Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "High seam precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

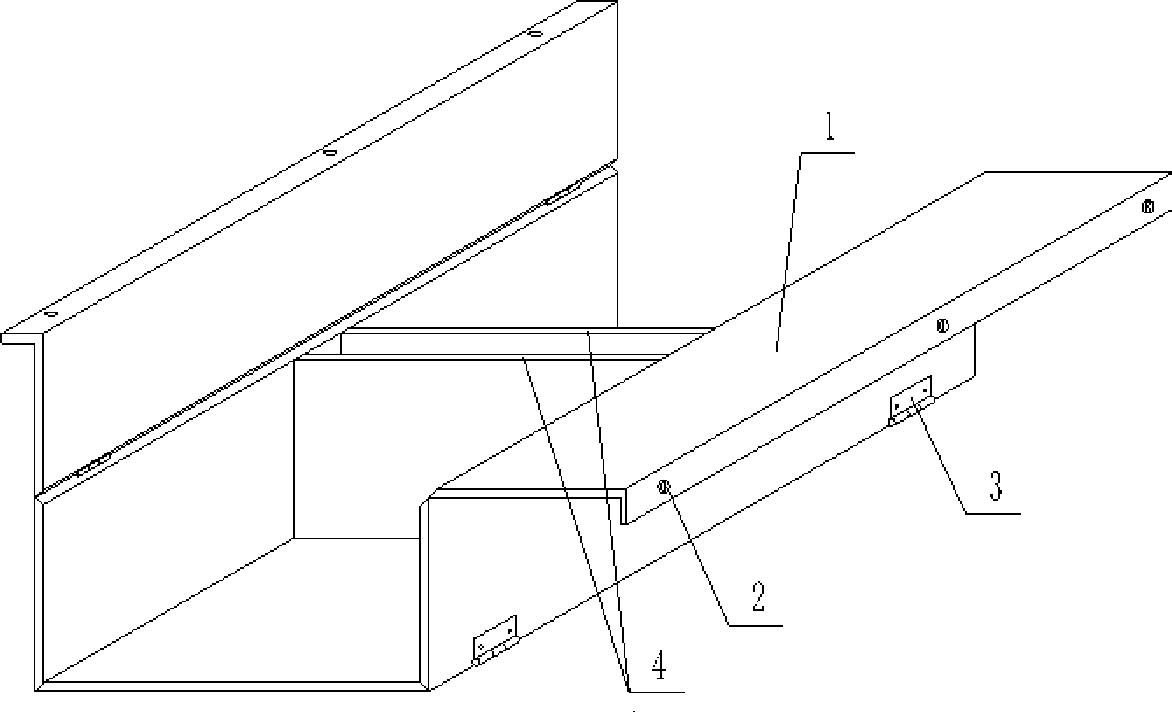

Forming die for component in polyhedron

InactiveCN1727148AEasy to splitEasy to assembleMould separation apparatusMouldsBiomedical engineeringFastener

Owner:湖南邱则有专利战略策划有限公司

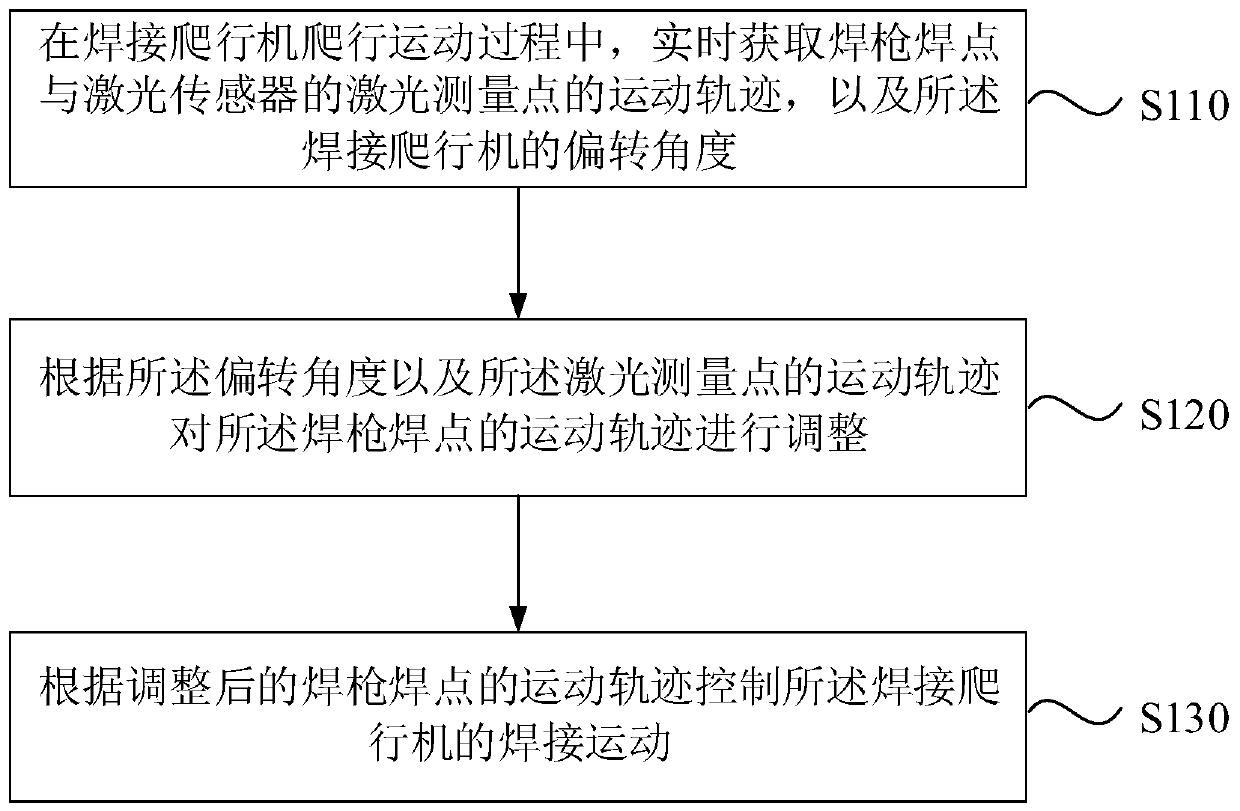

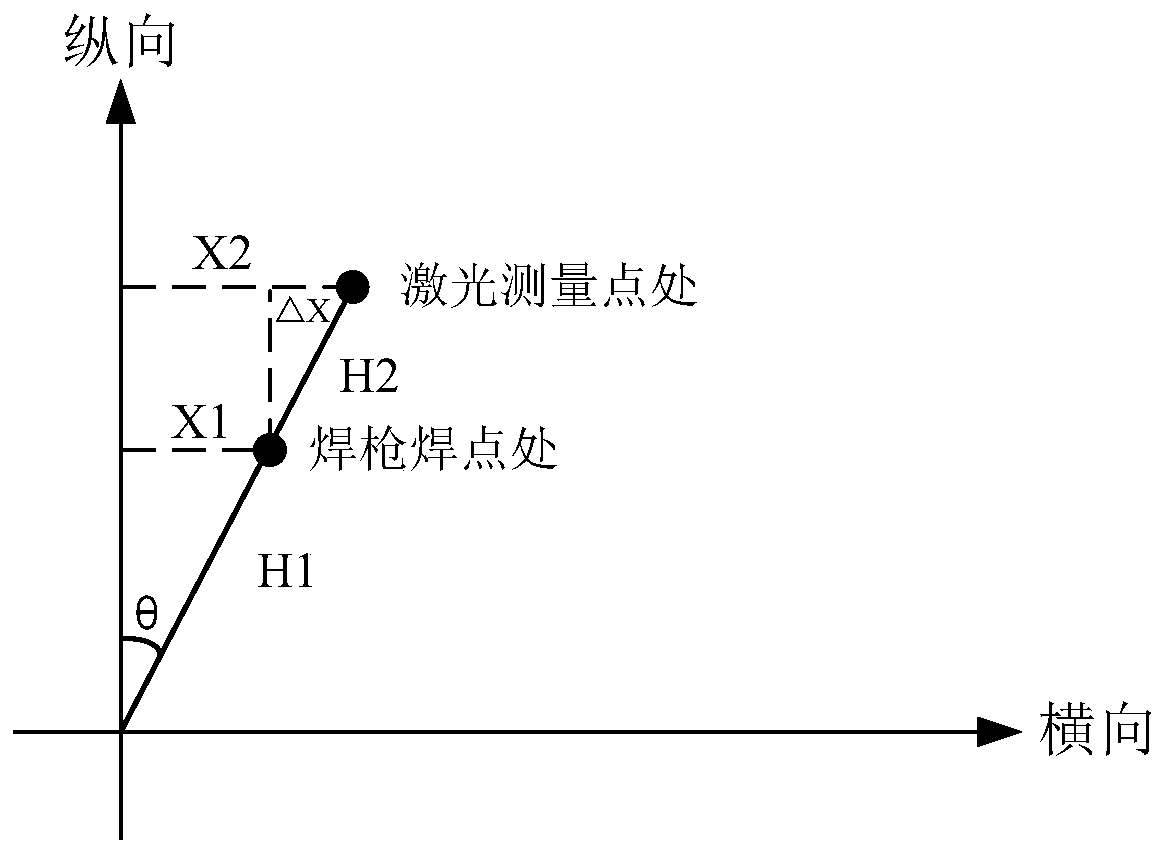

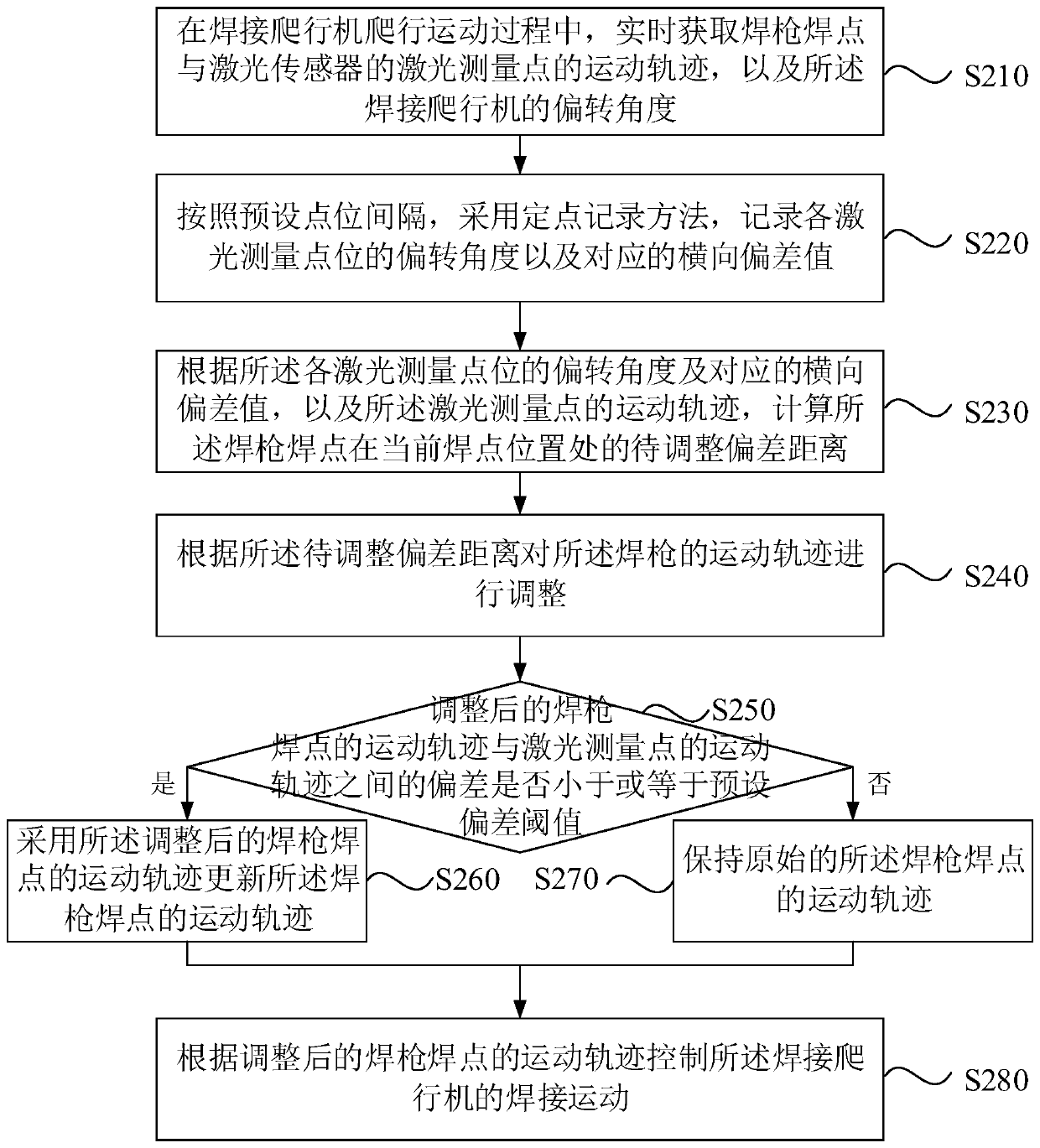

Welding movement control method, system and device, computer equipment and storage medium

ActiveCN111215772AImprove tracking accuracyImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesWeld seamMovement control

The embodiment of the invention discloses a welding movement control method, system and device, computer equipment and a storage medium. The method includes the steps of obtaining movement trajectories of a welding point of a welding gun and a laser measuring point of a laser sensor and the deflection angle of a welding crawler in real time in the crawling movement process of the welding crawler,adjusting the movement trajectory of the welding point of the welding gun according to the deflection angle and the movement trajectory of the laser measuring point, and controlling the welding movements of the welding crawler according to the adjusted movement trajectory of the welding point of the welding gun. By means of the technical scheme, the precision of the welding gun for tracking a weldjoint can be improved, and then the welding quality is improved.

Owner:BEIJING BO TSING TECH CO LTD

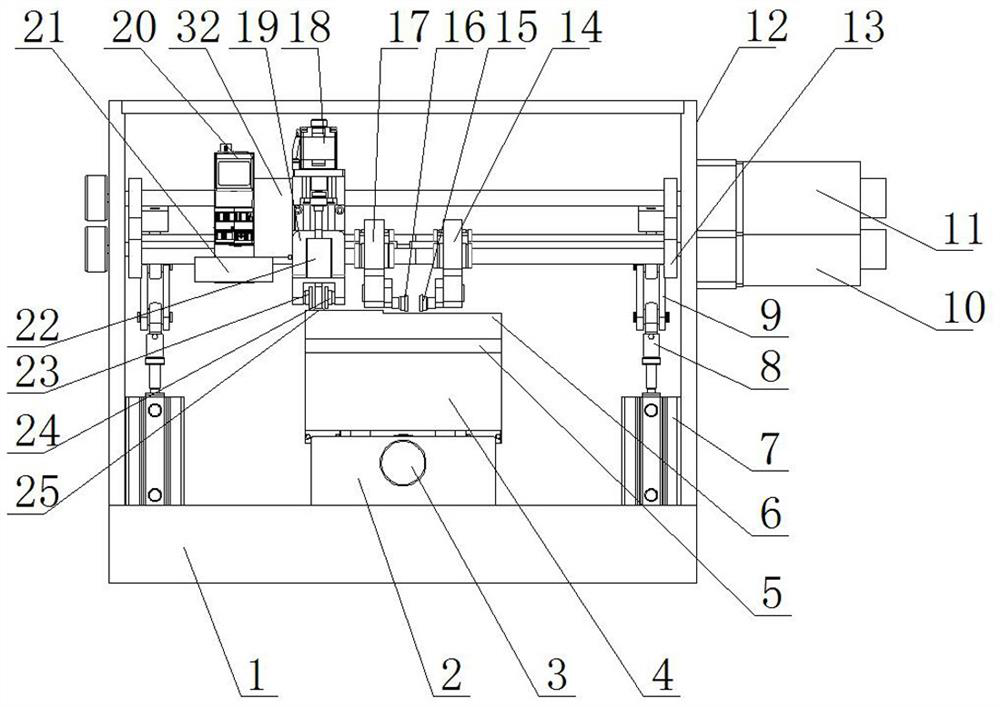

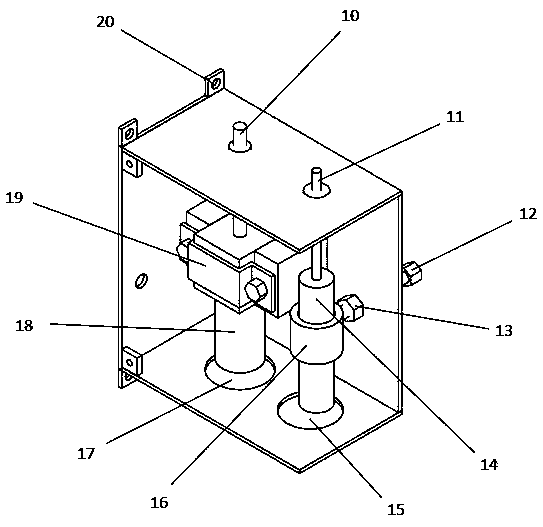

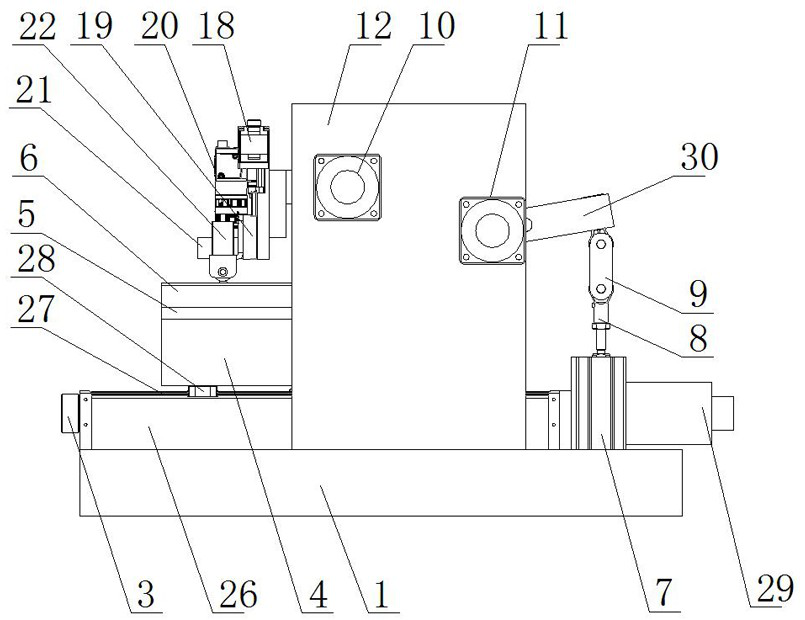

Automatic parallel seal welding device based on image recognition and seal welding method

ActiveCN111730185AAchieve absorptionAchieve releaseCurved planar seam weldingMetal working apparatusControl systemVisual inspection

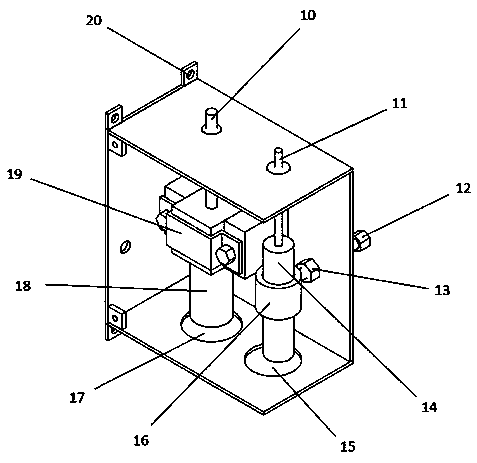

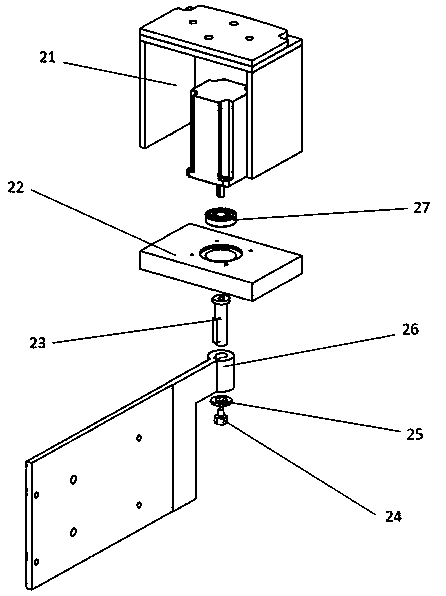

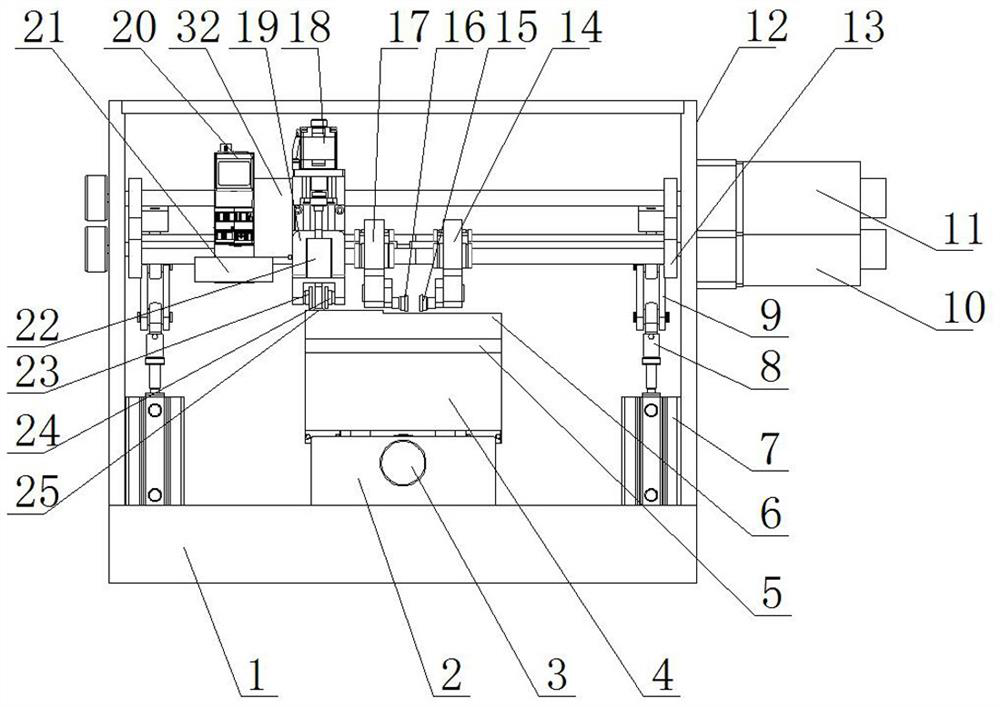

The invention relates to an automatic parallel seal welding device based on image recognition and a seal welding method, and belongs to the technical field of fine electronic product welding. The automatic parallel seal welding device comprises a baseplate as well as a product tooling positioning mechanism, a spot welding positioning mechanism, a seam welding positioning mechanism, a visual inspection system and a control system, wherein the product tooling positioning mechanism comprises a longitudinal reciprocating moving mechanism and a rotating mechanism; the longitudinal reciprocating moving mechanism is mounted on the baseplate; the rotating mechanism is mounted on the longitudinal reciprocating moving mechanism; a product tooling is mounted on the rotating mechanism; two parallelly-arranged rack vertical plates are mounted on the baseplate; the spot welding positioning mechanism and the seam welding positioning mechanism are both mounted on the rack vertical plates; spot weldingelectrode wheels are mounted on the spot welding positioning mechanism; seam welding electrode wheels are mounted on the seam welding positioning mechanism; and the visual inspection system is mounted on the spot welding positioning mechanism. The automatic parallel seal welding device is utilized for solving the technical problem that during the seal welding process in the prior art, the degreeof automation is low, the production efficiency is low, the product air-tightness is poor, and the appearance quality is poor.

Owner:烟台华创智能装备有限公司

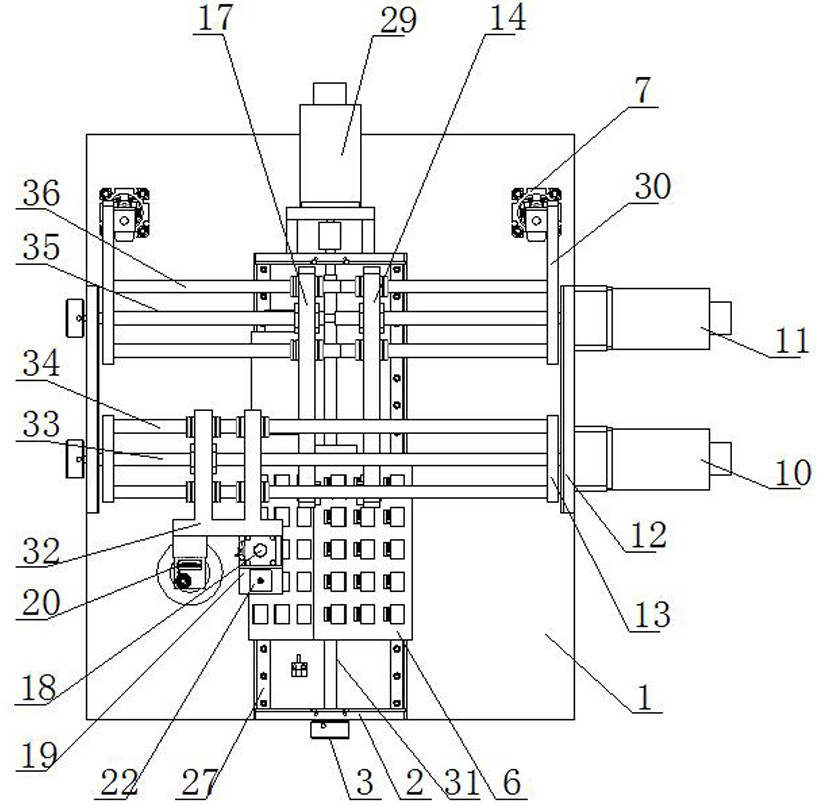

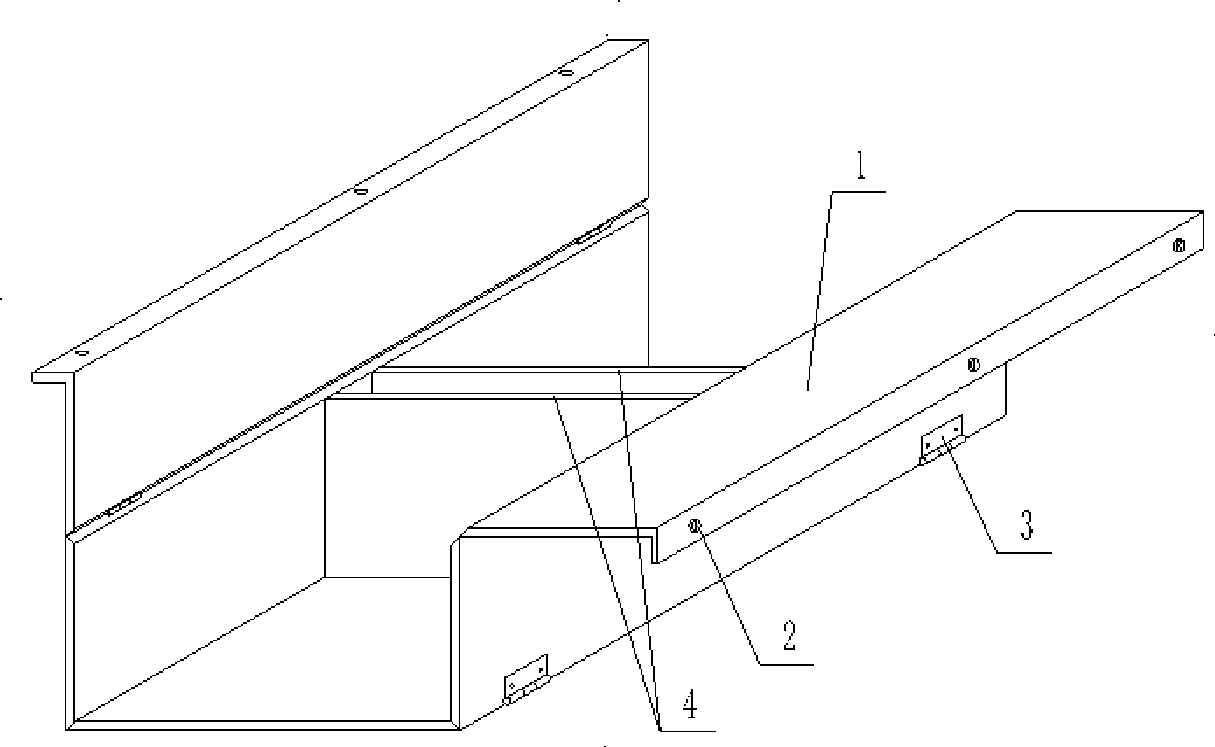

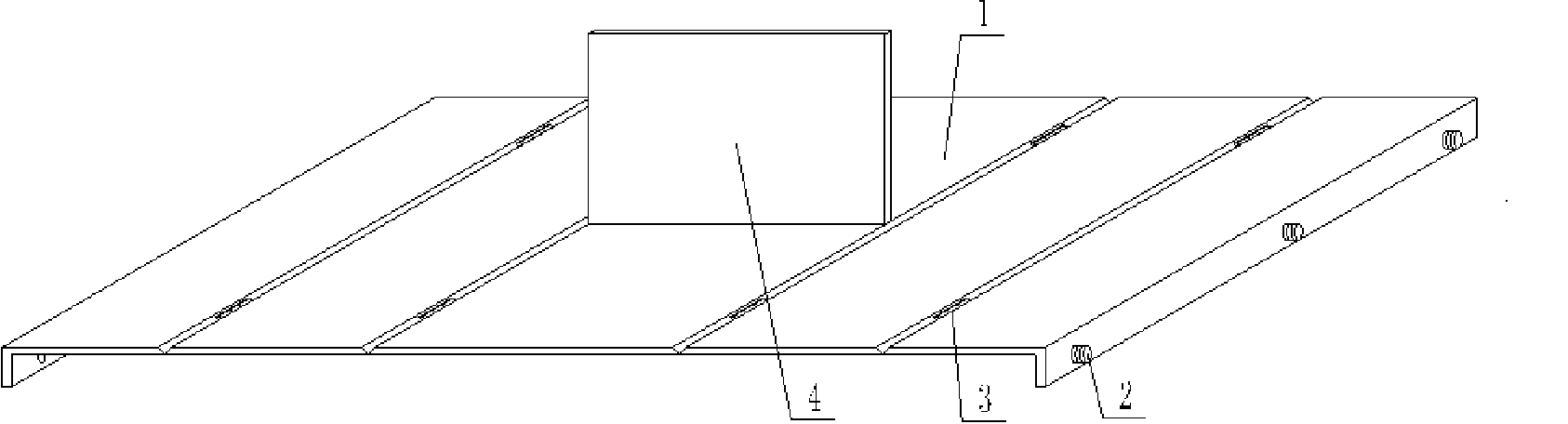

Automatic welding device and welding method with welding gun pose changing in real time

