Auxiliary device for improving cylindrical structure part machining efficiency

A technology of processing efficiency and auxiliary devices, which is applied in the field of mechanical parts processing, can solve the problems of parts quality impact, processing parts scrapping, falling off, etc., and achieve the effect of improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

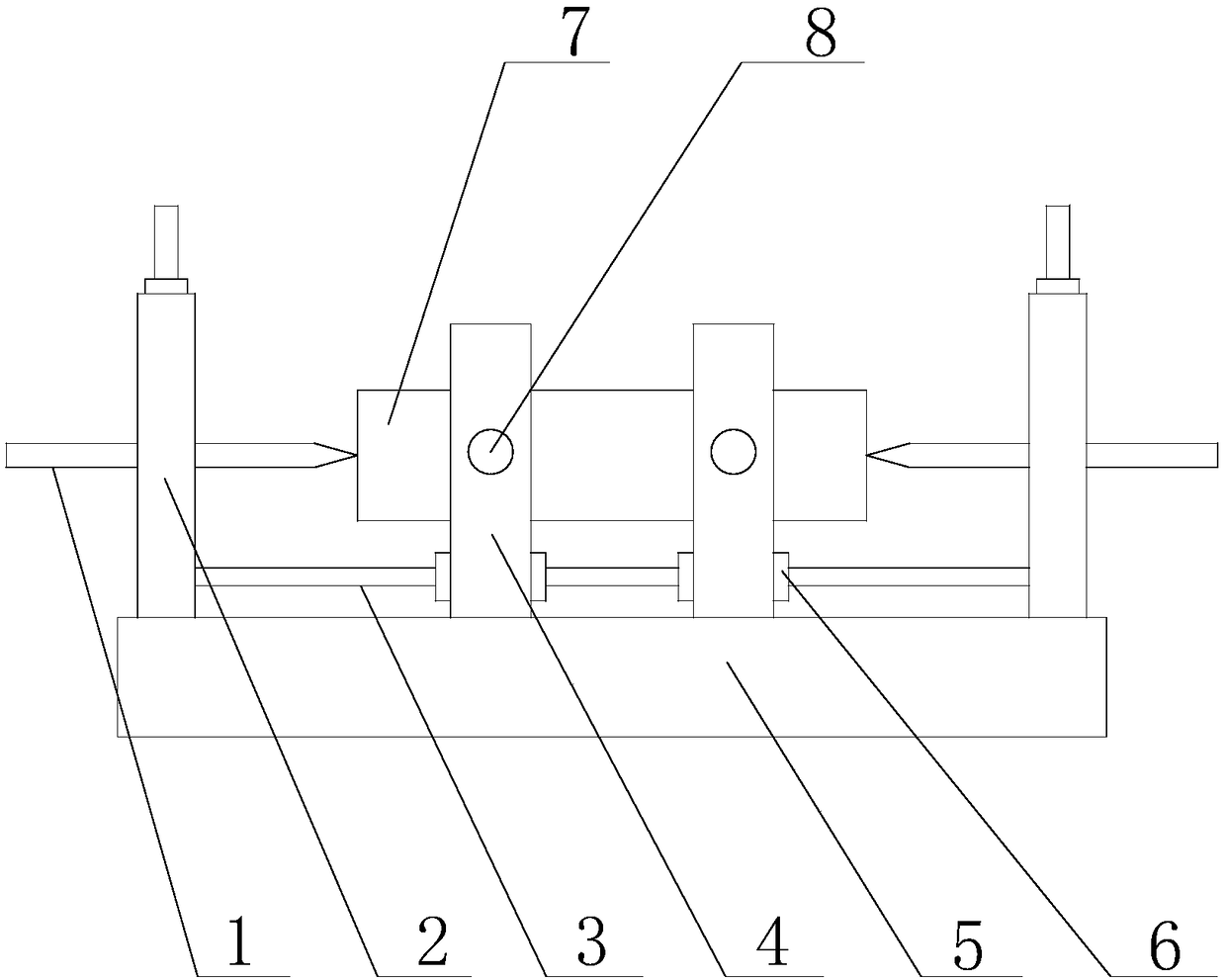

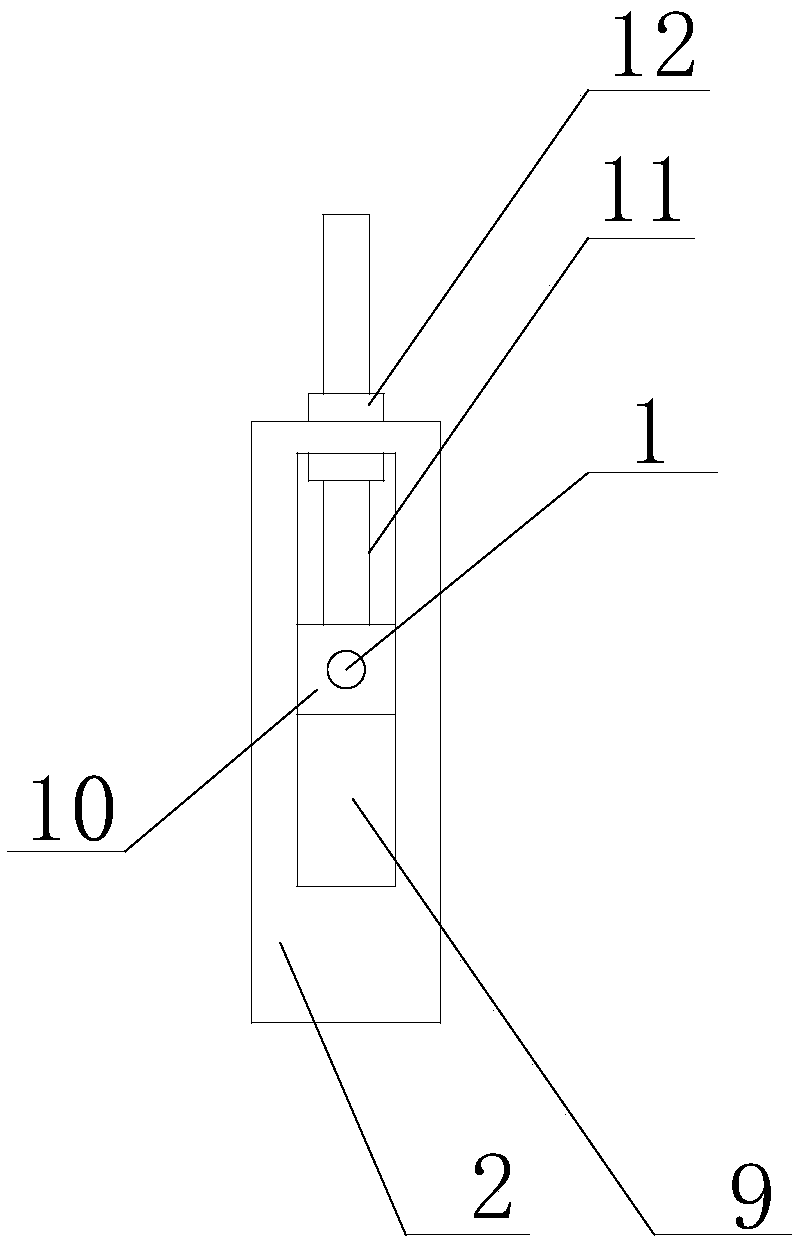

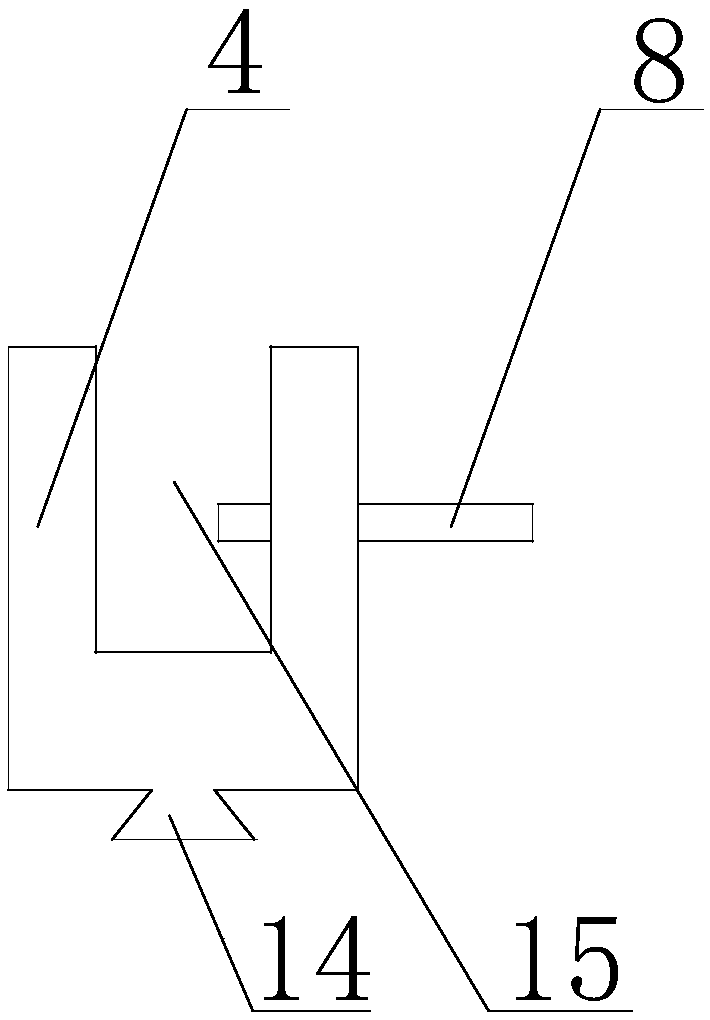

[0027] Such as Figure 1 to Figure 5 As shown, the auxiliary device for improving the processing efficiency of cylindrical structural parts in the present invention includes a base 5, the base 5 is a rectangular structure, and the top of the base 5 is provided with two vertical plates 2, and the two vertical plates 2 are respectively located at the bottom of the base 5. On both sides of the axis, strip grooves 9 are provided on the vertical plate 2, and the two side walls of the vertical plate 2 are connected by the strip grooves 9. Movable blocks 10 are arranged in the strip grooves 9, and the movable blocks 10 Both ends of the movable block 10 are provided with second sliders 16, and both sides of the inner wall of the strip groove 9 are provided with chutes matching the second sliders 16, and the second sliders 16 at both ends of the movable block 10 are respectively located in the bar shape In the two chutes of the groove 9, the second slider 16 can move in the chute, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com