Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Simple casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Be-RE high-strength heat-resisting aluminum alloy material and production method thereof

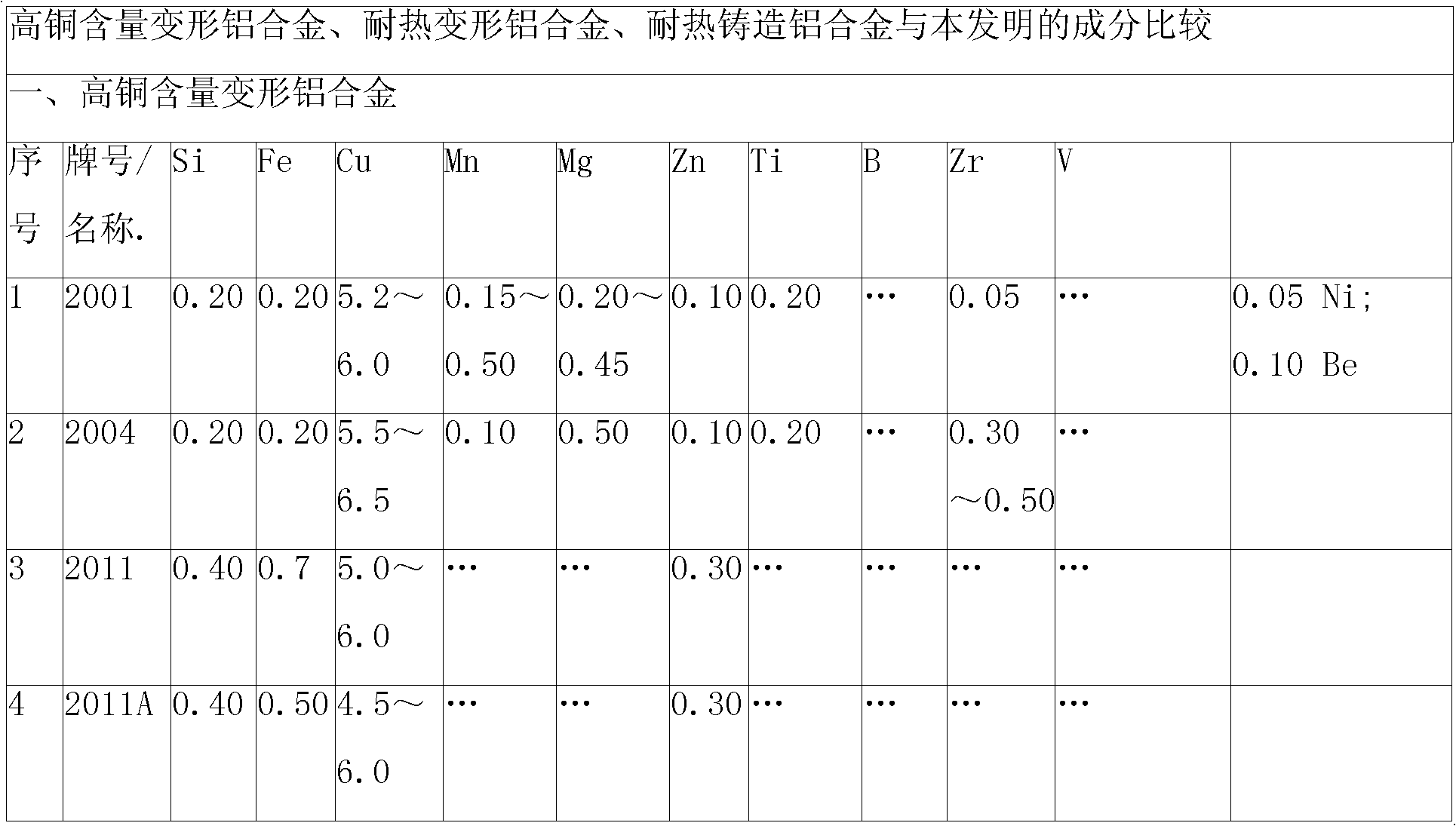

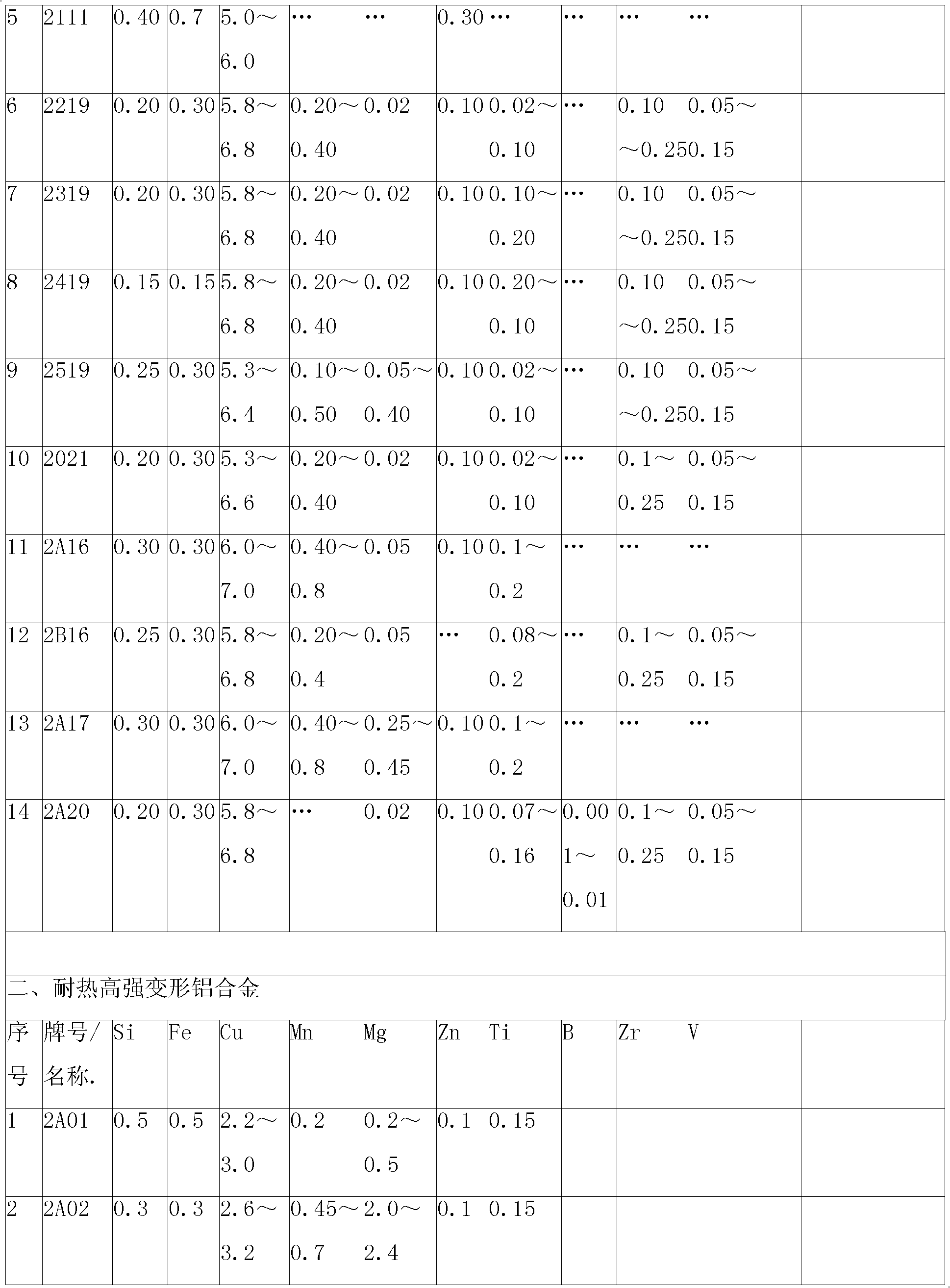

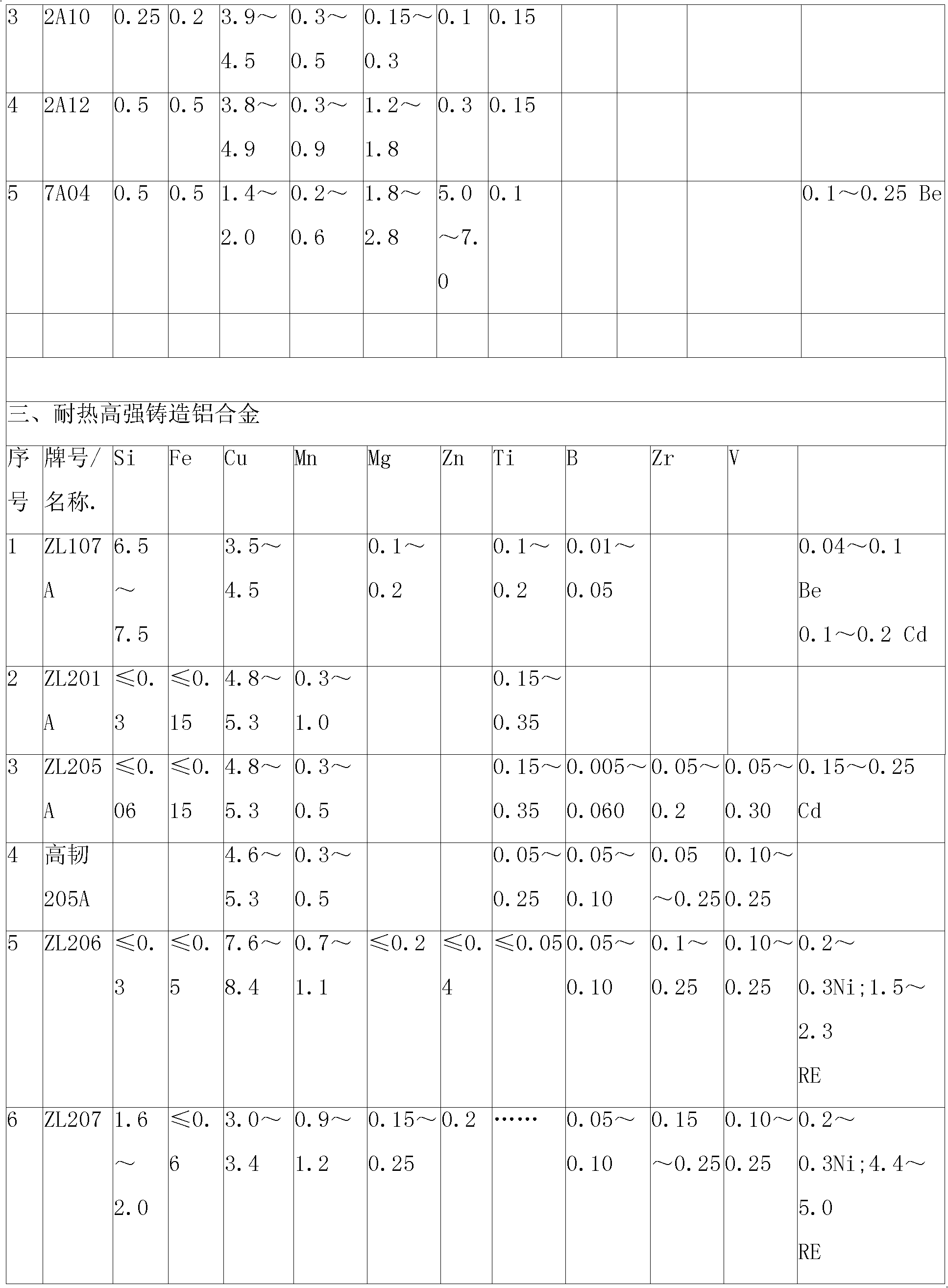

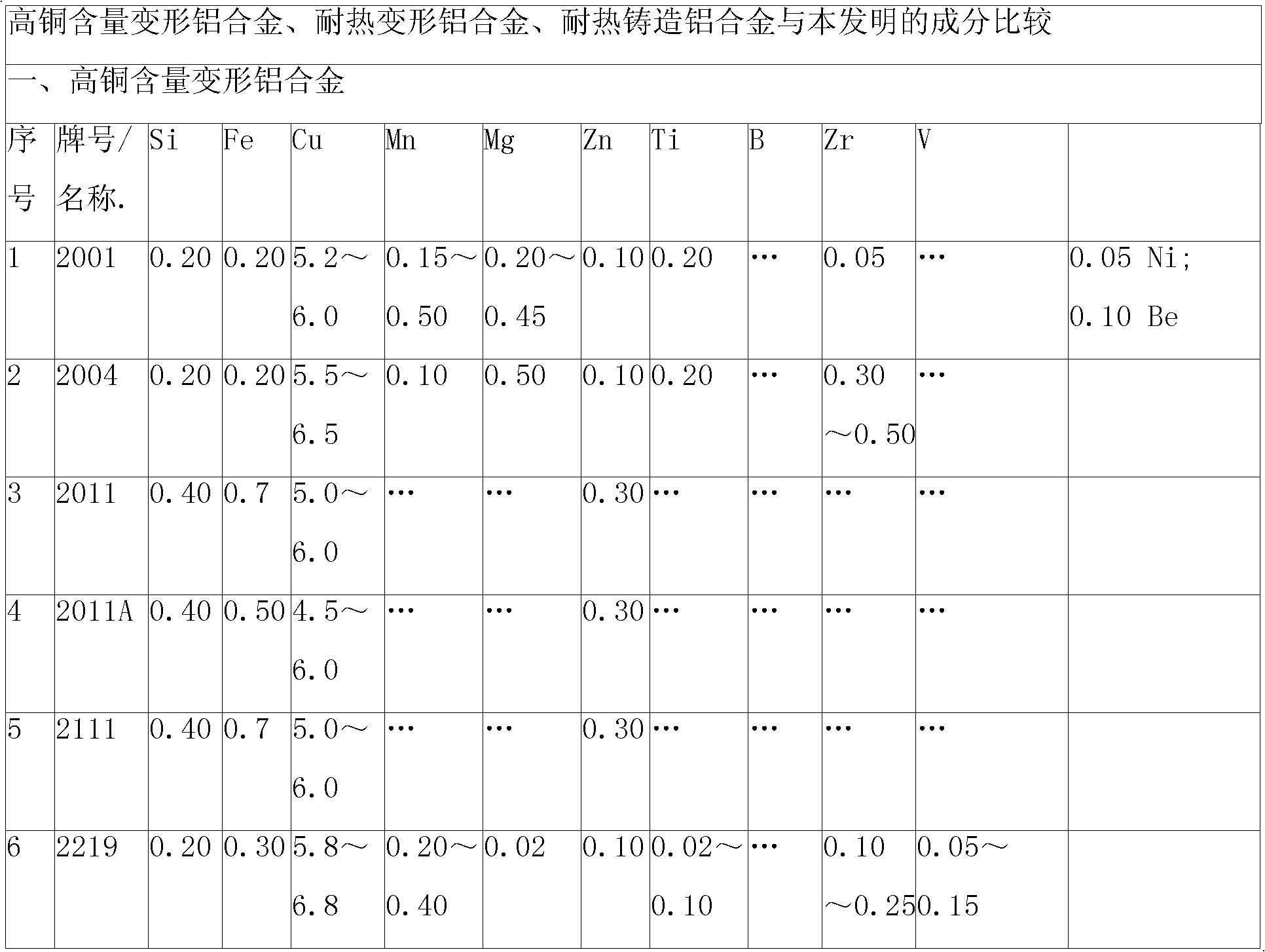

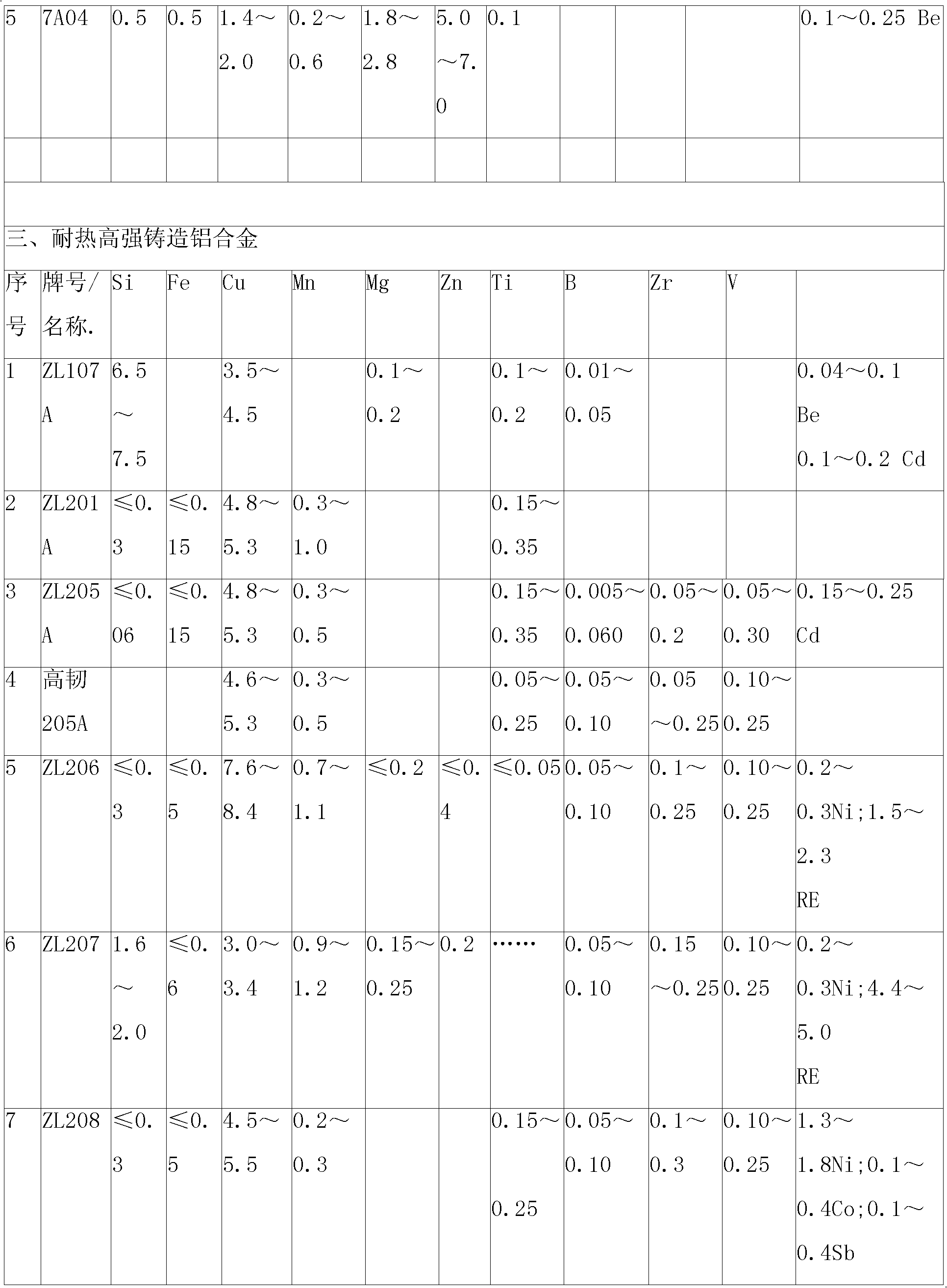

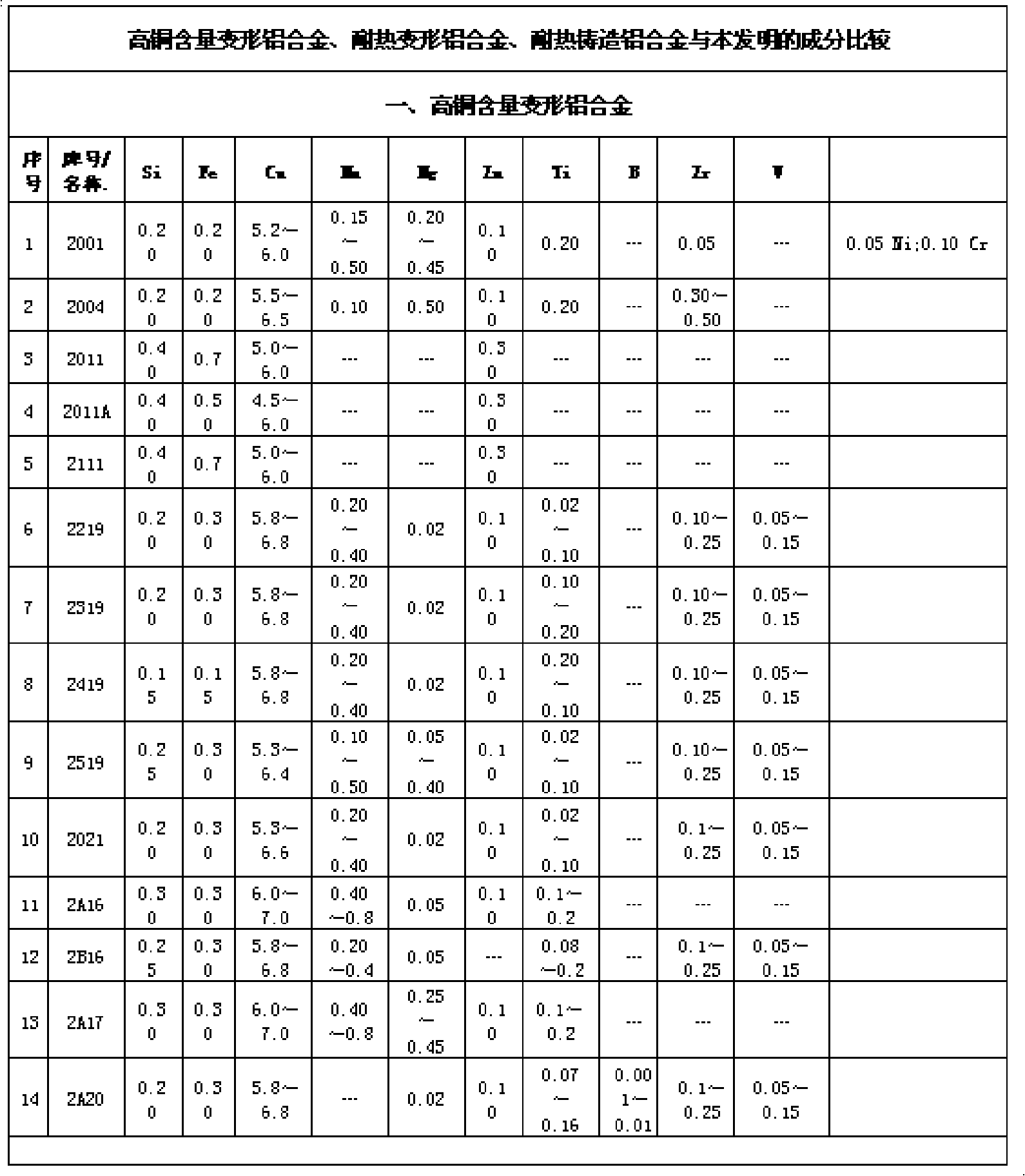

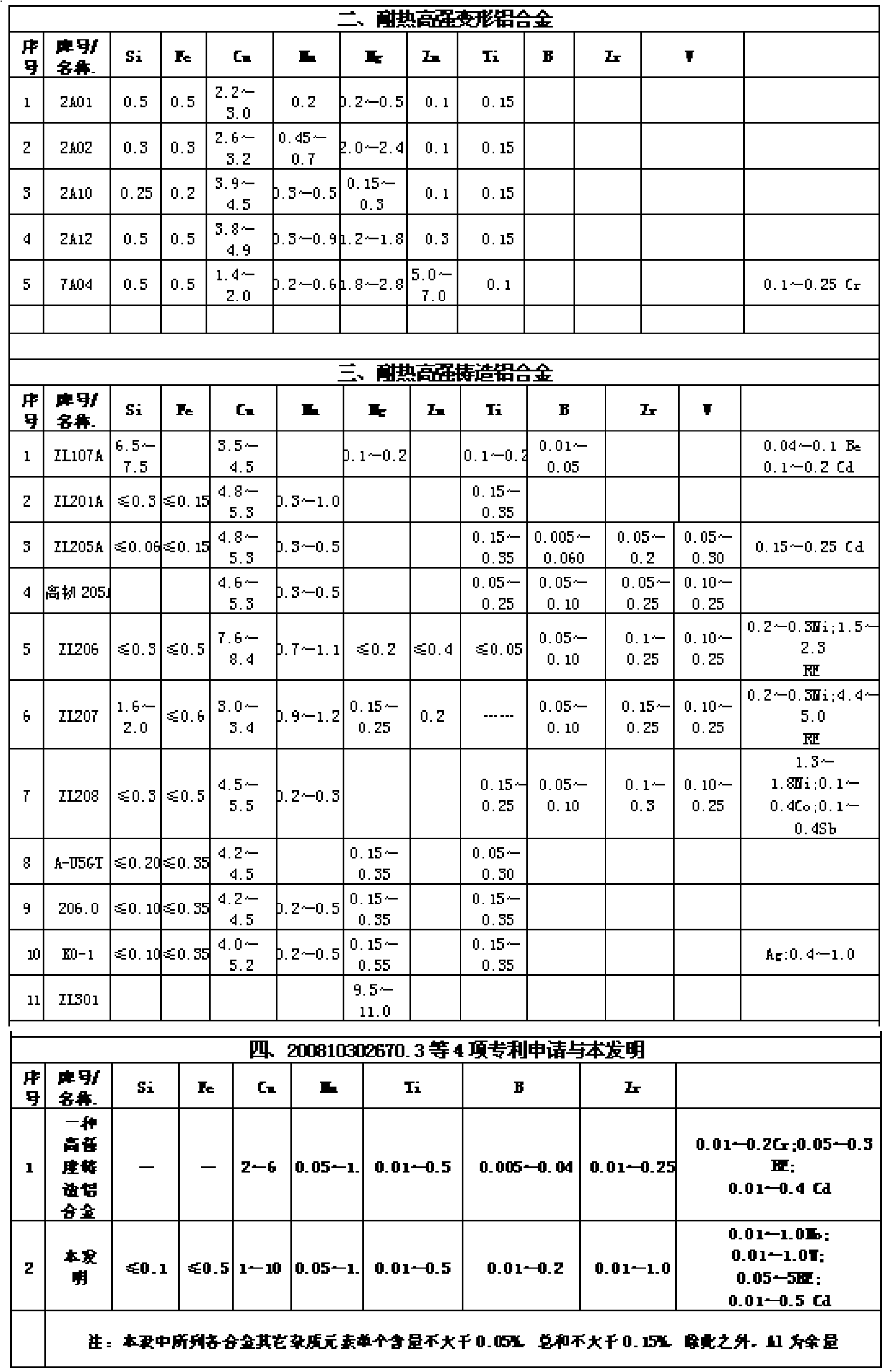

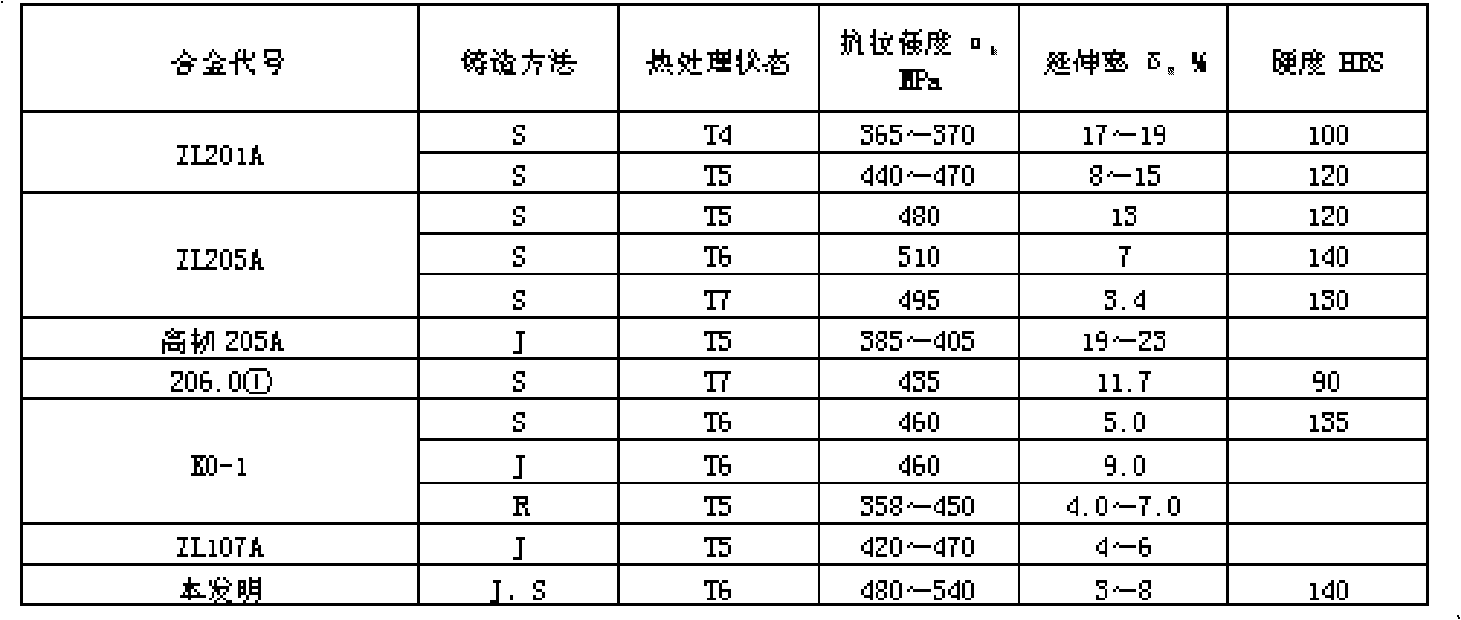

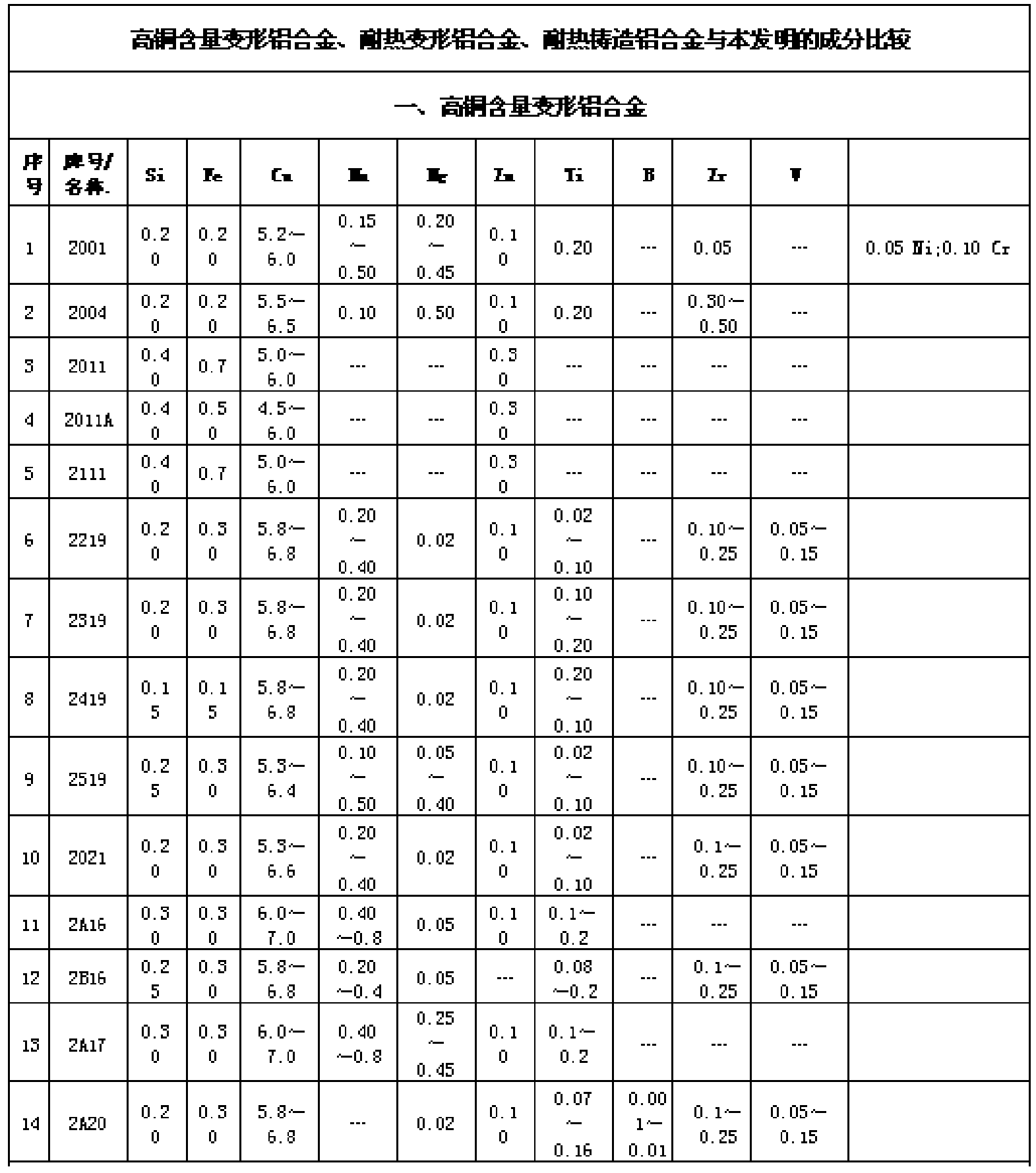

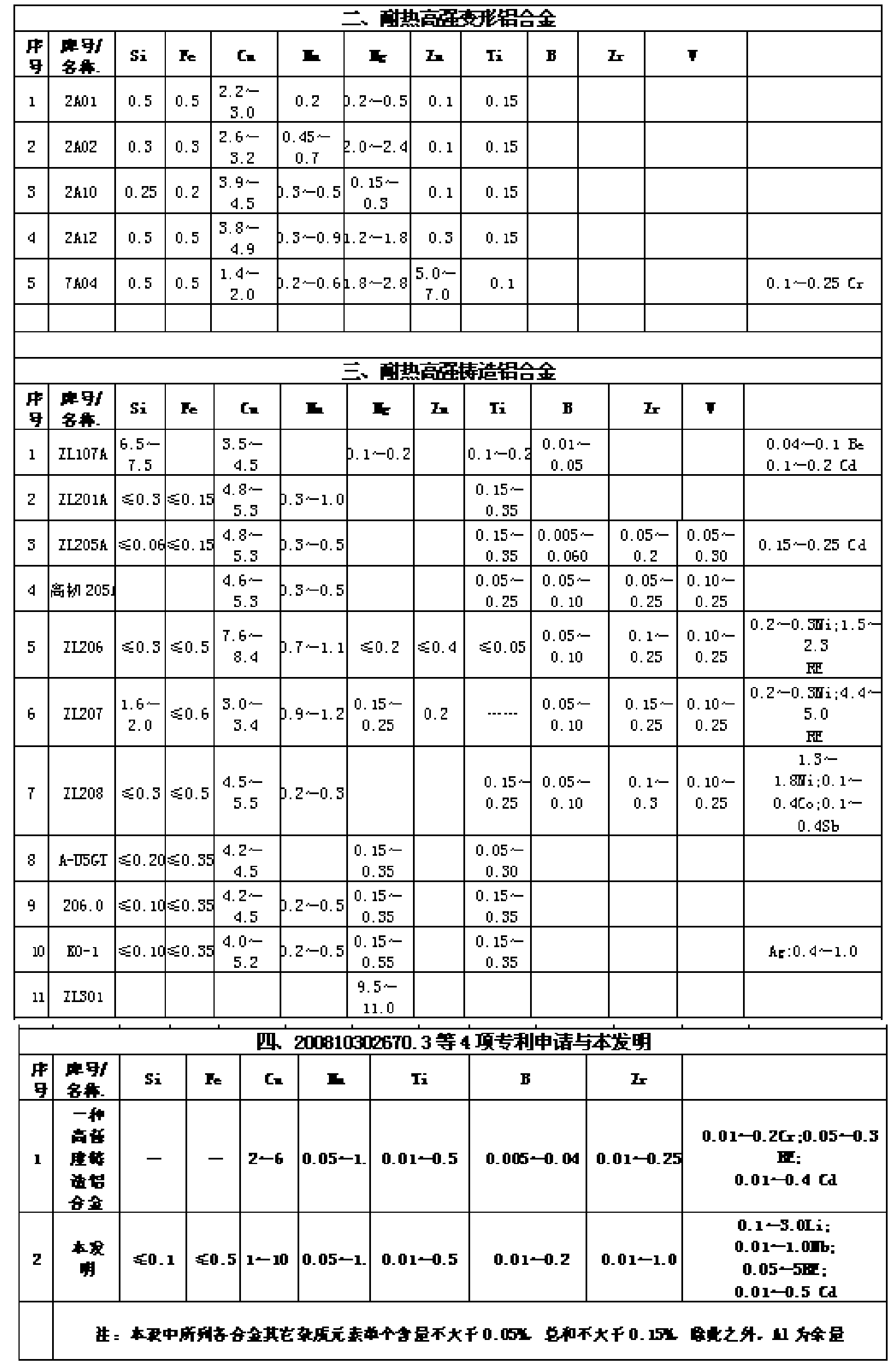

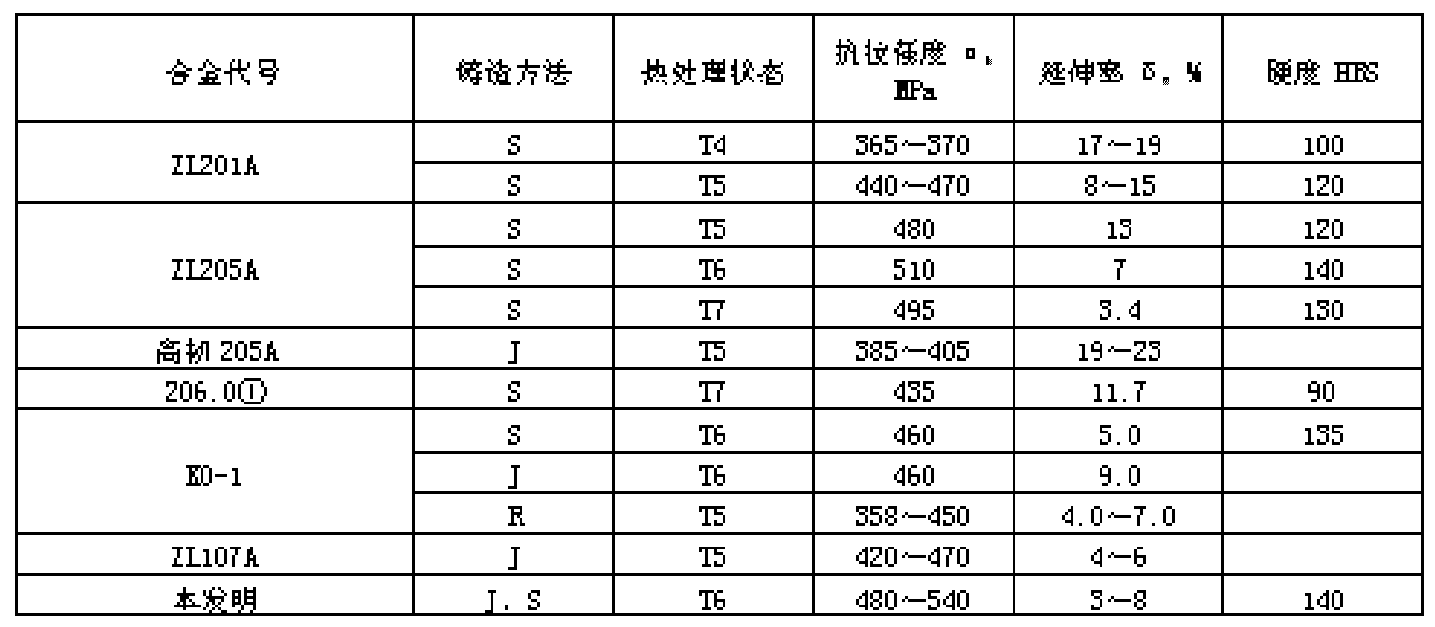

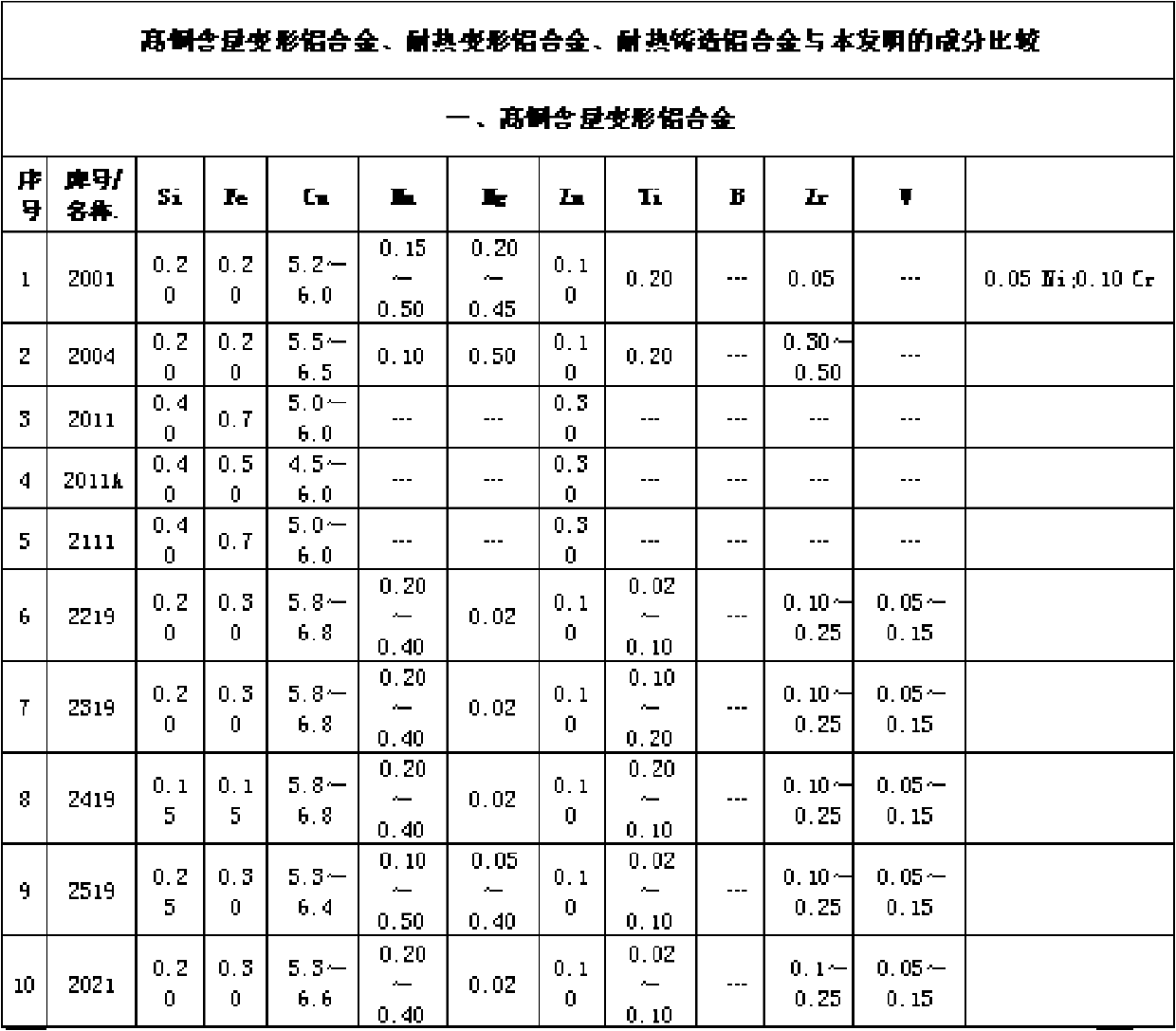

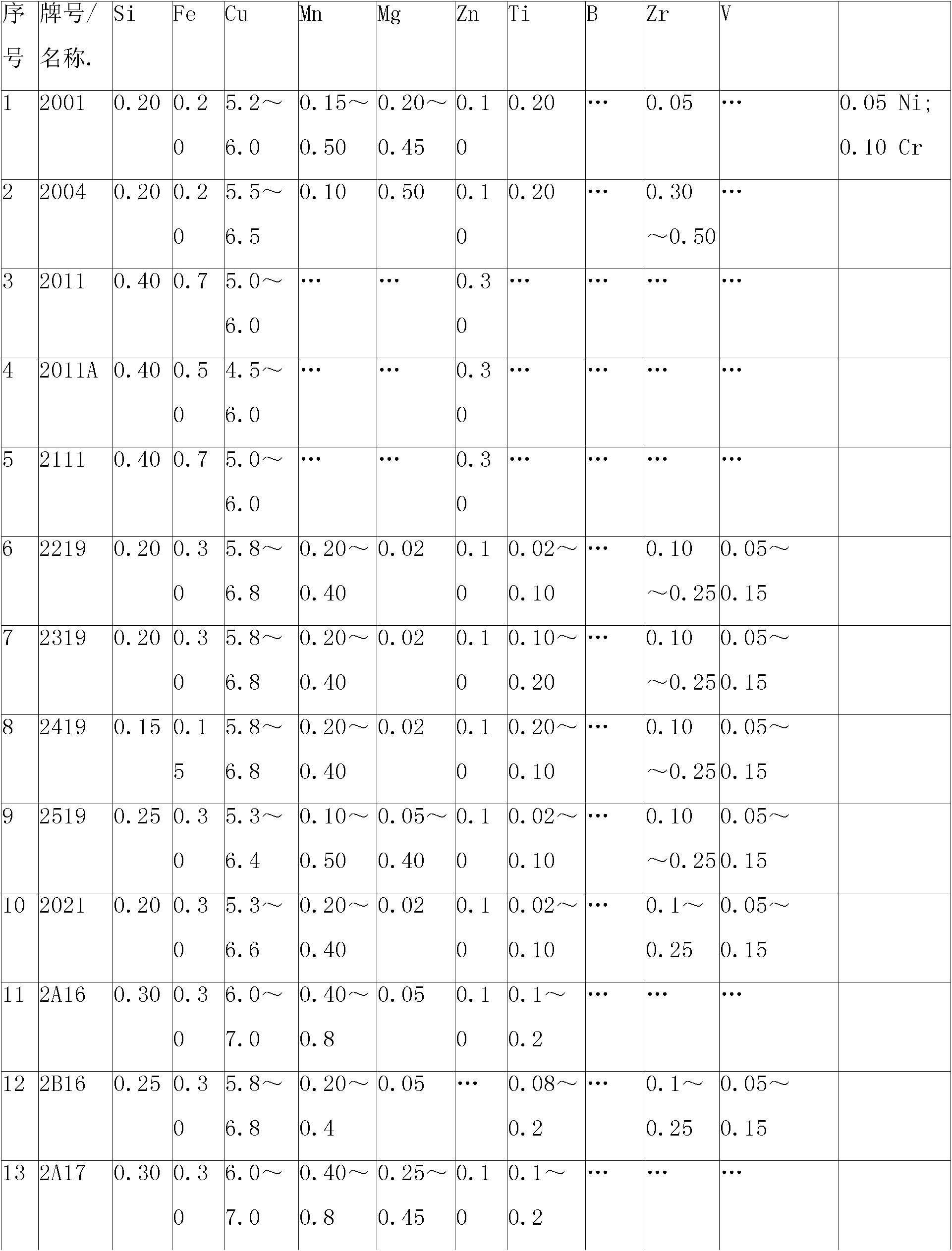

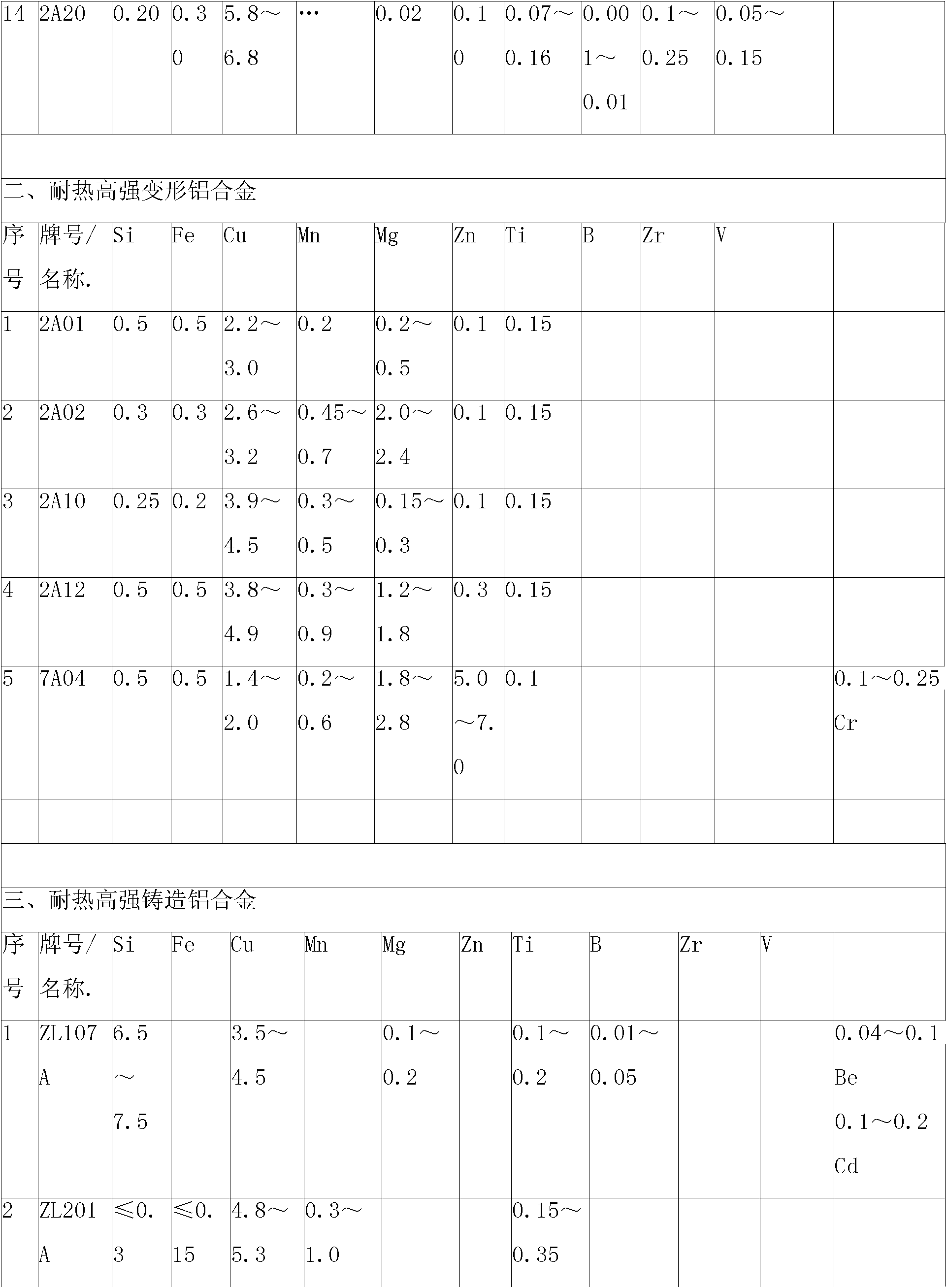

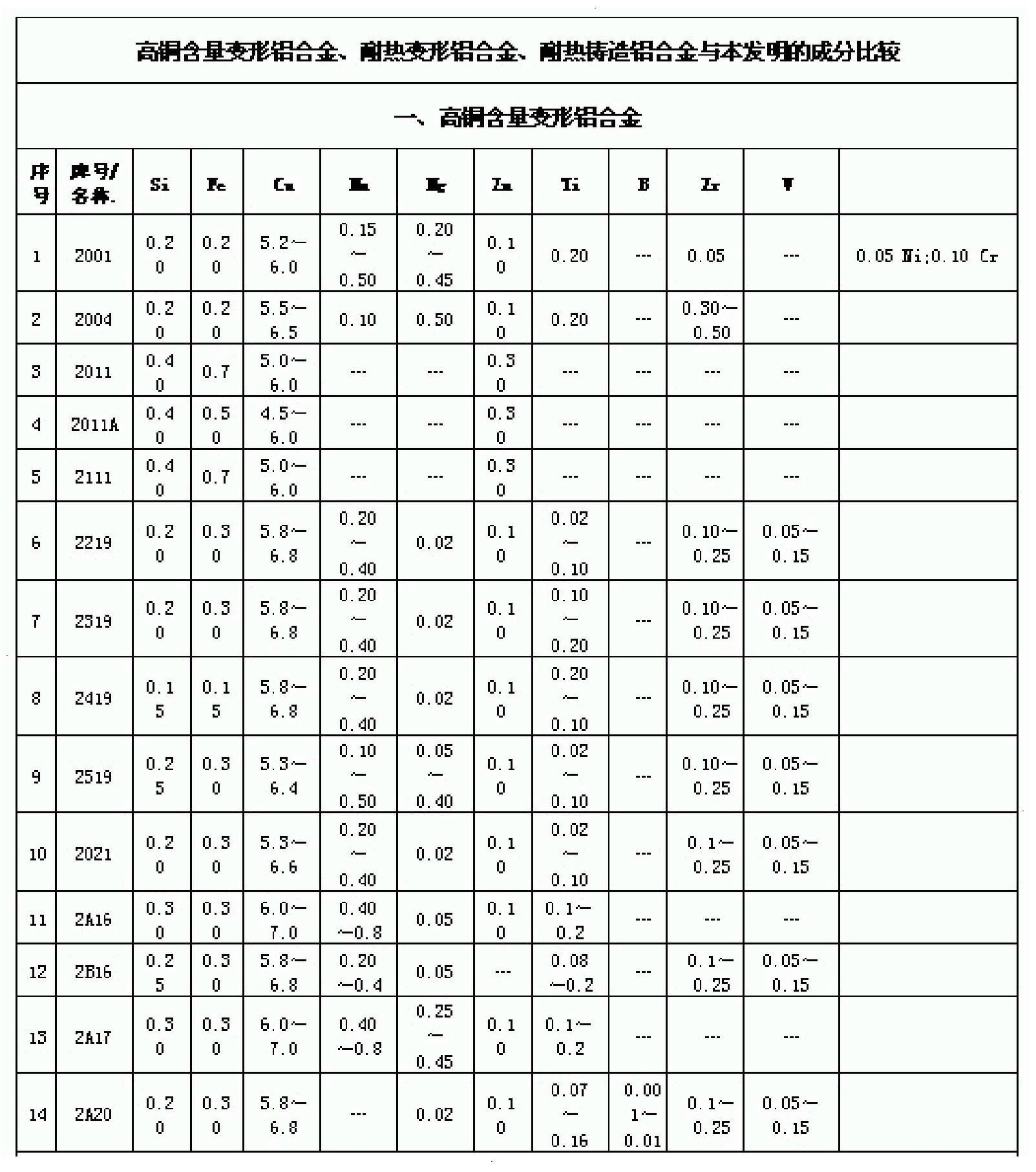

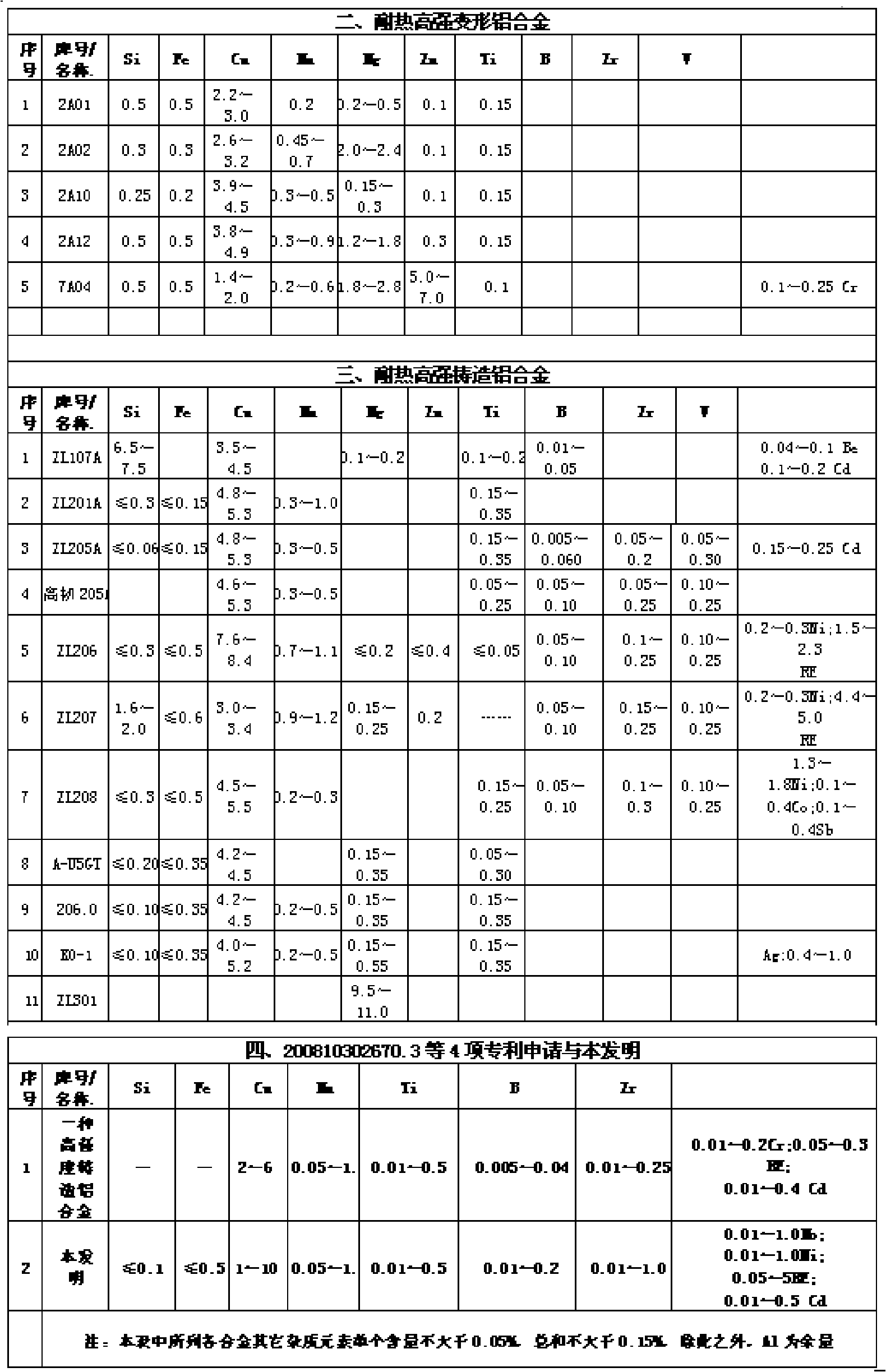

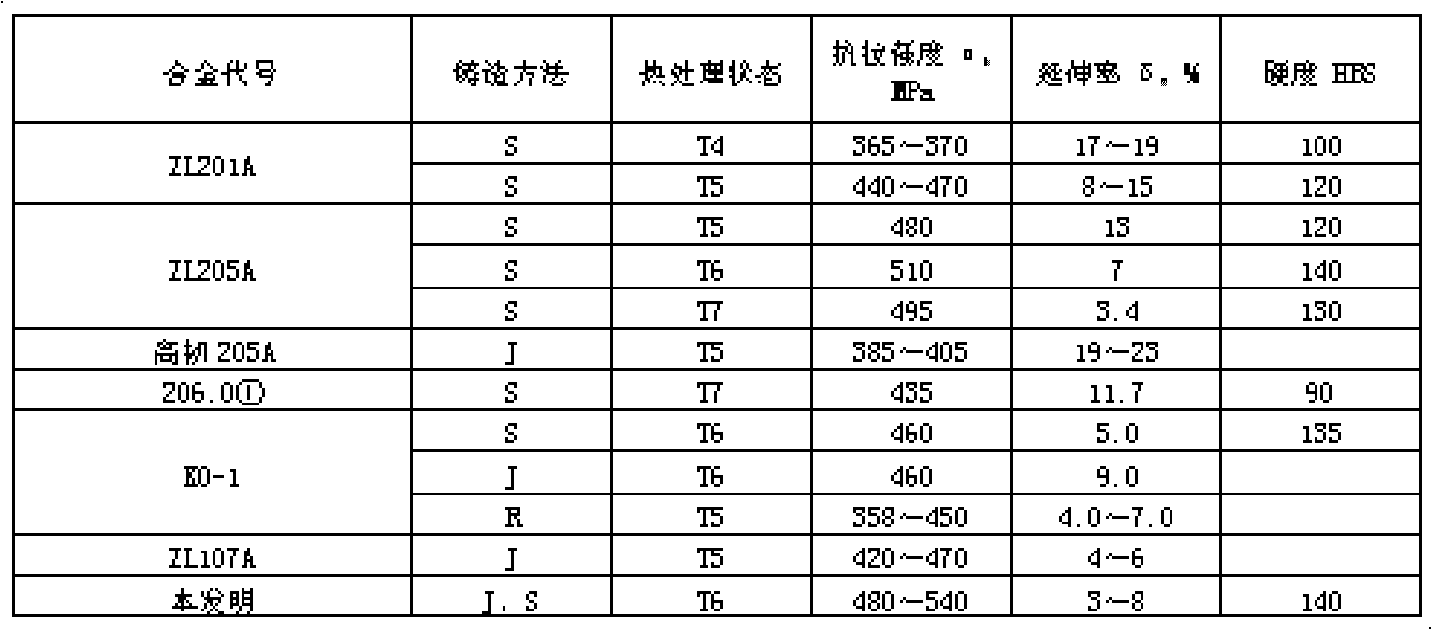

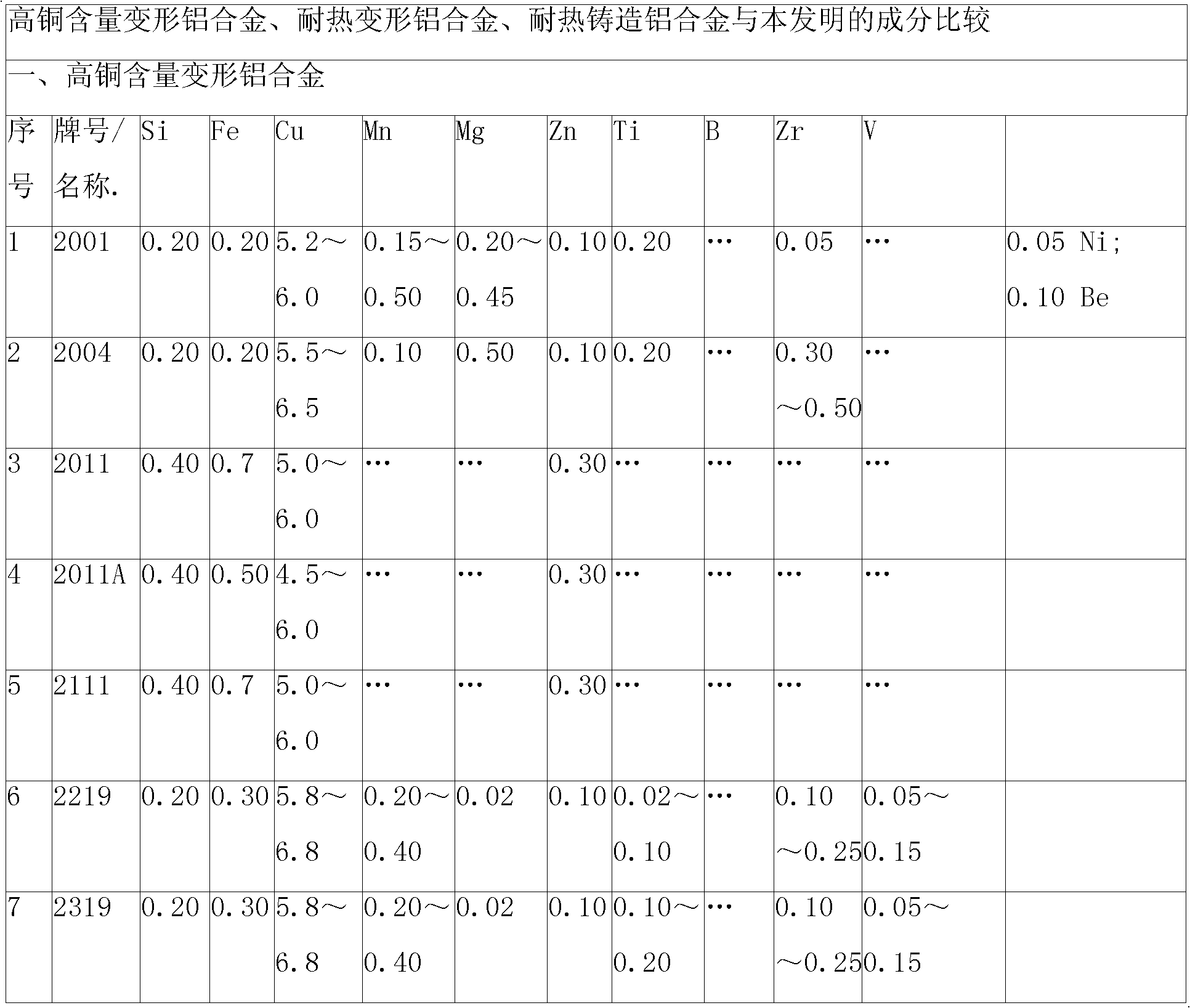

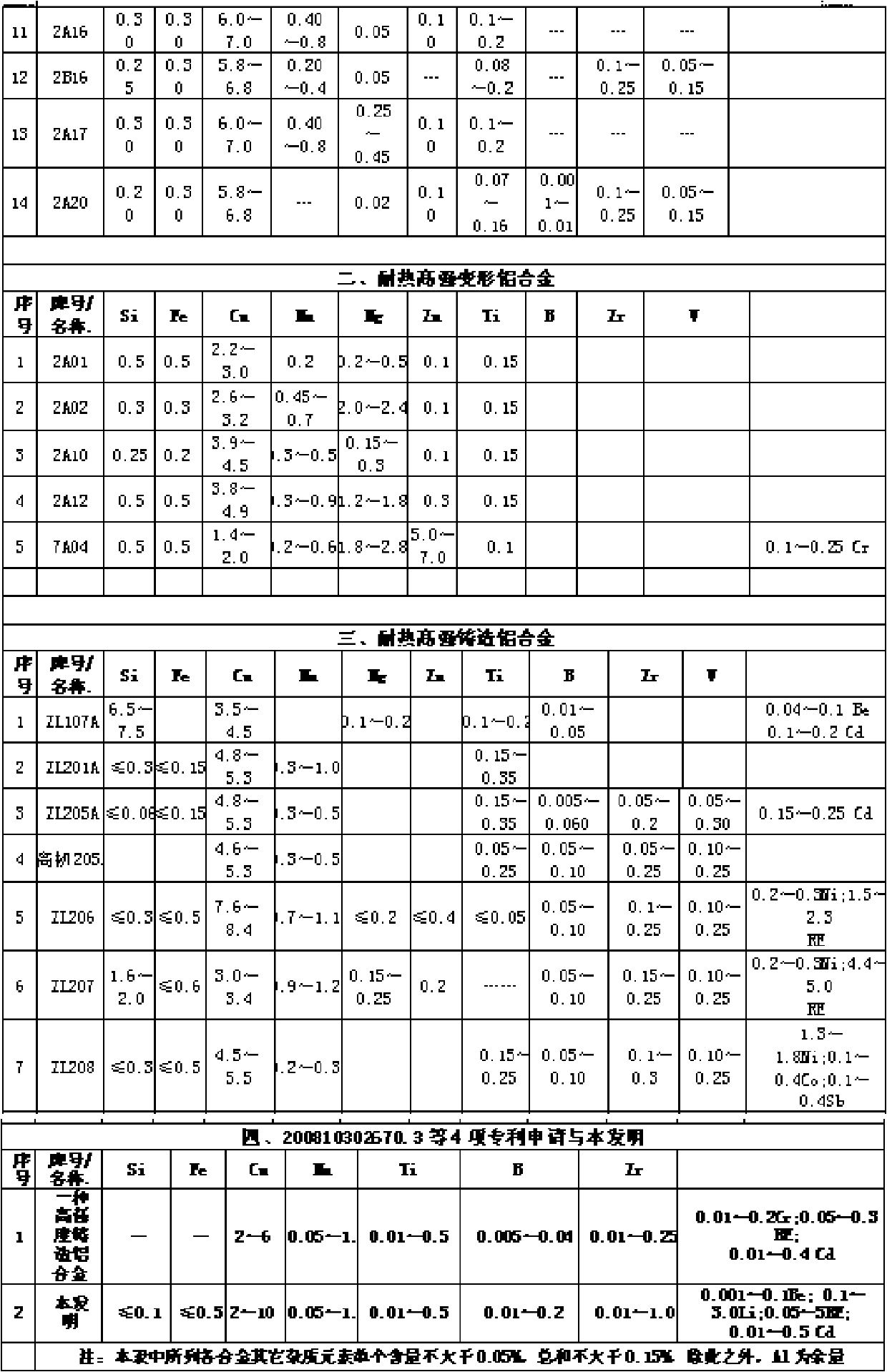

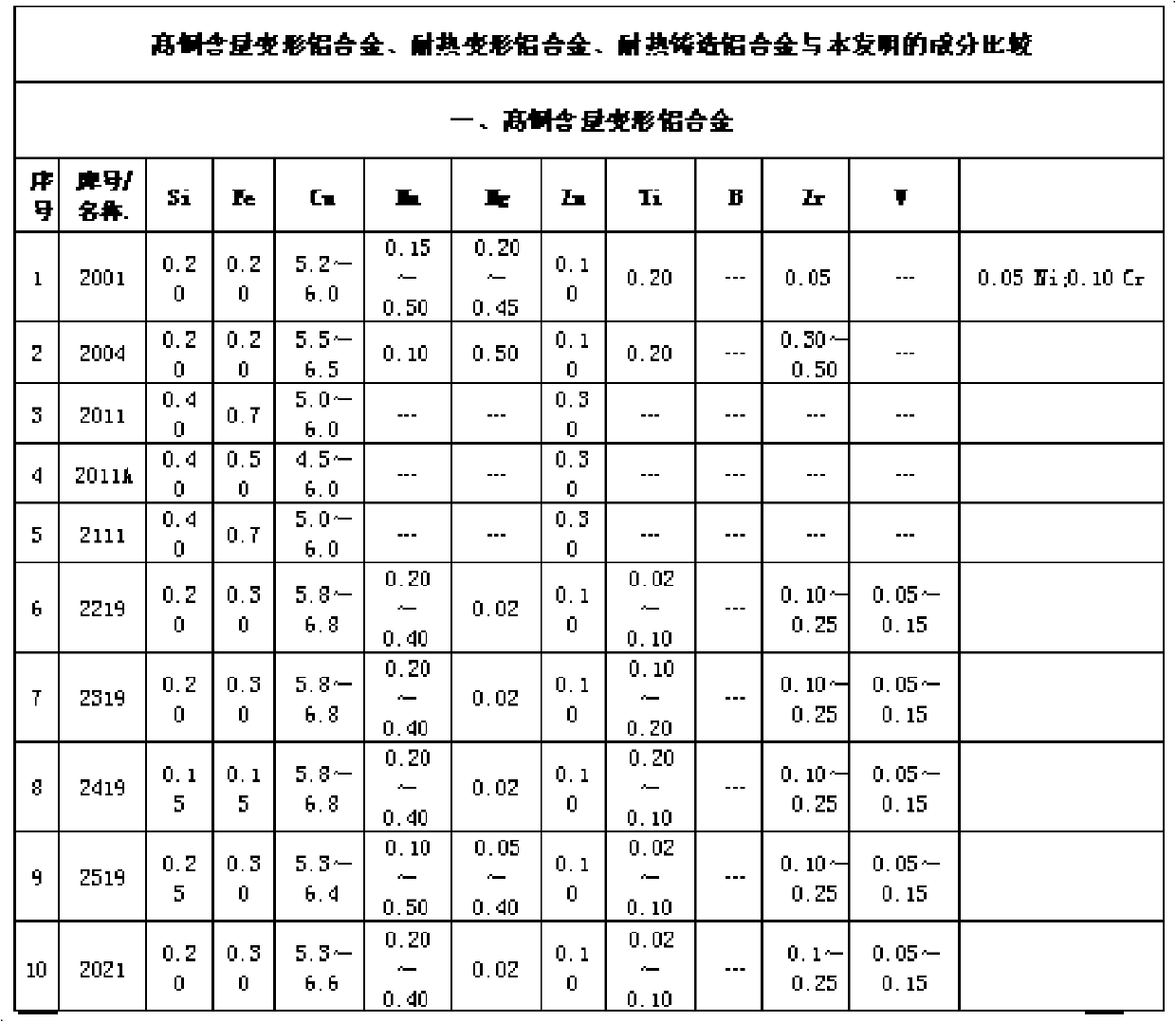

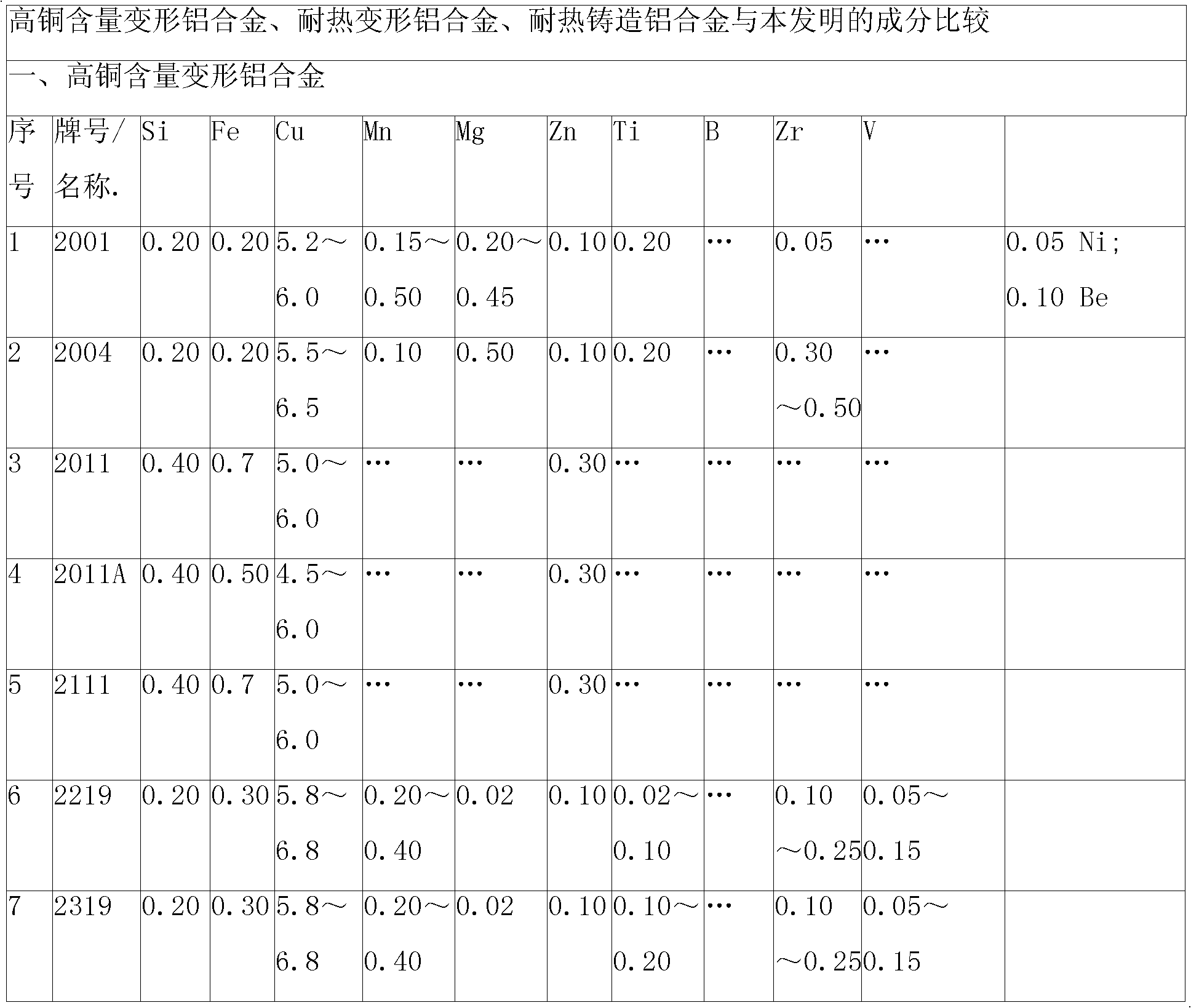

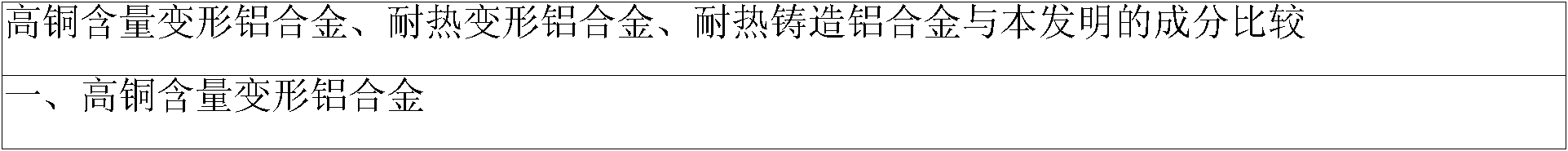

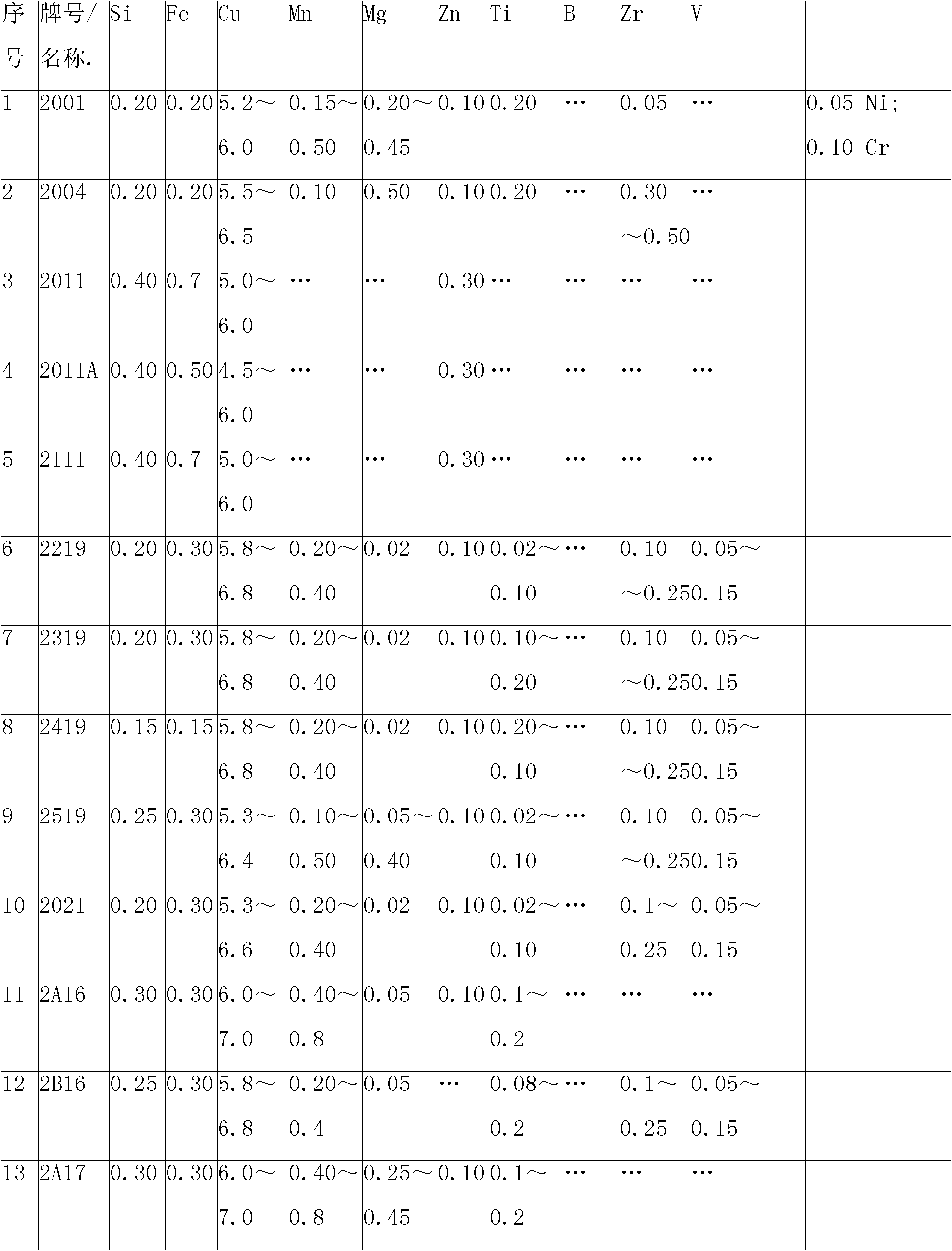

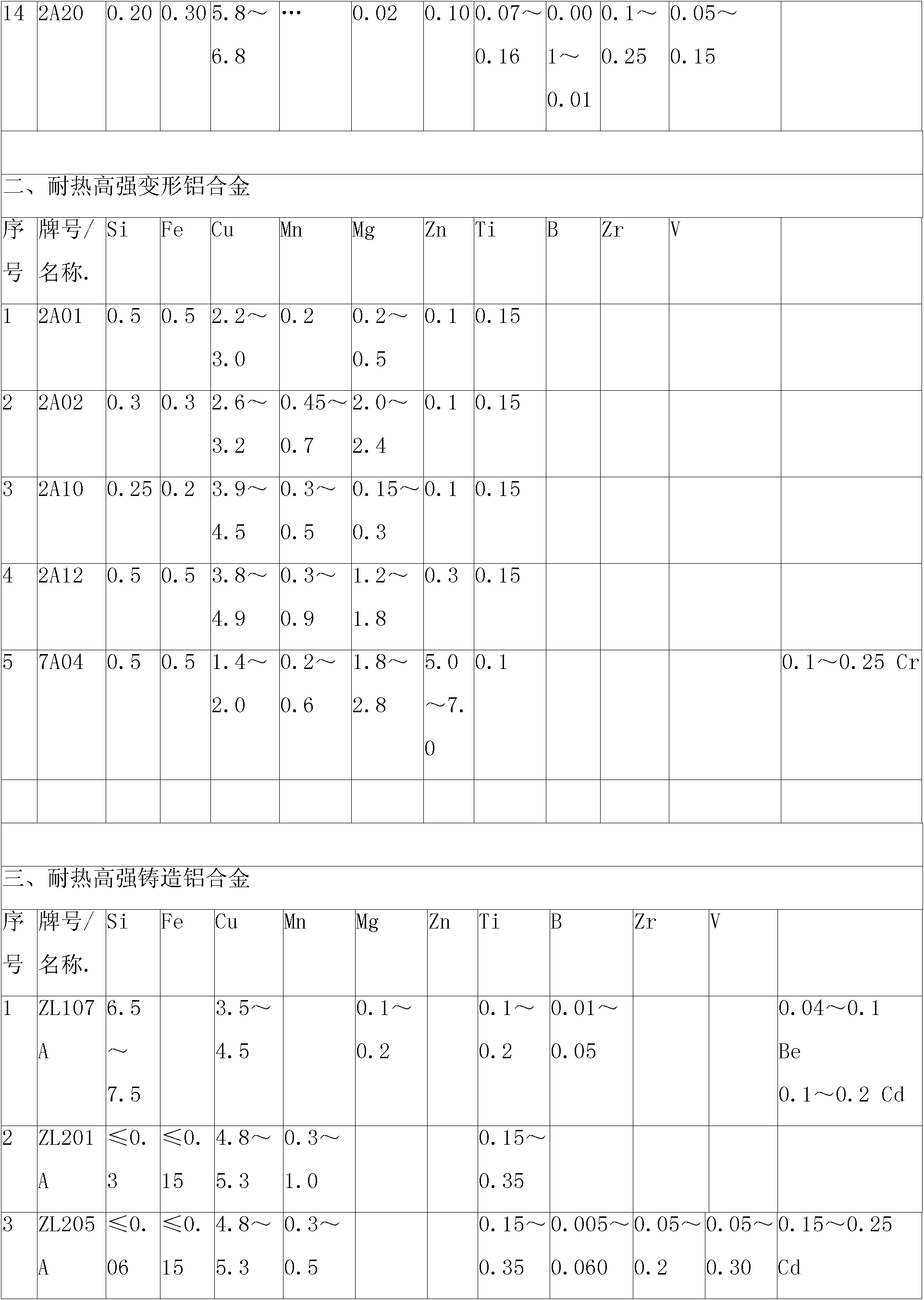

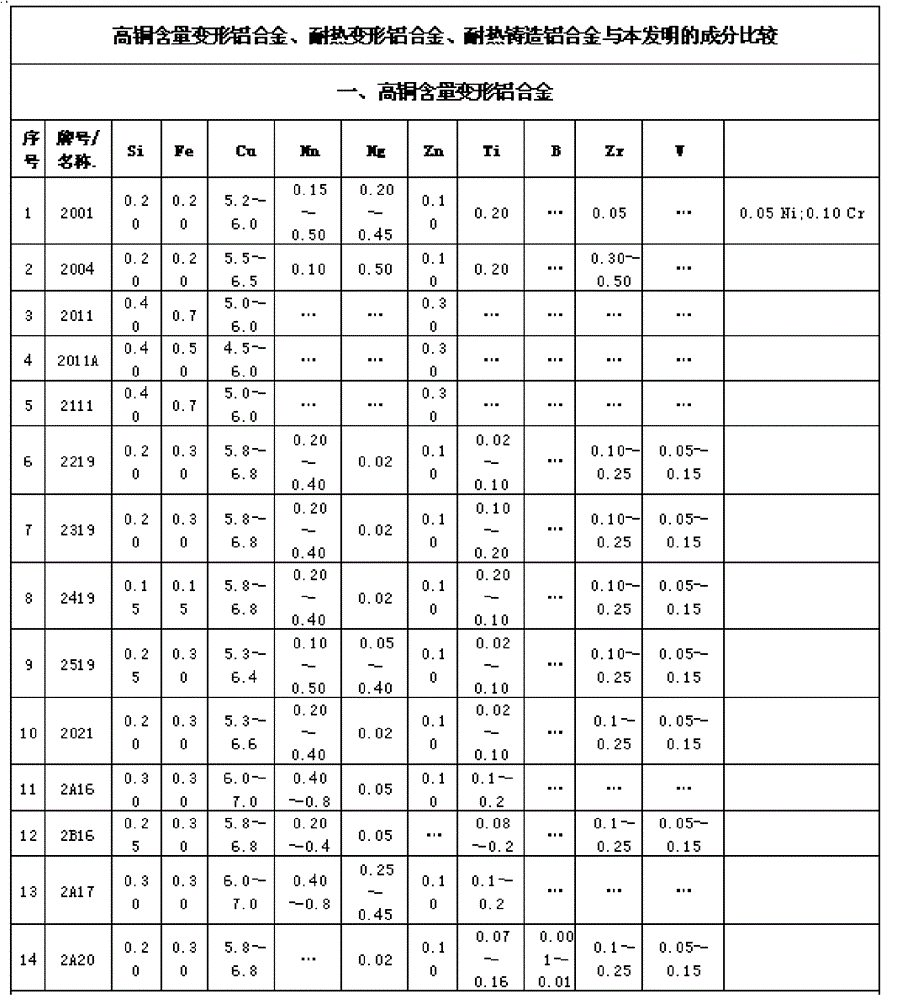

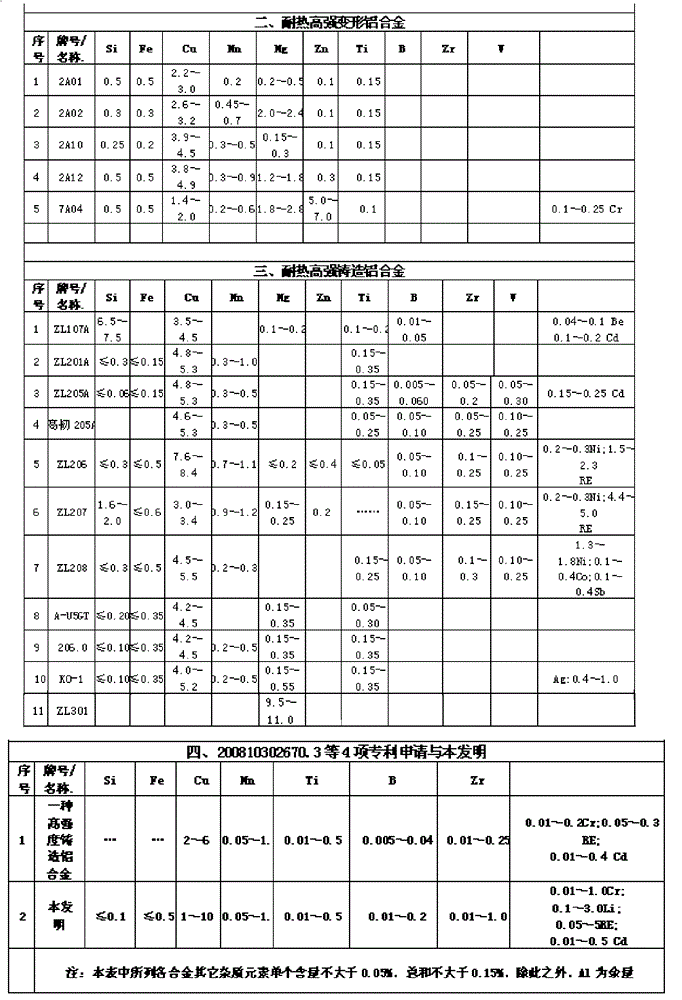

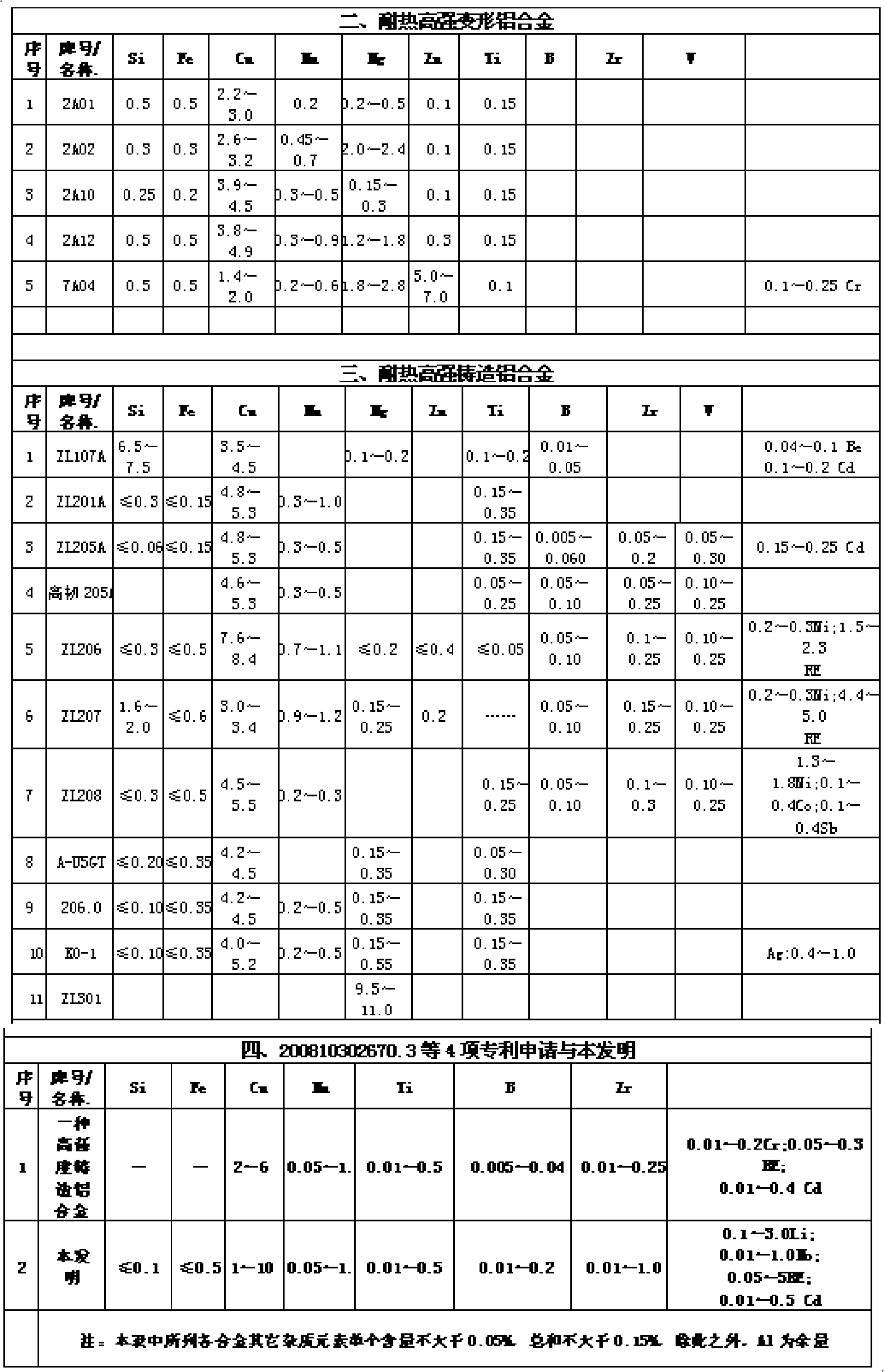

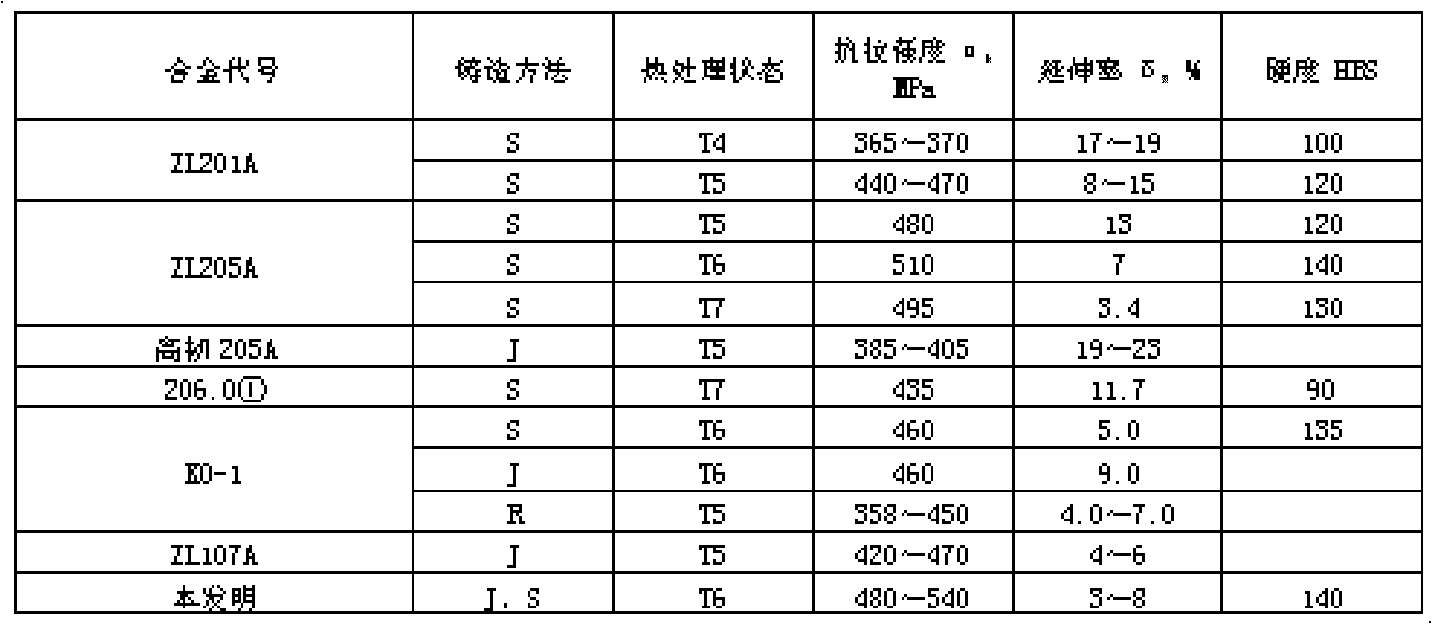

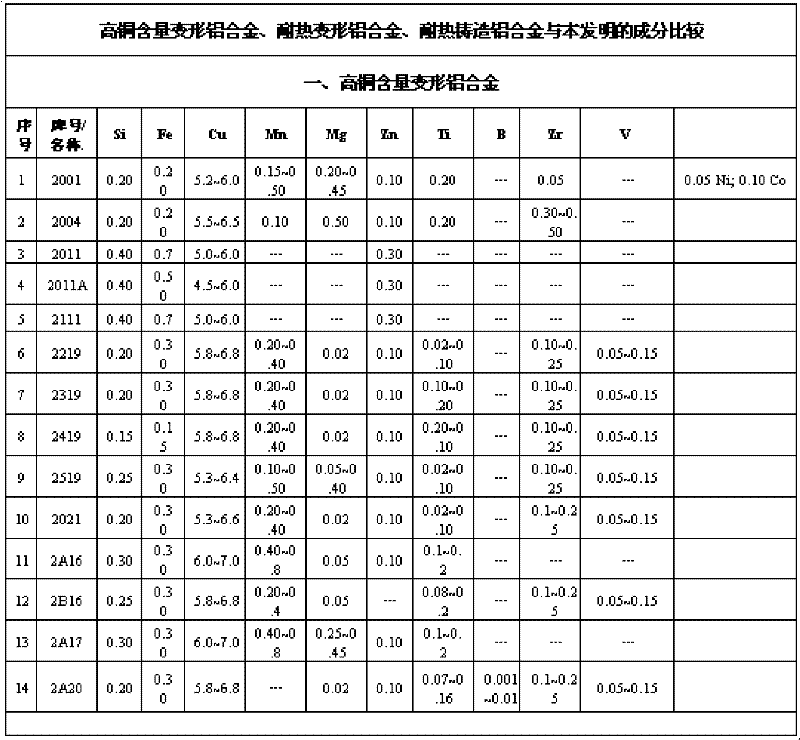

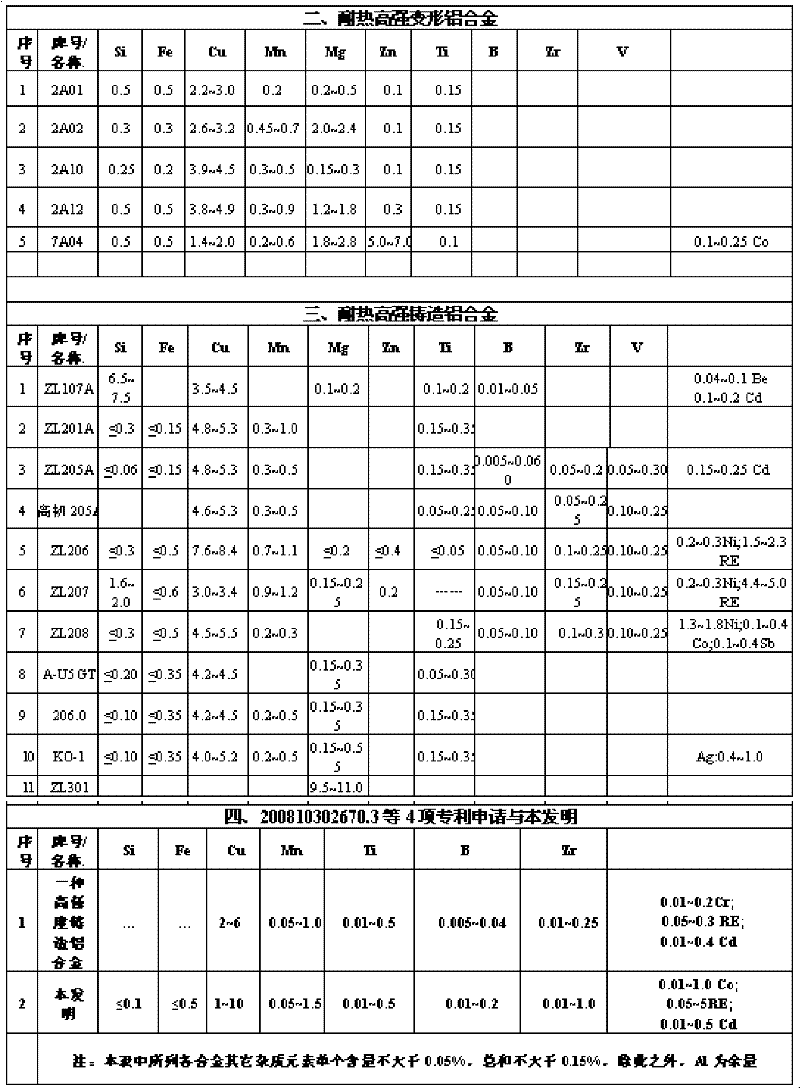

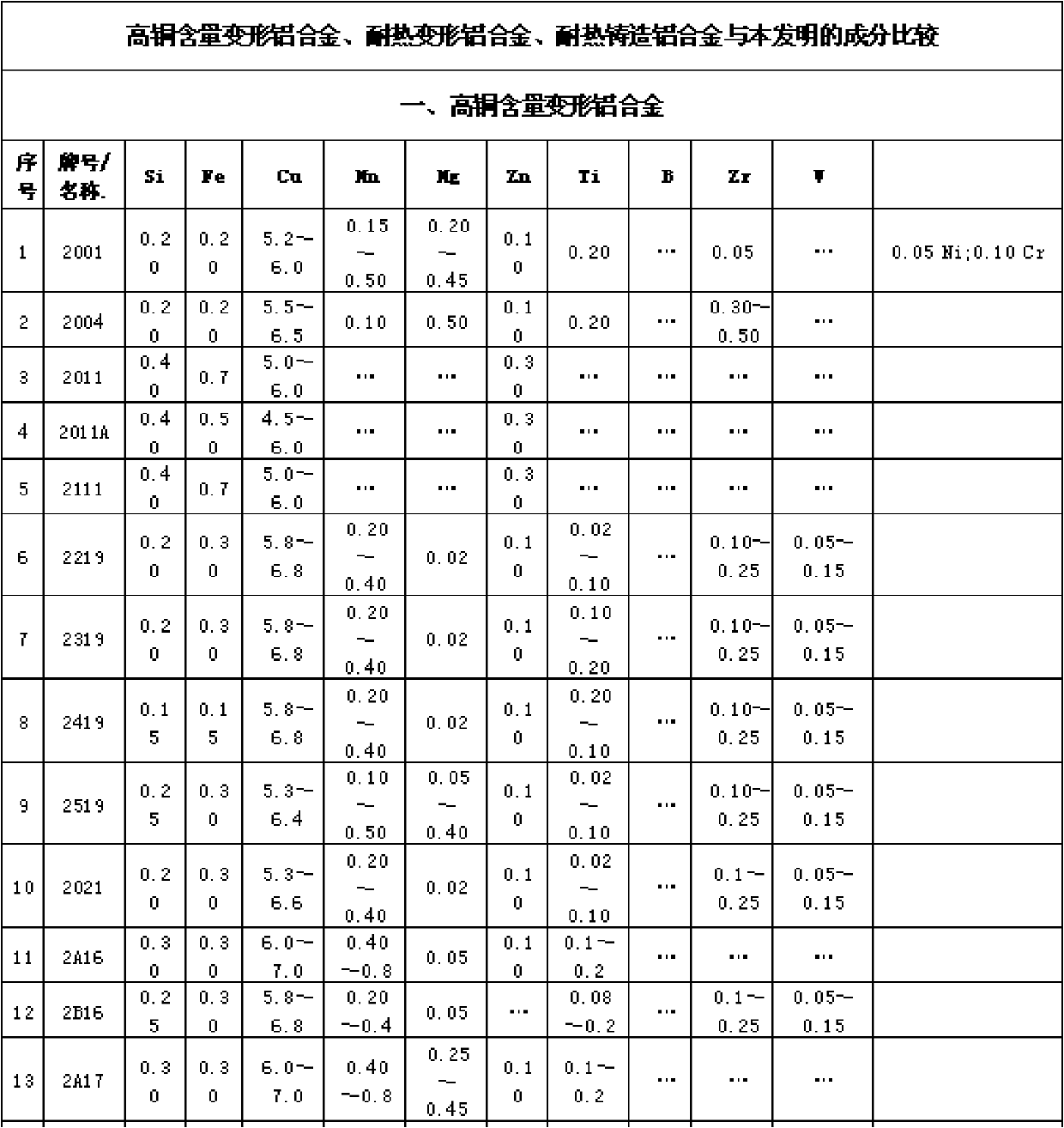

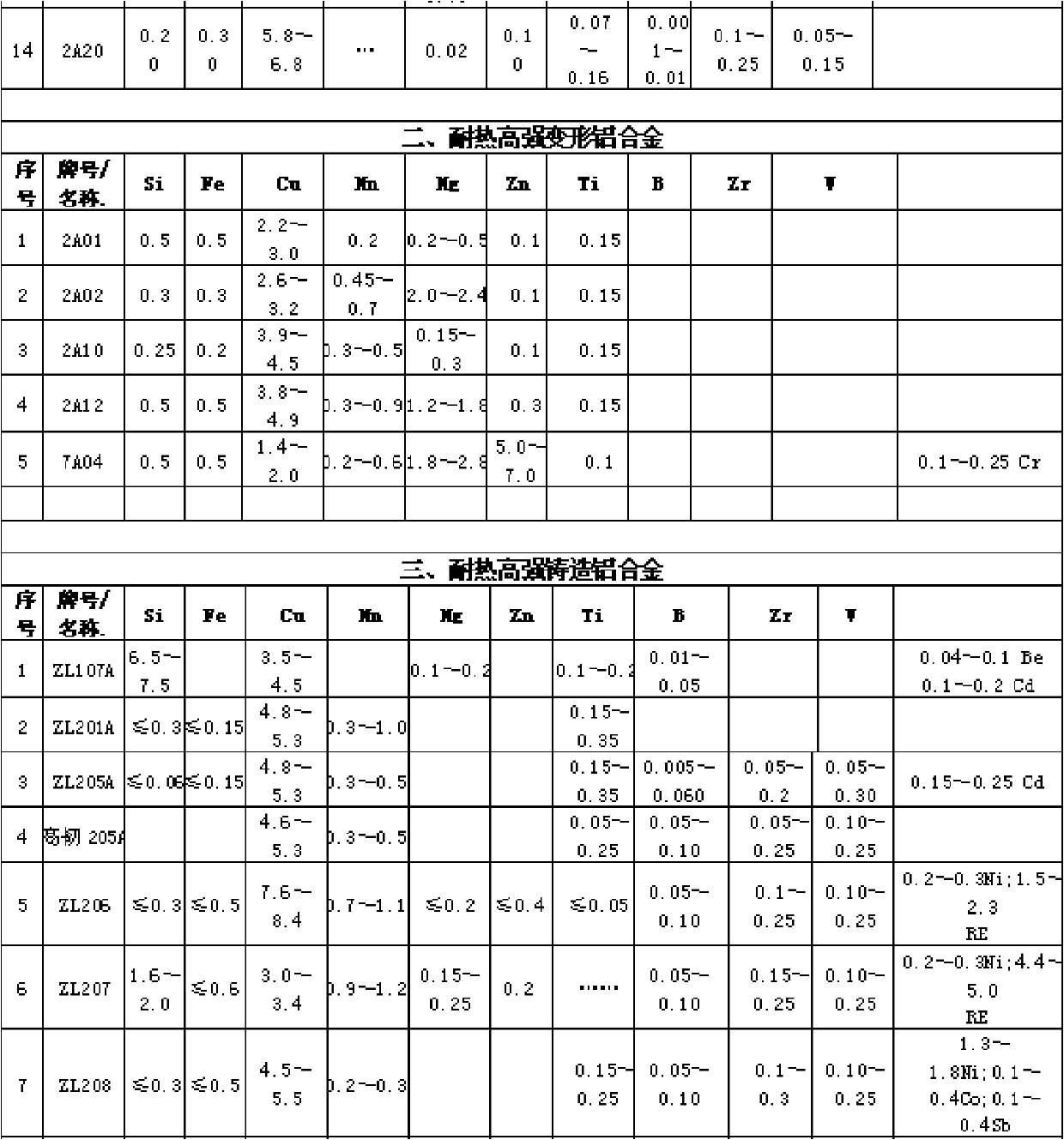

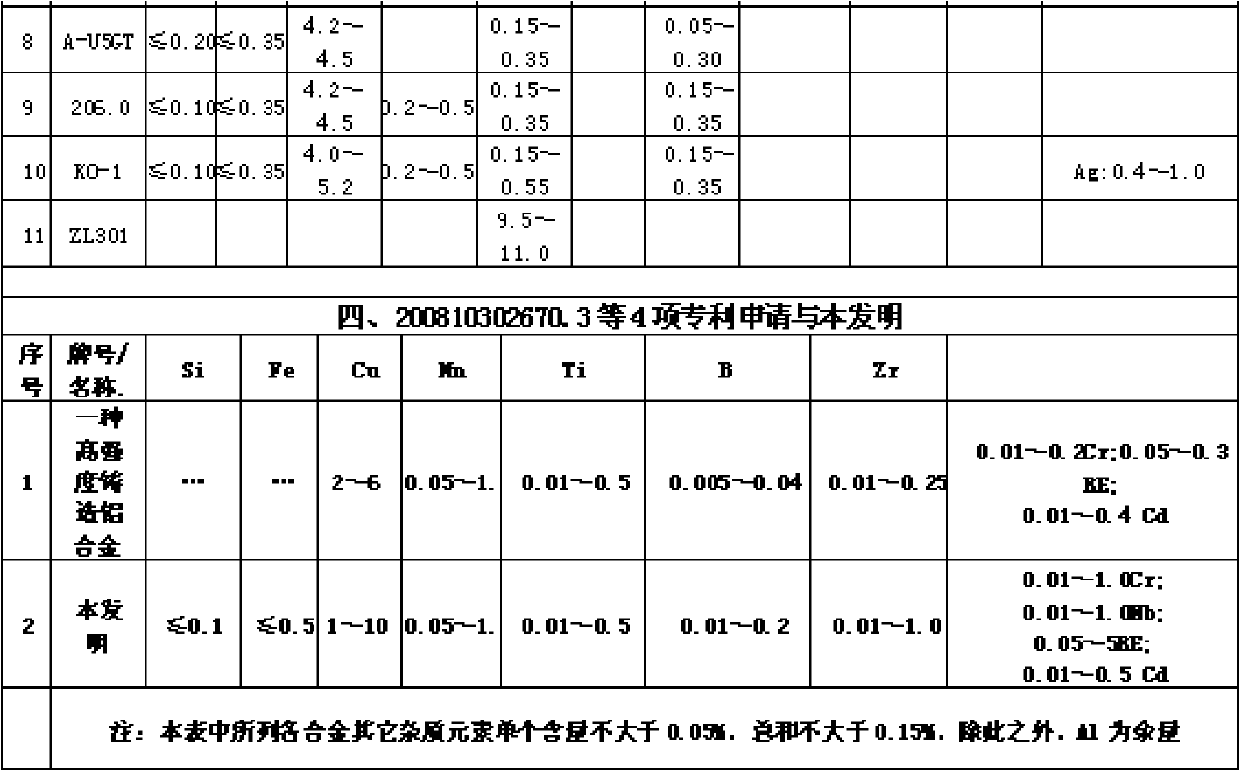

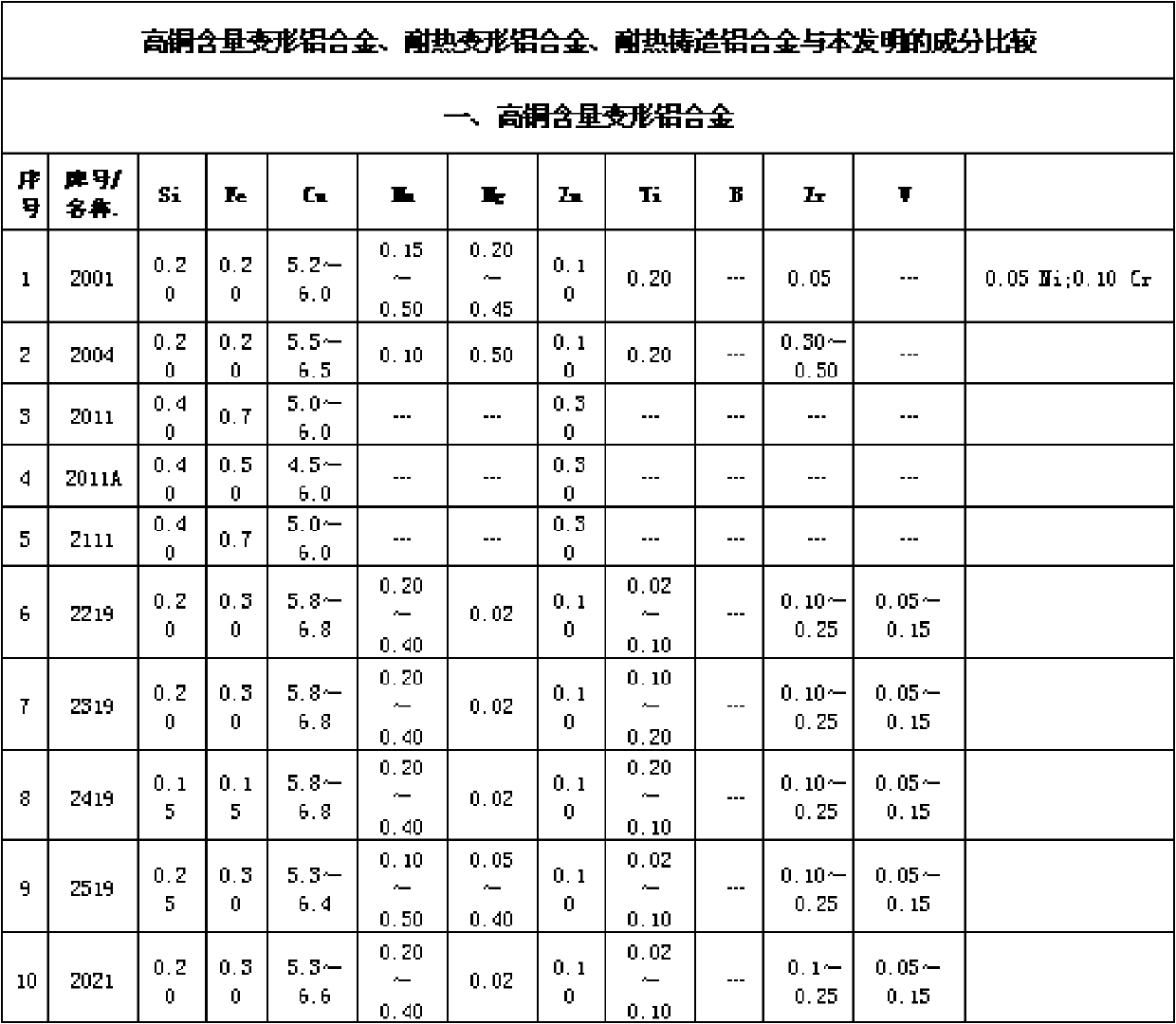

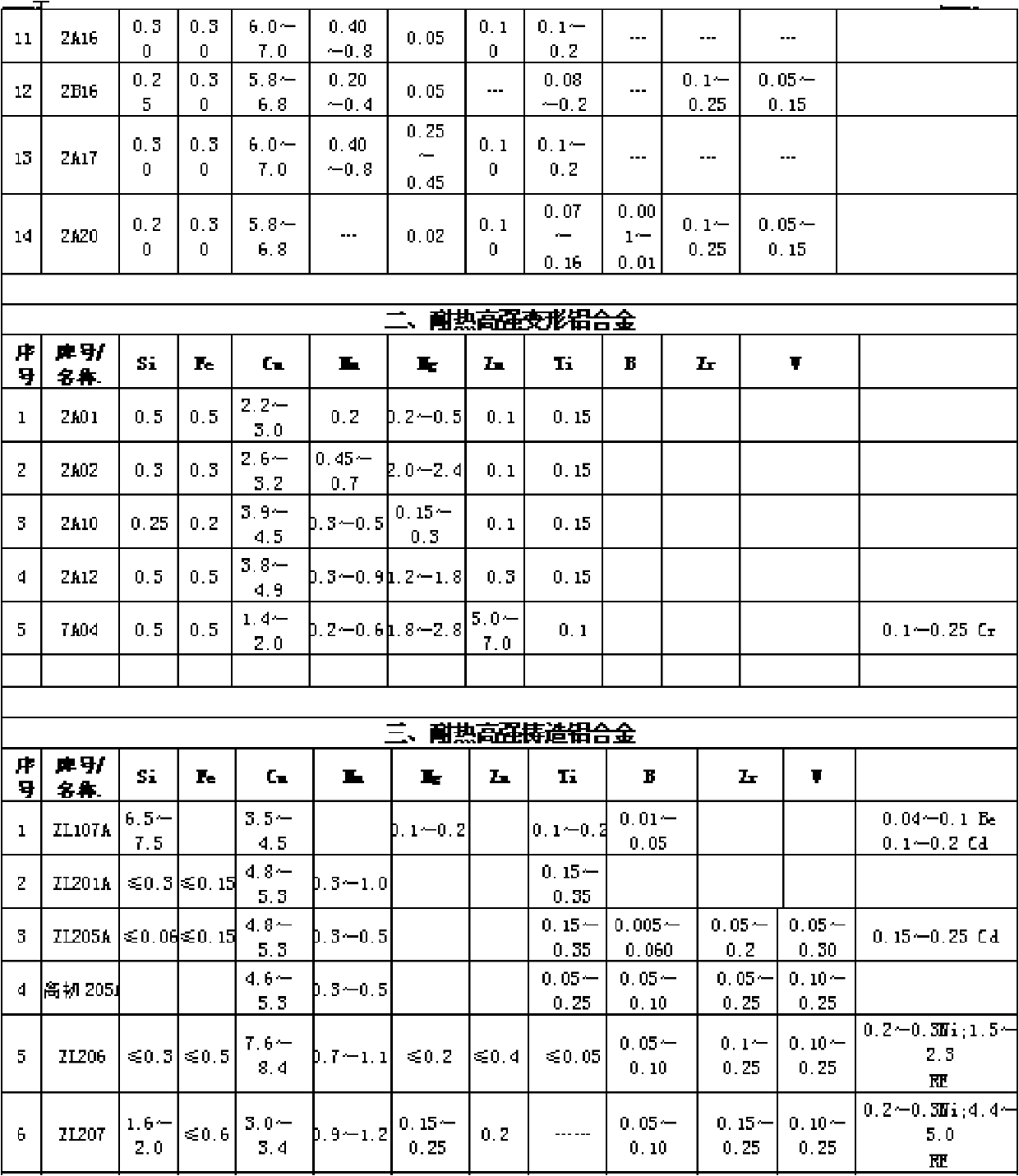

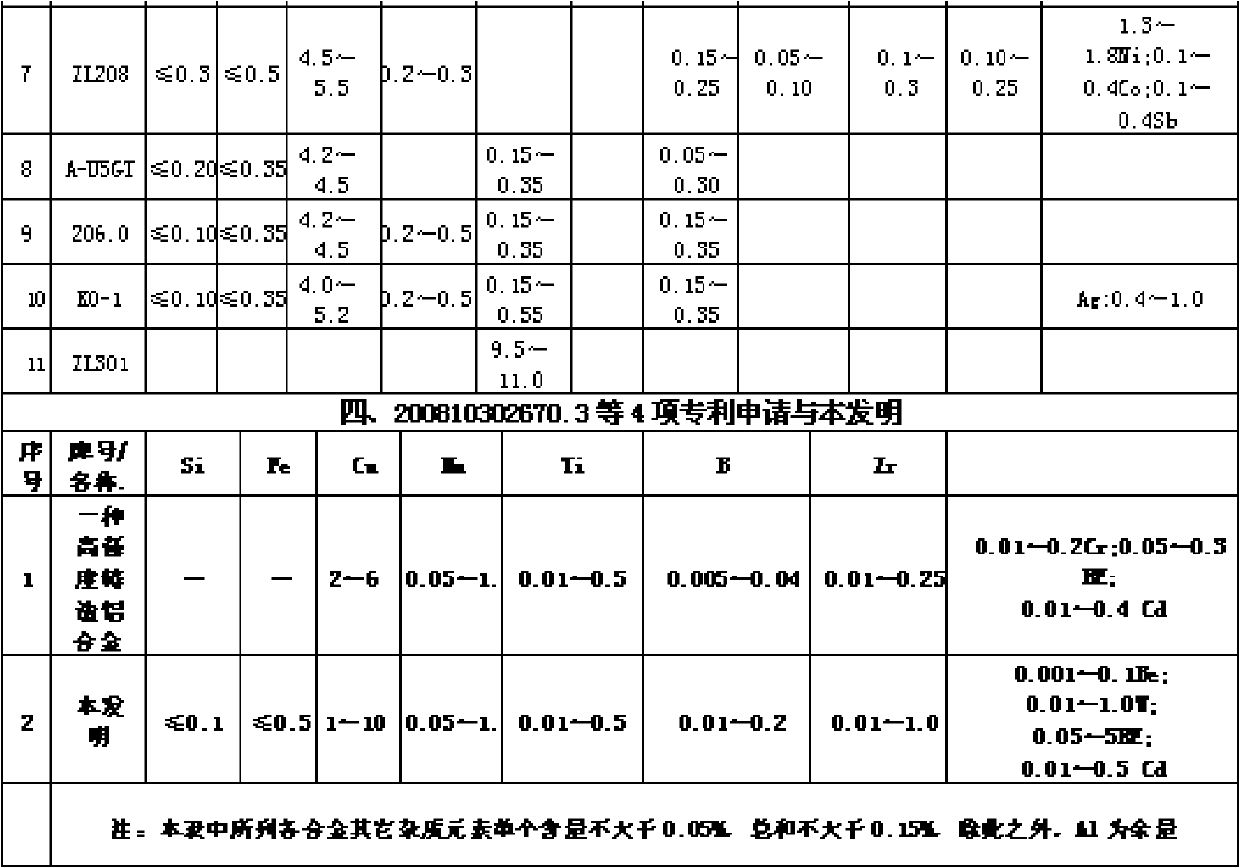

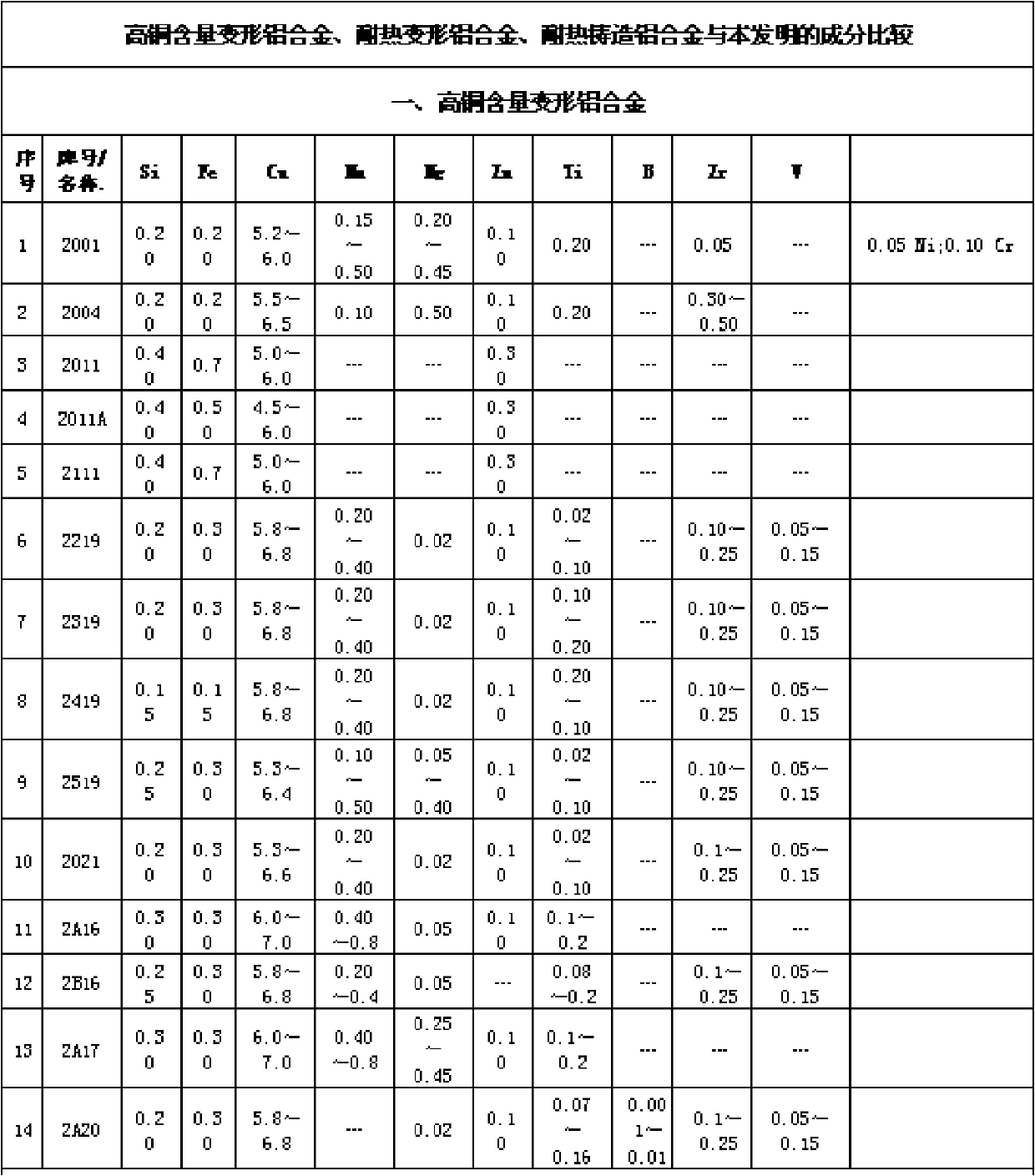

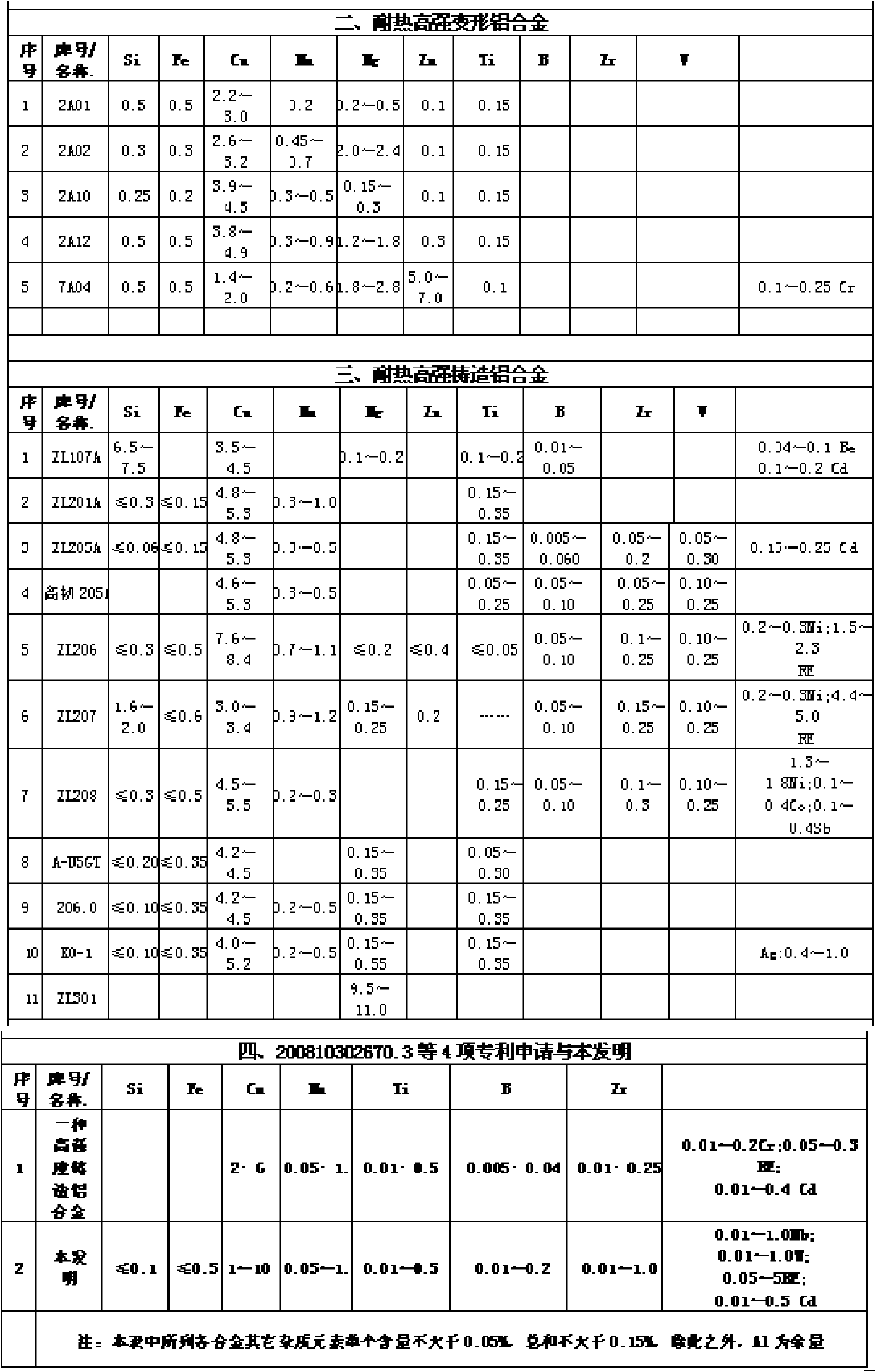

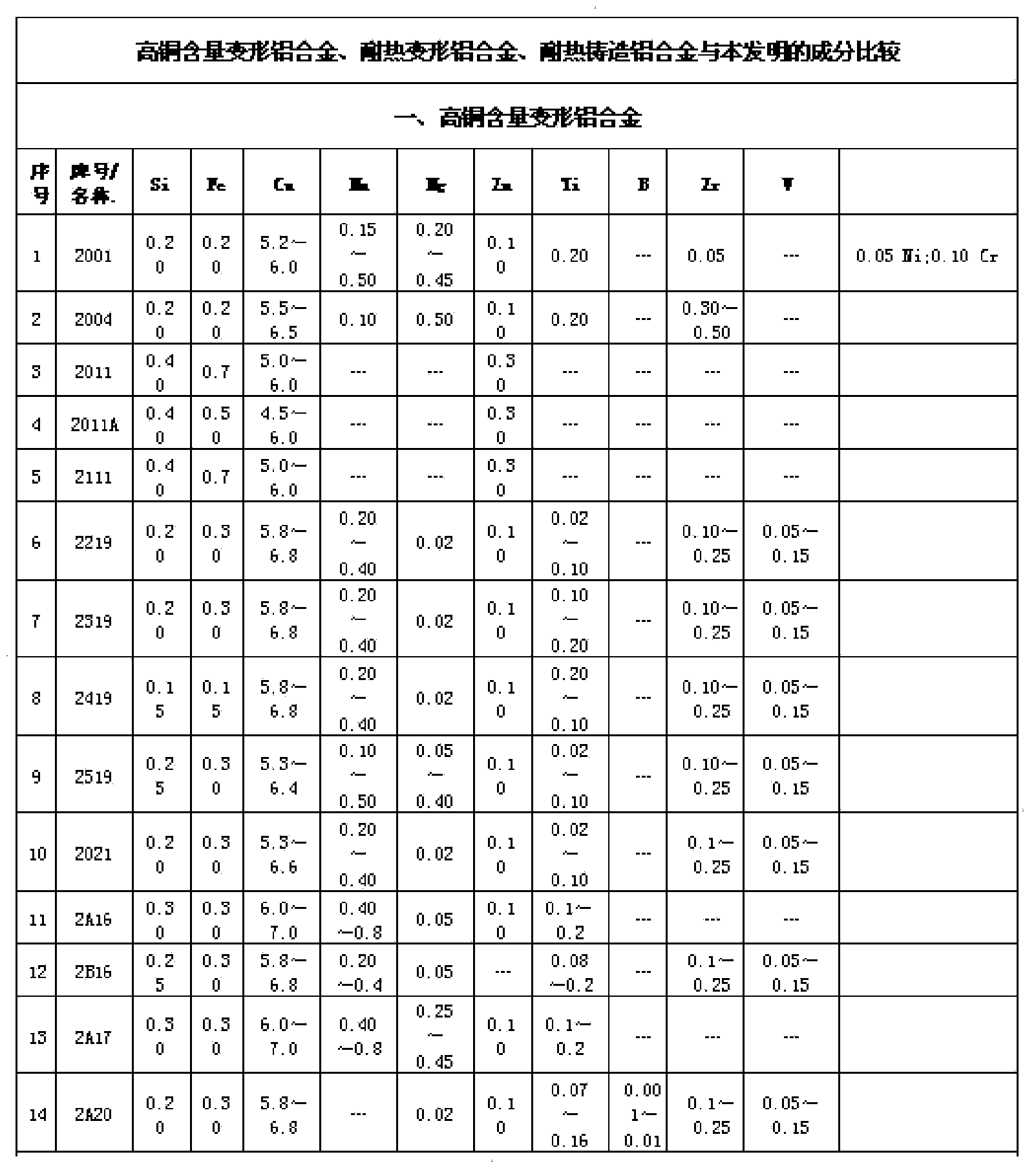

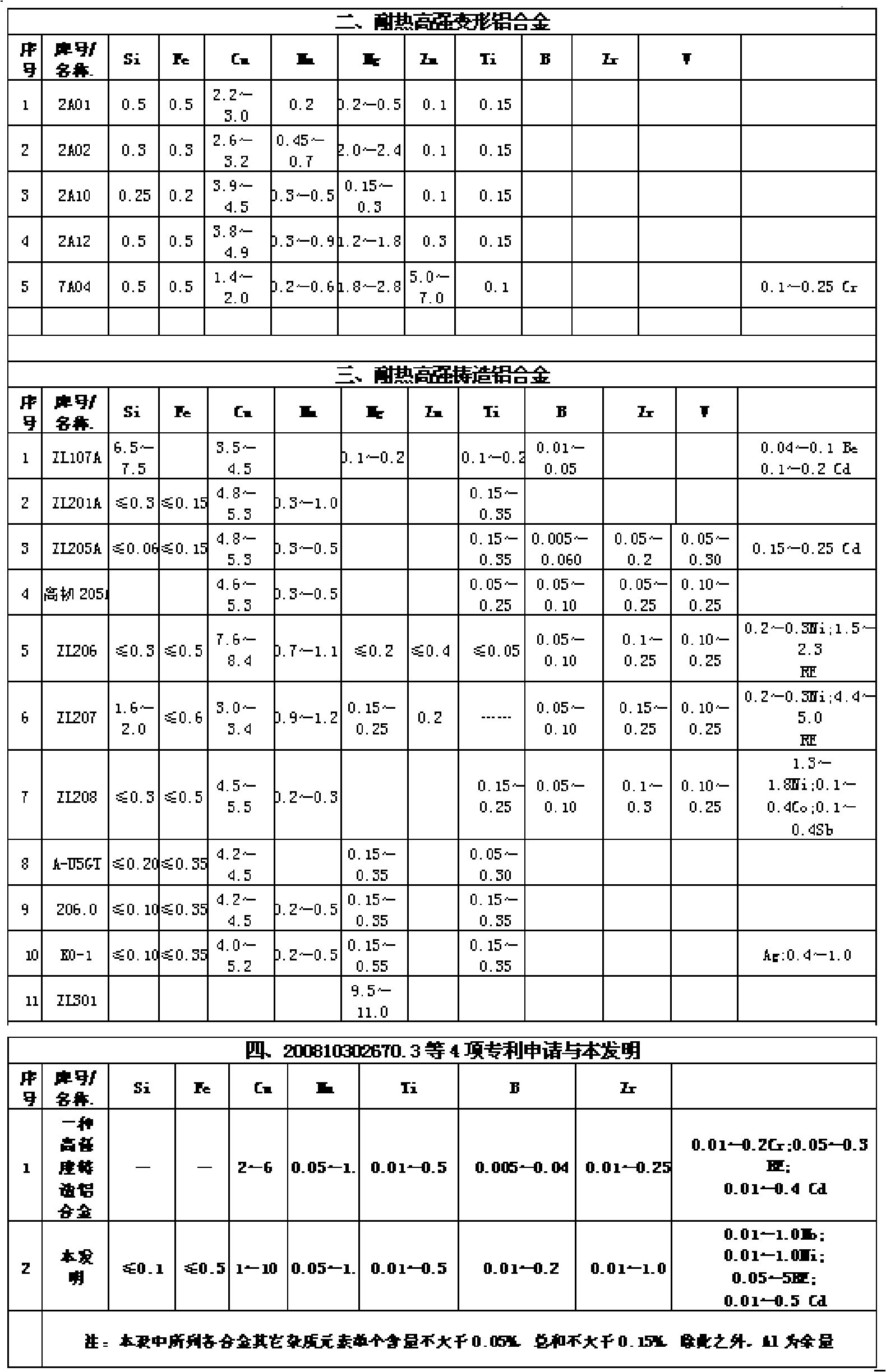

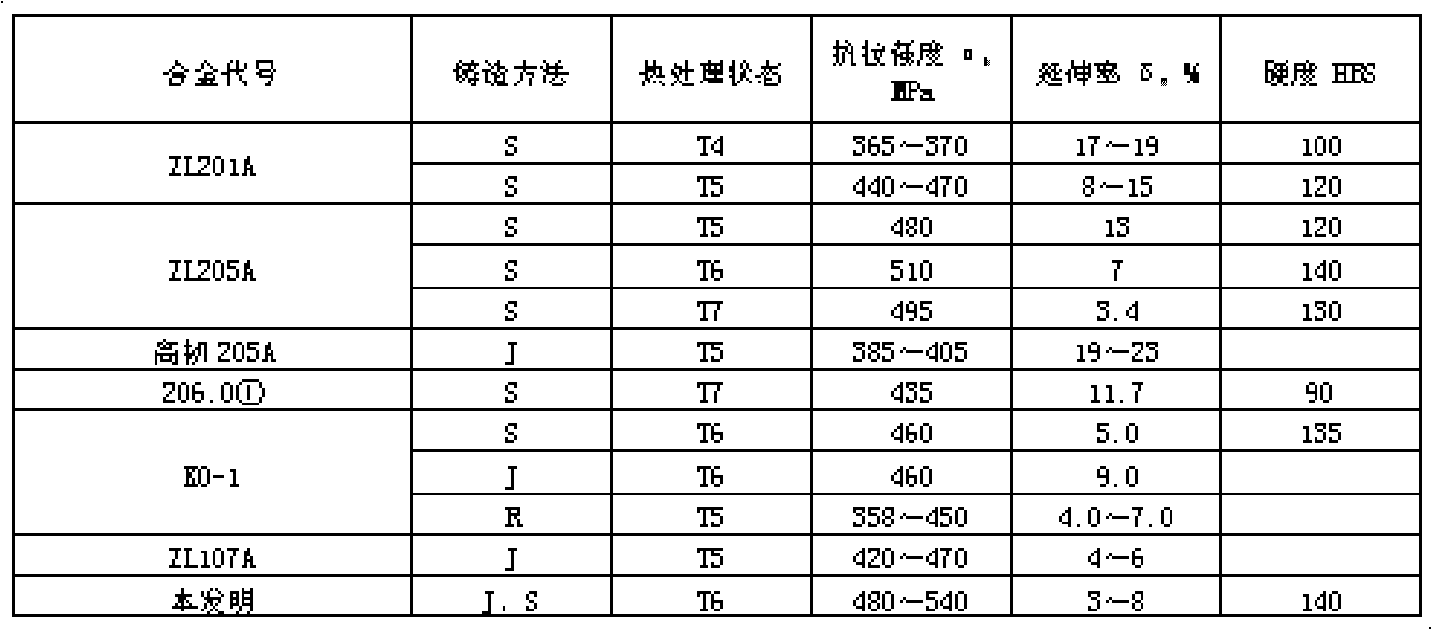

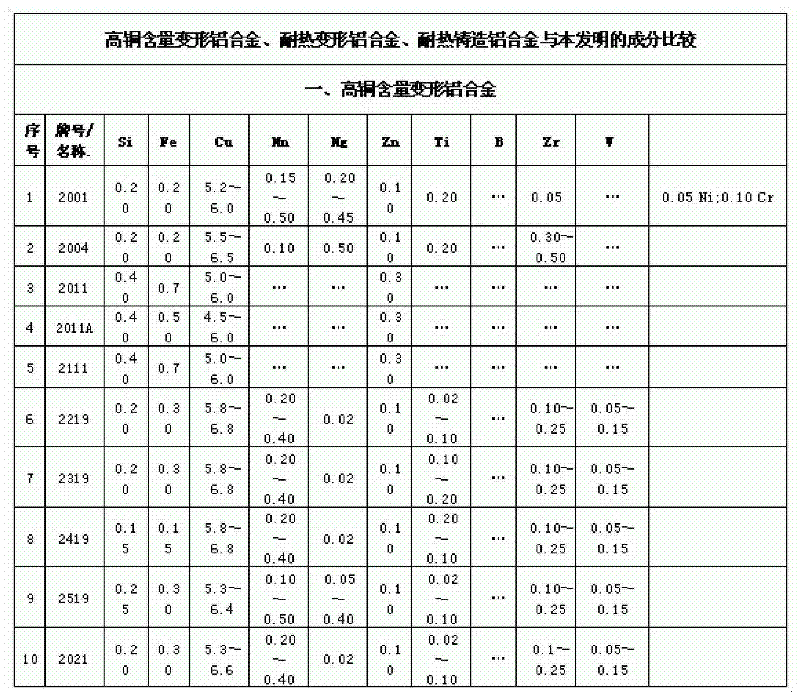

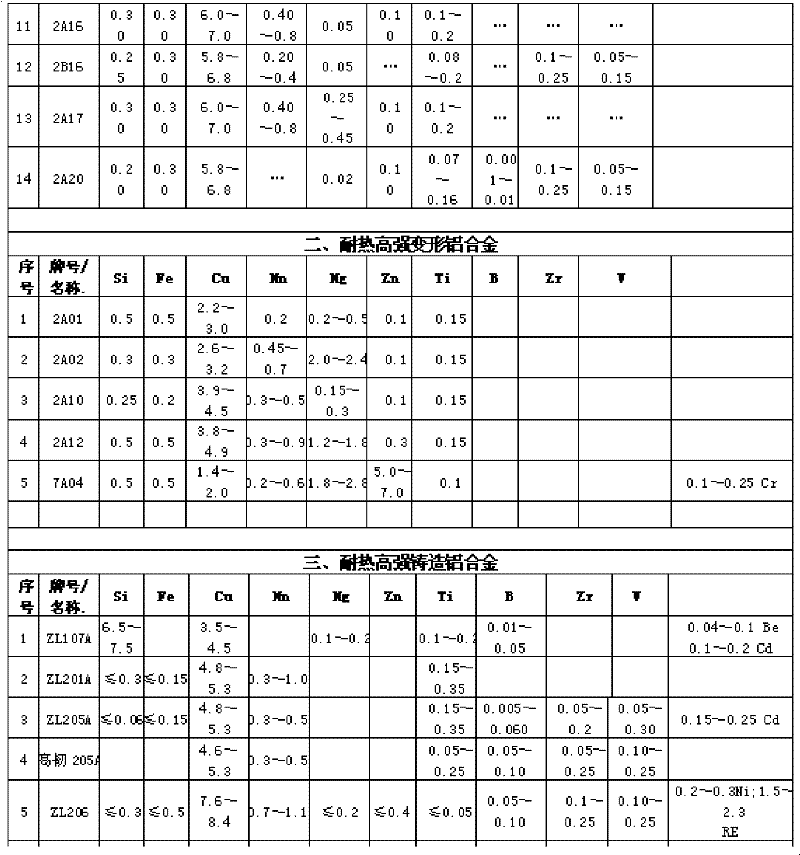

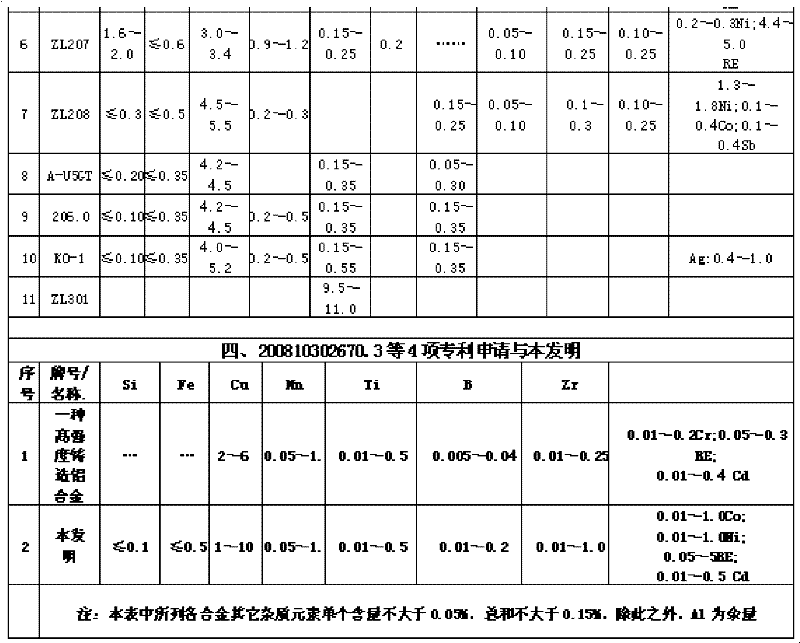

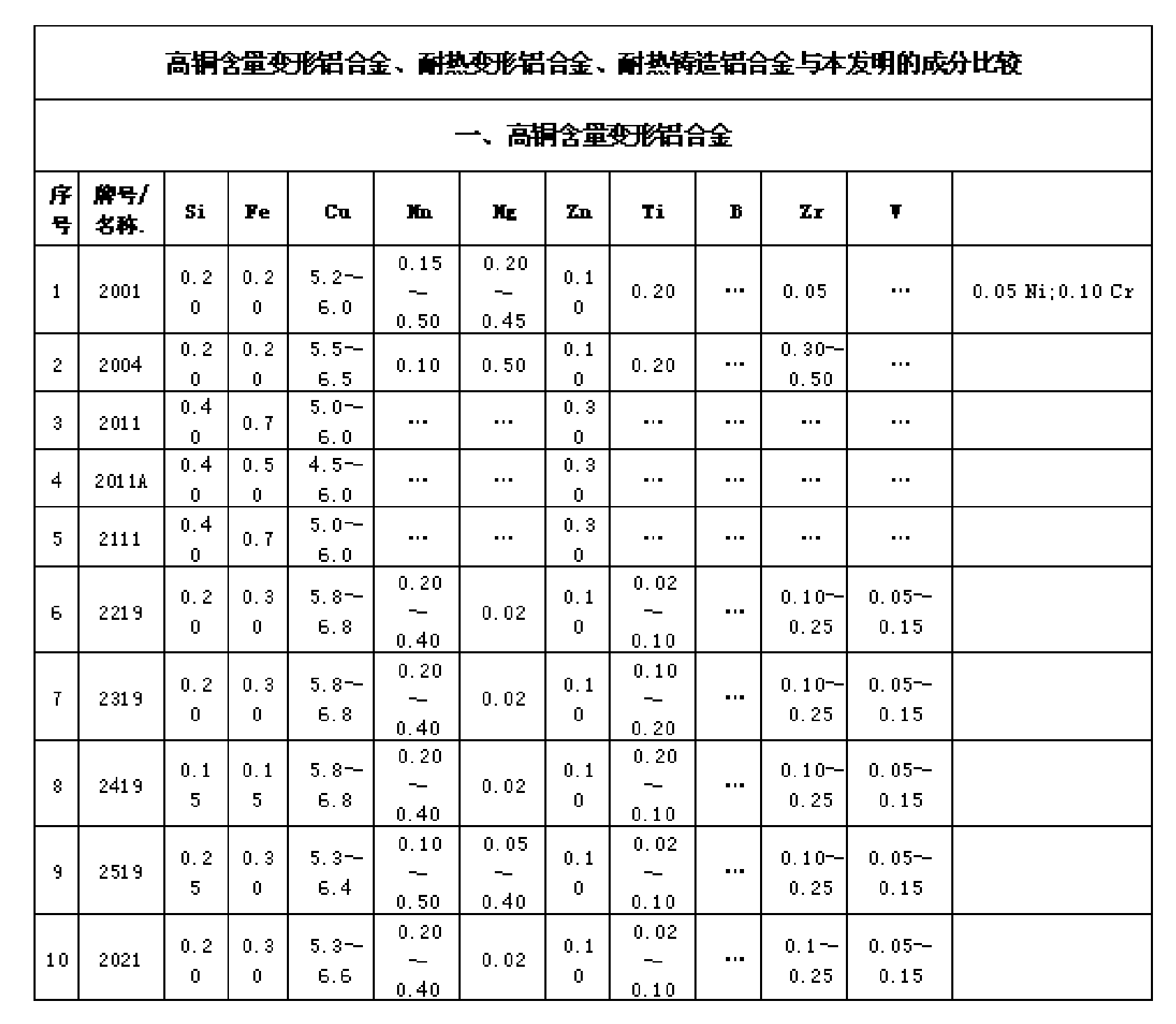

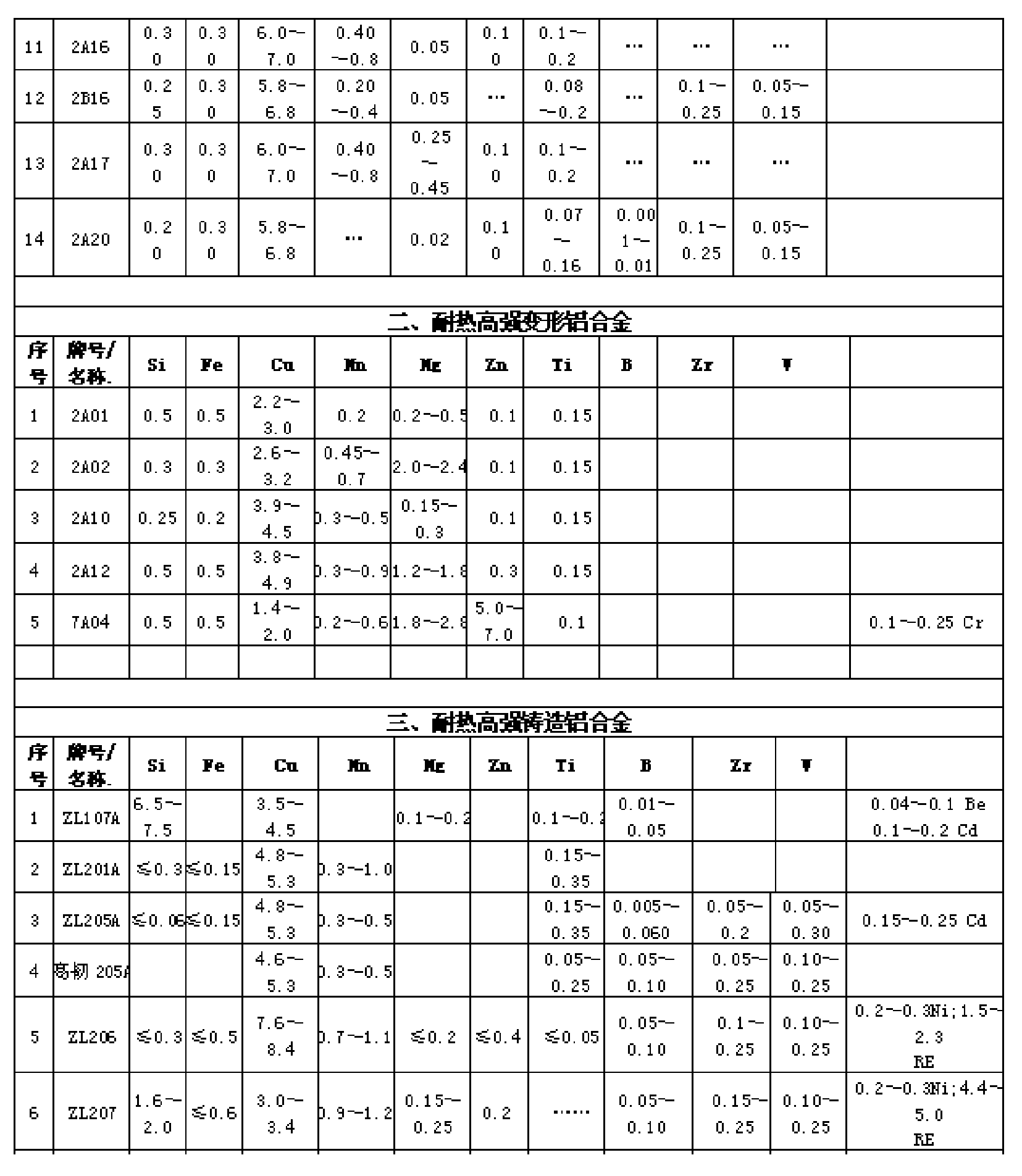

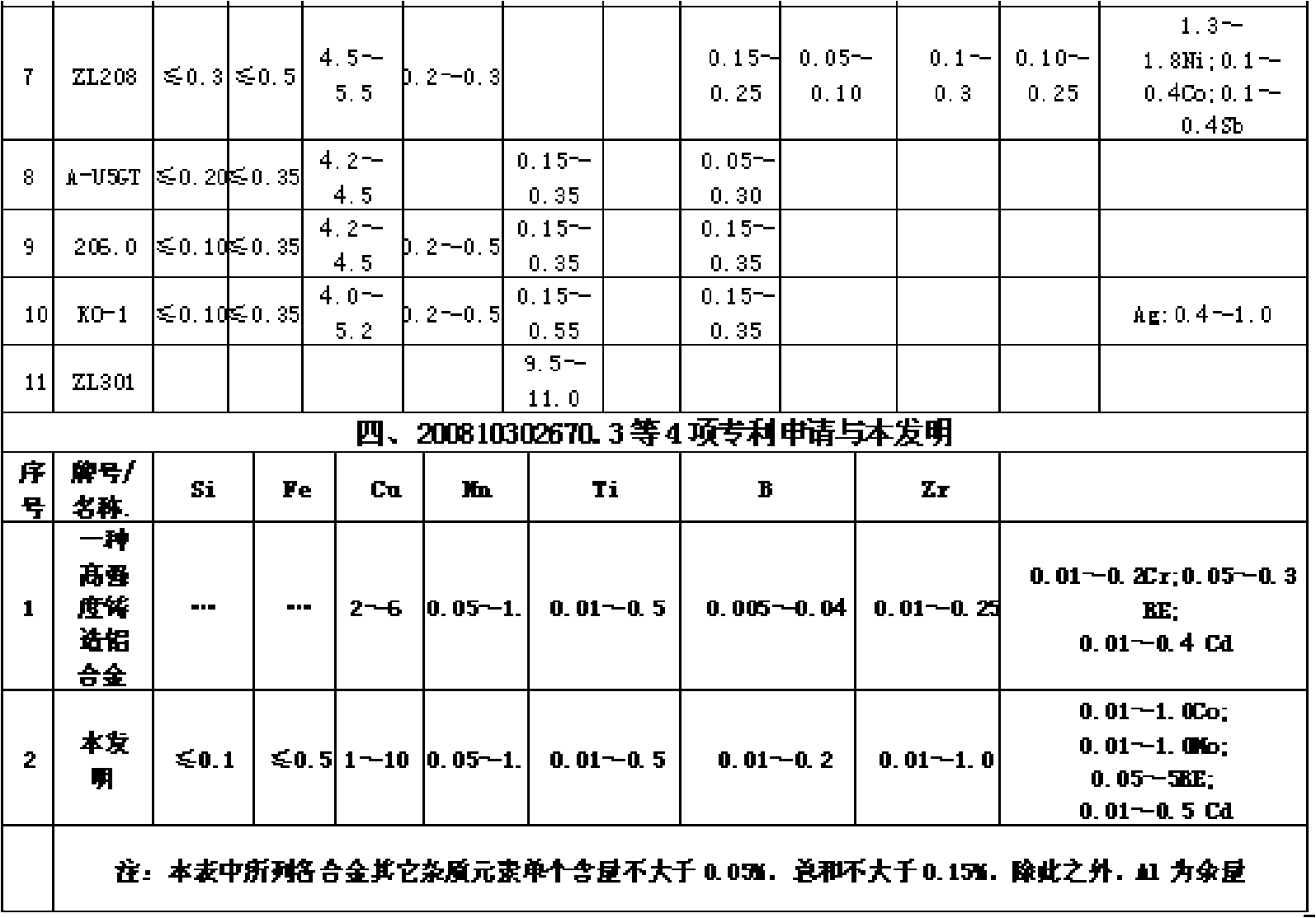

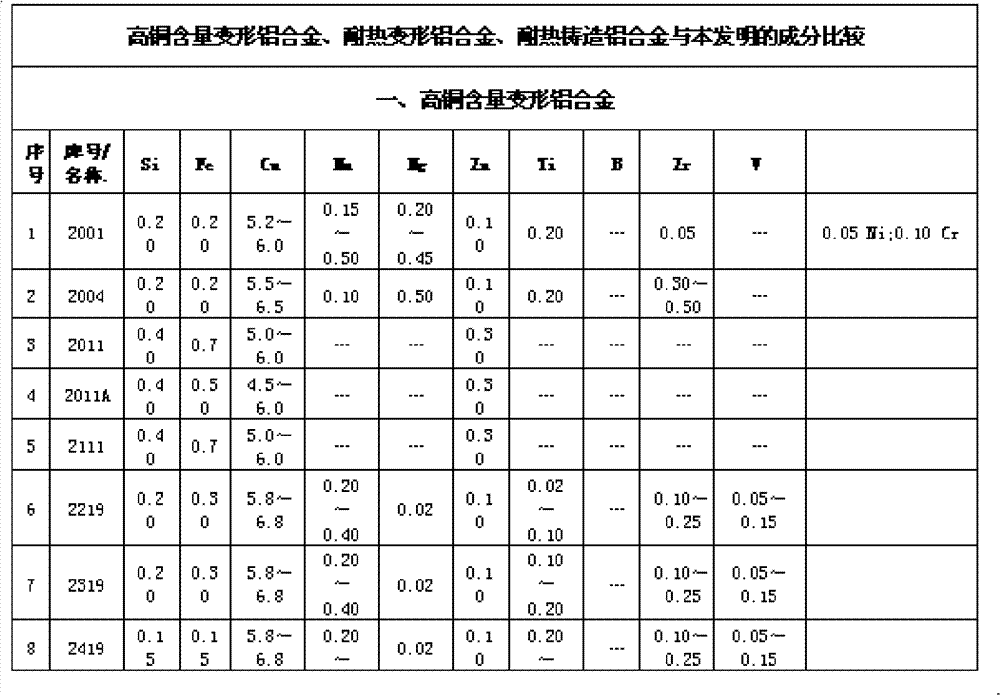

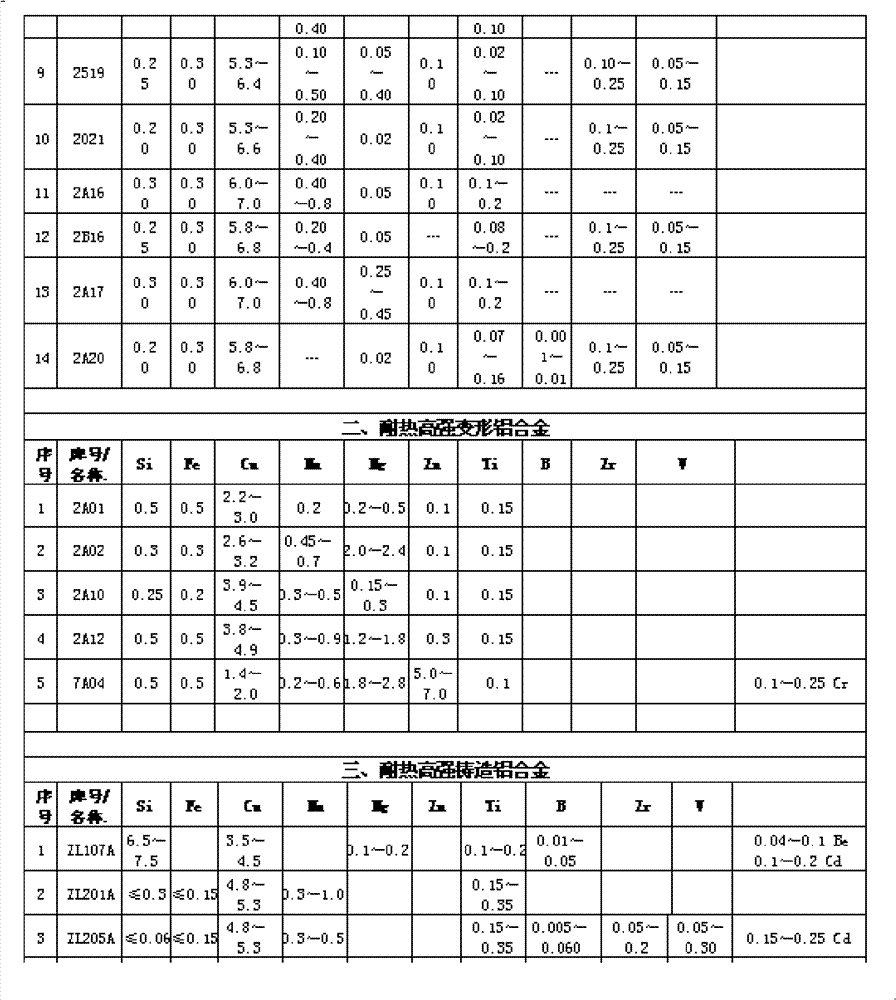

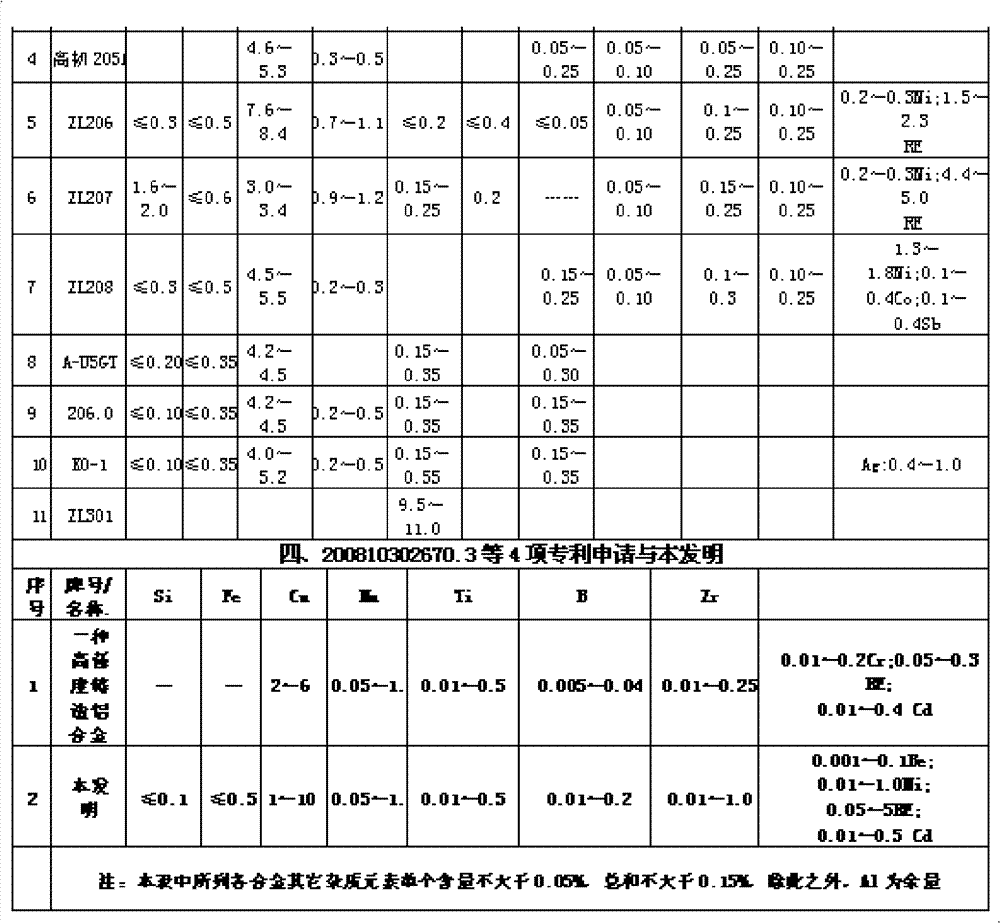

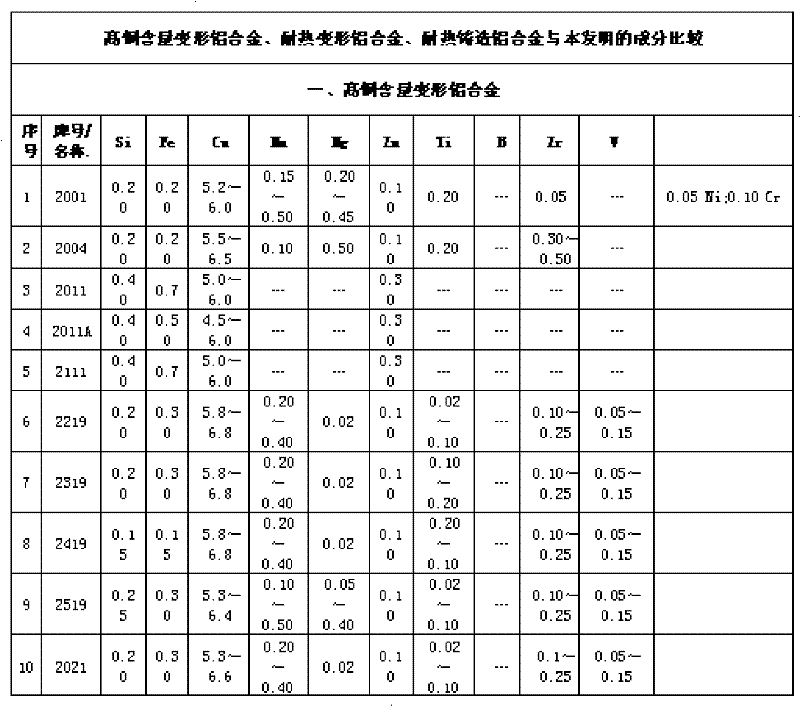

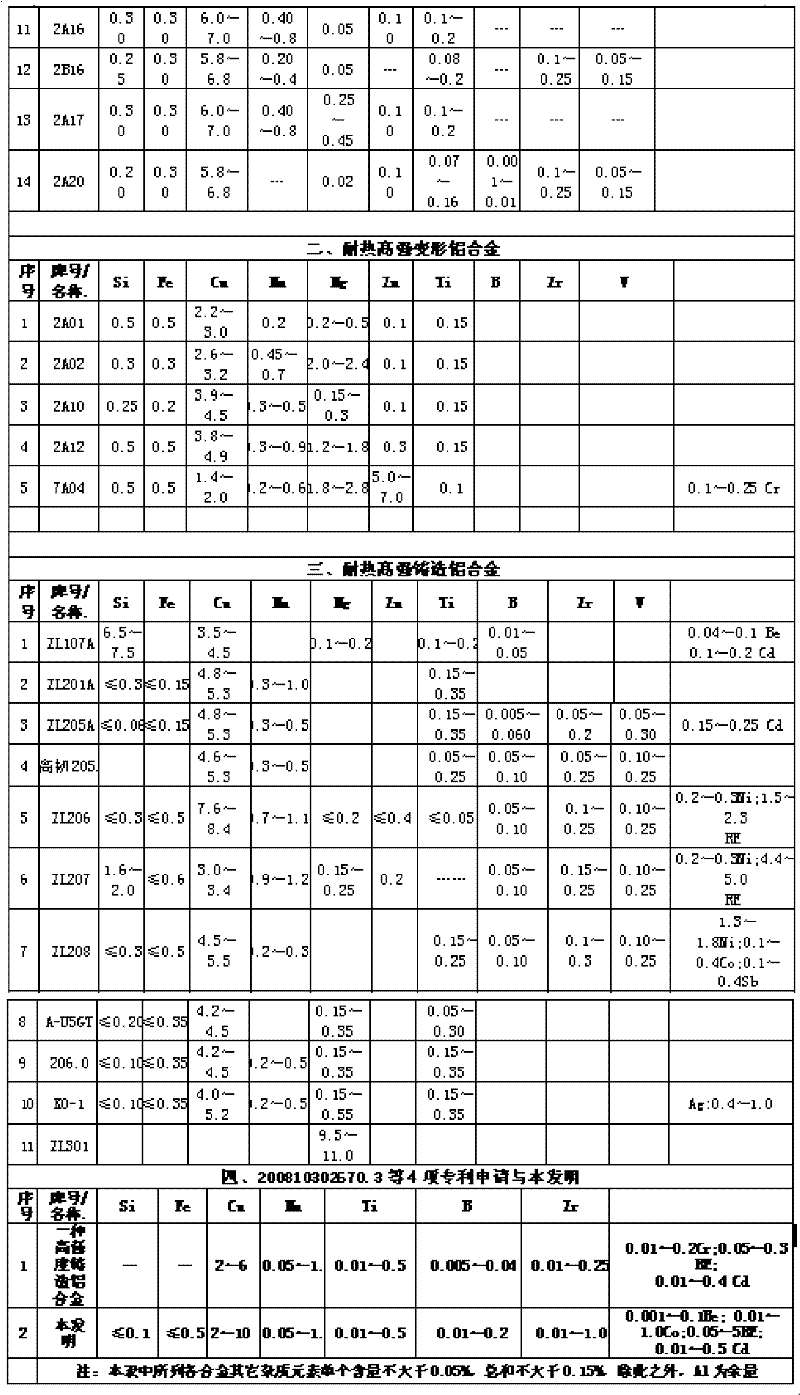

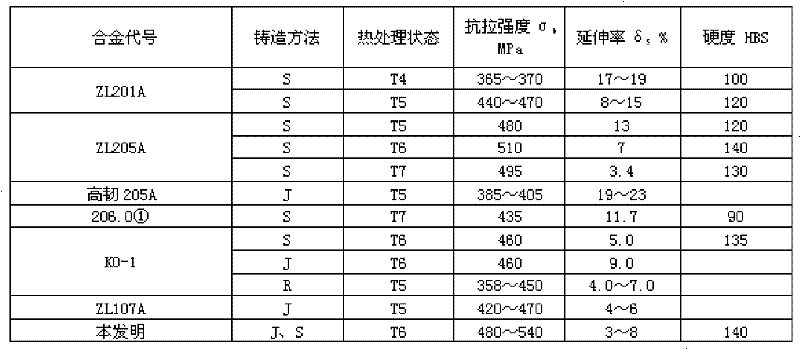

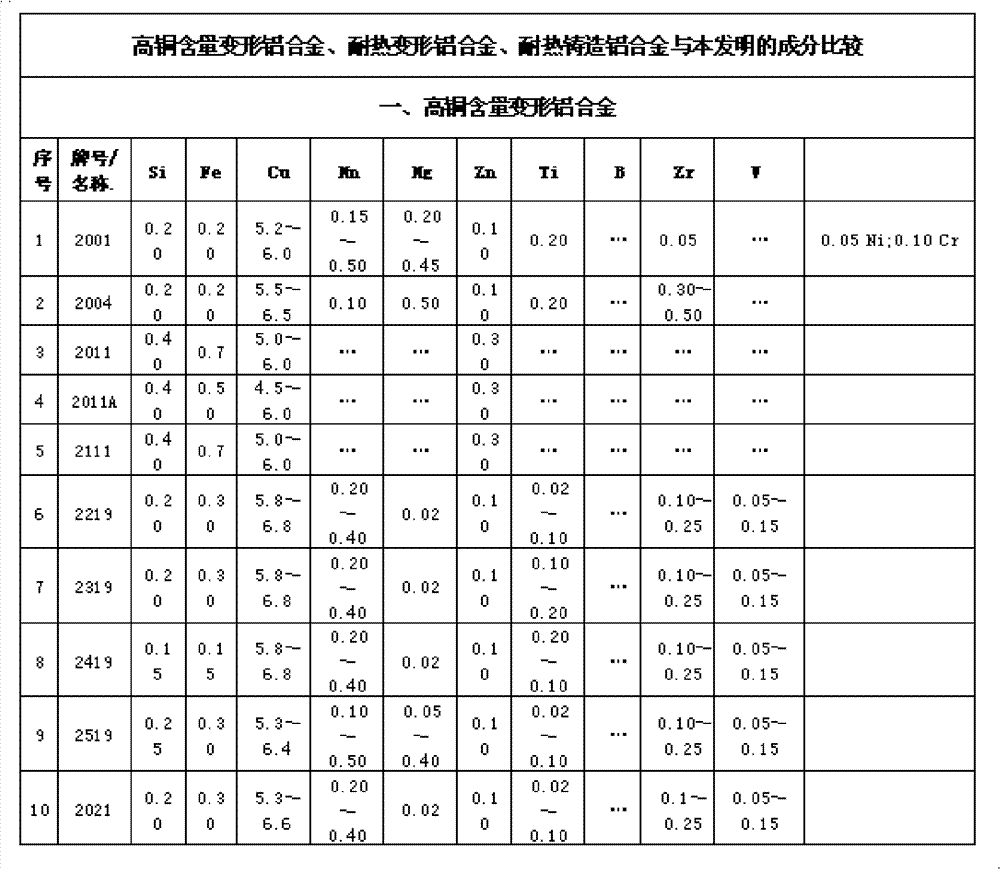

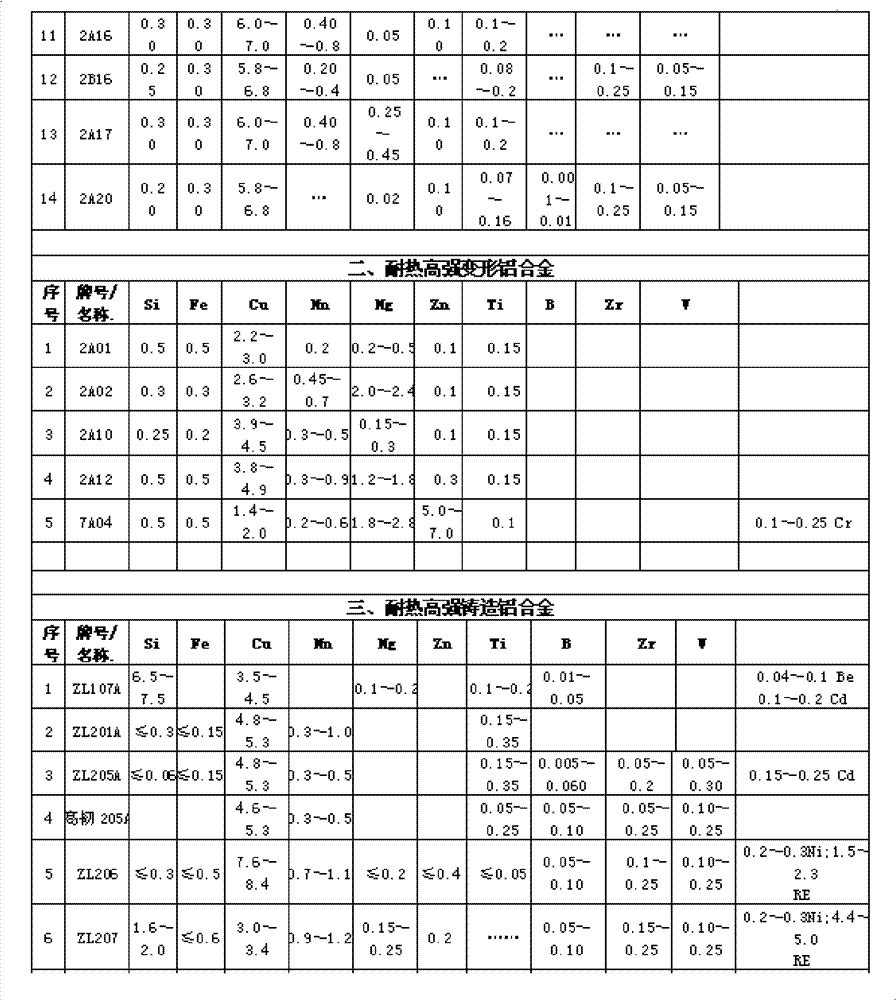

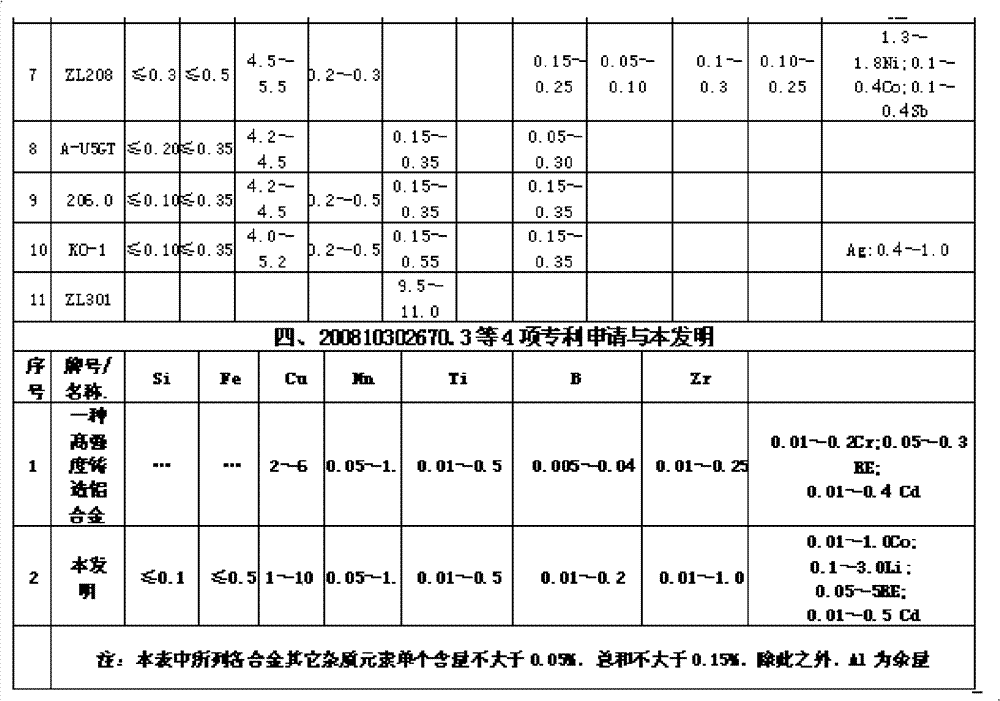

