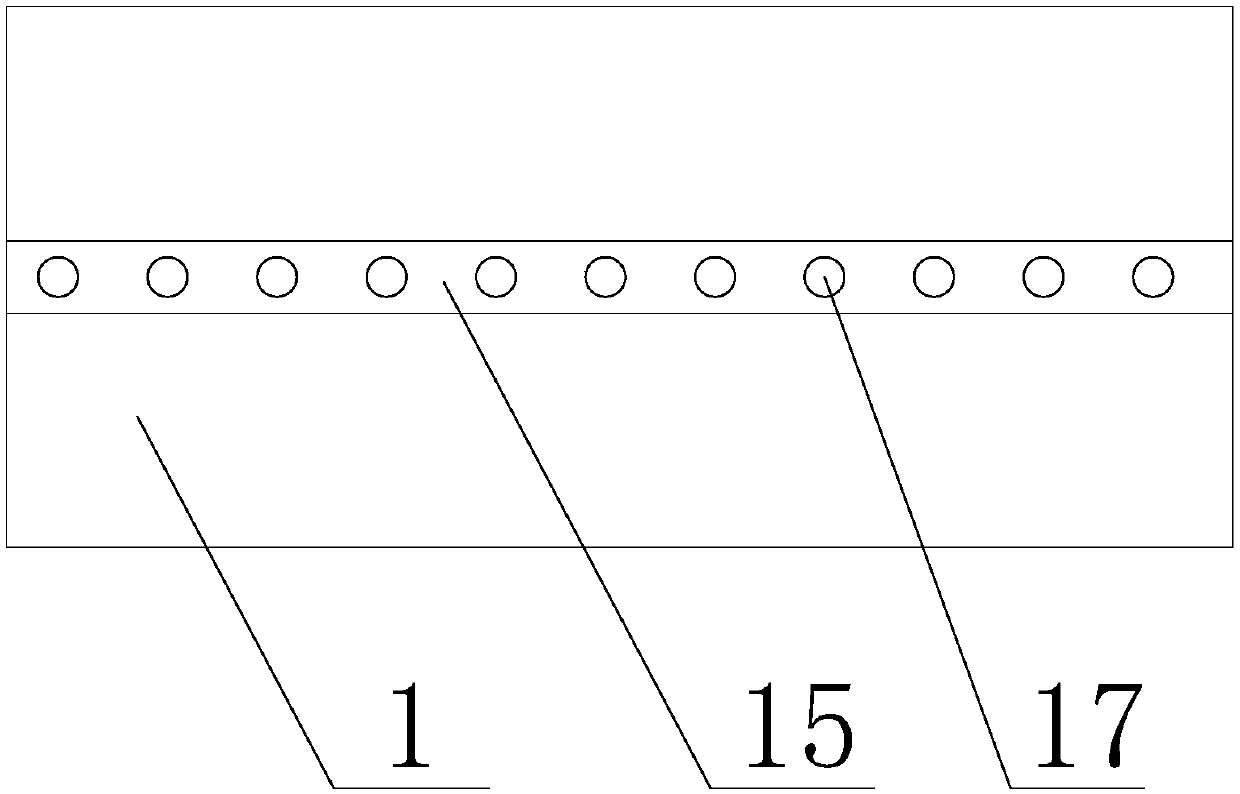

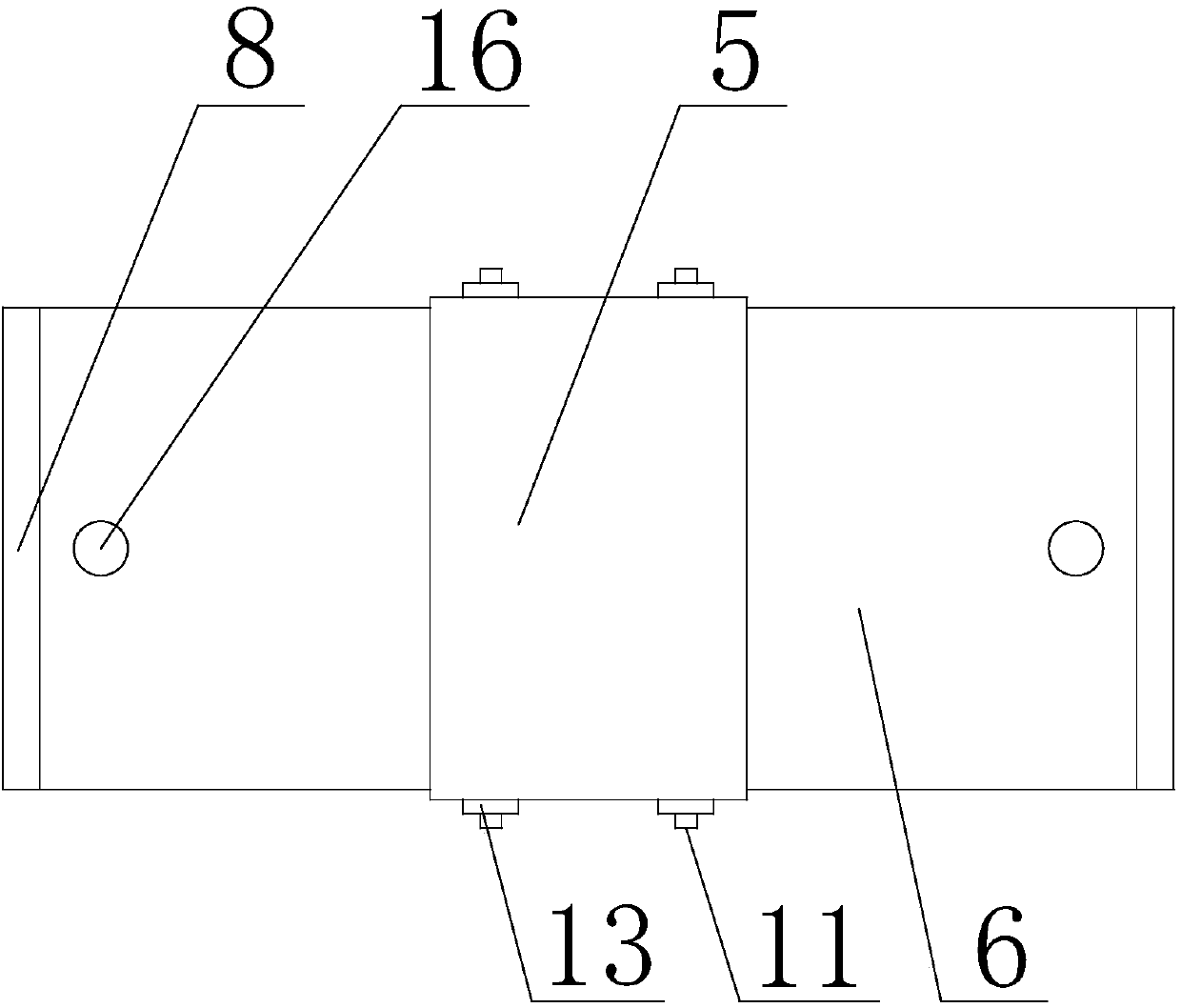

The invention relates to an electric conduction rail type mounting assembly which comprises a guide rail and at least one hanging assembly connected to the guide rail in a sliding mode. The guide rail is provided with a first rail body allowing the hanging assembly to slide thereon. The first rail body is internally provided with at least two electrodes. All the hanging assemblies comprise touch pieces for current breakover and corresponding to all the electrodes. The hanging assemblies in the electric conduction rail type mounting assembly can conduct breakover as well as hanging heavy objects, the positive electrodes and the negative electrodes are set and converted very cleverly and conveniently, the hanging assemblies can move on the guide rail, the interval can be adjusted freely, the electric conduction rail type mounting assembly is very suitable for mounting advertising lamp boxes, advertising machines, lamps and the like in public places and households, and lighting lamps can be arranged on the guide rail so that the electric conduction rail type mounting assembly can be widely applied to lighting of industrial production places, shop shopwindows, counters and the like; furthermore, the inner side of the guide rail can be provided with a plurality of electrodes, and different low-voltage direct current and low-voltage alternating current can be provided according to the requirements.

Owner:惠州市梧桐实业有限公司

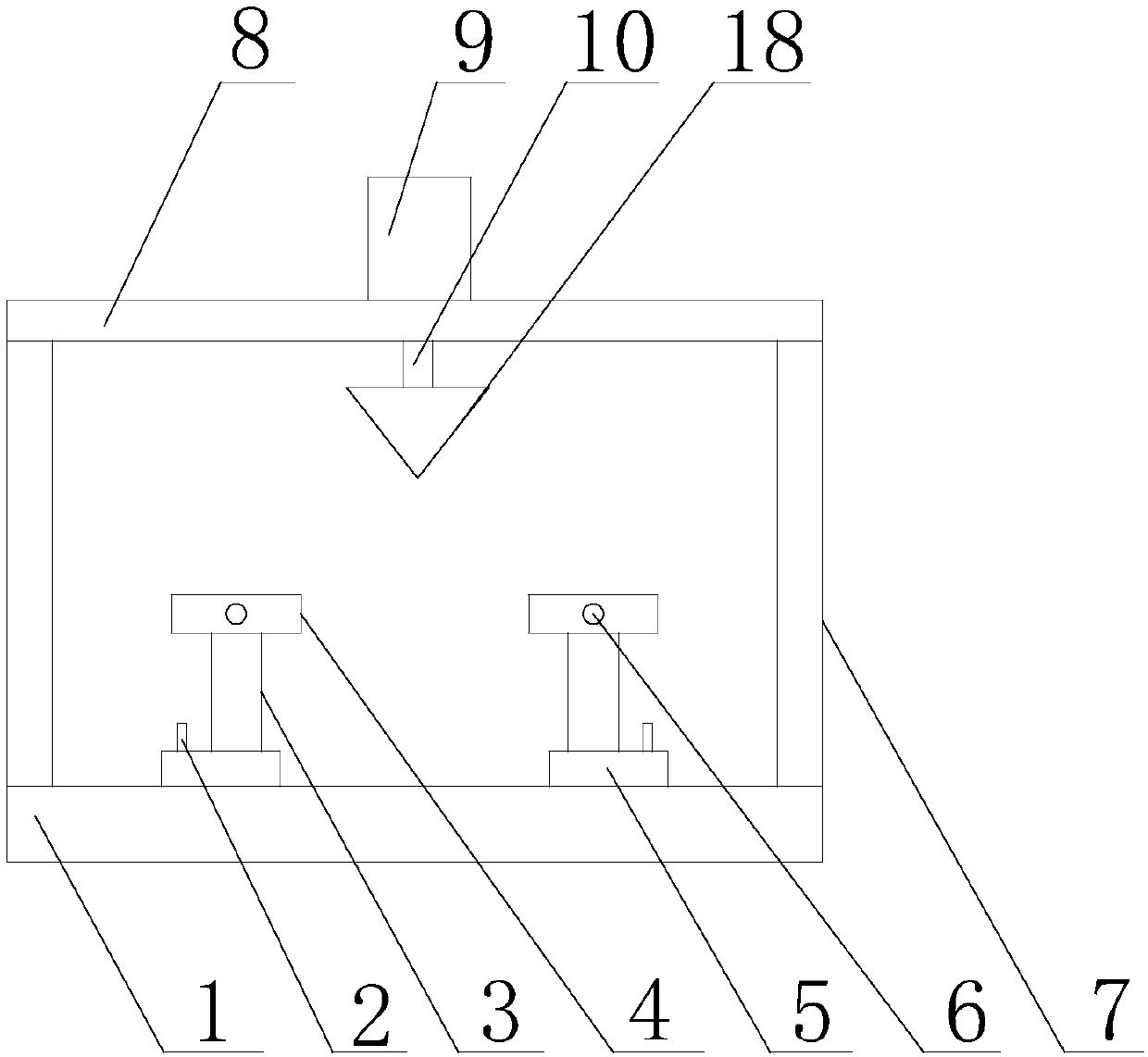

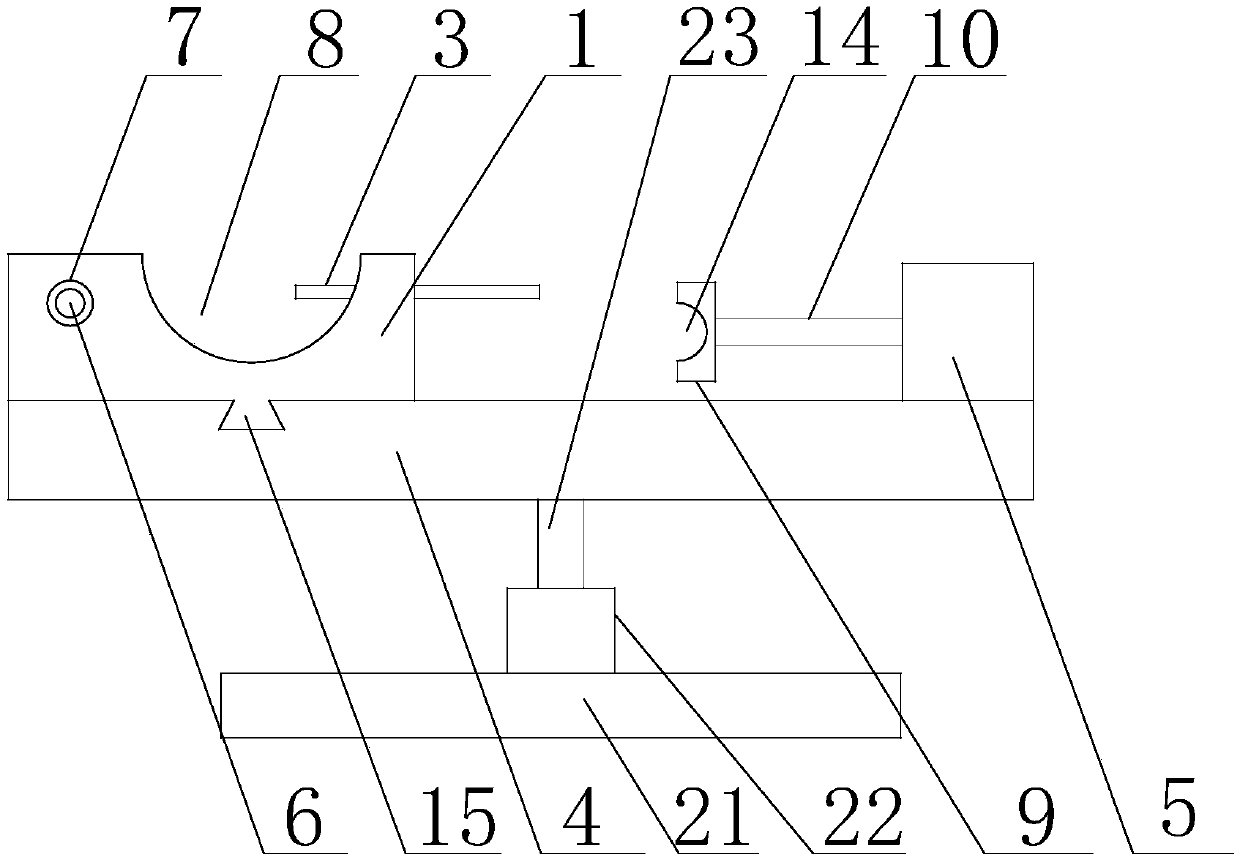

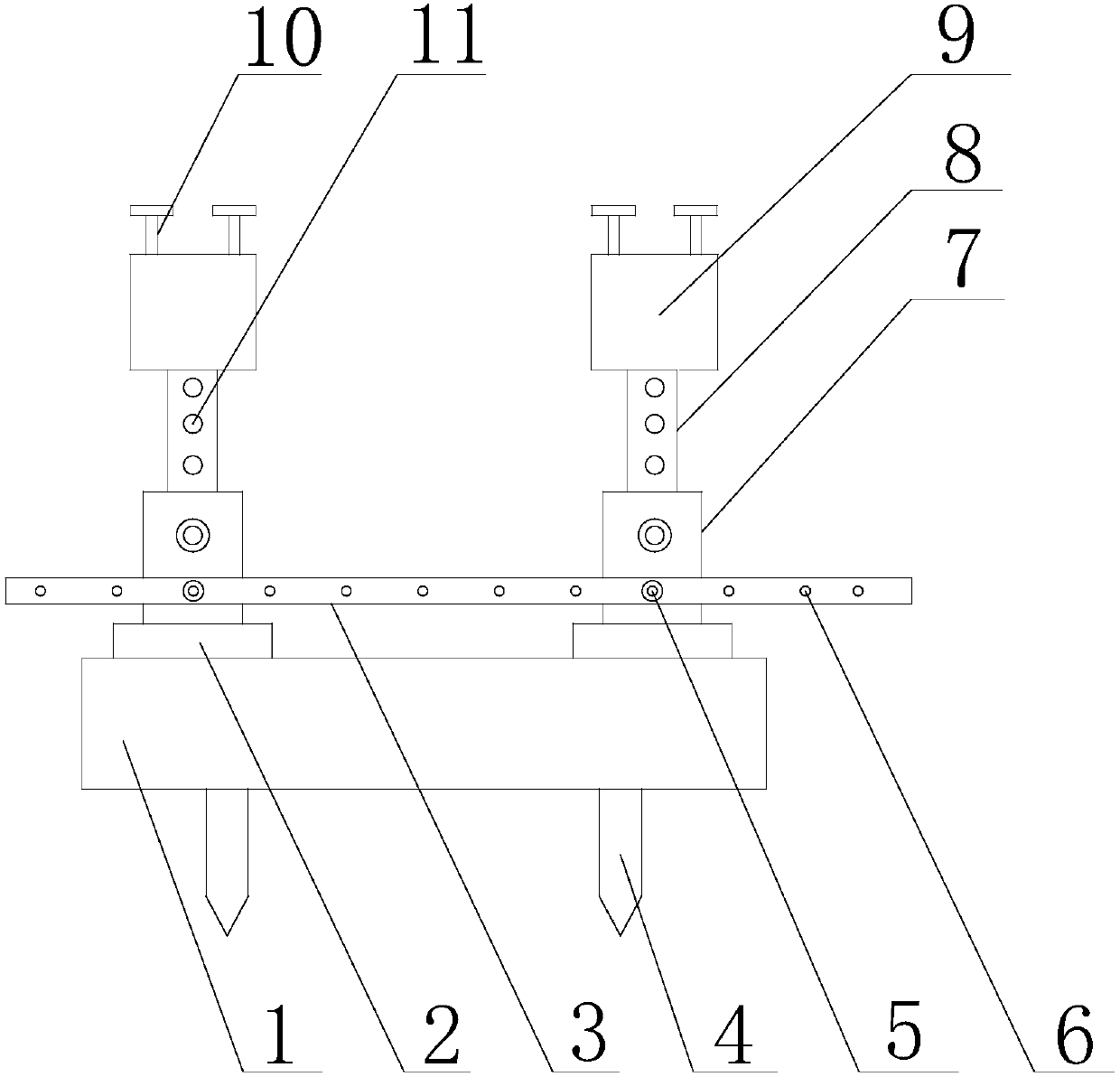

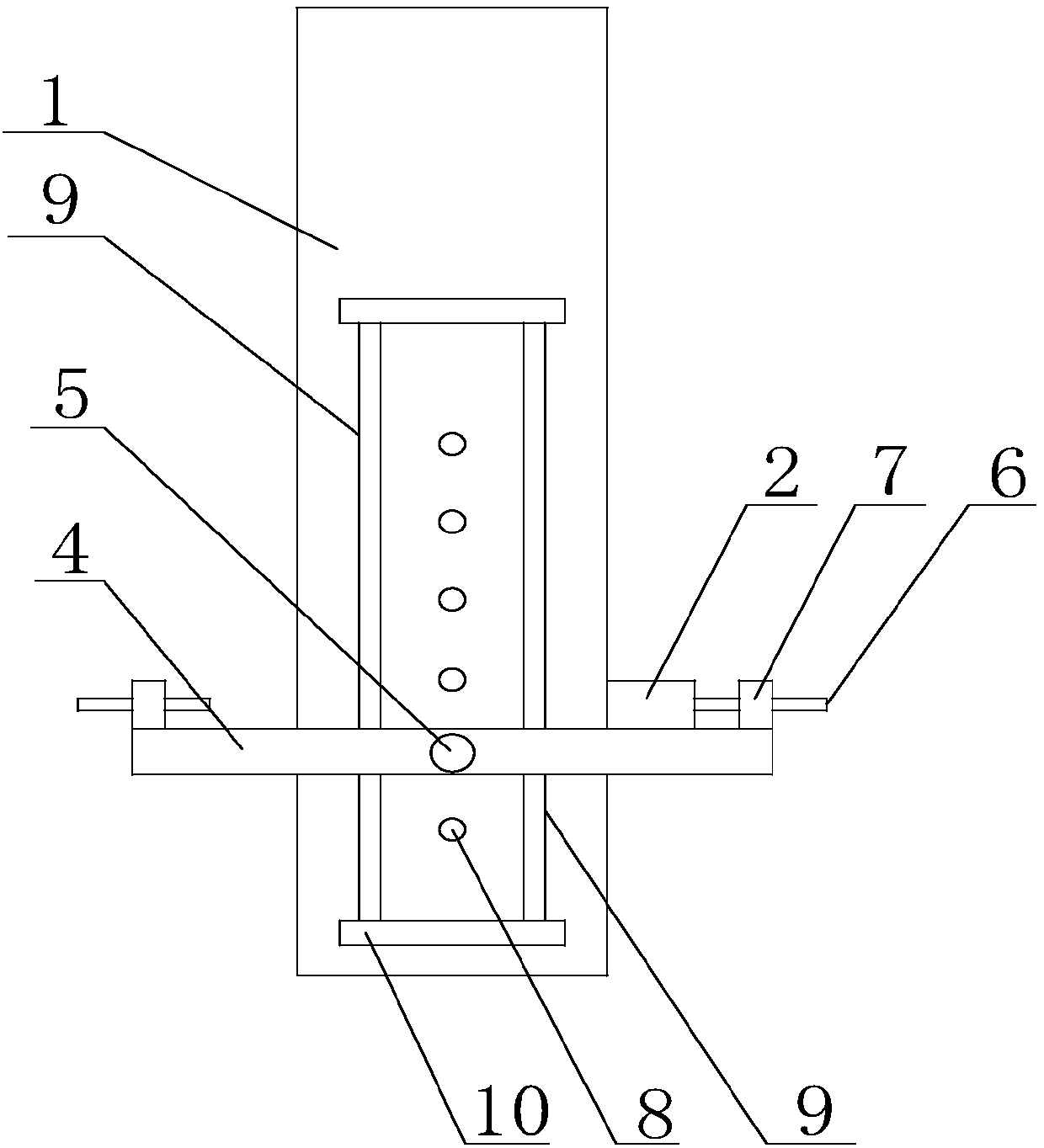

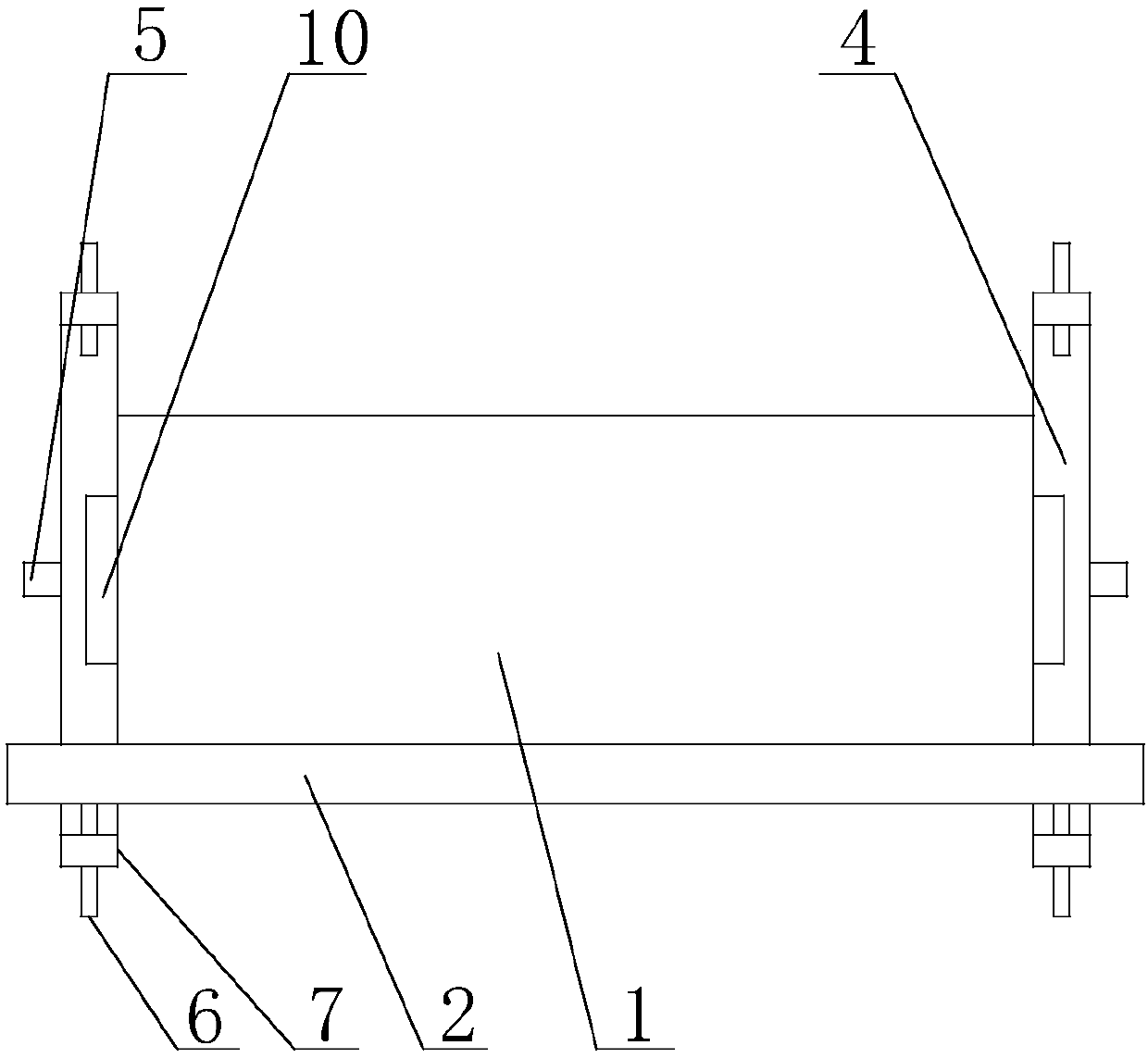

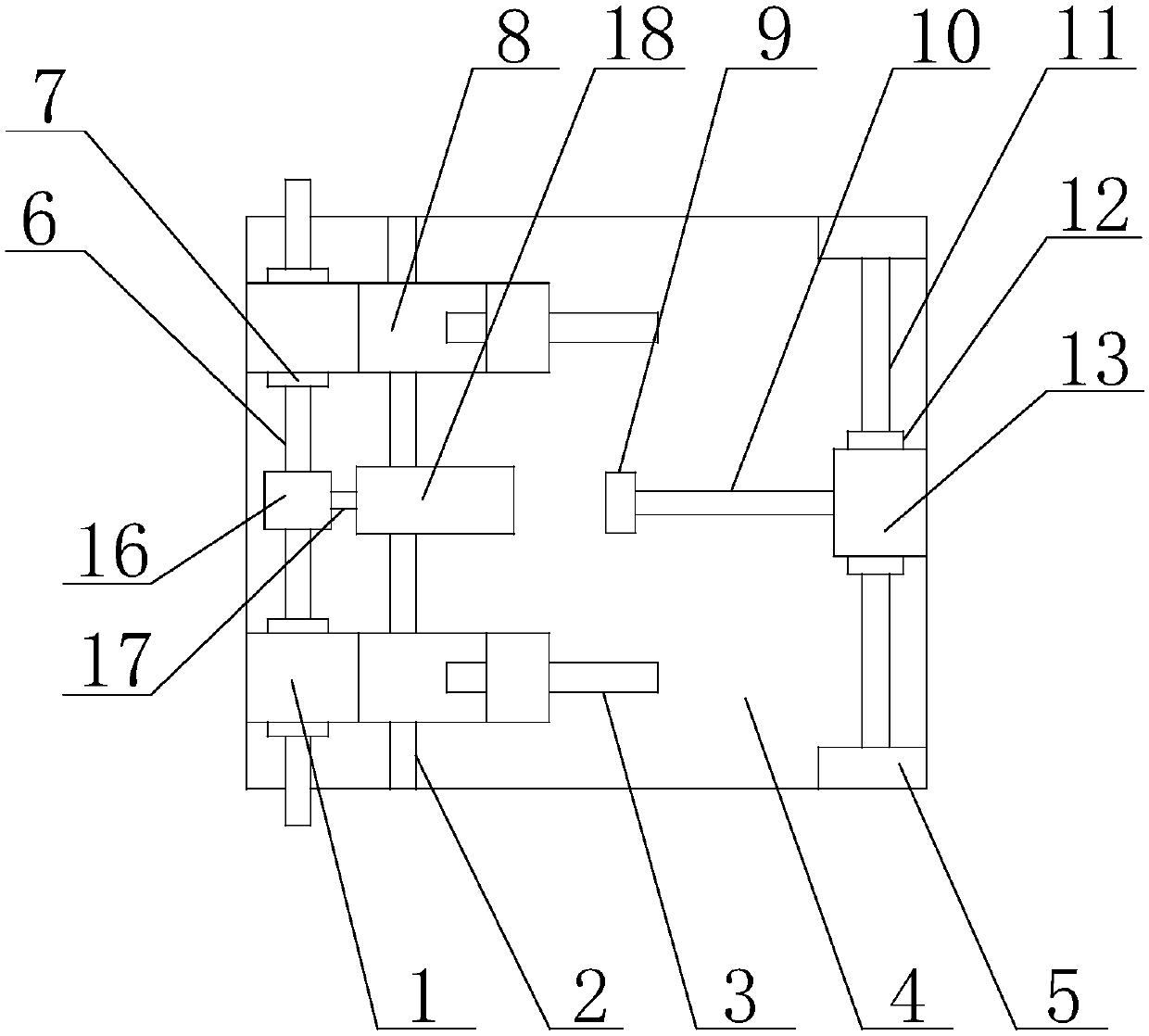

Bending and shaping device capable of absorbing bone plates

PendingCN108043914ARapid stampingApplicable useMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention discloses a bending and shaping device capable of absorbing bone plates. The bending and shaping device comprises a base, a driving mechanism and a punching head, two movable blocks arearranged at the top of the base, and the movable blocks can move on the base in the horizontal direction, supporting columns are arranged at the tops of the movable blocks; supporting tables are arranged at the top of the supporting columns, and grooves are formed in the top of the supporting tables; the two sides of the supporting tables are provided with movable rods, and the movable rods are horizontally connected with the supporting tables through threads; connecting blocks are arranged at the tail end, located in the grooves, of the movable rods, and the movable rods can rotate in the connecting block, and clamping plates are arranged on the connecting blocks, a plurality of supporting rods are further arranged at the top of the base, and a top plate is arranged at the top of the supporting rod; the bottom of the top plate is connected with the supporting rod, and the driving mechanism is located at the central position of the top plate; and the driving mechanism comprises an output shaft, the output shaft is vertically inserted into the top plate, and the bottom end of the output shaft is connected with the punching head.

