Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Seam gap is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

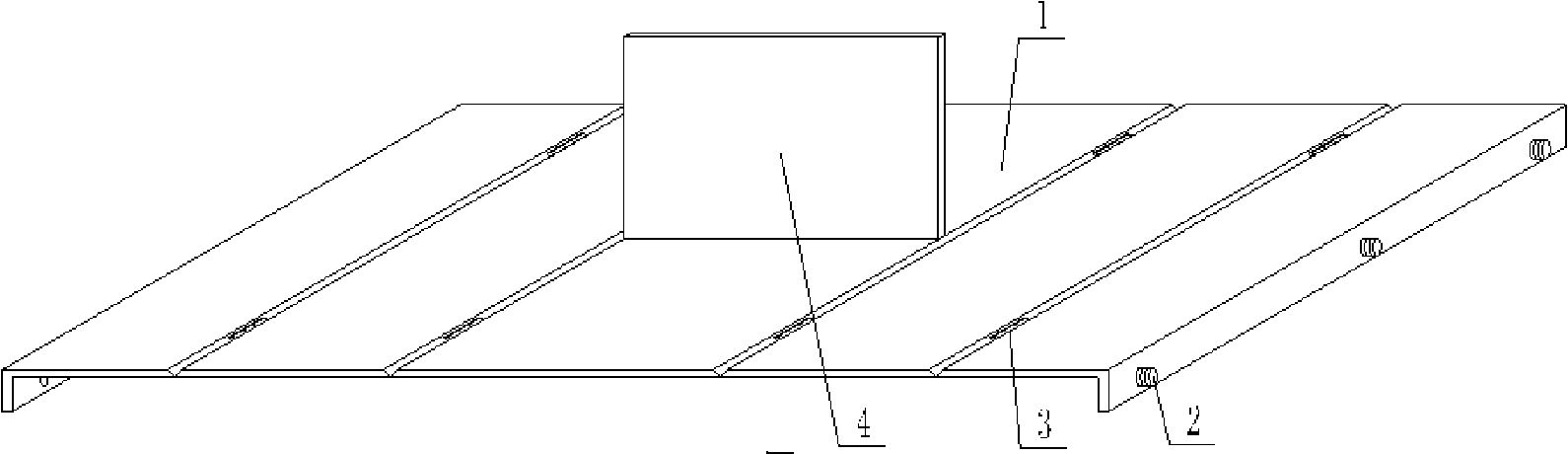

Forming die for component in polyhedron

InactiveCN1727148AEasy to splitEasy to assembleMould separation apparatusMouldsBiomedical engineeringFastener