The invention discloses a high-strength heat-resisting aluminum alloy material and a production method thereof. The high-strength heat-resisting aluminum alloy material comprises the following components in percentage by weight: Cu: 1.0-10.0%; Mn: 0.05-1.5%; Cd: 0.01-0.5%; Ti: 0.01-0.5%; B: 0.01-0.2%; Zr: 0.01-1.0%; Be: 0.001-0.1%; RE: 0.05-5%; and the balance of Al. By adopting a high-quality melt, solid solution and phase diagram theory as the guide and preferring main alloy element formula of Cu, Mn and RE, the invention reduces an alloy quasi solid phase temperature range and solves the problems of large heat crack tendency in casting, low high-temperature strength of products, and the like; in addition, by preferring a multiple microalloying element formula with low cost, the invention provides a material condition for culture and grain refining of a high temperature phase and a strengthening phase in the solid solution; and moreover, by optimizing smelting and technology for heating processing, the invention fully plays the quantum sufficient culture and grain refining of the high temperature phase and the strengthening phase in the solid solution and finally produces the high-strength heat-resisting aluminum alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Ni-RE high-strength heat-resistance aluminum alloy material and preparation method thereof

The invention discloses a high-strength heat-resistance aluminum alloy material and a preparation method thereof. The alloy material comprises the components in percentage by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.01-2.3% of Ni, 0.05-5% of RE and the balance of Al. By adopting high-quality melt and solid solution and phase diagram principle as guide and preferably choosing alloy main elements Cu, Mn and RE formula, the invention reduces alloy standard solid phase temperature range and solves the problems of large hot crack tendency, low high-temperature strength of products and the like in casting; in addition, by preferably choosing low-cost multielement microalloying element formula, the invention creates material condition for culturing and grain refining of medium-high and strengthening phases of the solid solution; and moreover, by optimizing the melting and heating processing technology, the invention realize sufficient culturing and full play of grain refining of the medium-high and strengthening phases of the solid solution so as to finally prepare the high-strength heat-resistance aluminum alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Mo-W-RE high-strength heat-resistance aluminium alloy material and preparation method thereof

The invention discloses a high-strength heat-resistance aluminium alloy material and a preparation method thereof. The alloy material comprises the components in percentage by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.01-1.0% of Mo, 0.01-1.0% of W, 0.05-5% of RE and the balance of Al. By adopting high-quality melt and solid solution and phase diagram principle as guide and preferably choosing alloy main elements Cu, Mn and RE