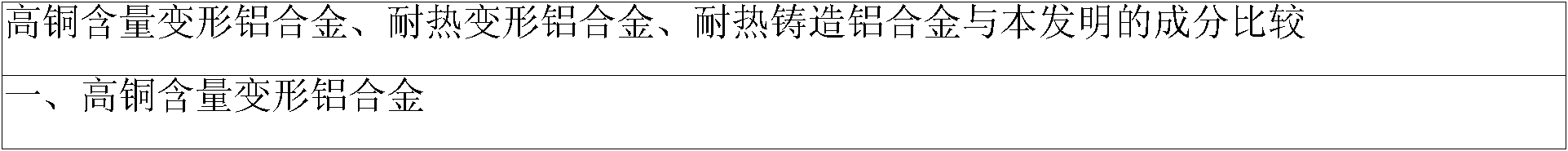

Cr-Sm high-strength heat resisting aluminum alloy material and preparation method thereof

An aluminum alloy material, cr-sm technology, which is applied in the field of aluminum alloy materials of microalloying elements and rare earth elements and its preparation, can solve the problems of reducing the quasi-solid phase temperature range of alloys, poor quality, and large hot cracking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

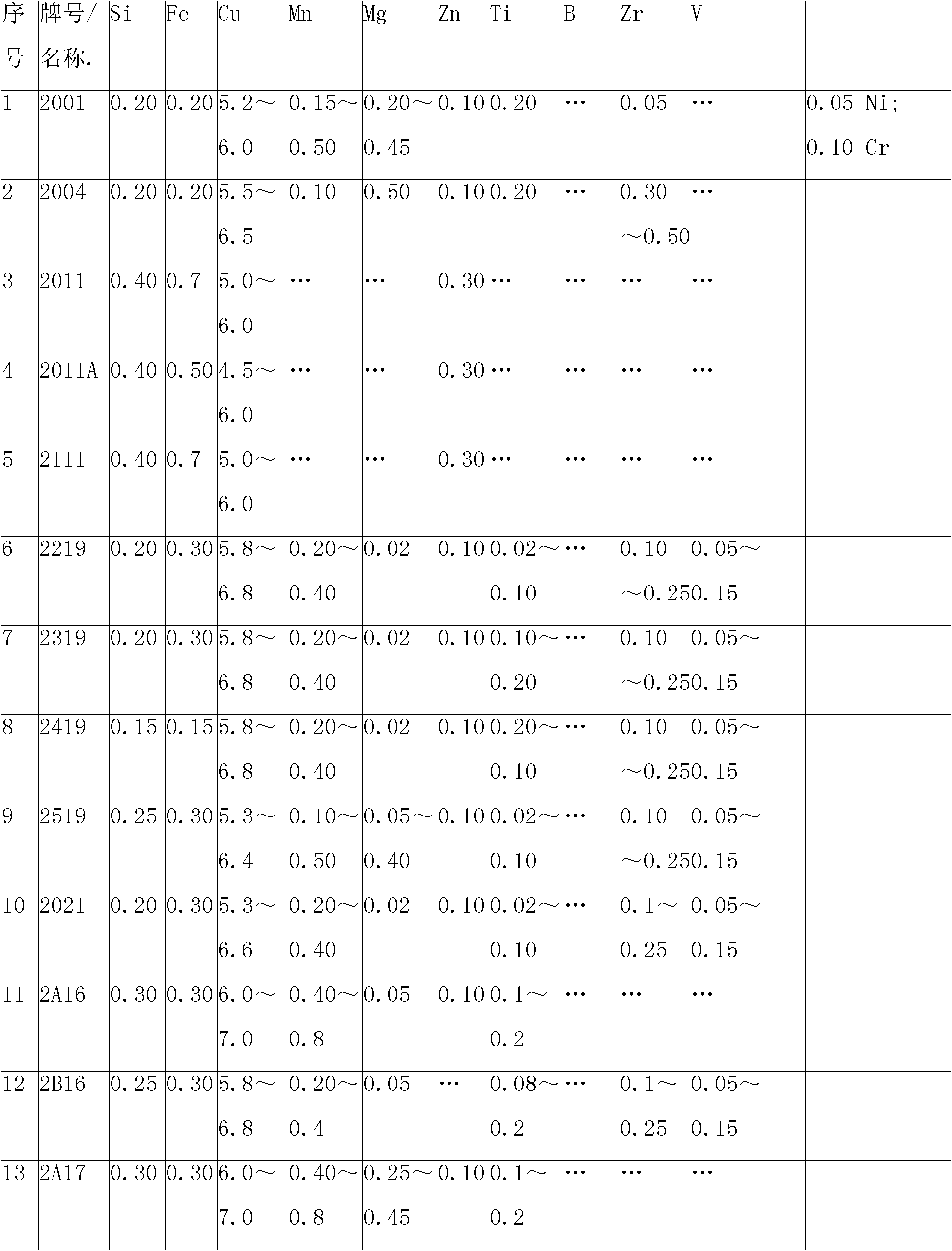

[0104] Example 1: Cu-1.0%, characteristic microalloying element-Cr, basic microalloying rare earth element-Sm

[0105] (1) Weigh the various alloying elements required according to the ingredient calculation table, as follows.

[0106]

[0107] (2) Add an appropriate amount of aluminum ingots to the melting furnace, heat it to melt it completely and keep it warm at 700-800°C; in order to prevent the melt from inhaling too much air, the melting process should be as short as possible in a closed environment Finish.

[0108] (3) Add Al-Mn, Al-Ti, Al-Cr, Al-Zr intermediate alloy or mixed metal additives (including salt compounds) according to the formula ratio, and then add Cu pure metal and Al-Cd intermediate Alloy or mixed metal additives, then add Al-B and Al-Sm master alloys, and stir evenly.

[0109] Mixed metal additives refer to cake-shaped or massive non-sintered powder metallurgy products for adding and adjusting alloy components, including manganese, copper, zirconi...