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

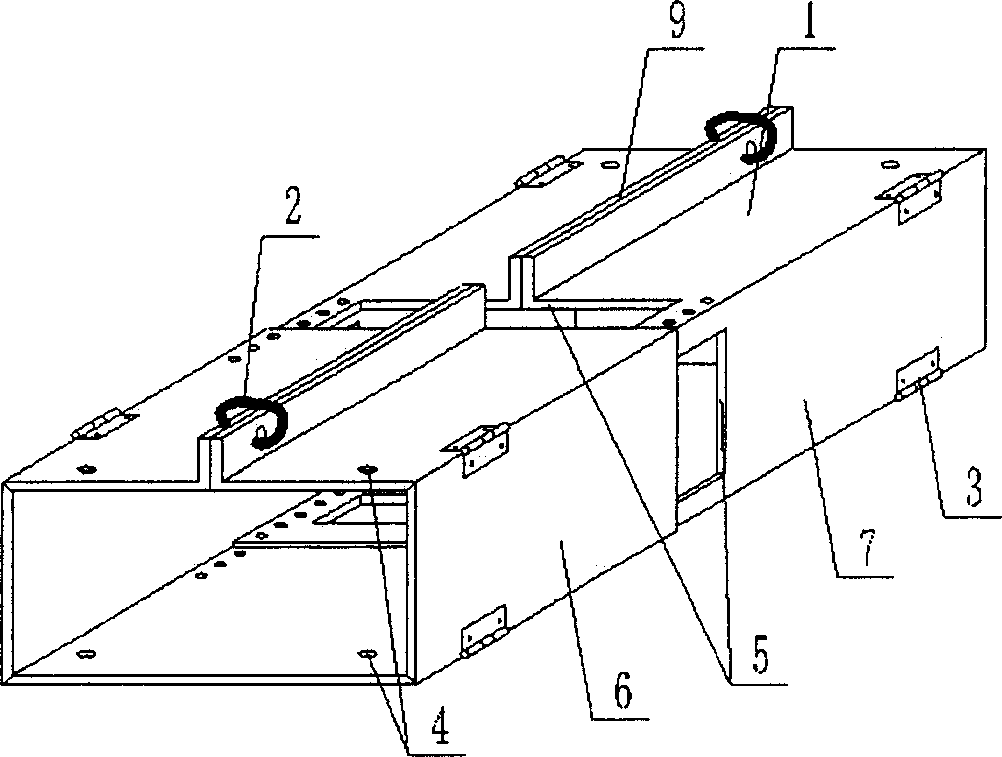

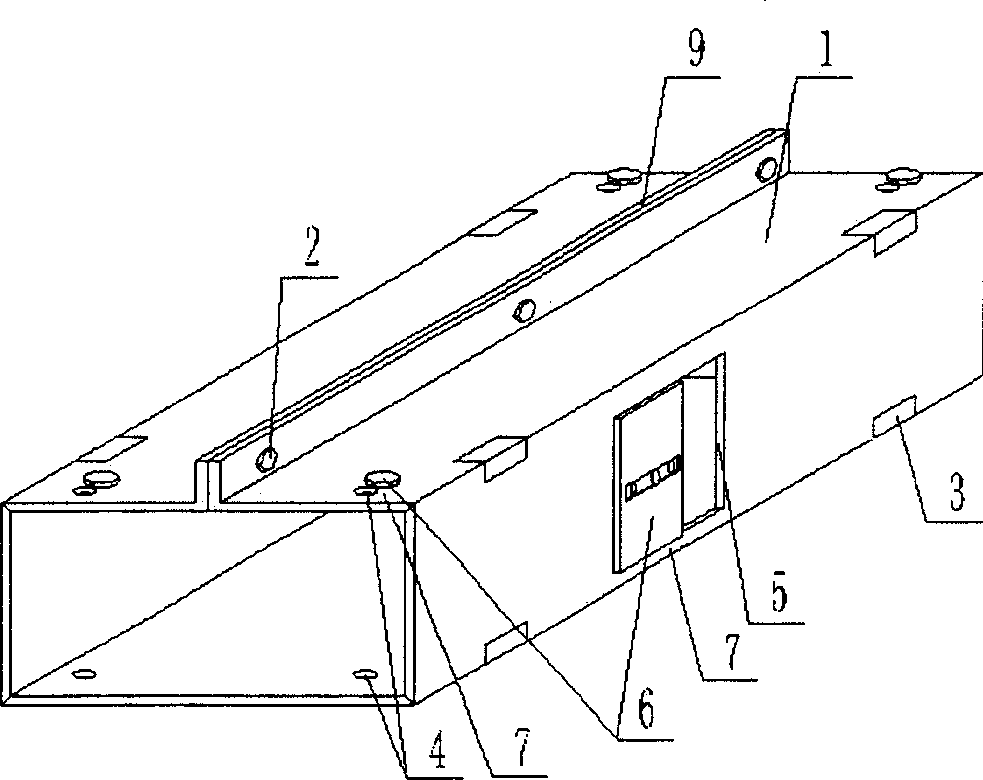

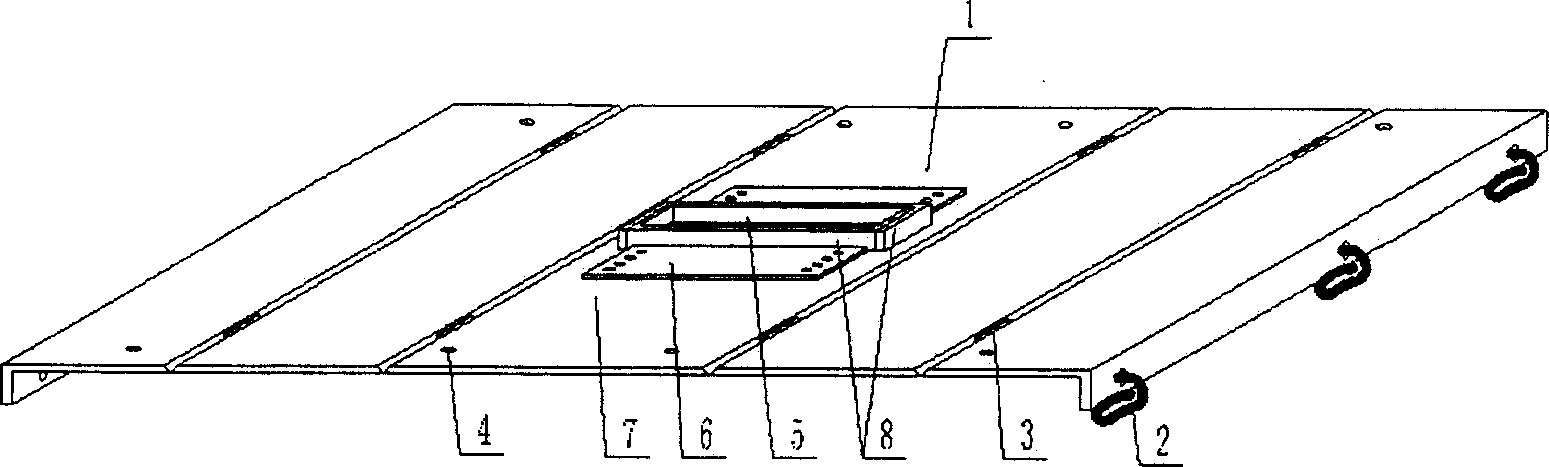

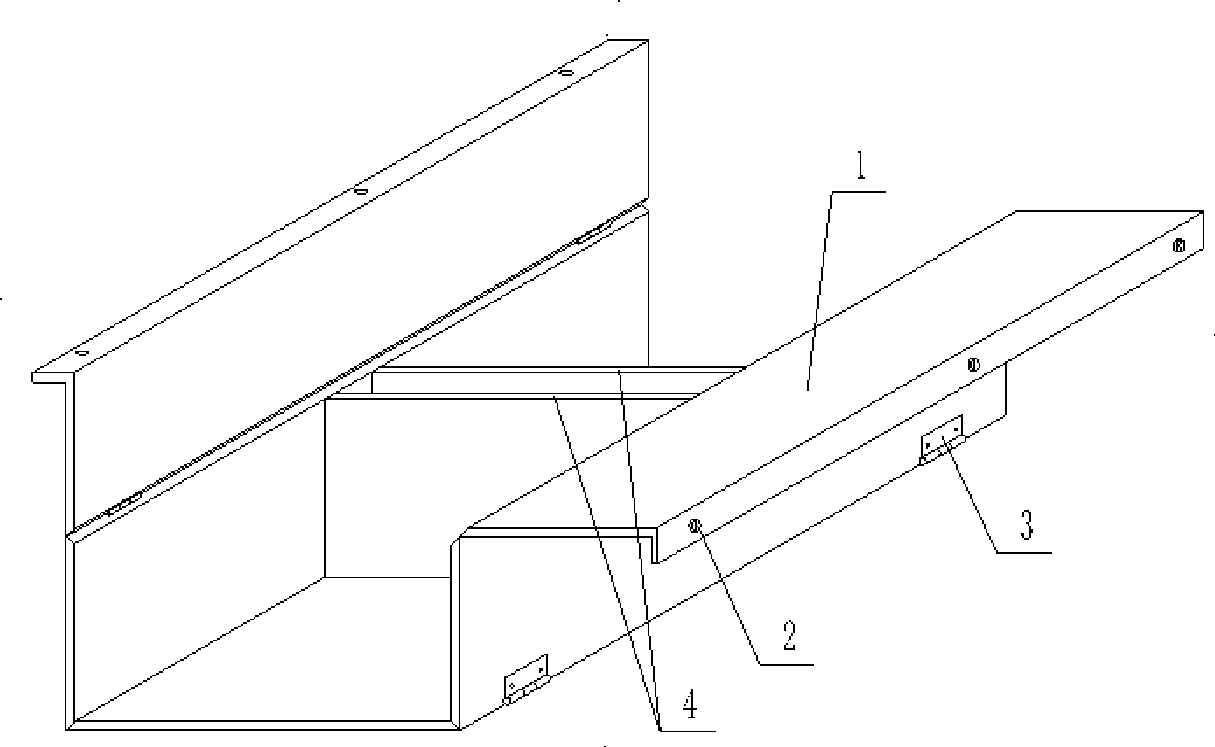

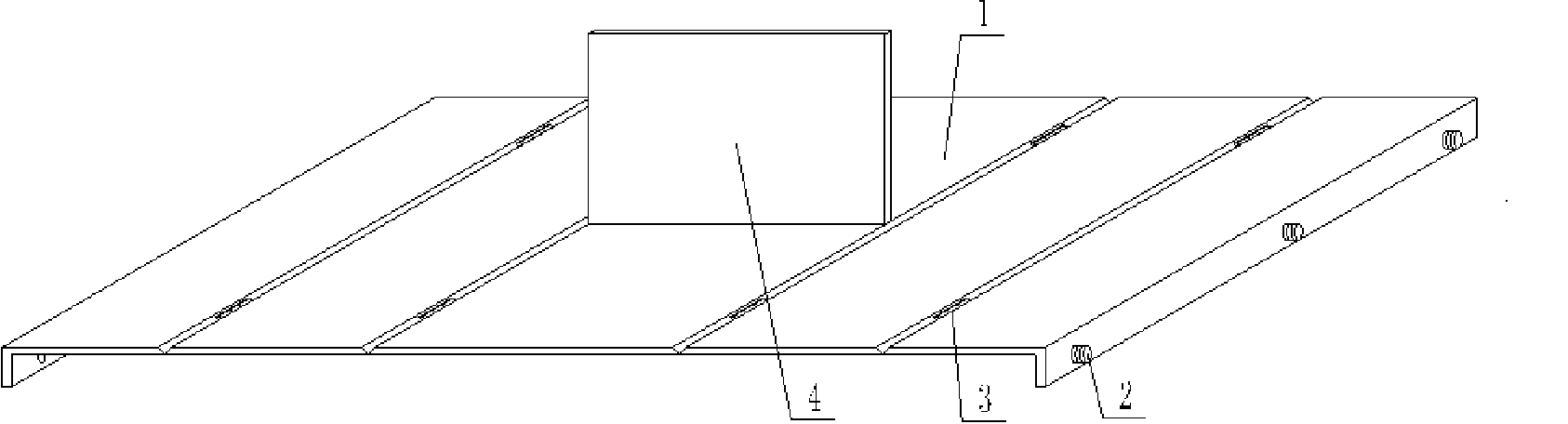

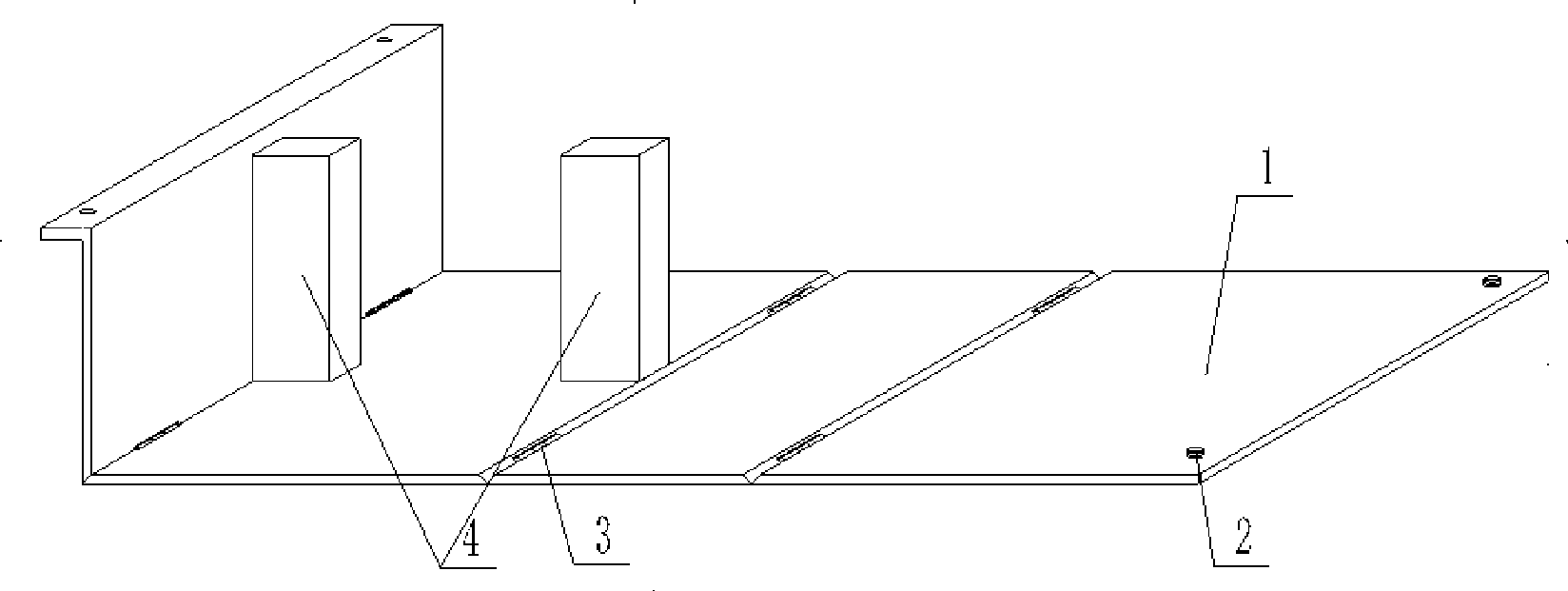

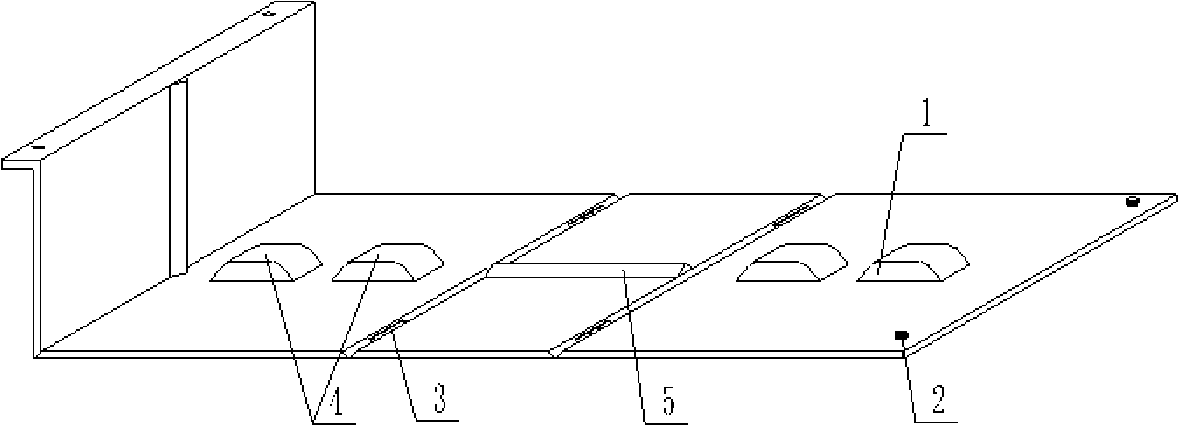

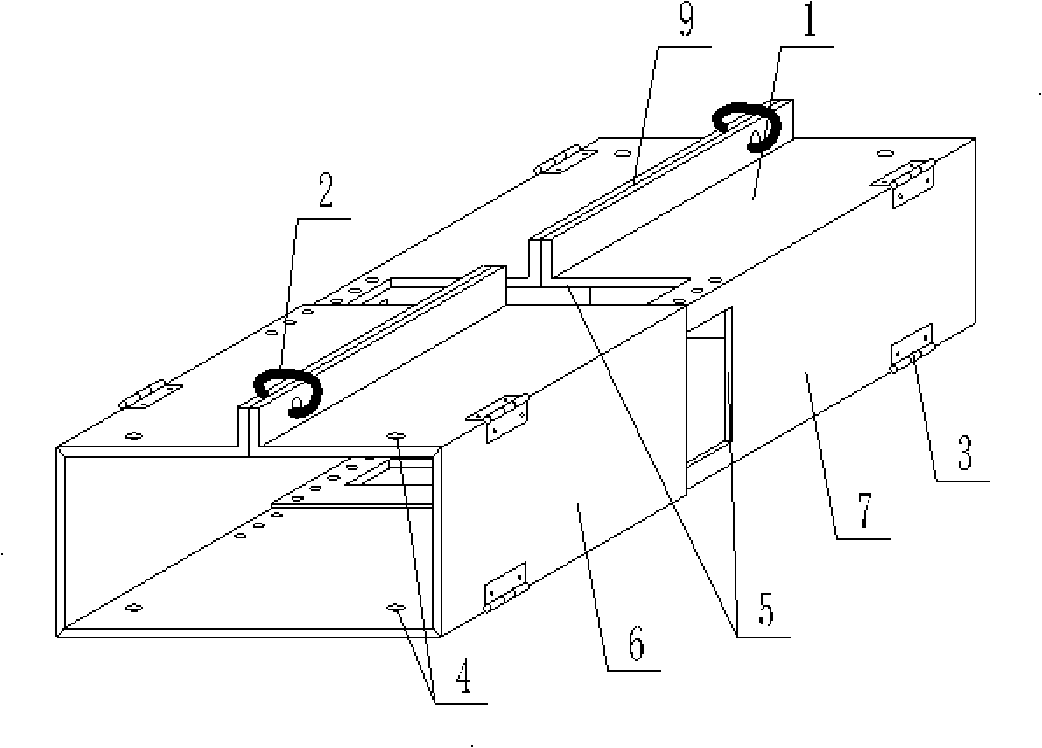

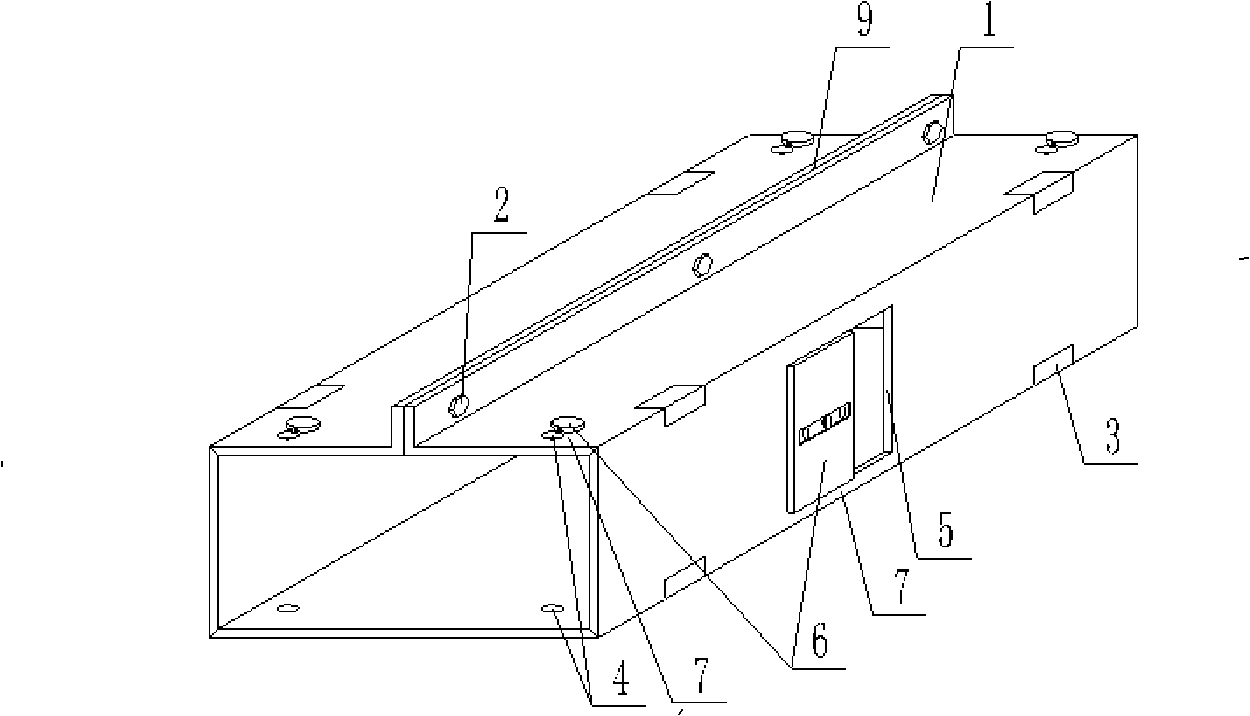

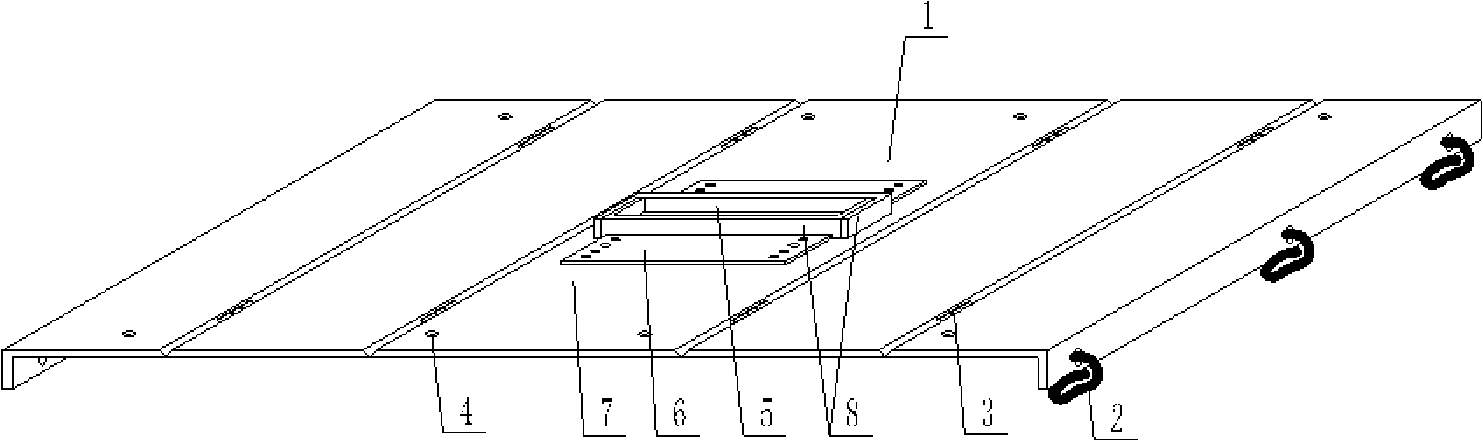

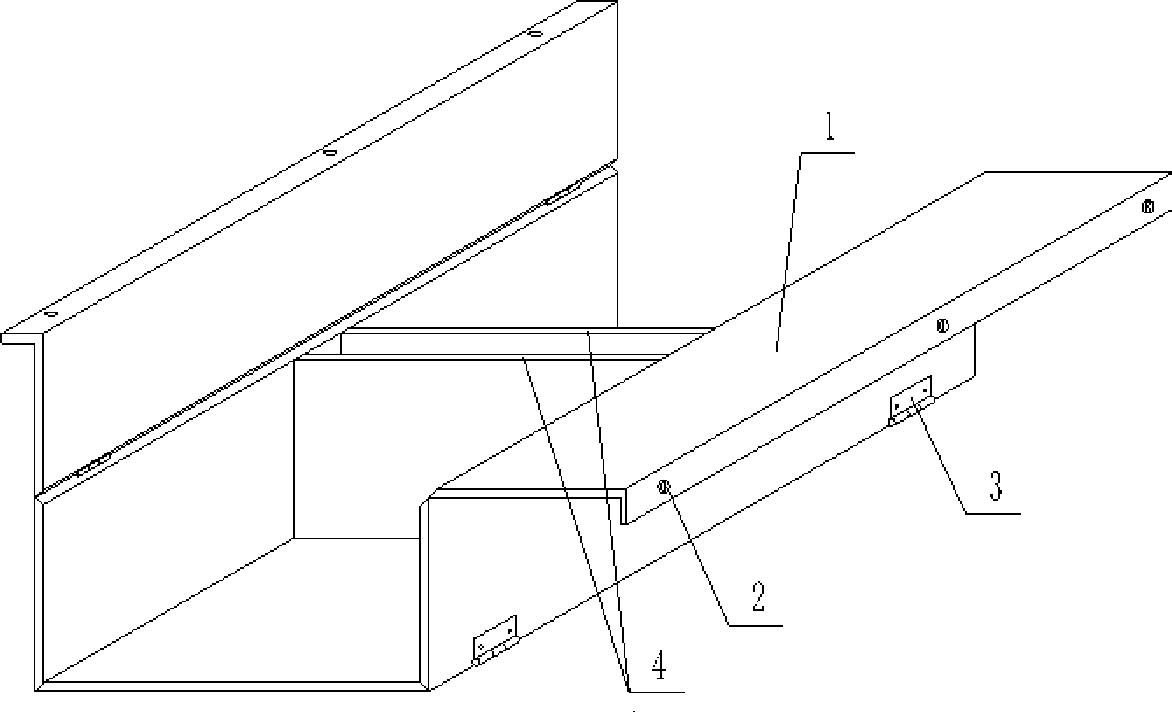