formula, the invention reduces alloy standard solid phase temperature range and solves the problems of large hot crack tendency, low high-temperature strength of products and the like in casting; in addition, by preferably choosing low-cost multielement microalloying element formula, the invention creates material condition for culturing and grain refining of medium-high and strengthening phases of the solid solution so as to finally prepare the high-strength heat-resistance aluminum alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Li-Nb-RE high-strength heat-resistance aluminium alloy material and preparation method thereof

The invention discloses a high-strength heat-resistance aluminum alloy material and a preparation method thereof. The material comprises the components in percentage by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.1-3.0% of Li, 0.01-1.0% of Nb, 0.05-5% of RE and the balance of Al. By adopting high-quality melt and solid solution and phase diagram principle as guide and preferably choosing alloy main elements Cu, Mn and RE formula, the invention reduces alloy standard solid phase temperature range and solves the problems of large hot crack tendency, low high-temperature strength of products and the like in casting; in addition, by preferably choosing low-cost multielement microalloying elemen formula, the invention creates material condition for culturing and grain refining of medium-high and strengthening phases of the solid solution so as to finally prepare the high-strength heat-resistance aluminum alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Be-Mo-RE high strength heat resistant aluminium alloy material and preparation method thereof

The invention discloses a high strength heat resistant aluminium alloy material and a preparation method thereof. The material comprises the following components in percent by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of T, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.001-0.1% of Be, 0.01-1.0% of Mo, 0.05-5% of RE the balance of Al. The invention reduces alloy quasi solid phase temperature range by utilizing high quality melt, solid solution and phase diagram theory as guidance and preferably selecting formula of host elements of Cu, Mn and RE and solves the problems that hot tear crack tendency is high when in casting process and strength of products is low at high temperature; through preferably selecting a low cost multielement microalloyed element formula, the invention creates material foundation conditions for culture and grain refining of high temperature phase and strengthening phase in solid solution, and finally a high strength heat resistant aluminium alloy material is developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Cr-Ho high-strength heat-resistant aluminum alloy material and preparation method thereof