ActiveCN111390351AIncrease flexibilityImprove welding efficiencyElectrode holder supportersWelding accessoriesWeld seamRigid body

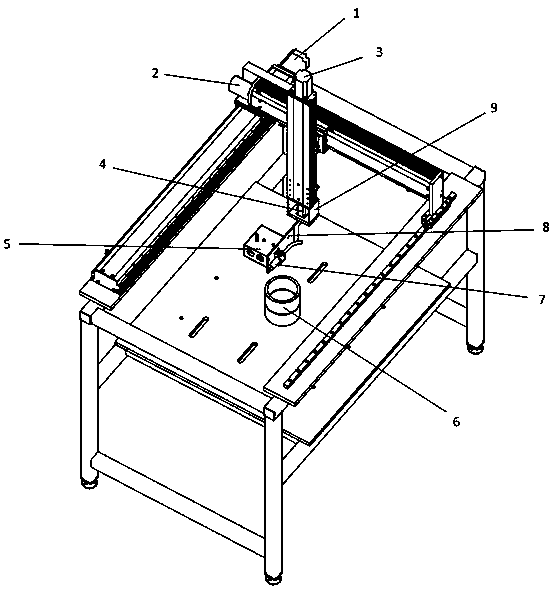

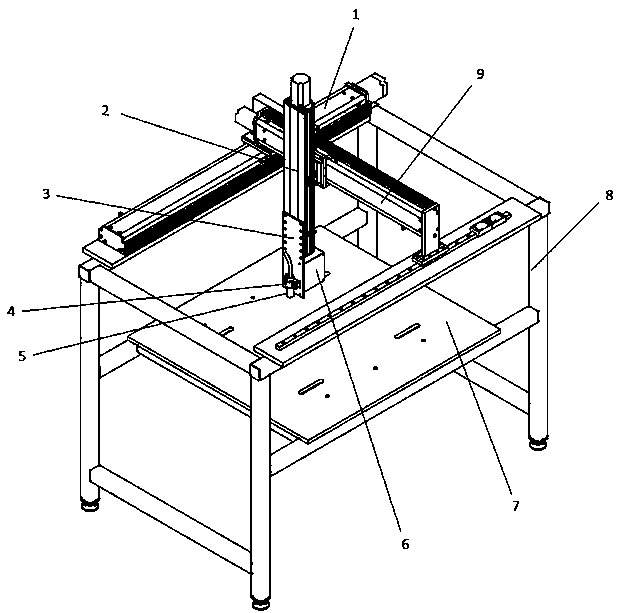

The invention relates to an automatic welding device and welding method with the welding gun pose changing in real time, and belongs to the field of welding automation. A gantry type three-axis welding platform is composed of a rigid body support, a welding platform operation area, a three-axis gantry type combined module and a welding gun rotating mechanism and is provided with an absolute coordinate system O-XYZ, wherein the three-axis gantry type combined module is divided into an X principal axis module with an X-axis auxiliary guide rail, a Y-axis module and a Z-axis module; and the welding platform operation area is fixed to the middle part of the rigid body support, the X principal axis module and the X-axis auxiliary guide rail are fixed to the upper part of the rigid body support,the two ends of the Y-axis module are connected to the X principal axis module and the X-axis auxiliary guide rail in a sliding mode correspondingly, the Z-axis module is connected to the Y-axis module in a sliding mode, and the welding gun rotating mechanism is rigidly fixed under the Z-axis module. The automatic welding device and welding method with the welding gun pose changing in real time have the advantages of automatically identifying the welding seam track in real time, automatically controlling a welding gun to move, removing manual teaching, improving the flexibility of the weldingdevice and improving the welding efficiency.

Owner:JILIN UNIV +1

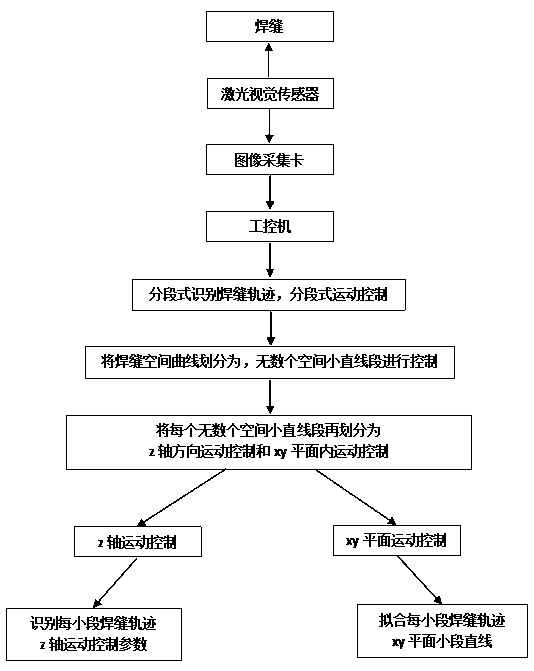

Gantry type three-axis welding device capable of automatically identifying weld joint track and welding method of gantry type three-axis welding device

ActiveCN111375945AIncrease flexibilityImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringVision sensor

The invention relates to a gantry type three-axis welding device capable of automatically identifying a weld joint track and a welding method of the gantry type three-axis welding device, and belongsto the field of welding automation. The device comprises a gantry type three-axis welding platform, a laser vision sensor, an image acquisition card, a welding gun, a welding machine and a control cabinet; the gantry type three-axis welding platform is composed of a rigid body support, a welding platform operation area and a gantry type three-axis combined module and is provided with an absolute coordinate system o-xyz; the gantry type three-axis combined module is divided into an x-main axis module comprising an x-axis auxiliary guide rail, a y-axis module and a z-axis module; and the weldingplatform operation area is fixed in the middle of the rigid support, the x-main axis module and the x-axis auxiliary guide rail are fixed to the upper portion of the rigid support, the two ends of the y-axis module are connected to the x-main axis module and the x-axis auxiliary guide rail in a sliding mode, and the z-axis module is connected to the y-axis module in a sliding mode. The device hasthe advantages that the weld joint track is automatically identified in real time, the welding gun is automatically controlled to move, manual teaching is removed, the flexibility of the welding device is improved and the welding efficiency is improved.