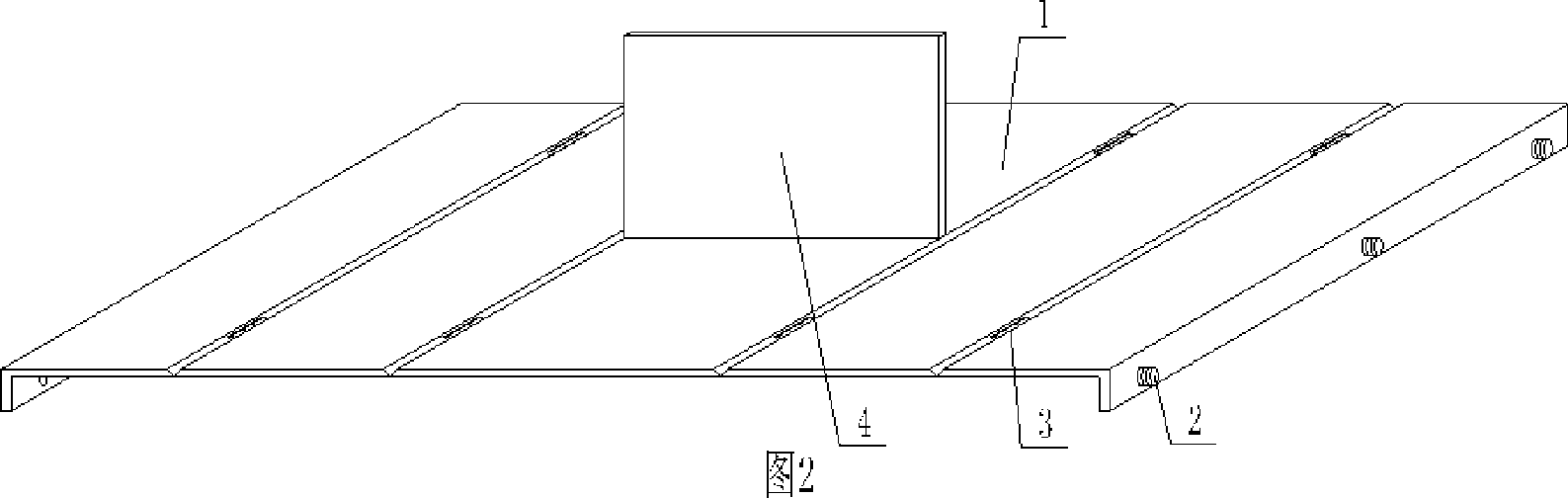

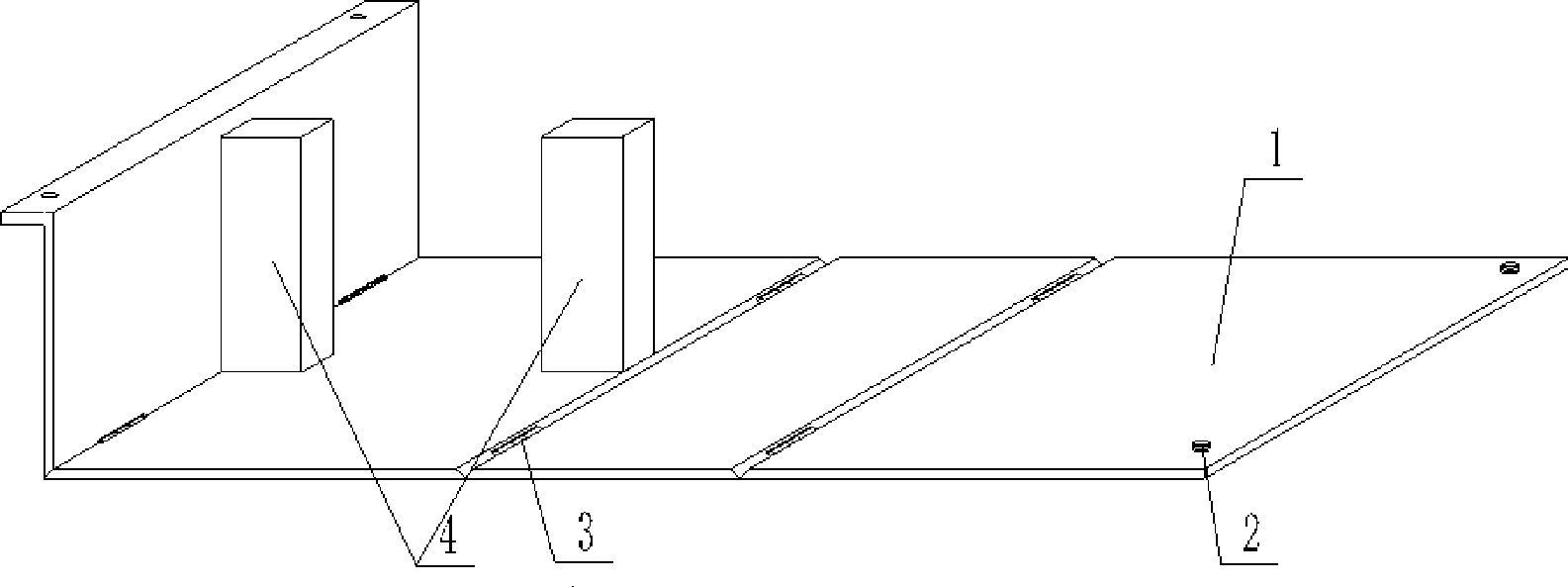

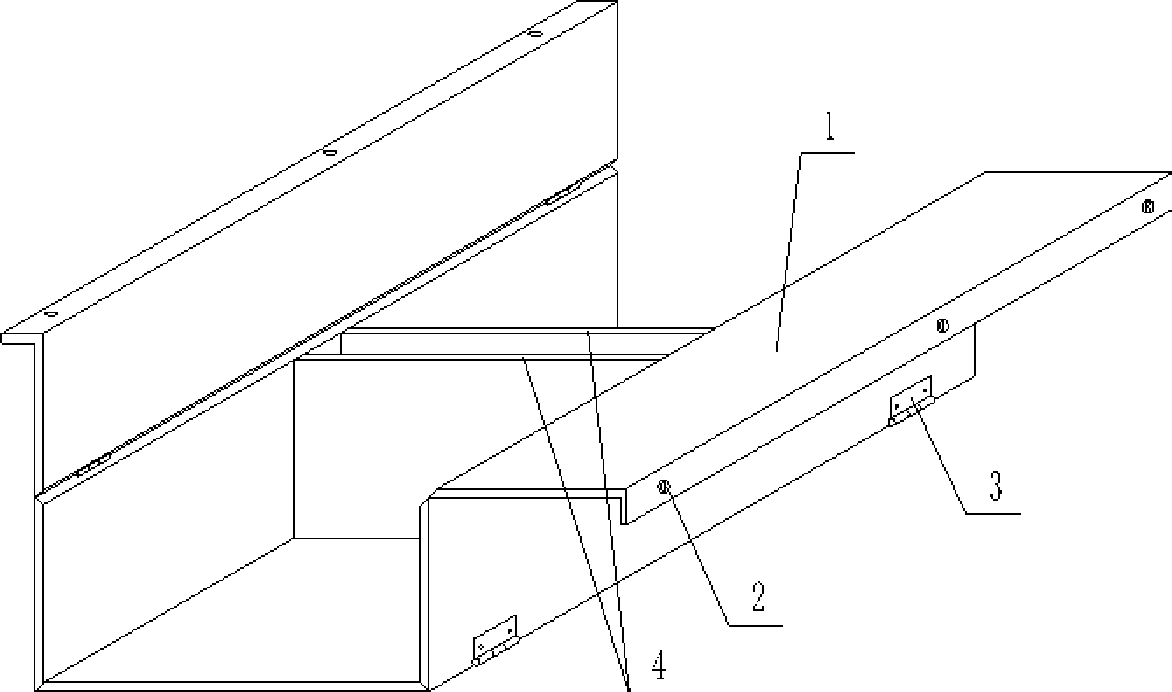

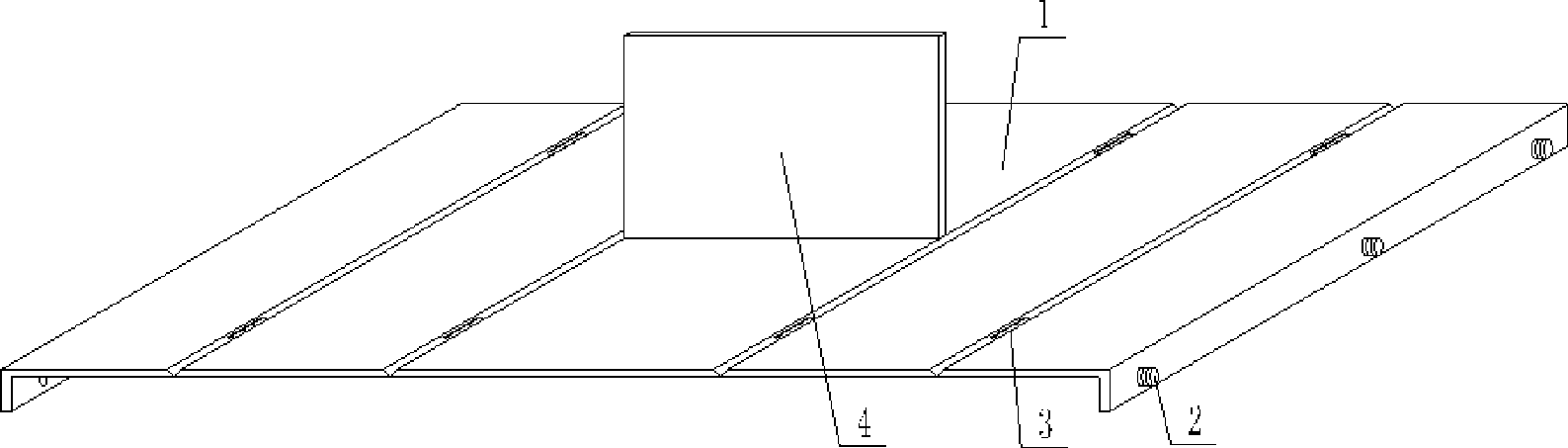

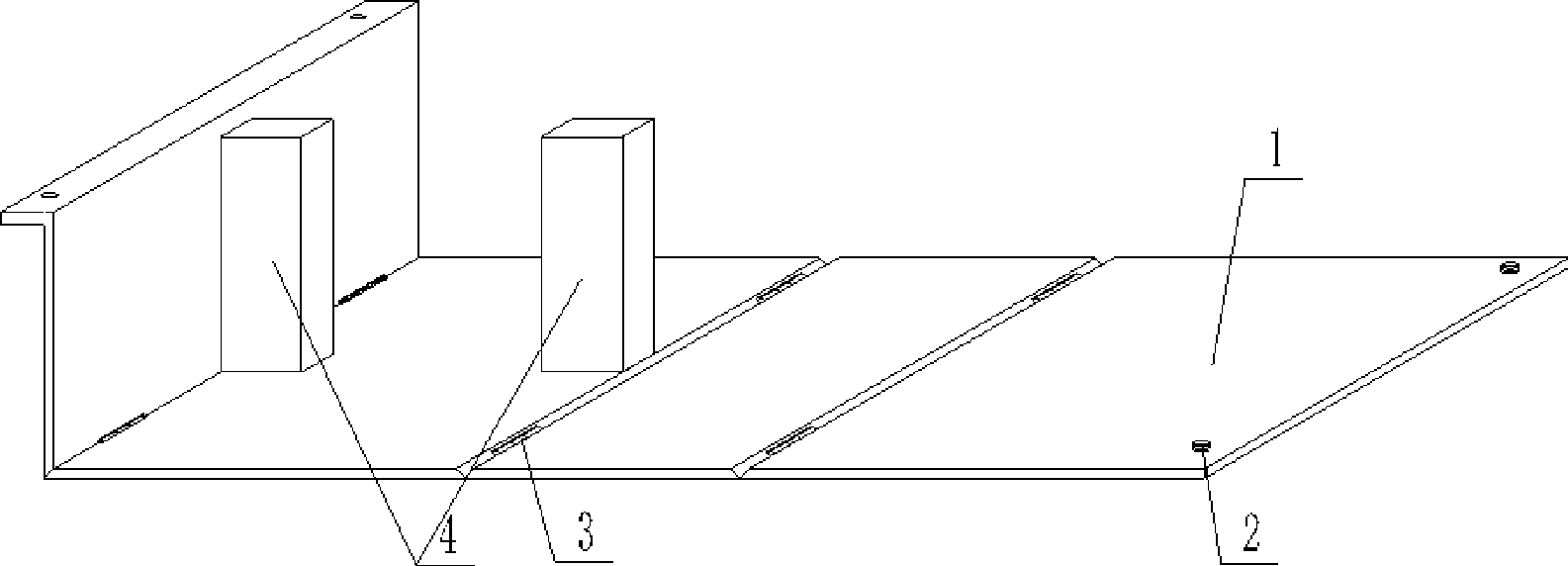

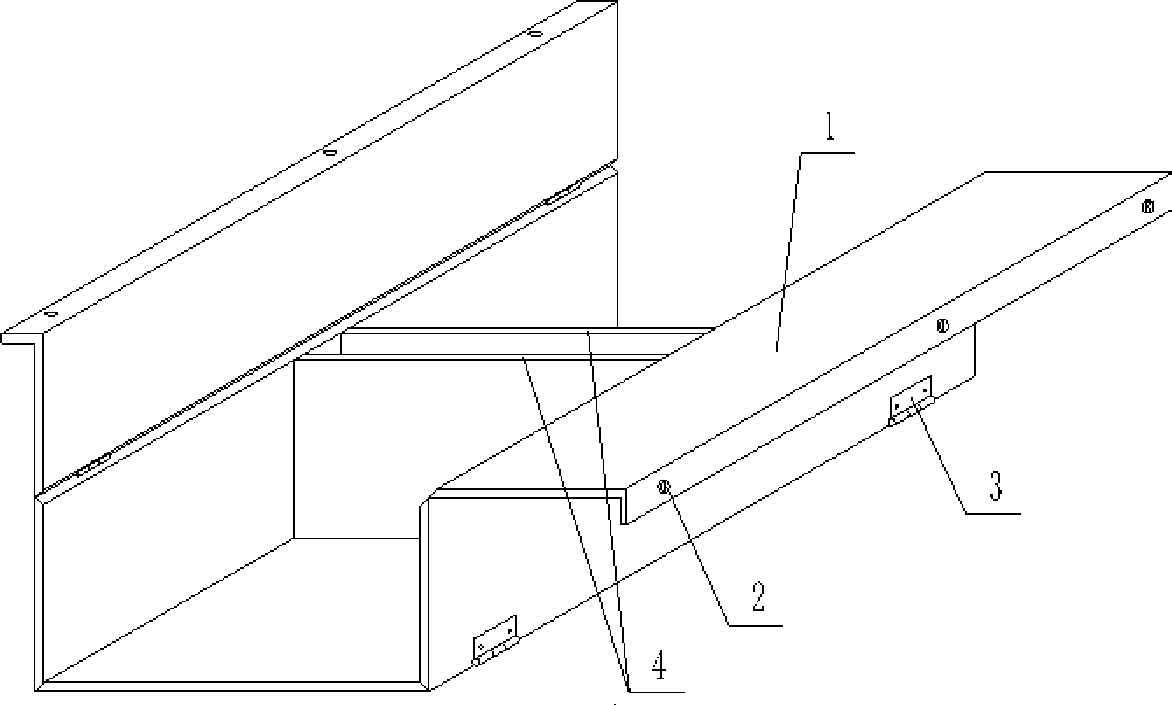

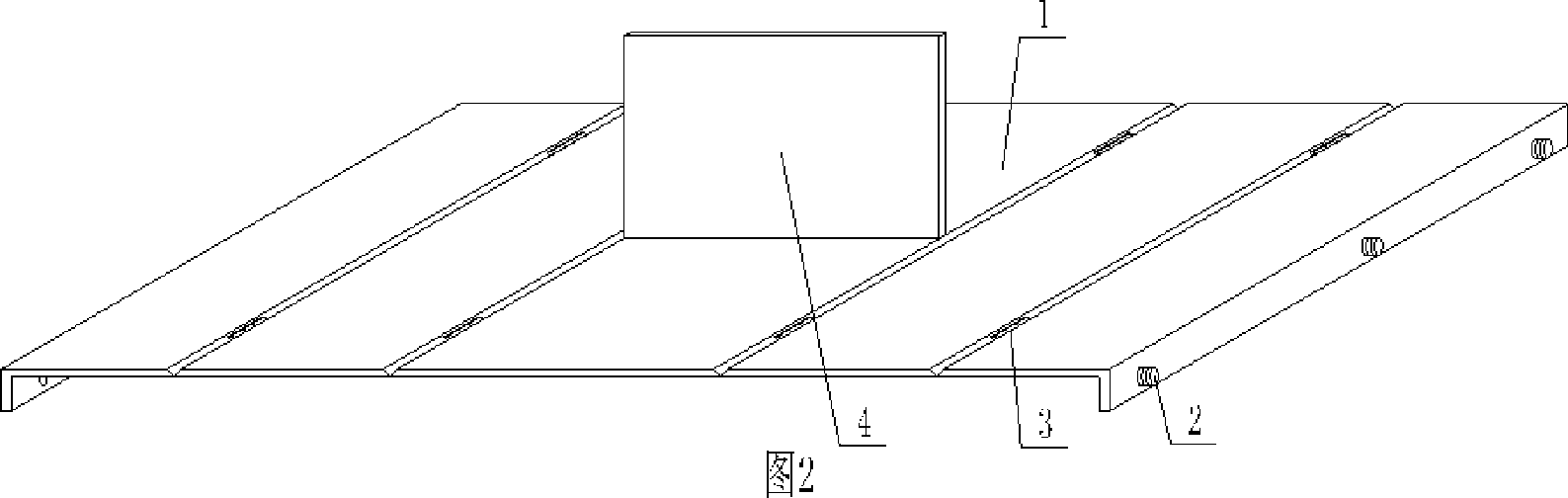

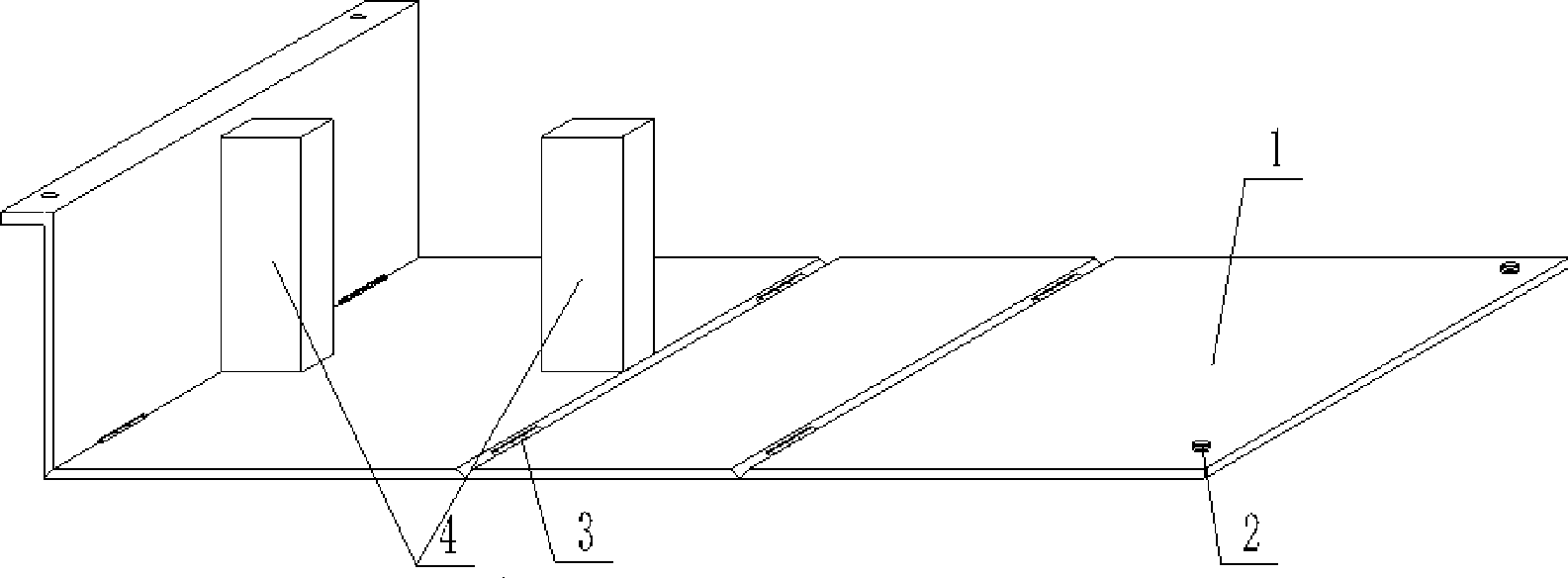

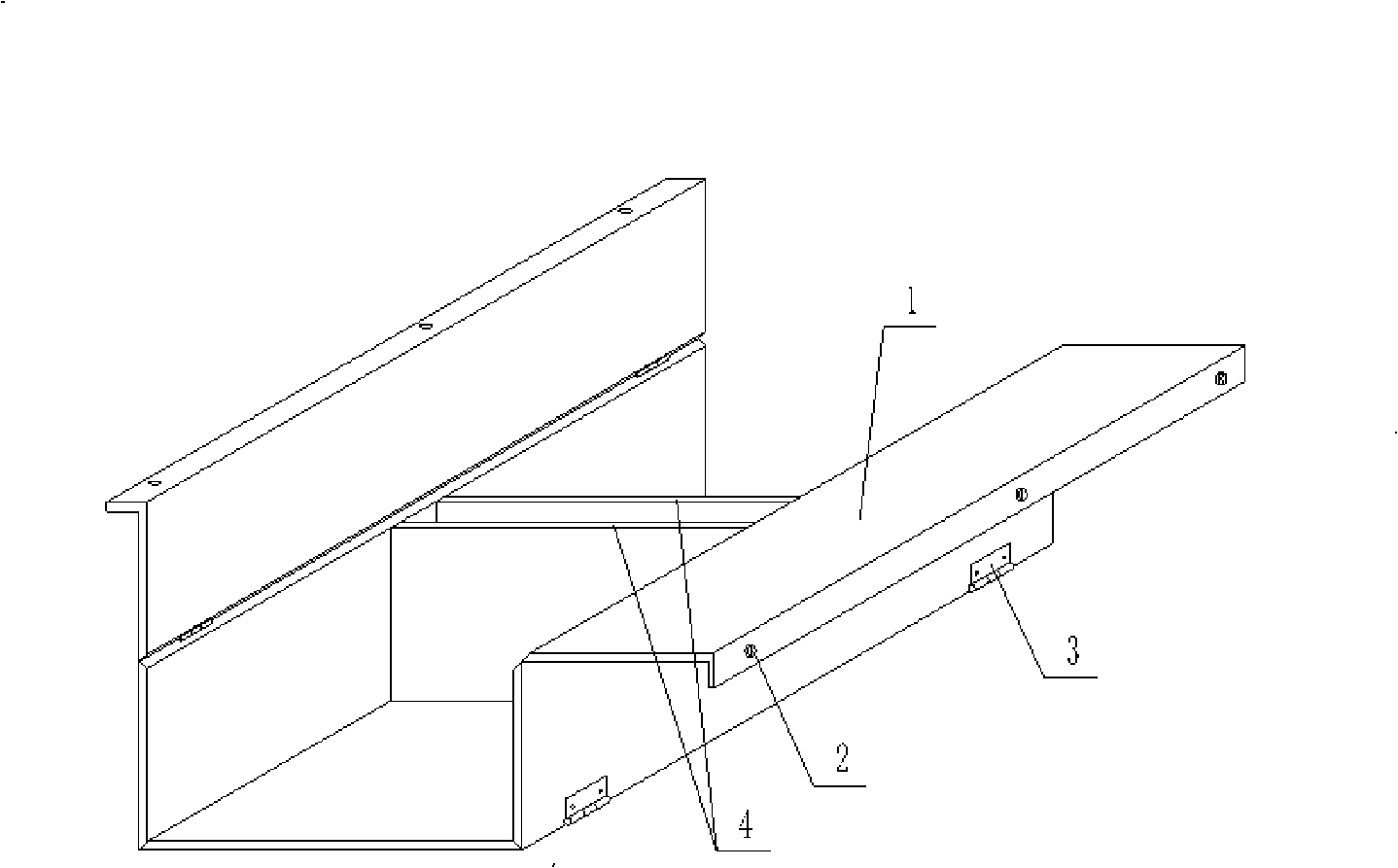

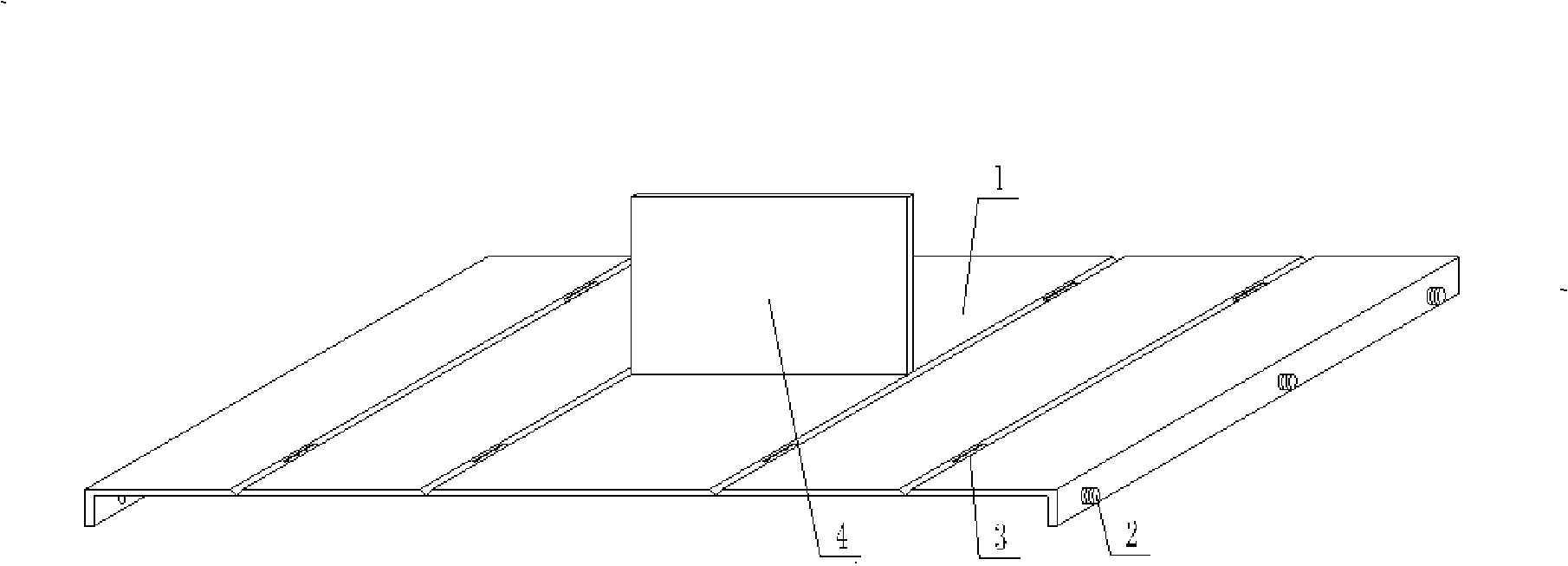

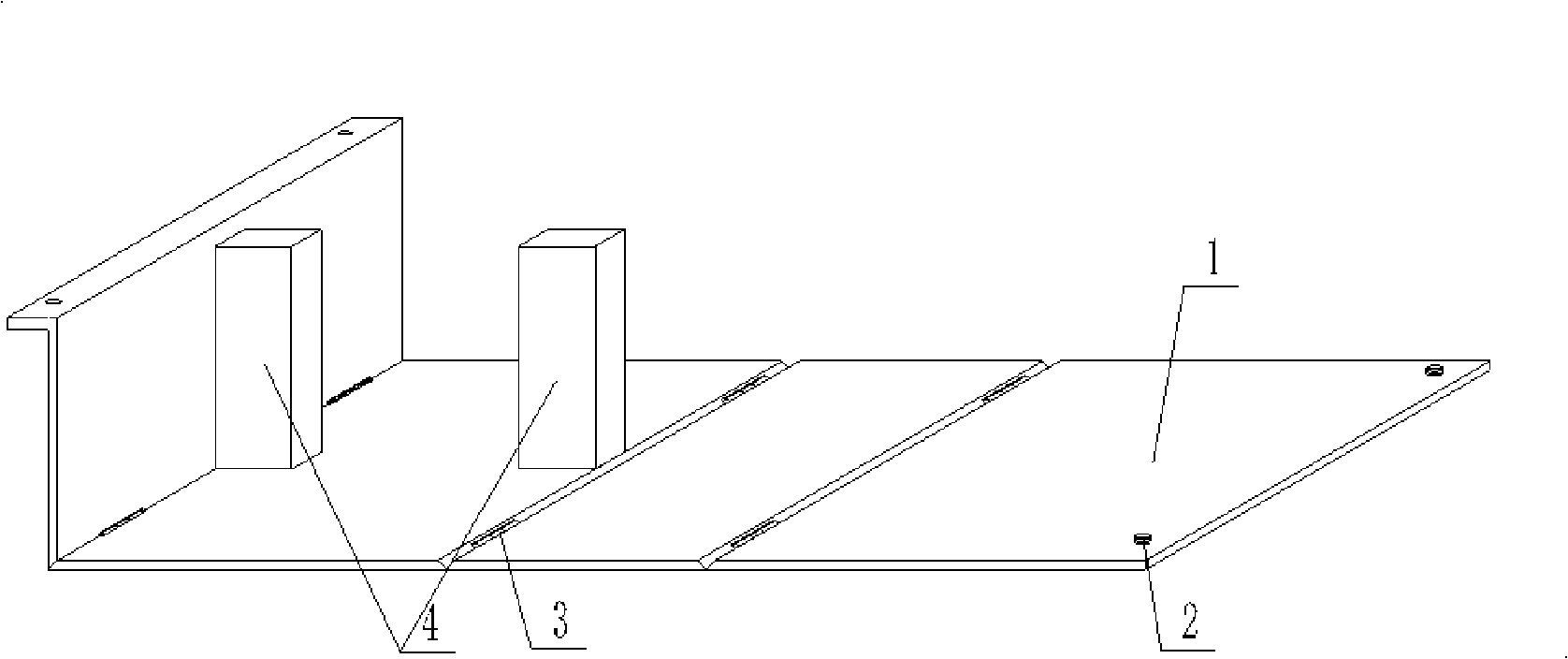

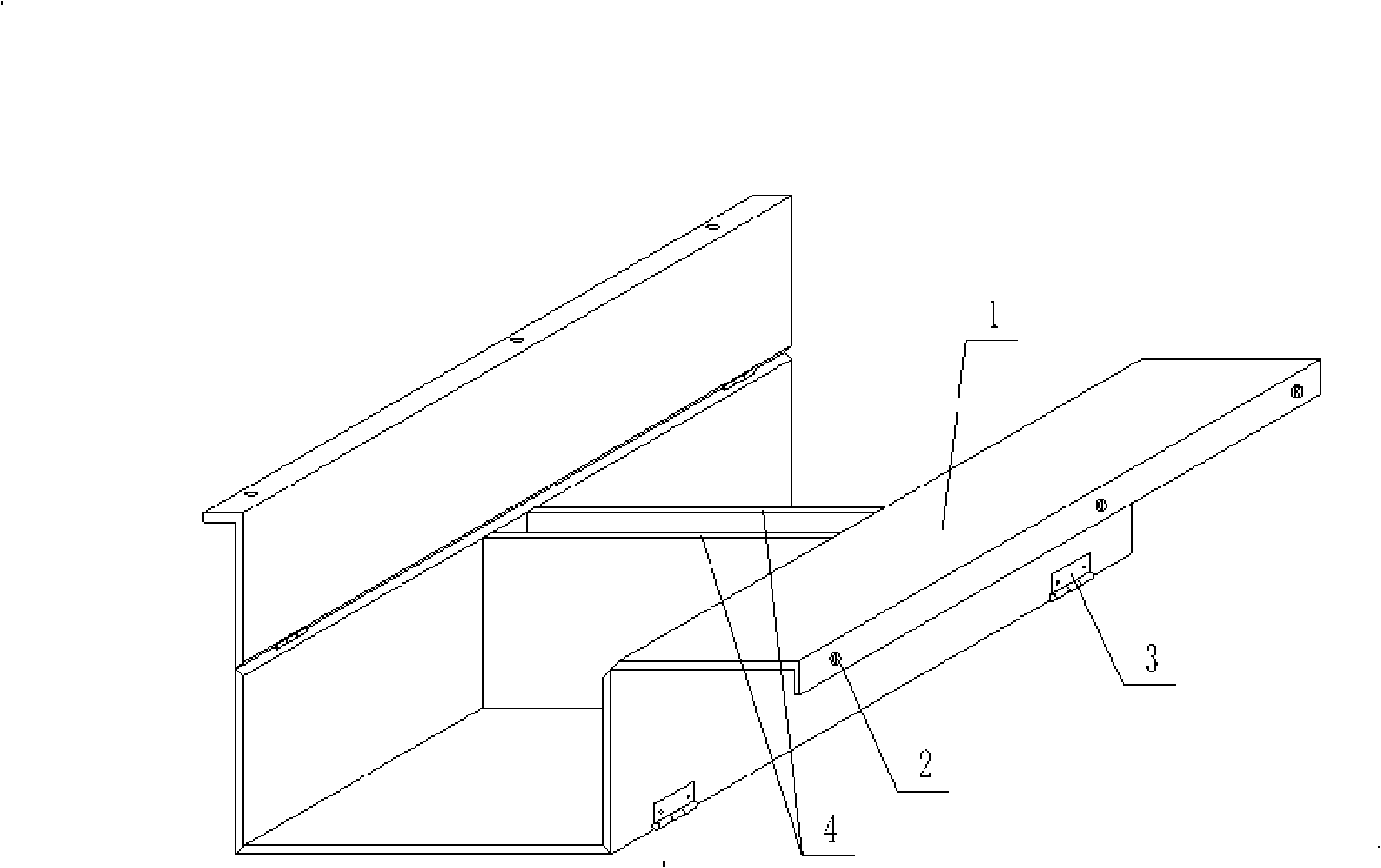