Embodiment 2

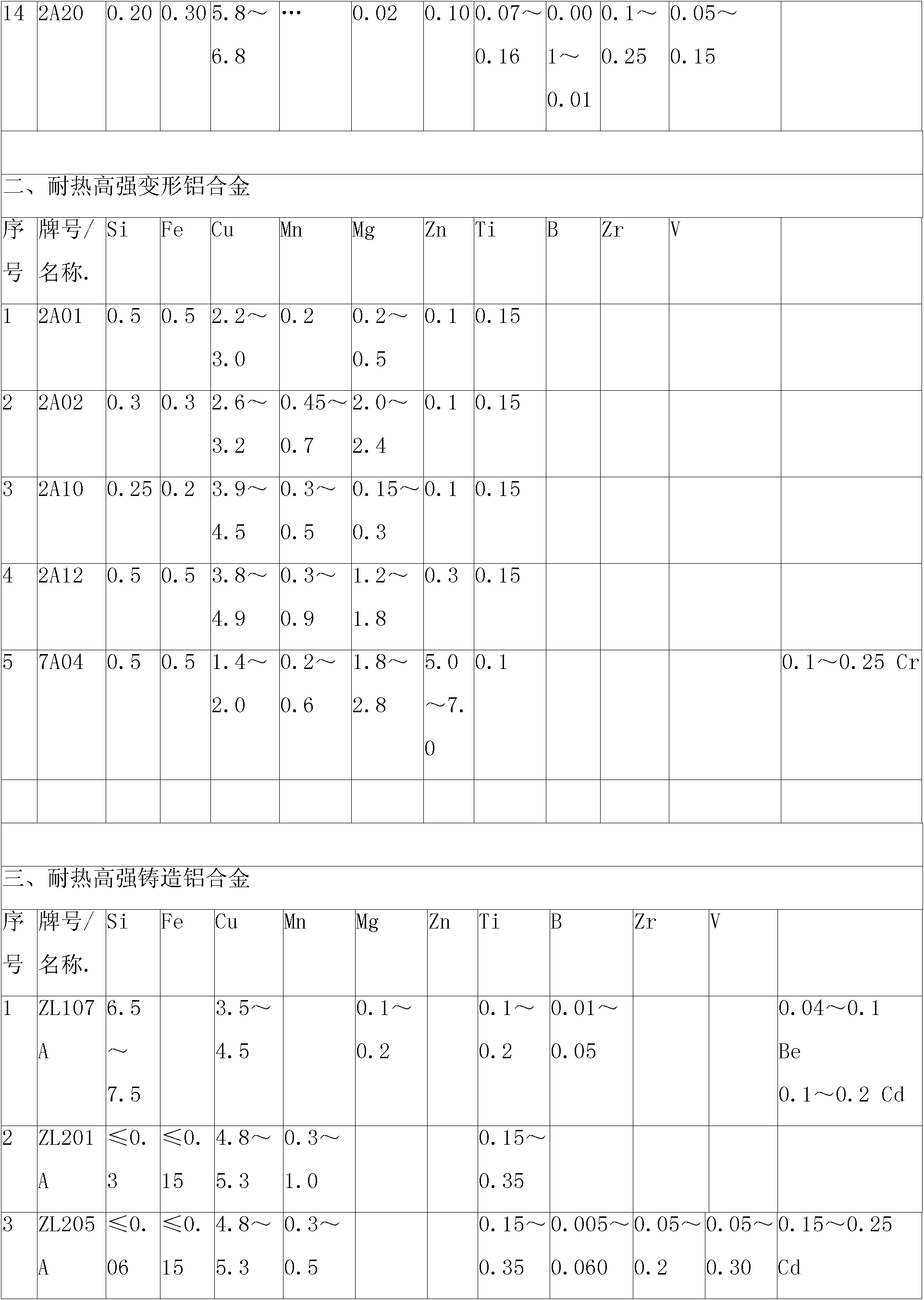

[0115] Example 2: Cu-4.2%, characteristic microalloying element-Cr, basic microalloying rare earth element-Sm

[0116] (1) Weigh the various alloying elements required according to the ingredient calculation table, as follows.

[0117]

[0118] (2) Add an appropriate amount of aluminum ingots to the melting furnace, heat it to melt it completely and keep it warm at 700-800°C; in order to prevent the melt from inhaling too much air, the melting process should be as short as possible in a closed environment Finish.

[0119] (3) Add Al-Mn, Al-Ti, Al-Cr, Al-Zr intermediate alloy or mixed metal additives (including salt compounds) according to the formula ratio, and then add Cu pure metal and Al-Cd intermediate Alloy or mixed metal additives, then add Al-B and Al-Sm master alloys, and stir evenly.

[0120] Mixed metal additives refer to cake-shaped or massive non-sintered powder metallurgy products for adding and adjusting alloy components, including manganese, copper, zirconi...

Embodiment 3

[0126] Example 3: Cu-6.01%, characteristic microalloying element-Cr, basic microalloying rare earth element-Sm (1) Weigh various required alloying elements according to the ingredient calculation table, as follows.

[0127]

[0128] (2) Add an appropriate amount of aluminum ingots to the melting furnace, heat it to melt it completely and keep it warm at 700-800°C; in order to prevent the melt from inhaling too much air, the melting process should be as short as possible in a closed environment Finish.

[0129] (3) Add Al-Mn, Al-Ti, Al-Cr, Al-Zr intermediate alloy or mixed metal additives (including salt compounds) according to the formula ratio, and then add Cu pure metal and Al-Cd intermediate Alloy or mixed metal additives, then add Al-B and Al-Sm master alloys, and stir evenly.

[0130] Mixed metal additives refer to cake-shaped or massive non-sintered powder metallurgy products for adding and adjusting alloy components, including manganese, copper, zirconium, chromium,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com