InactiveCN102031422AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a Cr-Ho high-strength heat-resistant aluminum alloy material and a preparation method thereof. The alloy material comprises the following components in percentage by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.01-1.0% of Cr, 0.05-5% of Ho and the balance of Al. By taking high-quality melt, sosoloid and the phase diagram theory as the guidance, the invention reduces the quasi solid-phase temperature range of the alloy material and solves the problems of great thermal cracking tendency during casting, low high-temperature strength of products and the like by preferably selecting the formation of main alloy elements of Cu, Mn and RE. The preferable selection of the formulation of low-cost multielement microalloy elements creates material base conditions for breeding and grain-refining a high-temperature phase and a strengthening phase in the sosoloid, and a novel aluminum alloy material is finally developed.

Owner:贵州铝厂有限责任公司 +2

Mo-Ni-RE high-strength heat-resistant aluminium alloy material and preparation method thereof

The invention discloses a high-strength heat-resistant aluminium alloy material and a preparation method thereof. The aluminium alloy material comprises the following components by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.01-1.0% of Mo, 0.01-1.0% of Ni, 0.05-5% of RE and the balance Al. By taking high-quality melt, solid solution and phase diagram theory as guidance and optimizing the formulas of the major alloy elements Cu, Mn and RE, the invention narrows the quasi-solid phase temperature range of the alloys and solves the problems of great hot crack tendency during casting, low high temperature strength of the products and the like, and by optimizing the formulas of the low cost multiple micro alloying elements, the invention creates material base conditions for cultivation and grain refining of medium-high temperature phase and strengthening phase of the solid solution and finally develops the high-strength heat-resistant aluminium alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

W-RE high-strength heat-resisting aluminium alloy material and preparation method thereof

InactiveCN101805851AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a high-strength heat-resisting aluminium alloy material and a preparation method thereof. The high-strength heat-resisting aluminium alloy material comprises the following components in percent by weight: 1.0-10.0 percent of Cu, 0.05-1.5 percent of Mn, 0.01-0.5 percent of Cd, 0.01-0.5 percent of Ti, 0.01-0.2 percent of B, 0.01-1.0 percent of Zr, 0.01-1.0 percent of W, 0.05-5 percent of RE and the balance of Al. By using high quality melt, solid solution and a phase diagram theory as guidance