Owner:JILIN UNIV +1

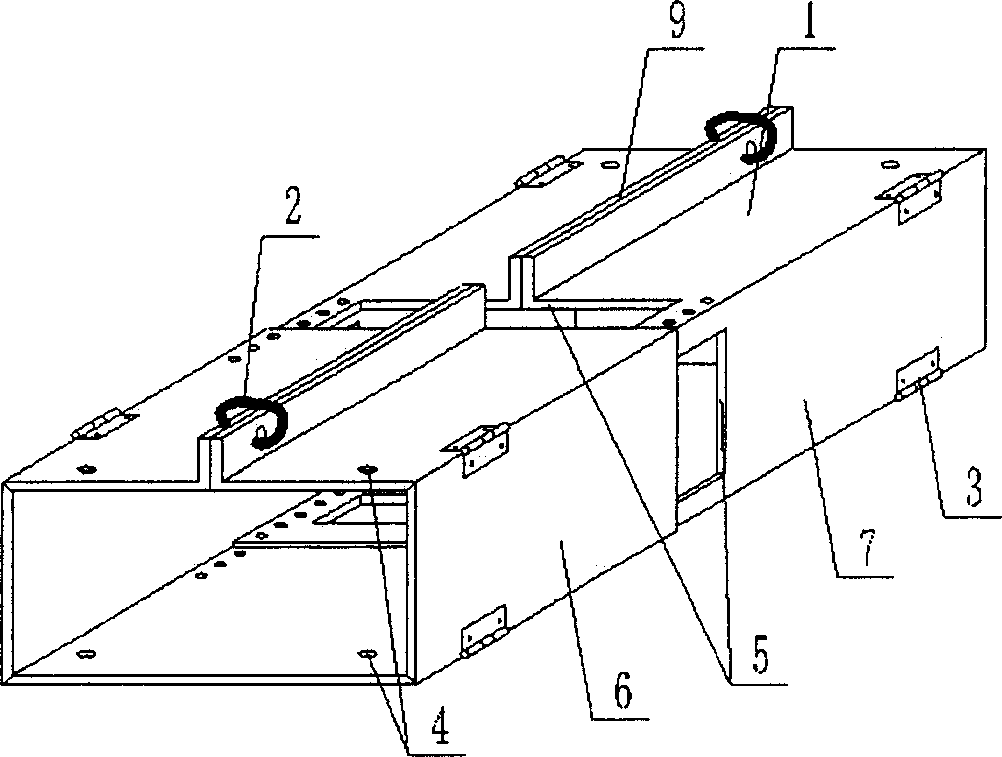

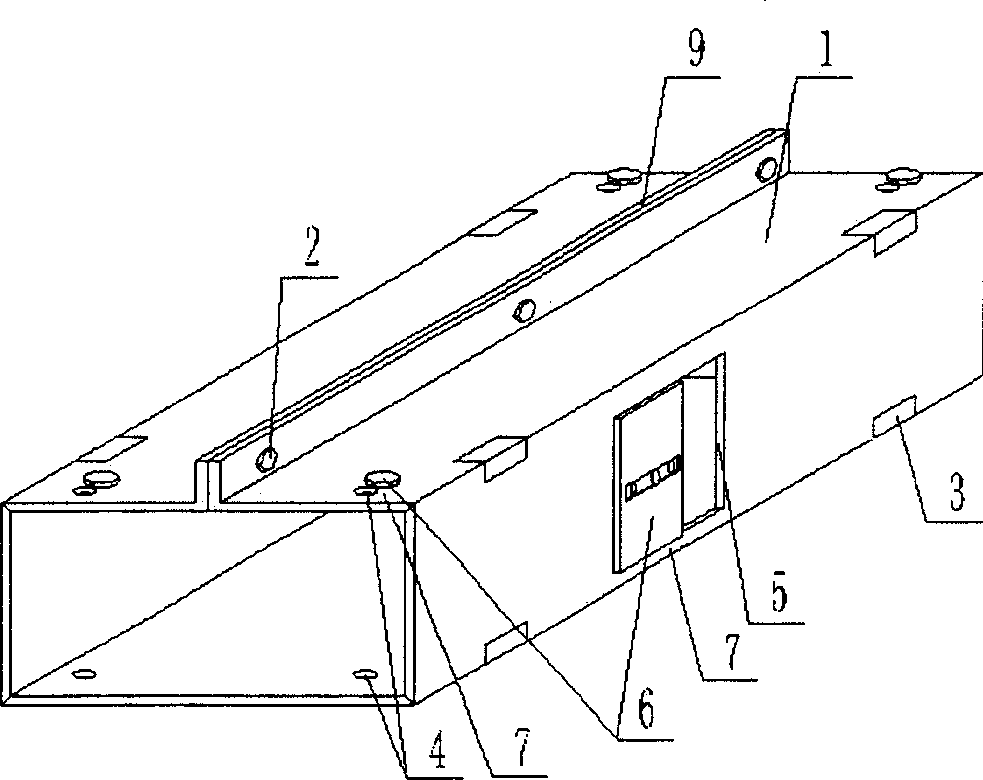

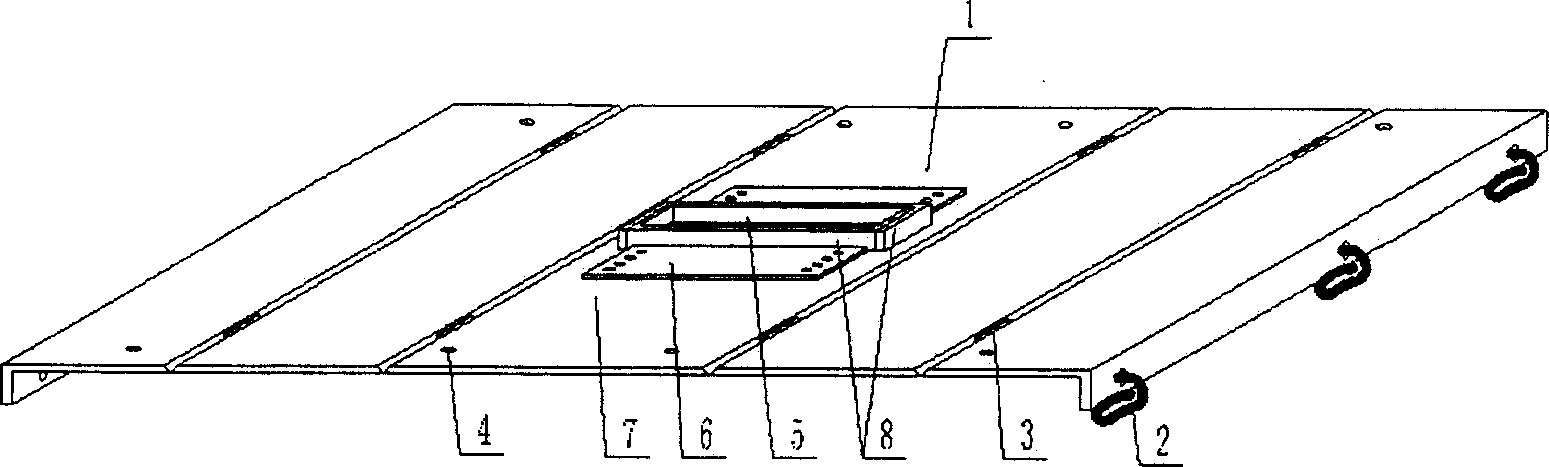

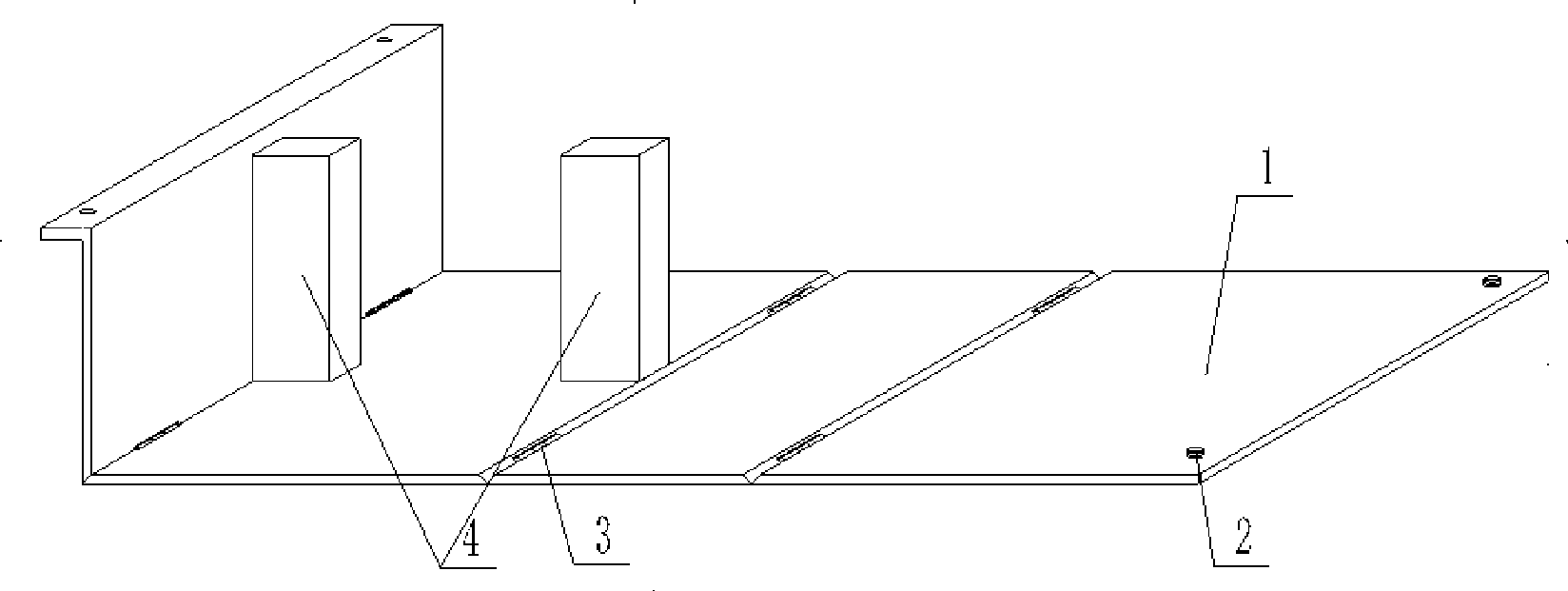

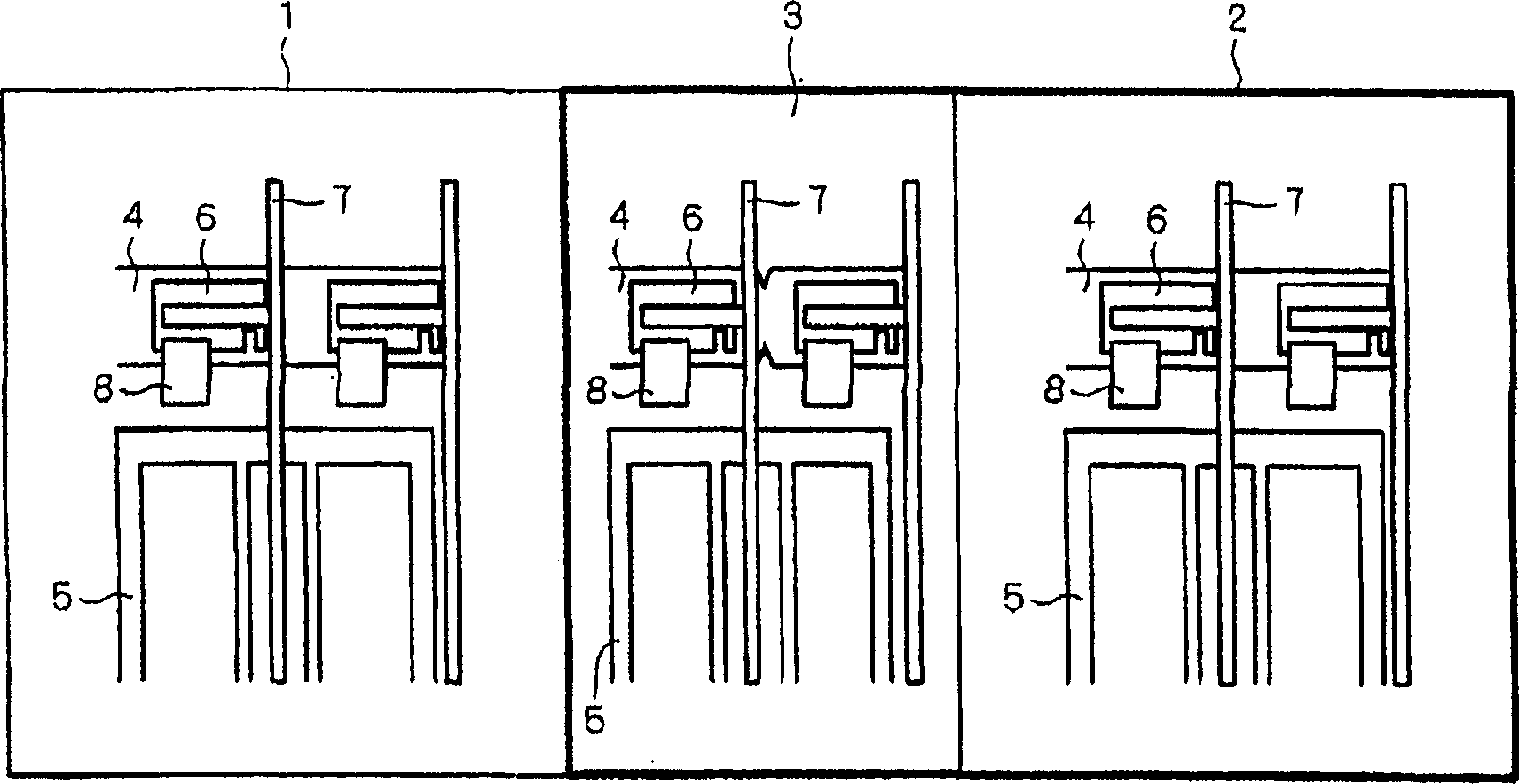

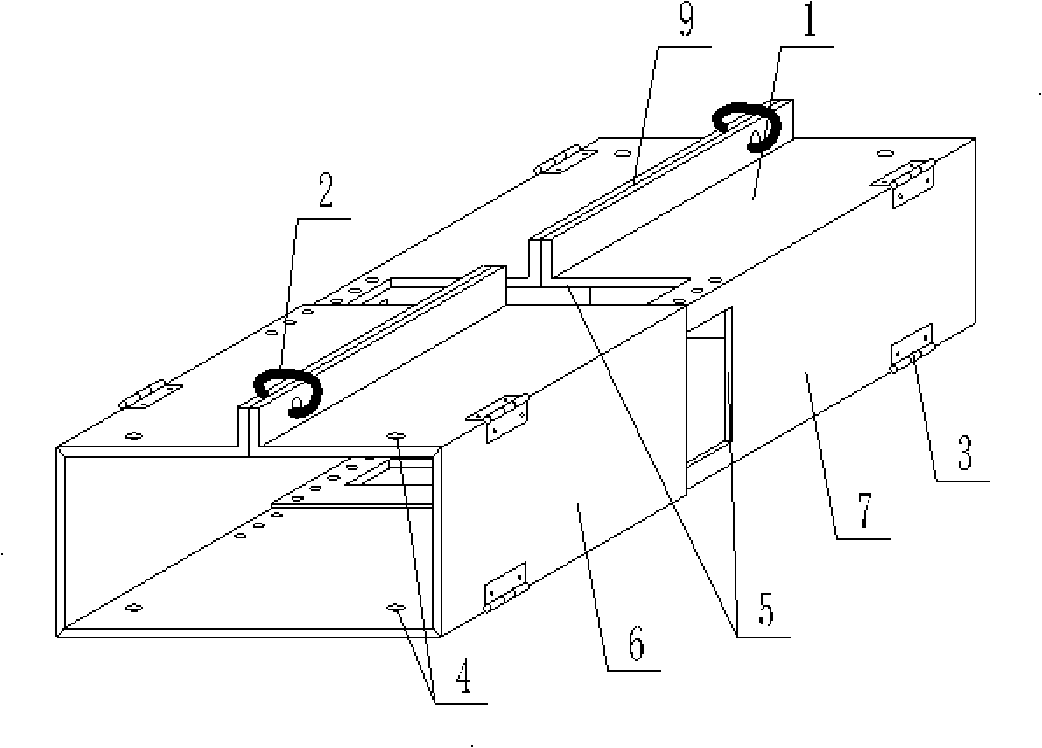

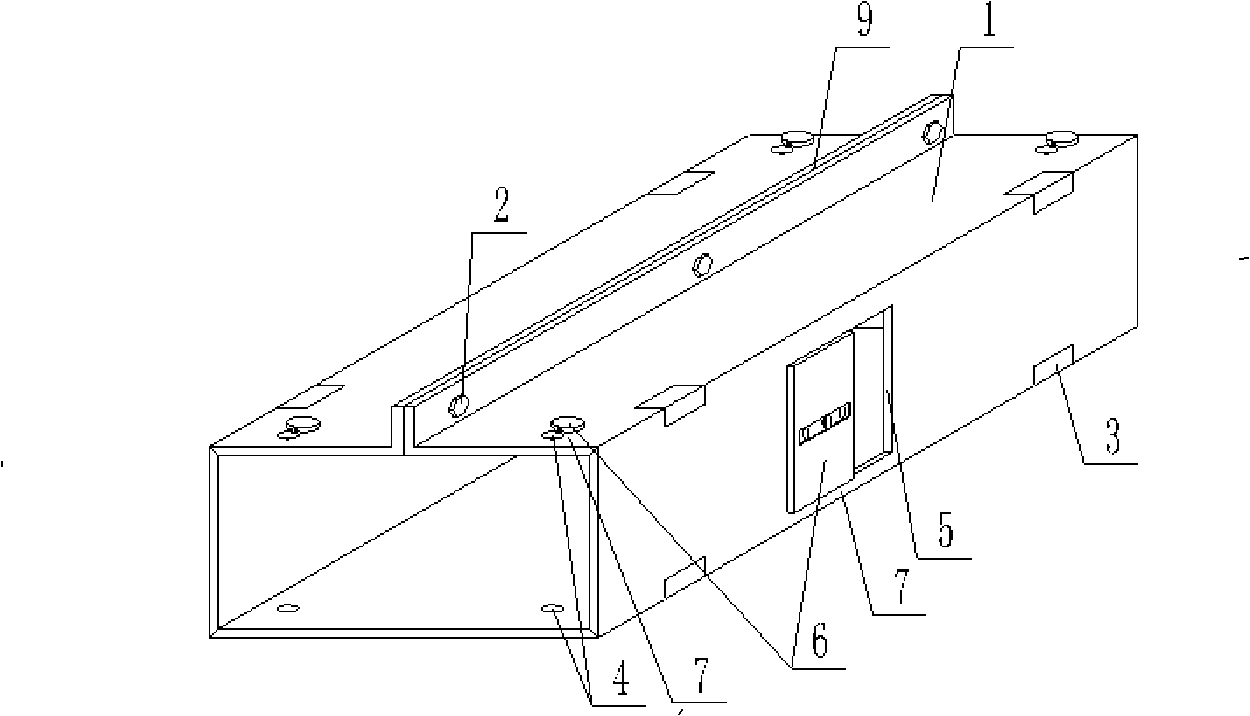

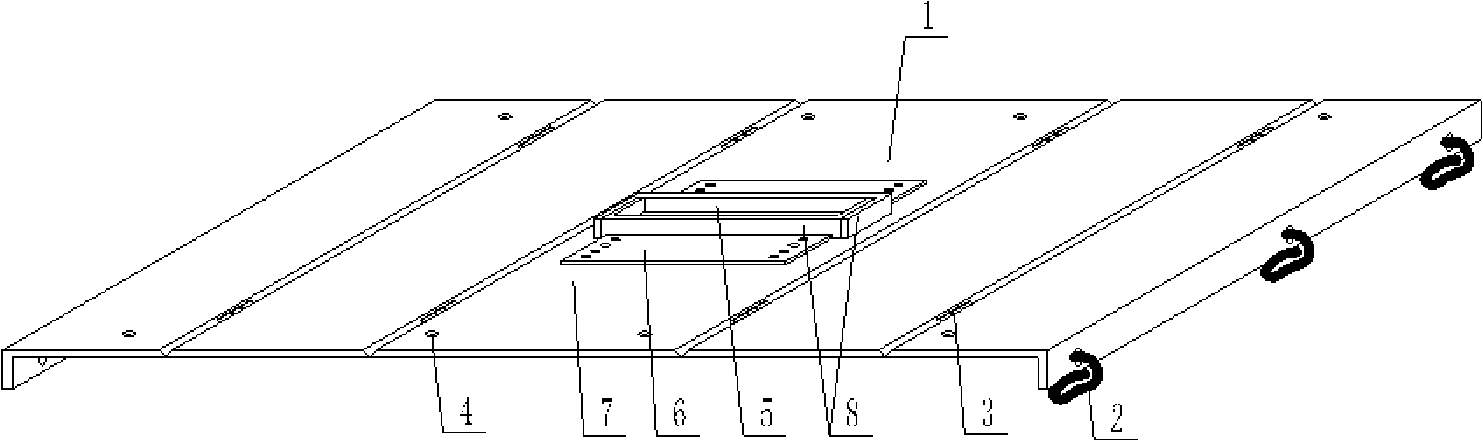

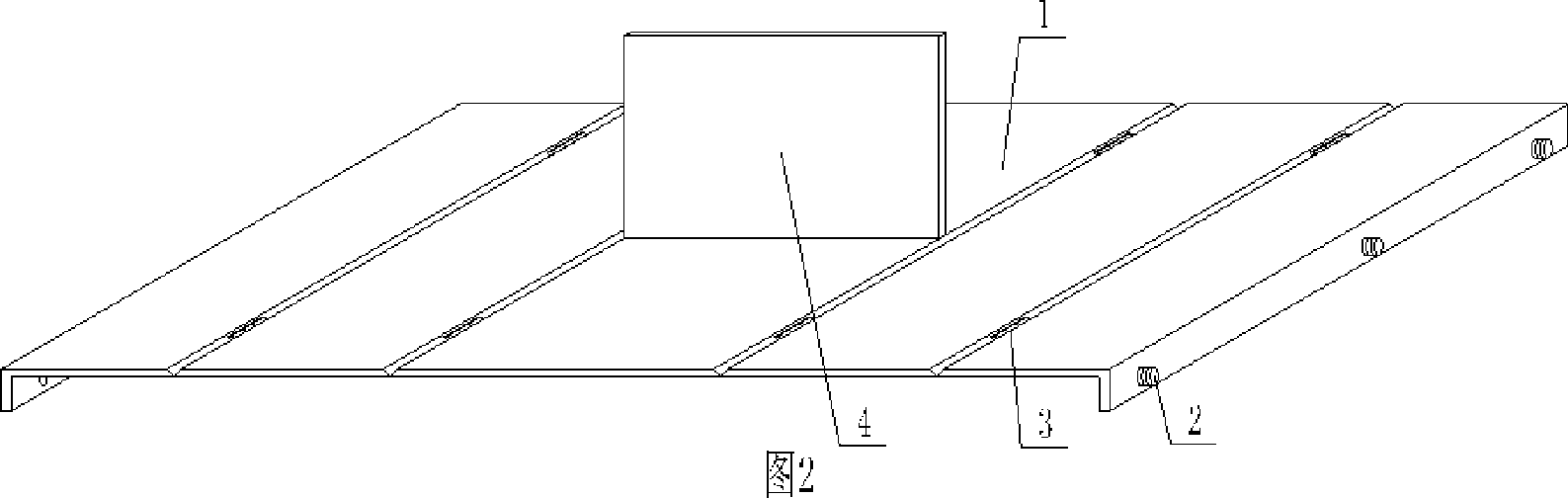

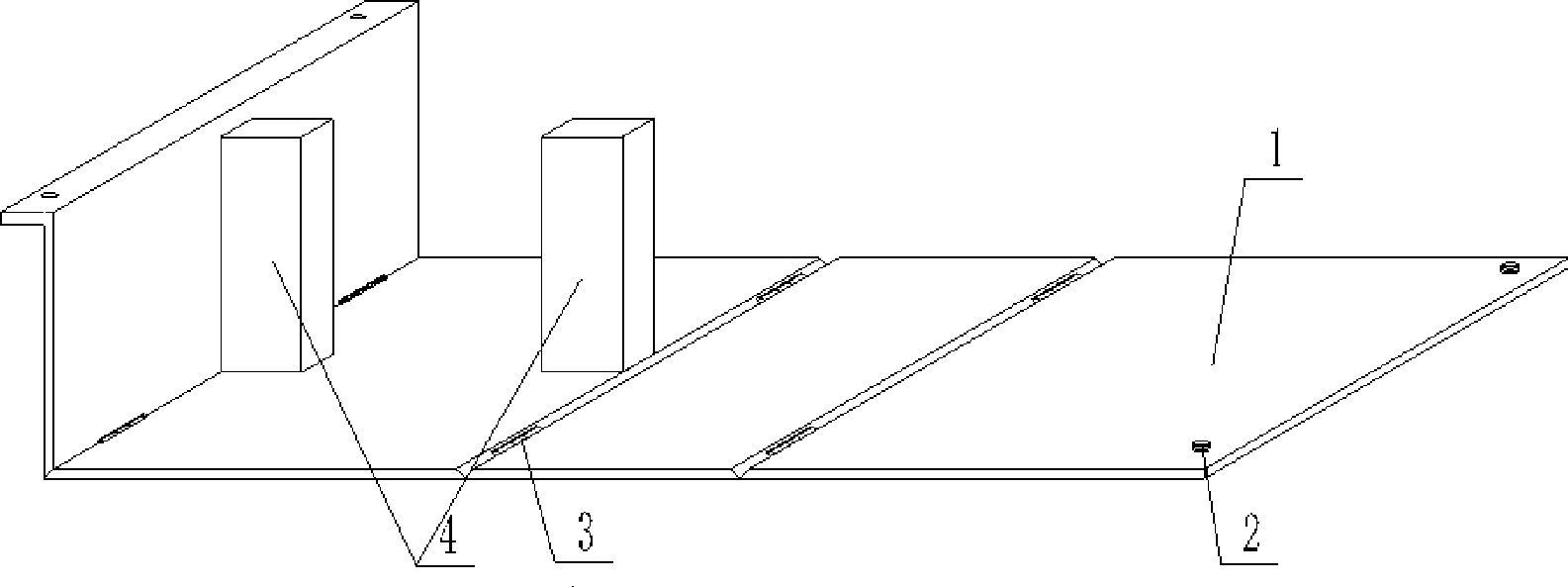

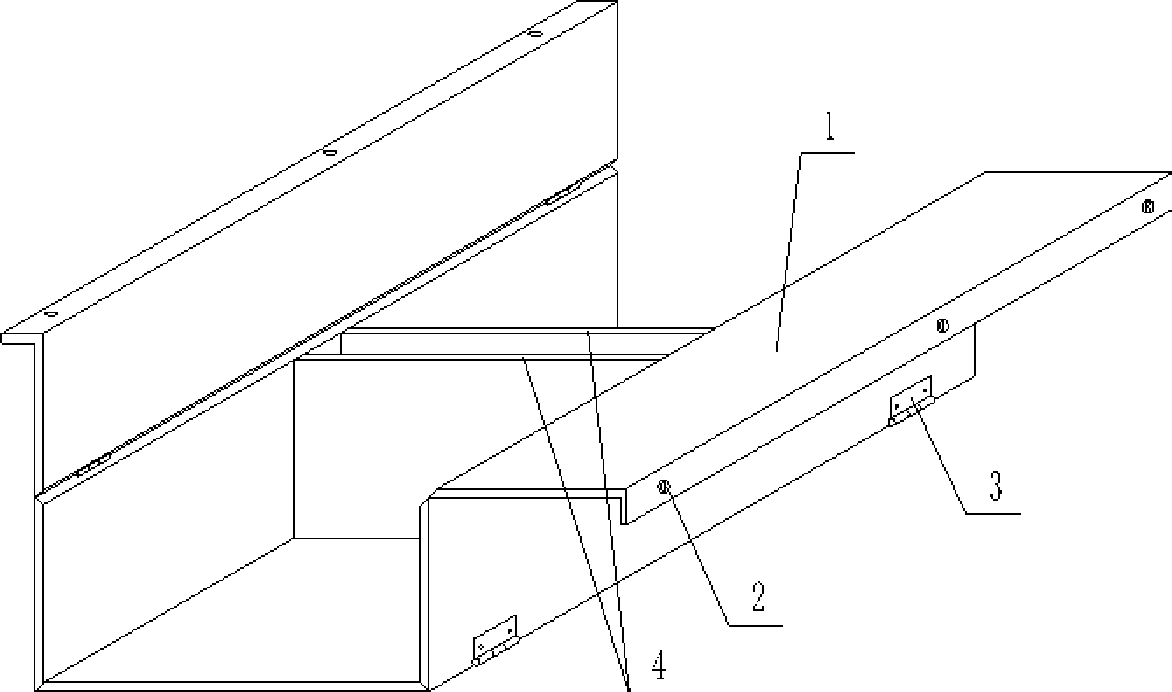

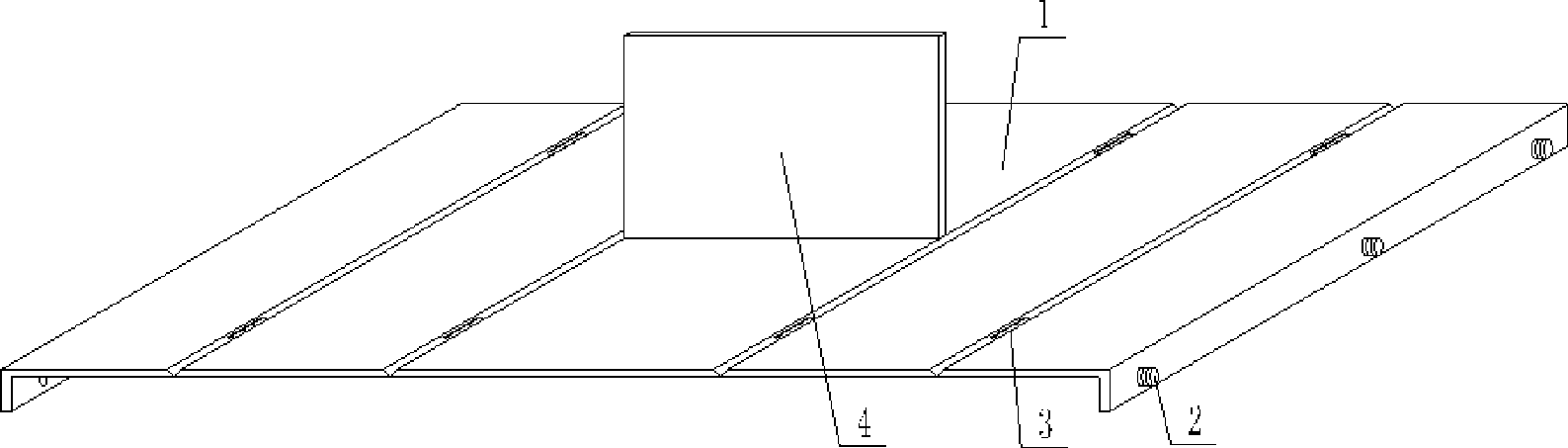

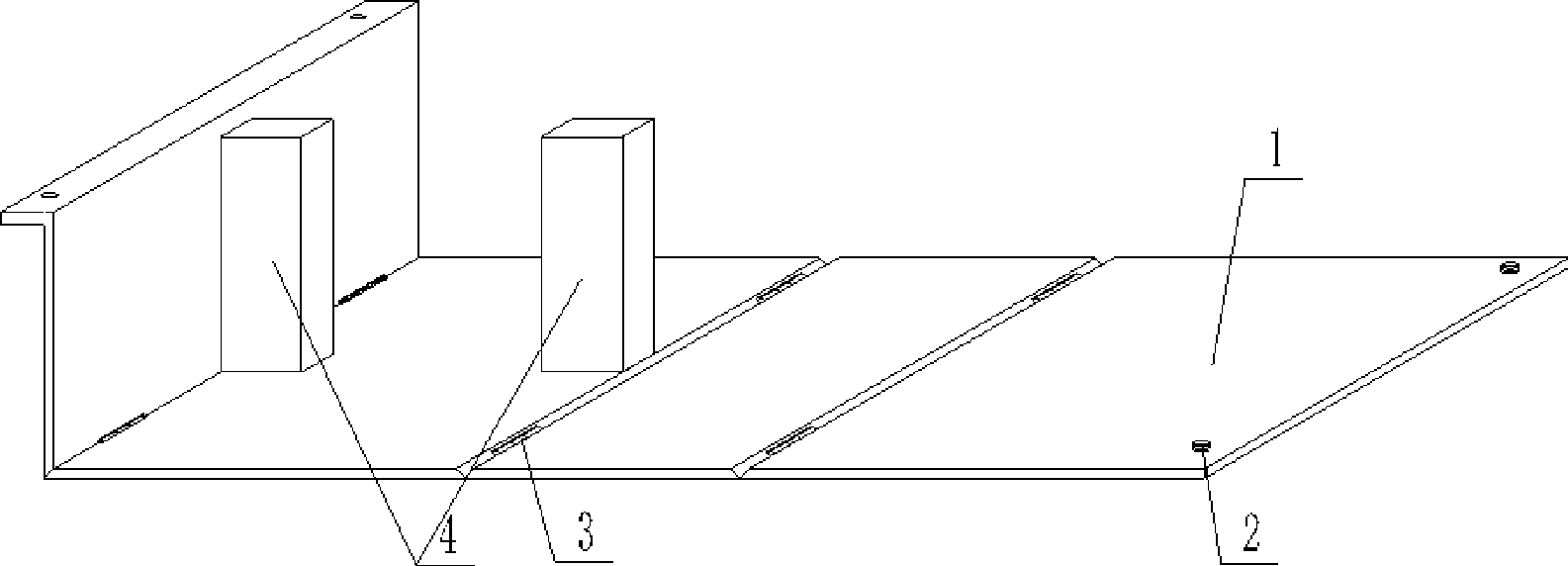

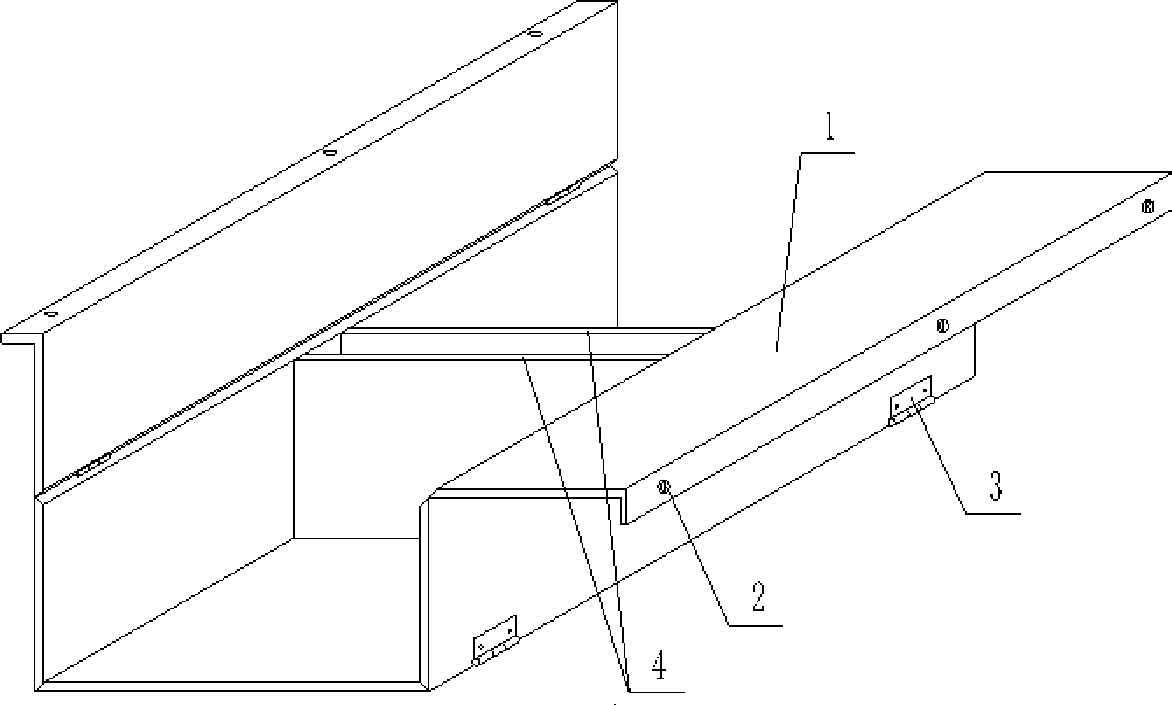

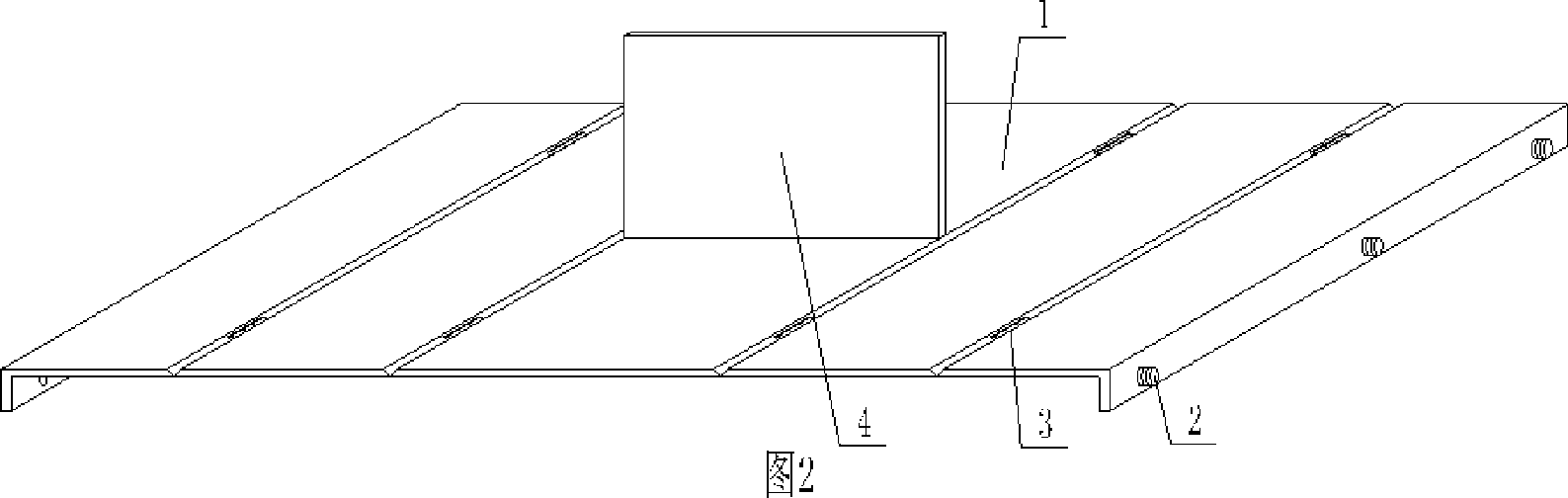

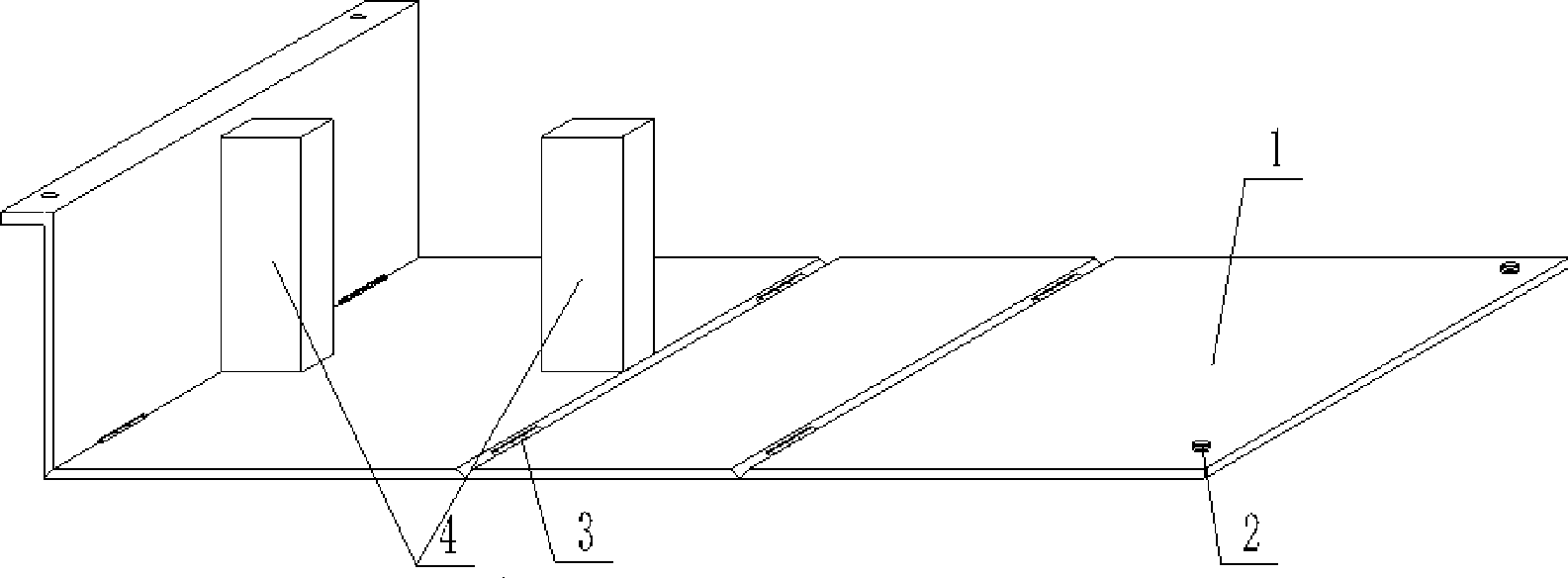

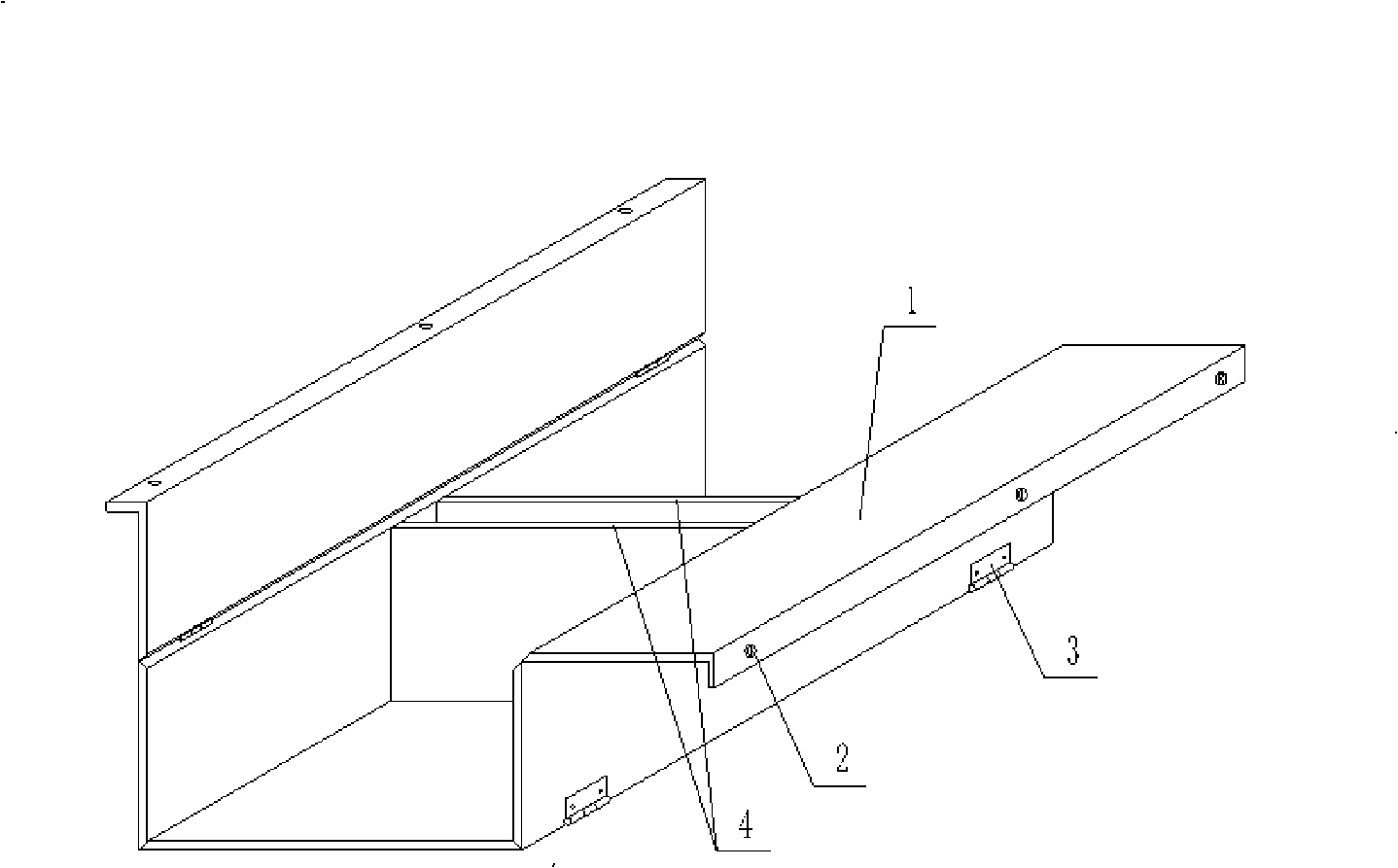

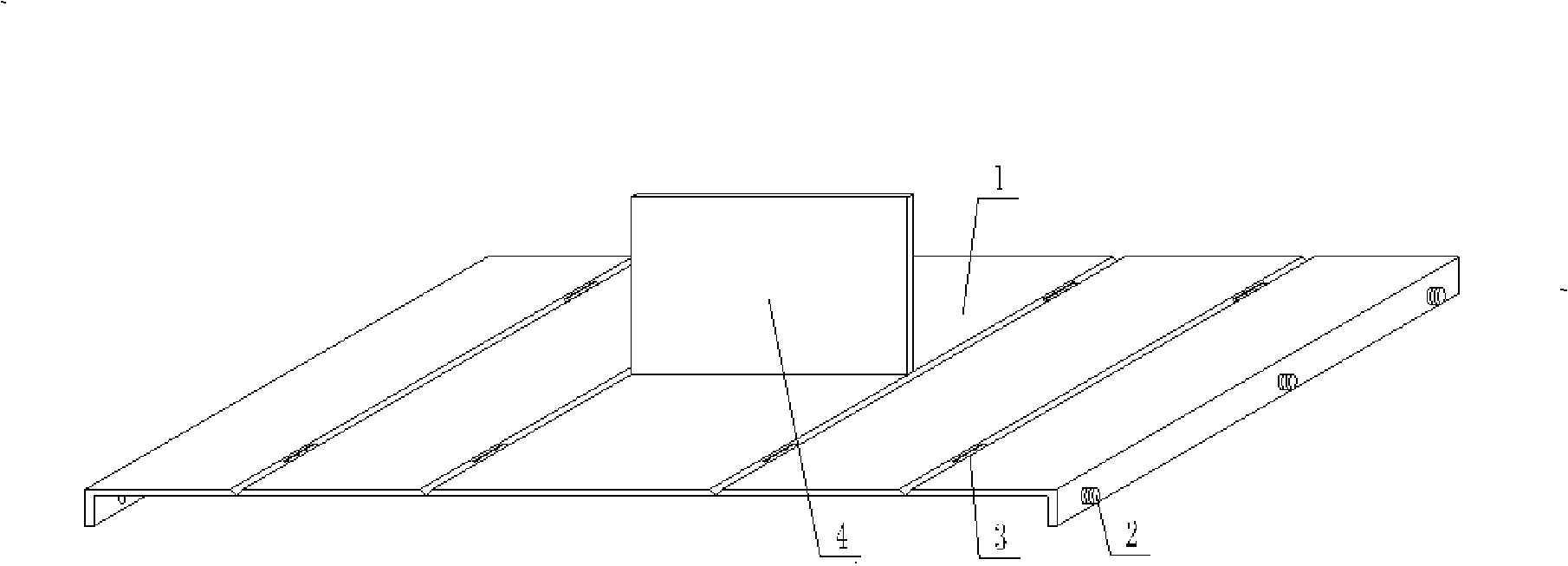

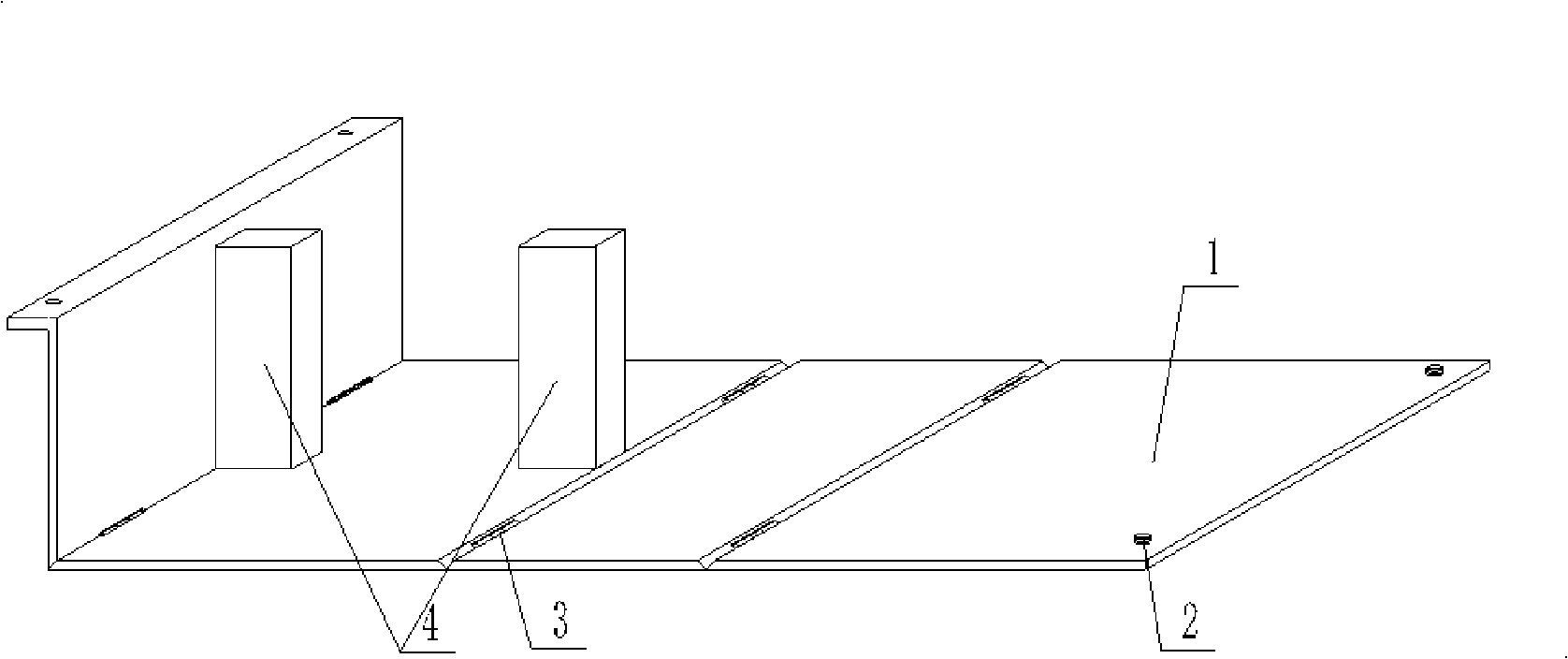

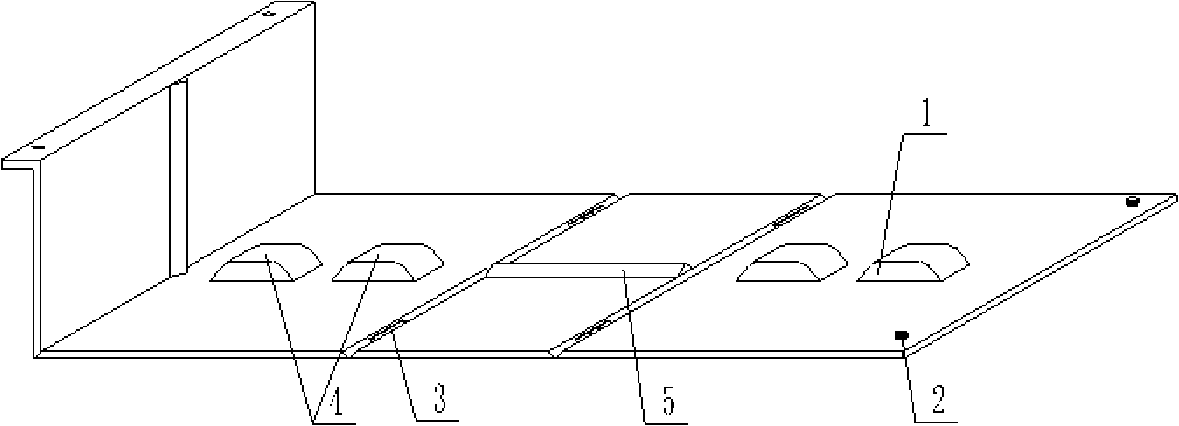

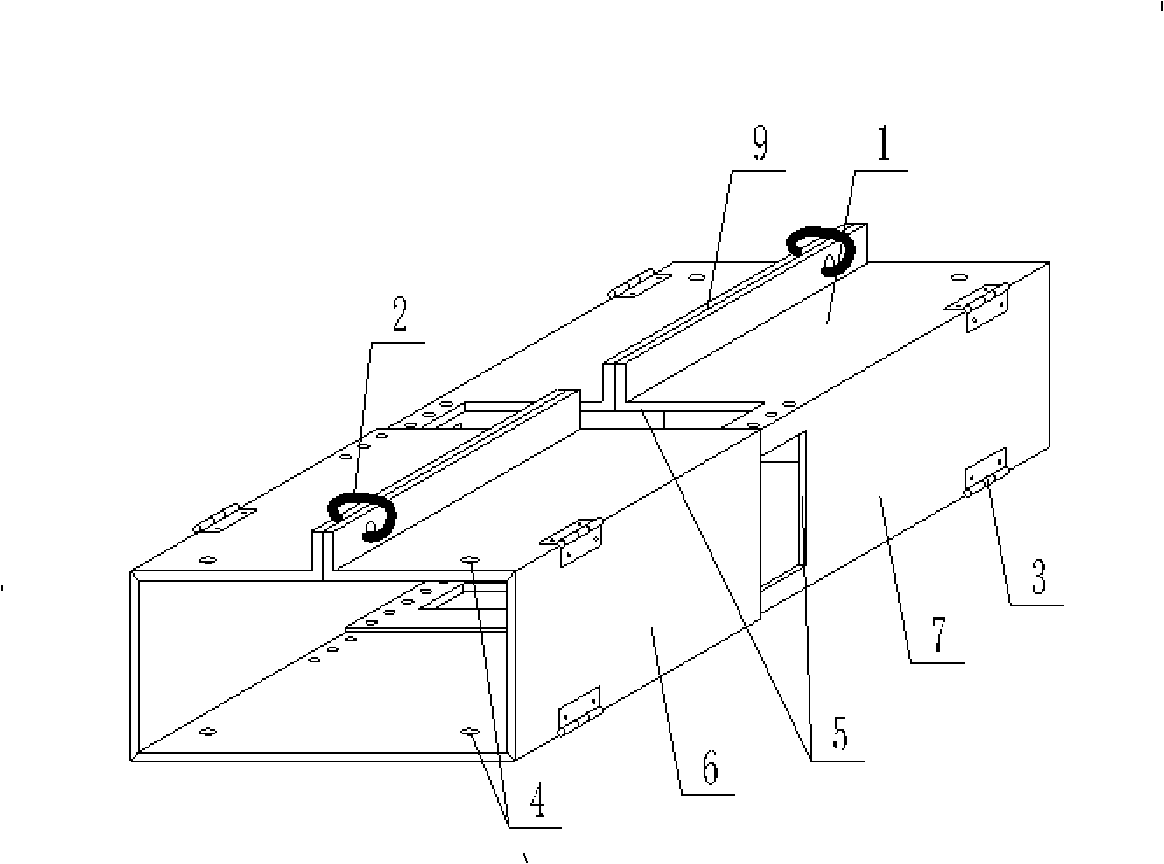

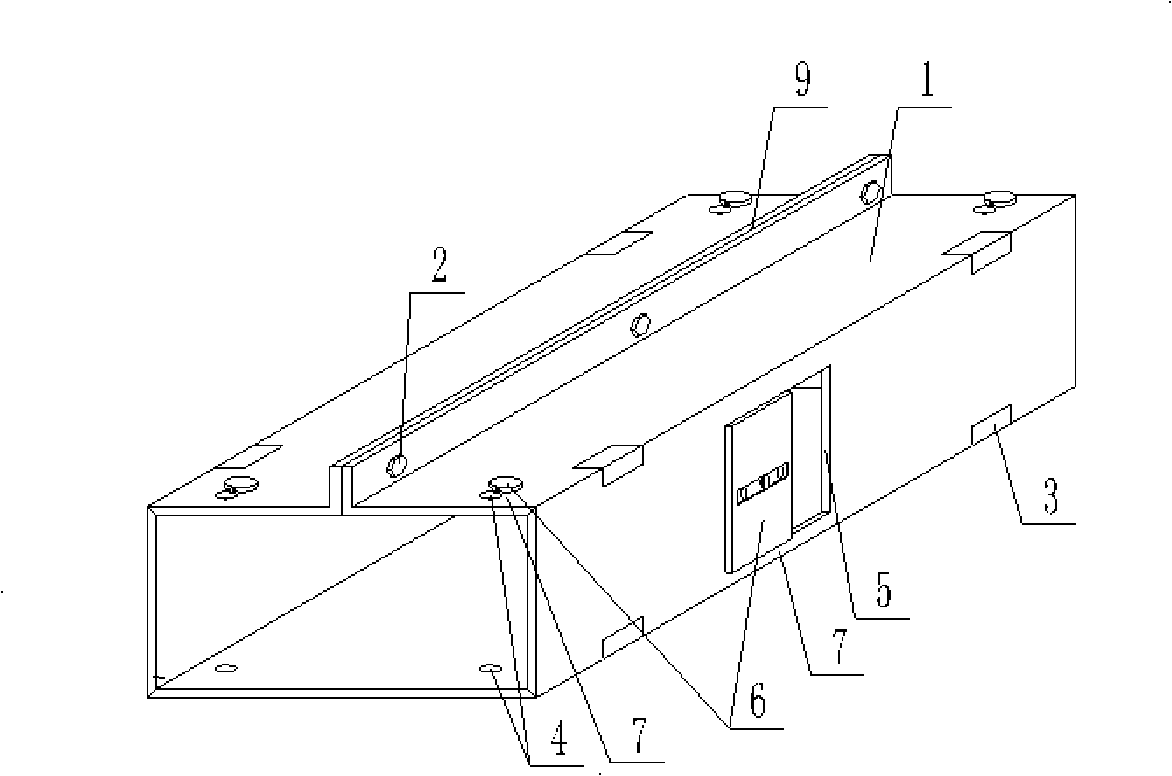

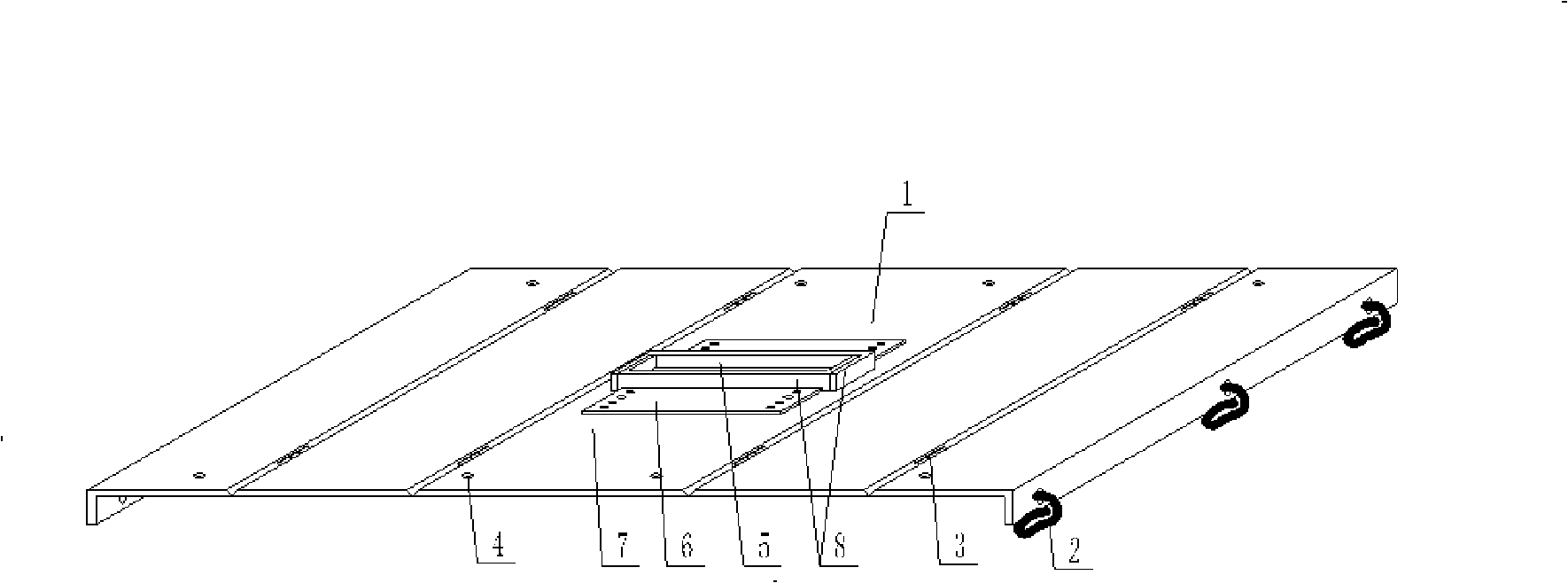