Owner:CHENGDU MEDART MEDICAL SCI CO LTD

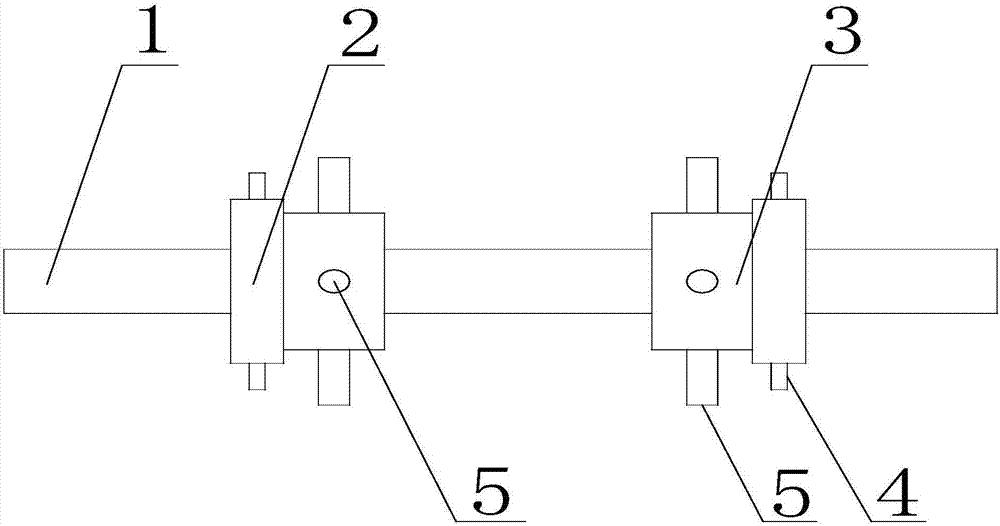

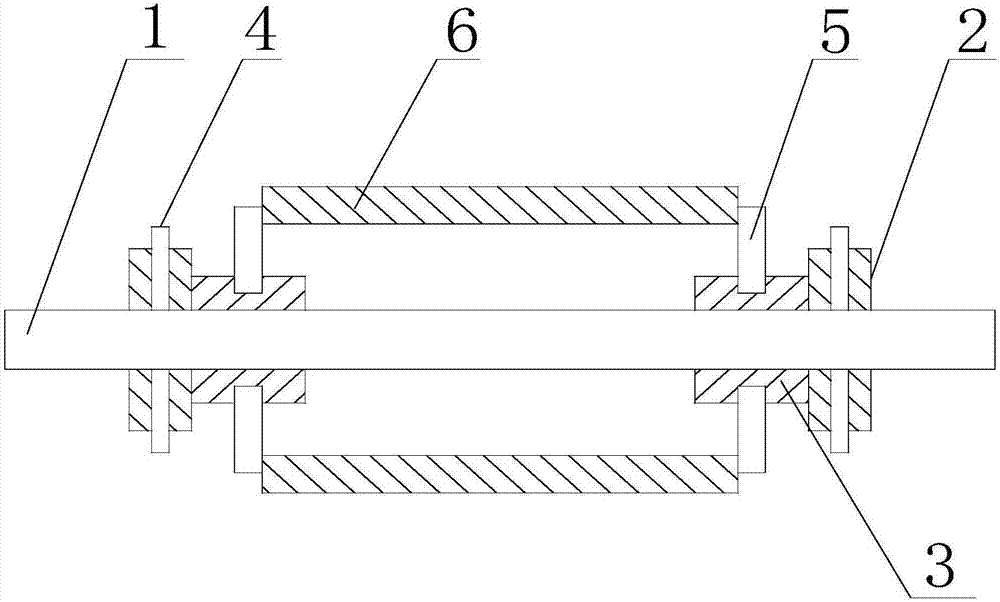

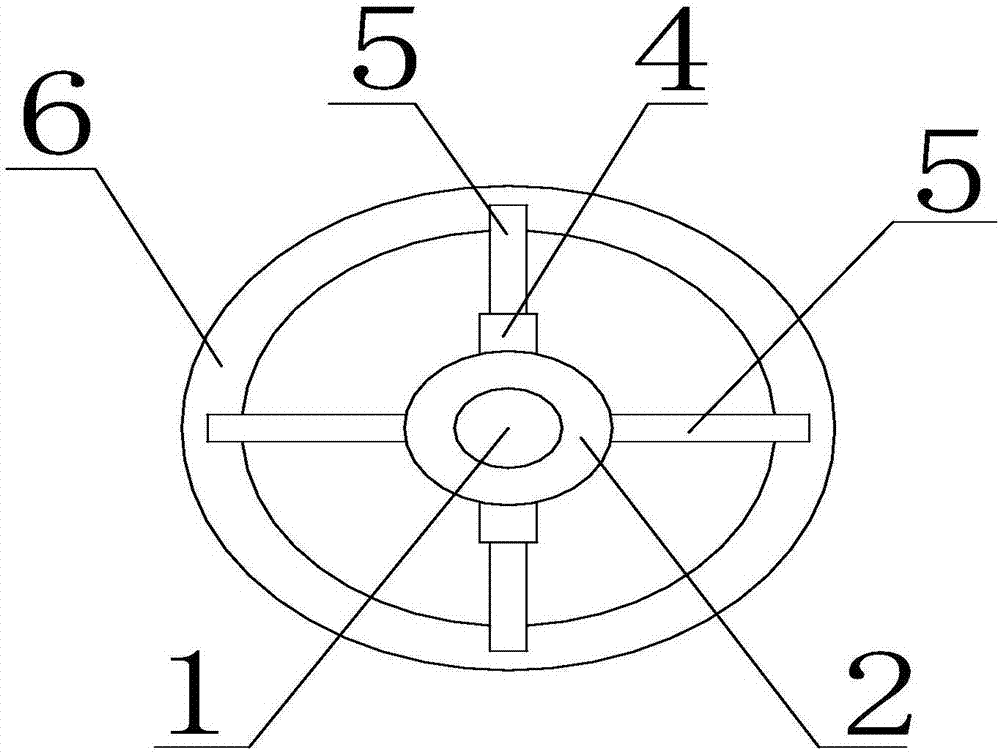

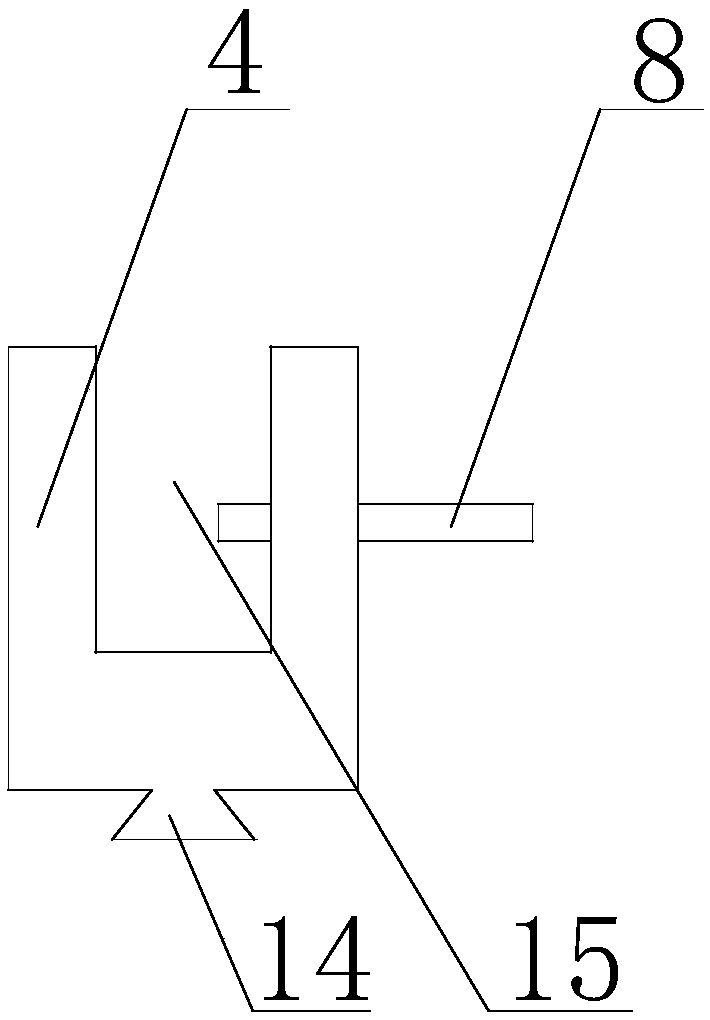

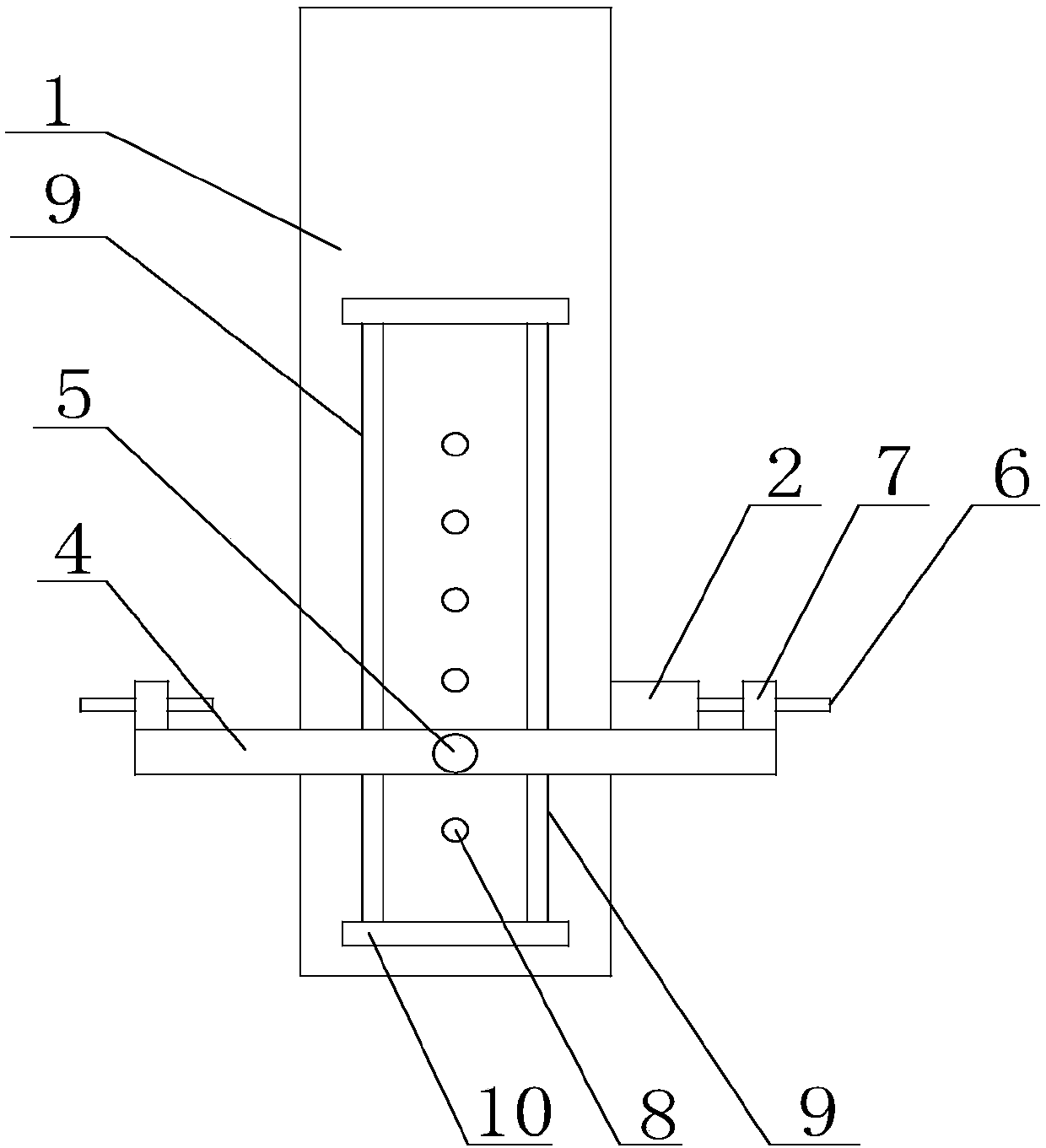

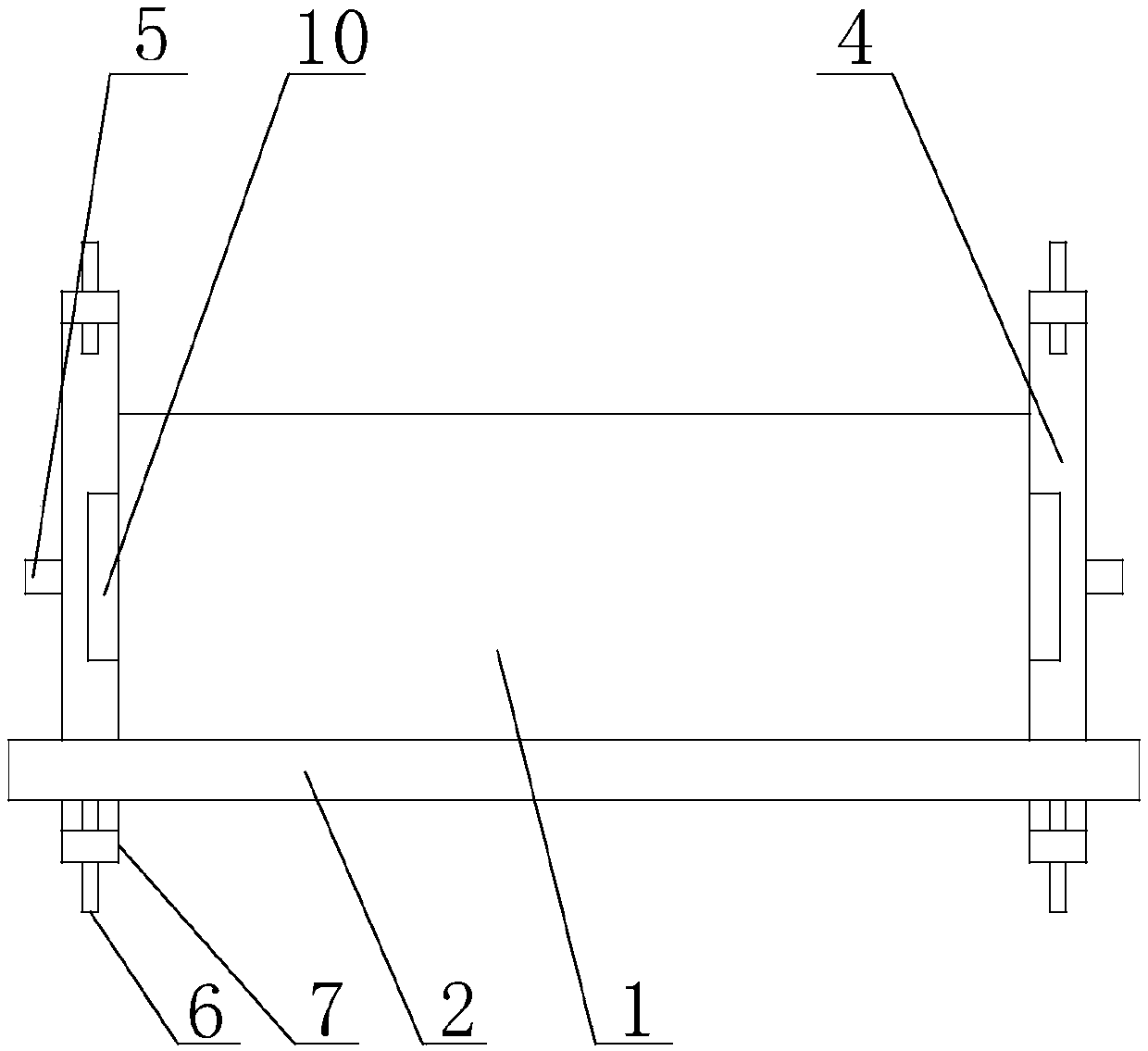

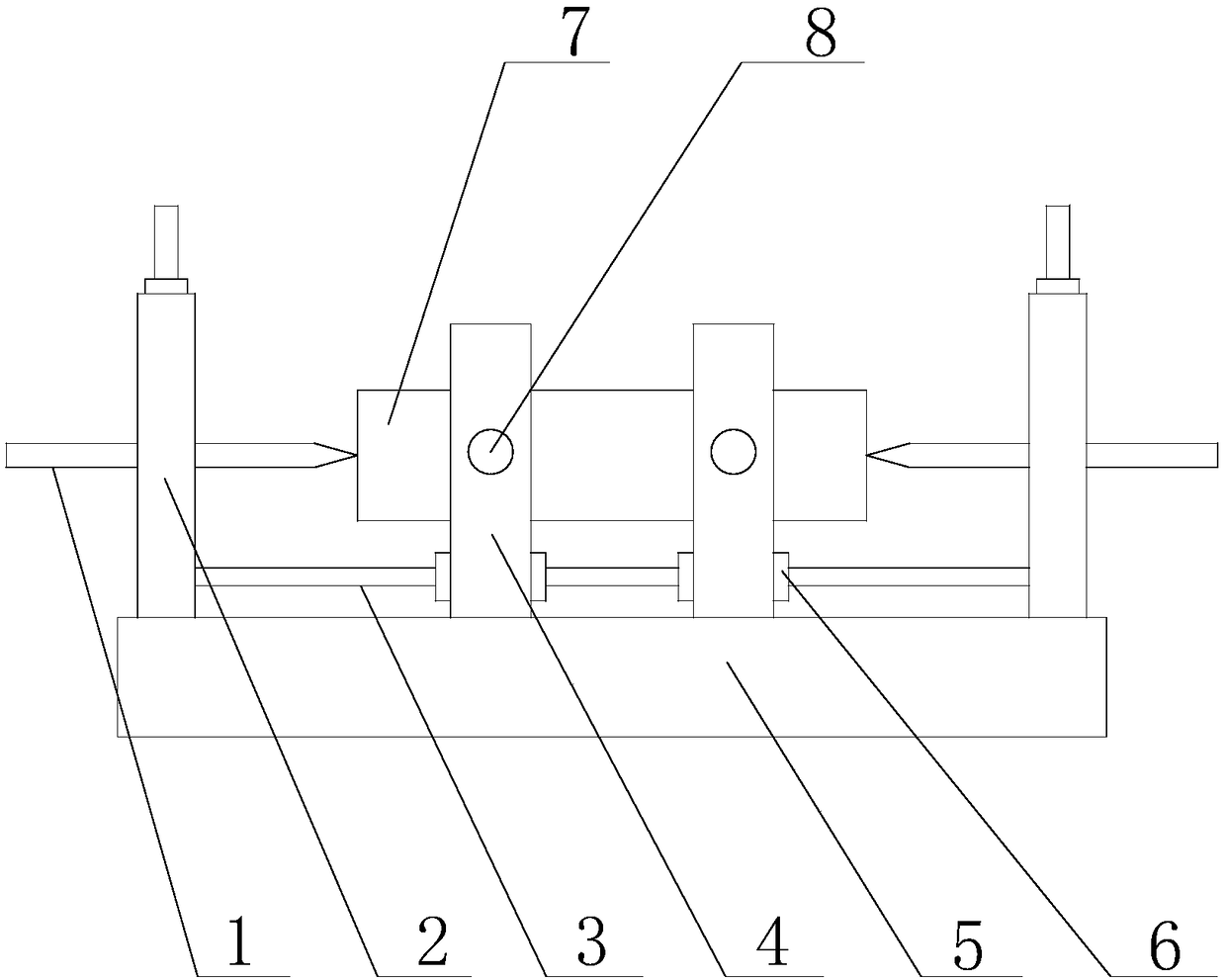

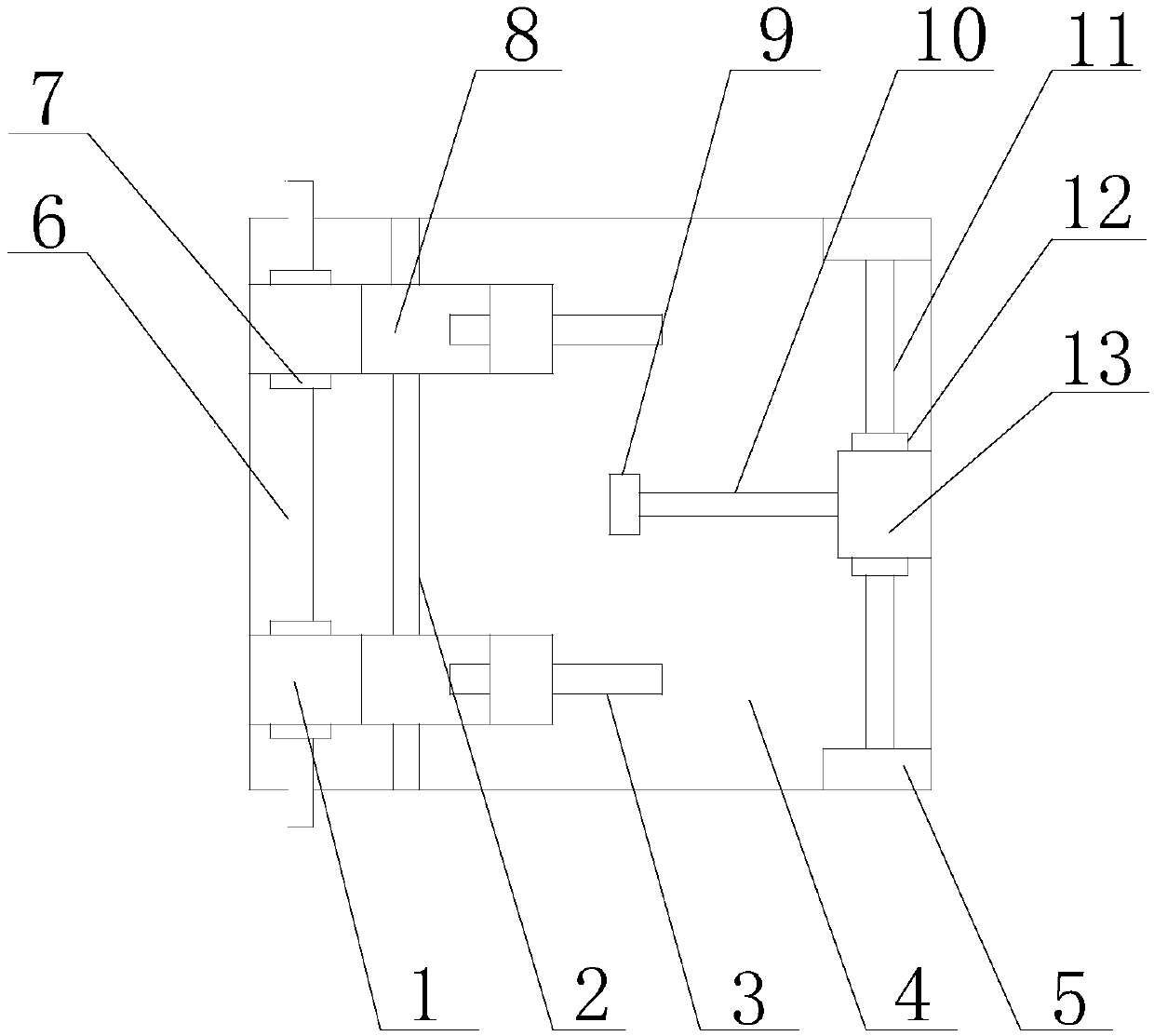

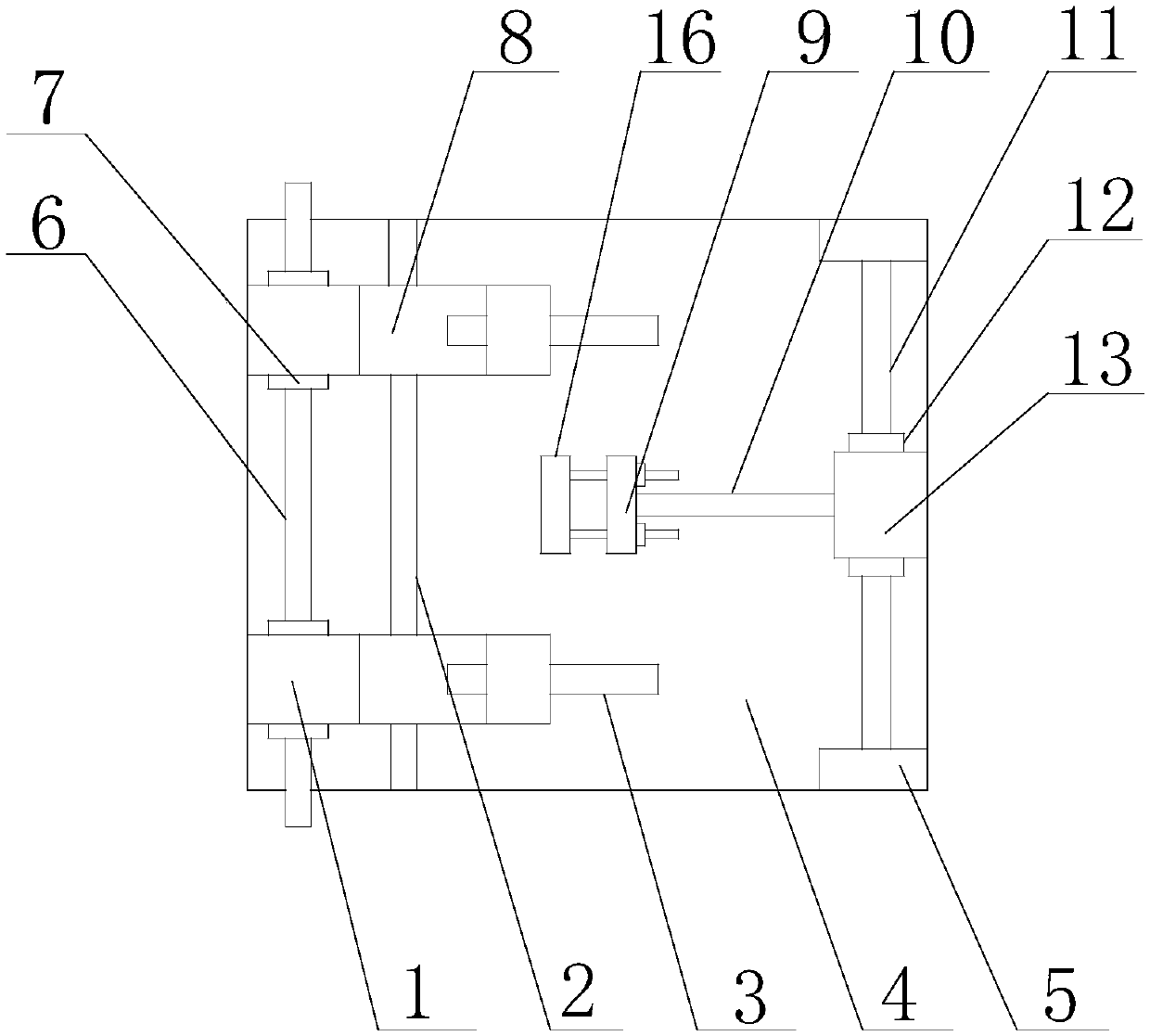

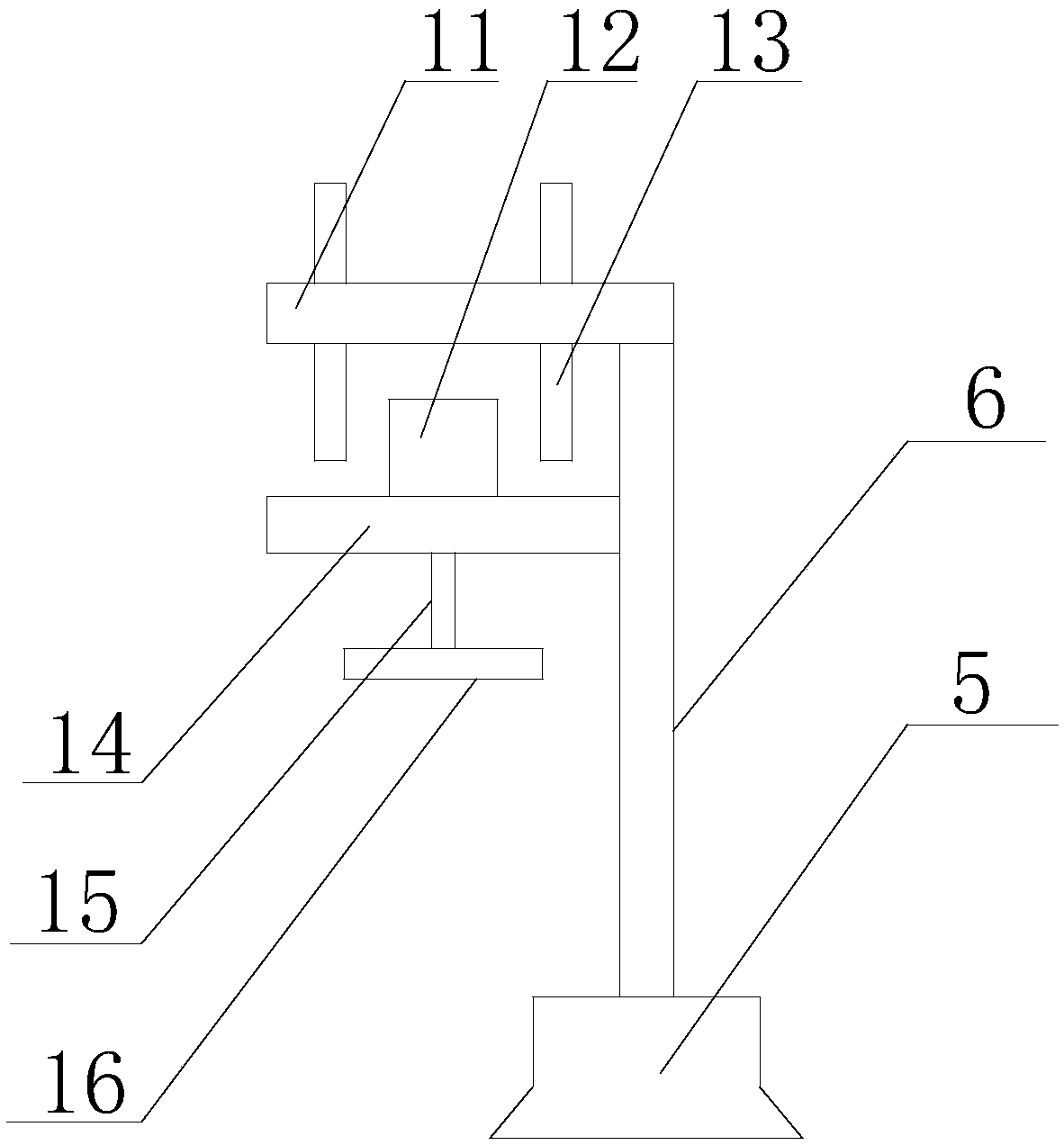

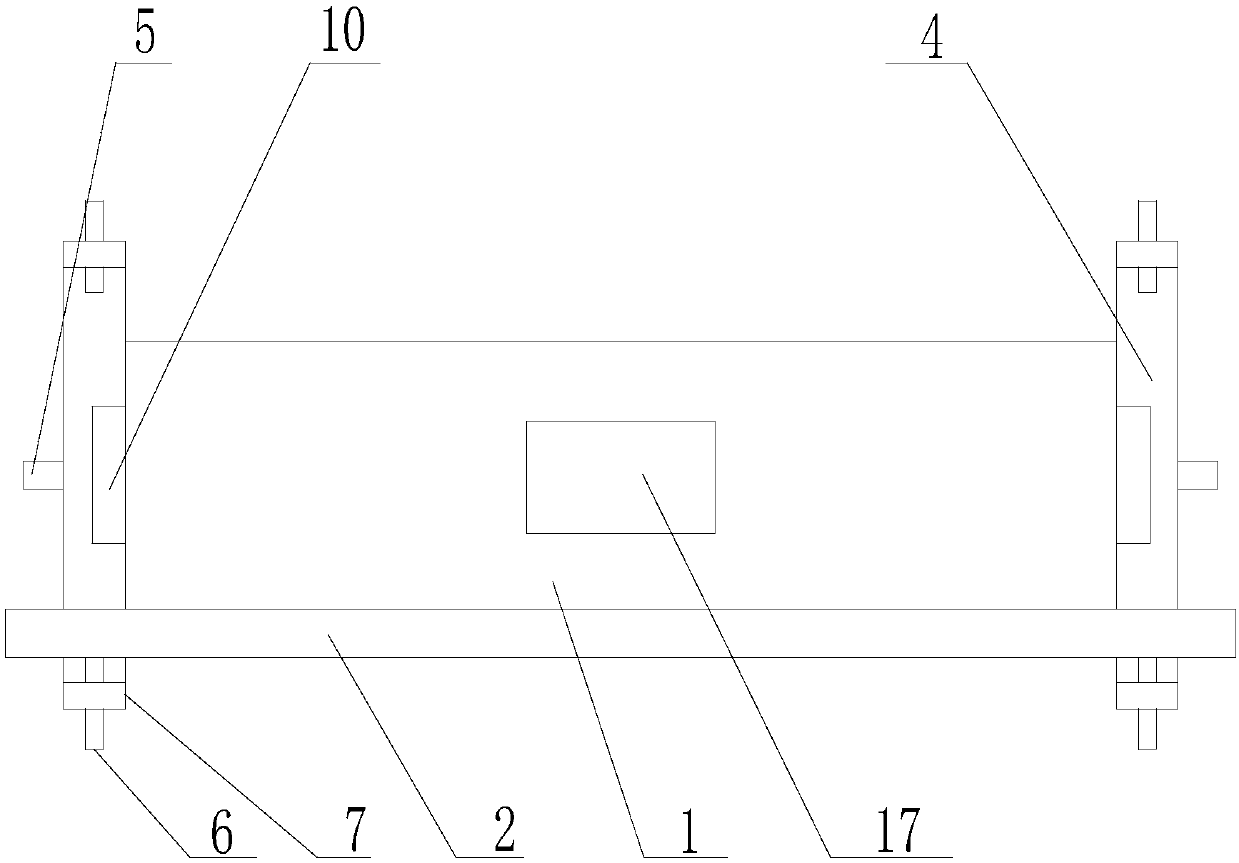

Fixing mechanism for external circle grinding of sleeve-like mechanical components

InactiveCN107052918AAvoid inconsistent depth of cutThe spacing can be adjusted arbitrarilyRevolution surface grinding machinesGrinding work supportsMechanical componentsEngineering

The invention discloses a fixing mechanism for cylindrical grinding of sleeve mechanical parts, which includes a shaft rod, a positioning block and a clamping block are arranged on the shaft rod, two adjusting rods are arranged on the positioning block, and the adjusting rod connects with the positioning block through a screw thread. Connection, used to fix the positioning block on the shaft rod, there are several baffles on the clamping block, the baffles are connected with the clamping block through threads, and the baffles are used to block the side of the sleeve parts between the two clamping blocks The height of the baffle can be adjusted by rotating the baffle to meet the clamping of sleeve parts with different diameters. The invention is simple in structure, easy to operate, can ensure that the outer circle of the sleeve workpiece is coaxial with the shaft, improves the cutting accuracy, and can hold multiple sleeve workpieces at the same time, satisfying the simultaneous processing of multiple sleeve workpieces, and improving the accuracy of sleeve workpieces. production efficiency.