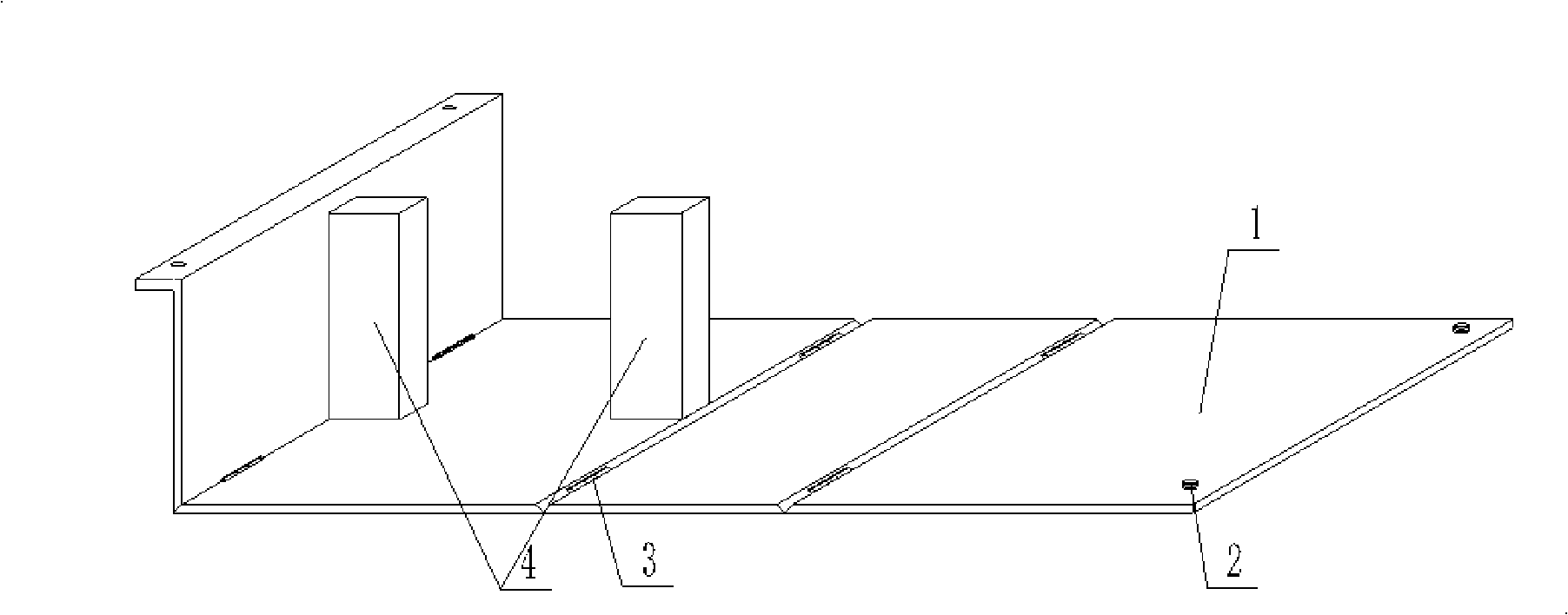

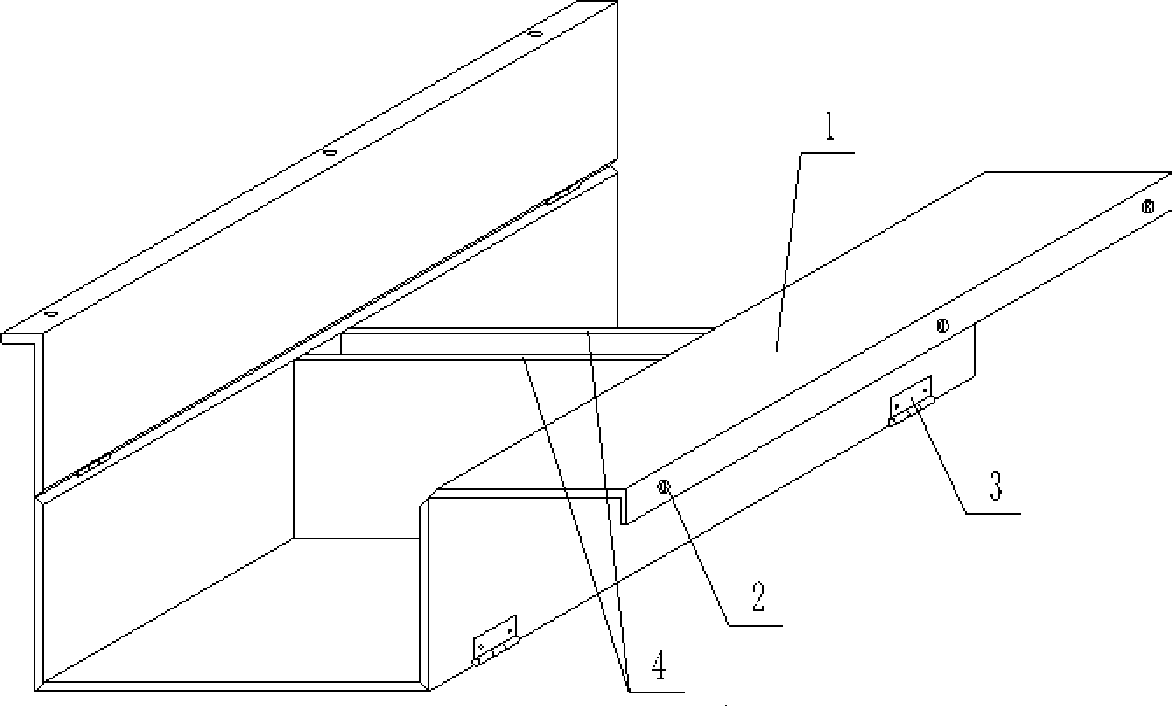

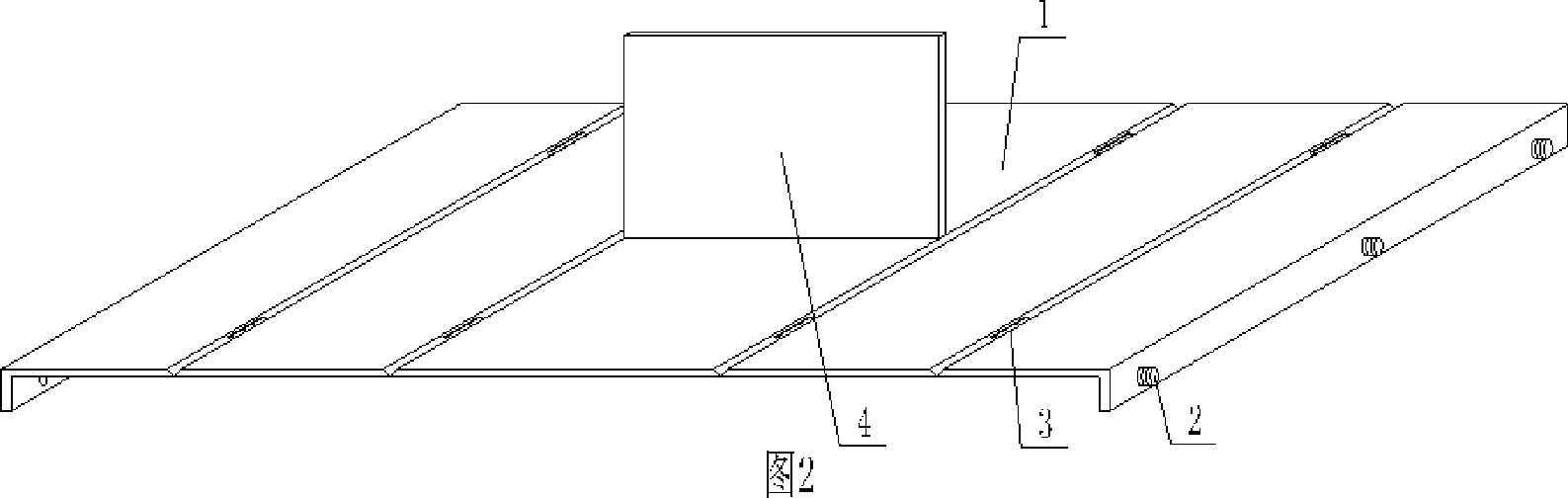

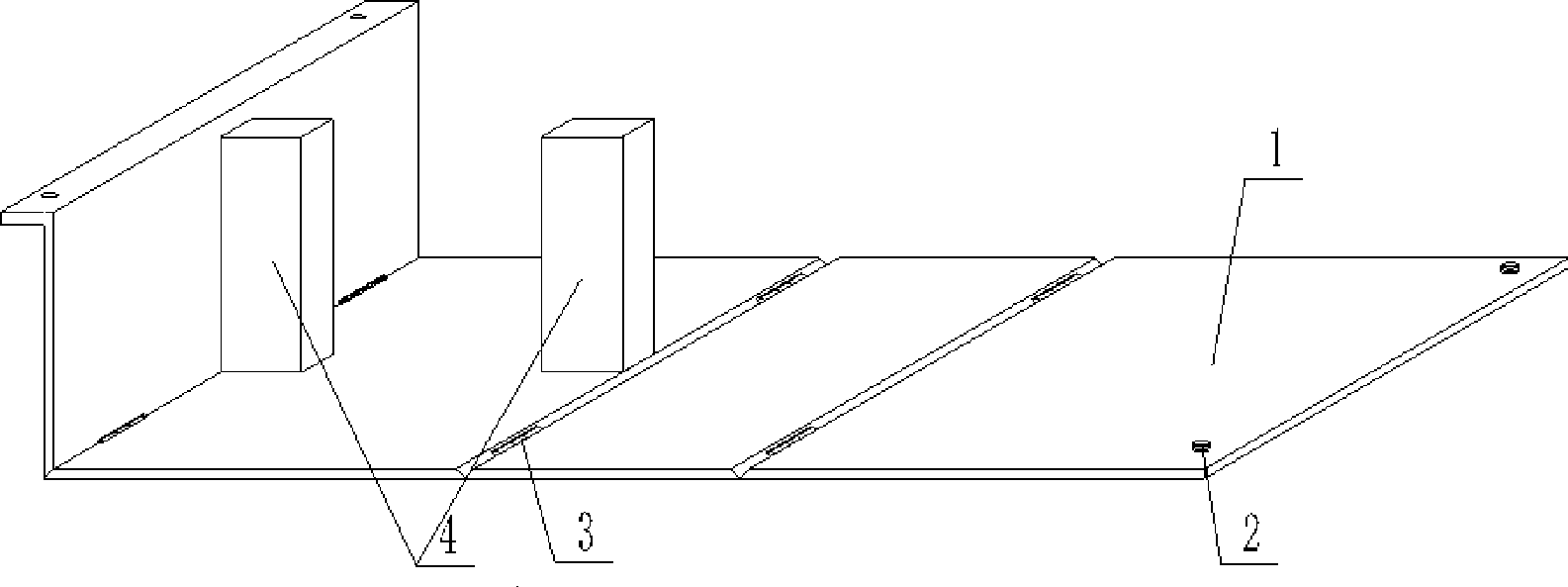

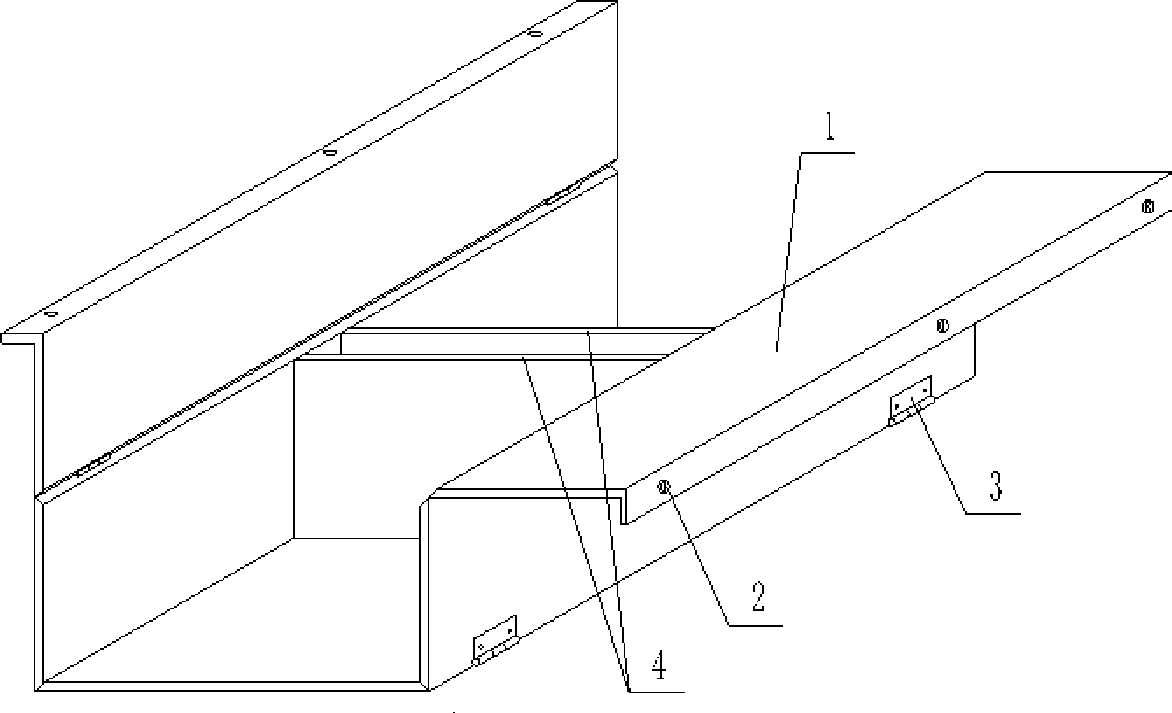

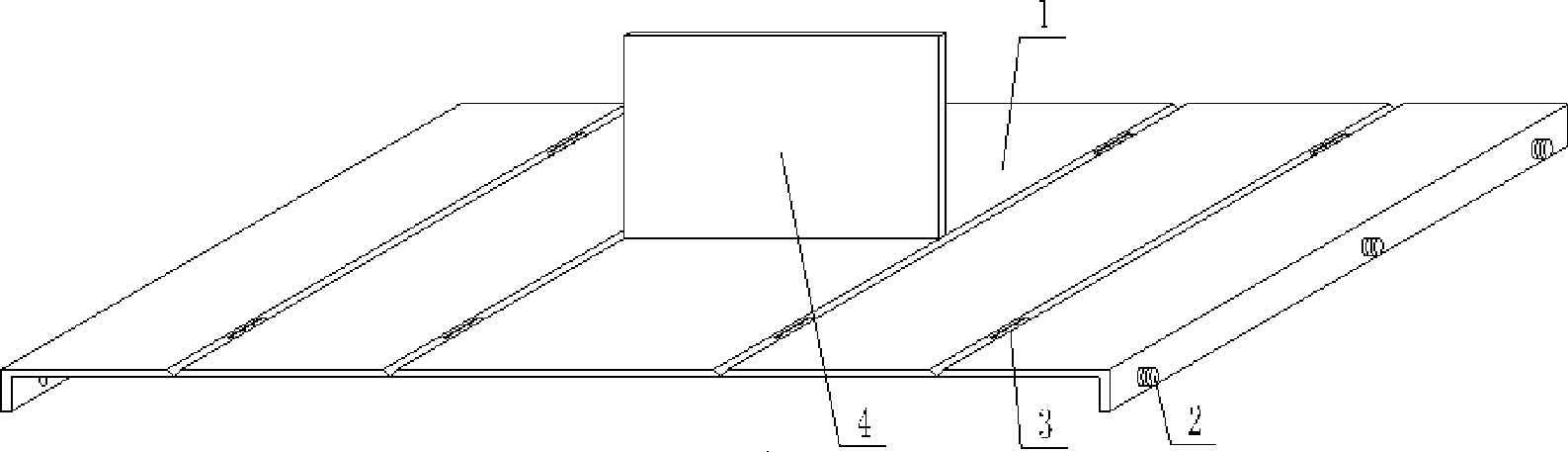

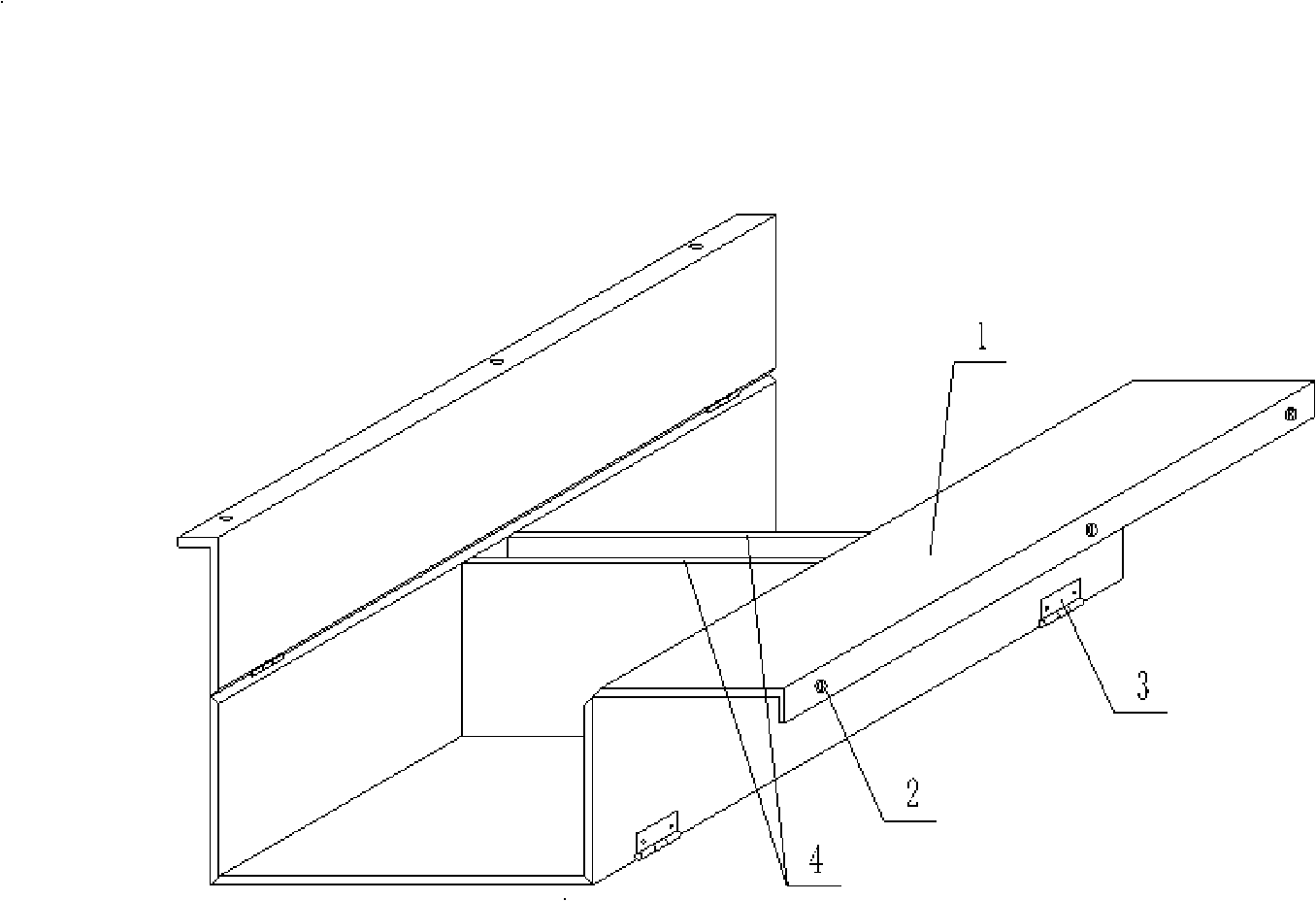

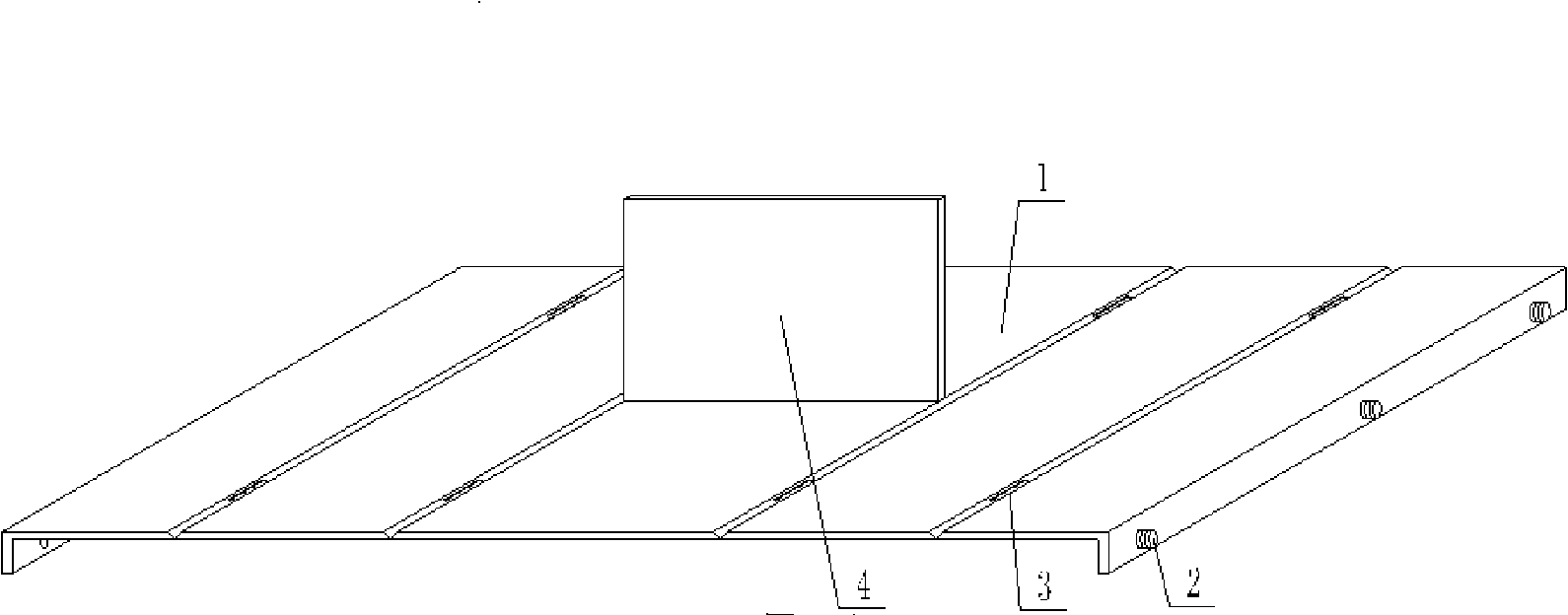

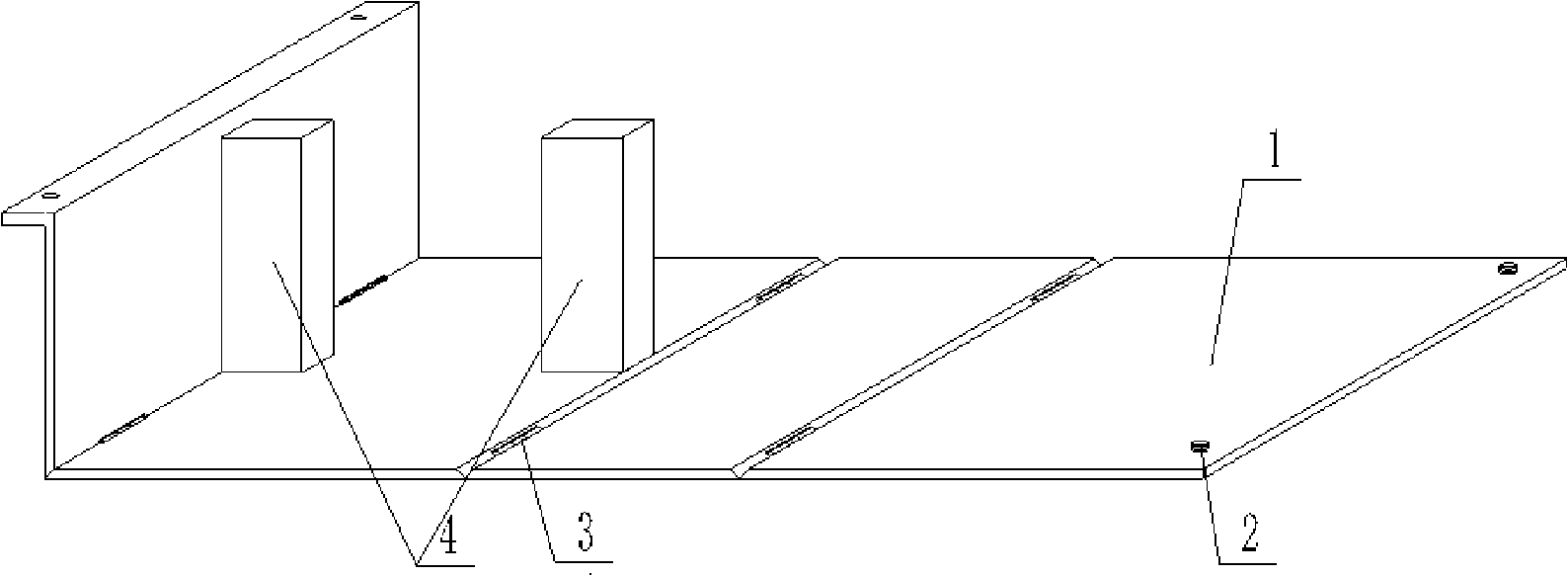

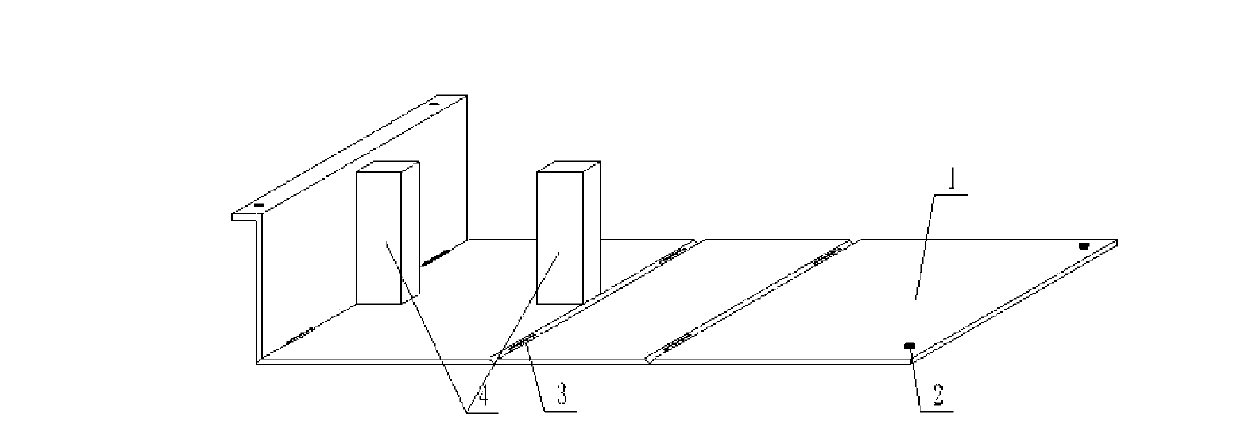

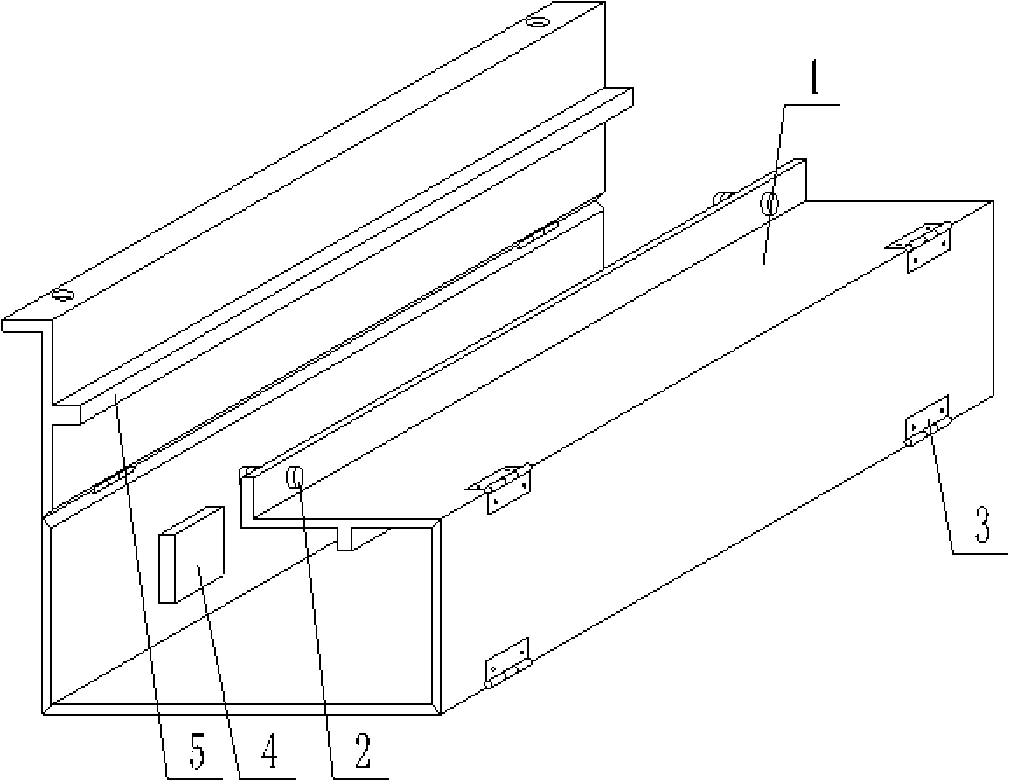

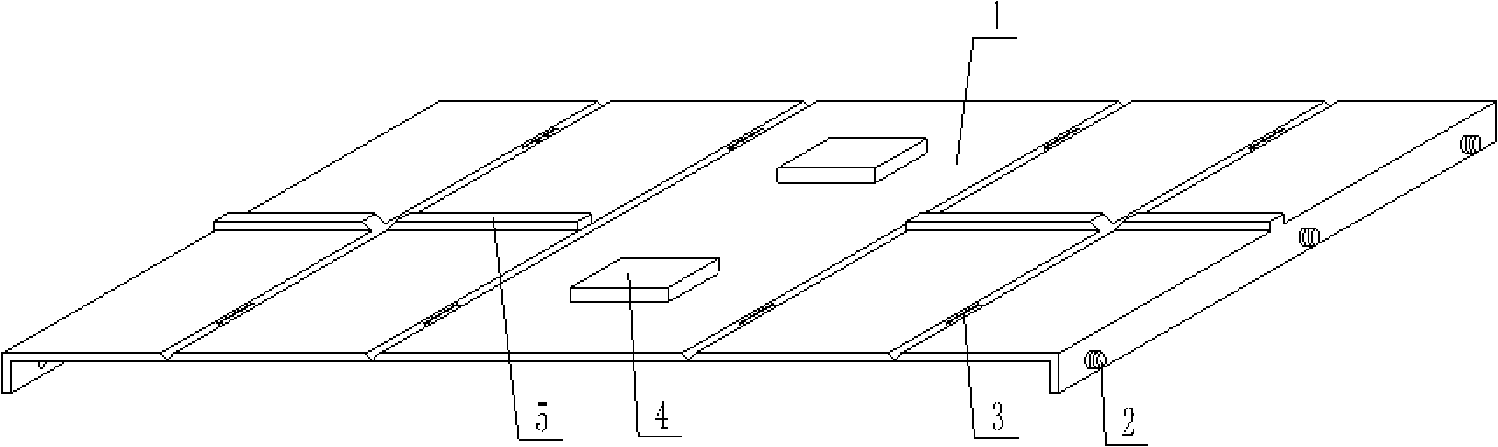

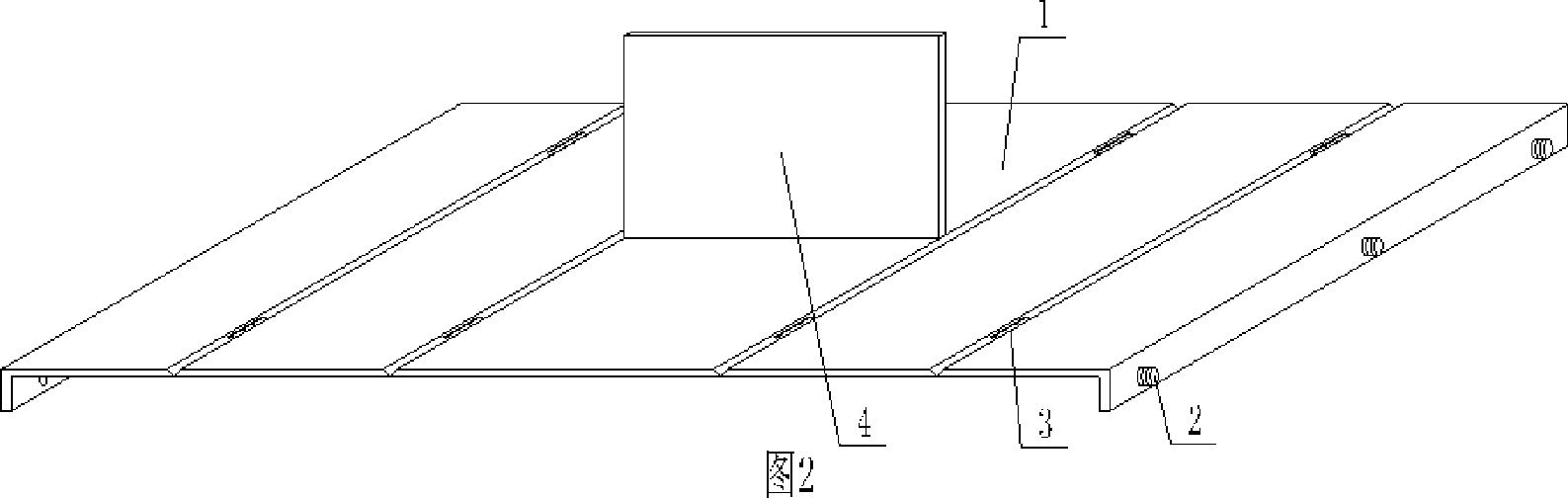