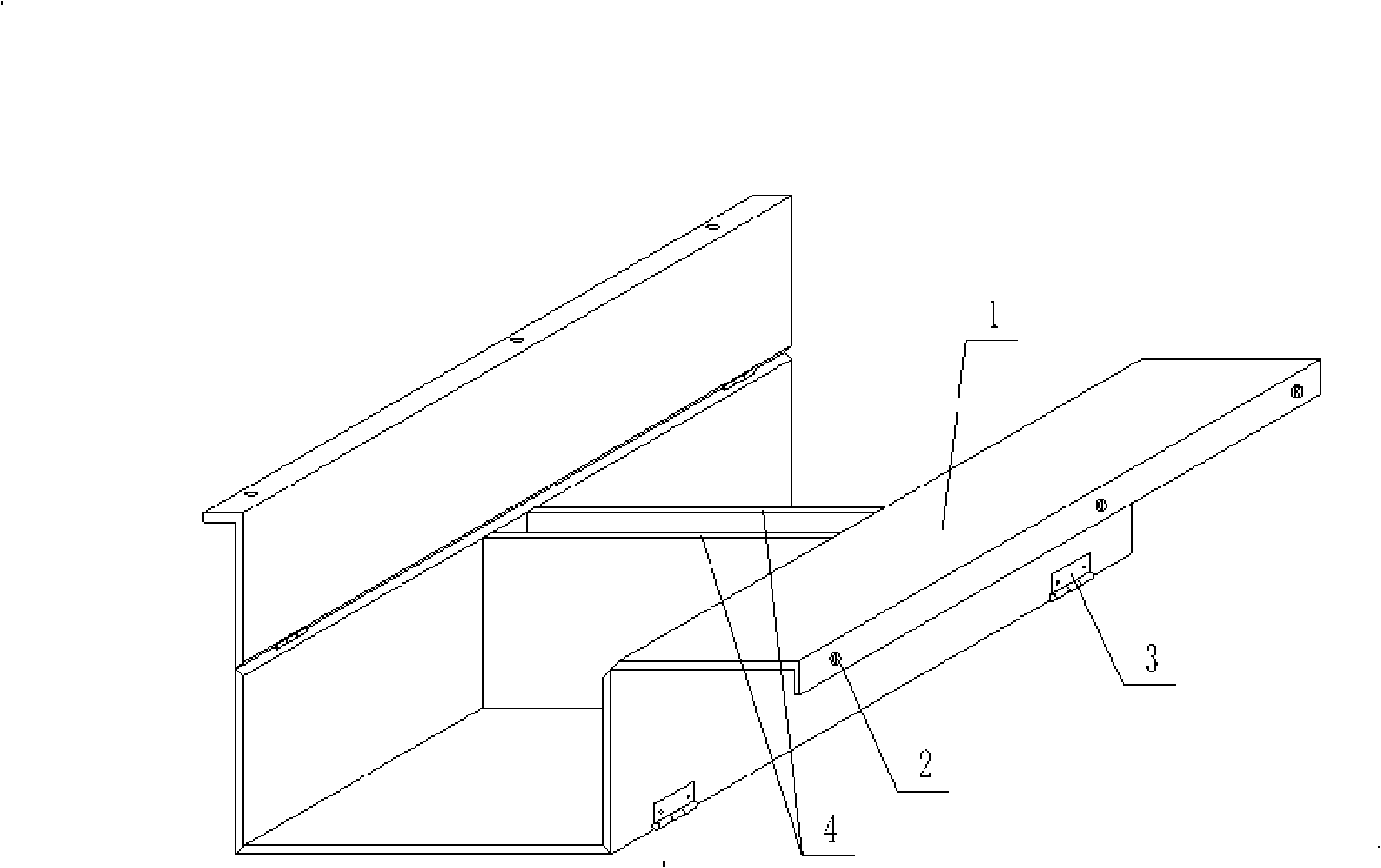

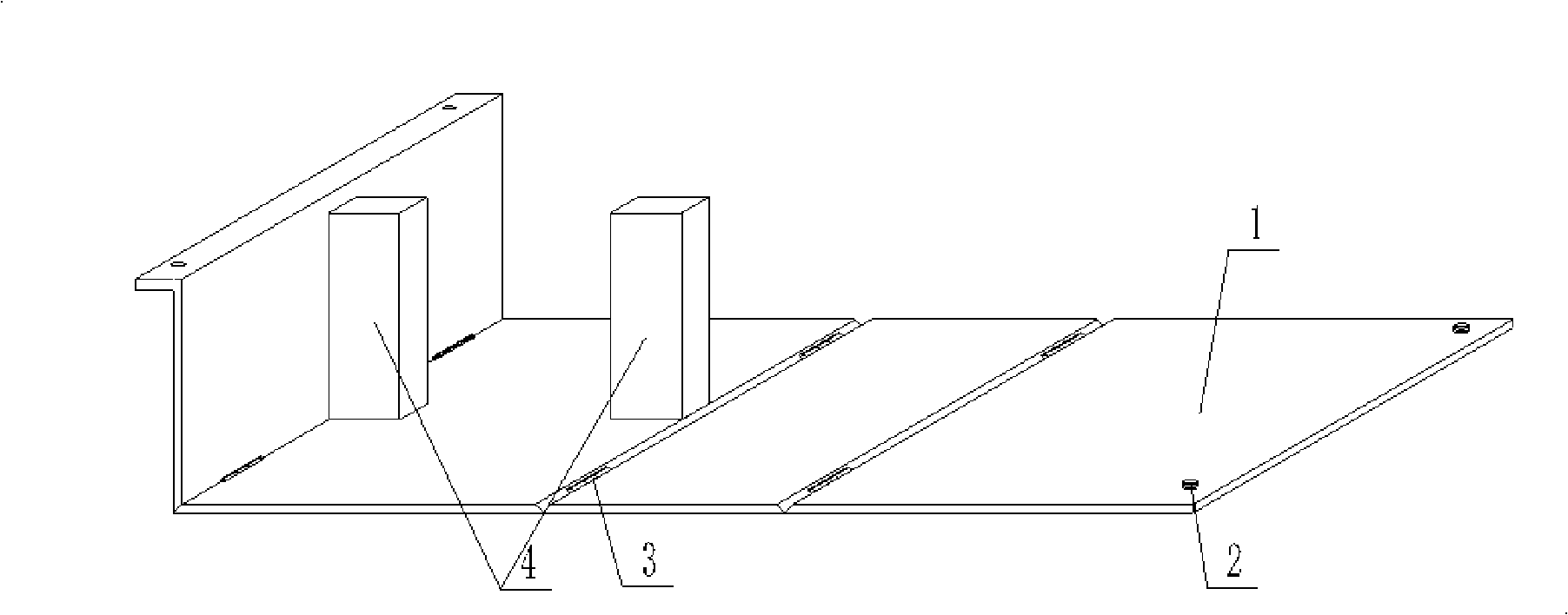

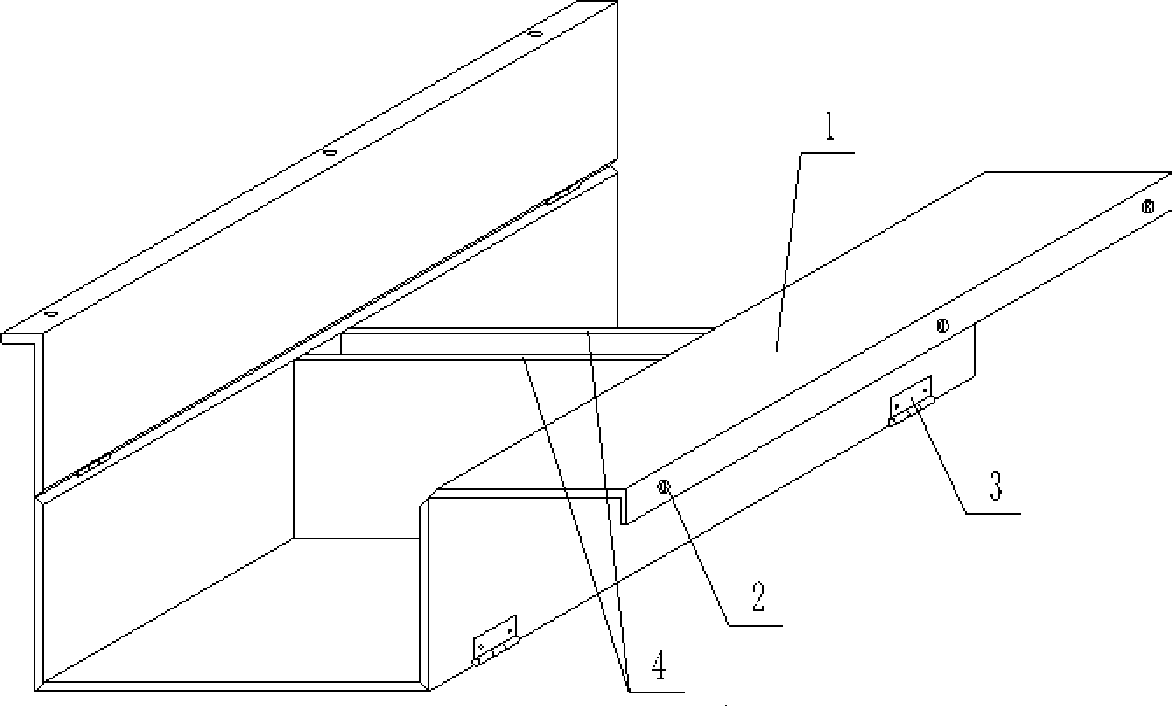

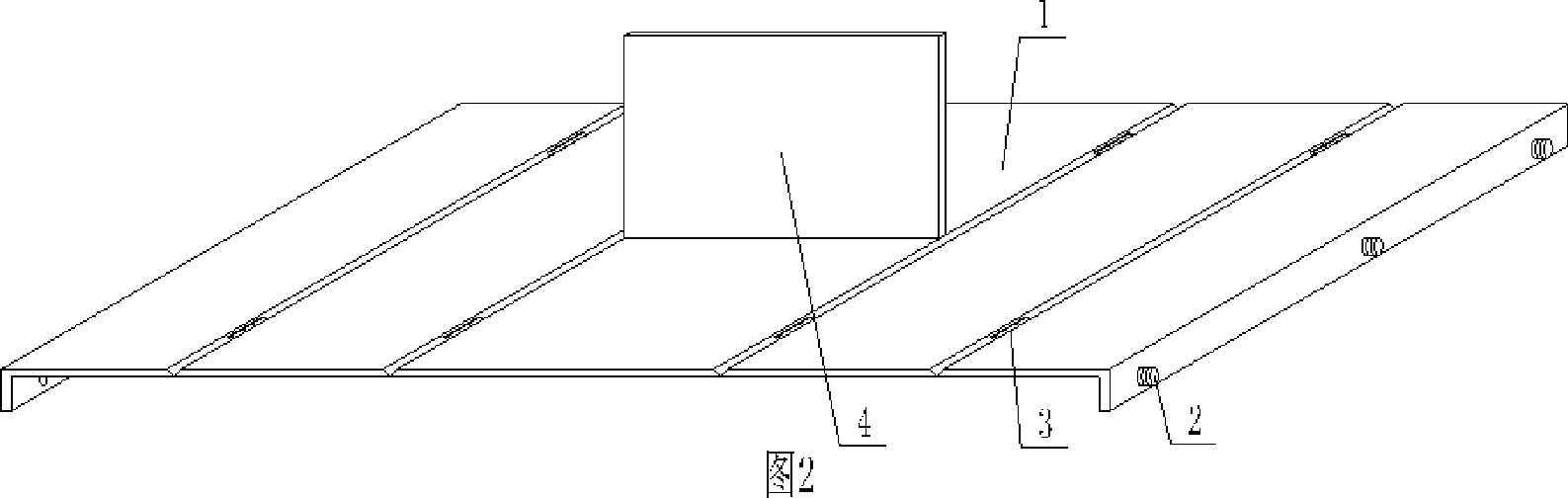

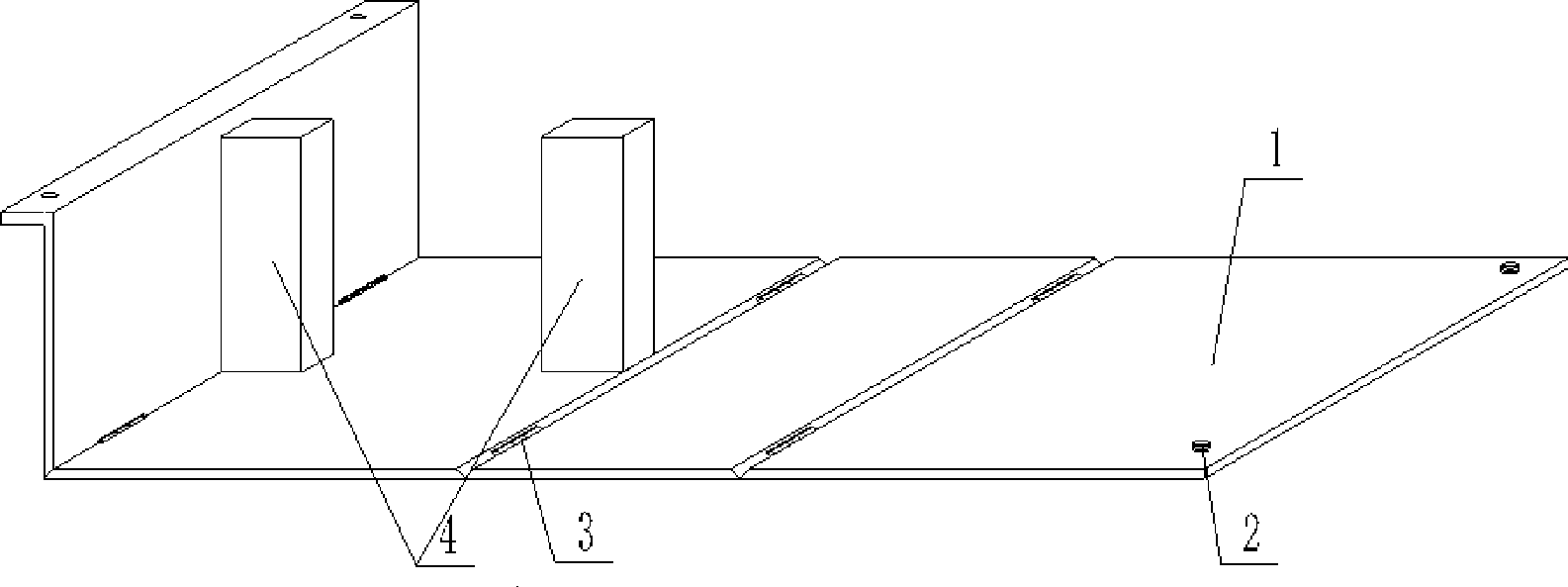

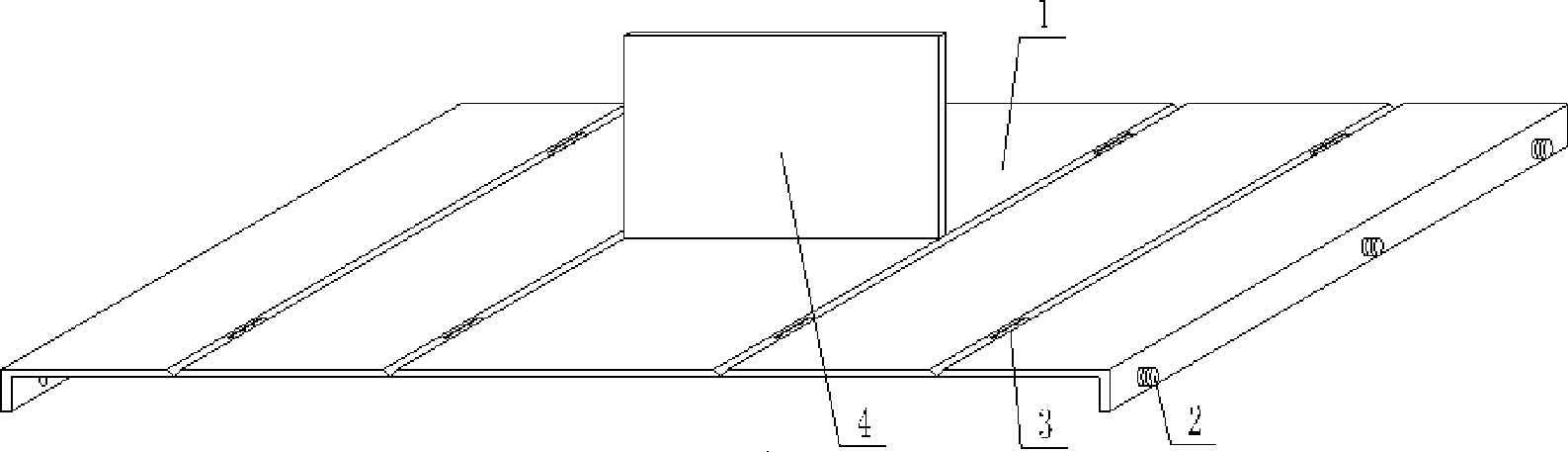

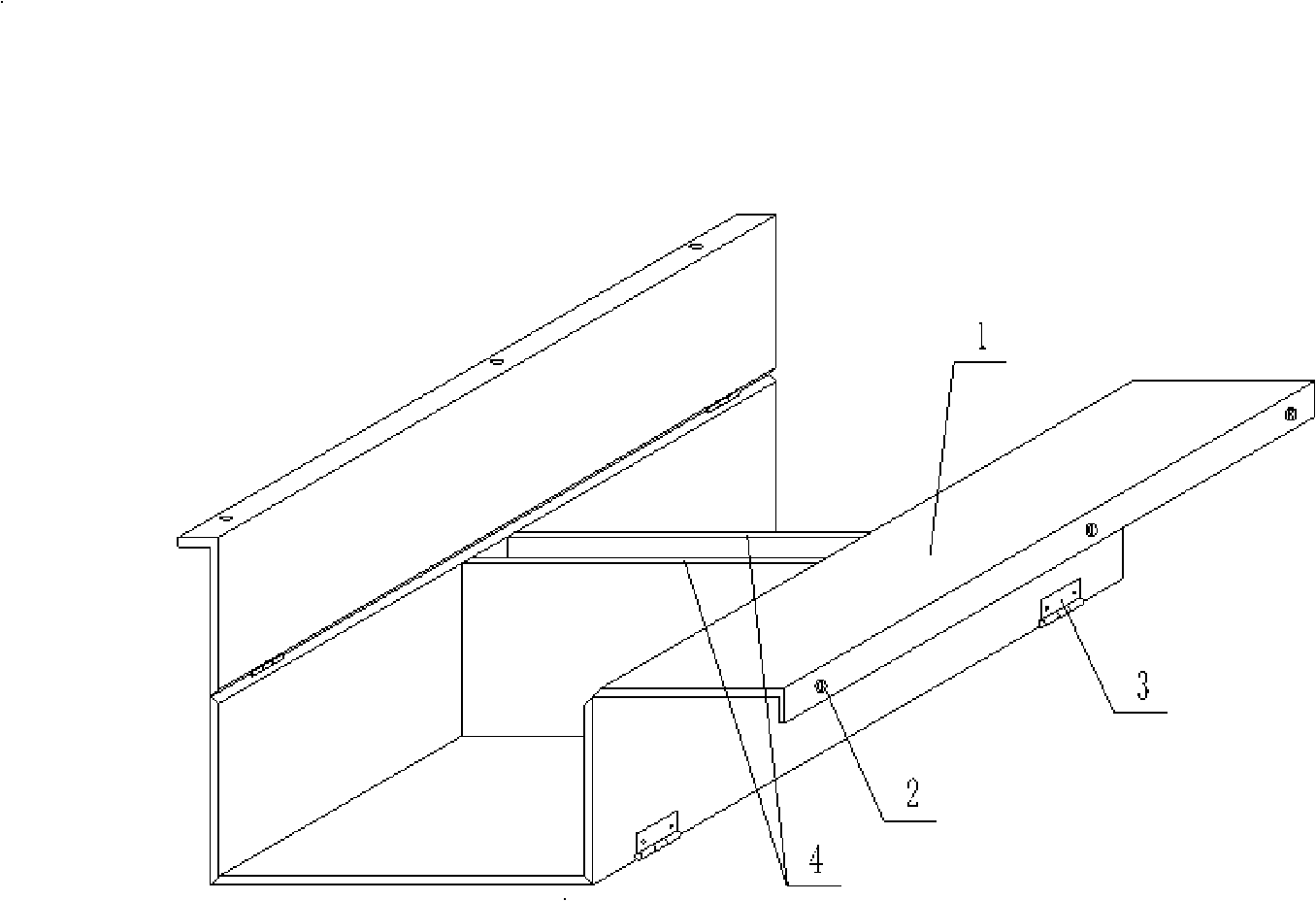

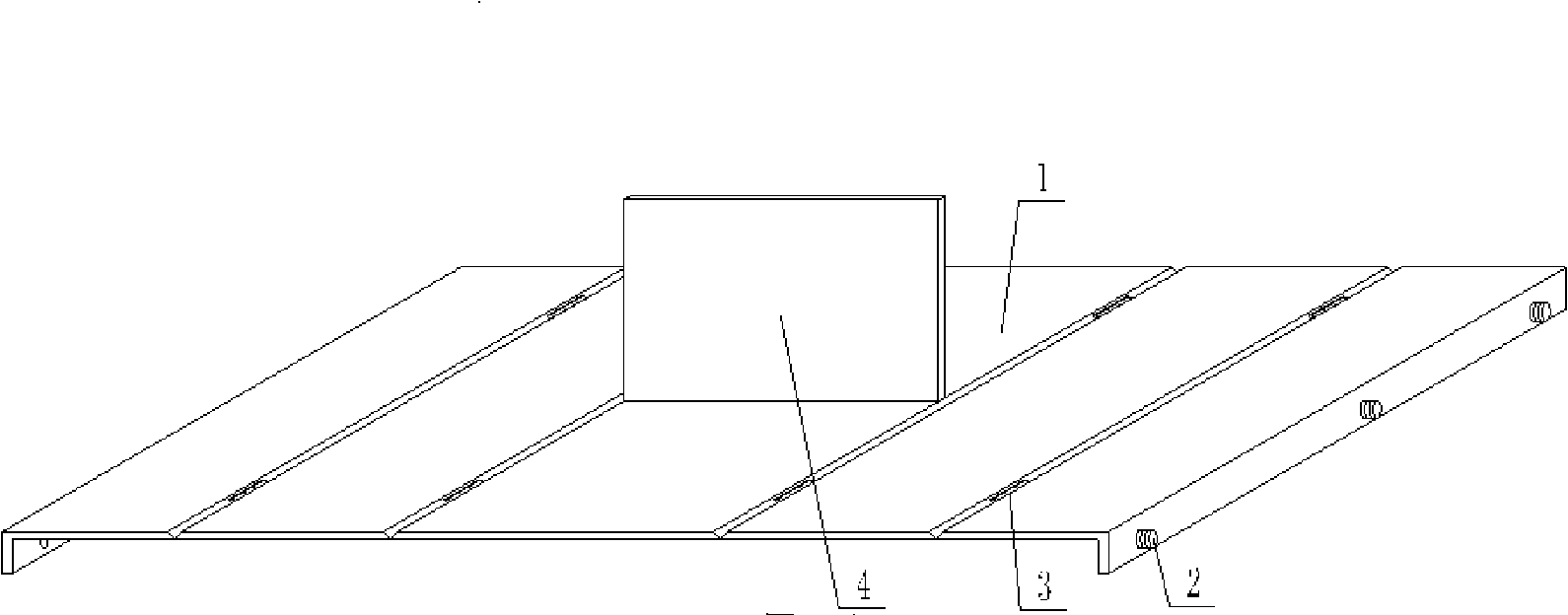

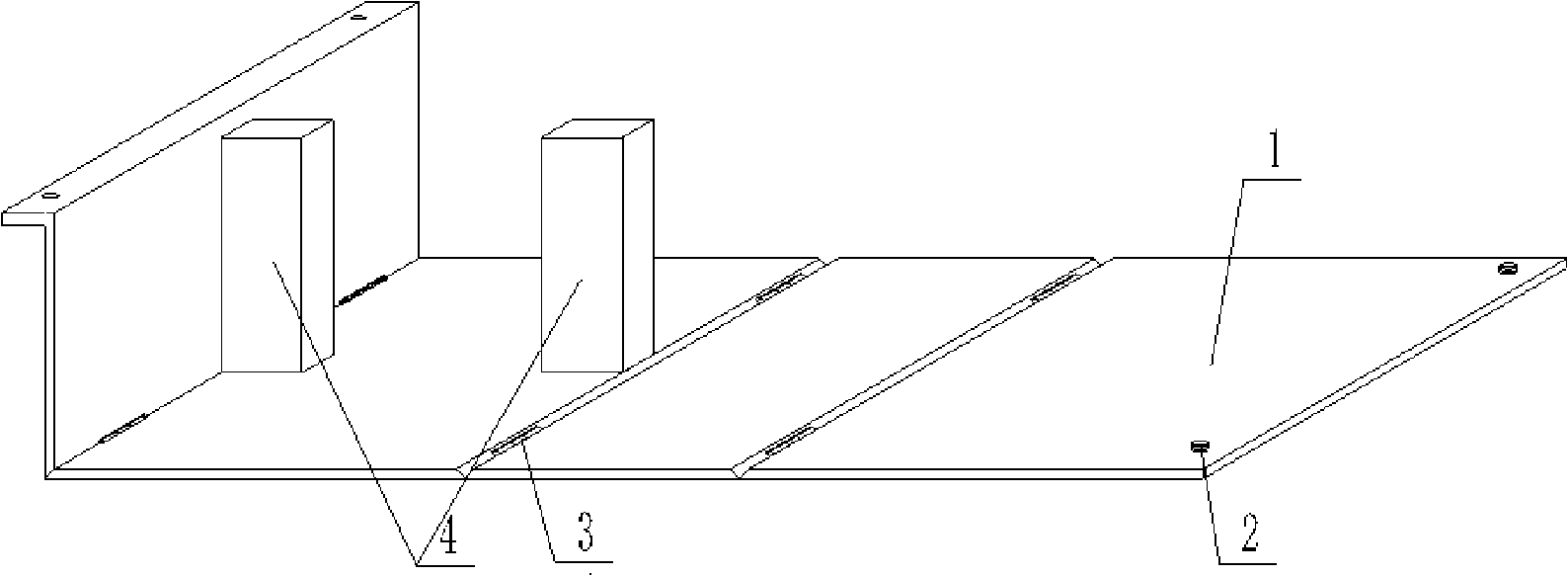

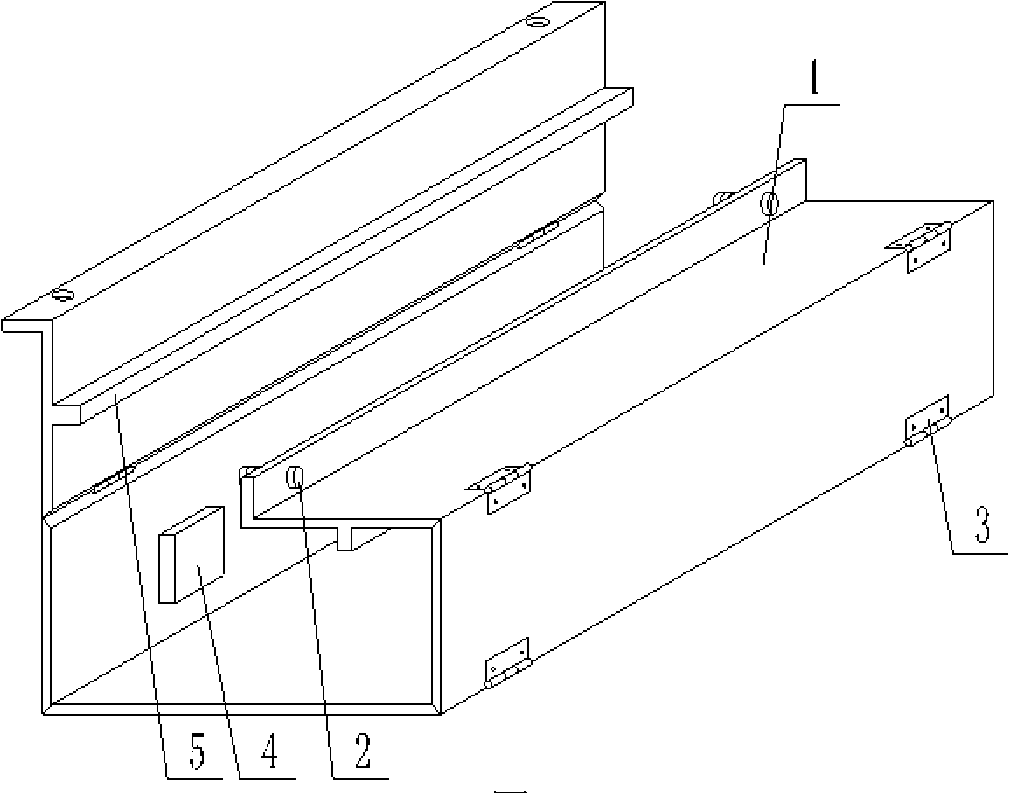

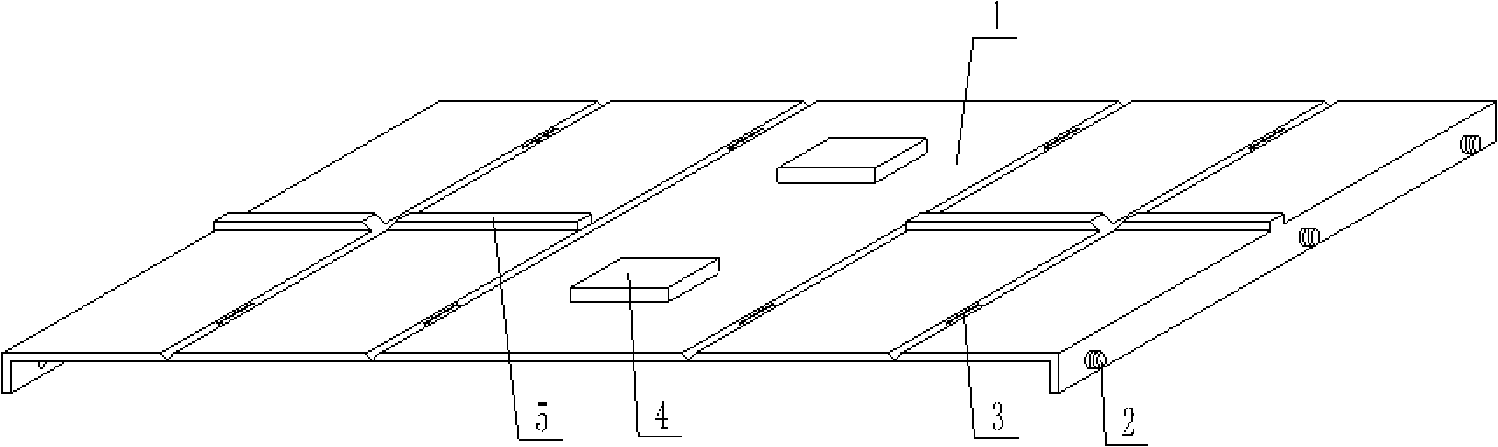

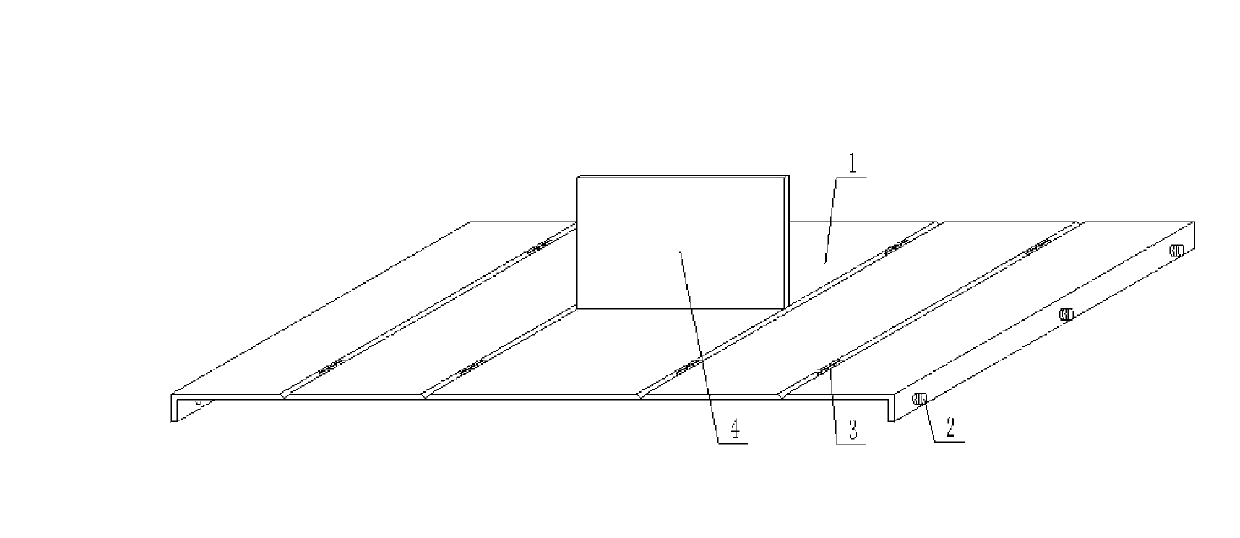

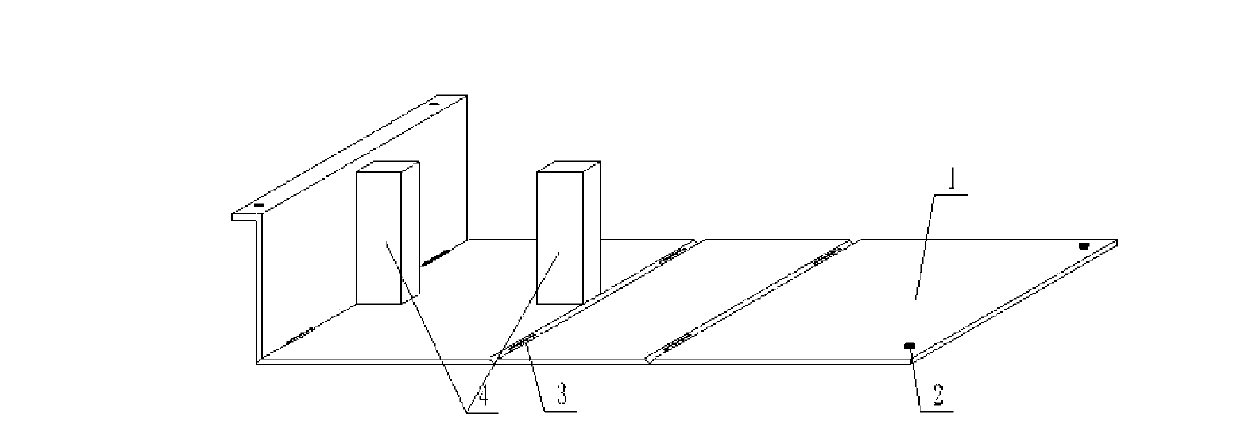

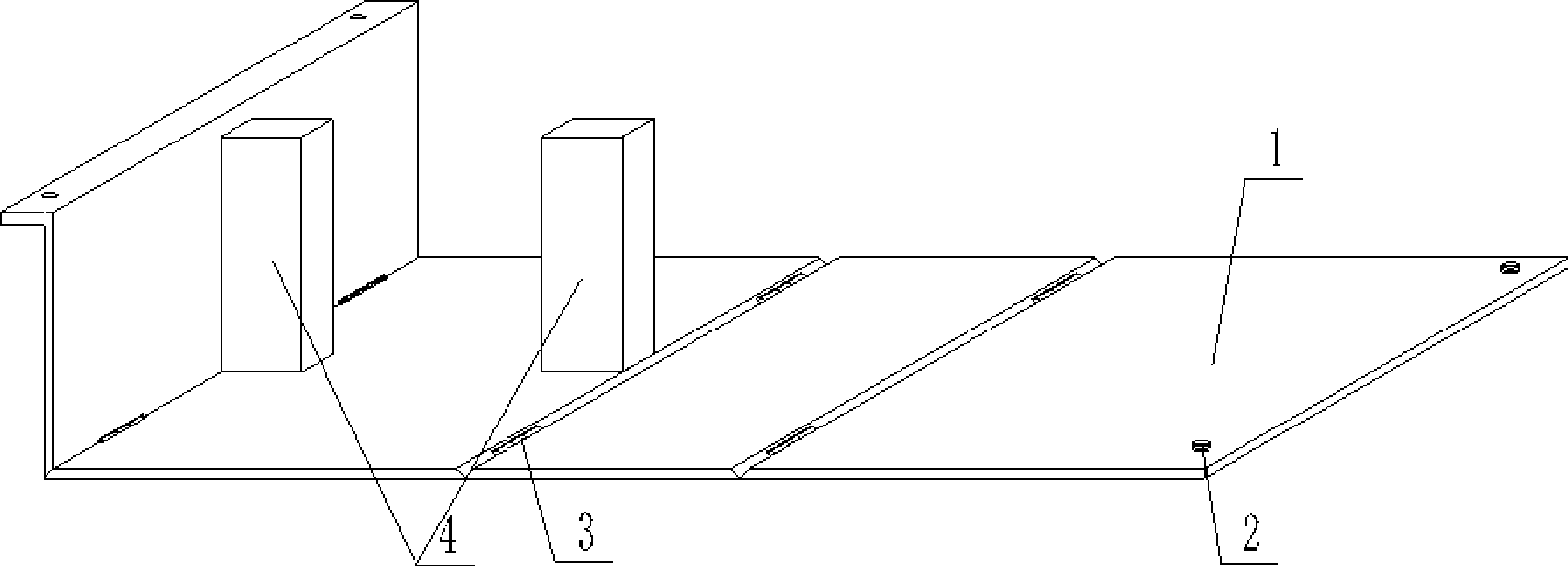

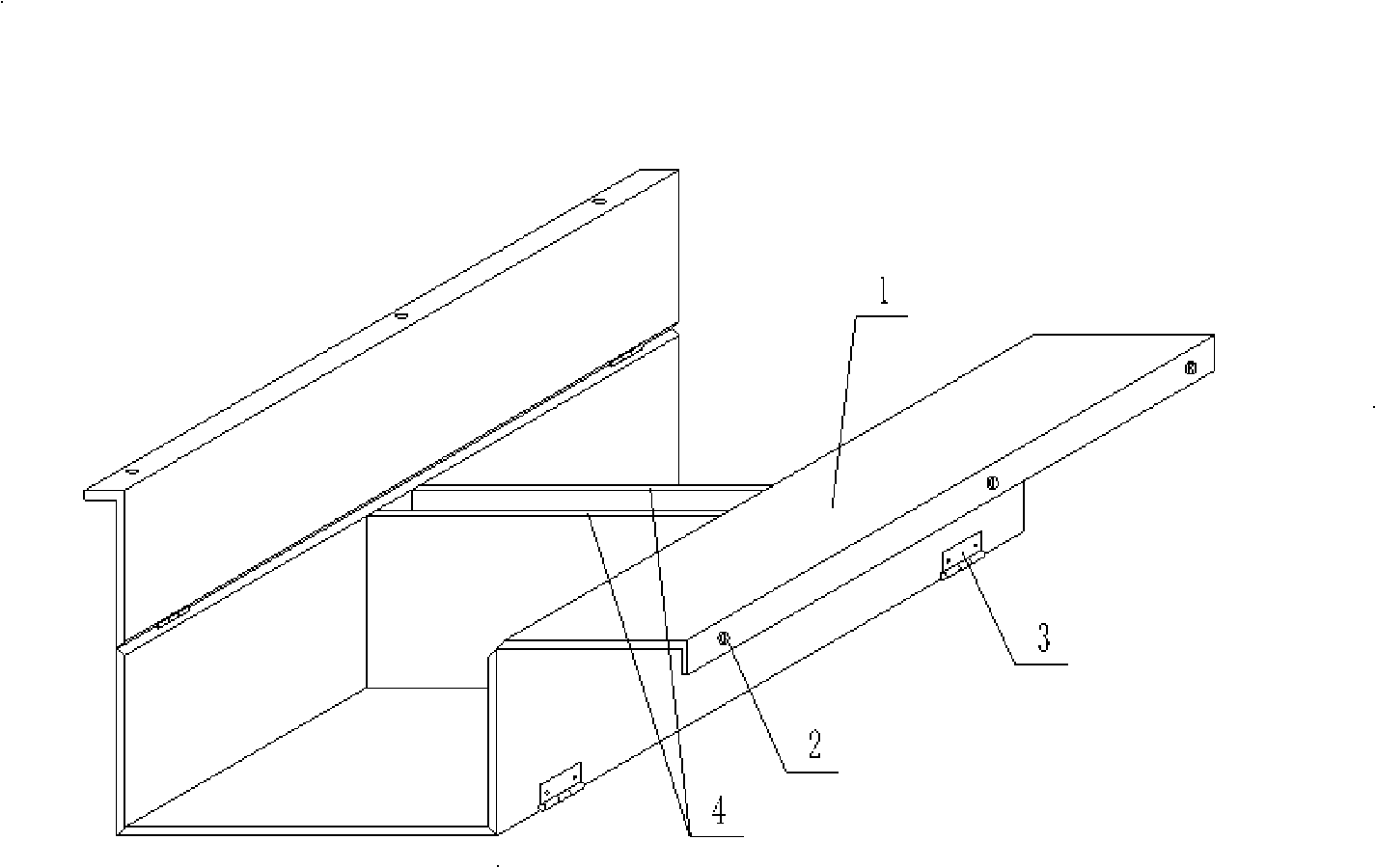

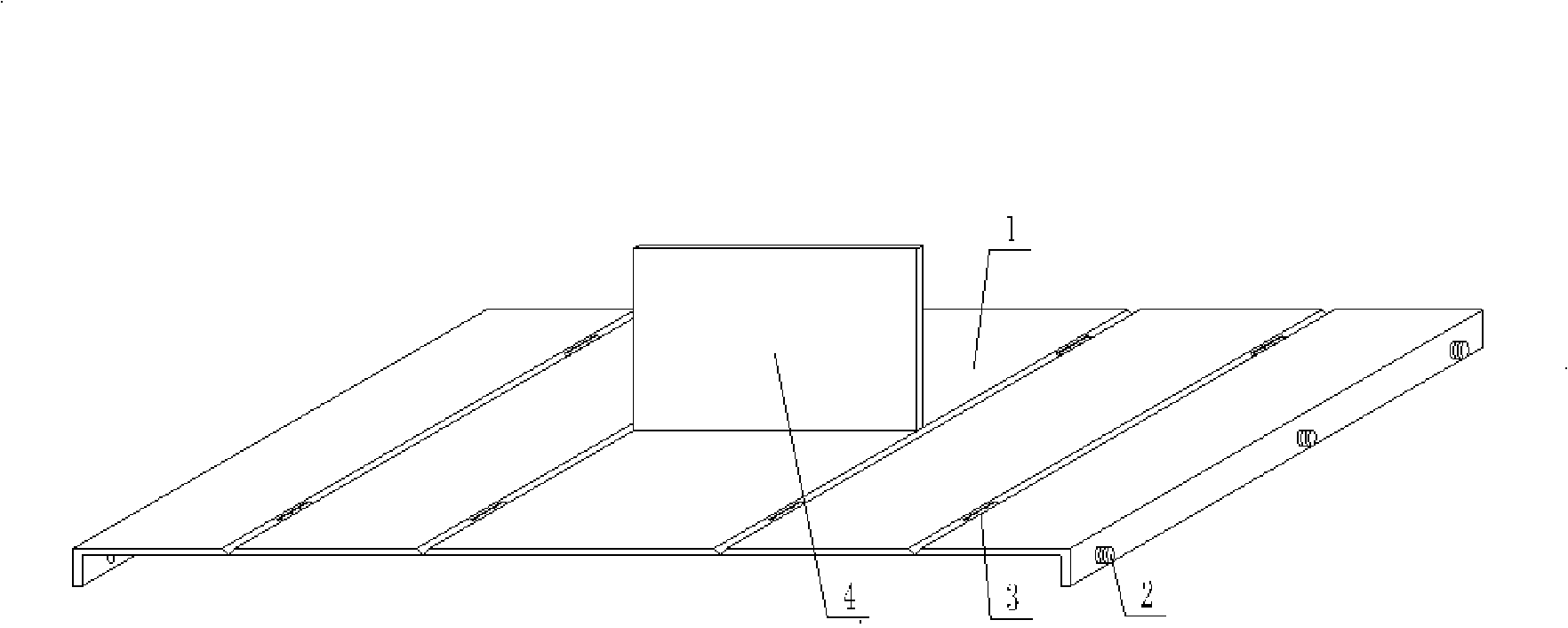

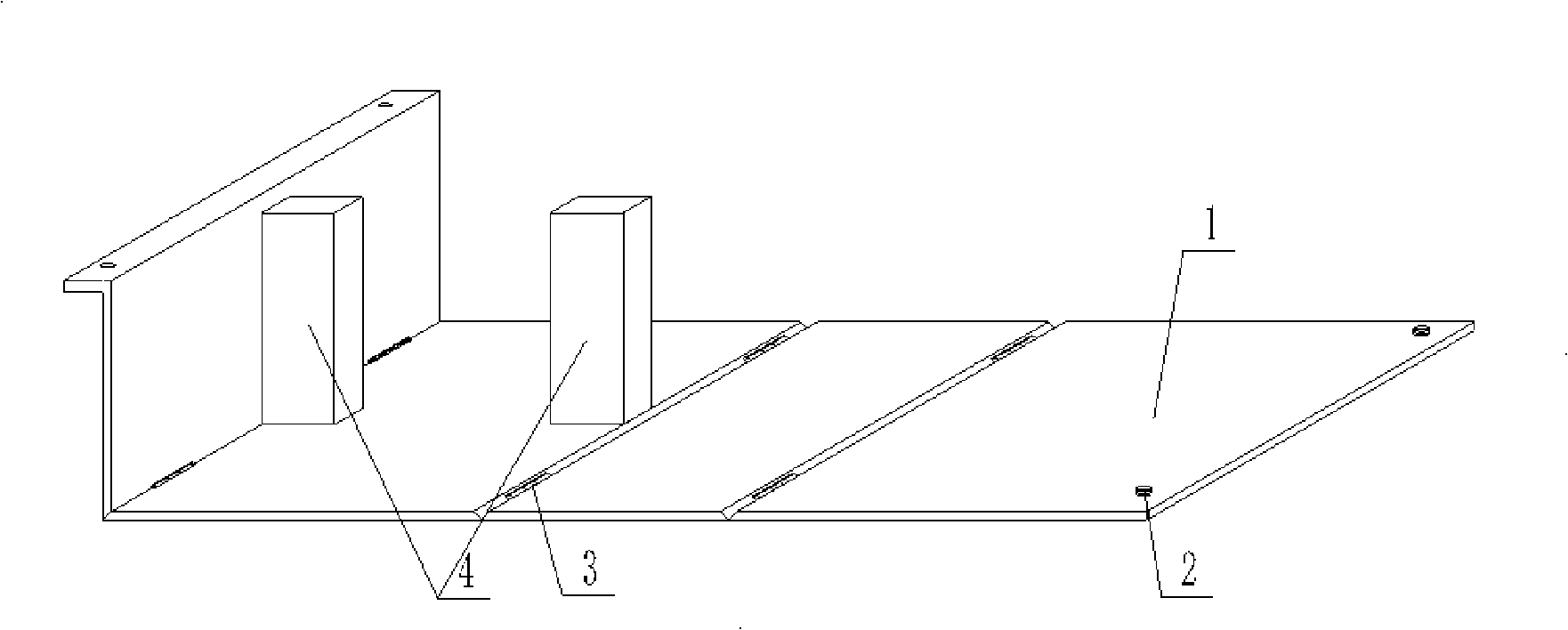

Mold for molding hollow thin wall component for filling concrete

A shaping die for a concrete-filled hollow thin-wall component includes templates (1), fasteners (2) and rotatable parts (3). The templates (1) are connected by the rotatable parts (3); the connected templates (1) can rotate oppositely; the templates (1) after being folded are fixed by the fasteners (2). The invention is characterized in that at least three templates (1) are connected in sequence side by side in the die; at least one template (1) is provided with at least one transverse isolating die (4) which is a clapboard; the surface of the transverse isolating die (4) is a shaping die surface. In this way, after the fasteners are loosened, the die is very convenient to be released; simultaneously, when a polyhedron component is produced, a concave structure can be correspondingly formed on the polyhedron component or a conjoined or non-conjoined polyhedron component is manufactured; the production requirements for different polyhedron components can be met; besides, the die is also characterized by simple structure, easy manufacture, high intensity, low cost, and the like. The shaping die for a concrete-filled hollow thin-wall component is suitable for manufacturing various opened or closed polyhedron components.