Owner:绵竹市凯瑞机械加工有限公司

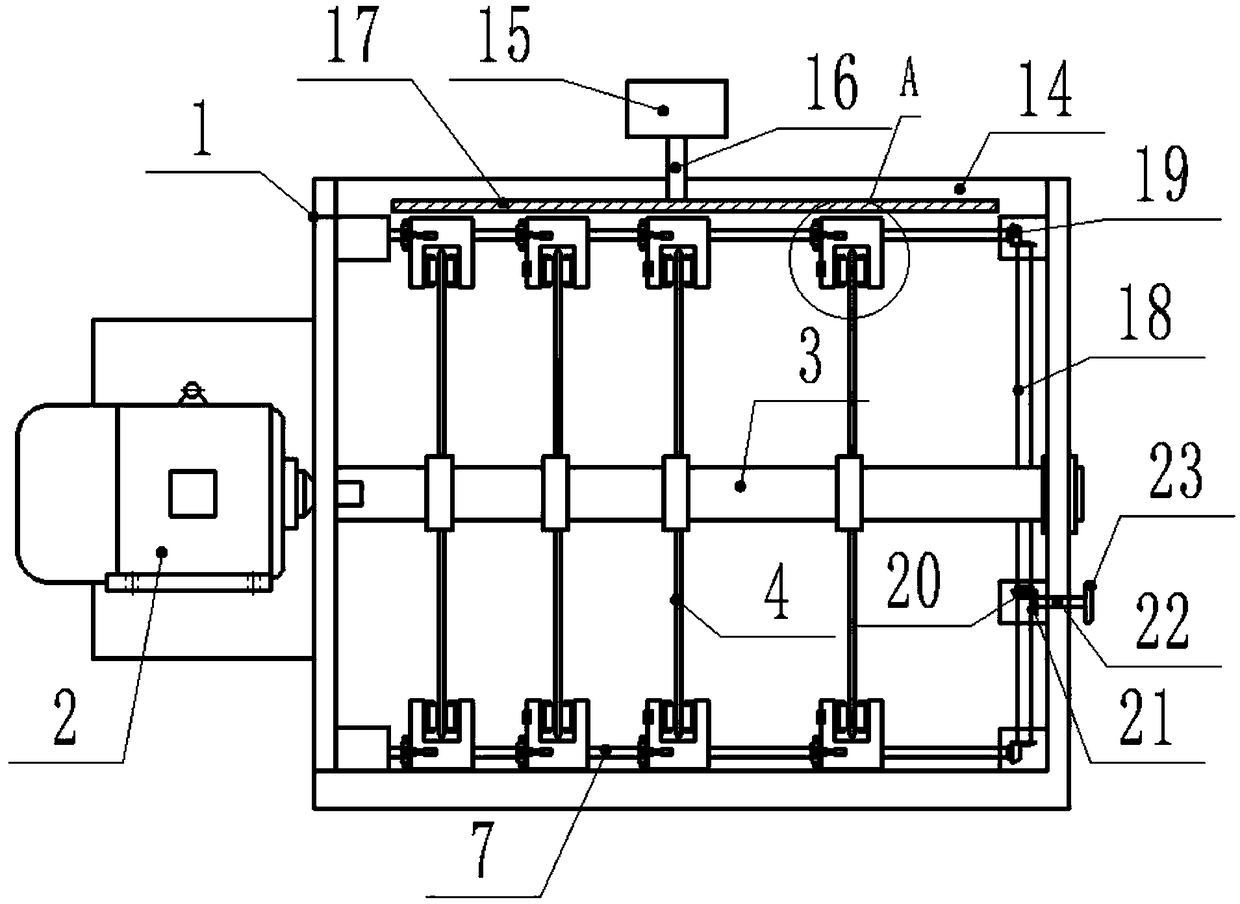

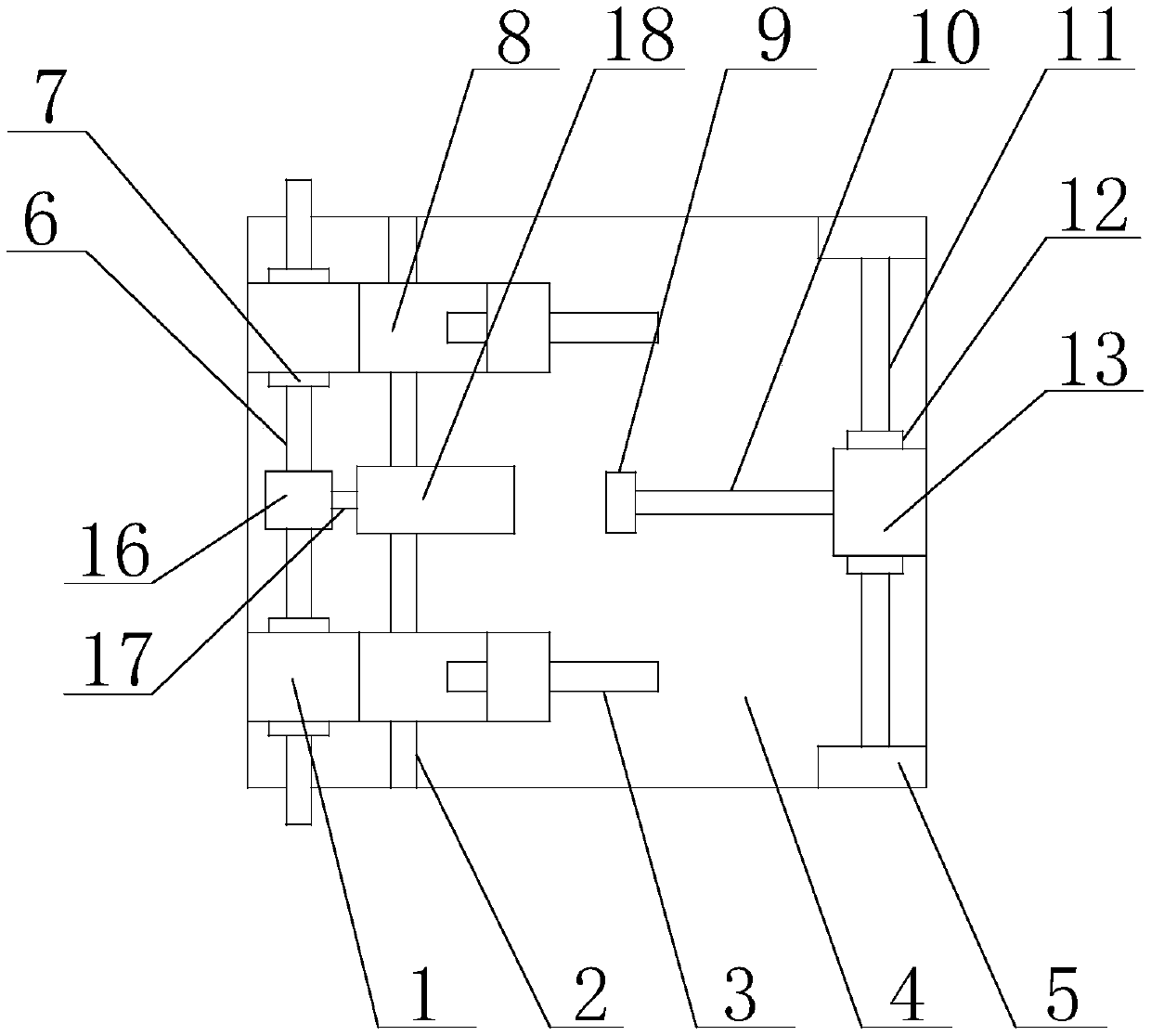

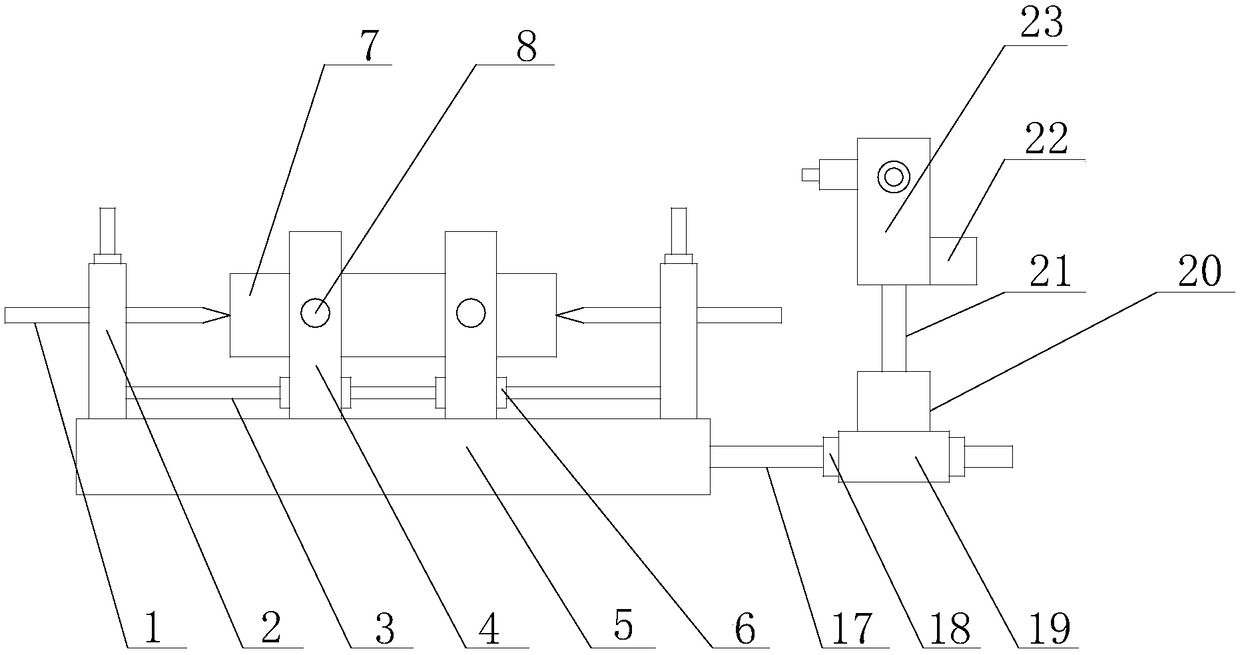

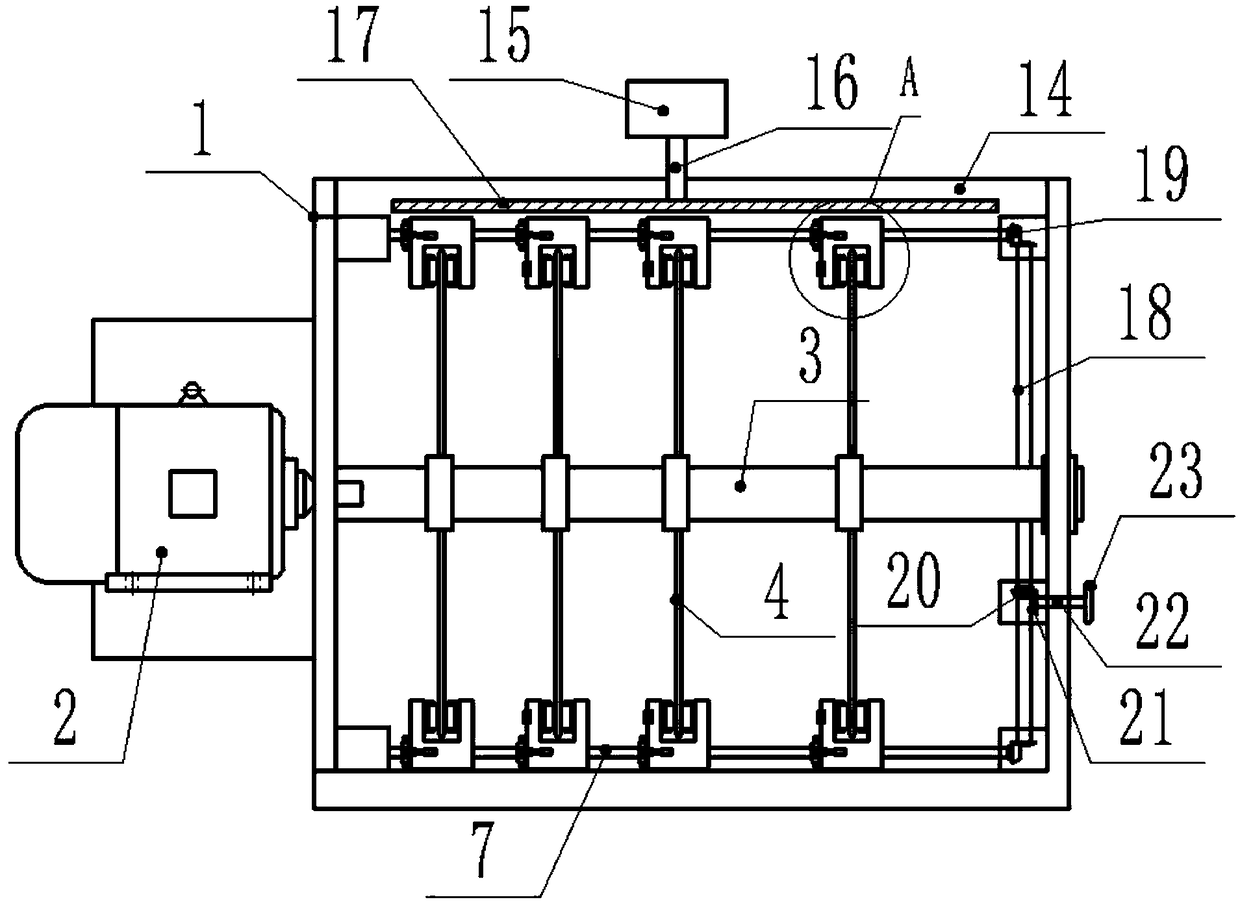

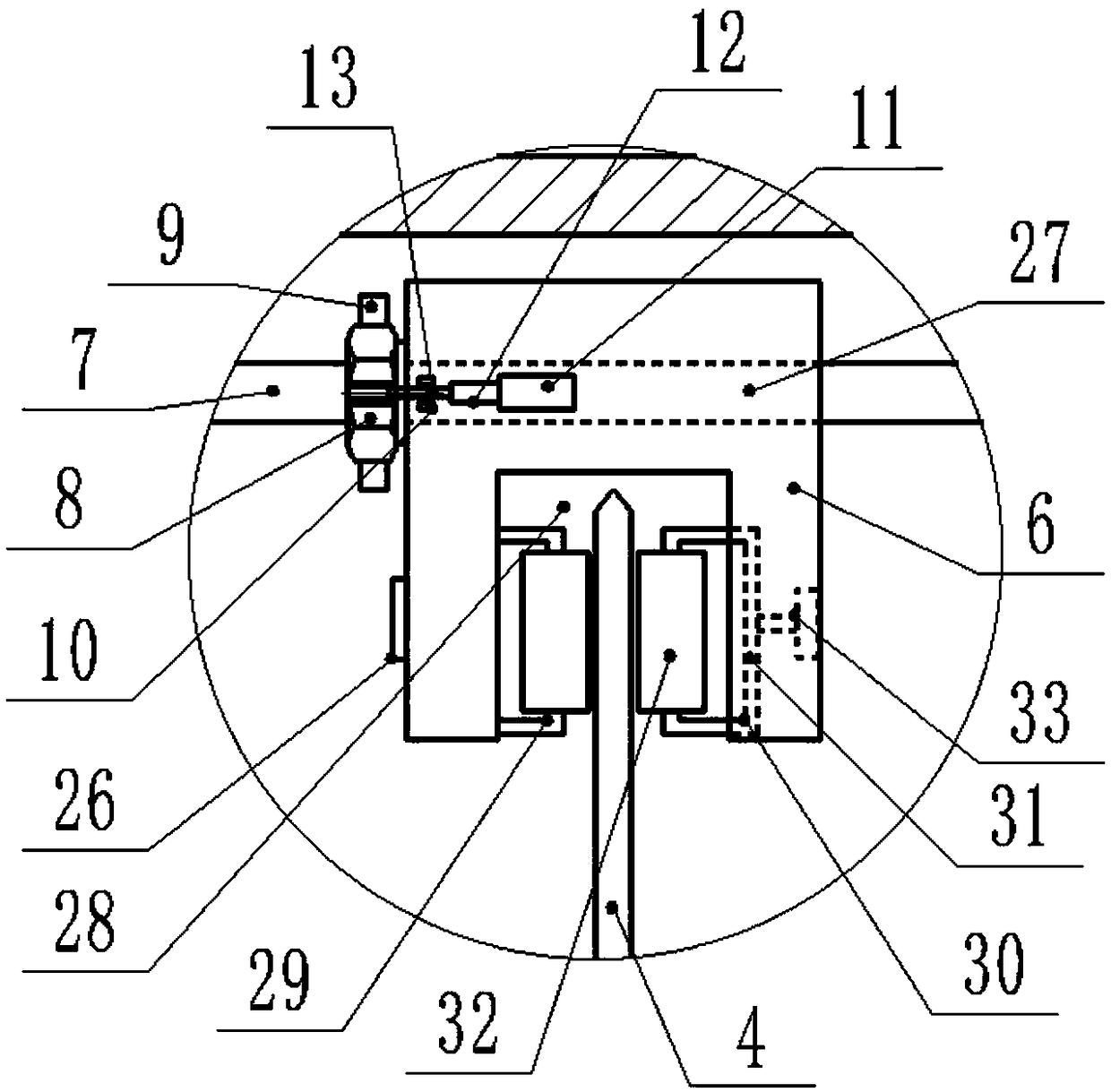

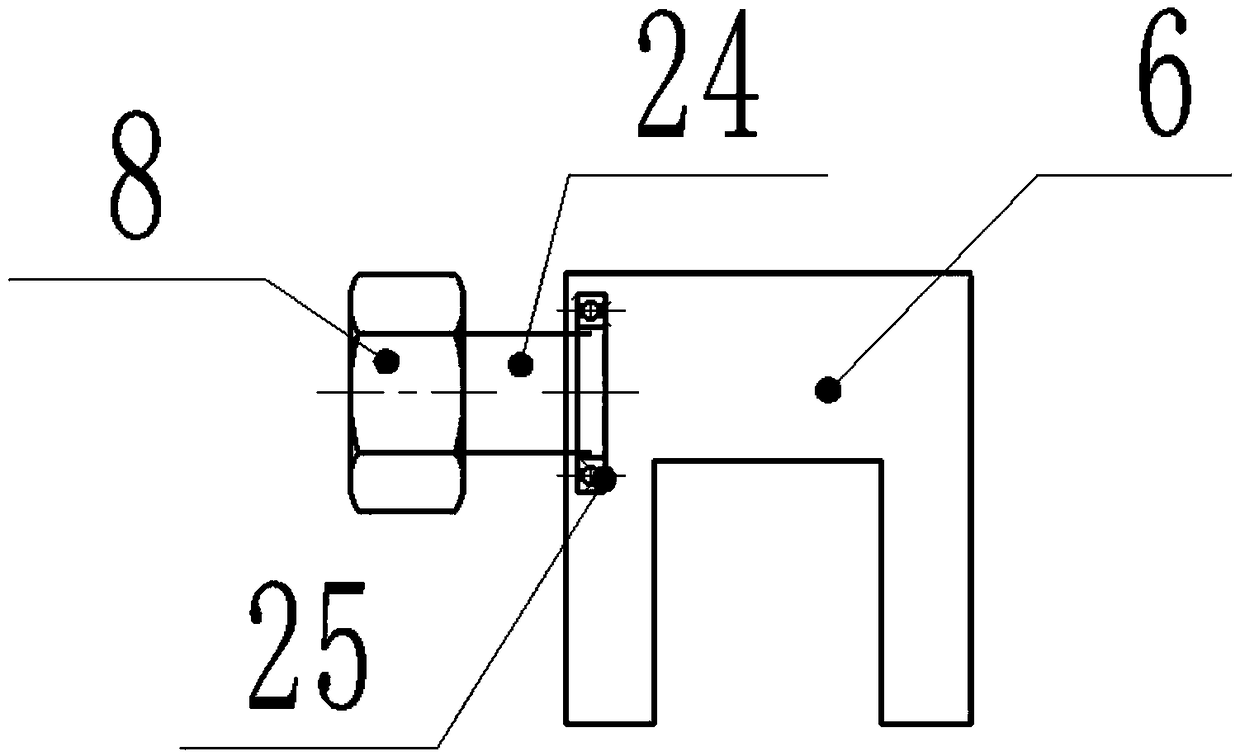

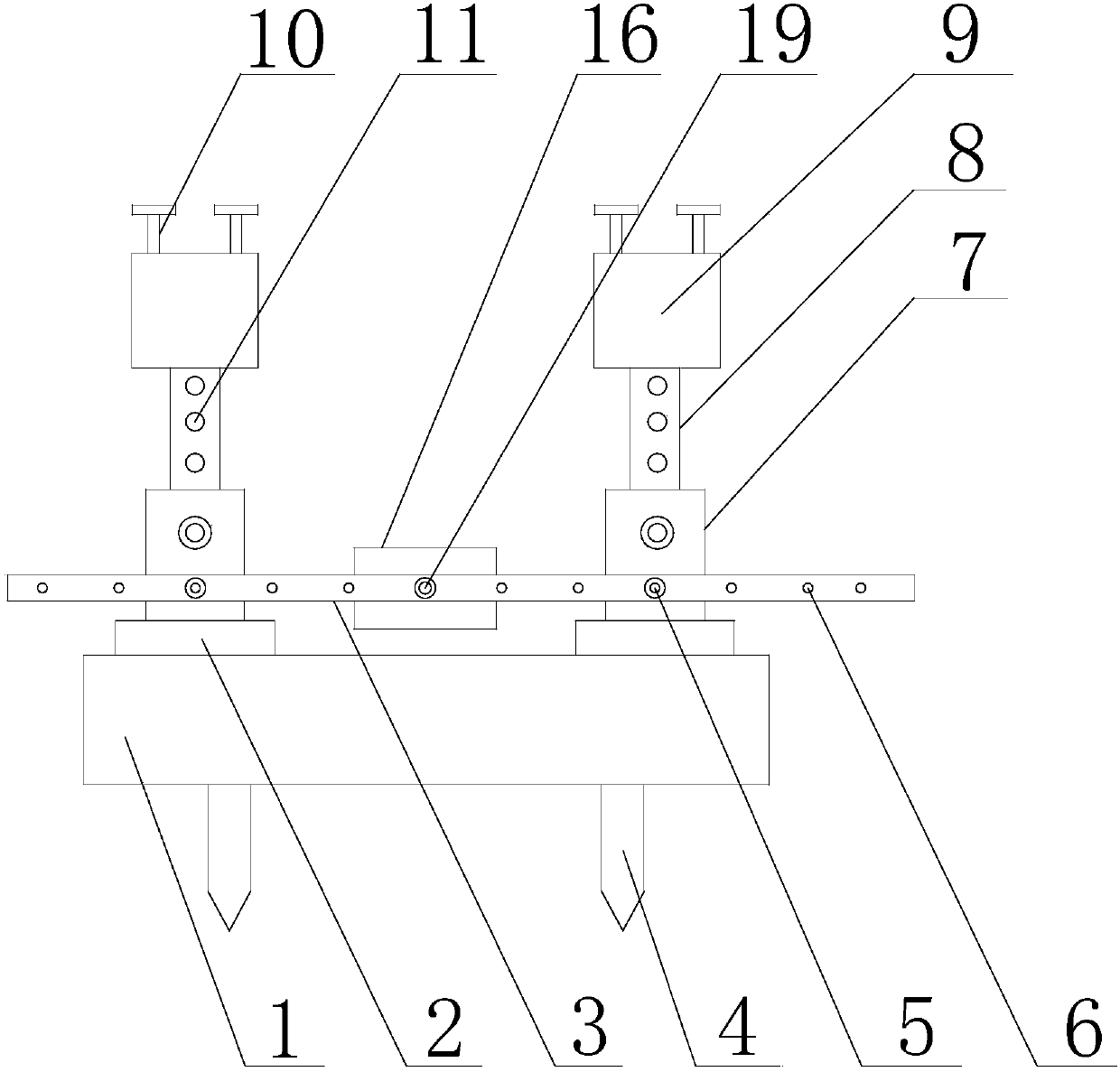

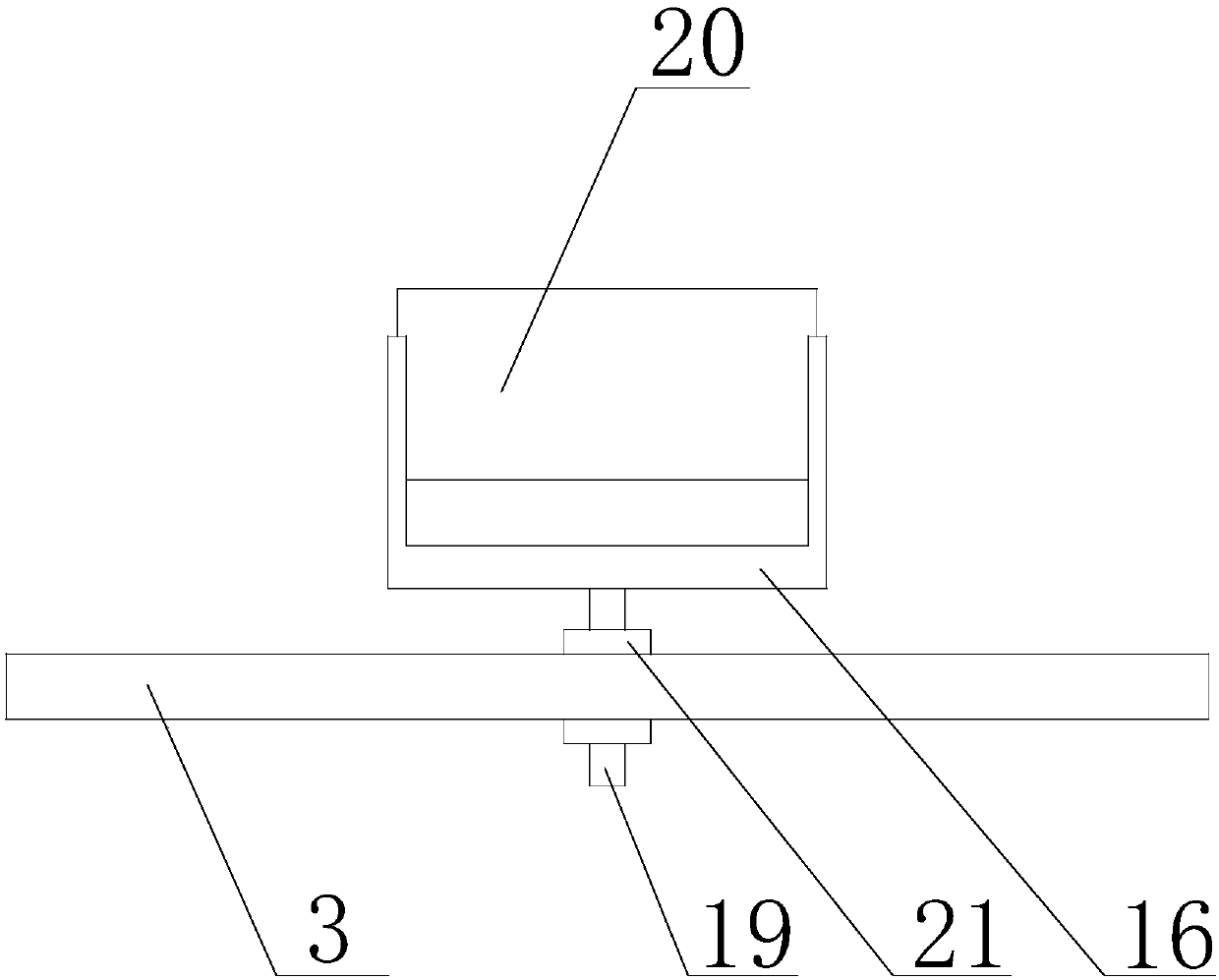

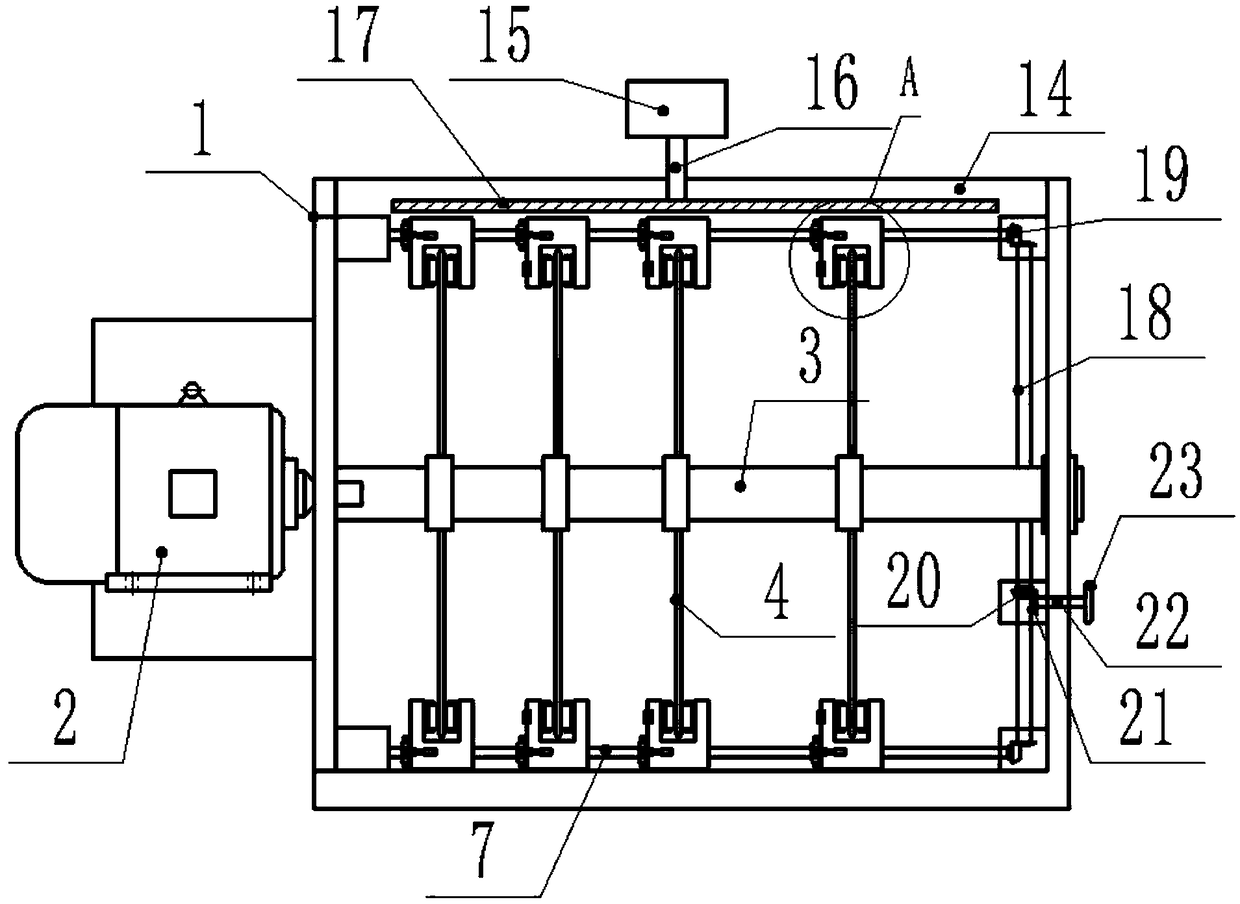

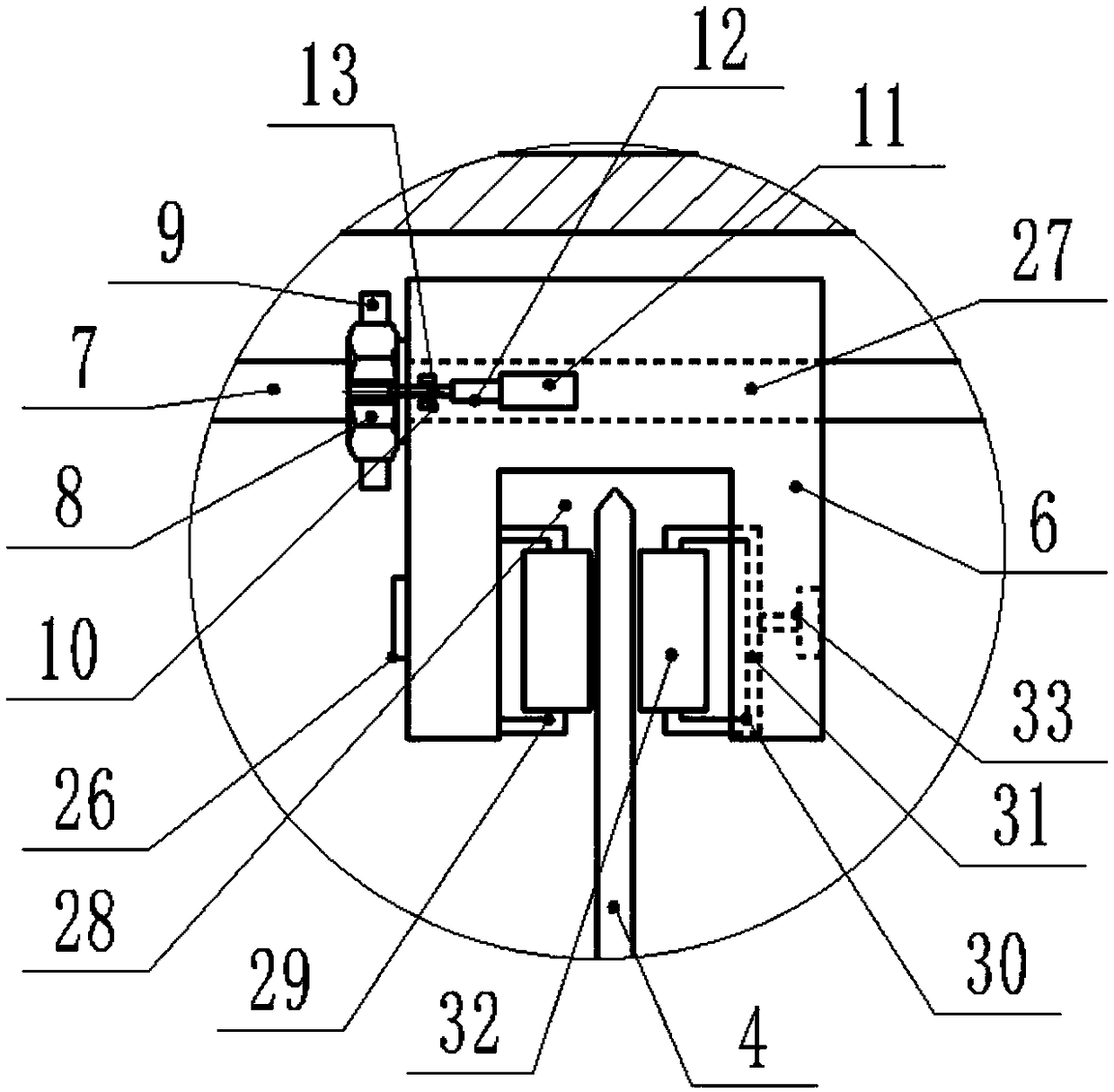

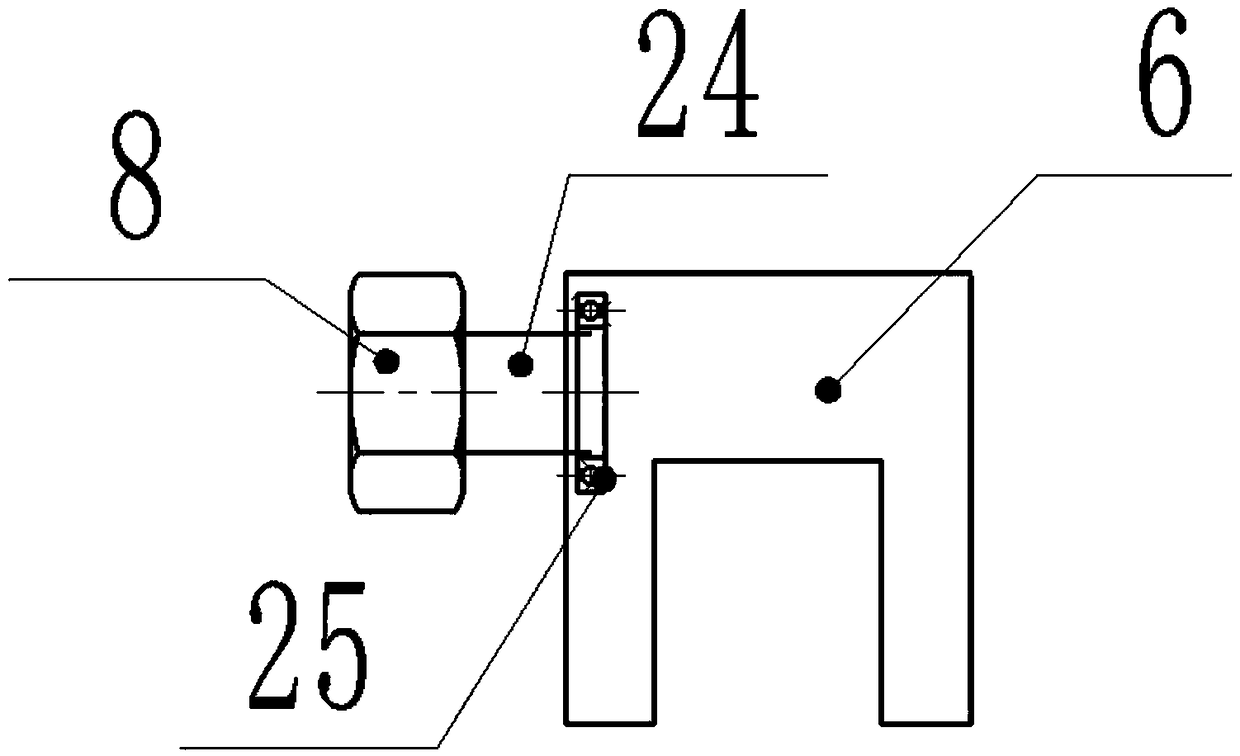

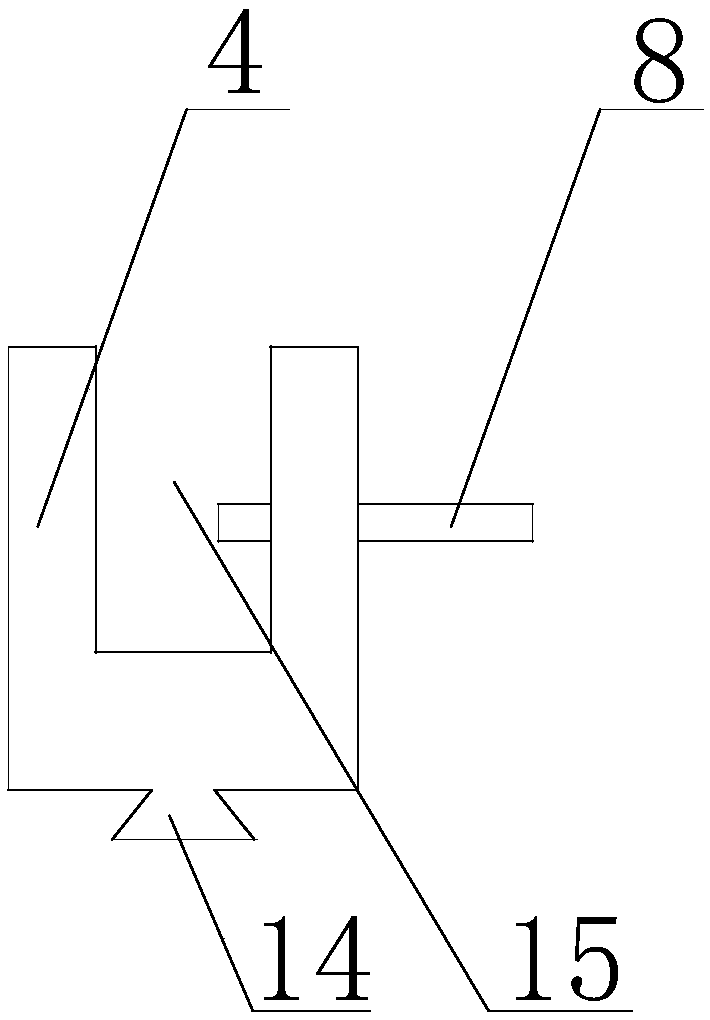

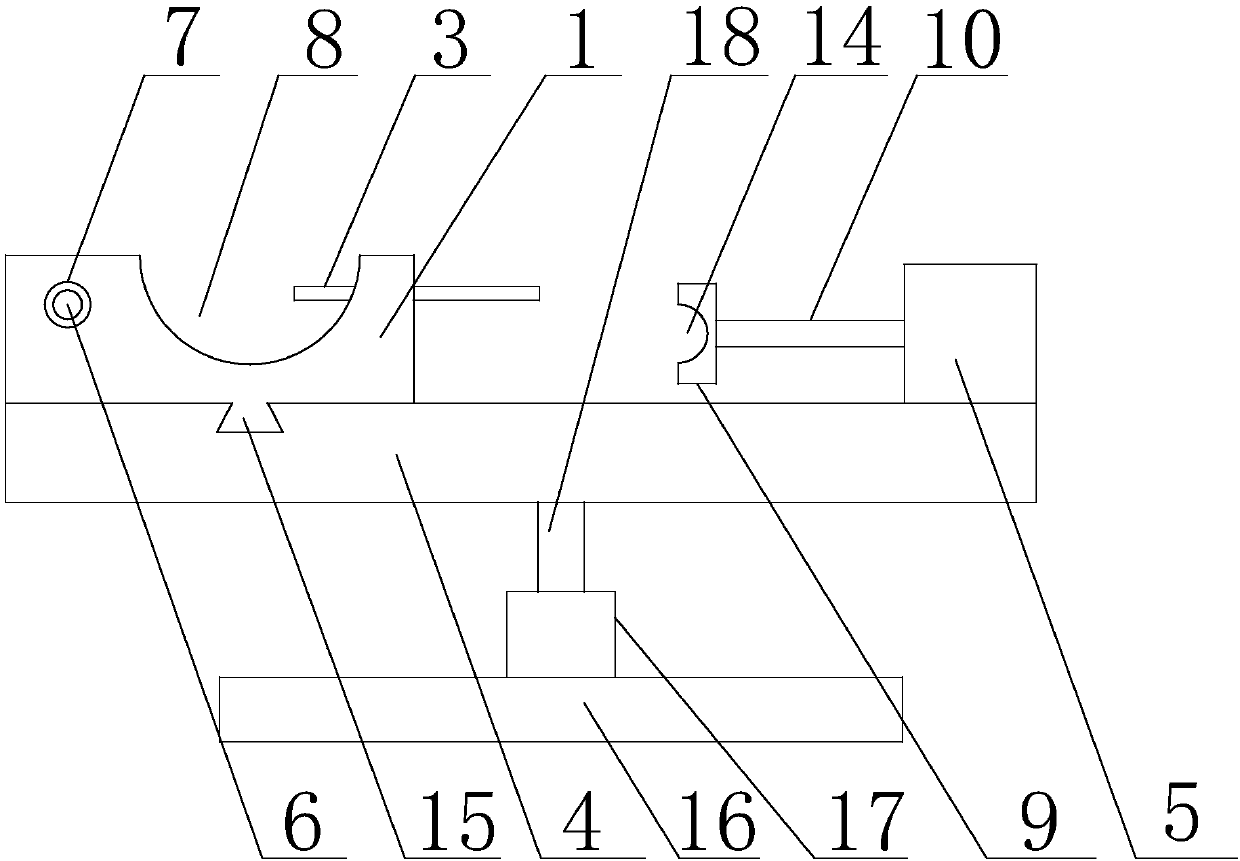

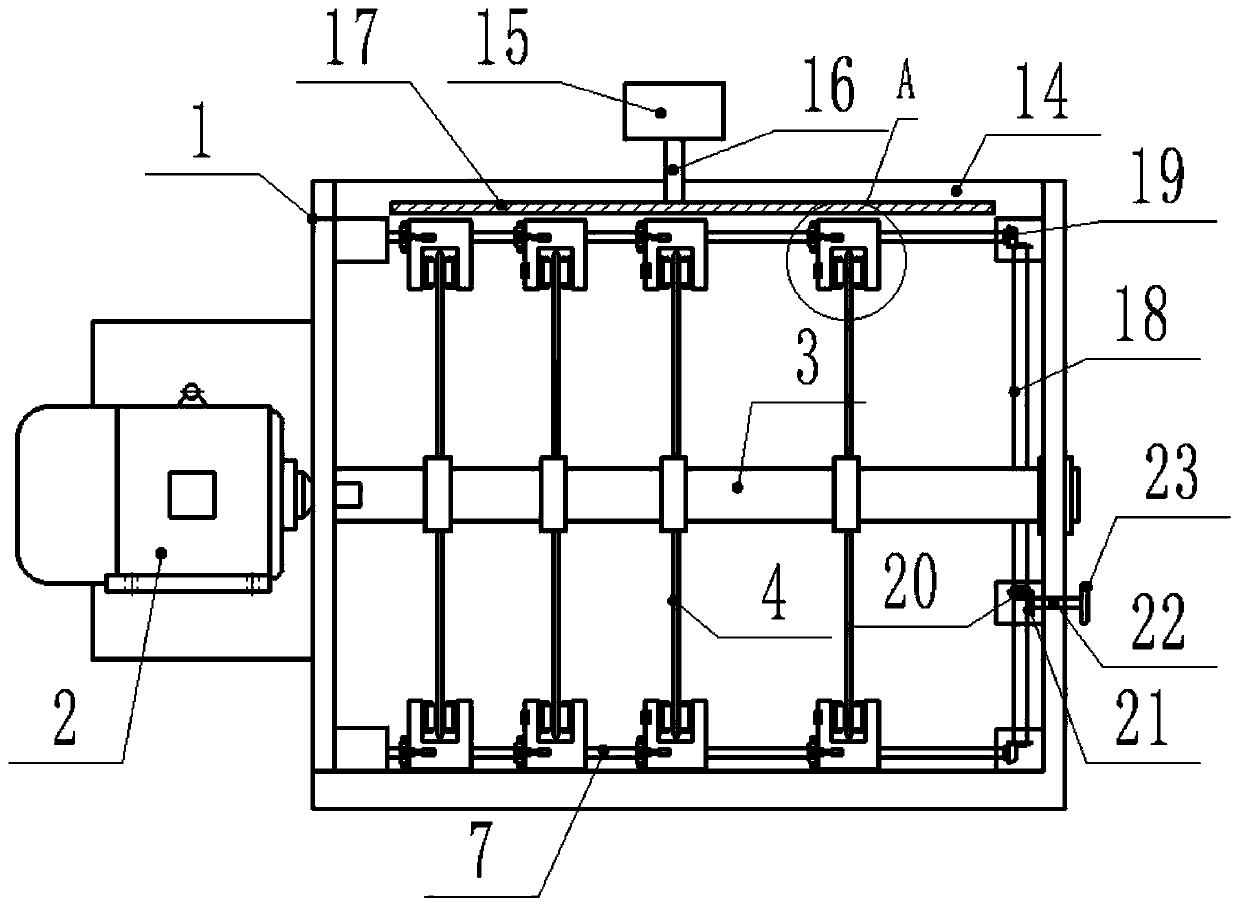

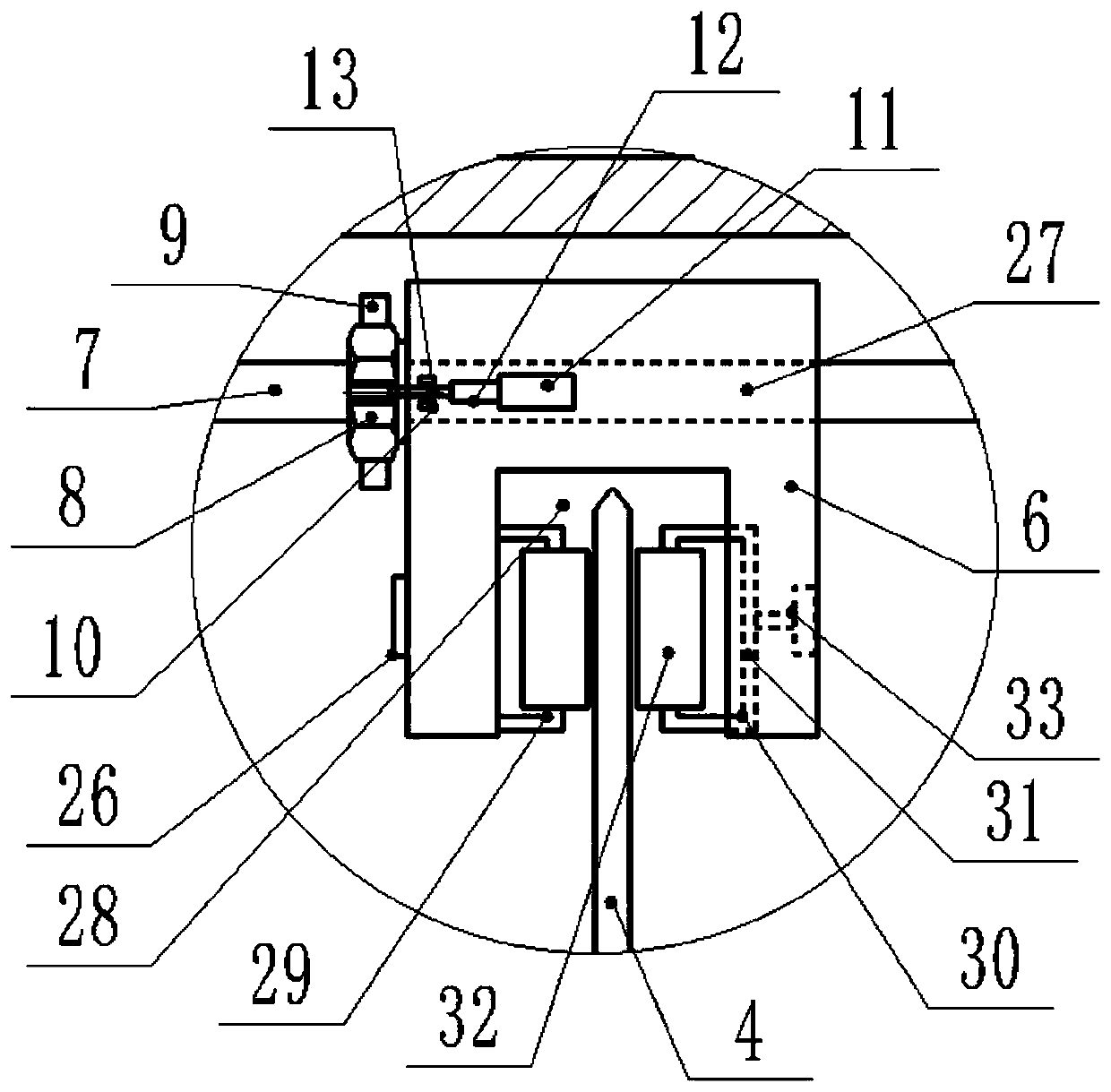

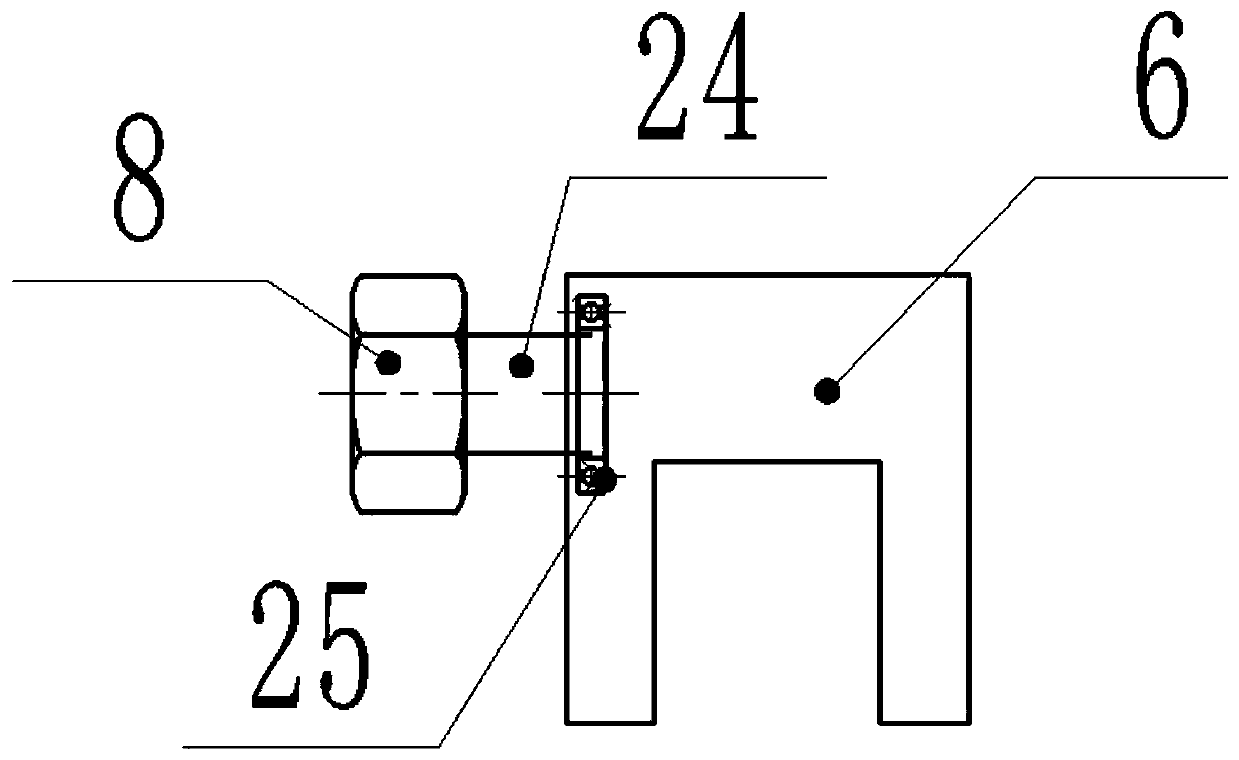

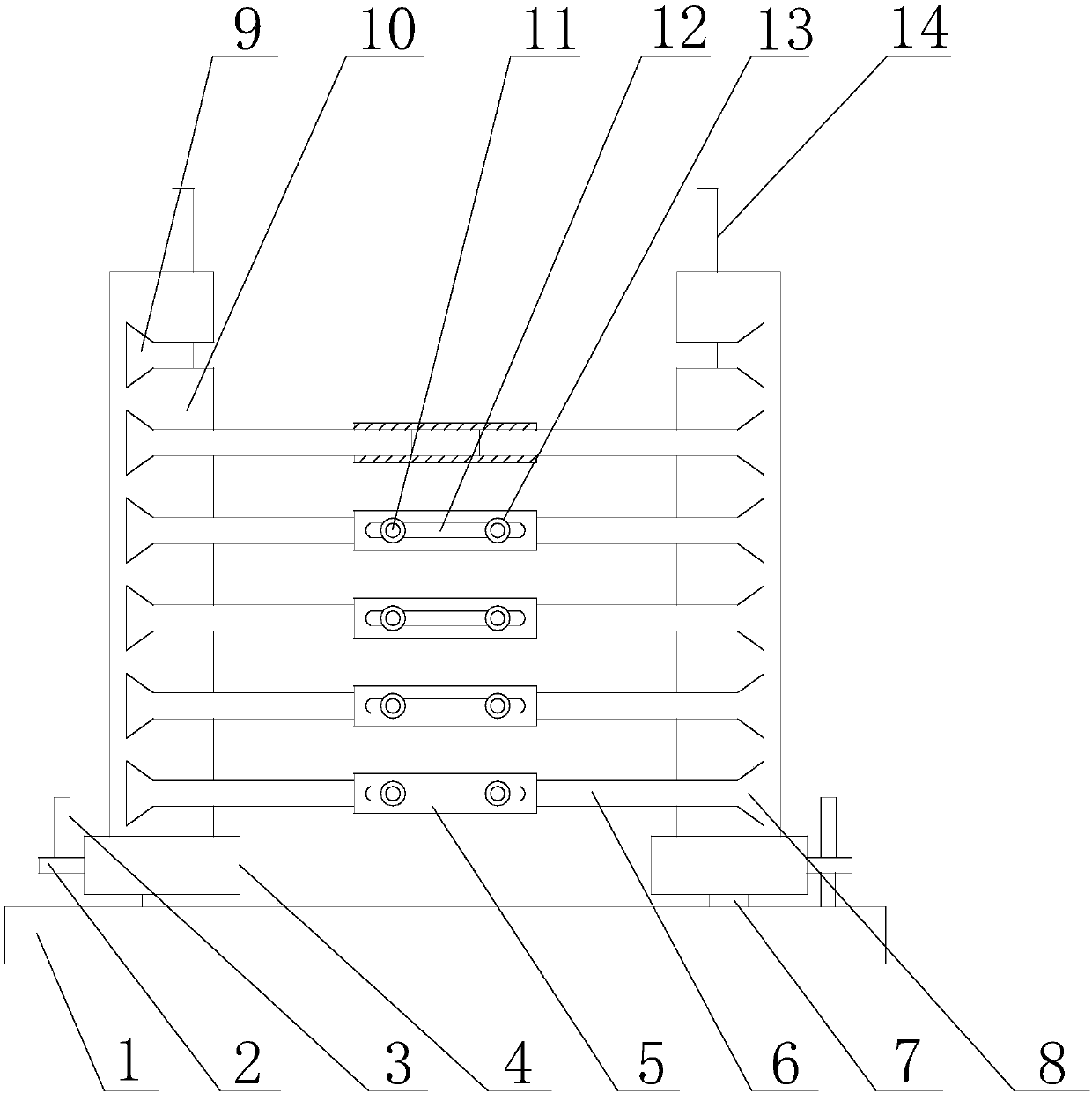

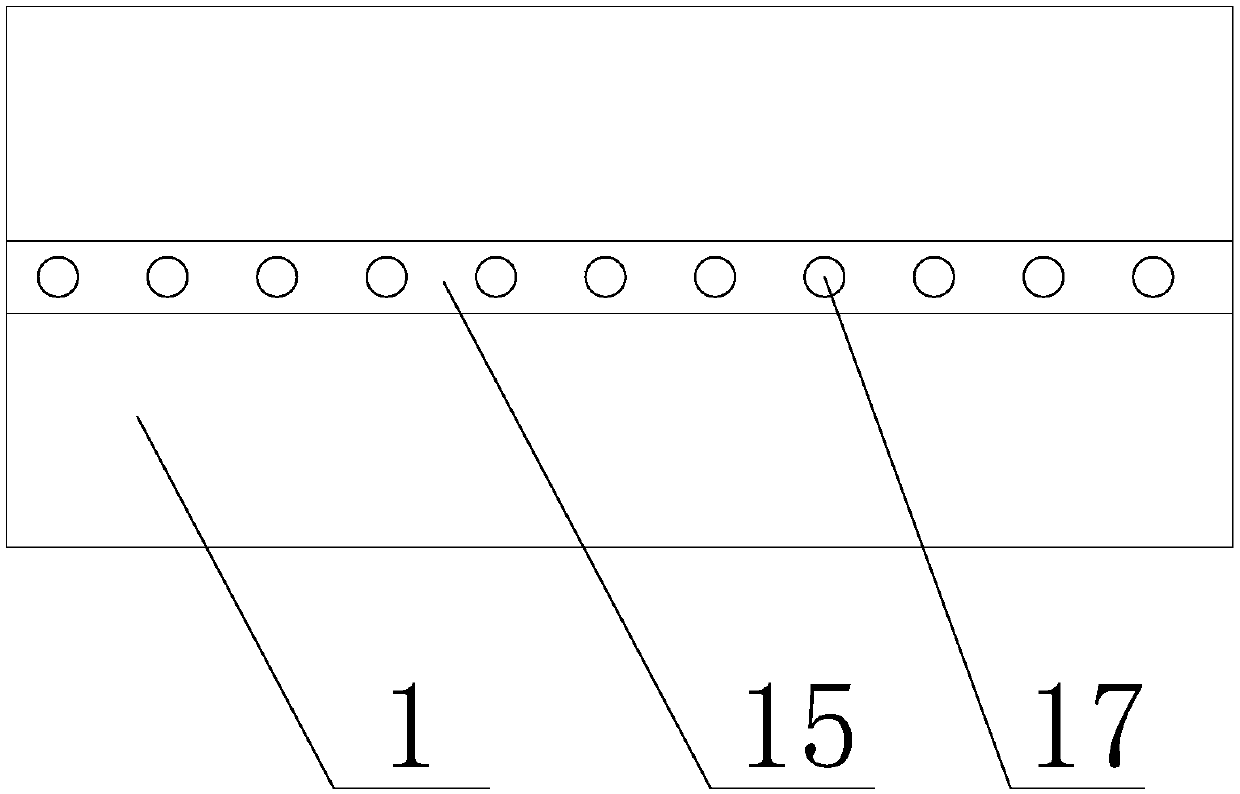

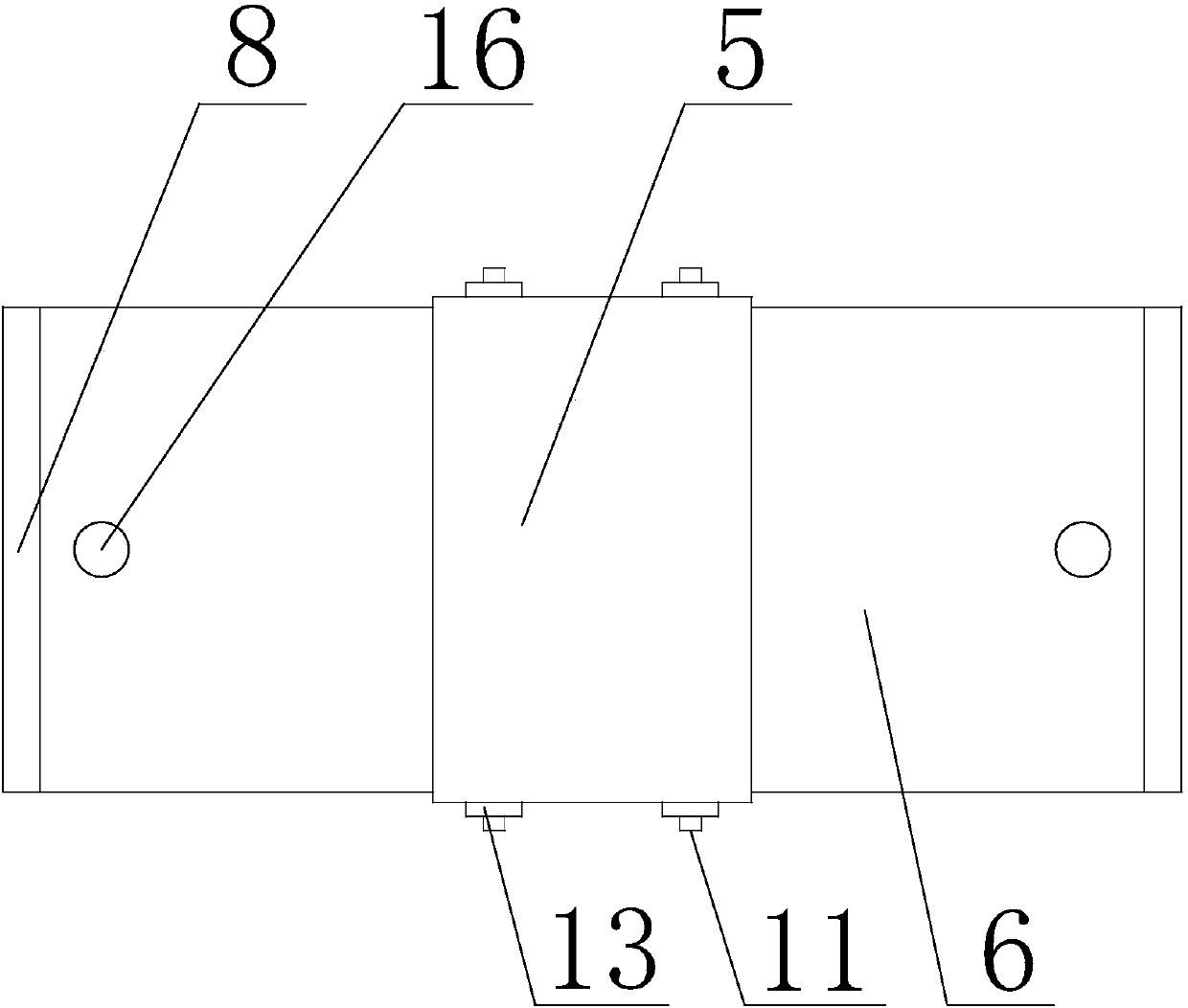

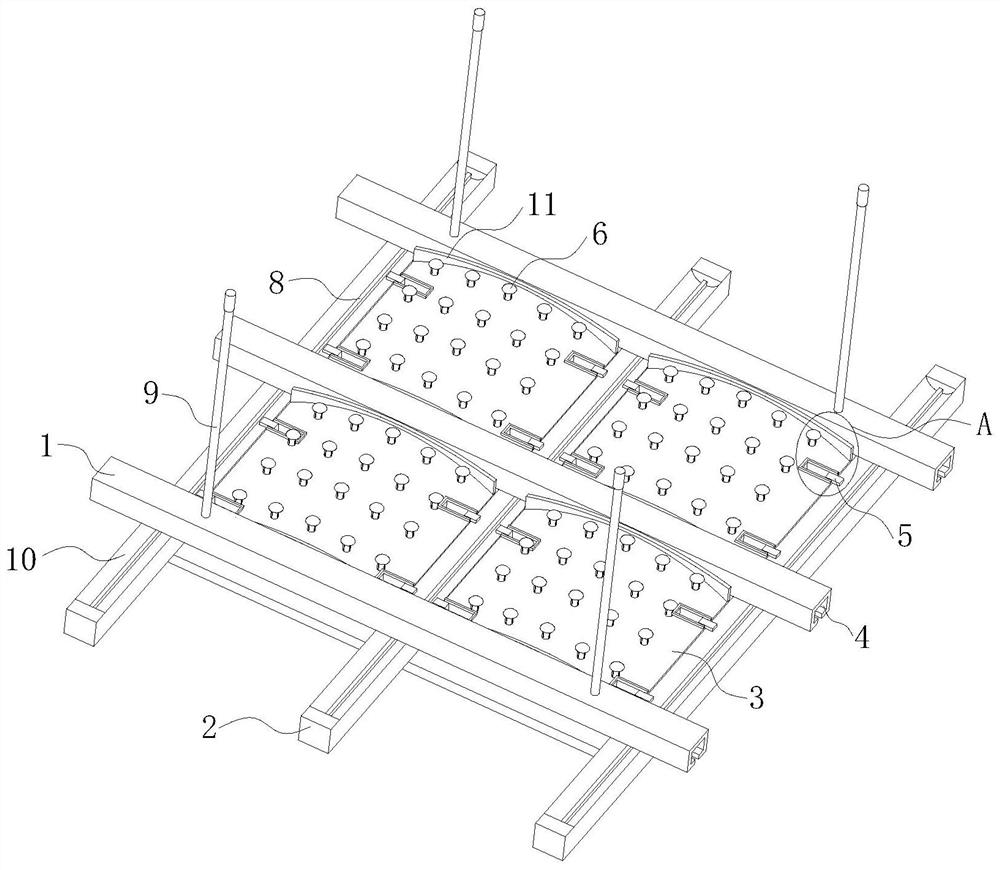

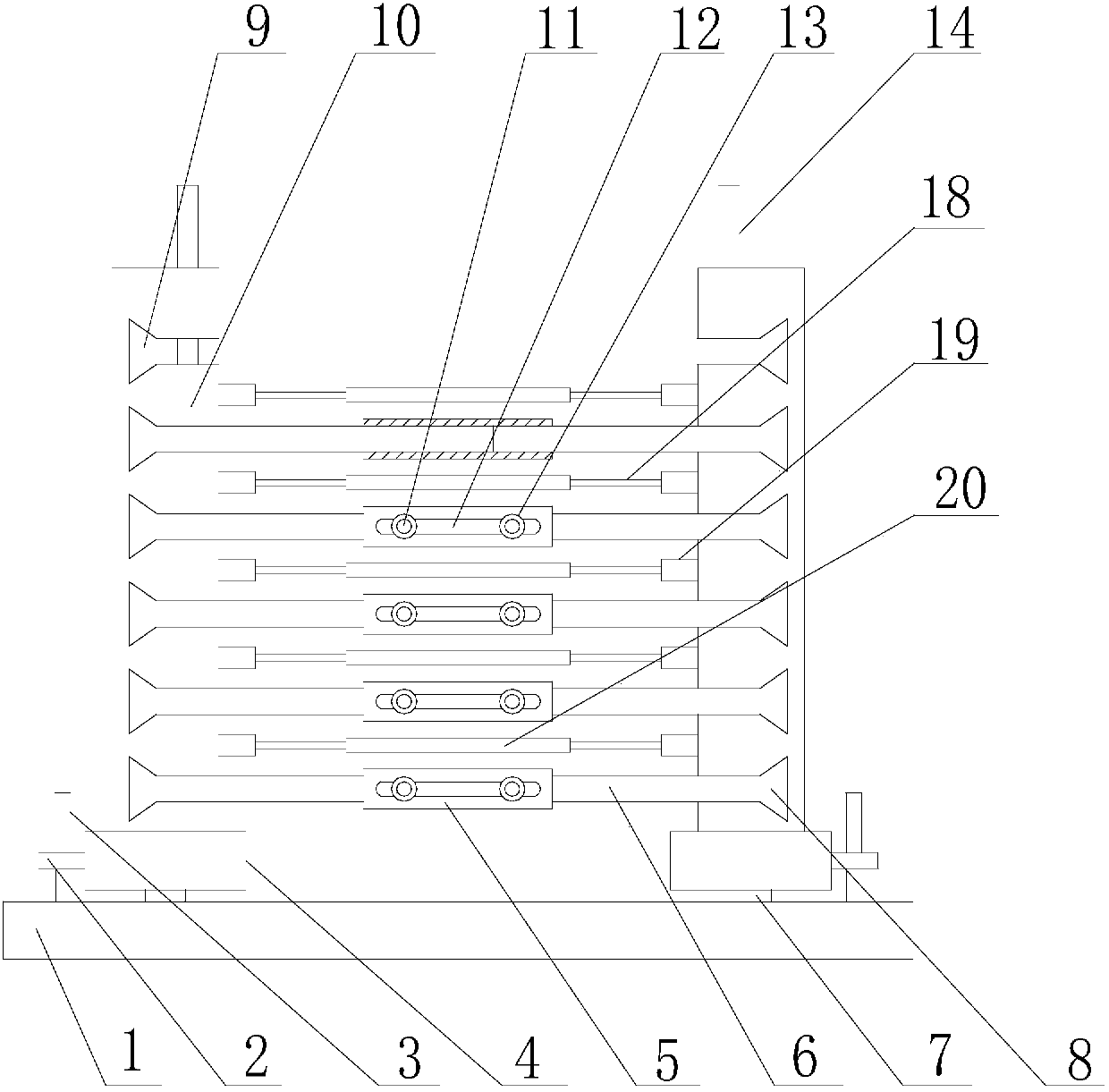

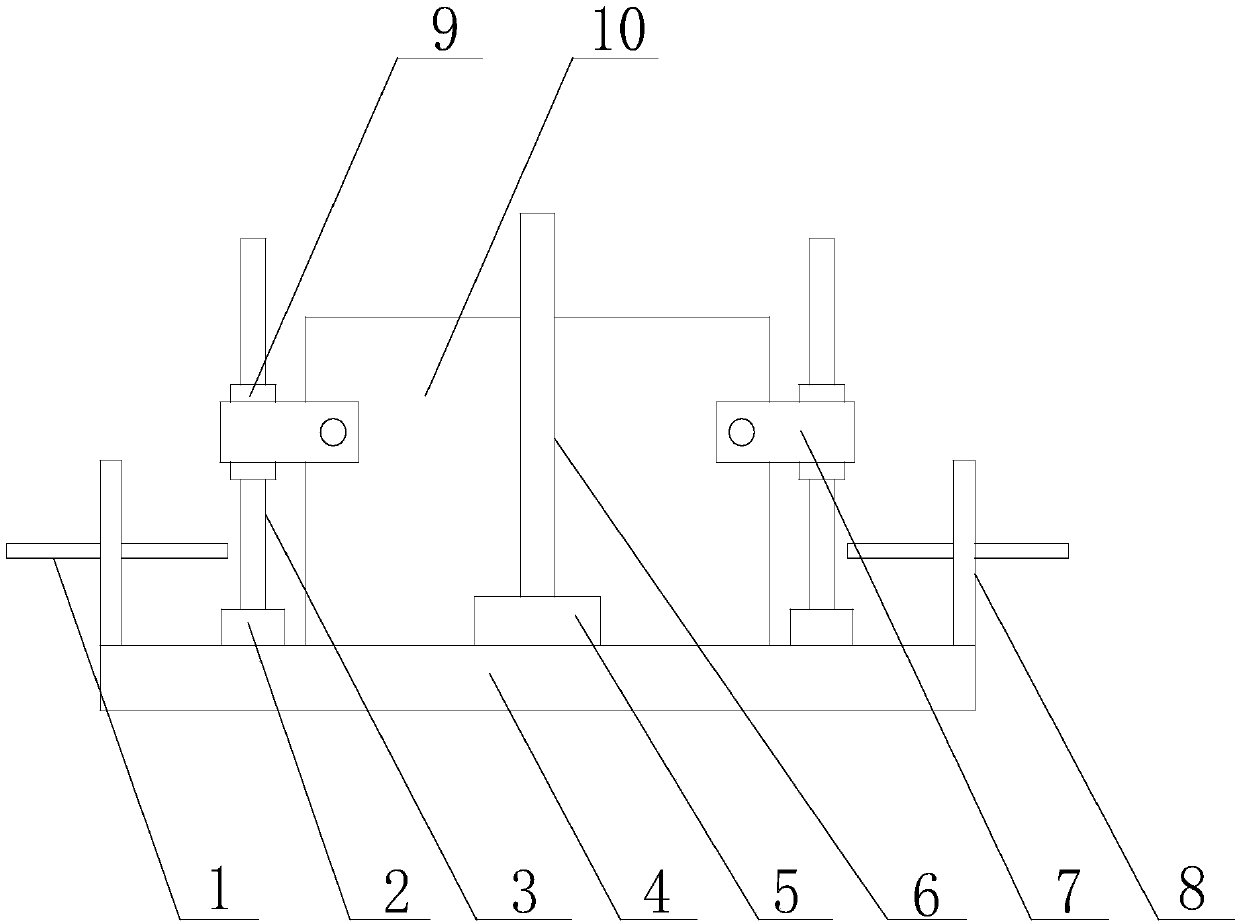