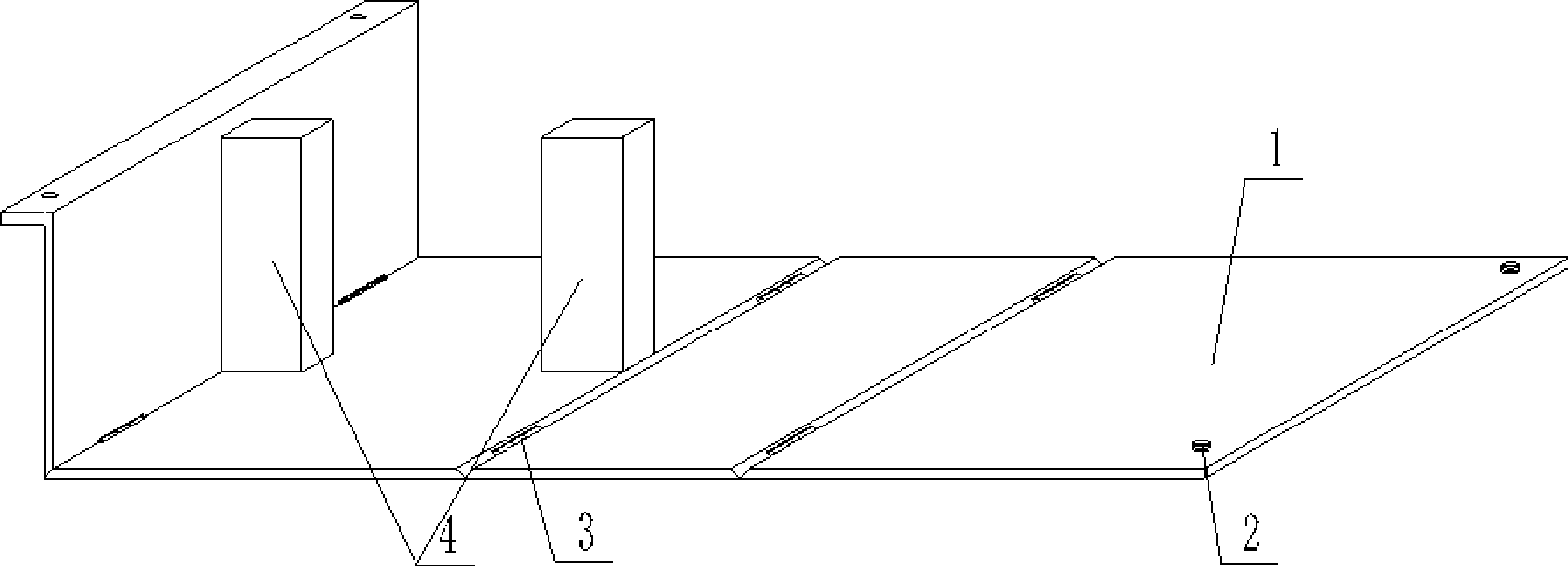

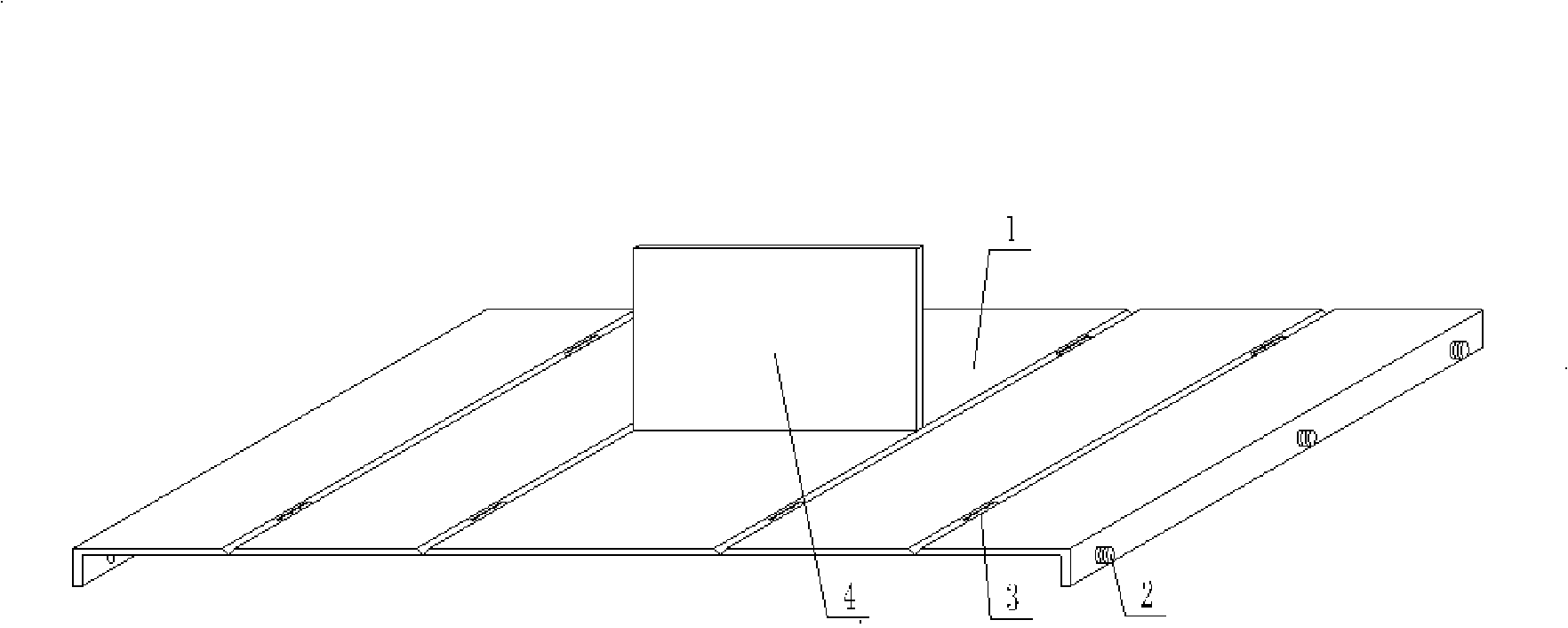

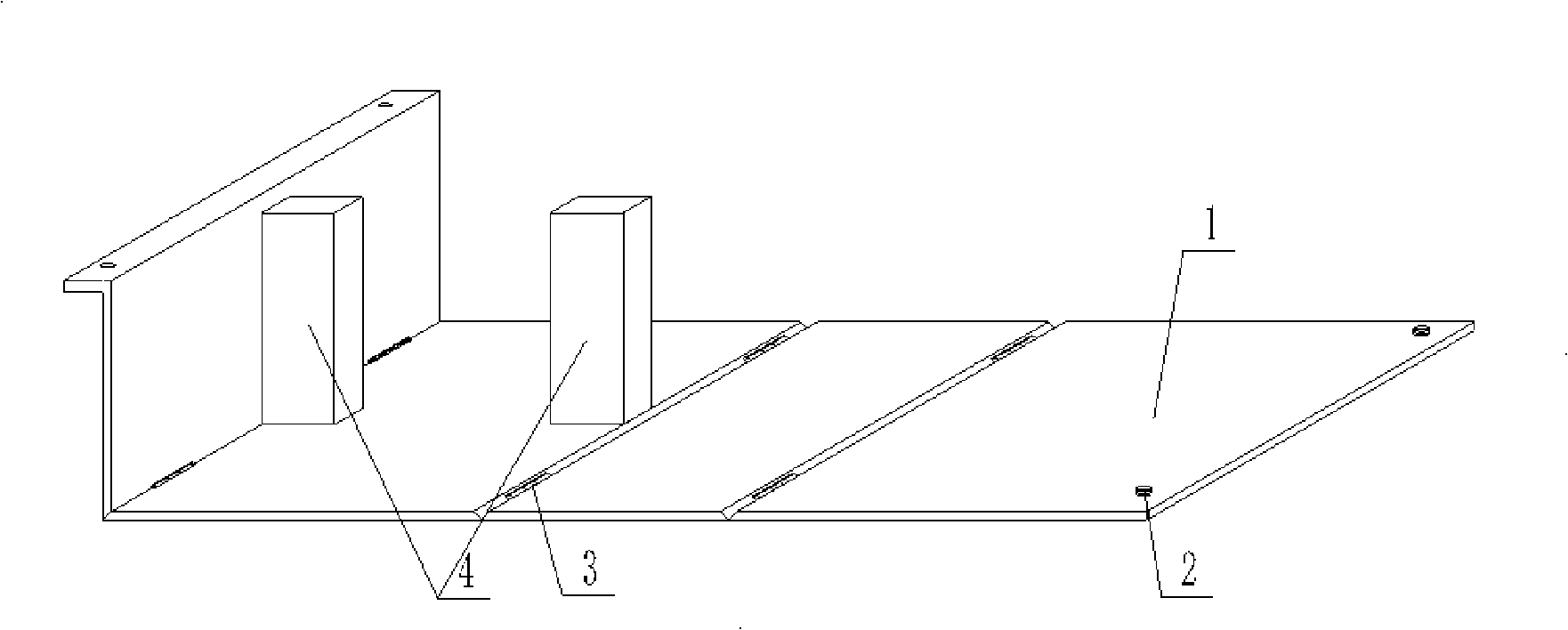

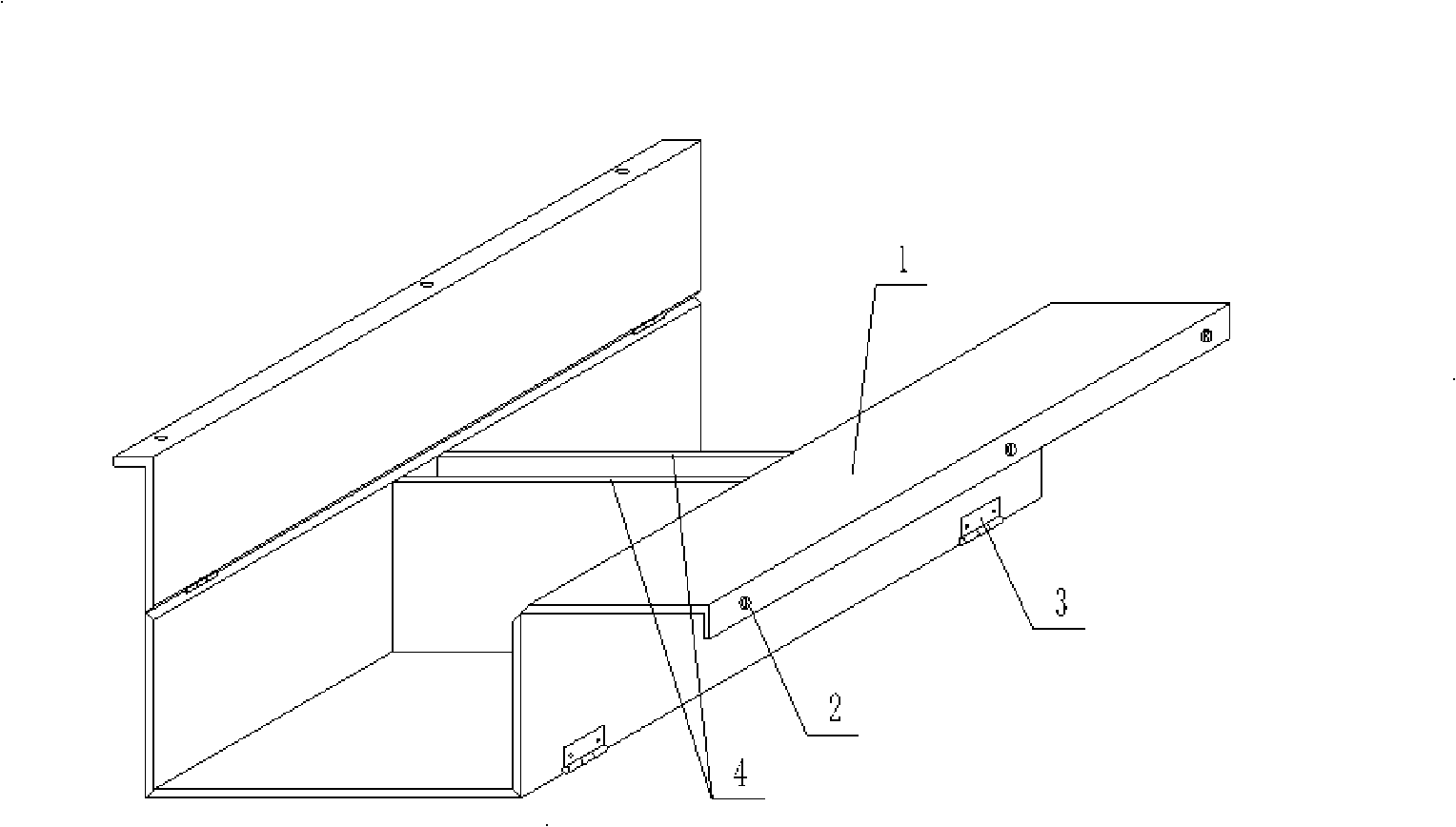

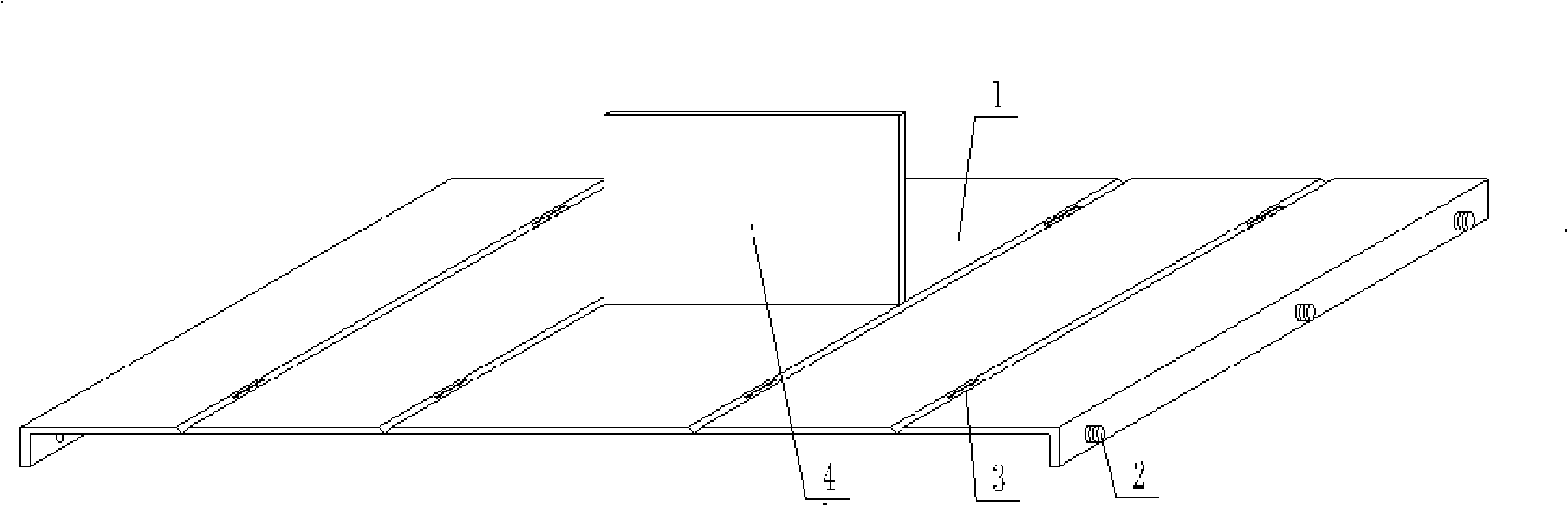

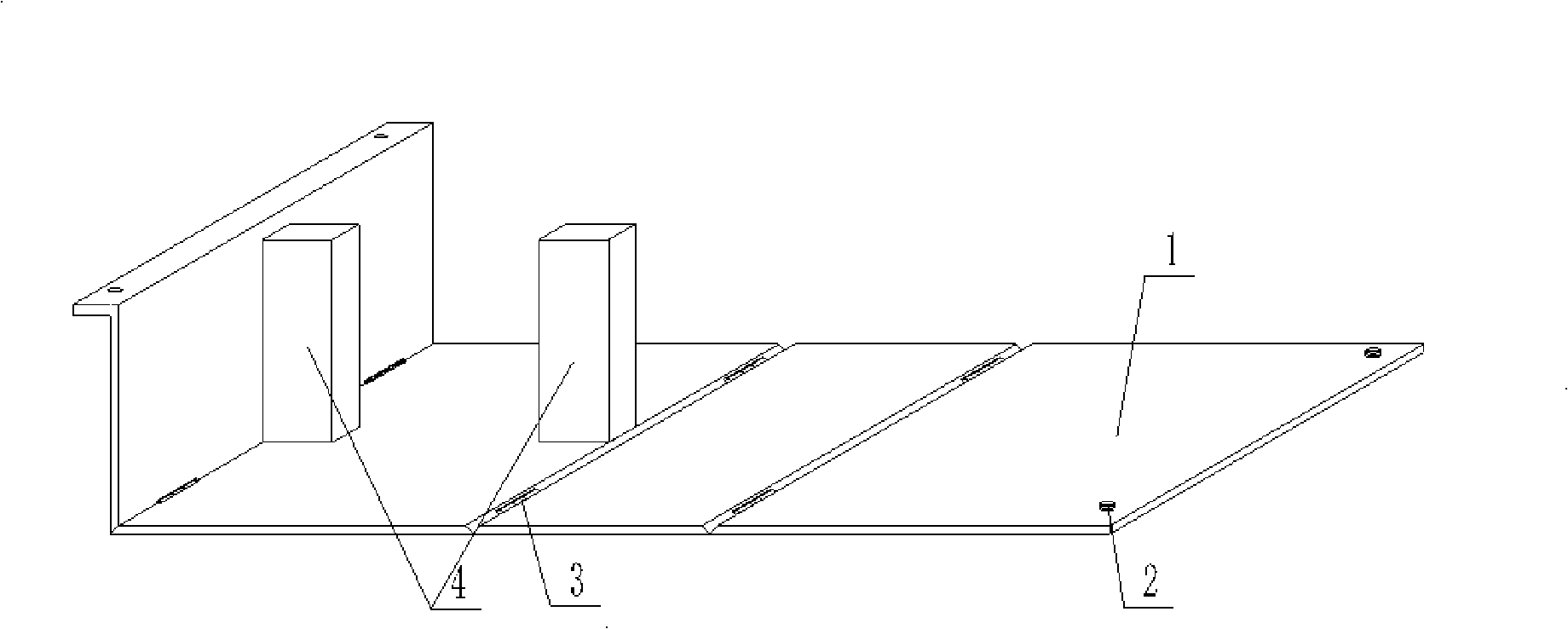

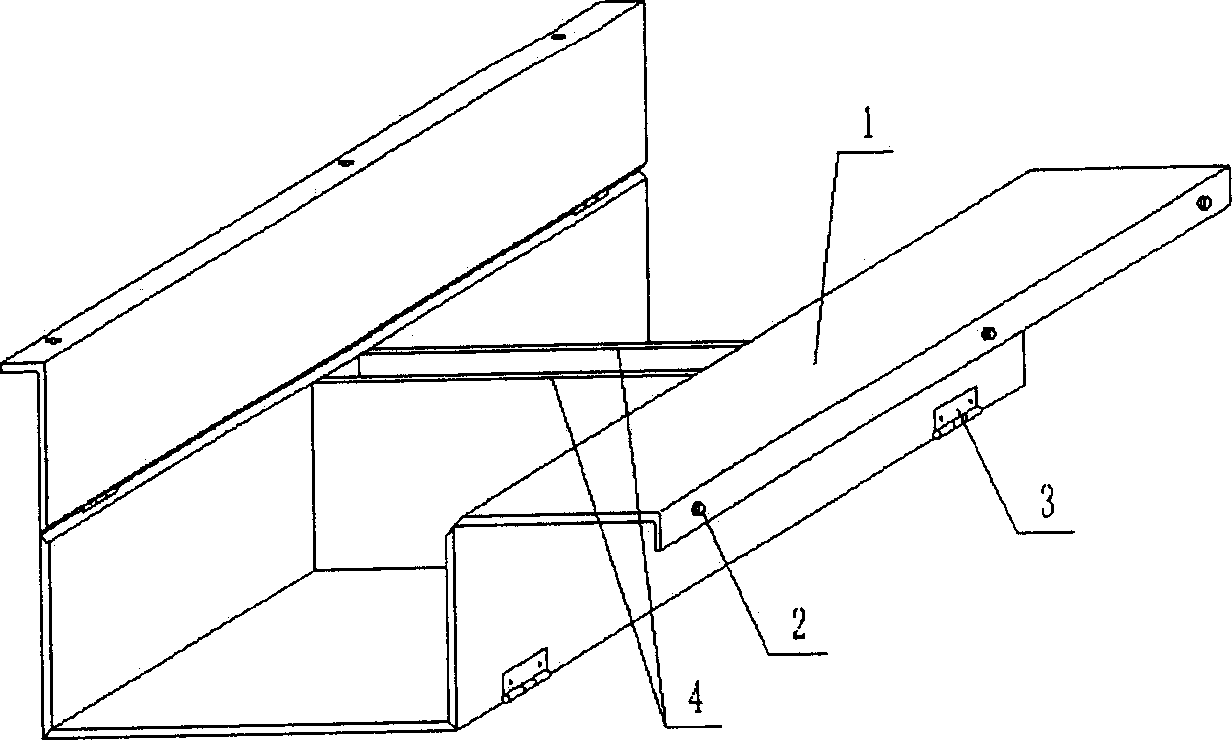

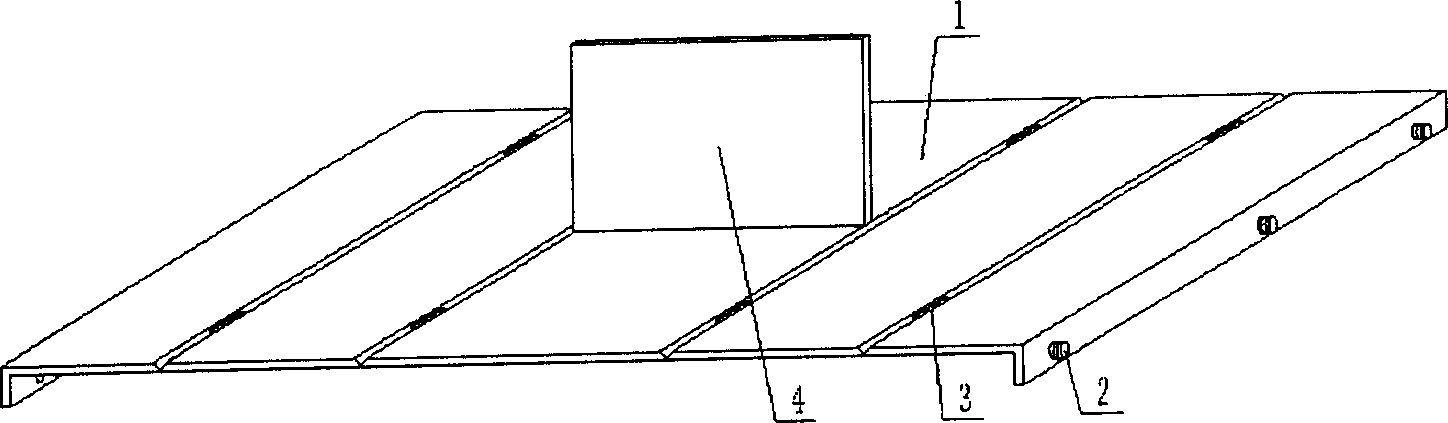

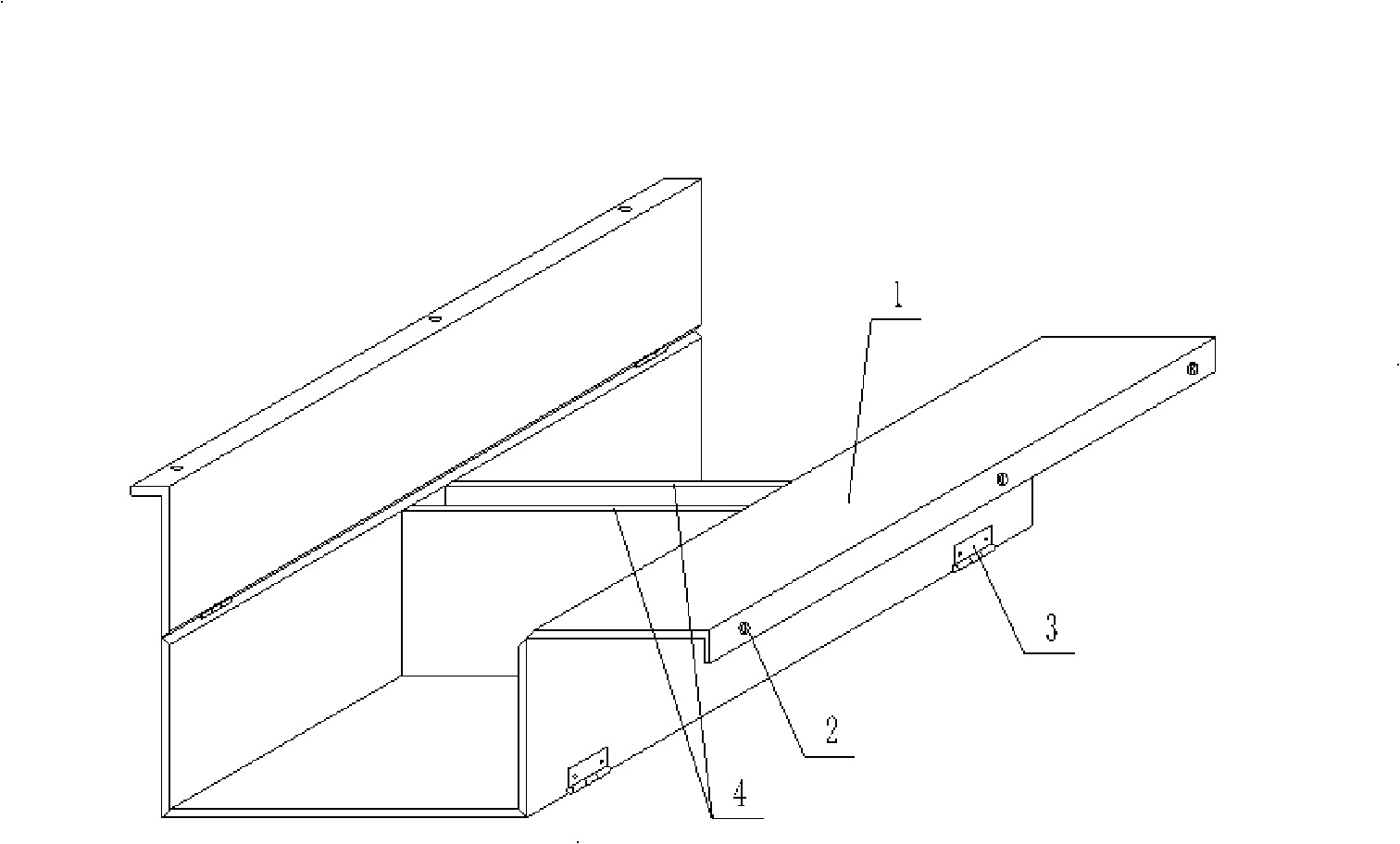

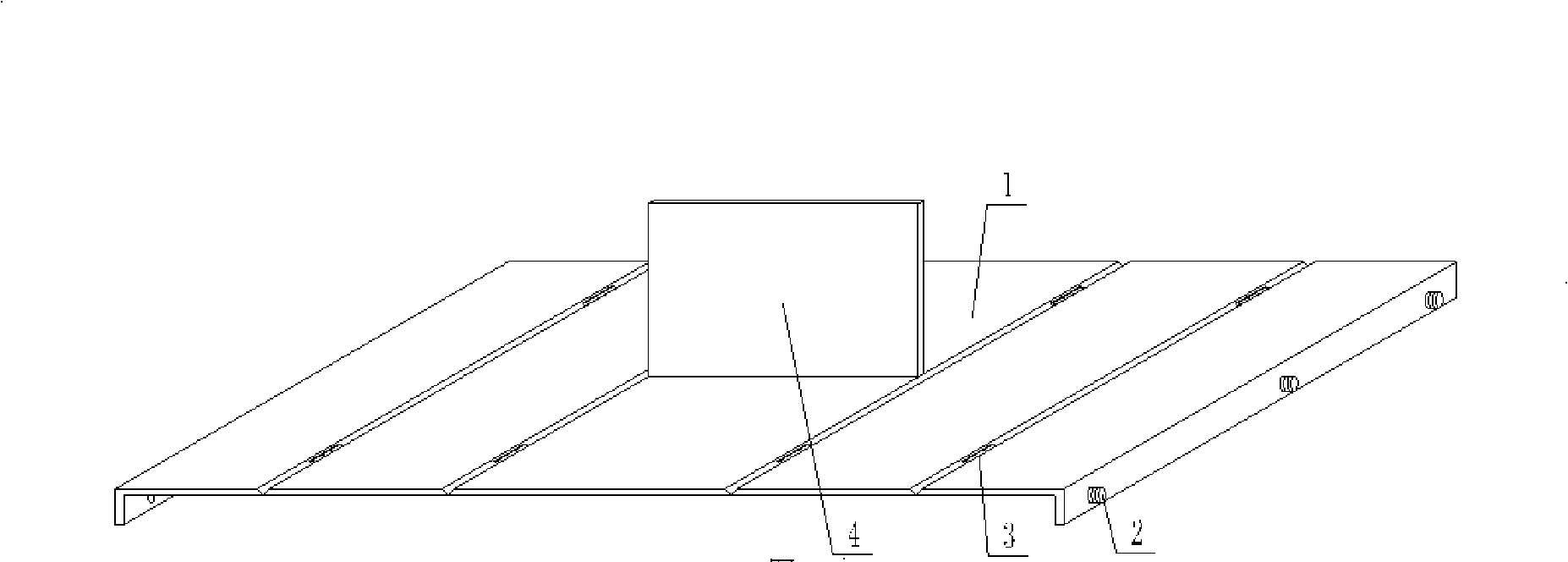

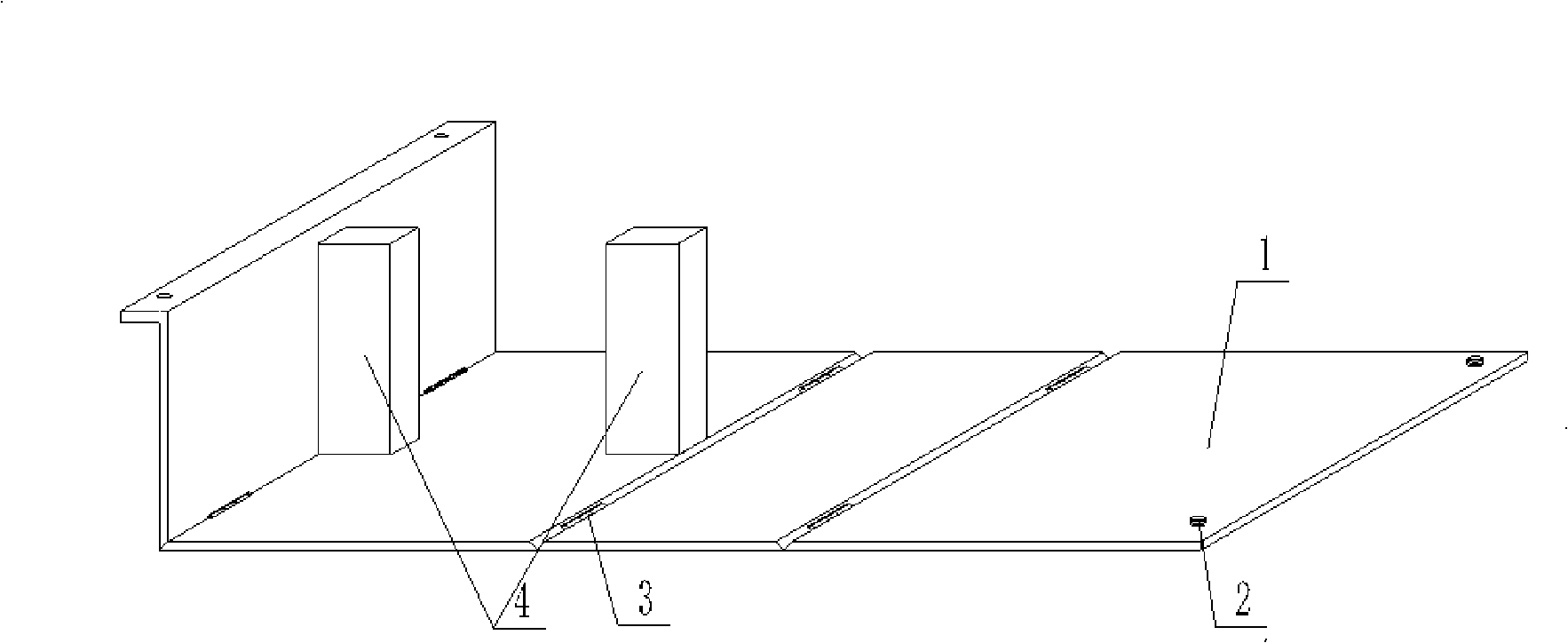

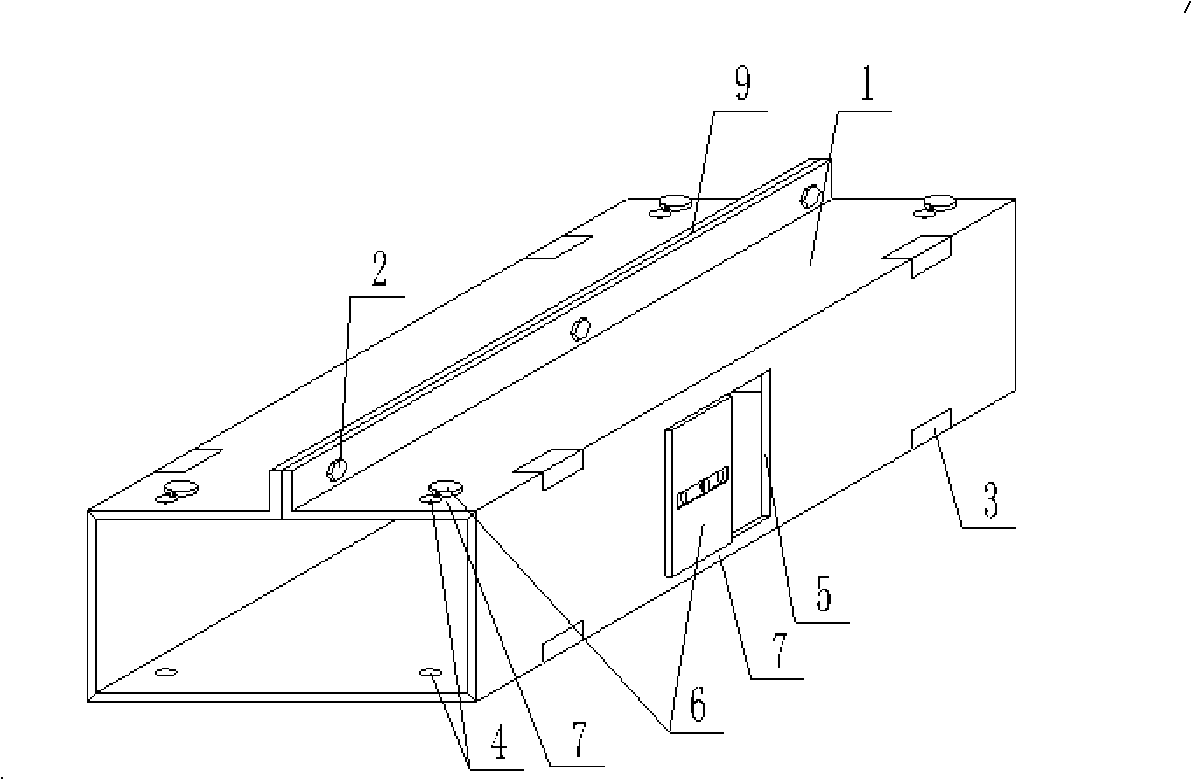