Owner:邱则有

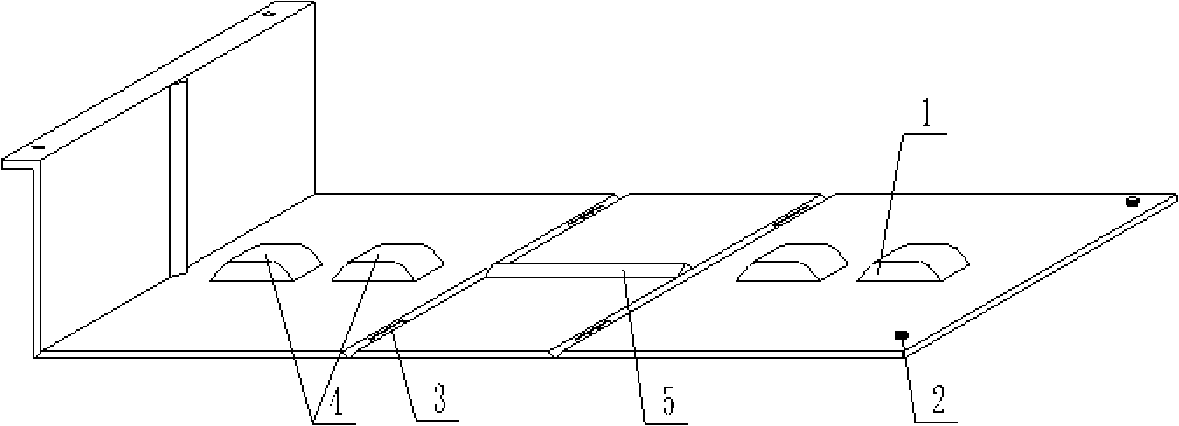

Mold for molding hollow thin wall component for filling concrete

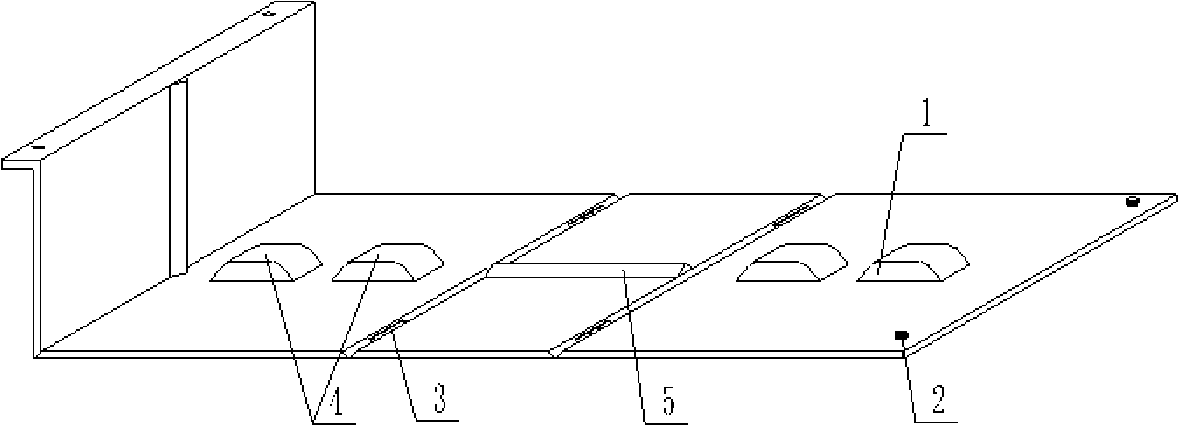

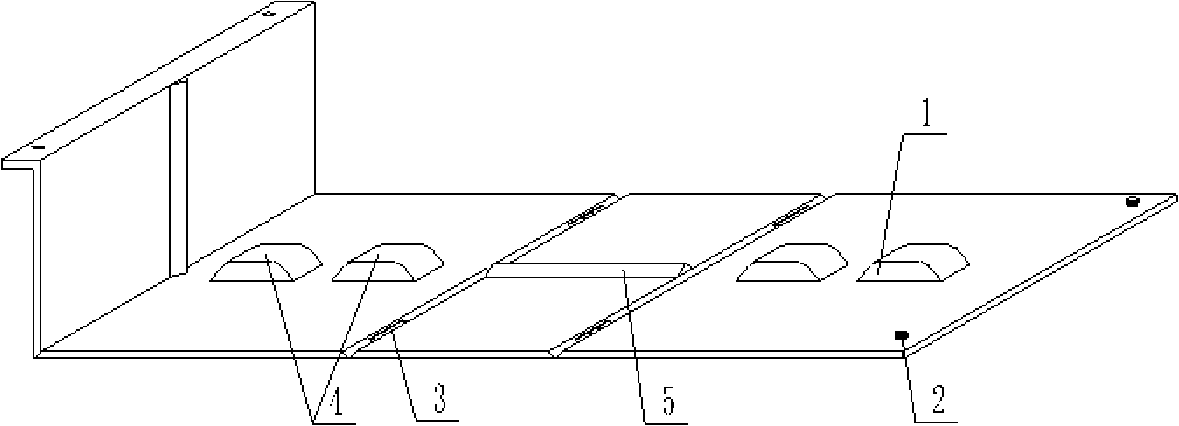

The invention relates to a concrete-filled hollow thin-walled member forming mould which comprises templates (1), a joint and tight piece (2), and rotatable components (3). The templates (1) are connected by the rotatable components (3). The connected templates (1) can relatively rotate. After the templates (1) are folded, the templates are fixed by the joint and tight piece (2). The mould is characterized in that at least three templates (1) are sequentially connected with each other side by side in the mould; wherein, a projection (4) or sand strip (5) protruding the surface of the templates is arranged on at least one of the three templates. The projection (4) or the sand strip (5) and the templates (1) are a whole body integrally formed. At least one of a gemel, a hinge, a bolt hinge, a film, a rotatable tenon, a rotatable slot or a rotatable jack, a rotatable bolt, a rotatable connector pin and a rotatable sliding bush serves as the rotatable components (3). Therefore, a very convenient demoulding can be ensured after the joint and tight piece is loosed; at the same time, a concave structure can be correspondingly formed on the polyhedron members during the production of polyhedron members, thus meeting requirements for a variety of hollow floor systems; furthermore, the mould is characterized by simple structure, easy manufacture, high intensity, low cost, etc., and is suitable for manufacturing a variety of open or closed polyhedral components.

Owner:湖南邱则有专利战略策划有限公司

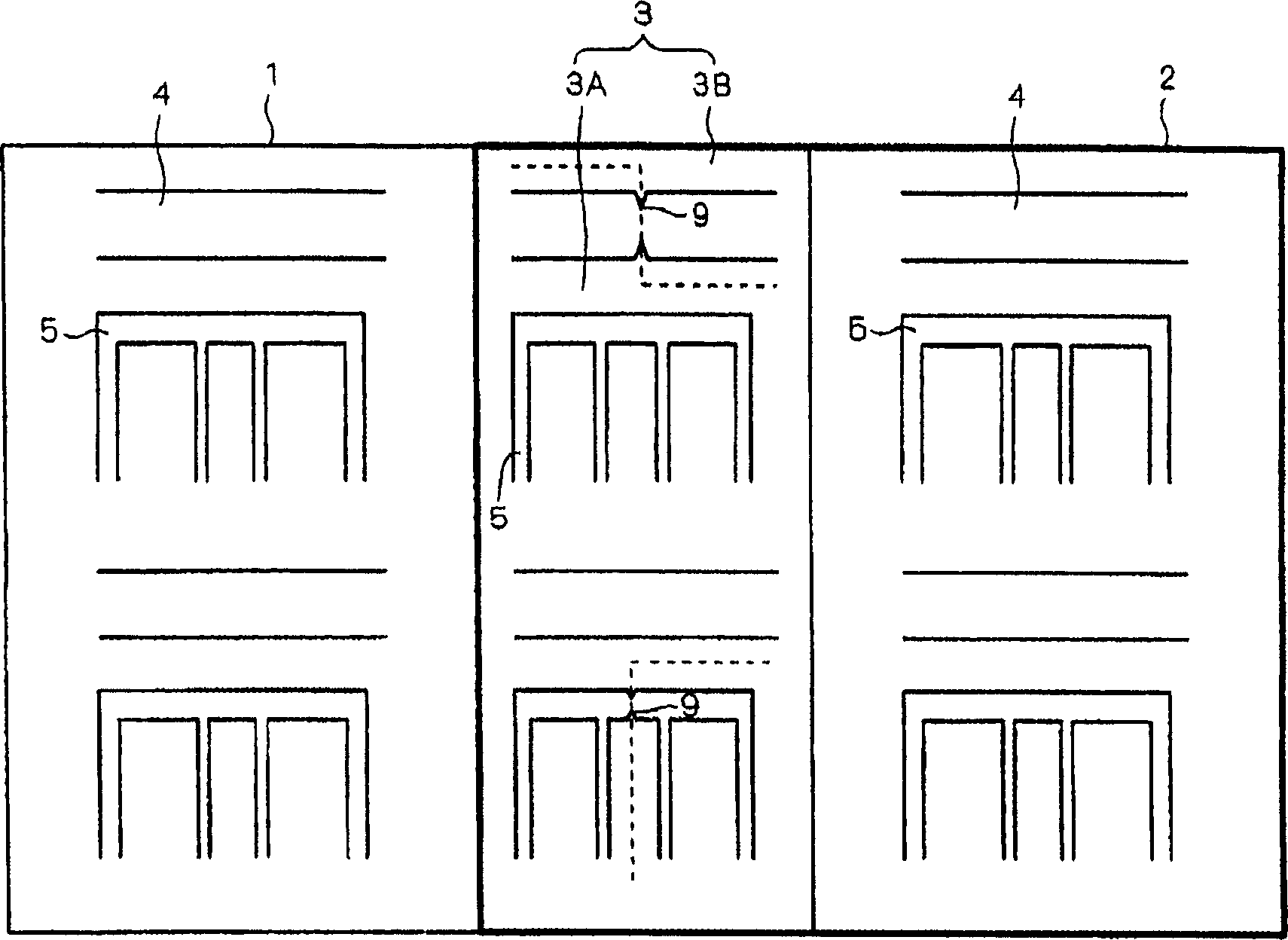

Checking method and method for preparation liquid crystal display device using the same

InactiveCN1873538ASeam precision can be quantitatively managedHigh seam precisionSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPattern recognitionLiquid-crystal display

The invention provides a method for checking and increasing joint accuracy of pattern and process of producing liquid crystal display device employing said checking method. The method forms intended pattern by exposing substrate areas and then checks pattern joint accuracy with different exposure, and it comprises following steps: measuring the first pattern factor exposed at the first area in overlapped area of the first area and the second area, and measuring the first distance of the second pattern factor relevant to the first area exposure which is allocated paralleled to the first pattern factor; measuring the third pattern factor sewed with the first pattern factor relevant to the second area exposure and the second distance of the second pattern factor; computing differential value of the first and second distance and measuring quantification of joint accuracy.

Owner:MITSUBISHI ELECTRIC CORP

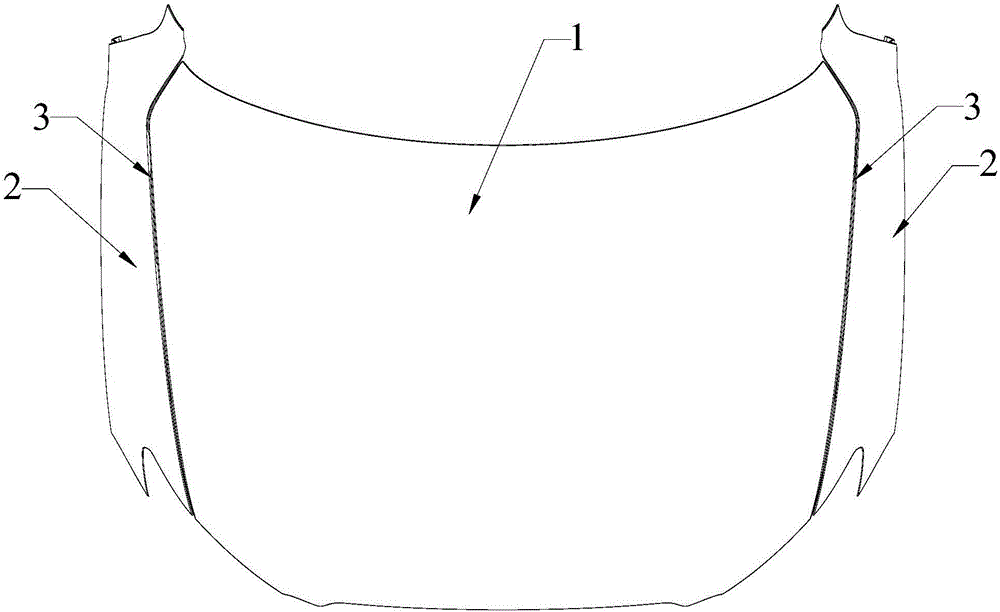

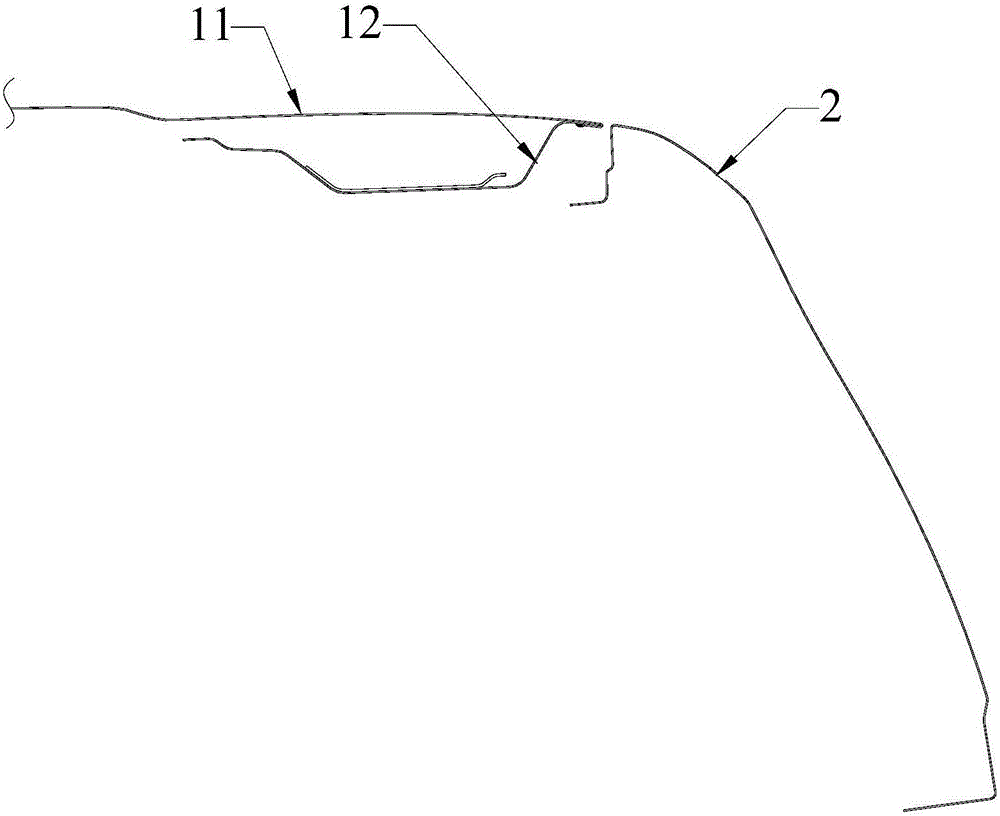

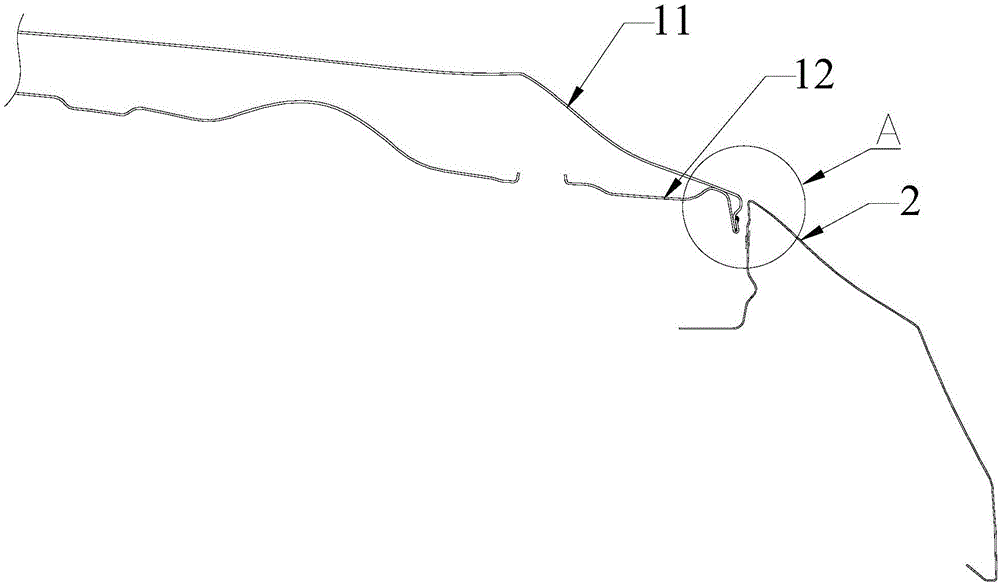

Automobile engine hood and processing method

The invention discloses an automobile engine hood, comprising an outer plate arranged on the outer surface and an inner plate arranged on the inner surface. The two side edges, opposite to automobile wheel fenders, of the outer plate are bent downwards inwards, and flanges opposite to the wheel fenders are formed on the side face of the engine hood; the edge of the inner plate is bent downwards and wraps the edge of the outer plate from the bottom to the top, to form a binding, folding glue is arranged on the binding in a pasting way, and the folding glue is arranged between the inner plate and the outer plate in a pasting way. The invention also discloses a processing method of the automobile engine hood. The automobile engine hood and the processing method can effectively improve the parting precision between the engine hood and the wheel fenders and improve the overall quality of the automobile engine hood.

Owner:FJ MOTOR GRP YUDO NEW ENERGY AUTOMOBILE CO LTD

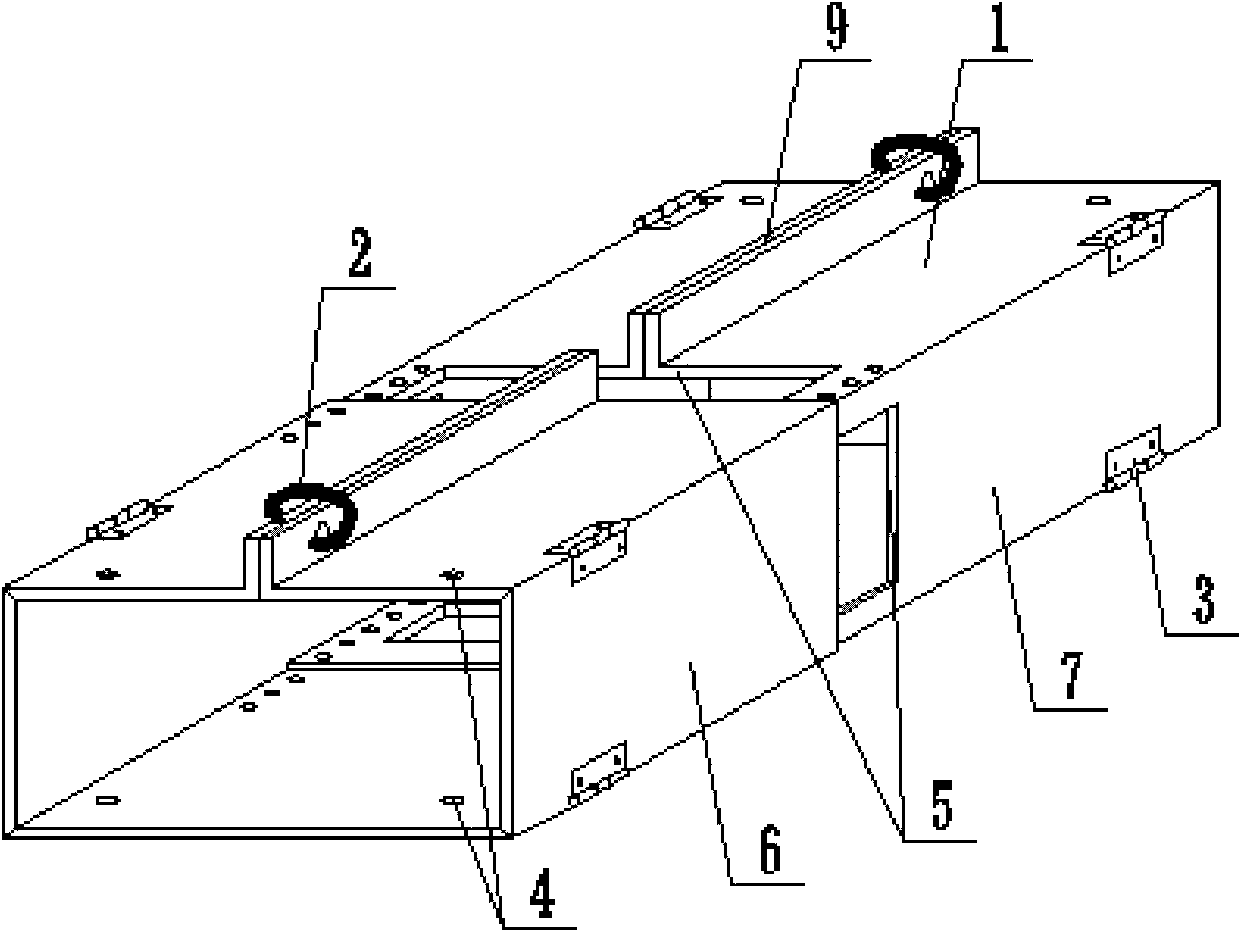

Polyhedral member shaping mould

InactiveCN102172986AEasy to splitEasy to assembleMould separation apparatusMouldsUltimate tensile strength