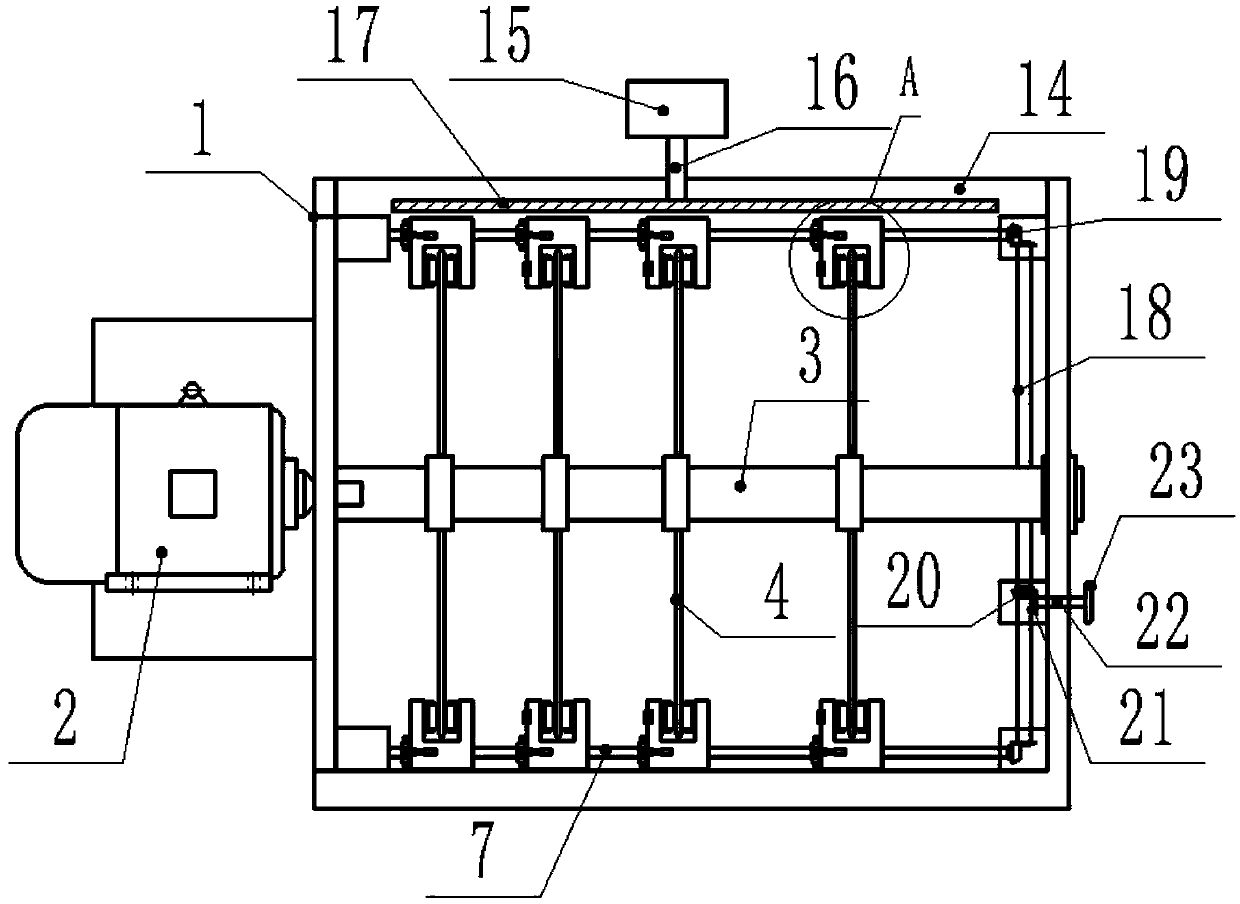

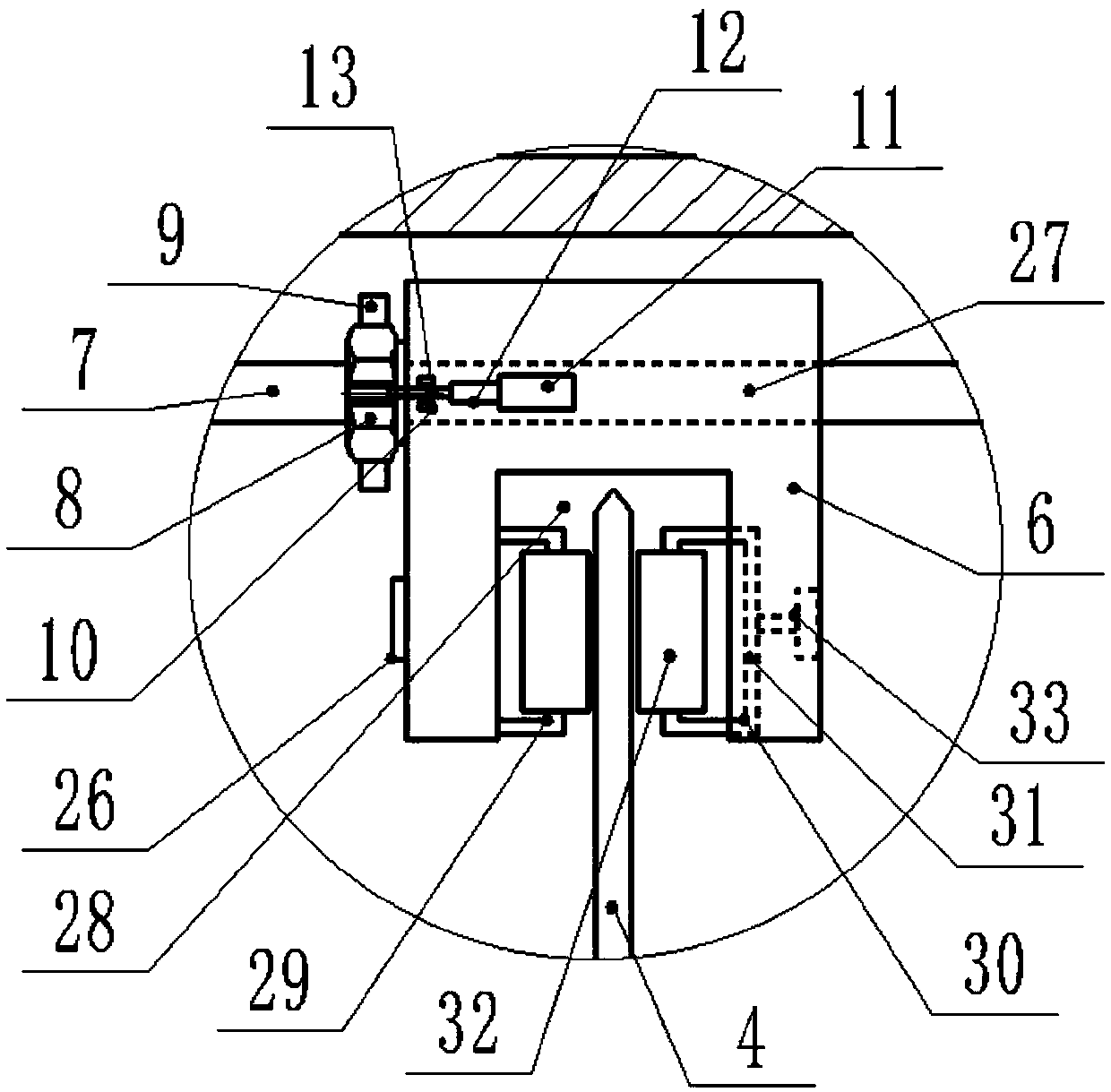

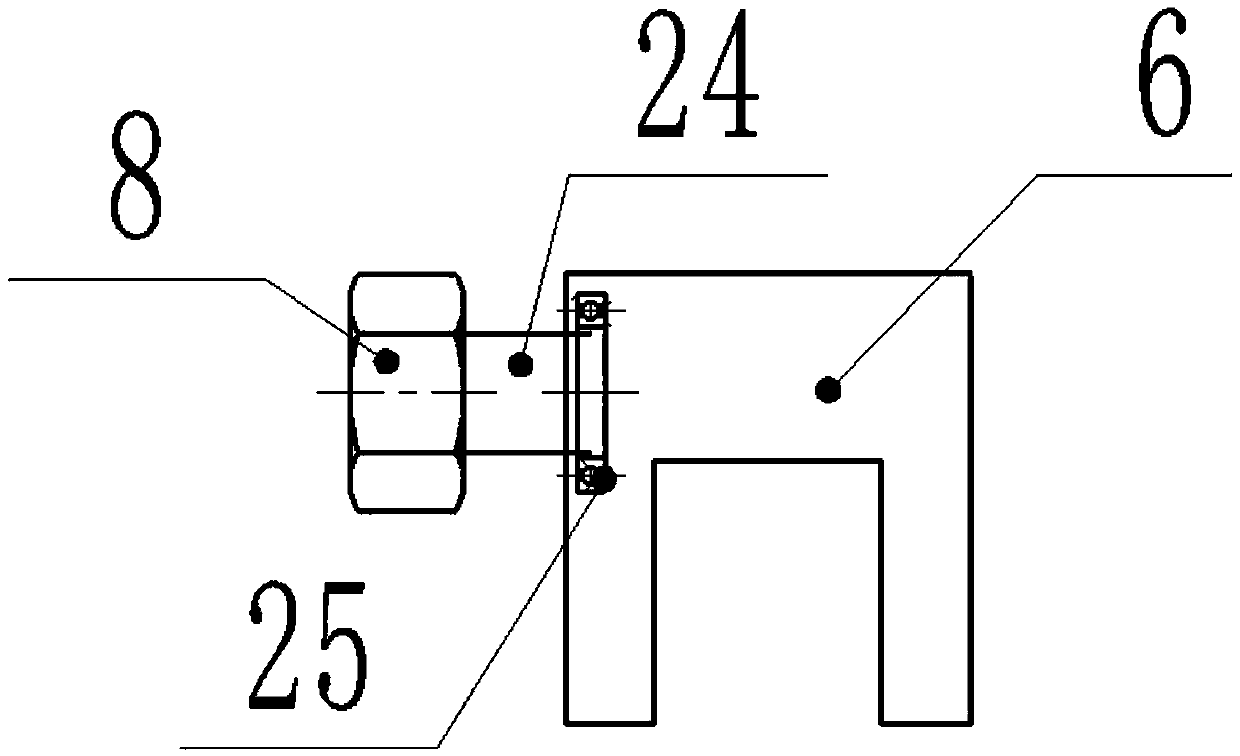

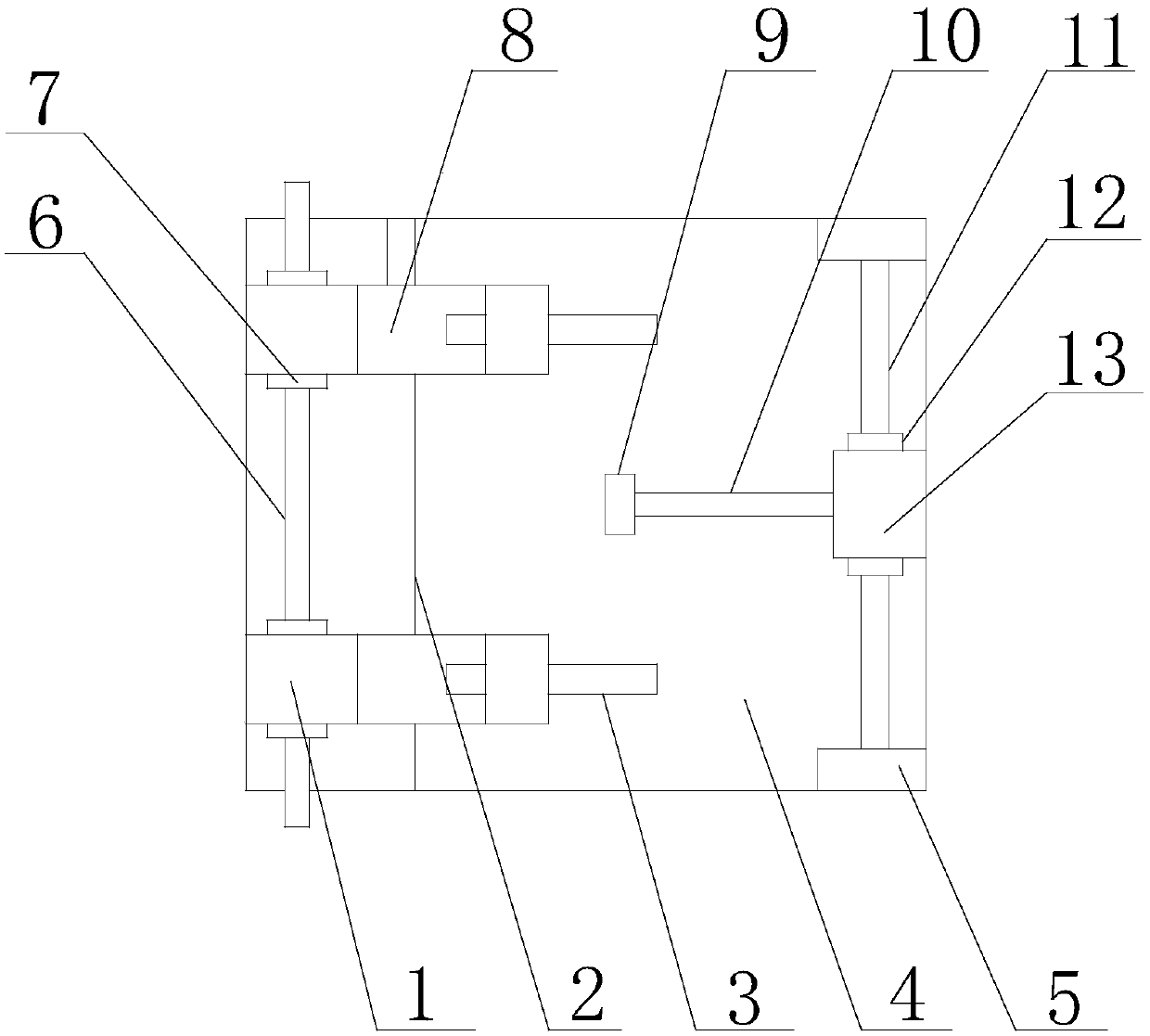

Manual adjusting system for any distance between saw blades for cutting plates of different thicknesses

ActiveCN109014401AEasy to operateImprove regulation efficiencyMetal sawing devicesEngineeringMechanical engineering

The invention discloses a manual adjusting system for any distance between saw blades for cutting plates of different thicknesses. A saw blade spline rotating shaft is arranged in the middle of an electric saw supporting frame. The multiple saw blades are arranged on the saw blade spline rotating shaft through spline sleeves in a sleeving manner. A motor is connected to one end of the saw blade spline rotating shaft. The saw blade spline rotating shaft and the saw blades on the saw blade spline rotating shaft are driven through the motor to work. Saw blade adjusting clamp blocks are arranged on the two sides of each saw blade, the saw blade adjusting clamp blocks on one corresponding sides of all the saw blades are arranged on a lead screw in a sleeving manner, and the two lead screws arecorrespondingly mounted on the two sides of the electric saw supporting frame. An adjusting nut is arranged at the position, on one side of each saw blade adjusting clamp block, of the corresponding lead screw. A nut limiting clamp groove is arranged on each adjusting nut in a surrounding manner. Clamp block limiting clamp grooves corresponding to the nut limiting clamp grooves are arranged on thesaw blade adjusting clamp blocks. A set of air cylinder is arranged on each saw blade adjusting clamp block, a pin block is arranged on a telescopic arm of each air cylinder, and the nut limiting clamp grooves and the clamp block limiting clamp grooves are in pinned connection by controlling the pin blocks through the air cylinders.