and the formula of optimally selecting main alloy elements of Cu, Mn and RE, the invention reduces the alloy quasi solid phase temperature range and solves the problems of large heat cracking tendency, low high-temperature strength of products and the like occurred during casting. A preferentially selected low-cost multiple microalloying element formula creates the material base condition for culture and grain refining of high temperature phase and strengthened phase in the solid solution. By optimizing melting and heat treating processes, the full development of enough culture and grain refining of the high temperature phase and strengthened phase in the solid solution can be realized, and the high-strength heat-resisting aluminium alloy material is finally developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Be-Li-RE high-strength heat-resistant aluminum alloy material and preparation method thereof

The invention discloses a high-strength heat-resistant aluminum alloy material and a preparation method thereof. The high-strength heat-resistant aluminum alloy material comprises the following components in percentage by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.001-0.1% of Be, 0.01-3.0% of Li, 0.05-5% of RE and the balance of Al. With high-quality melt, sosoloid and the phase diagram theory as the guidance, the invention reduces the quasi solid-phase temperature range of the alloy and solves the problems of great thermal cracking tendency during casting, low high-temperature strength of products and the like by preferably selecting the formation of main alloy elements of Cu, Mn and RE. The preferable selection of the formulation of low-cost multielement microalloy elements creates material base conditions for breeding and grain-refining a high-temperature phase and a strengthening phase in the sosoloid, and a high-strength heat-resistant aluminum alloy material is finally developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Be-Co-RE high-strength heat-resistant aluminum alloy material and preparation method thereof

InactiveCN102021366AGood value for moneyOvercoming cost barriersUltimate tensile strengthMaterials science

The invention discloses a high-strength heat-resistant aluminum alloy material and a preparation method thereof. The high-strength heat-resistant aluminum alloy material comprises the following components in percentage by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.001-0.1% of Be, 0.01-1.0% of Co, 0.05-5% of RE and the balance of Al. With high-quality melt, sosoloid and the phase diagram theory as guidance, the invention reduces the quasi solid-phase temperature range of the alloy and solves the problems of great thermal cracking tendency during casting, low high-temperature strength of products and the like by preferably selecting