Automobile engine hood and processing method

A processing method and engine cover technology, which is applied to vehicle components, superstructures, superstructure sub-assemblies, etc., can solve problems affecting product appearance quality, improve appearance quality and precision, improve seam precision, and improve precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

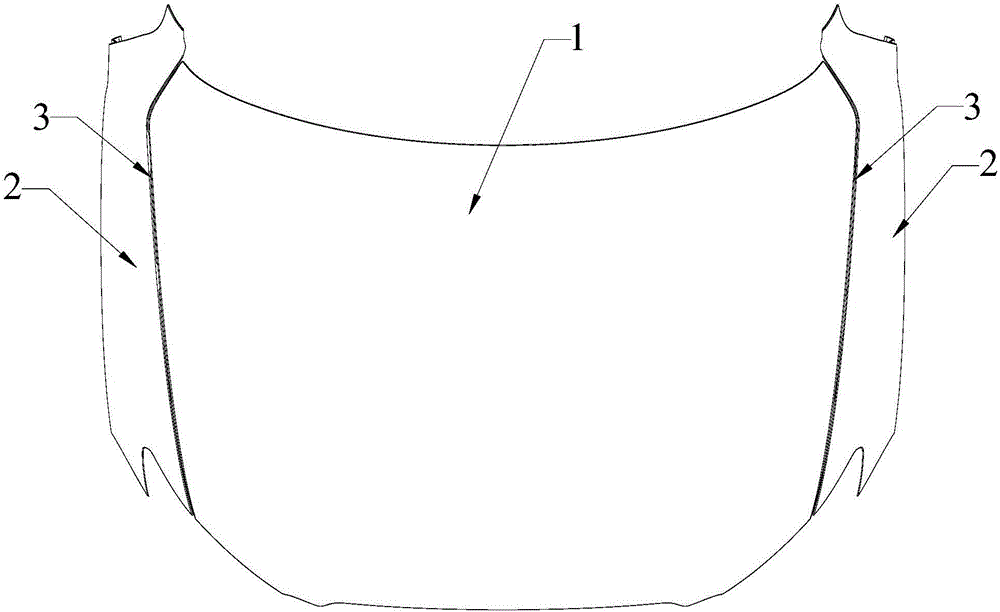

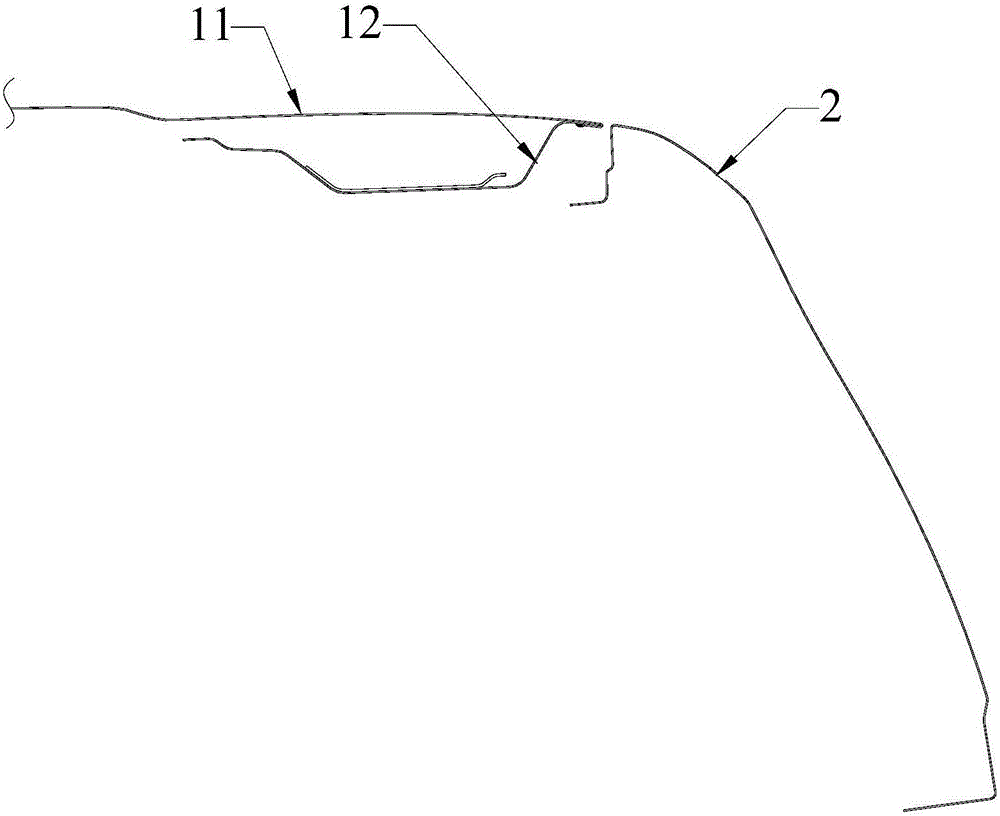

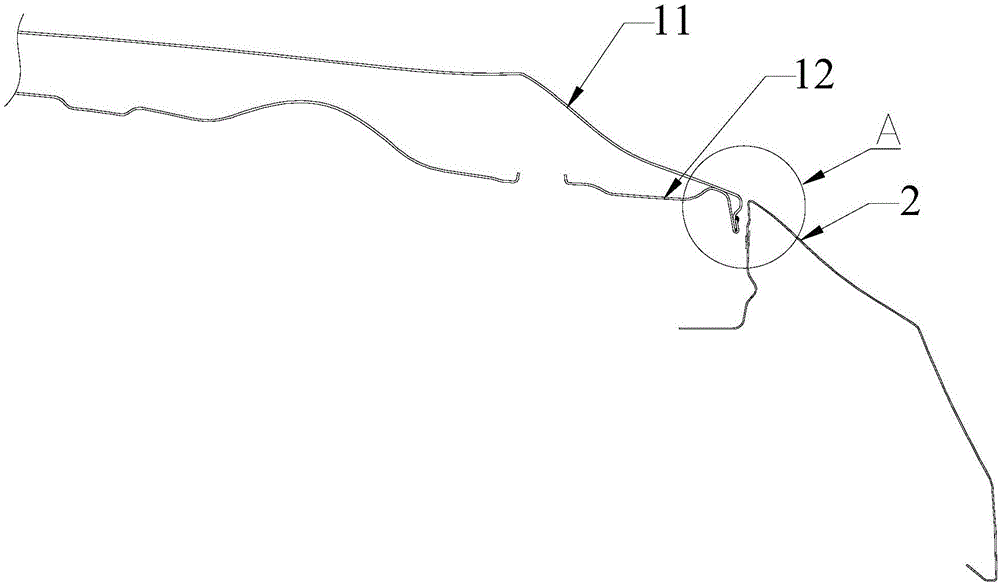

[0031] see image 3 as well as Figure 4 , the embodiment of the present invention is a kind of automobile engine cover, namely the engine cover of automobile, and this engine cover 1 comprises the outer plate 11 of engine cover and the inner plate 12 of engine cover, and the edge of outer plate 11 and inner plate 12 adopts hemming process to carry out The hemming forms the hood assembly. Wherein, the two sides of the outer panel 11 are respectively bent downwards and inwards to form a rib 111 opposite (parallel) to the fender 2 on the side of the hood; the outer panel 11 and the rib 111 It is stamped and formed by a stamping die at one time.

[0032] The edge of the inner panel 12 is bent downward and wraps the edge of the outer panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com