Owner:MIANYANG FEIYUAN TECH CO LTD

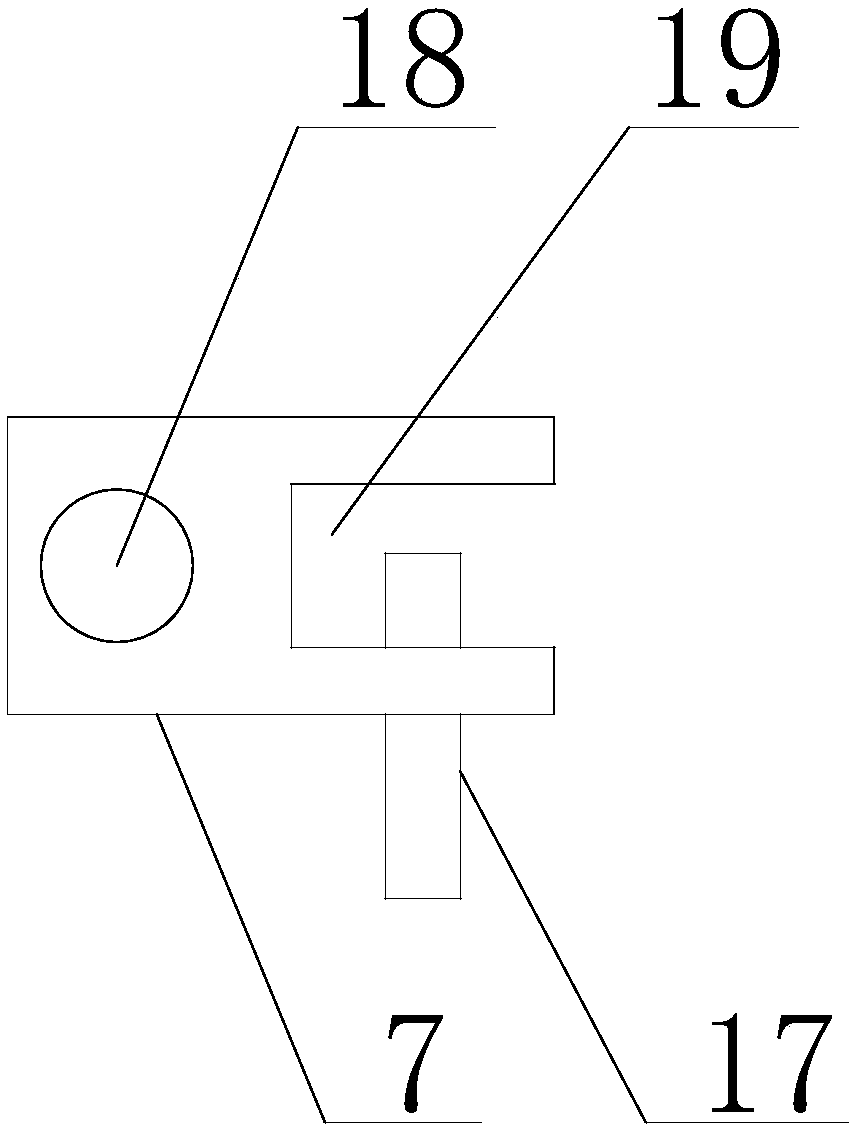

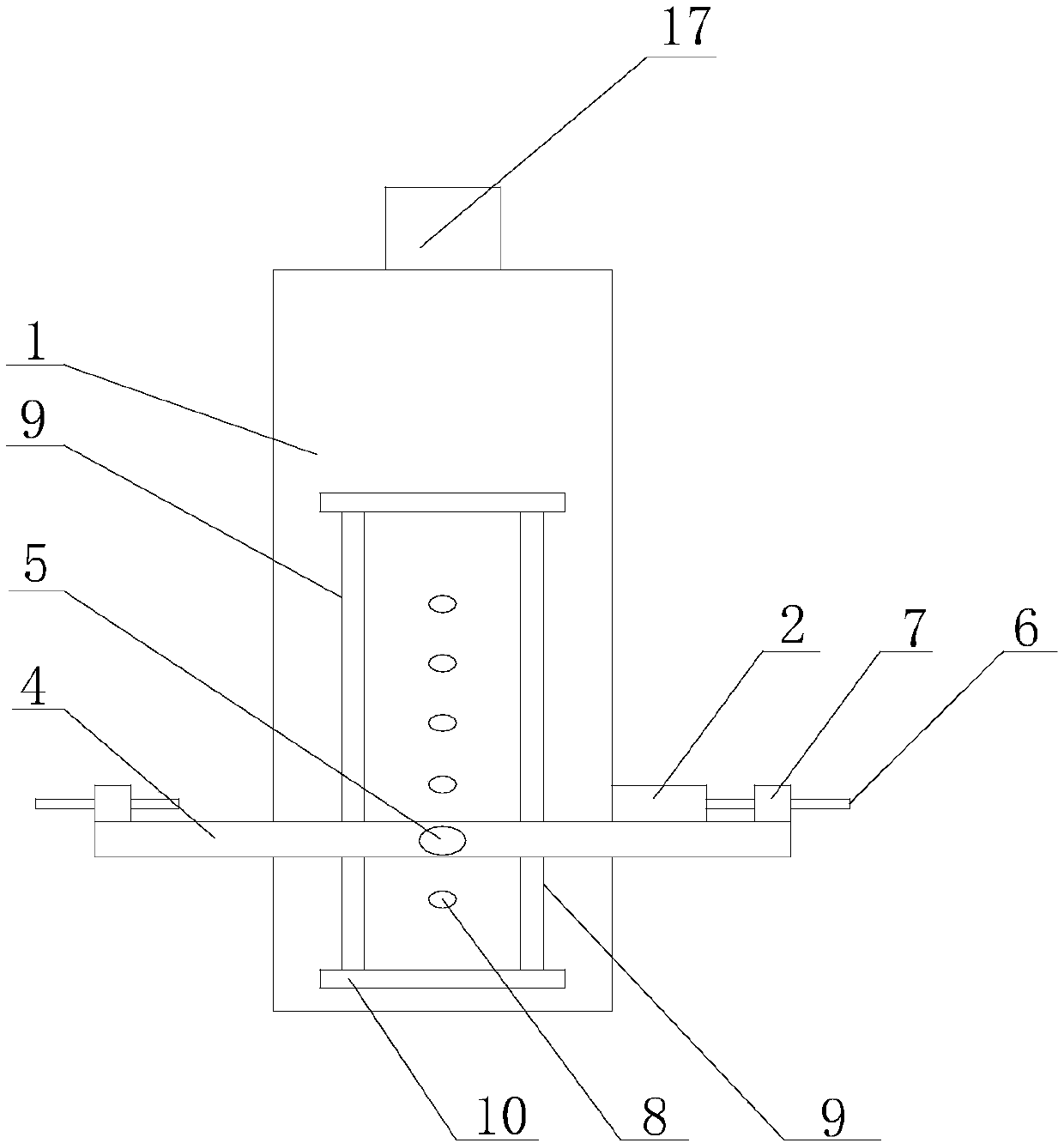

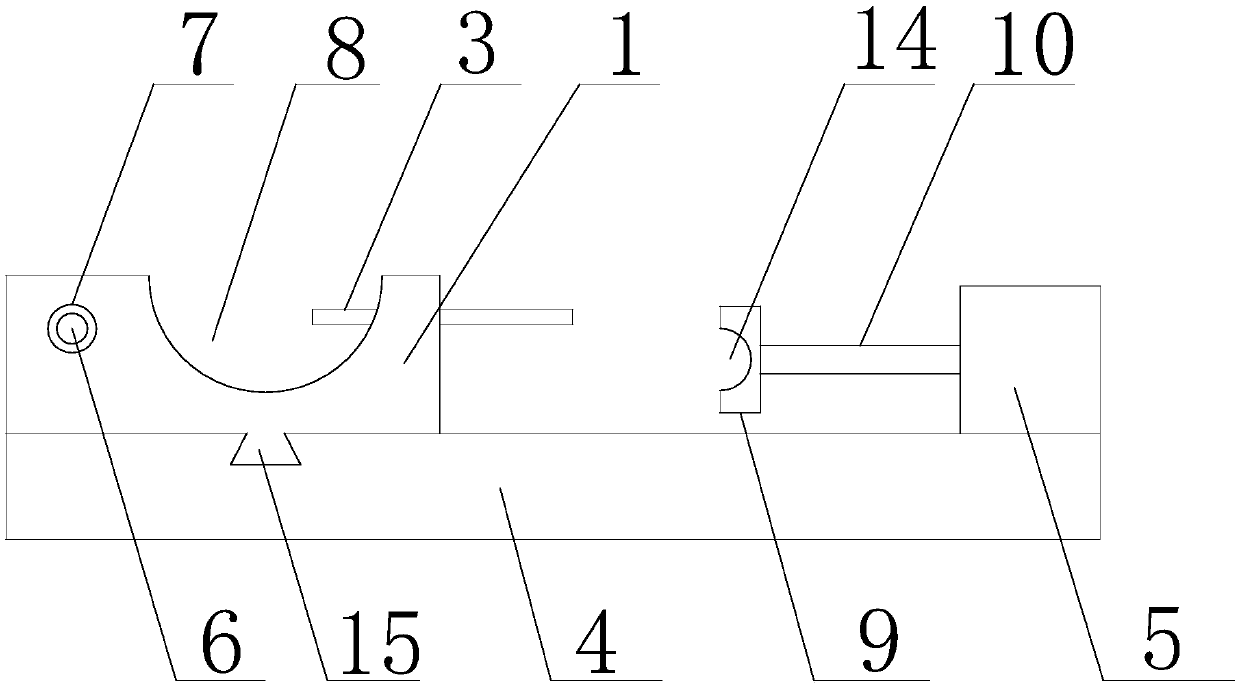

Steel bar straightening device for outdoor power construction

The invention discloses a steel bar straightening device for outdoor power construction. A first base is included; two supporting blocks are arranged at the top of the first base; the supporting blockcan move on the first base; arc-shaped grooves are formed in the tops of the supporting blocks; movable rods are arranged on the side walls of the supporting blocks. The movable rod is horizontally connected with the supporting block through a thread; the movable rod can be rotated to move into the groove; a driving mechanism is further arranged at the top of the first base; the driving mechanismcan move on the first base; the driving mechanism comprises an output shaft, a pressing plate is arranged at the output end of the output shaft, a movable block is further arranged between the two supporting blocks, the movable block can move towards the two supporting blocks on the first base; an opening is further formed in the side wall, facing the pressing plate, of the movable block, and a heating layer is further arranged on the inner wall of the opening.

Owner:蒲芳芳

Used fixing device based on cylindrical structure manufacturing

InactiveCN108818035ANo displacementImprove processing qualityPositioning apparatusMaintainance and safety accessoriesEngineeringCam

The invention discloses a used fixing device based on cylindrical structure manufacturing. The used fixing device comprises a base, two vertical plates are arranged at the top of the base and positioned on two sides of an axis of the base, movable blocks are arranged in the vertical plates and cam vertically move in the vertical plates, adjusting rods are arranged on the movable blocks and horizontally connected with the movable blocks in a threaded manner, two supporting blocks are arranged at the top of the base and positioned between the two vertical plates and can move on the base towardsthe vertical plates, placing grooves are formed in the tops of the supporting blocks, strip-type grooves are formed in the vertical plates, two side walls of the vertical plates are communicated by the strip-type grooves, the movable blocks are positioned in the movable blocks, sliding grooves are formed in two sides of the inner walls of the strip-type grooves, and second sliders matched with the sliding grooves are arranged on two sides of the movable blocks and positioned in the sliding grooves and can move in the sliding grooves.

Owner:绵竹市凯瑞机械加工有限公司

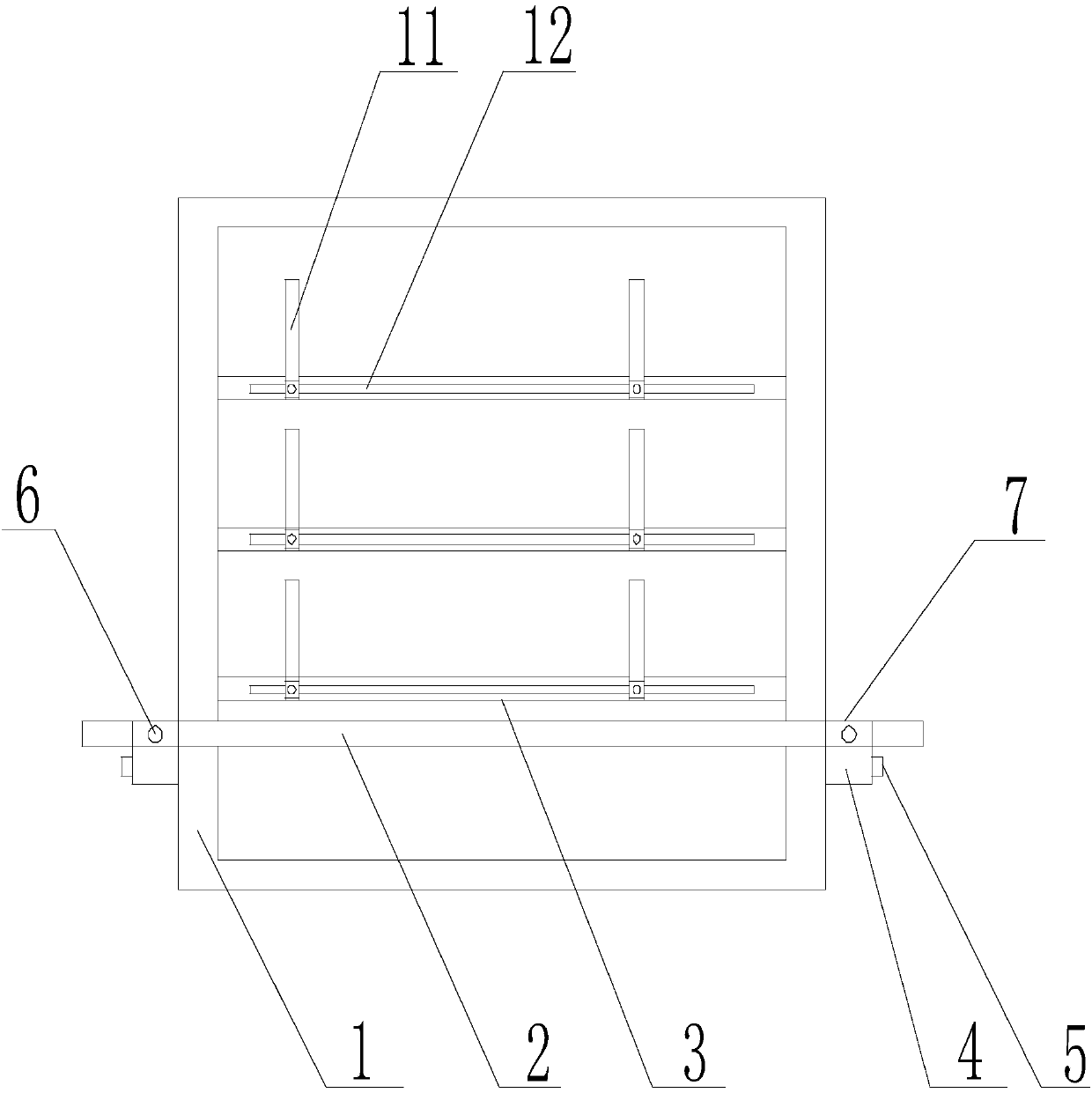

Electric adjusting system for any distance between saw blades for simultaneously sawing plates of different thicknesses

ActiveCN109015902AEasy to operateImprove regulation efficiencyCircular sawsEngineeringMechanical engineering

The invention discloses an electric adjusting system for any distance between saw blades for simultaneously sawing plates of different thicknesses. A saw blade spline rotating shaft is arranged in themiddle of an electric saw supporting frame. The multiple saw blades are arranged on the saw blade spline rotating shaft through spline sleeves in a sleeving manner. A motor is connected to one end ofthe saw blade spline rotating shaft. The saw blade spline rotating shaft and the saw blades on the saw blade spline rotating shaft are driven through the motor to work. Saw blade adjusting clamp blocks are arranged on the two sides of each saw blade, the saw blade adjusting clamp blocks on one corresponding sides of all the saw blades are arranged on a lead screw in a sleeving manner, and the twolead screws are correspondingly mounted on the two sides of the electric saw supporting frame. An adjusting nut is arranged at the position, on one side of each saw blade adjusting clamp block, of the corresponding lead screw. A nut limiting clamp groove is arranged on each adjusting nut in a surrounding manner. Clamp block limiting clamp grooves corresponding to the nut limiting clamp grooves are arranged on the saw blade adjusting clamp blocks. A set of air cylinder is arranged on each saw blade adjusting clamp block, a pin block is arranged on a telescopic arm of each air cylinder, and thenut limiting clamp grooves and the clamp block limiting clamp grooves are in pinned connection by controlling the pin blocks through the air cylinders.

Owner:MIANYANG FEIYUAN TECH CO LTD

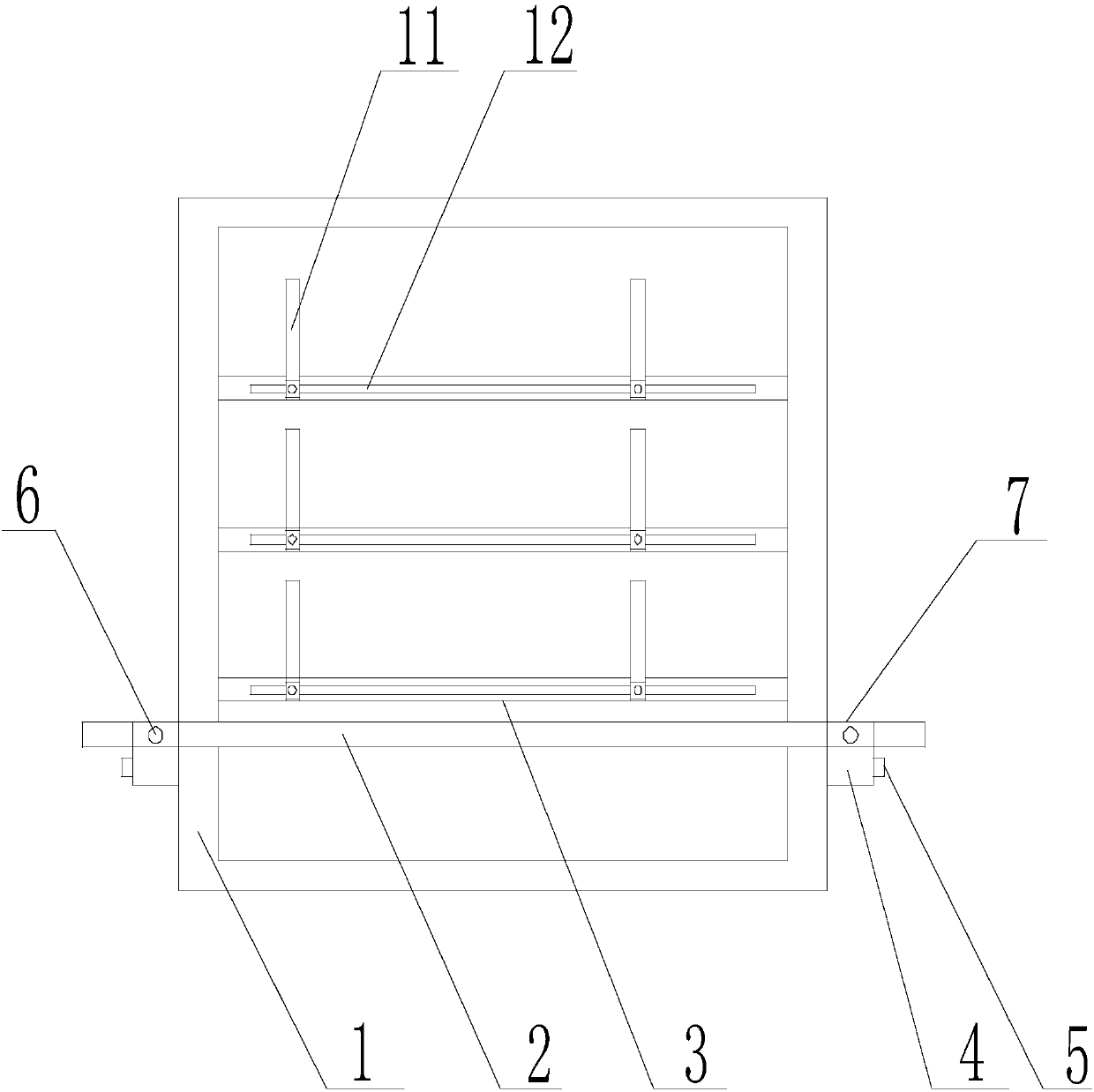

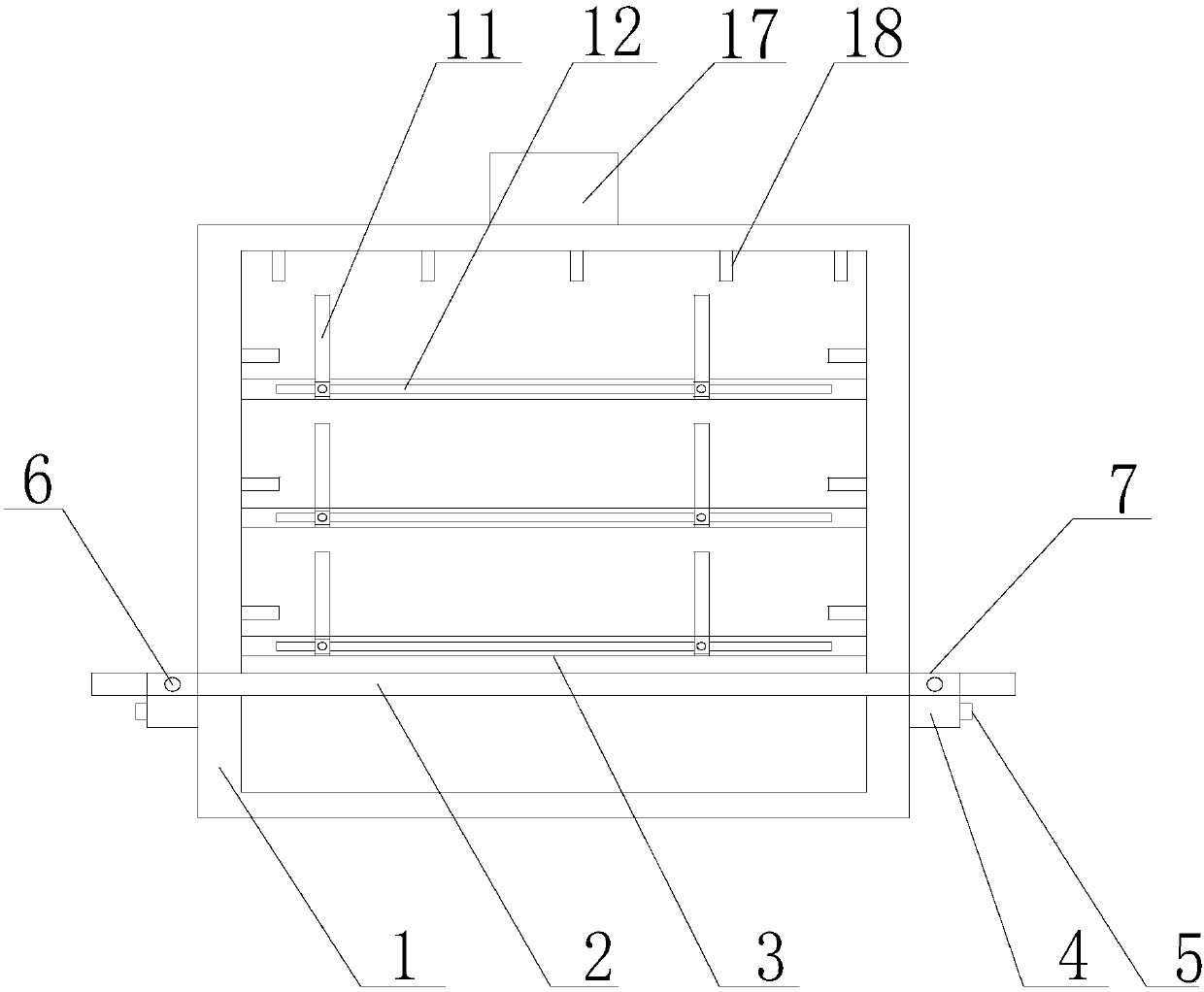

Book placement shelf suitable for use in library

InactiveCN107752459AFree height adjustmentMeet the needs of useBook cabinetsDismountable cabinetsArchitectural engineering

Owner:华蓥市双河小学

Processing device applied to civil construction steel

InactiveCN107639376AImprove welding precisionGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesTransverse planeBuilding construction

The invention discloses a processing device applied to civil construction steel. The processing device comprises a base, two moving plates are arranged at the top of the base and capable of horizontally moving along the base, a vertical rod is arranged on a connection barrel which is arranged at the top of each moving plate, each vertical rod is capable of axially moving along the corresponding connection barrel, a supporting block is arranged at the top of each vertical rod, and the side wall of each supporting block is provided with an opening. Fixing rods are arranged at the top of each supporting block and connected with the corresponding supporting block through threads, a transverse plate is arranged between the connection barrels, two ends of the transverse plate are connected withthe two connection barrels respectively, a connection rod is arranged on the transverse plate and horizontally penetrates the transverse plate, a fixing block which is internally provided with a cavity is arranged on the connection rod, the top and one side wall of the fixing block are communicated through the cavity, a moving plate is arranged in the cavity, two sides of the moving plate are connected with the inner walls of the cavity, and the moving plate is capable of moving horizontally along the inner walls of the cavity.

Owner:廖方奎

Manual saw web any distance adjusting method for cutting panels different in thickness

ActiveCN109047908AEasy to operateImprove regulation efficiencyMetal sawing devicesMetal sawing toolsMechanical engineeringExtrusion

The invention discloses a manual saw web any distance adjusting method for cutting panels different in thickness. The method comprises the steps that firstly, a locking air cylinder is used for controlling contraction of a locking telescopic arm, and an extrusion block is made to leave from saw web adjusting clamping blocks corresponding to one sides of all saw webs; secondly, air cylinders on thetwo sides of the saw webs needing to be adjusted are controlled, the air cylinders are used for controlling pin blocks to conduct pin lock connection on nut limiting clamping grooves and block limiting clamping grooves, and air cylinders on the two sides of the rest of saw webs are in a contraction state; thirdly, an adjusting hand wheel is rotated to sequentially drive an adjusting rotation shaft, an adjusting lead screw and two lead screws to rotate, and the two lead screws then drive adjusting nuts and the saw web adjusting clamping blocks corresponding to the saw webs needing to be adjusted to move; fourthly, the second step and the third step are repeatedly conducted, the movement of the other saw webs is sequentially adjusted, and the distance between the two saw webs reaches the needed cutting size; and fifthly, the locking air cylinder is used for controlling the locking telescopic arm to stretch, the extrusion block is made to tightly press the saw web adjusting clamping blocks corresponding to one sides of all the saw webs, and saw web distance adjustment is finished.

Owner:MIANYANG FEIYUAN TECH CO LTD

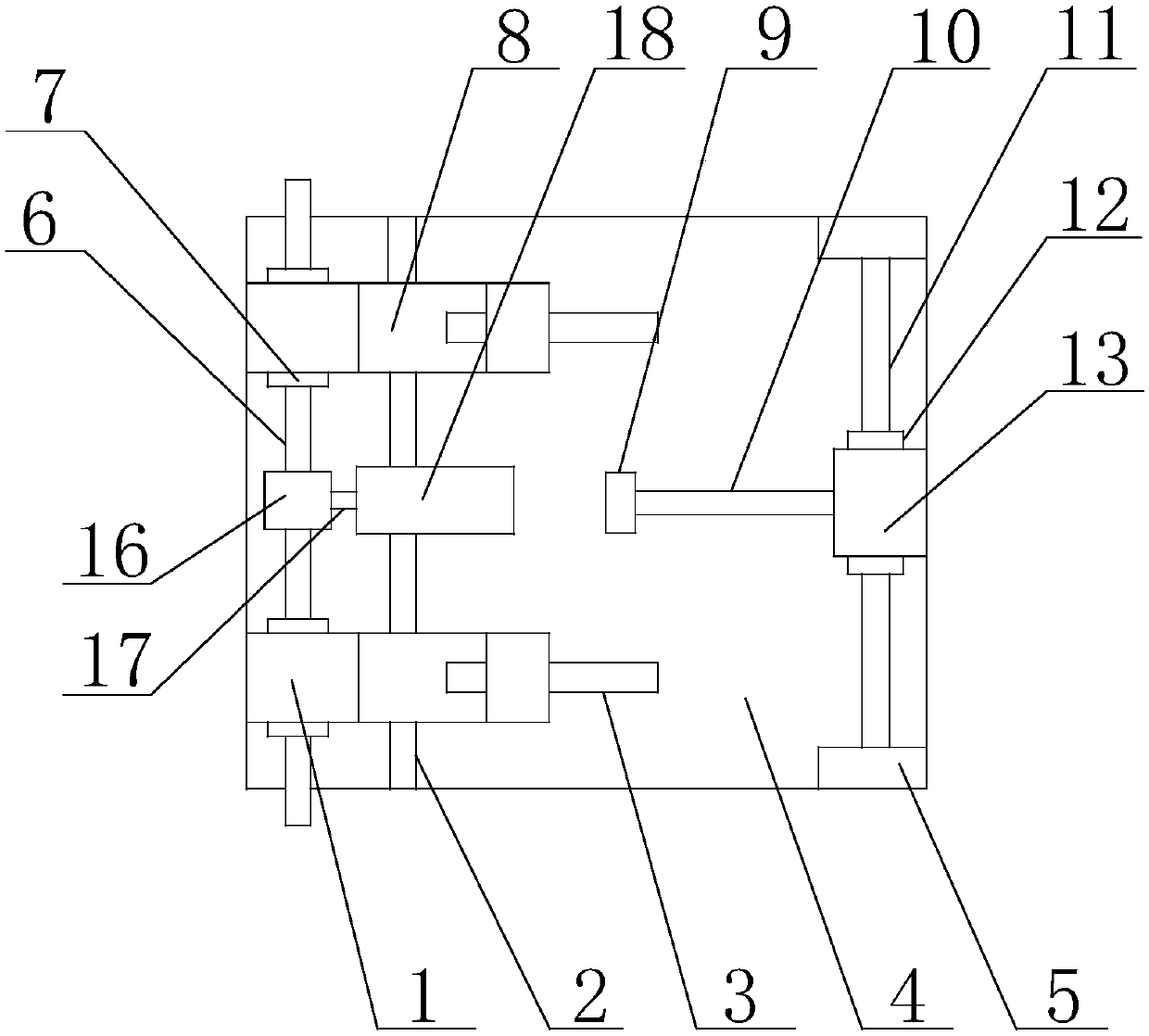

Auxiliary device for improving cylindrical structure part machining efficiency

InactiveCN108789219AImprove processing efficiencyImprove processing qualityWork holdersWork benchesEngineeringBlock match

The invention discloses an auxiliary device for improving the cylindrical structure part machining efficiency. The auxiliary device comprises a base, two vertical plates are arranged on the top of thebase and located on the two sides of the axis of the base, a movable block is arranged in each vertical plate and can move in the corresponding vertical plate in the vertical direction, and an adjusting rod is arranged on each movable block and horizontally connected with the corresponding movable block through a thread; two supporting blocks are arranged on the top of the base and located between the two vertical plates, and the supporting blocks can move towards the vertical plate on the base; a containing groove is formed in the top of each supporting block; and the vertical plates are each provided with a strip-shaped groove, the two side walls of each vertical plate communicate with each other through the corresponding strip-shaped groove, the movable blocks are located in the strip-shaped grooves, the two sides of the inner wall of each strip-shaped groove are provided with sliding grooves, the two sides of the movable blocks are provided with second sliding blocks matched withthe sliding grooves, and the second sliding blocks are located in the sliding grooves and can move in the sliding grooves.