the formation of main alloy elements of Cu, Mn and RE. The preferable selection of the formulation of low-cost multielement microalloy elements creates material base conditions for breeding and grain-refining a high-temperature phase and a strengthening phase in the sosoloid, and a high-strength heat-resistant aluminum alloy material is finally developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Li-Ni-RE high-strength heat-resistant aluminium alloy material and preparation method thereof

InactiveCN101994038AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a high-strength heat-resistant aluminium alloy material and a preparation method thereof. The aluminium alloy material comprises the following components by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.1-3.0% of Li, 0.01-1.0% of Ni, 0.05-5% of RE and the balance Al. By taking high-quality melt, solid solution and phase diagram theory as guidance and optimizing the formulas of the major alloy elements Cu, Mn and RE, the invention narrows the quasi-solid phase temperature range of the alloys and solves the problems of great hot crack tendency during casting, low high temperature strength of the products and the like, and by optimizing the formulas of the low cost multiple micro alloying elements, the invention creates material base conditions for cultivation and grain refining of medium-high temperature phase and strengthening phase of the solid solution and finally develops the high-strength heat-resistant aluminium alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Mo-Nb-RE high-strength heat-resistant aluminium alloy material and preparation method thereof

InactiveCN101994035AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a high-strength heat-resistant aluminium alloy material and a preparation method thereof. The aluminium alloy material comprises the following components by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.01-1.0% of Mo, 0.01-1.0% of Nb, 0.05-5% of RE and the balance Al. By taking high-quality melt, solid solution and phase diagram theory as guidance and optimizing the formulas of the major alloy elements Cu, Mn and RE, the invention narrows the quasi-solid phase temperature range of the alloys and solves the problems of great hot crack tendency during casting, low high temperature strength of the products and the like, and by optimizing the formulas of the low cost multiple micro alloying elements, the invention creates material base conditions for cultivation and grain refining of medium-high temperature phase and strengthening phase of the solid solution and finally develops the high-strength heat-resistant aluminium alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

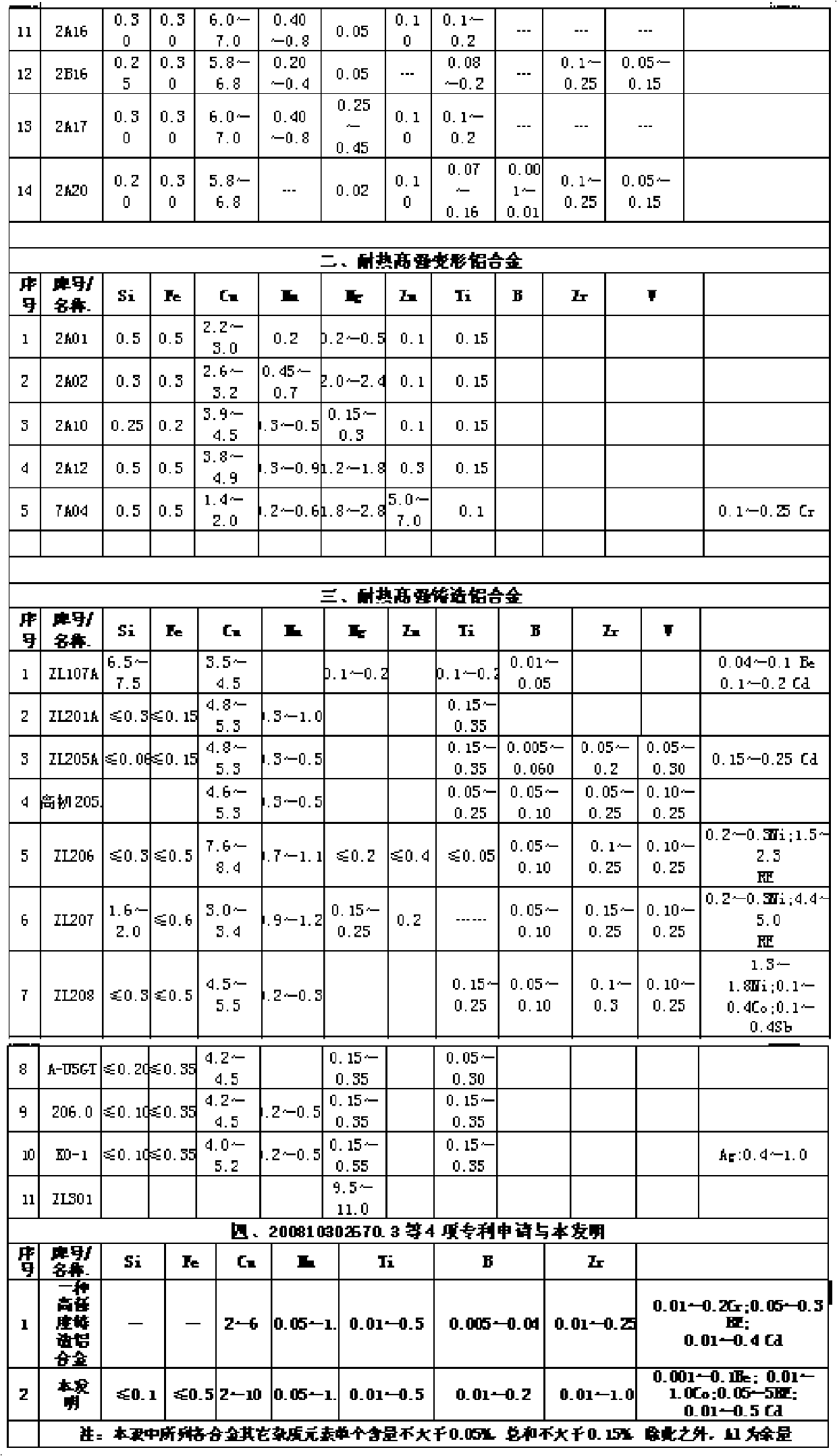

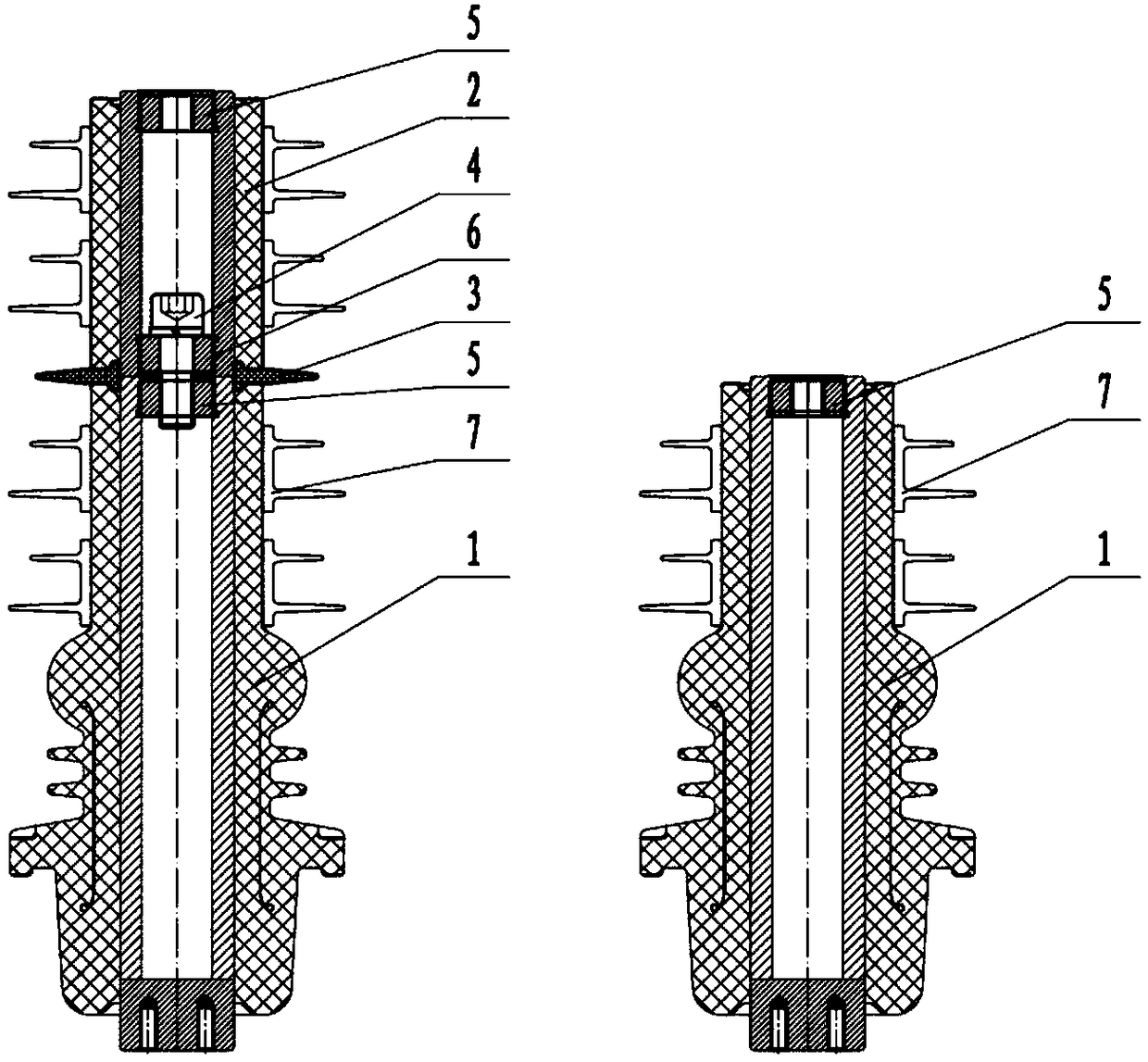

