Checking method and method for preparation liquid crystal display device using the same

An inspection method and area technology, which is applied in semiconductor/solid-state device manufacturing, photo-plate-making process exposure device, optics, etc., can solve problems such as difficult to distinguish display unevenness, and achieve the effect of improving seam precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

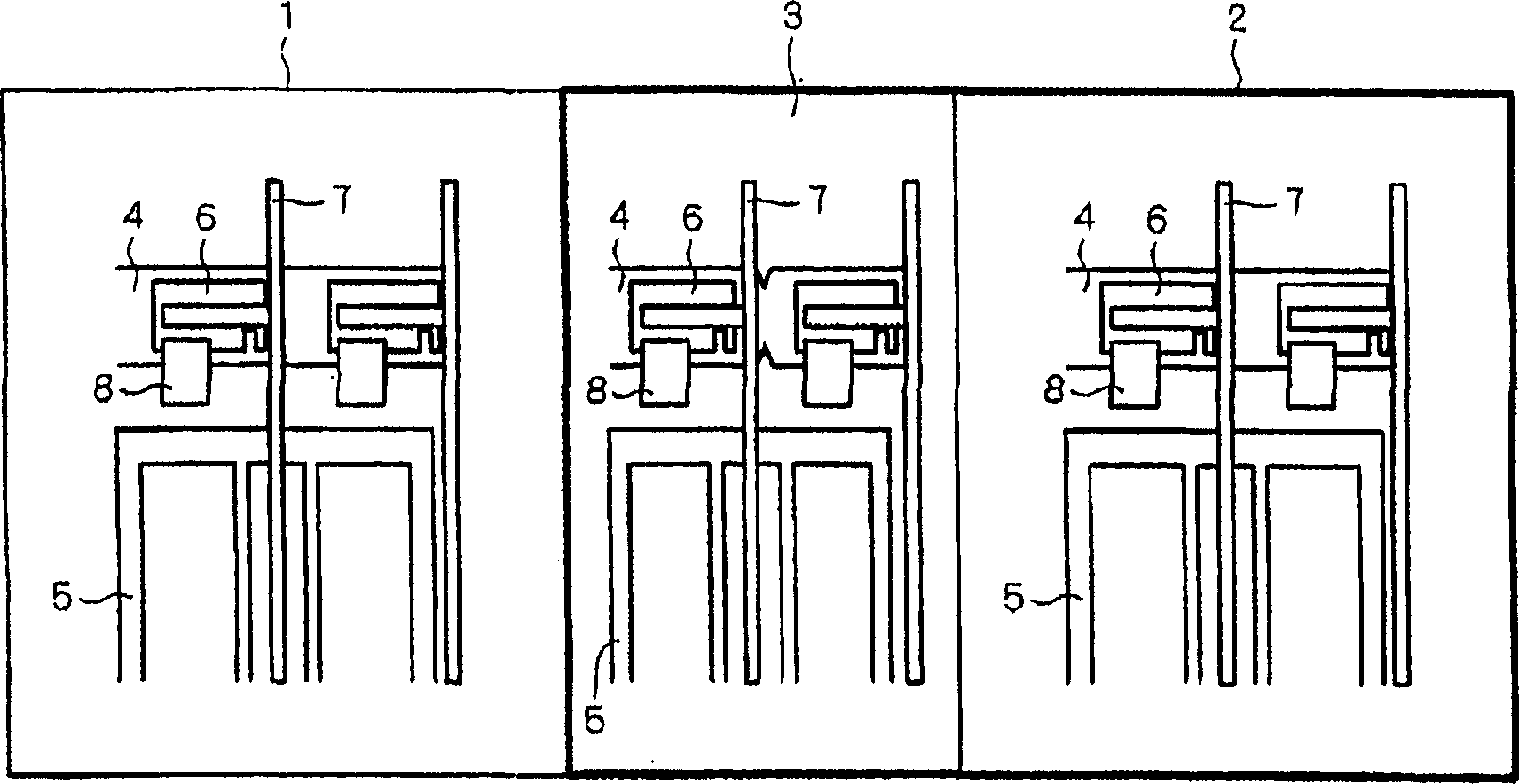

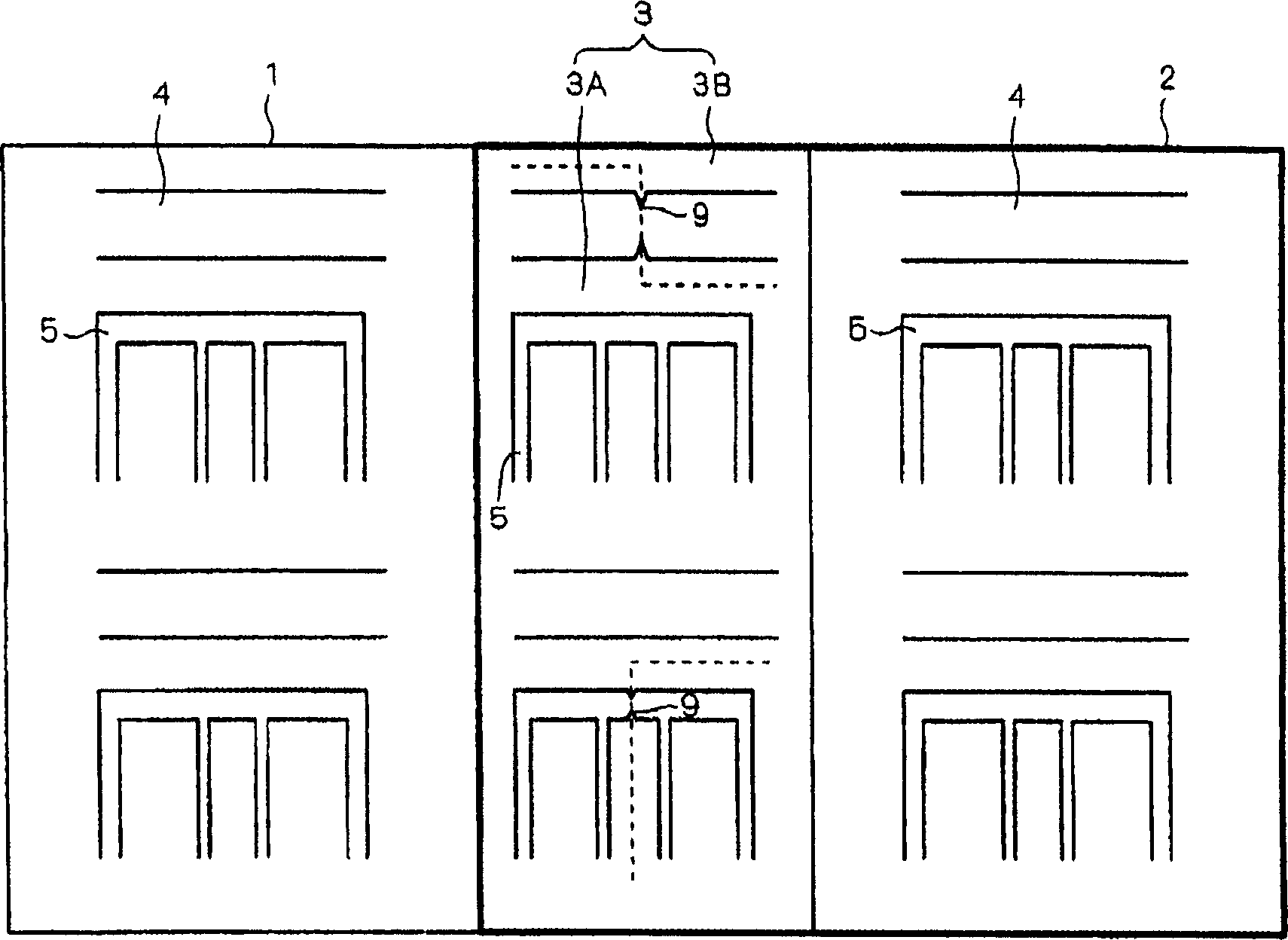

[0035] In the case where the predetermined pattern is formed by dividing the substrate into multiple regions and exposing them respectively, especially, in this embodiment, as figure 1 As shown in (a), two regions are provided, and each region is exposed using a mask to form one pattern on the substrate. figure 1 (a) shows a region 1 indicated by a thin line on the left and an area 2 indicated by a thick line on the right. When exposing area 1 and area 2 on the substrate, it is not simply exposing area 1 and area 2 side by side, but as figure 1 As shown in (b), exposure is provided with an overlapping region 3 in which region 1 and region 2 overlap. In addition, it does not matter whether to start exposure from area 1 or to start exposure from area 2. In addition, the overlapping region 3 is a mixture of a region that is exposed when the region 1 is exposed but not exposed when the region 2 is exposed, and a region that is exposed when the region 2 is exposed but not exposed...

Embodiment 2

[0052] In this embodiment, another inspection method different from the inspection method shown in Embodiment 1 is shown. In addition, in this embodiment, the substrate is also divided into a plurality of regions and then exposed respectively to form predetermined patterns. Therefore, if figure 1 As shown in (a), a predetermined pattern is patterned on the substrate by dividing the region 1 and the region 2 . However, the region 1 and the region 2 are not patterned entirely in the region, but are patterned only in a part of the region (hereinafter also referred to as a pixel portion), and the rest are non-pattern forming portions where no pattern is formed. Also, the pixel portion constitutes a part of a predetermined pattern formed on the substrate.

[0053] Specifically, Figure 8 Masks for region 1 and region 2 are shown. Figure 8 In the shown mask, a mask pattern for exposing the pixel portion 12 is provided at the center. Then, Figure 8 In the shown mask, measurem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com