Owner:绵竹市凯瑞机械加工有限公司

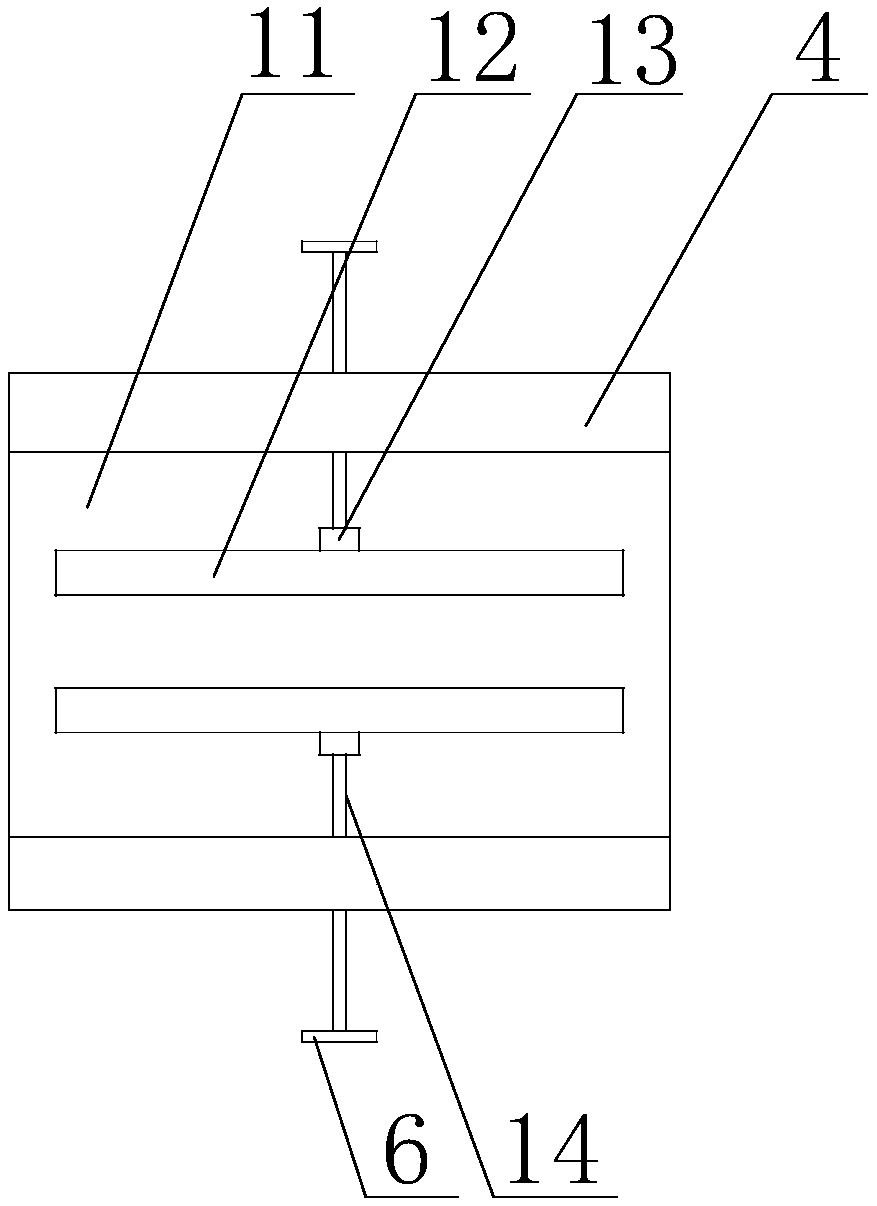

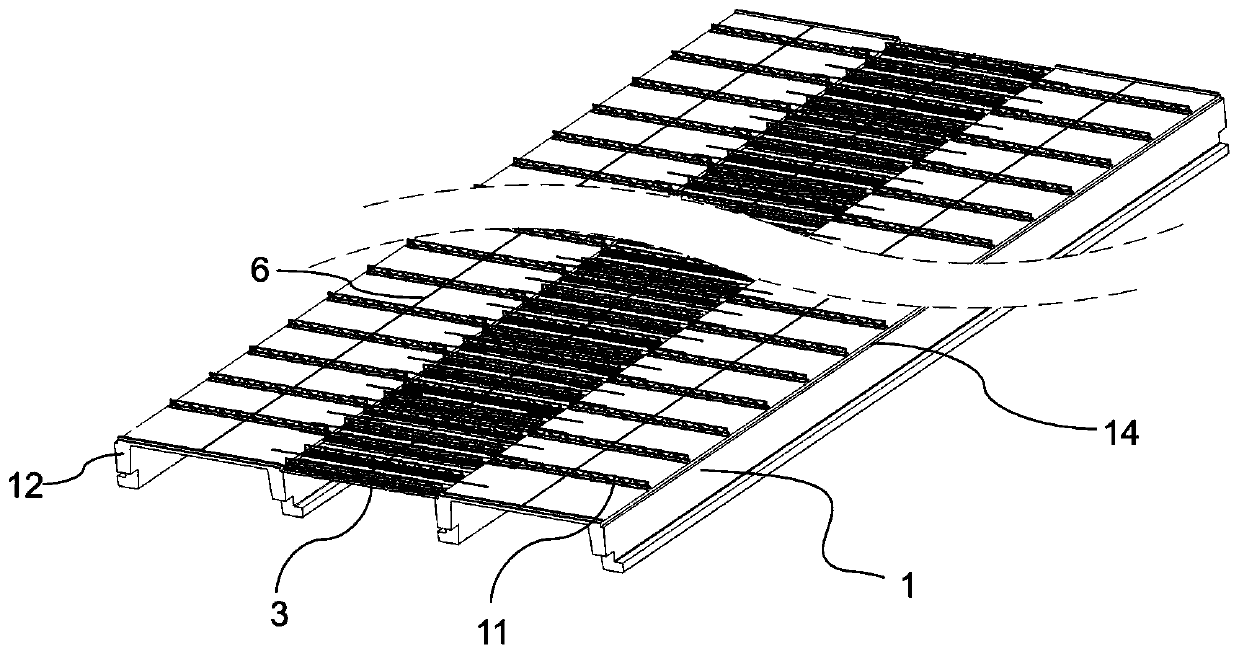

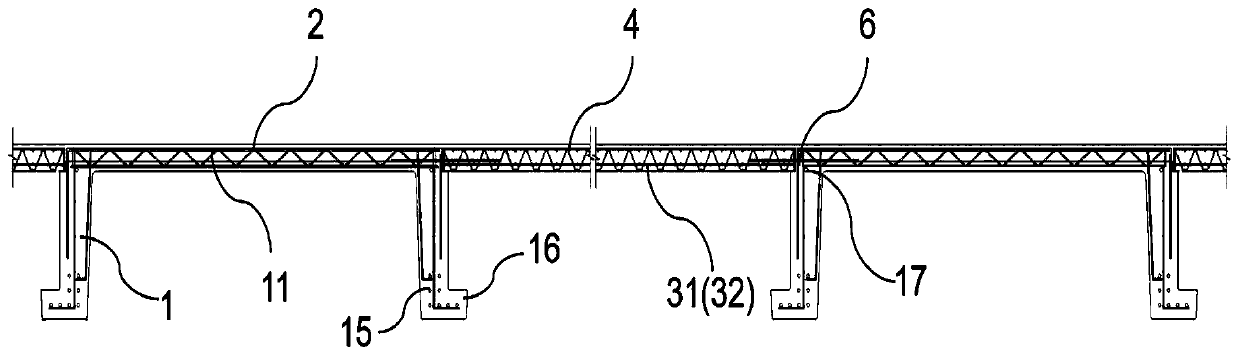

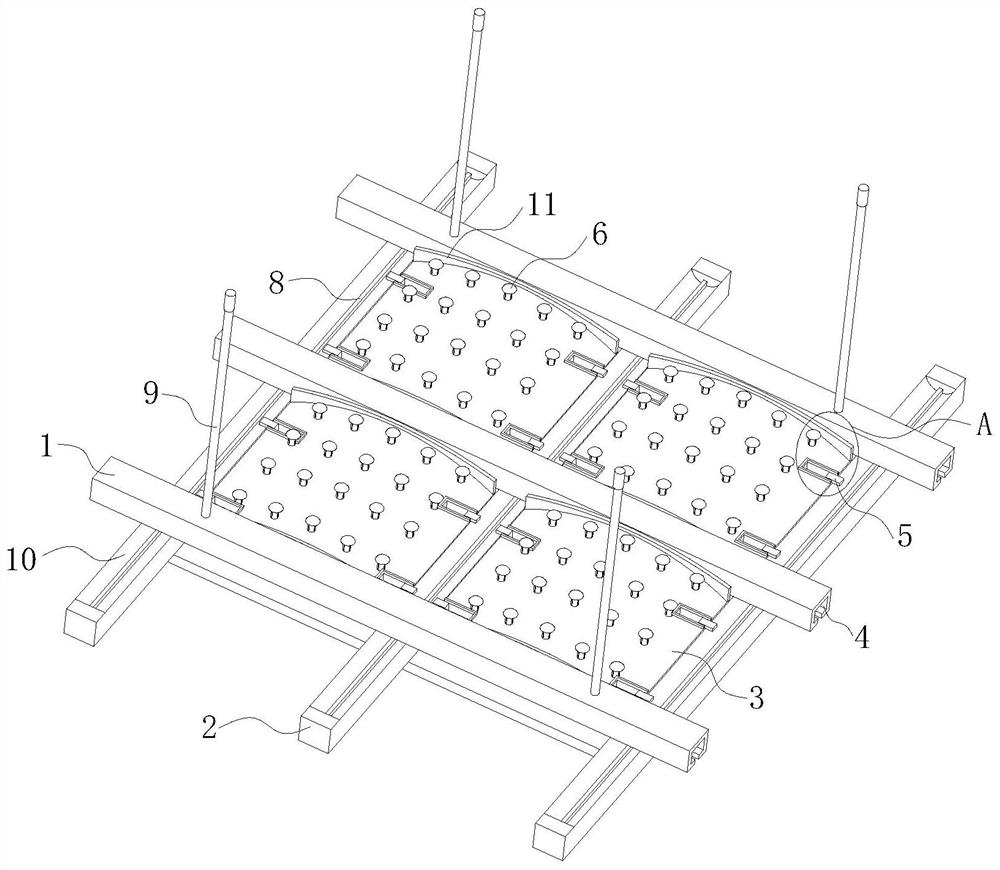

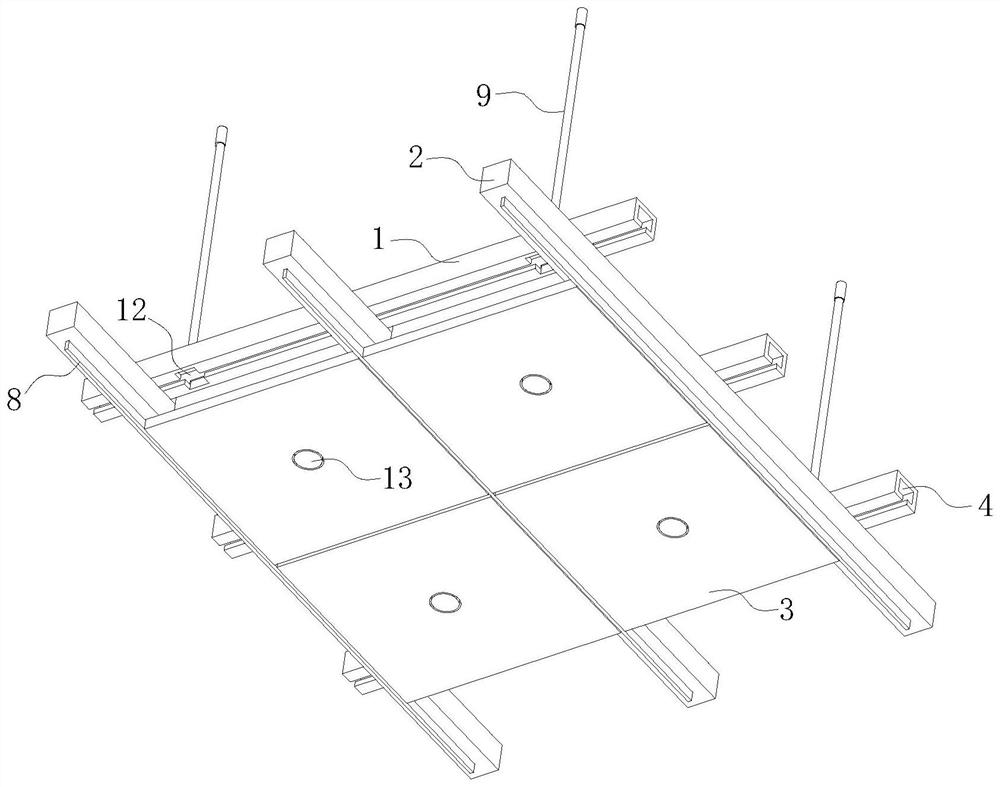

Interval-type prestressed special-shaped grooved plate combined floor slab

PendingCN110629918AThe spacing can be adjusted arbitrarilyImprove versatilityFloorsFloor slabPre stress

The invention provides an interval-type prestressed special-shaped grooved plate combined floor slab. The interval-type prestressed special-shaped grooved plate combined floor slab comprises a prefabricated prestressed special-shaped grooved plate, post-cast concrete poured on the upper part of the prefabricated pre-stressed shaped grooved pate, a floor bearing plate and cast-in-place concrete poured on the upper part of the floor bearing plate. The interval-type prestressed special-shaped grooved plate combined floor slab is characterized in that the prefabricated prestressed special-shaped grooved plate and the floor bearing plate are arranged at intervals, placing notches in the longitudinal direction are formed in two sides of the prefabricated prestressed special-shaped grooved plate,the two ends of the floor bearing plate are placed on the placing notches in the prefabricated prestressed special-shaped grooved plate, and the four parts, that is, the prefabricated prestressed special-shaped grooved plate, the post-cast concrete poured on the upper part of the prefabricated prestressed special-shaped grooved plate, the floor bearing plate and the cast-in-place concrete pouredon the upper part of the floor bearing plate, are cast into the whole. A method of combination of the prefabricated prestressed special-shaped grooved plate and cast-in-place is adopted, the applicability and integrity of the combined floor slab are improved, the cast-in-place part is free of a formwork and free of supporting, the construction progress is greatly increased, the project cost is reduced, and the prefabricated prestressed special-shaped grooved plate is high in single-rib bearing capacity and suitable for large live load.

Owner:宁波优造建筑科技有限公司

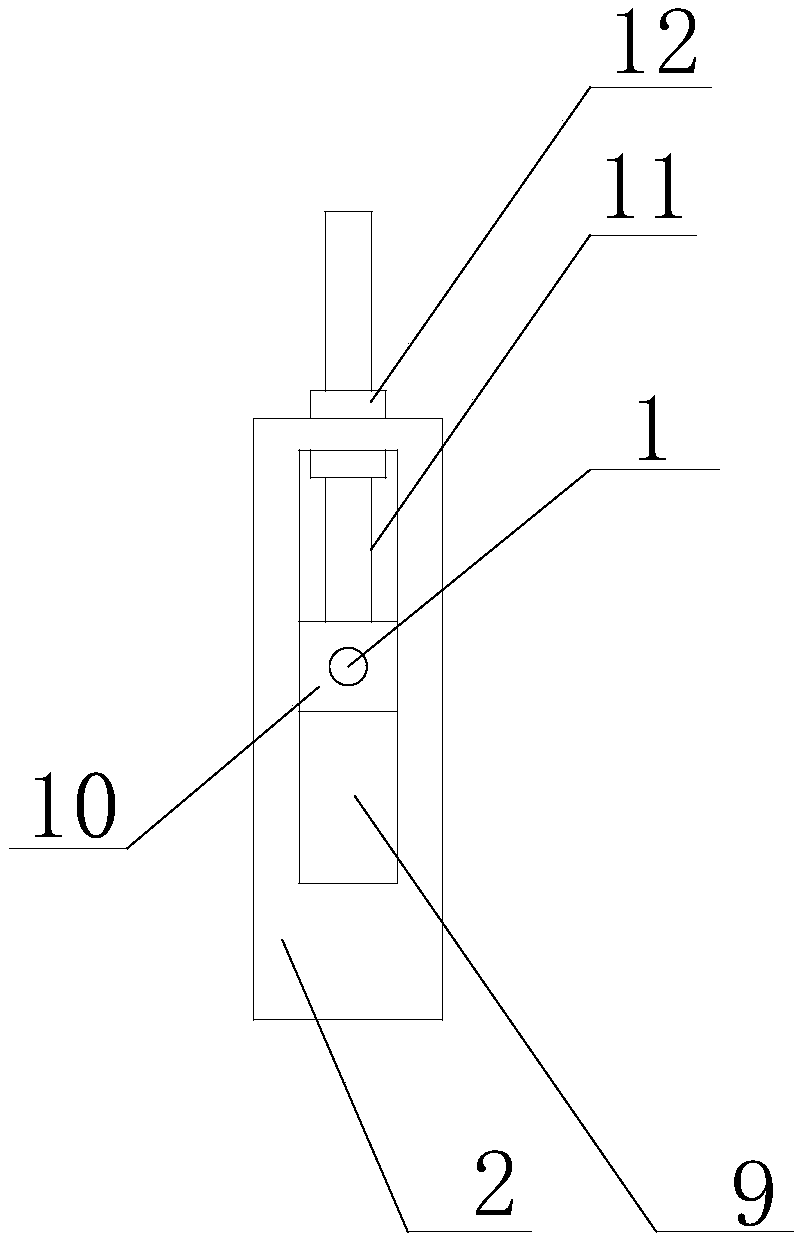

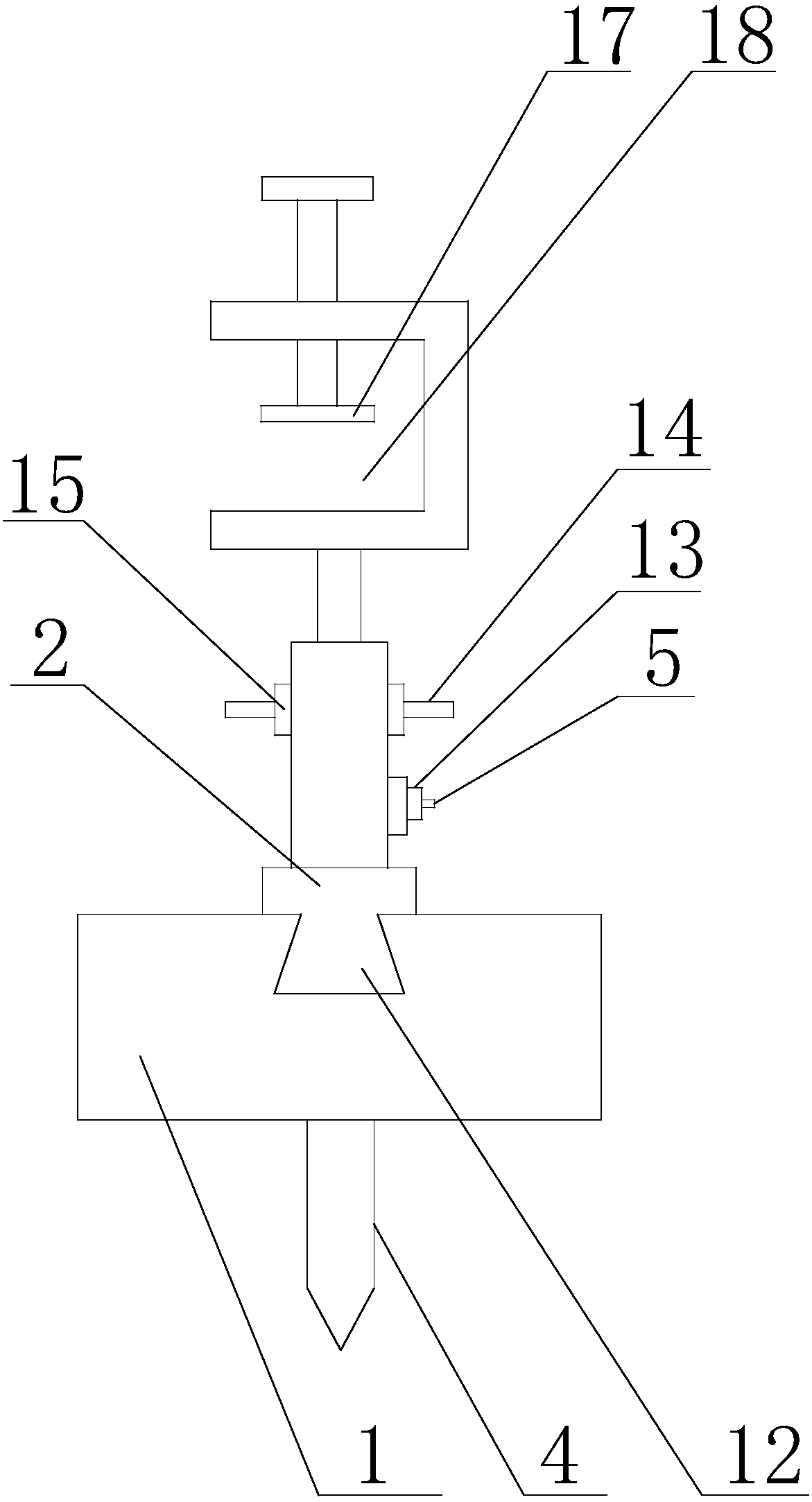

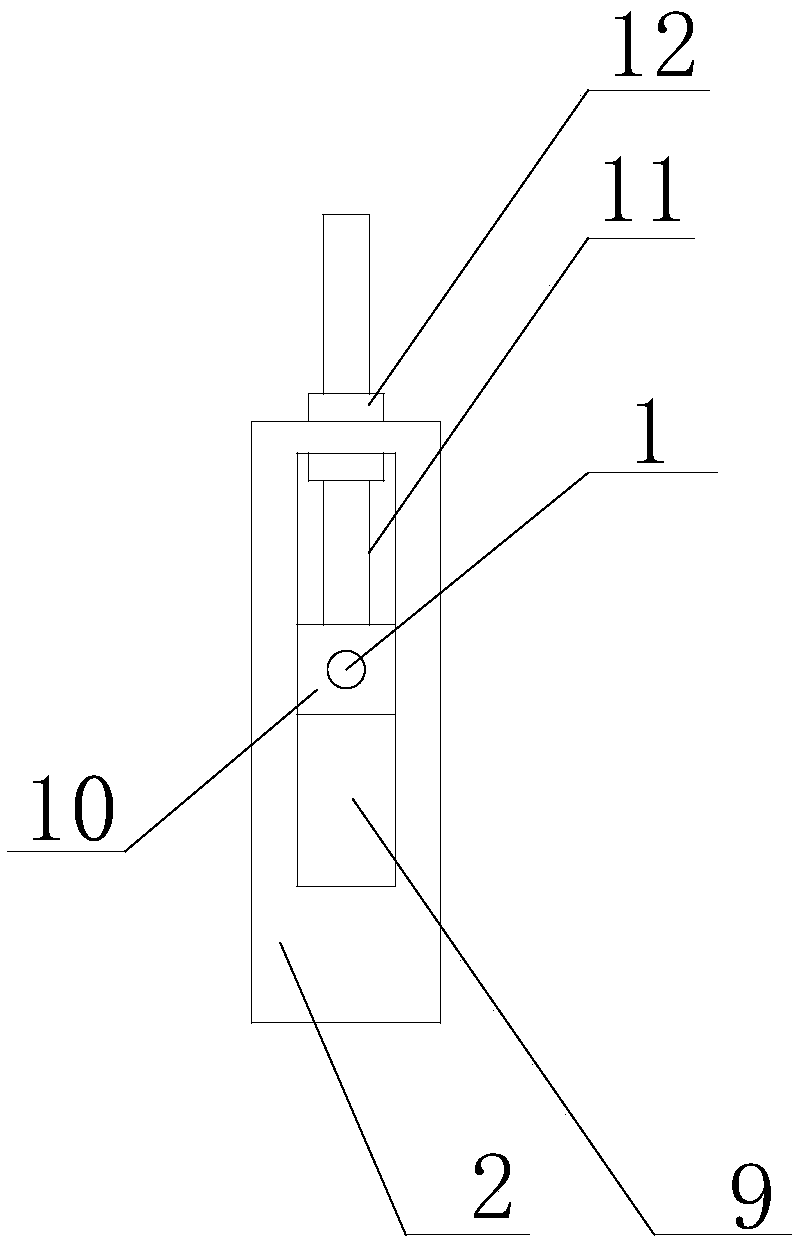

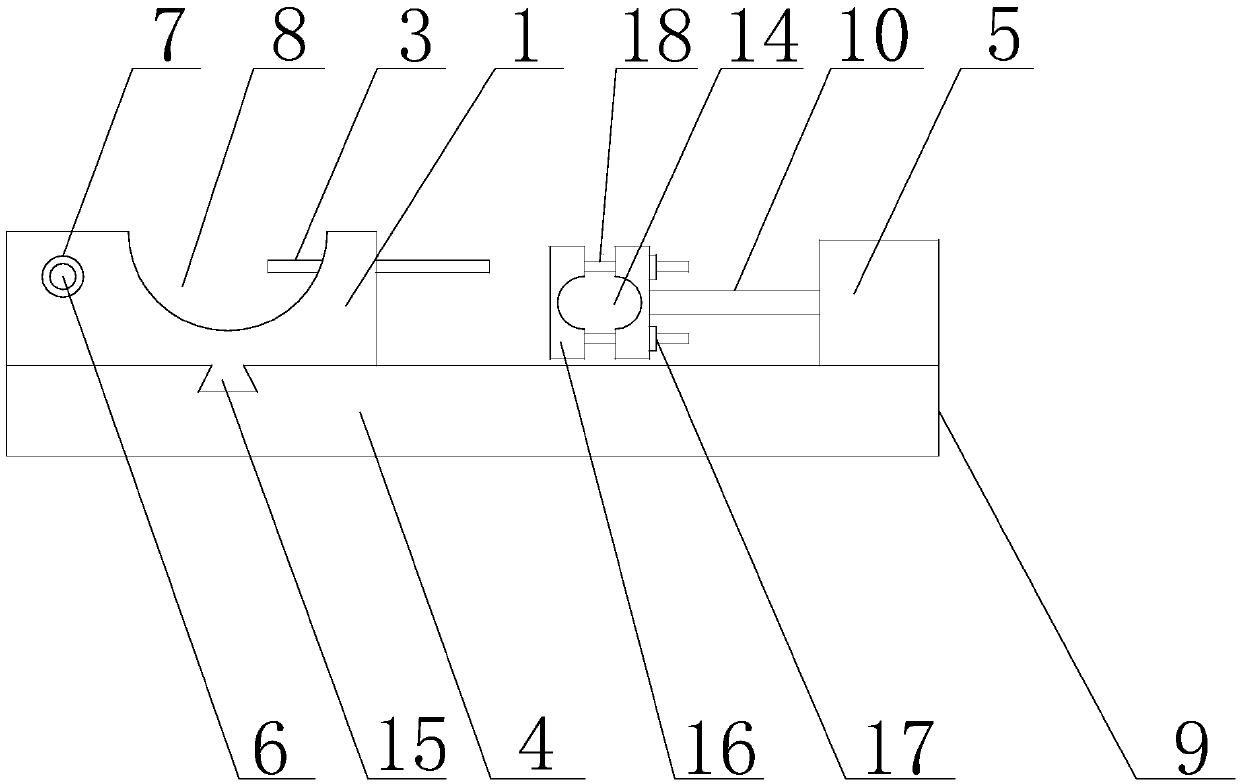

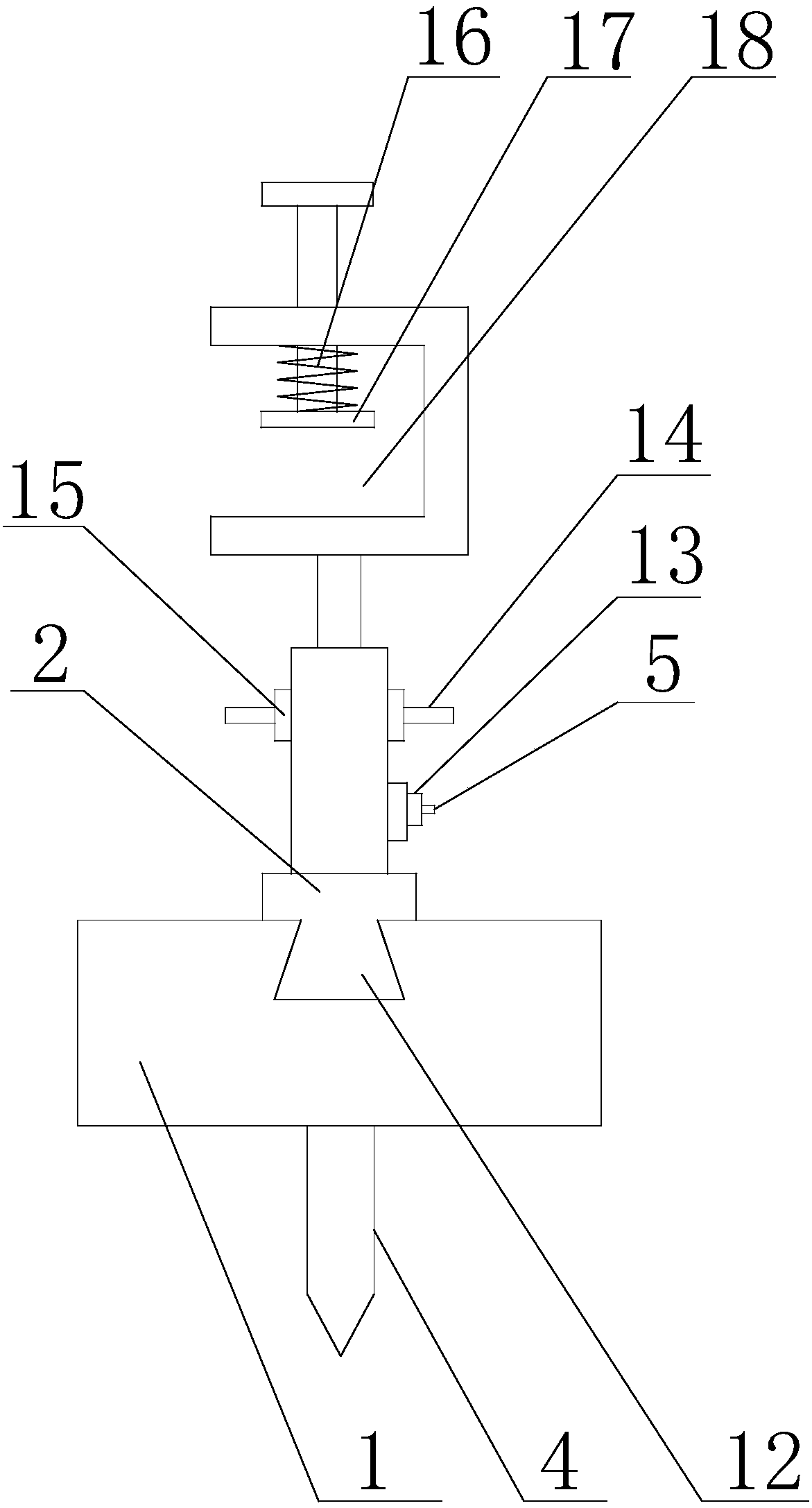

Bending steel bar straightening mechanism

InactiveCN110523885ACorrective satisfactionThe spacing can be adjusted arbitrarilyRebarMechanical engineering

The invention discloses a bending steel bar straightening mechanism including a first base; two supporting blocks are arranged at the top of the first base; the supporting block can move on the firstbase; arc-shaped grooves are formed in the tops of the supporting blocks; movable rods are arranged on the side walls of the supporting blocks. The movable rod is horizontally connected with the supporting block through a thread; the movable rod can be rotated to move into the groove; a driving mechanism is further arranged at the top of the first base; the driving mechanism can move on the firstbase; the driving mechanism comprises an output shaft; a pressing plate is arranged at the output end of the output shaft, a supporting cylinder is arranged at the top of a second base, a second supporting cylinder can rotate on the second base, a supporting rod is arranged at the top of the supporting cylinder, the supporting rod is vertically connected with the supporting cylinder through threads, and the top of the supporting rod is connected with the bottom of the first base.

Owner:蒲芳芳

A method for manually adjusting the arbitrary spacing of saw blades for cutting plates of different thicknesses

ActiveCN109047908BThe spacing can be adjusted arbitrarilyImplement pin-lock connectionMetal sawing devicesMetal sawing toolsMechanical engineeringExtrusion

The invention discloses a manual saw web any distance adjusting method for cutting panels different in thickness. The method comprises the steps that firstly, a locking air cylinder is used for controlling contraction of a locking telescopic arm, and an extrusion block is made to leave from saw web adjusting clamping blocks corresponding to one sides of all saw webs; secondly, air cylinders on thetwo sides of the saw webs needing to be adjusted are controlled, the air cylinders are used for controlling pin blocks to conduct pin lock connection on nut limiting clamping grooves and block limiting clamping grooves, and air cylinders on the two sides of the rest of saw webs are in a contraction state; thirdly, an adjusting hand wheel is rotated to sequentially drive an adjusting rotation shaft, an adjusting lead screw and two lead screws to rotate, and the two lead screws then drive adjusting nuts and the saw web adjusting clamping blocks corresponding to the saw webs needing to be adjusted to move; fourthly, the second step and the third step are repeatedly conducted, the movement of the other saw webs is sequentially adjusted, and the distance between the two saw webs reaches the needed cutting size; and fifthly, the locking air cylinder is used for controlling the locking telescopic arm to stretch, the extrusion block is made to tightly press the saw web adjusting clamping blocks corresponding to one sides of all the saw webs, and saw web distance adjustment is finished.