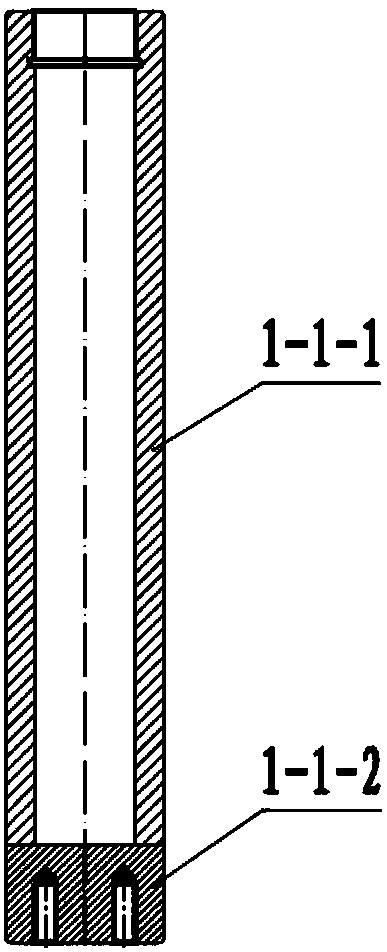

Outgoing line insulation sleeve and method of using same

The invention discloses an outgoing line insulation sleeve, which comprises an outgoing line sleeve main body, a heightening joint, a silicone rubber insulation piece, a fastening connection device and a silicone rubber umbrella skirt. The heightening joint can be spliced with the outgoing line sleeve main body to increase the outer insulation height of the outgoing line sleeve. The silicone rubber insulation member is in interference fit with the outgoing line sleeve main body and the heightening joint to form a stable insulating layer to prevent the electrified body at the joint portion frombeing discharged to the outside. The silicone rubber umbrella skirt is wrapped in the surface of an epoxy insulation layer of the outgoing line insulation sleeve. The invention provides an outgoing line insulation sleeve, which is a combined splicing type outgoing line insulation sleeve, and can be configured with a suitable outer insulation height of the sleeve according to different needs. Thecost of raw materials and the weight of the product are reduced, the installation strength is increased, the product umbrella skirt is not easy to damage, and at the same time the installation and positioning of the outgoing line insulation sleeve is facilitated.

Owner:TAIPINGYANG POWER EQUIP GROUP CHANGZHOU

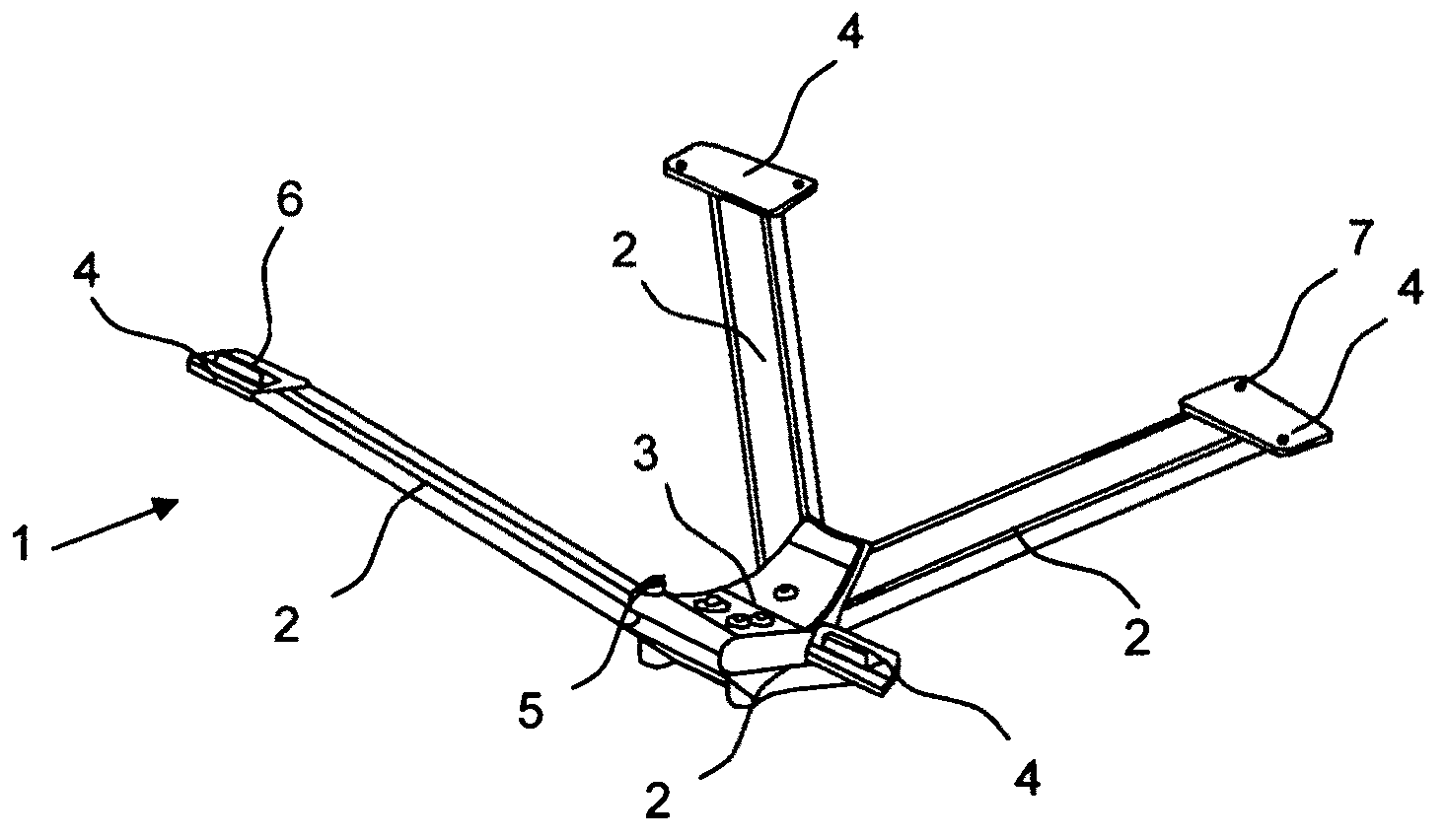

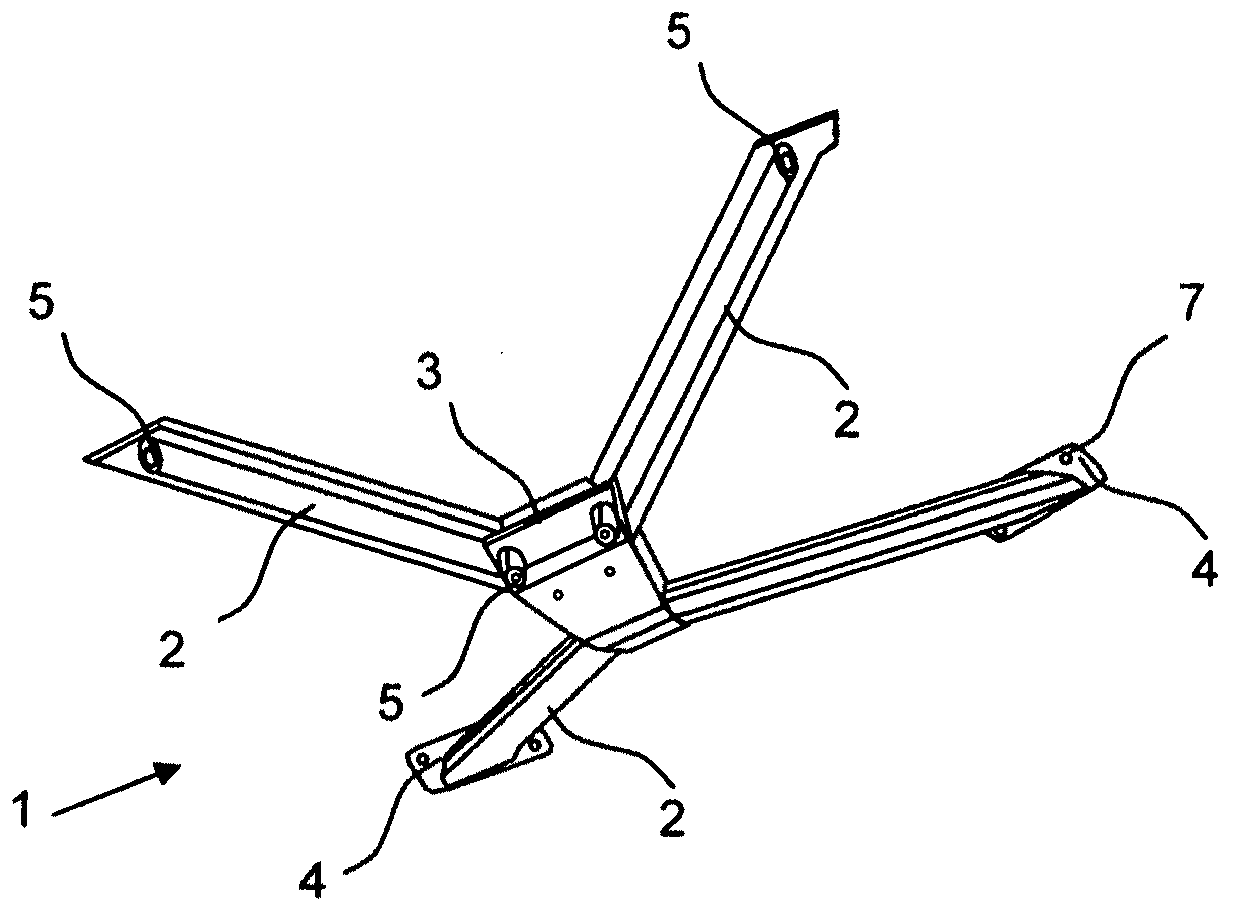

Diagonal strut device, method for manufacturing same and motor vehicle underfloor reinforced by means of diagonal structure device

InactiveCN103237714AReduce weightIncreased torsional stiffnessUnderstructuresSuperstructure subunitsFiberEngineering

The present invention provides a diagonal strut device (1) for reinforcing arrangement on an underfloor of a motor vehicle, wherein the diagonal strut device (1) comprises a plurality of struts (2) composed of a fibre-reinforced plastic composite material, which struts (2) extend away from a central node element (3). Each strut (2) can be connected by the end of each strut (2) to the underfloor, wherein the end of each strut (2) faces away from the central node element (3). For this purpose a connecting node element (4) is arranged at the end of each strut (2), the end faces away from the central node element (3), wherein the central node element (3) and the connecting node elements (4) are embodied from a lightweight metal material. The central node element (3) and the connecting node elements (4) are connected here to the struts (2) by means of an at least materially joined cast connection. In addition, the present invention relates to a method for manufacturing the diagonal strut device (1) and to the motor vehicle underfloor which uses the diagonal strut device (1) for reinforcement.