Owner:湖南邱则有专利战略策划有限公司

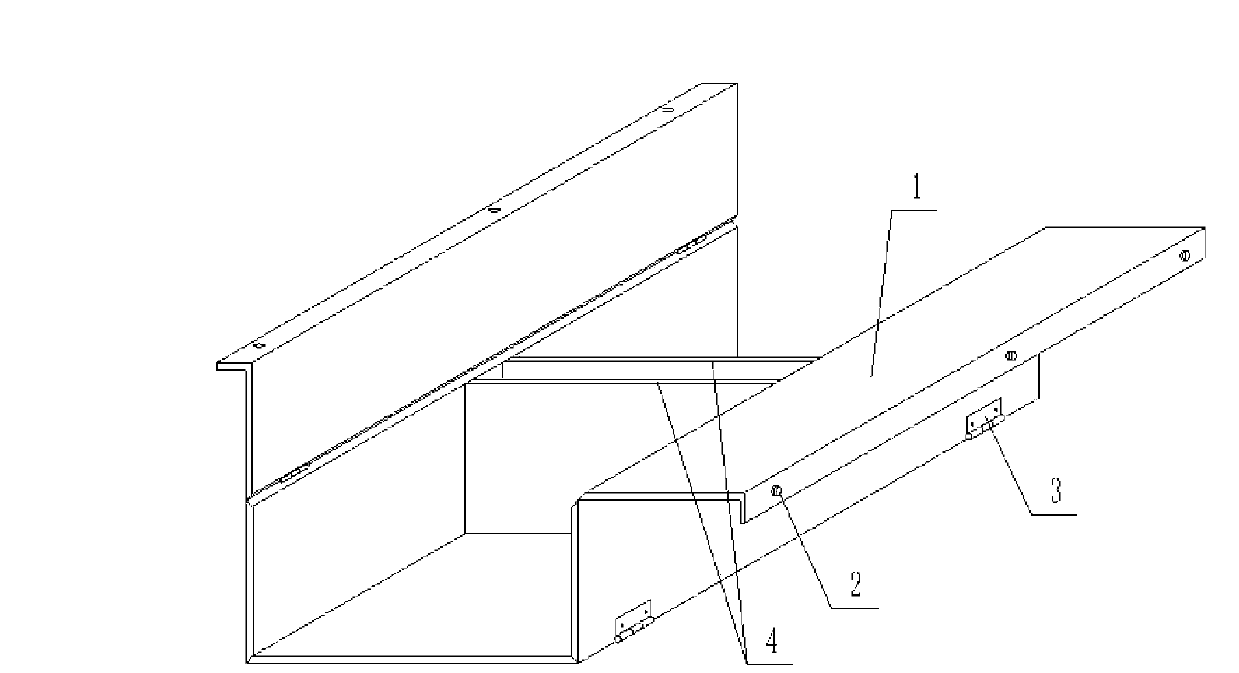

Polyhedron component molding mould

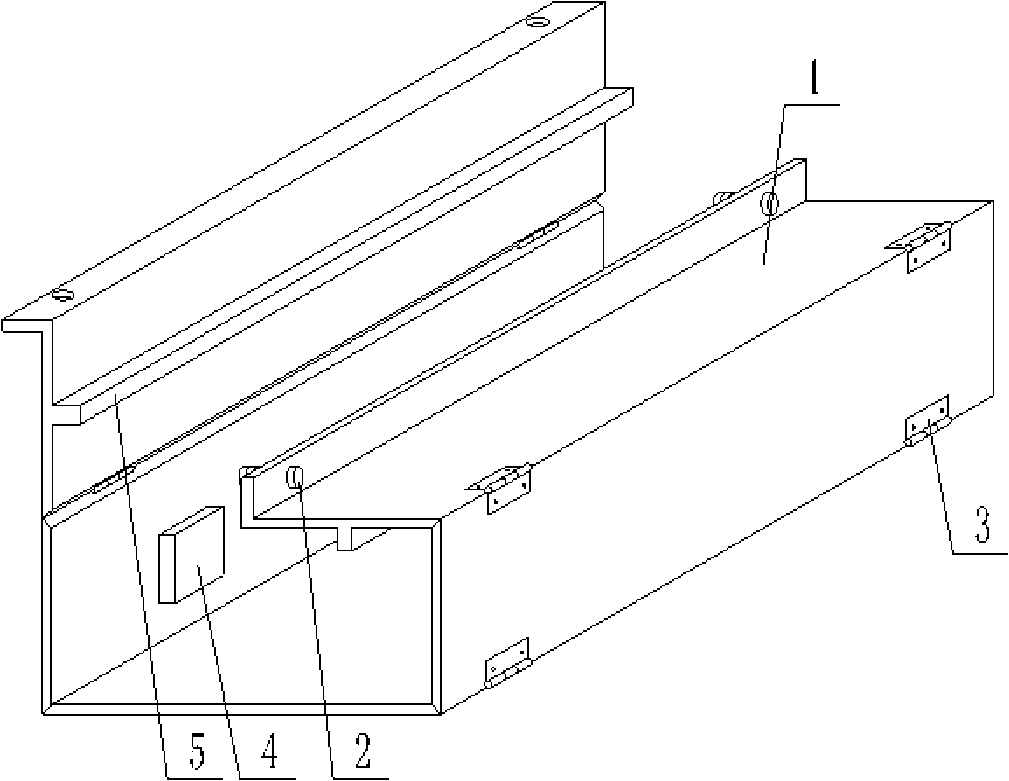

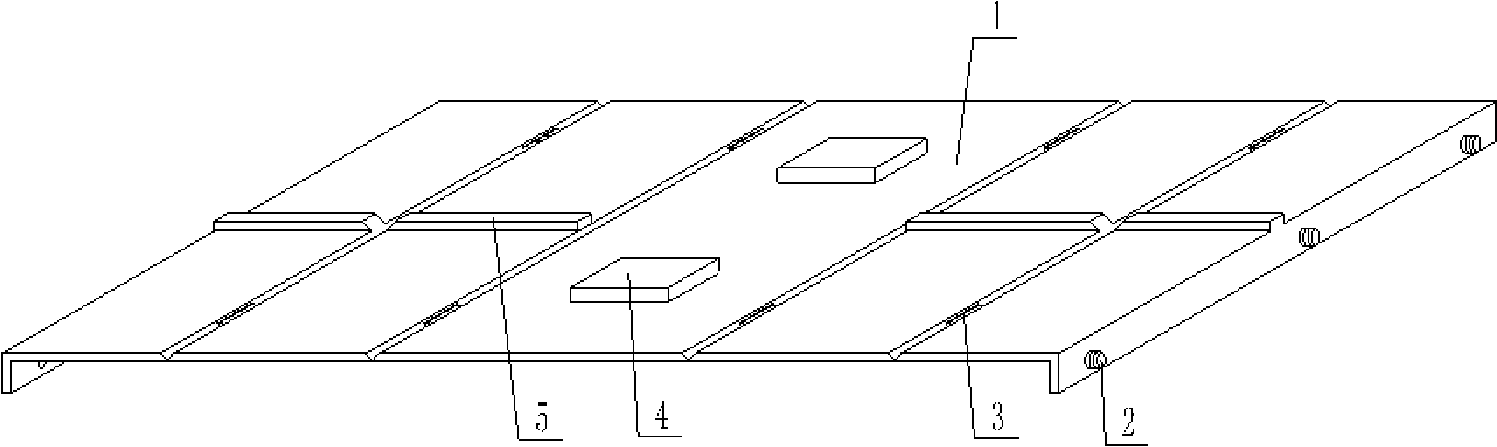

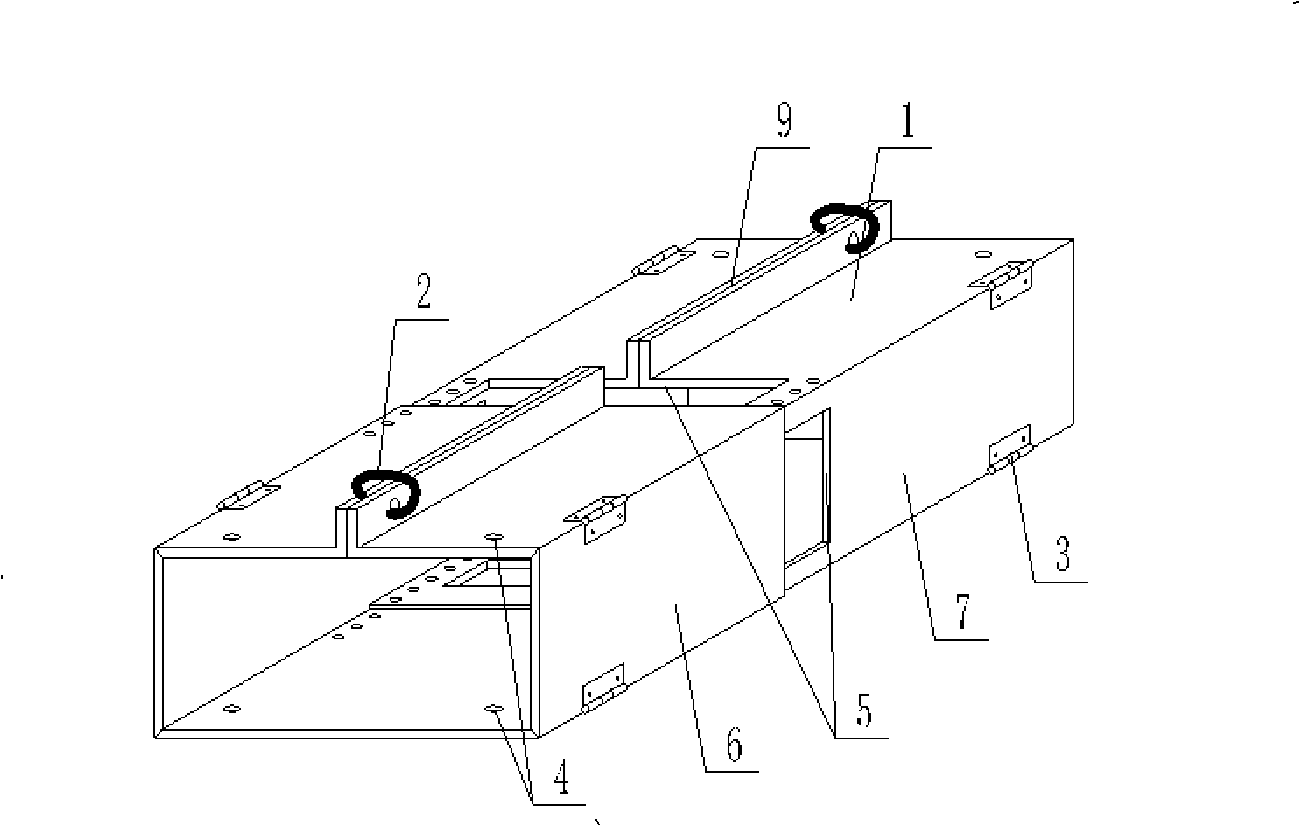

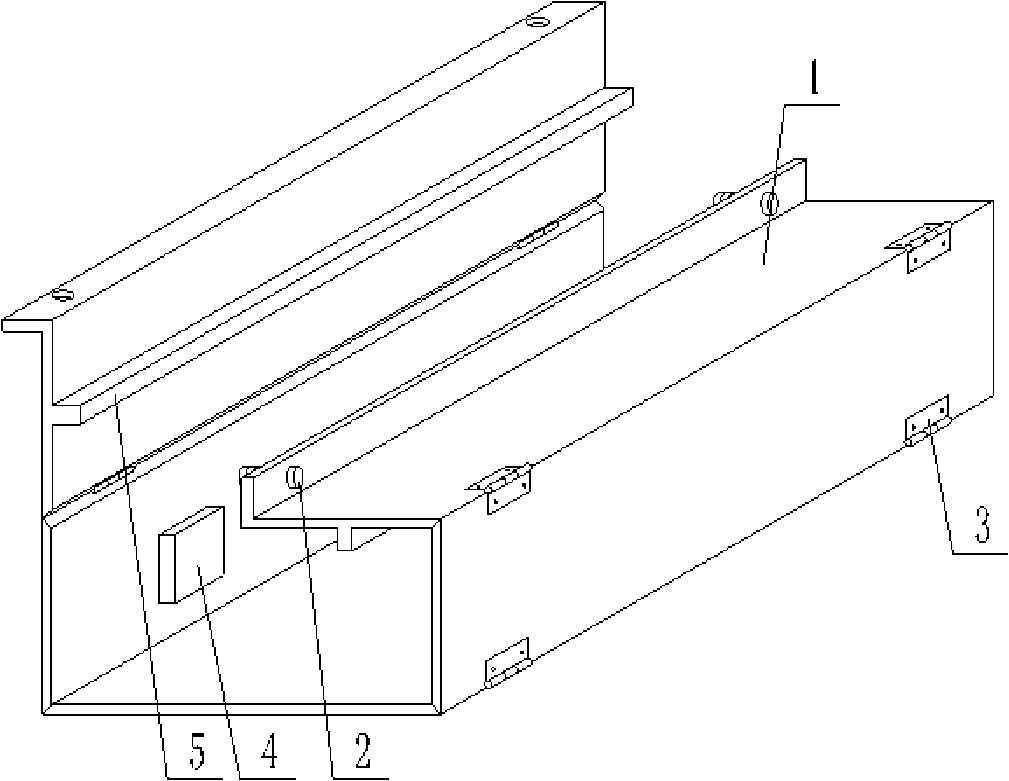

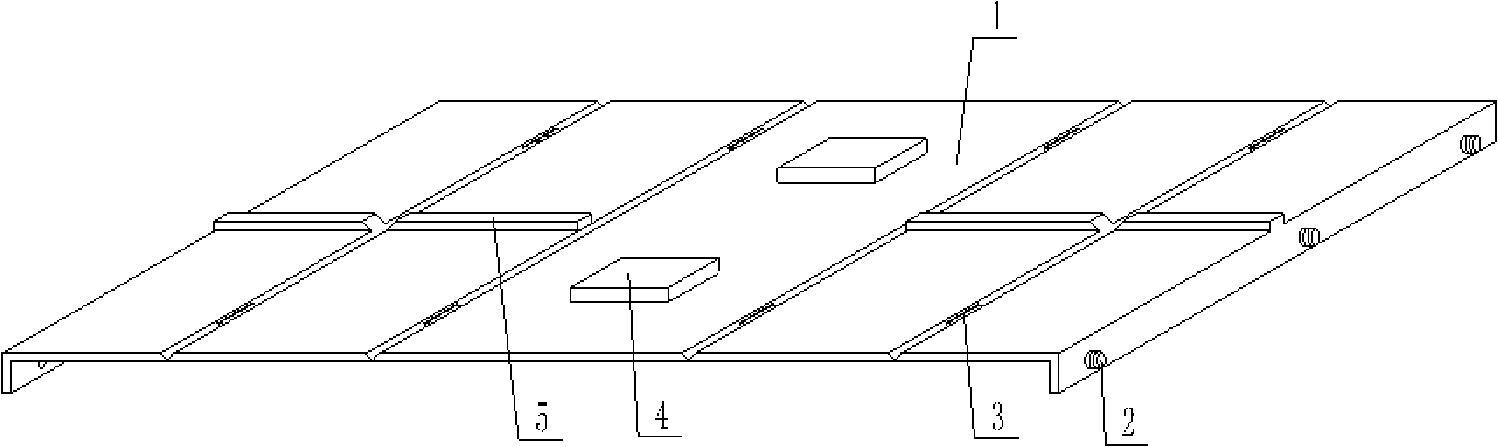

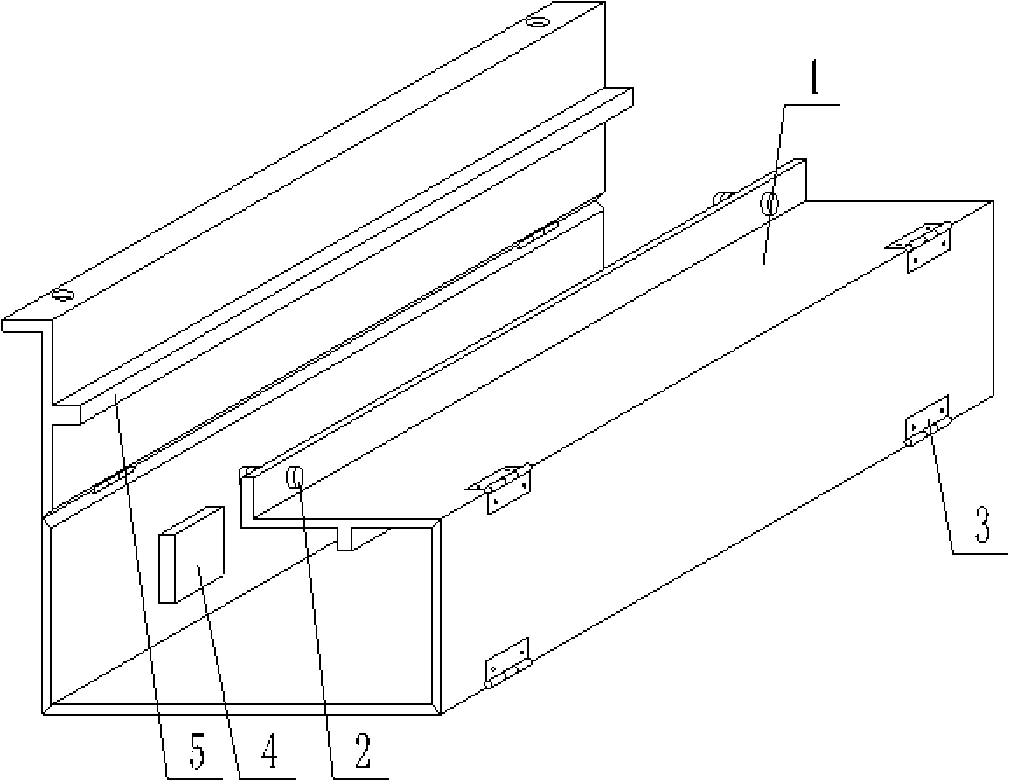

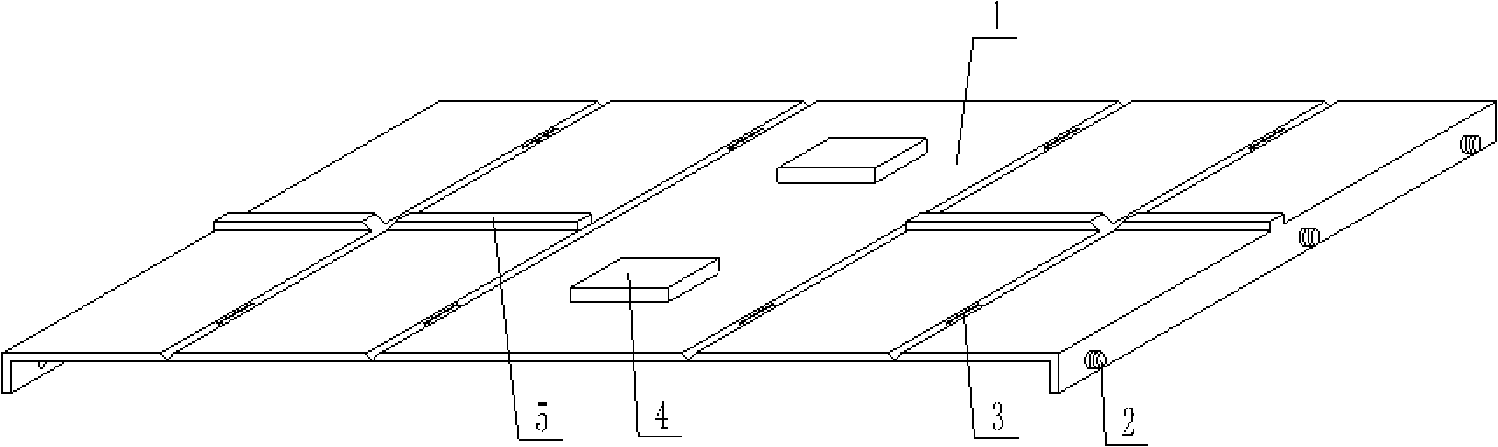

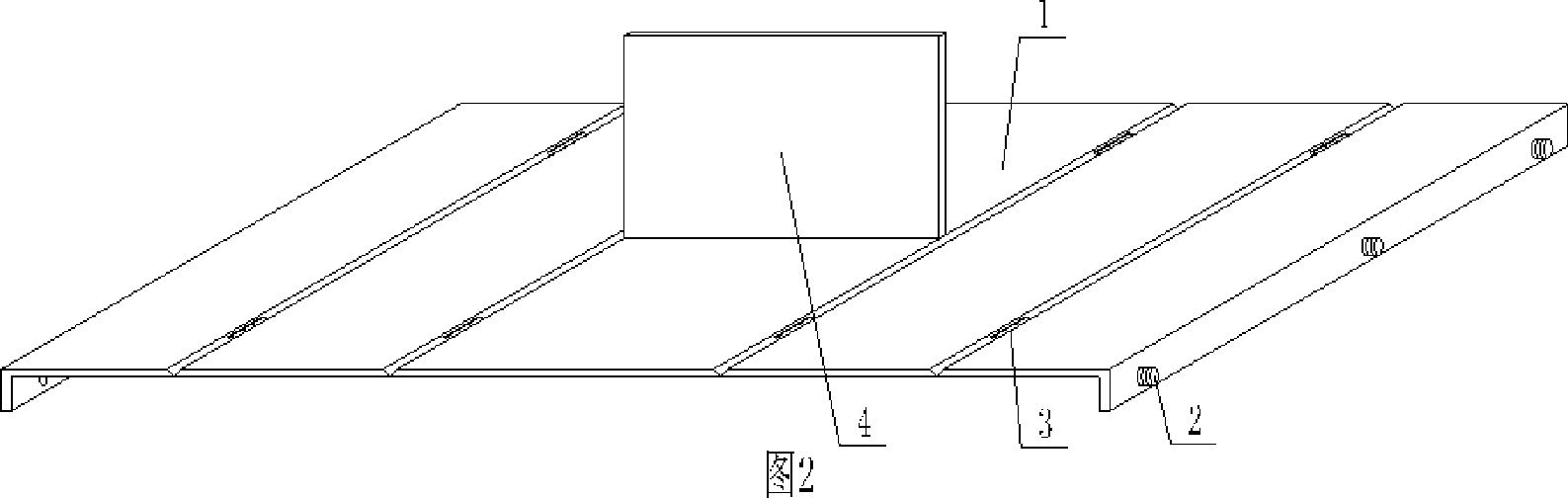

The invention provides a mould for moulding a polyhedral component, which comprises templets (1), fasteners (2) and a rotary component (3). The templets (1) are connected with each other by the rotary component (3); the connected templets (1) can turn relatively; after the templets (1) are folded, the templets are fixed with the fastener (3). The mould is characterized in that at least three templets are connected in turn side by side; at least one templet (1) is provided with a clear opening (4) and / or a continuous groove (5); four templets (1) are connected through hinges in turn side by side. The mould provided by the invention has the characteristics of being unloaded conveniently, simple structure, high strength, low cost and so on.

Owner:湖南邱则有专利战略策划有限公司

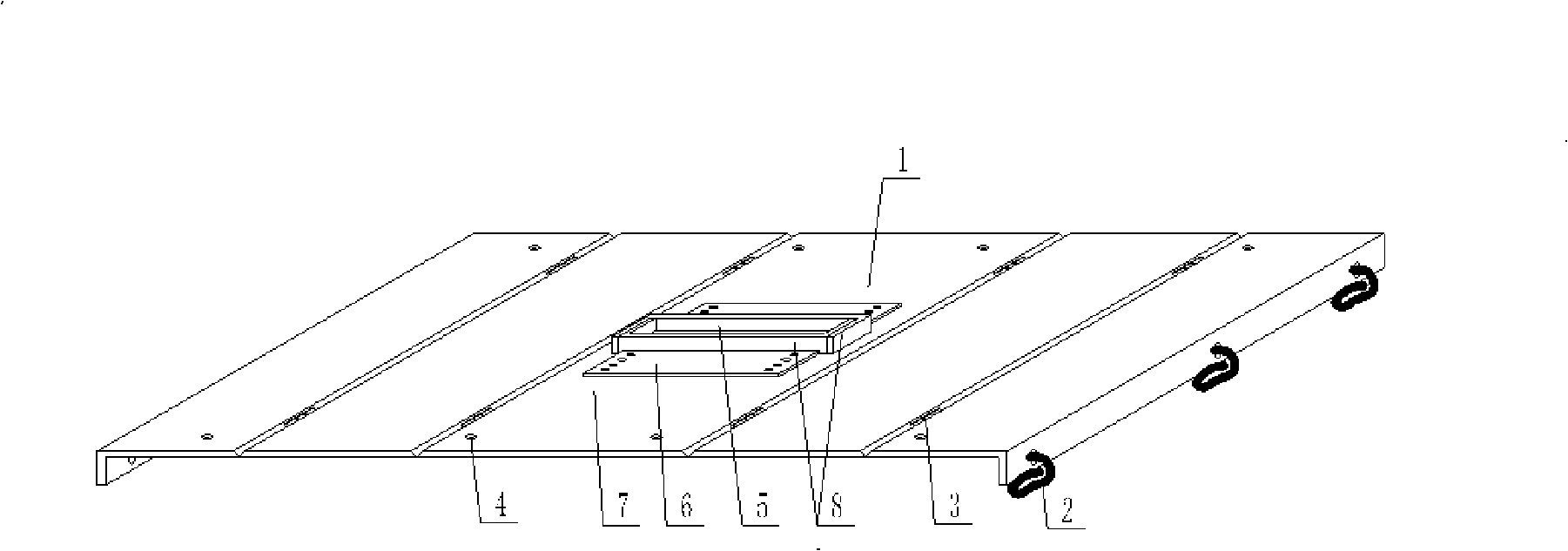

Mold for molding hollow thin wall component for filling concrete

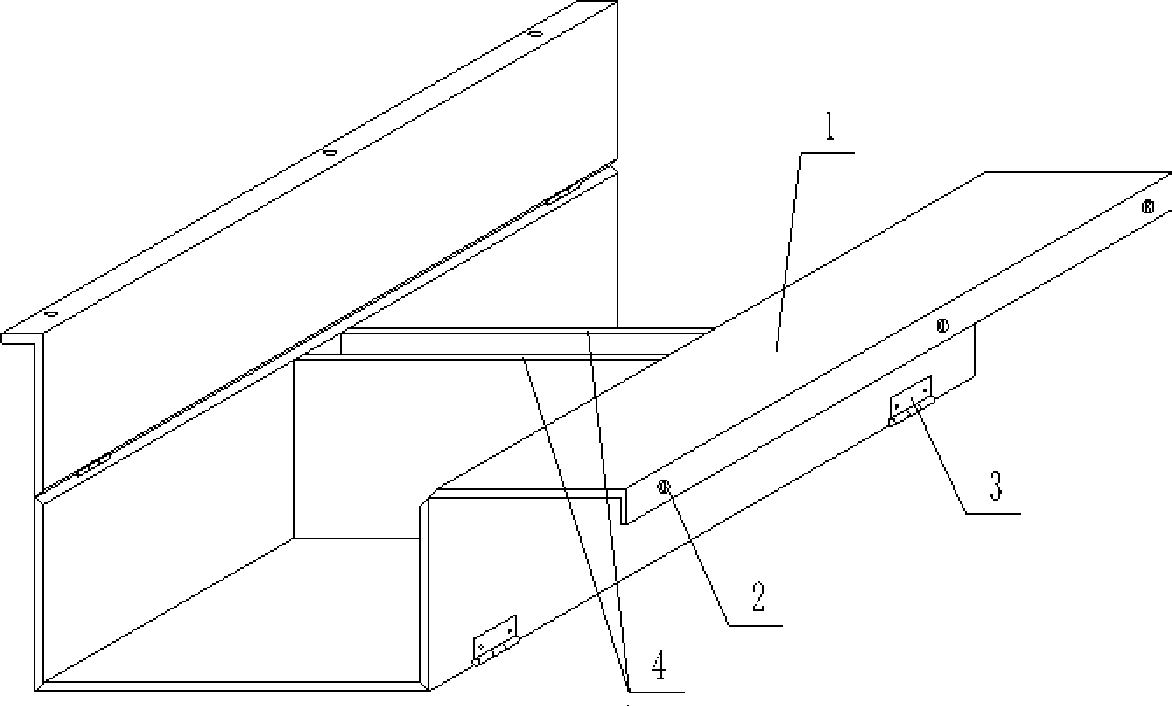

A shaping die for a concrete-filled hollow thin-wall component includes templates (1), fasteners (2) and rotatable parts (3). The templates (1) are connected by the rotatable parts (3); the connected templates (1) can rotate oppositely; the templates (1) after being folded are fixed by the fasteners (2). The invention is characterized in that at least three templates (1) are connected in sequence side by side in the die; at least one template (1) is provided with at least one transverse isolating die (4); the transverse isolating die (4) is formed by joining at least two movable parts (5) together; the transverse isolating die (4) is a clapboard and is a one-off die which is combined with the product to become one part of the product. The shaping die for a concrete-filled hollow thin-wall component is applicable to manufacturing various opened or closed polyhedron components.

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

A shaping die for a concrete-filled hollow thin-wall component includes templates (1), fasteners (2) and rotatable parts (3). The templates (1) are connected by the rotatable parts (3); the connected templates (1) can rotate oppositely; the templates (1) after being folded are fixed by the fasteners (2). The invention is characterized in that at least three templates (1) are connected in sequence in the die side by side; at least one template (1) is provided with at least one transverse isolating die (4) which is a clapboard; the transverse isolating die (4) is a double isolating die. In this way, after the fasteners are loosened, the die is very convenient to be released; simultaneously, when a polyhedron component is produced, a concave structure can be correspondingly formed on the polyhedron component or a conjoined or non-conjoined polyhedron component is manufactured; the production requirements for different polyhedron components can be met; besides, the die is also characterized by simple structure, easy manufacture, high intensity, low cost, and the like. The shaping die for a concrete-filled hollow thin-wall component is suitable for manufacturing various opened or closed polyhedron components.

Owner:湖南邱则有专利战略策划有限公司

Polyhedron component molding mould

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

A shaping die for a concrete-filled hollow thin-wall component includes templates (1), fasteners (2) and rotatable parts (3). The templates (1) are connected by the rotatable parts (3); the connected templates (1) can rotate oppositely; the templates (1) after being folded are fixed by the fasteners (2). The invention is characterized in that at least three templates (1) are connected in sequence side by side in the die; at least one template (1) is provided with at least one transverse isolating die (4); at least one end of at least one of the side-by-side templates (1) is connected with a movable template (1); the surface of the transverse isolating die (4) is a shaping die surface. In this way, after the fasteners are loosened, the die is very convenient to be released; simultaneously, when a polyhedron component is produced, a concave structure can be correspondingly formed on the polyhedron component; the production requirements for different polyhedron components can be met; besides, the die is also characterized by simple structure, easy manufacture, high intensity, low cost, and the like. The shaping die for a concrete-filled hollow thin-wall component is applicable to manufacturing various opened or closed polyhedron components.

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

InactiveCN101347949AQuick assemblyQuick dismantlingMould separation apparatusMouldsEngineeringHigh intensity

The invention relates to a concrete-filled hollow thin-walled member forming mould which comprises templates (1), a joint and tight piece (2), and rotatable components (3). The templates (1) are connected by the rotatable components (3). The connected templates (1) can relatively rotate. After the templates (1) are folded, the templates are fixed by the joint and tight piece (2). The mould is characterized in that at least three templates (1) are sequentially connected with each other side by side in the mould; wherein, a projection (4) or sand strip (5) protruding the surface of the templates is arranged on at least one of the three templates. The four templates (1) are folded into a tube-shaped mould. At least one of a gemel, a hinge, a bolt hinge, a film, a rotatable tenon, a rotatable slot or a rotatable jack, a rotatable bolt, a rotatable connector pin and a rotatable sliding bush serves as the rotatable components (3). Therefore, a very convenient demoulding can be ensured after the joint and tight piece is loosed; at the same time, a concave structure can be correspondingly formed on the polyhedron members during the production of polyhedron members, thus meeting requirements for a variety of hollow floor systems; furthermore, the mould is characterized by simple structure, easy manufacture, high intensity, low cost, etc., and is suitable for manufacturing a variety of open or closed polyhedral components.