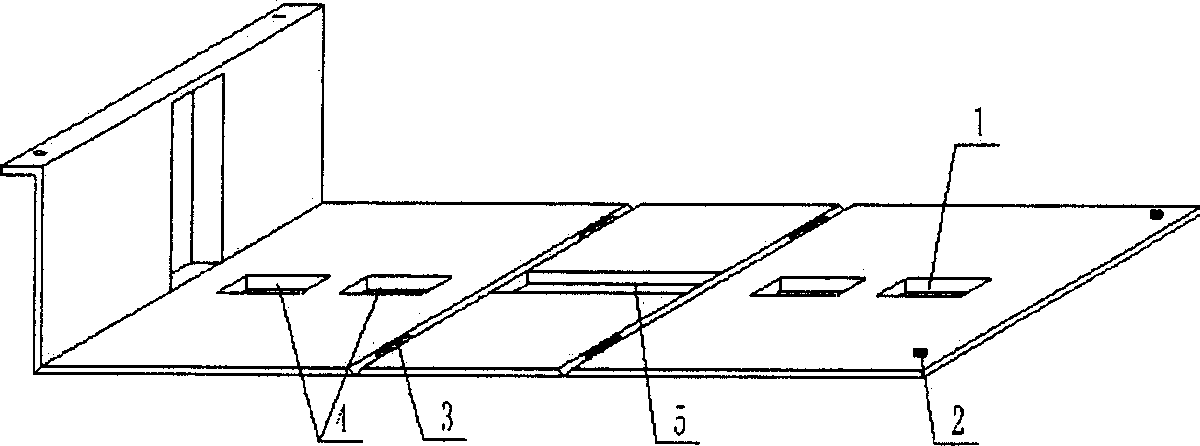

A shaping die for a concrete-filled hollow thin-wall component includes templates (1), fasteners (2) and rotatable parts (3). The templates (1) are connected by the rotatable parts (3); the connected templates (1) can rotate oppositely; the templates (1) after being folded are fixed by the fasteners (2). The invention is characterized in that at least three templates (1) are connected in sequence side by side in the die; at least one template (1) is provided with at least one