Owner:MIANYANG FEIYUAN TECH CO LTD

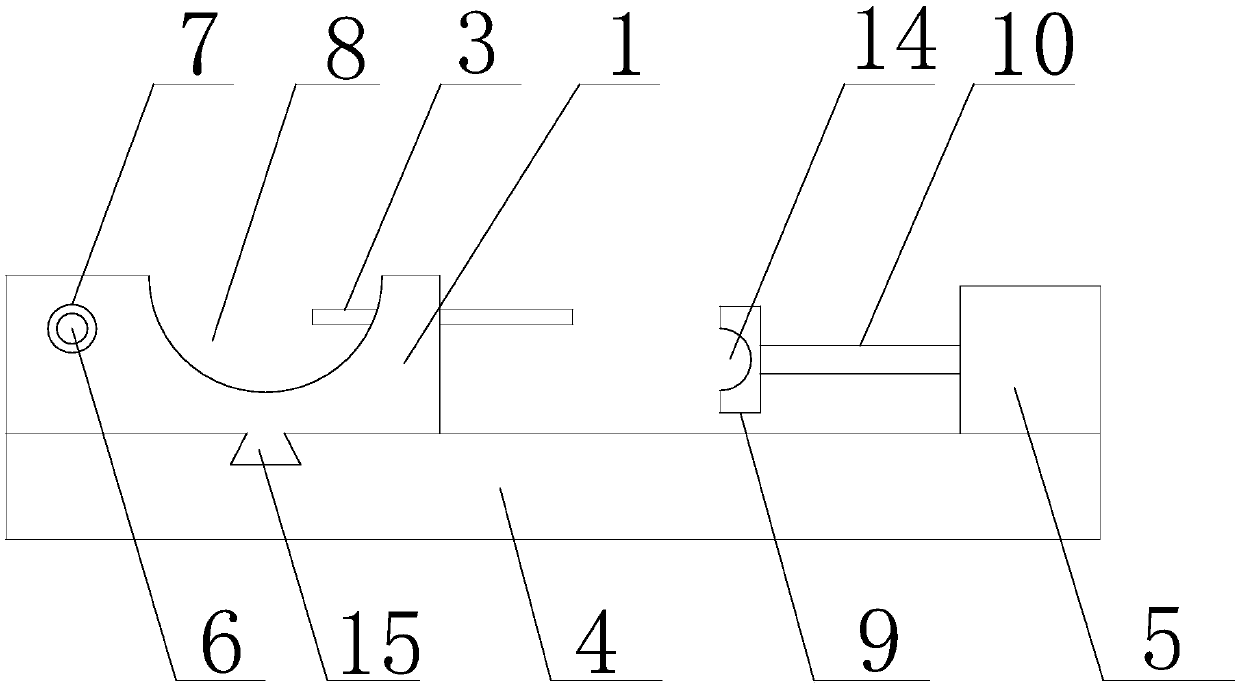

Auxiliary device suitable for reinforcing steel bars in power construction

The invention discloses an auxiliary device suitable for reinforcing steel bars in power construction. The auxiliary device includes a base; two supporting blocks are arranged at the top of the base.The supporting blocks can move on the base; arc-shaped grooves are formed in the tops of the supporting blocks; movable rods are arranged on the side walls of the supporting blocks. The movable rod ishorizontally connected with the supporting block through a thread; the movable rod can be rotated to move into the groove; a driving mechanism is further arranged at the top of the base; the drivingmechanism can move on the base, the driving mechanism comprises an output shaft; a pressing plate is arranged at the output end of the output shaft, four threaded rods are arranged on the pressing plate, the threaded rods are all horizontally inserted into the pressing plate in a penetrating mode, one end of each threaded rod is inserted into the pressing plate in a penetrating mode, a fixing plate is arranged at the other end of each threaded rod, and the four threaded rods are all connected with the fixing plate.

Owner:蒲芳芳

Using method of steel bar straightening equipment

The invention discloses a using method of steel bar straightening equipment. A base is included; two supporting blocks are arranged at the top of the base. The supporting block can move on the base; arc-shaped grooves are formed in the tops of the supporting blocks; movable rods are arranged on the side walls of the supporting blocks. The movable rod is horizontally connected with the supporting block through a thread; the movable rod can be rotated to move into the groove; a driving mechanism is further arranged at the top of the base; the driving mechanism can move on the base; the driving mechanism comprises an output shaft, a pressing plate is arranged at the output end of the output shaft, a movable block is further arranged between the two supporting blocks, the movable block can move on the base towards the two supporting blocks; an opening is further formed in the side wall, facing the pressing plate, of the movable block, and a heating layer is further arranged on the inner wall of the opening.

Owner:范亦能

Electric adjustment system for arbitrary spacing of saw blades for simultaneous sawing of different thickness plates

ActiveCN109015902BImplement pin-lock connectionThe spacing can be adjusted arbitrarilyCircular sawsMechanical engineeringEngineering

The invention discloses an electric adjusting system for any distance between saw blades for simultaneously sawing plates of different thicknesses. A saw blade spline rotating shaft is arranged in themiddle of an electric saw supporting frame. The multiple saw blades are arranged on the saw blade spline rotating shaft through spline sleeves in a sleeving manner. A motor is connected to one end ofthe saw blade spline rotating shaft. The saw blade spline rotating shaft and the saw blades on the saw blade spline rotating shaft are driven through the motor to work. Saw blade adjusting clamp blocks are arranged on the two sides of each saw blade, the saw blade adjusting clamp blocks on one corresponding sides of all the saw blades are arranged on a lead screw in a sleeving manner, and the twolead screws are correspondingly mounted on the two sides of the electric saw supporting frame. An adjusting nut is arranged at the position, on one side of each saw blade adjusting clamp block, of the corresponding lead screw. A nut limiting clamp groove is arranged on each adjusting nut in a surrounding manner. Clamp block limiting clamp grooves corresponding to the nut limiting clamp grooves are arranged on the saw blade adjusting clamp blocks. A set of air cylinder is arranged on each saw blade adjusting clamp block, a pin block is arranged on a telescopic arm of each air cylinder, and thenut limiting clamp grooves and the clamp block limiting clamp grooves are in pinned connection by controlling the pin blocks through the air cylinders.

Owner:MIANYANG FEIYUAN TECH CO LTD

Cooling mechanism for improving maintenance efficiency

InactiveCN107943248AImprove maintenance efficiencyImprove cooling effectDigital data processing detailsSlide plateEngineering

Owner:成都西河散热器厂

Multifunctional top wall decorative plate

Owner:浙江奥普家居有限公司

A conductive track type installation component

Owner:惠州市梧桐实业有限公司

Cooling apparatus capable of preventing dust blockage

InactiveCN107748611AAvoid cloggingQuick releaseDigital data processing detailsEngineeringMechanical engineering

Owner:成都西河散热器厂

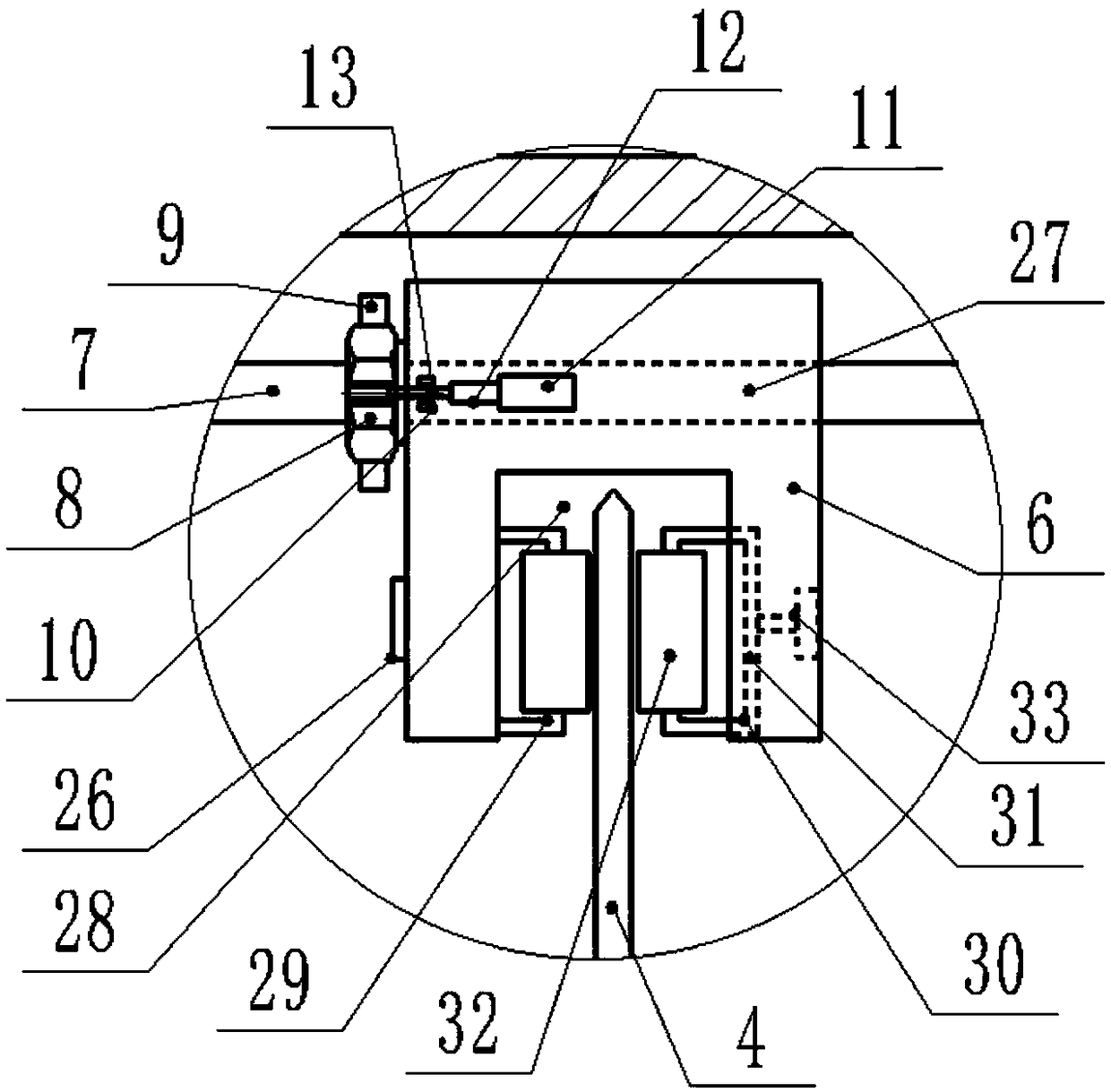

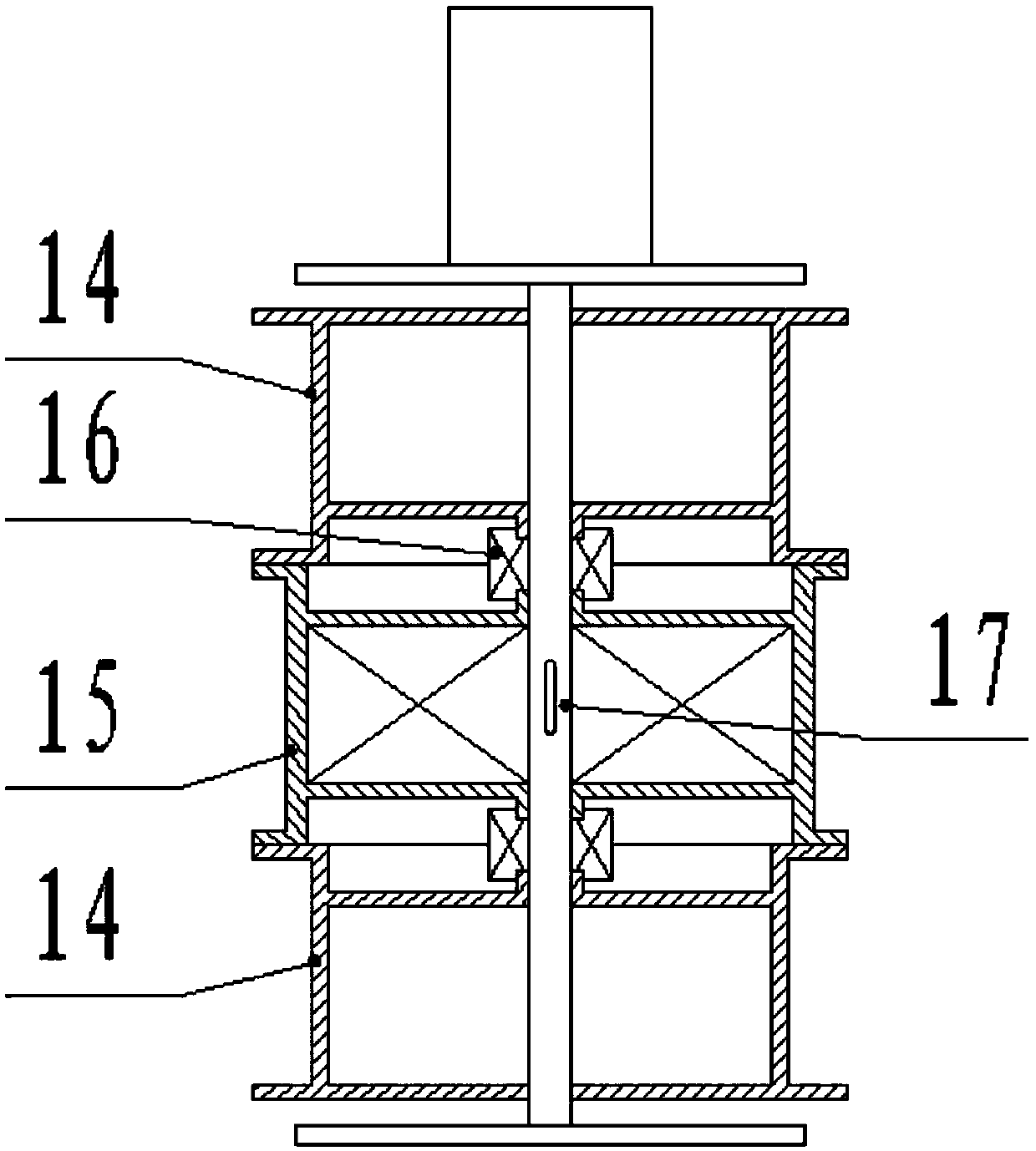

One machine and two wells production equipment and technology

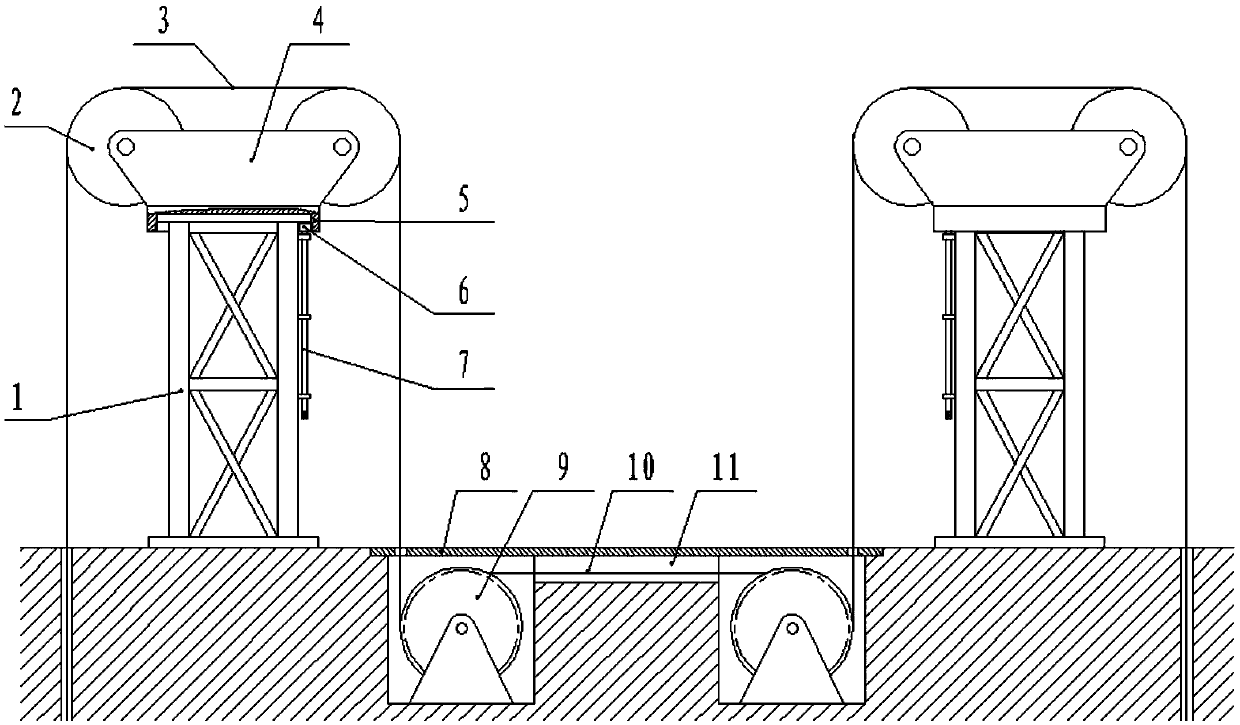

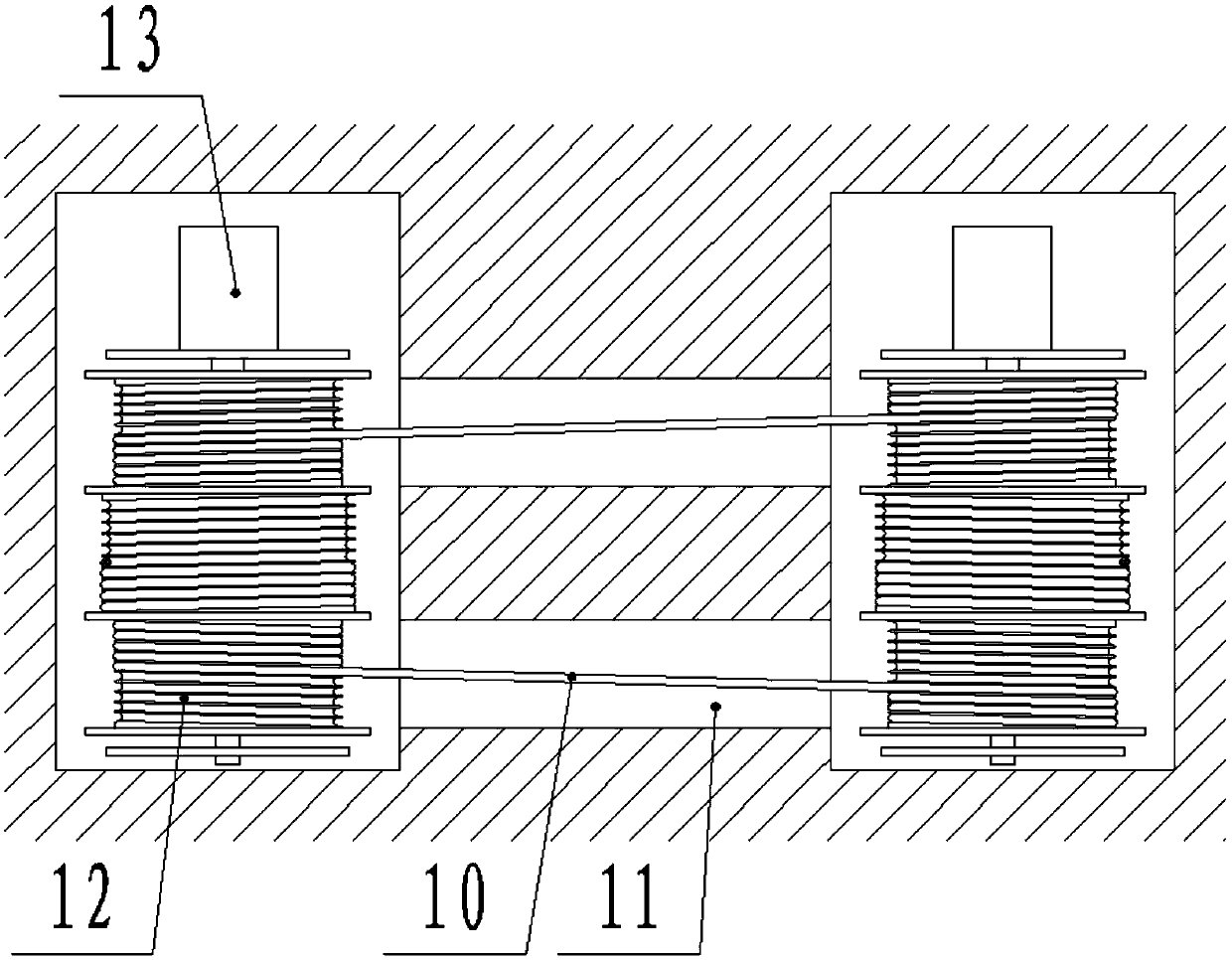

ActiveCN109057754BThe spacing can be adjusted arbitrarilyReduce consumptionFluid removalOil fieldOil production

The invention belongs to the field of oil-field oil production equipment, and particularly relates to a one-machine double-well oil production device and process. The one-machine double-well oil production device comprises two derricks, two driving mechanisms and two oil pumping ropes; a fixed pulley bracket is installed at the upper end of each derrick, two fixed pulleys are symmetrically installed on each fixed pulley bracket, and the two driving mechanisms are arranged in two square pits located under the ground respectively; for the two fixed pulleys on each fixed pulley bracket, the fixedpulley close to one sides of rollers and the oil pumping rope between the corresponding rollers are in the vertical direction, each roller is provided with an oil pumping rope winding section and twolinkage rope winding sections, and each oil pumping rope winding section is located between the two corresponding linkage rope winding sections. By means of the one-machine double-well oil productiondevice and process, the problems mentioned in the background art can be effectively solved that the ground space is seriously wasted, the requirement for the structural strength of the derricks is high, the weight of work vehicles and other heavy equipment cannot be borne due to the excessive span of cover plates.

Owner:DAQING CITY HUAYU PETROLEUM MASCH MFG CO LTD

Clamping device for improving steel fixing capacity

InactiveCN107740584AEasy to fixImprove welding precisionBuilding material handlingEngineeringScrew thread

The invention discloses a clamping device for improving the steel fixing capacity. The clamping device comprises a bottom seat. The top of the bottom seat is provided with two movable blocks. The movable blocks can move on the bottom seat in the horizontal direction. The top of each movable block is provided with a supporting barrel. Each supporting barrel is provided with a supporting rod. The supporting rods can move in the axial direction of the supporting barrels. The top of each supporting rod is provided with a supporting block. An opening used for placing steel is formed in the side wall of the each supporting block. The top of each supporting block is provided with a pressing rod. The pressing rods are connected through threads. The pressing rods are rotated, the bottom ends of thepressing rods can move to the interior of the openings. A connecting plate is further arranged between the supporting barrels. A plurality of positioning holes are formed in the connecting plates. Apositioning rod is further arranged on the side wall of each supporting barrel. The positioning rods are inserted in the positioning holes in a penetrating mode. According to the clamping device for improving the steel fixing capacity, the to-be-welded steel can be stabilized and fixed, and the steel welding precision is improved.

Owner:廖方奎

Method for quickly taking down high books

InactiveCN107692571AFree height adjustmentMeet the needs of useBook cabinetsBook-troughsEngineeringFootplate

Owner:华蓥市双河小学

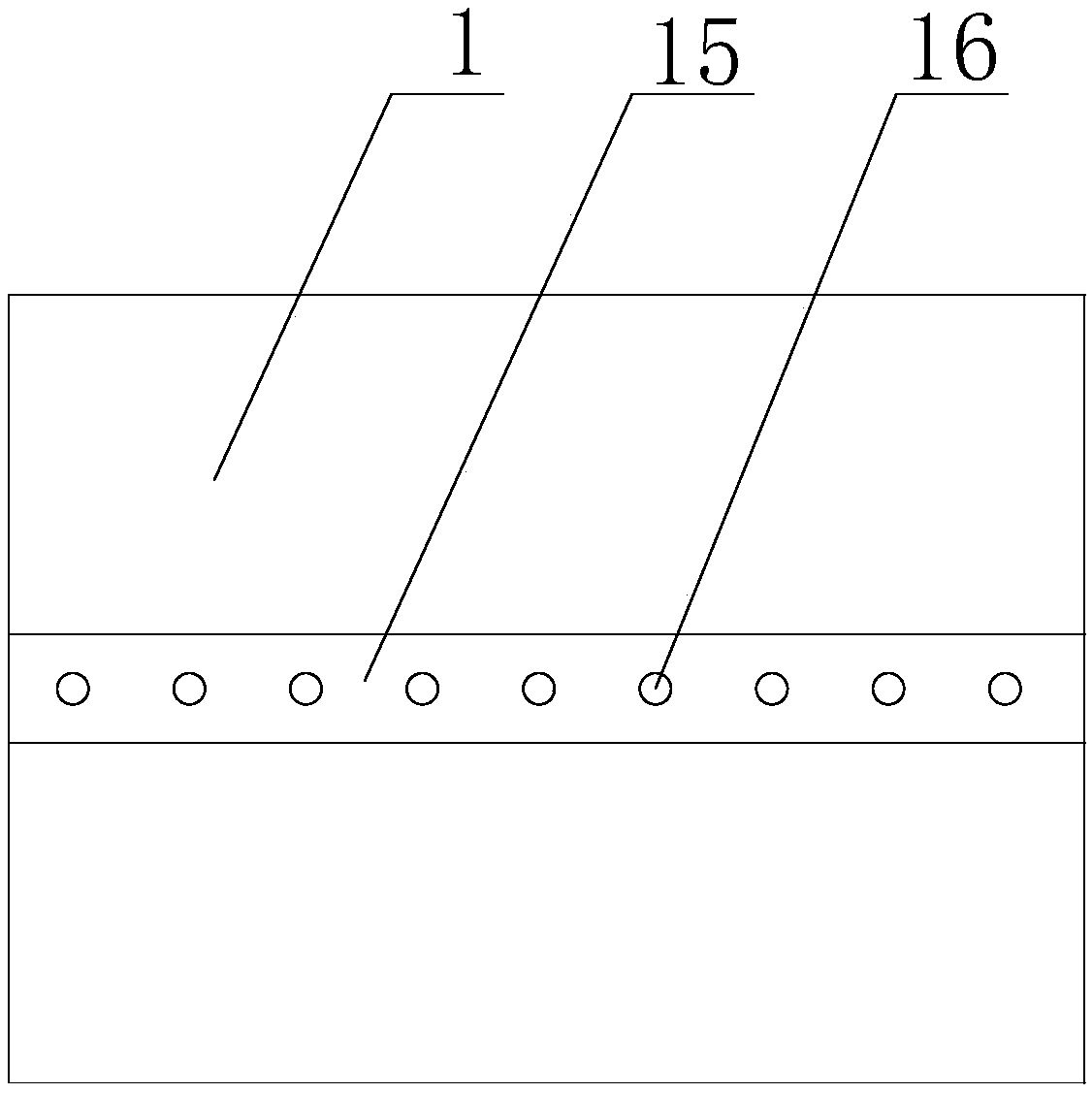

A multifunctional top wall decorative board

The invention belongs to the technical field of top wall decorative boards, in particular to a multifunctional top wall decorative board, which includes a first keel, a second keel and a decorative board; The distance is arranged linearly; the top of the first keel is fixed with a suspender that fixes the first keel to the top wall; the bottom of the first keel is provided with a T-shaped slide rail; there are several sets of second keels below the first keel; In the present invention, by setting the movable push plate and the columnar block, the contraction and ejection of the columnar block can be controlled by pushing the movable push plate through the pull cord, thereby facilitating the installation and disassembly of the decorative board, and bringing convenience to the installation and maintenance of lighting and heating equipment. It is convenient; at the same time, since the second keel is slidably installed in the T-shaped slide rail at the bottom of the first keel through the sliding assembly, this installation method does not require various buckles and other workpieces for fixing the first keel and the second keel, In turn, materials can be saved, and the installation time can be greatly shortened at the same time.

Owner:浙江奥普家居有限公司

Machining device for new energy vehicle charging station

InactiveCN108673281AThe spacing can be adjusted arbitrarilyEdge grinding machinesGrinding carriagesNew energyEngineering

The invention discloses a machining device for a new energy vehicle charging station. The machining device for a new energy vehicle charging station comprises a base; two vertical rods are arranged atthe top of the base and can move in the horizontal direction on the base, and a clamping block is arranged on each vertical rod; the clamping blocks can move in the vertical direction on the verticalrods, a storing groove is formed in each clamping block, and a fixing rod is arranged on each clamping block; the fixing rod is horizontally connected with the clamping blocks through threads, and the fixing rods are rotated ad can move into the storing grooves; a supporting rod is further arranged at the top of the base and can also move in the horizontal direction on the base, and a transverseplate is arranged on the supporting rod and can move in the vertical direction on the supporting rod; and a motor is arranged on the transverse plate and comprises an output shaft, the output shaft isinserted into the transverse plate in a penetrating mode, and a grinding tray is arranged at the tail end of the output shaft.

Owner:陈统宪

A manual adjustment system for arbitrary spacing of saw blades for cutting plates of different thicknesses

ActiveCN109014401BThe spacing can be adjusted arbitrarilyImplement pin-lock connectionMetal sawing devicesMechanical engineering

The invention discloses a manual adjusting system for any distance between saw blades for cutting plates of different thicknesses. A saw blade spline rotating shaft is arranged in the middle of an electric saw supporting frame. The multiple saw blades are arranged on the saw blade spline rotating shaft through spline sleeves in a sleeving manner. A motor is connected to one end of the saw blade spline rotating shaft. The saw blade spline rotating shaft and the saw blades on the saw blade spline rotating shaft are driven through the motor to work. Saw blade adjusting clamp blocks are arranged on the two sides of each saw blade, the saw blade adjusting clamp blocks on one corresponding sides of all the saw blades are arranged on a lead screw in a sleeving manner, and the two lead screws arecorrespondingly mounted on the two sides of the electric saw supporting frame. An adjusting nut is arranged at the position, on one side of each saw blade adjusting clamp block, of the corresponding lead screw. A nut limiting clamp groove is arranged on each adjusting nut in a surrounding manner. Clamp block limiting clamp grooves corresponding to the nut limiting clamp grooves are arranged on thesaw blade adjusting clamp blocks. A set of air cylinder is arranged on each saw blade adjusting clamp block, a pin block is arranged on a telescopic arm of each air cylinder, and the nut limiting clamp grooves and the clamp block limiting clamp grooves are in pinned connection by controlling the pin blocks through the air cylinders.

Owner:MIANYANG FEIYUAN TECH CO LTD

Implementation method for correcting reinforcing steel bars

InactiveCN110523891ACorrective satisfactionThe spacing can be adjusted arbitrarilySteel barBuilding construction

The invention discloses an implementation method for correcting reinforcing steel bars. The method comprises the following steps: firstly, a base is horizontally placed on the construction ground; a reinforcing steel bar to be corrected is horizontally placed in grooves of two supporting blocks, the protruding part of the reinforcing steel bar faces a pressing plate, then a movable rod is rotated,the two ends of the reinforcing steel bar are fixed to the supporting blocks, finally a driving mechanism is started, the pressing plate moves towards the protruding part of the reinforcing steel bar, and the protruding part of the reinforcing steel bar is corrected through the pressing plate.

Owner:蒲芳芳

Method capable of removing dust attaching to books on shelf

InactiveCN107639079AFree height adjustmentMeet the needs of useCleaning using gasesEngineeringComputer engineering

Owner:华蓥市双河小学

Steel bar straightening equipment for electric power construction

The invention discloses steel bar straightening equipment for electric power construction. A base is included; two supporting blocks are arranged at the top of the base. The supporting block can moveon the base; arc-shaped grooves are formed in the tops of the supporting blocks; movable rods are arranged on the side walls of the supporting blocks. The movable rod is horizontally connected with the supporting block through a thread;the movable rod can be rotated to move into the groove; a driving mechanism is further arranged at the top of the base; the driving mechanism can move on the base;the driving mechanism comprises an output shaft, a pressing plate is arranged at the output end of the output shaft, a movable block is further arranged between the two supporting blocks, the movableblock can move on the base towards the two supporting blocks; an opening is further formed in the side wall, facing the pressing plate, of the movable block, and a heating layer is further arranged onthe inner wall of the opening.

Owner:范亦能

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com