Owner:湖南邱则有专利战略策划有限公司

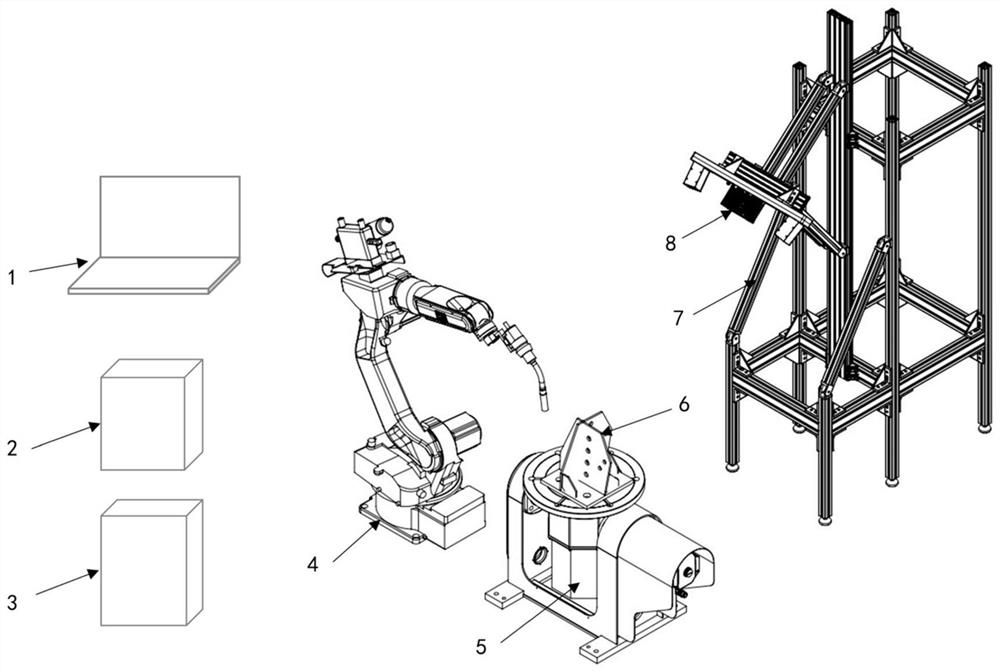

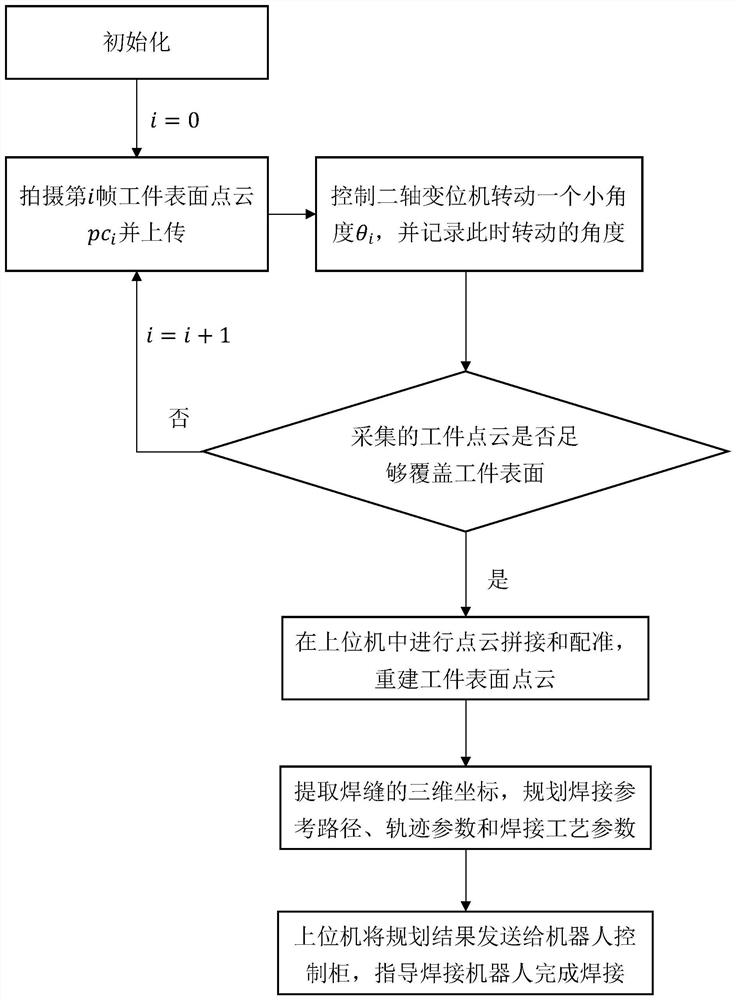

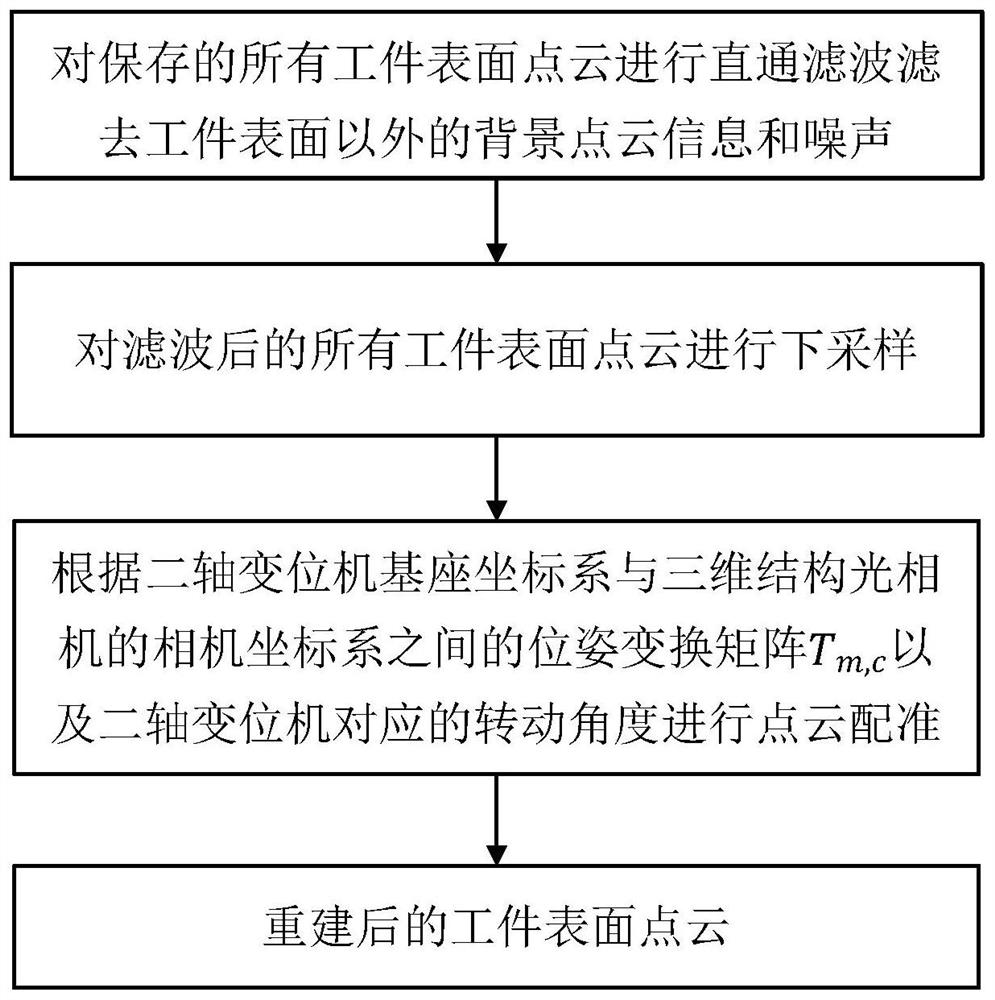

Tower foot workpiece automatic welding system and method based on weld joint recognition

ActiveCN114515924AImprove welding efficiencyImprove welding precisionProgramme-controlled manipulatorWelding/cutting auxillary devicesPoint cloudWeld seam

The invention discloses a tower foot workpiece automatic welding system and method based on weld joint recognition, and the system comprises an upper computer, a robot control cabinet, a welding robot, a two-axis positioner and a three-dimensional structured light camera which are matched with one another; the upper computer is used for receiving the workpiece surface point cloud information shot by the three-dimensional structured light camera, performing point cloud splicing and workpiece surface reconstruction, and completing weld joint extraction and welding path planning of the welding robot; the robot control cabinet is used for controlling welding of the welding robot and movement of the two-axis positioner. The two-shaft positioner is used for fixing a welding workpiece and adjusting the angle of the welding workpiece; and the three-dimensional structured light camera is used for shooting surface point cloud information of the welding workpiece. By utilizing the method, the welding path planning of the welding robot can be directly guided by extracting the three-dimensional coordinate information of all the welding seams of the welding part of the welding workpiece, the welding efficiency and the welding precision of the tower foot workpiece can be improved, and the method has universality for tower foot workpieces of different specifications.

Owner:ZHEJIANG UNIV

Polyhedron component molding mould

Owner:湖南邱则有专利战略策划有限公司

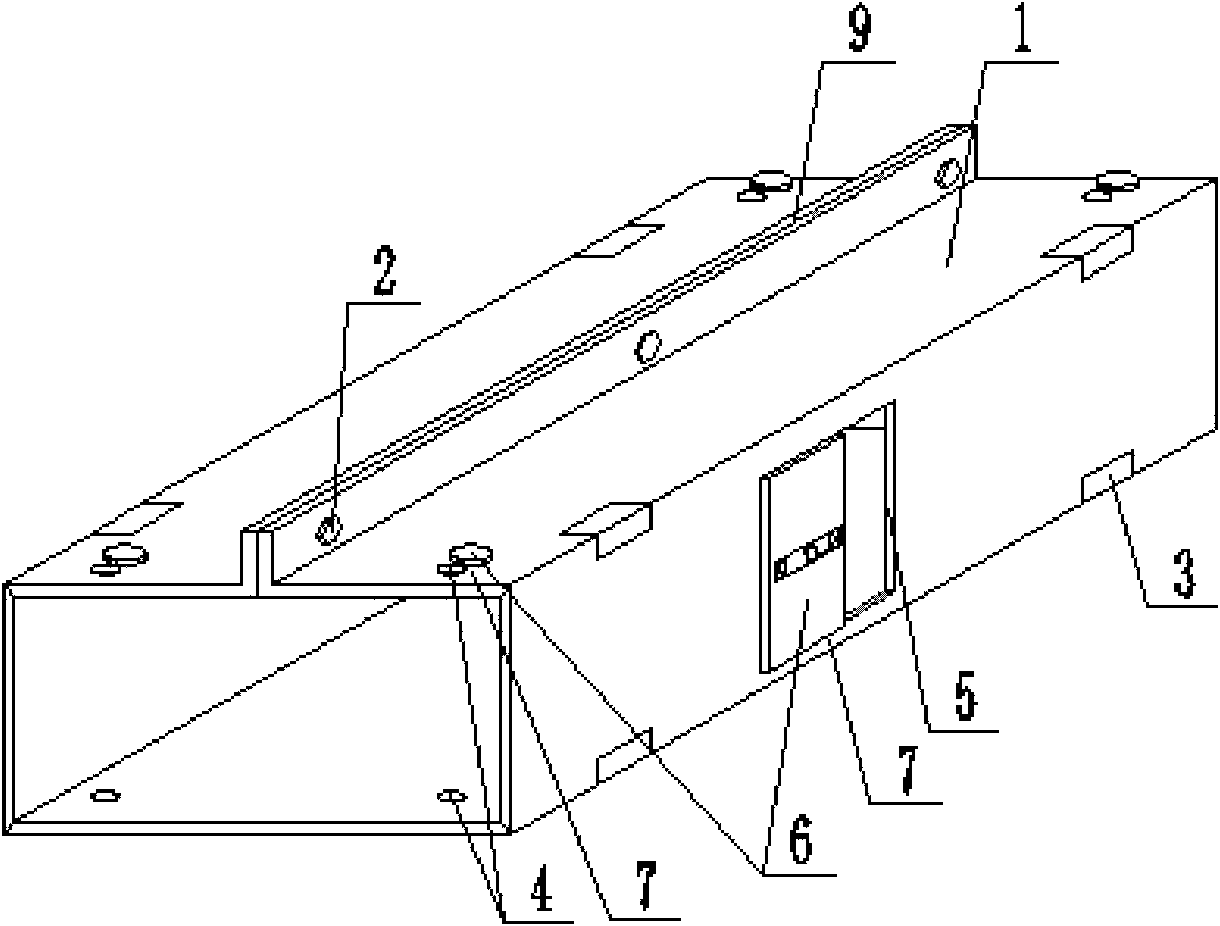

Mould for molding concrete filled hollow thin wall component

The invention provides a mould for moulding a concrete filled hollow thin wall component, which comprises templets (1), fasteners (2) and rotary components (3). The templets (1) are connected with each other by the rotary components (3); the connected templets (1) can turn relatively; after the templets are folded, the fasteners (2) fix the templets (1). The mould for moulding the concrete filled hollow thin wall component is characterized in that at least three templets in the mould are connected in turn side by side; at least one templet (1) is provided with at least one cross spacing mould (4) which is a movable spacing mould; the surface of the cross spacing mould is a moulding surface. In this way, after the fasteners become loose, the mould can be unloaded conveniently. When polyhedral components are produced, the mould can form concave structures on the polyhedral components, or be used for manufacturing connected or disconnected polyhedral components. Accordingly, the mould meets the requirements for producting various polyhedral components. In addition, the mould has the characteristics of simple structure, being manufactured easily, high strength, low cost and so on, which is applicable for manufacturing various open-end or closed-end polyhedral components.

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

A shaping die for a concrete-filled hollow thin-wall component includes templates (1), fasteners (2) and rotatable parts (3). The templates (1) are connected by the rotatable parts (3); the connected templates (1) can rotate oppositely; the templates (1) after being folded are fixed by the fasteners (2). The invention is characterized in that at least three templates (1) are connected in sequence side by side in the die; at least one template (1) is provided with at least one transverse isolating die (4); the die clamping opening of a cylindrical die formed by folding four templates (1) is arranged at a corner part; the surface of the transverse isolating die (4) is a shaping die surface. In this way, after the fasteners are loosened, the die is very convenient to be released; simultaneously, when a polyhedron component is produced, a concave structure can be correspondingly formed on the polyhedron component or a conjoined or non-conjoined polyhedron component is manufactured; the production requirements for different polyhedron components can be met; besides, the die is also characterized by simple structure, easy manufacture, high intensity, low cost, and the like. The shaping die for a concrete-filled hollow thin-wall component is applicable to manufacturing various opened or closed polyhedron components.

Owner:湖南邱则有专利战略策划有限公司

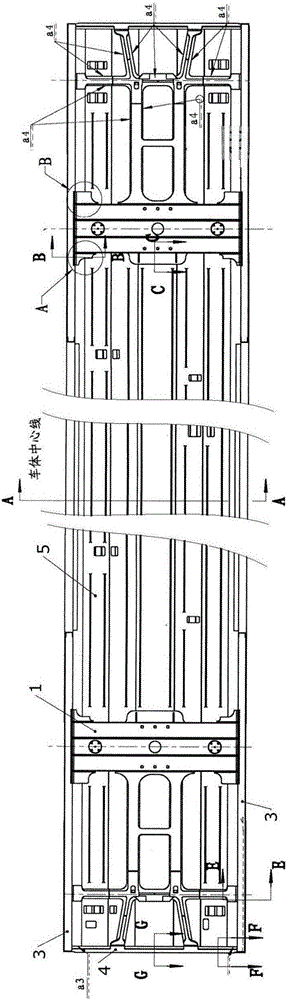

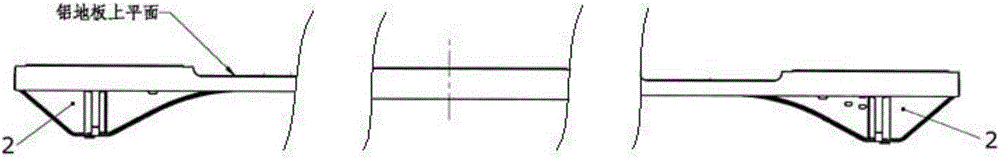

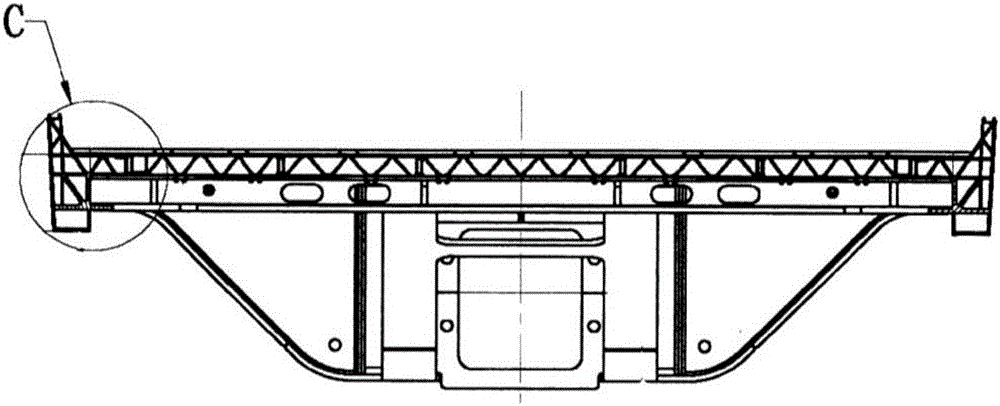

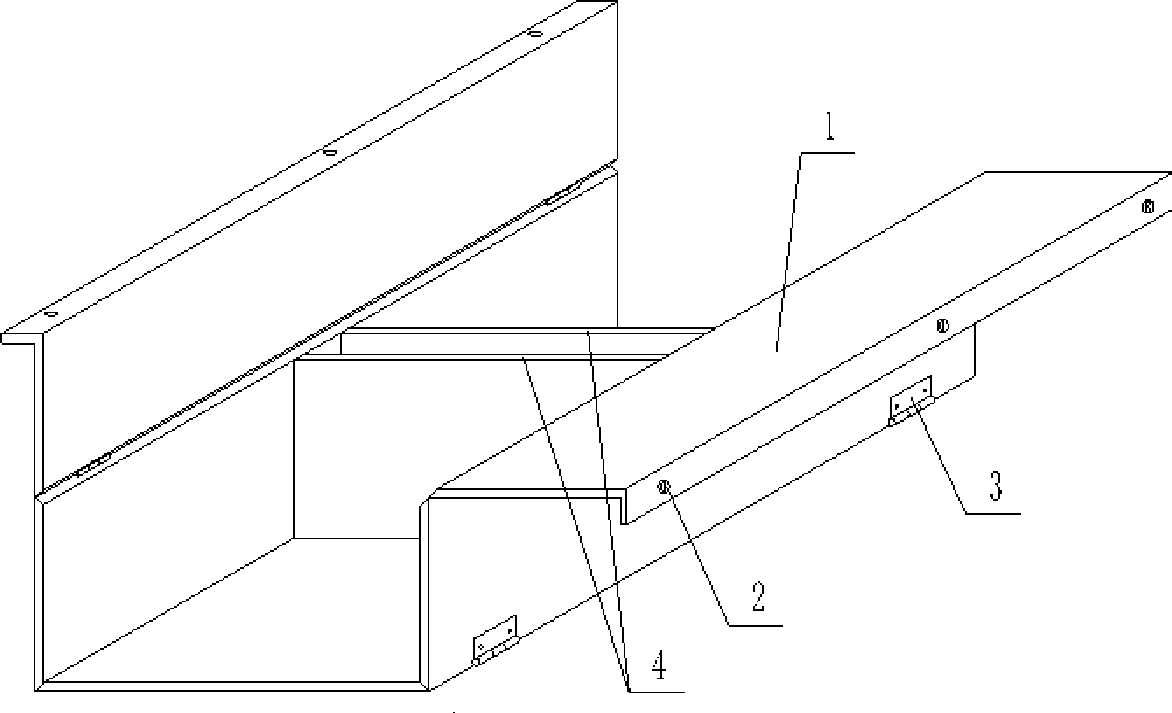

Welding process of aluminum alloy car body chassis for subway

ActiveCN104625319BShorten the lengthReduce consumptionVehicle componentsWelding/soldering/cutting articlesEngineeringEnergy consumption

The invention discloses a welding technology for an aluminum alloy vehicle chassis for a subway. The welding technology mainly comprises the following steps of chassis forward assembly, chassis reverse assembly, accessory welding and detection. According to the welding technology, all the tack fixing processes are conducted on forwards assembled tools, a base plate and a boundary beam are welded in the mode that welding is conducted from the middle to the two sides, and sequence welding is adopted in the welding process of a sleeper beam and a floor; in addition, the welding deformation is controlled by additionally arranging a transverse supporting device; the welding technology has the remarkable advantages that the deformation amount and the alignment tolerance are controlled, the welding performance is improved, the size deviation is reduced, the percent of pass of products is improved, and energy consumption is reduced.

Owner:辽宁忠旺铝合金精深加工有限公司

Mold for molding hollow thin wall component for filling concrete

A shaping die for a concrete-filled hollow thin-wall component includes templates (1), fasteners (2) and rotatable parts (3). The templates (1) are connected by the rotatable parts (3); the connected templates (1) can rotate oppositely; the templates (1) after being folded are fixed by the fasteners (2). The invention is characterized in that at least three templates (1) are connected in sequence side by side in the die; at least one template (1) is provided with at least one transverse isolating die (4); the transverse isolating die (4) is a clapboard and a one-off die which is combined with the product to become one part of the product; the transverse isolating die (4) is formed by joining at least two movable parts (5) together. The shaping die for a concrete-filled hollow thin-wall component is applicable to manufacturing various opened or closed polyhedron components.

Owner:湖南邱则有专利战略策划有限公司

Mould for molding concrete filled hollow thin wall component

The invention provides a mould for moulding a concrete filled hollow thin wall component, which comprises templets (1), a rotary component (3) and fasteners (2). The templets (1) are connected with each other by the rotary component (3); the connected templets (1) can turn relatively; after the templets (1) are folded, the templets are fixed with the fastener (2). The mould for moulding the concrete filled hollow thin wall component is characterized in that at least three templets in the mould are connected in turn side by side; at least one templet (1) is provided with at least one cross spacing mould (4) which is a partition; the cross partition (4) is connected with the templets in a movable way or detachable way. In this way, after the fasteners become loose, the cylindrical mould can be unloaded conveniently. When polyhedral components are produced, the mould can form concave structures on the polyhedral components, or be used for manufacturing connected or disconnected polyhedral components. Accordingly, the mould meets the requirements for production of various polyhedral components. In addition, the mould has the characteristics of simple structure, being manufactured easily, high strength, low cost and so on, which is applicable for manufacturing various open-end or closed-end polyhedral components.

Owner:湖南邱则有专利战略策划有限公司

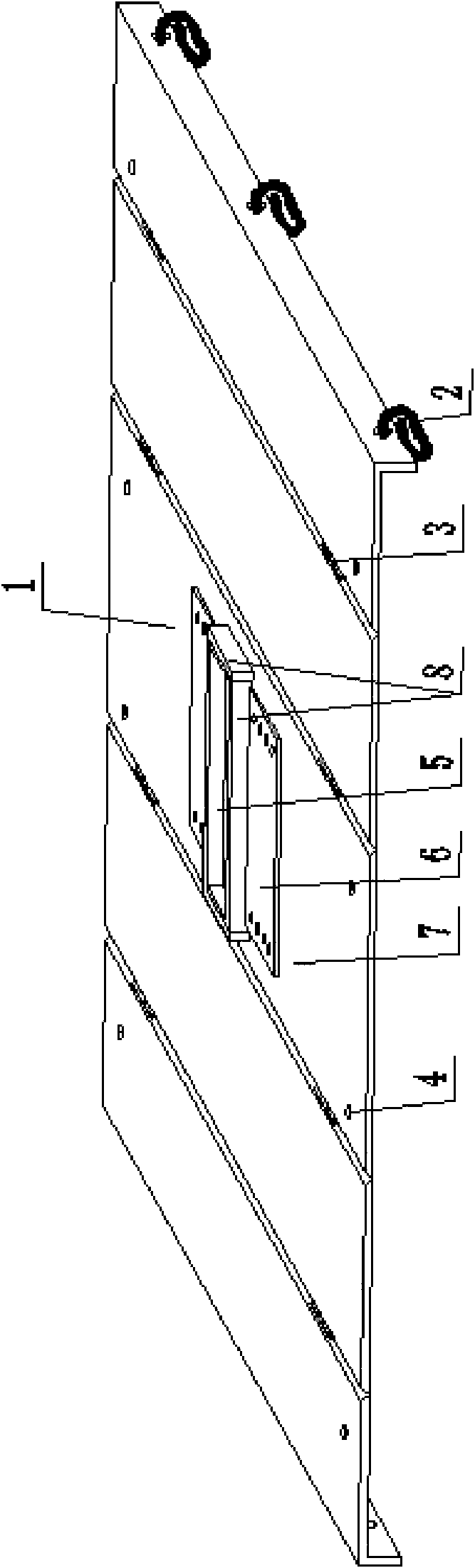

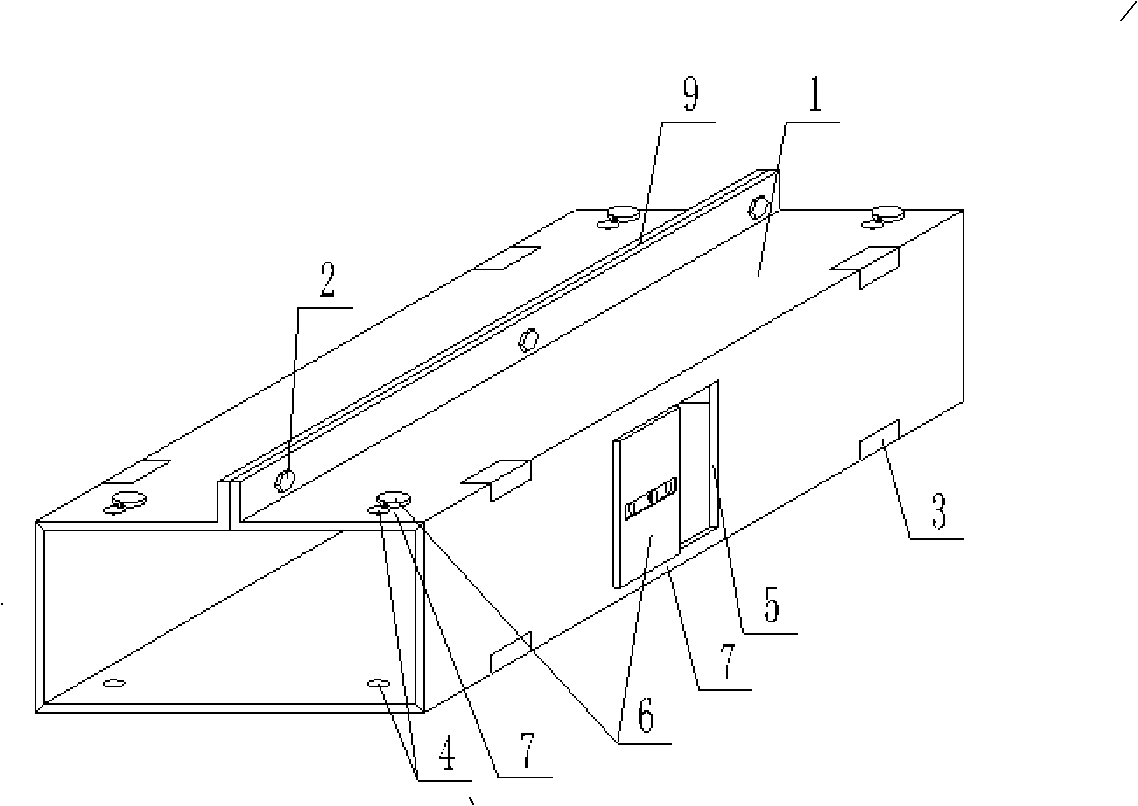

Mold for molding hollow thin wall component for filling concrete

The invention relates to a concrete-filled hollow thin-walled member forming mould which comprises templates (1), a joint and tight piece (2), and rotatable components (3). The templates (1) are connected by the rotatable components (3). The connected templates (1) can relatively rotate. After the templates (1) are folded, the templates are fixed by the joint and tight piece (2). The mould is characterized in that at least three templates (1) are sequentially connected with each other side by side in the mould; wherein, a projection (4) or sand strip (5) protruding the surface of the templates is arranged on at least one of the three templates. A hole or a stitch (7) is arranged on the projection (4) or the sand strip (5). At least one of a gemel, a hinge, a bolt hinge, a film, a rotatable tenon, a rotatable slot or a rotatable jack, a rotatable bolt, a rotatable connector pin and a rotatable sliding bush serves as the rotatable components (3). Therefore, a very convenient demoulding can be ensured after the joint and tight piece is loosed; at the same time, a concave structure can be correspondingly formed on the polyhedron members during the production of polyhedron members, thus meeting requirements for a variety of hollow floor systems; furthermore, the mould is characterized by simple structure, easy manufacture, high intensity, low cost, etc., and is suitable for manufacturing a variety of open or closed polyhedral components.

Owner:湖南邱则有专利战略策划有限公司

Die in user for molding component of concrete filled double thin wall

InactiveCN1727151BQuick assemblyQuick dismantlingMould separation apparatusMouldsEngineeringUltimate tensile strength

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

The invention relates to a concrete-filled hollow thin-walled member forming mould which comprises templates (1), a joint and tight piece (2), and rotatable components (3). The templates (1) are connected by the rotatable components (3). The connected templates (1) can relatively rotate. After the templates (1) are folded, the templates are fixed by the joint and tight piece (2). The mould is characterized in that at least three templates (1) are sequentially connected with each other side by side in the mould; wherein, a projection (4) or sand strip (5) protruding the surface of the templates is arranged on at least one of the three templates. The projection (4) or the sand strip (5) is fixedly or movably connected with the templates (4) or the sand strip (5) is parallel to or vertical to the rotatable axes of the rotatable components (3). At least one of a gemel, a hinge, a bolt hinge, a film, a rotatable tenon, a rotatable slot or a rotatable jack, a rotatable bolt, a rotatable connector pin and a rotatable sliding bush serves as the rotatable components (3). Therefore, a very convenient demoulding can be ensured after the joint and tight piece is loosed; at the same time, a concave structure can be correspondingly formed on the polyhedron members during the production of polyhedron members, thus meeting requirements for a variety of hollow floor systems; furthermore, the mould is characterized by simple structure, easy manufacture, high intensity, low cost, and the like, and is suitable for manufacturing a variety of open or closed polyhedral components.

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

Owner:湖南邱则有专利战略策划有限公司

An automatic parallel sealing welding device and sealing welding method based on image recognition

ActiveCN111730185BAchieve absorptionAchieve releaseCurved planar seam weldingMetal working apparatusControl systemVisual inspection

The invention relates to an automatic parallel seal welding device based on image recognition and a seal welding method, and belongs to the technical field of fine electronic product welding. The automatic parallel seal welding device comprises a baseplate as well as a product tooling positioning mechanism, a spot welding positioning mechanism, a seam welding positioning mechanism, a visual inspection system and a control system, wherein the product tooling positioning mechanism comprises a longitudinal reciprocating moving mechanism and a rotating mechanism; the longitudinal reciprocating moving mechanism is mounted on the baseplate; the rotating mechanism is mounted on the longitudinal reciprocating moving mechanism; a product tooling is mounted on the rotating mechanism; two parallelly-arranged rack vertical plates are mounted on the baseplate; the spot welding positioning mechanism and the seam welding positioning mechanism are both mounted on the rack vertical plates; spot weldingelectrode wheels are mounted on the spot welding positioning mechanism; seam welding electrode wheels are mounted on the seam welding positioning mechanism; and the visual inspection system is mounted on the spot welding positioning mechanism. The automatic parallel seal welding device is utilized for solving the technical problem that during the seal welding process in the prior art, the degreeof automation is low, the production efficiency is low, the product air-tightness is poor, and the appearance quality is poor.

Owner:烟台华创智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com