Owner:DAIMLER AG

Mo-RE high-strength heat-resistance aluminum alloy material and preparation method thereof

The invention discloses a high-strength heat-resistance aluminum alloy material and a preparation method thereof. The alloy material comprises the components in percentage by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.01-1.0% of Mo, 0.05-5% of RE and the balance of Al. By adopting high-quality melt and solid solution and phase diagram principle as guide and preferably choosing alloy main elements Cu, Mn and RE formula, the invention reduces alloy standard solid phase temperature range and solves the problems of large hot crack tendency, low high-temperature strength of products and the like in casting; in addition, by preferably choosing low-cost multielement microalloying element formula, the invention creates material condition for culturing and grain refining of medium-high and strengthening phases of the solid solution; and moreover, by optimizing the melting and heating processing technology, the invention realizes sufficient culturing and full play of grain refining of the medium-high and strengthening phases of the solid solution so as to finally prepare the high-strength heat-resistance aluminum alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Cr-Sm high-strength heat resisting aluminum alloy material and preparation method thereof

The invention discloses a Cr-Sm high-strength heat resisting aluminum alloy material and a preparation method thereof. The alloying components in percentage by weight are as follows: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2 % Of B, 0.01-1.0% of Zr, 0.01-1.0% of Cr, 0.05-5% of Sm and the balance Al. In the invention, high-quality fusant, a solid solution and a phase diagram theory are used as instruction, and the formula of the main alloying elements Cu, Mn and Sm is optimized, so that the quasi-solid phase temperature range of the alloy is reduced, and the problems of high thermal cracking inclination during casting, low high-temperature strength of the product and the like are solved; because the formula of low-cost multi-element microalloying elements is optimized, a material basis condition is created for culture of the high temperature phase and the strengthening phase in the solid solution and the grain refining effect; and finally a novel aluminum alloy material is developed by optimizing a smelting and heat treatment technology.

Owner:贵州铝厂有限责任公司 +2

cr-li-re high-strength heat-resistant aluminum alloy material and preparation method thereof

InactiveCN102021378BGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a high-strength heat-resistant aluminium alloy material and preparation method thereof. The aluminium alloy comprises the following components by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B,0.01-1.0% of Zr, 0.01-1.0% of Cr, 0.1-3.0% of Li, 0.05-5% of RE, and the balance of Al. By adopting high-quality melt, solid solution and phase diagram principle as a guide and preferably choosing alloy main elements Cu, Mn and RE formula, the method reduces the temperature range of the quasi-solid phase of the alloy, solves the problems of strong crack forming tendency in casting and low product strength at higher temperatures; by preferably choosing low-cost multi-component micro-alloying element formula, the method creates basic material conditions for the cultivation and the grain refining of medium-high and strengthening phases of the solid solution so as to finally prepare the high-strength heat-resistant aluminum alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

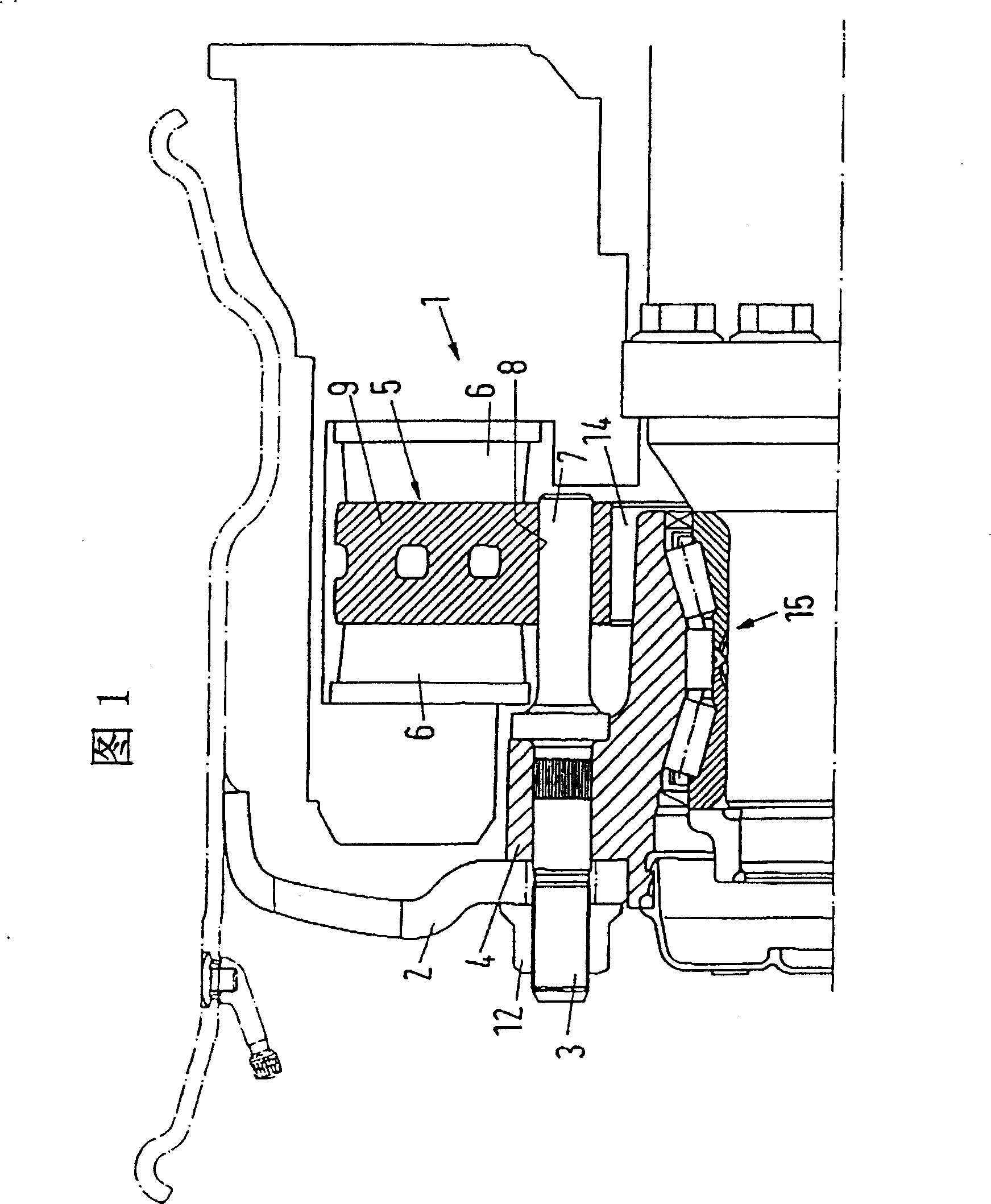

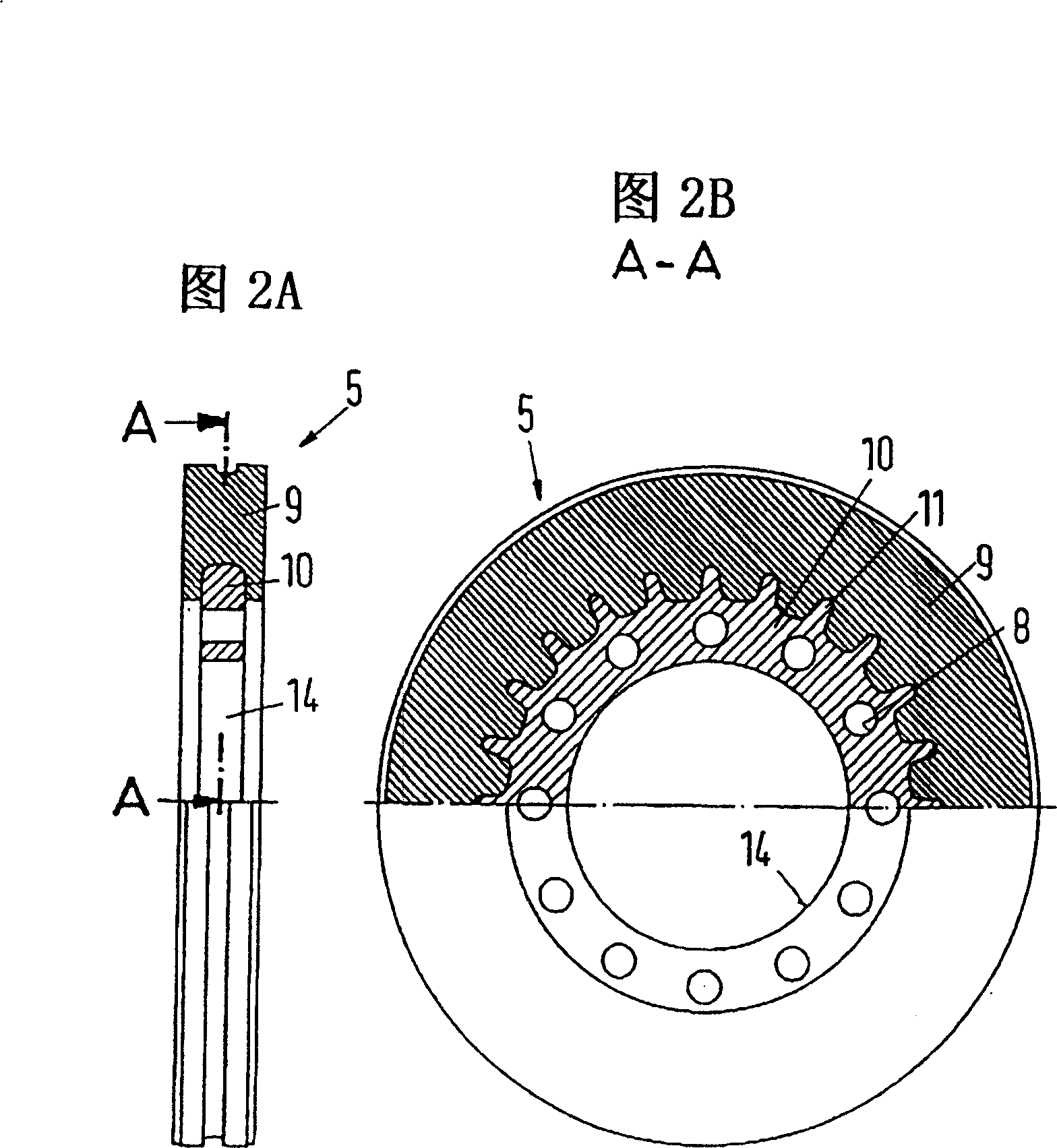

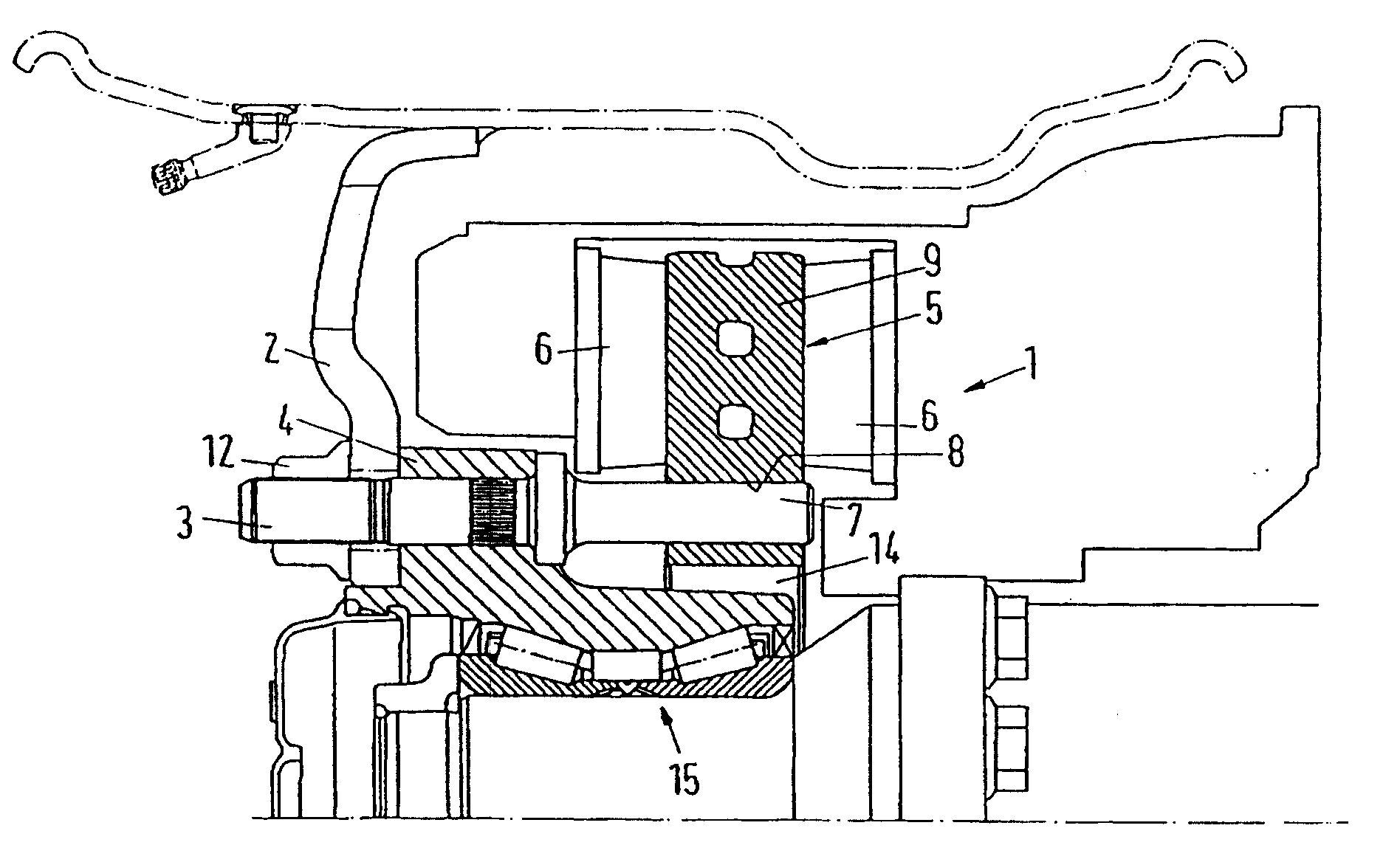

Fixed disc type brake

The present invention relates to a fixed clamp disk type brake for vehicle, and is characterized by that its every wheel is respectively fixed on the wheel hup by means of every wheel screw bolts, in the zone of wheel hup of brake disk capable of axially shifting is supported, and can be clamped between the brake blocks. According to said invention the brake disk can utilize at least one bolt extended portion toward interior, specially utilize the balt extended portion of wheel self-body to make axial mobile guide relatively to hup. Said invention can use this mode to make simple, low-cost and reliable compensation of wear and tear of the brake disk.

Owner:SAF HOLLAND GMBH

Li-Mo-RE high-strength heat-resistant aluminium alloy material and preparation method thereof

The invention discloses a high-strength heat-resistant aluminium alloy material and a preparation method thereof. The aluminium alloy material comprises the following components by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.1-3.0% of Li, 0.01-1.0% of Mo, 0.05-5% of RE and the balance Al. By taking high-quality melt, solid solution and phase diagram theory as guidance and optimizing the formulas of the major alloy elements Cu, Mn and RE, the invention narrows the quasi-solid phase temperature range of the alloys and solves the problems of great hot crack tendency during casting, low high temperature strength of the products and the like, and by optimizing the formulas of the low cost multiple micro alloying elements, the invention creates material base conditions for cultivation and grain refining of medium-high temperature phase and strengthening phase of the solid solution and finally develops the high-strength heat-resistant aluminium alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Cr-RE high-strength heat-resistant aluminum alloy material and preparation method thereof

InactiveCN102021441AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a high-strength heat-resistant aluminum alloy material and a preparation method thereof. The alloy comprises the following components in percentage by weight: 1.0 to 10.0 percent of Cu, 0.05 to 1.5 percent of Mn, 0.01 to 0.5 percent of Cd, 0.01 to 0.5 percent of Ti, 0.01 to 0.2 percent of B, 0.01 to 1.0 percent of Zr, 0.01 to 1.0 percent of Cr, 0.05 to 5 percent of RE, and the balance of Al. Under the guidance of a high-quality melt, solid solution and phase diagram theory, a preferable formula of main alloy elements, namely Cu, Mn and RE is adopted, so that the quasi-solid phase temperature range of the alloy is reduced, and problems such as large heat cracking tendency during casting, low strength of a product at high temperature and the like are solved; a preferable formula of low-cost multiple microalloying elements is adopted, so that a material base condition is created for the culture and grain refining of a high-temperature phase and a strengthening phase in solid solution; and smelting and heat treatment process technology is optimized, so that the sufficient culture of the high-temperature phase and the strengthening phase in the solid solution is realized, the grain refining action is fully exerted, and the high-strength heat-resistant aluminum alloy material is finally developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Co-RE high-strength heat-resisting aluminum alloy material and production method thereof

InactiveCN101805855BGood value for moneyOvercoming cost barriersUltimate tensile strengthHeat treated

The invention discloses a high-strength heat-resisting aluminum alloy material and a production method thereof. The high-strength heat-resisting aluminum alloy material comprises the following components in percentage by weight: Cu: 1.0-10.0%; Mn: 0.05-1.5%; Cd: 0.01-0.5%; Ti: 0.01-0.5%; B: 0.01-0.2%; Zr: 0.01-1.0%; Co: 0.01-1.0%; RE: 0.05-5%; and the balance of Al. By adopting a high-quality melt, solid solution and phase diagram theory as the guide and preferring main alloy element formula of Cu, Mn and RE, the invention reduces an alloy quasi solid phase temperature range and solves the problems of large heat crack tendency in casting, low high-temperature strength of products and the like; in addition, by preferring a multiple microalloying element formula, the invention provides material condition for culture and grain refining of a high temperature phase and a strengthening phase in the solid solution; by optimizing smelting and technology for heating processing, the invention fully plays the quantum sufficient culture and grain refining of the high temperature phase and the strengthening phase in the solid solution and finally produces the high-strength heat-resisting aluminum alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Cr-Nb-RE high-strength heat resistant aluminum alloy material and preparation method thereof

The invention discloses a Cr-Nb-RE high-strength heat resistant aluminum alloy material and a preparation method thereof. The material comprises the following component in percentage by weight: 1.0-10.0 percent of Cu, 0.05-1.5 percent of Mn, 0.01-0.5 percent of Cd, 0.01-0.5 percent of Ti, 0.01-0.2 percent of B, 0.01-1.0 percent of Zr, 0.01-1.0 percent of Cr, 0.01-1.0 percent of Nb, 0.05-5 percent of RE and the balance of Al. In the invention, high-quality melts, solid solutions and a phase diagram theory are used as a guide, and the alloy quasi solid-phase temperature range is reduced through optimizing the formulas of main alloy elements of Cu, Mn and RE so as to solve the problems of large heat tearing tendency, low product high-temperature strength, and the like; and a low-cost multiple microalloying element formula is optimized, thus a material base condition is created for the culture and the grain refining of a high-temperature phase and a strengthening phase in solid solutions so as to finally develop the high-strength heat resistant aluminum alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Be-W-RE high-strength heat resistant aluminum alloy material and preparation method thereof

InactiveCN102021368AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a high-strength heat resistant aluminum alloy material and a preparation method thereof. The material comprises the following components in percentage by weight: 1.0-10.0 percent of Cu, 0.05-1.5 percent of Mn, 0.01-0.5 percent of Cd, 0.01-0.5 percent of Ti, 0.01-0.2 percent of B, 0.01-1.0 percent of Zr, 0.001-0.1 percent of Be, 0.01-1.0 percent of W, 0.05-5 percent of RE and the balance of Al. In the invention, under the guidance of high-quality melts, solid solutions and a phase diagram theory, through optimizing the formulas of main alloy elements of Cu, Mn and RE ,the alloy quasi solid-phase temperature range is reduced and the problems of large heat tearing tendency, low product high-temperature strength, and the like are solved; and a low-cost multielement microalloy element formula is optimized, which creates a material base condition for the culture and the grain refining of a high-temperature phase and a strengthening phase in solid solutions so as to finally develop the high-strength heat resistant aluminum alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Nb-W-RE high-strength heat-resistant aluminum alloy material and preparation method thereof

InactiveCN102021377AGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a high-strength heat-resistant aluminum alloy material and a preparation method thereof. The material comprises the following components in percentage by weight: 1.0 to 10.0 percent of Cu, 0.05 to 1.5 percent of Mn, 0.01 to 0.5 percent of Cd, 0.01 to 0.5 percent of Ti, 0.01 to 0.2 percent of B, 0.01 to 1.0 percent of Zr, 0.01 to 1.0 percent of Nb, 0.01 to 1.0 percent of W, 0.05 to 5 percent of RE and the balance of Al. A high-quality melt, solid solution and a phase diagram theory are taken as guidance, a preferable formula of main alloy elements, namely Cu, Mn and RE is adopted, so that the quasi-solid phase temperature range of the alloy is narrowed, and problems such as high heat cracking tendency during casting, low strength of a product at high temperature and the like are solved; and a preferable formula of low-cost multiple microalloying elements is adopted to create a material base condition for culture and grain refining of a high-temperature phase and a strengthening phase in solid solution, so that the high-strength heat-resistant aluminum alloy material is finally developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Mo-Ni-RE high-strength heat-resistant aluminium alloy material and preparation method thereof

InactiveCN101994036BGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Co-Ni-RE high-strength heat-resisting aluminum alloy material and production method thereof

The invention discloses a high-strength heat-resisting aluminum alloy material and a production method thereof. The high-strength heat-resisting aluminum alloy material comprises the following components in percentage by weight: Cu: 1.0-10.0%; Mn: 0.05-1.5%; Cd: 0.01-0.5%; Ti: 0.01-0.5%; B: 0.01-0.2%; Zr: 0.01-1.0%; Co: 0.01-1.0%; Ni: 0.001-0.1%; RE: 0.05-5%; and the balance of Al. By adopting a high-quality melt, solid solution and phase diagram theory as the guide and preferring main alloy element formula of Cu, Mn and RE, the invention reduces an alloy quasi solid phase temperature range and solves the problems of large heat crack tendency in casting, low high-temperature strength of products, and the like; in addition, by preferring a multiple microalloying element formula, the invention provides material condition for culture and grain refining of a high temperature phase and a strengthening phase in the solid solution and finally produces the high-strength heat-resisting aluminum alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Co-Mo-RE high-strength heat resistant aluminum alloy material and preparation method thereof

InactiveCN102021372BGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a high-strength heat resistant aluminum alloy material and a preparation method thereof. The material comprises the following components in percentage by weight: 1.0-10.0 percent of Cu, 0.05-1.5 percent of Mn, 0.01-0.5 percent of Cd, 0.01-0.5 percent of Ti, 0.01-0.2 percent of B, 0.01-1.0 percent of Zr, 0.01-1.0 percent of Co, 0.01-1.0 percent of Mo, 0.05-5 percent of RE and the balance of aluminum. In the invention, under the guidance of high-quality melts, solid solutions and a phase diagram theory, through optimizing the formulas of main alloy elements of Cu, Mn andRE, the alloy quasi solid-phase temperature range is reduced and the problems of large heat tearing tendency, low product high-temperature strength, and the like are solved; and a low-cost multielement microalloy element formula is optimized, which creates a material base condition for the culture and the grain refining of a high-temperature phase and a strengthening phase in solid solutions so as to finally develop the high-strength heat resistant aluminum alloy material.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Be-Ni-RE high-strength heatproof aluminum alloy material and preparation method thereof

InactiveCN102021370BGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a high-strength heatproof aluminum alloy material and a preparation method thereof. The high-strength heatproof aluminum alloy material comprises the following components in percentage by weight: 1.0-10.0 percent of Cu, 0.05-1.5 percent of Mn, 0.01-0.5 percent of Cd, 0.01-0.5 percent of Ti, 0.01-0.2 percent of B, 0.01-1.0 percent of Zr, 0.001-0.1 percent of Be, 0.01-1.0 percent of Ni, 0.05-5 percent of RE, and the balance of AI. In the invention, the theory of high-quality melts, solid solutions and phase diagrams is used as guidance, and a formula of main alloy elements Cu and Mn and RE is preferentially selected to reduce the temperature range of an alloy quasi-solid phrase and solve the problems of large heat crack tendency during, low high-temperature strength of products and the like; and a formula of low-cost multiple microalloying element is preferentially selected to create substance basic conditions for the cultivation and grain refining action of a high-temperature phase and a strengthening phase in the solid solutions, and finally, the high-strength heatproof aluminum alloy material is prepared.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Be-Co-RE high-strength heat-resistant aluminum alloy material and preparation method thereof

InactiveCN102021366BGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a high-strength heat-resistant aluminum alloy material and a preparation method thereof. The high-strength heat-resistant aluminum alloy material comprises the following components in percentage by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.001-0.1% of Be, 0.01-1.0% of Co, 0.05-5% of RE and the balance of Al. With high-quality melt, sosoloid and the phase diagram theory as guidance, the invention reduces the quasi solid-phase temperature range of the alloy and solves the problems of great thermal cracking tendency during casting, low high-temperature strength of products and the like by preferably selecting the formation of main alloy elements of Cu, Mn and RE. The preferable selection of the formulation of low-cost multielement microalloy elements creates material base conditions for breeding and grain-refining a high-temperature phase and a strengthening phase in the sosoloid, and a high-strength heat-resistant aluminum alloy material is finally developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Co-Li-RE high-strength heat-resistant aluminium alloy material and preparation method thereof

InactiveCN102021373BGood value for moneyOvercoming cost barriersSolid solutionUltimate tensile strength

The invention discloses a high-strength heat-resistant aluminium alloy material and a preparation method thereof. The aluminium alloy material comprises the following components by weight: 1.0-10.0% of Cu, 0.05-1.5% of Mn, 0.01-0.5% of Cd, 0.01-0.5% of Ti, 0.01-0.2% of B, 0.01-1.0% of Zr, 0.01-1.0% of Co, 0.1-3.0% of Li, 0.05-5% of RE and the balance Al. The invention finally develops the high-strength heat-resistant aluminium alloy material by taking the high-quality melt, solid solution and phase diagram theory as the guidance, giving preference to the main alloying elements Cu, Mn and RE as formulas, reducing the temperature range of the quasi-solid phase of the alloys, solving the problems of great hot cracking tendency, low high temperature strength of the products and the like during casting and giving preference to multiple microalloying elements with low cost as formulas to create basic material conditions for cultivation and grain refining functions of the high temperature phase and strengthening phase in the solid solution.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com