transverse isolating die (4) which is a clapboard; the surface of the transverse isolating die (4) is a shaping die surface. In this way, after the fasteners are loosened, the die is very convenient to be released; simultaneously, when a polyhedron component is produced, a concave structure can be correspondingly formed on the polyhedron component or a conjoined or non-conjoined polyhedron component is manufactured; the production requirements for different polyhedron components can be met; besides, the die is also characterized by simple structure, easy manufacture, high intensity, low cost, and the like. The shaping die for a concrete-filled hollow thin-wall component is suitable for manufacturing various opened or closed polyhedron components.

Owner:邱则有

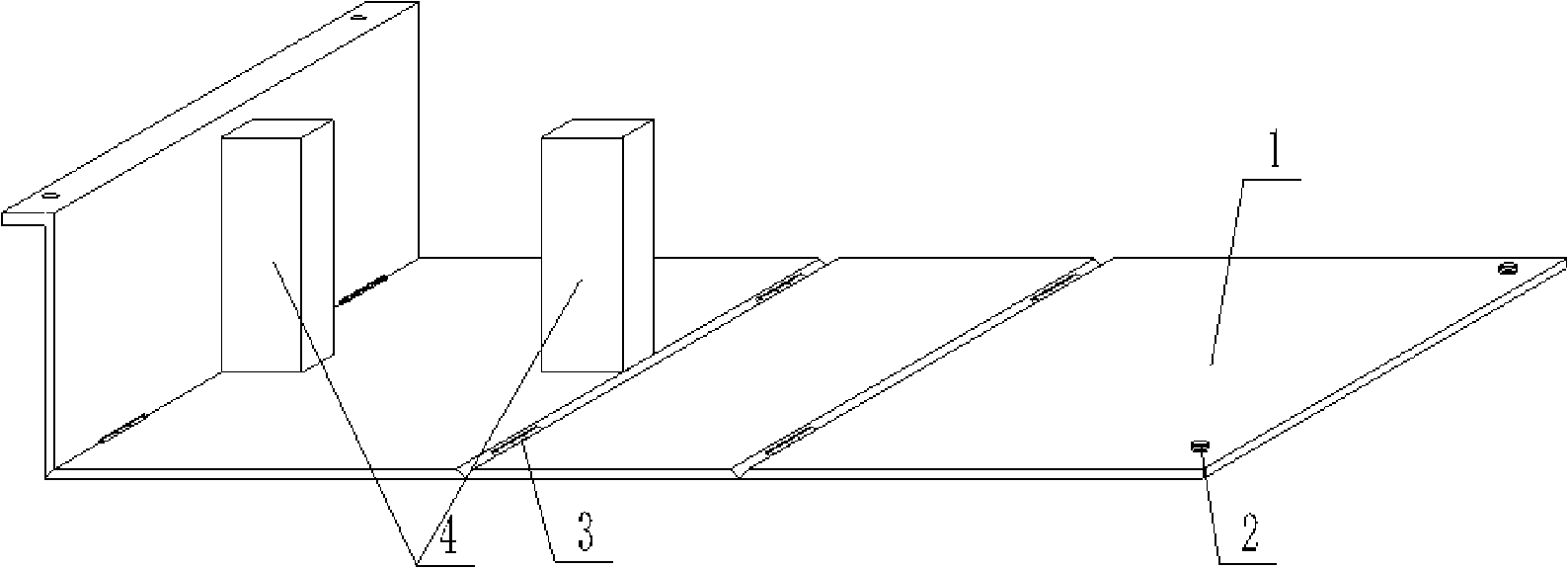

Mold for molding hollow thin wall component for filling concrete

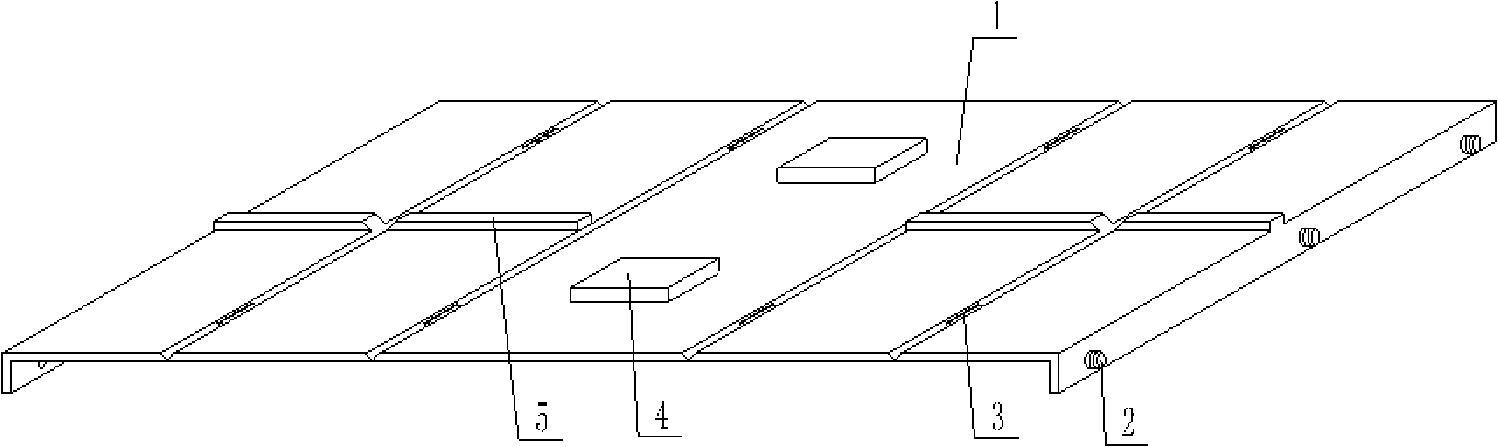

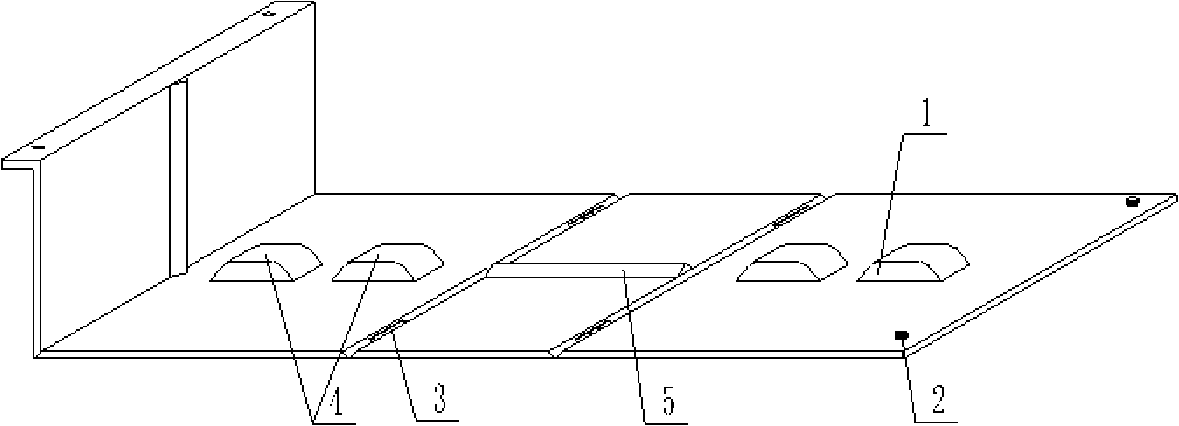

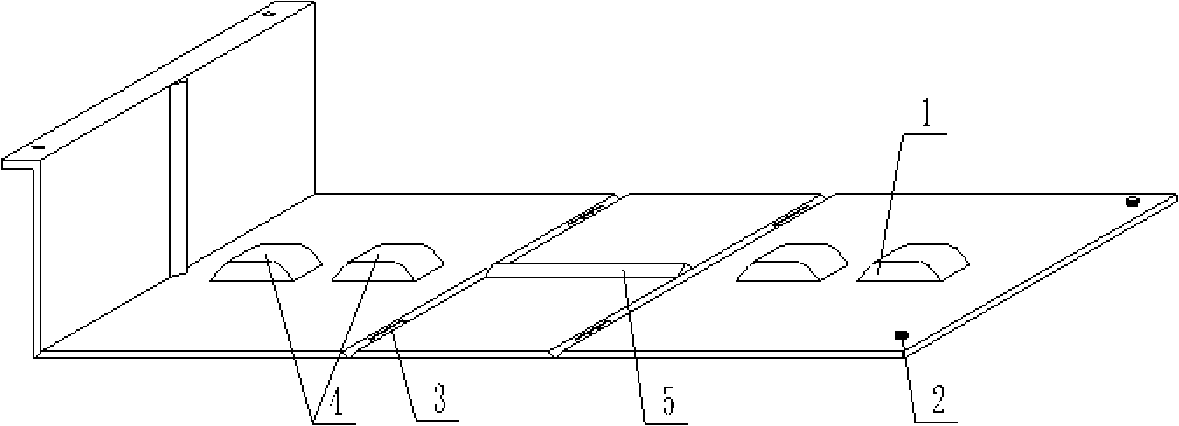

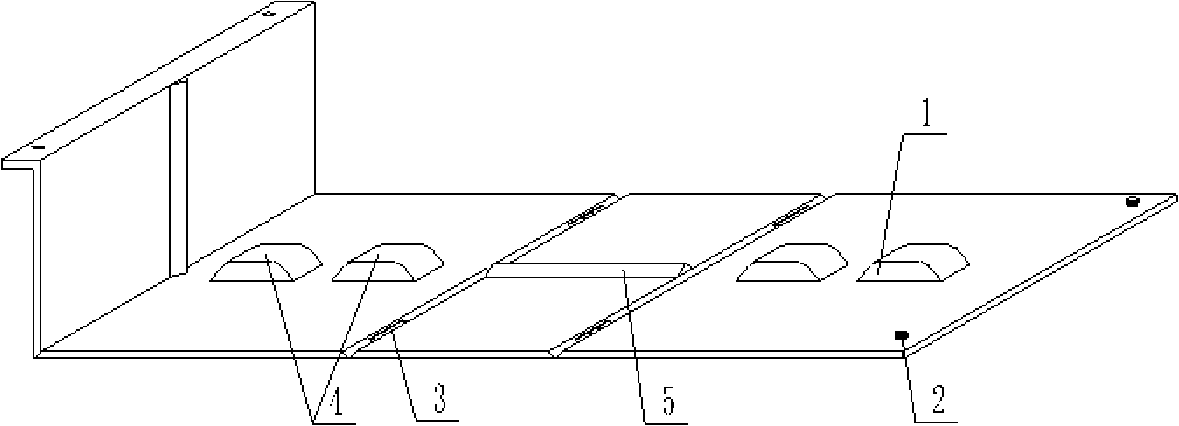

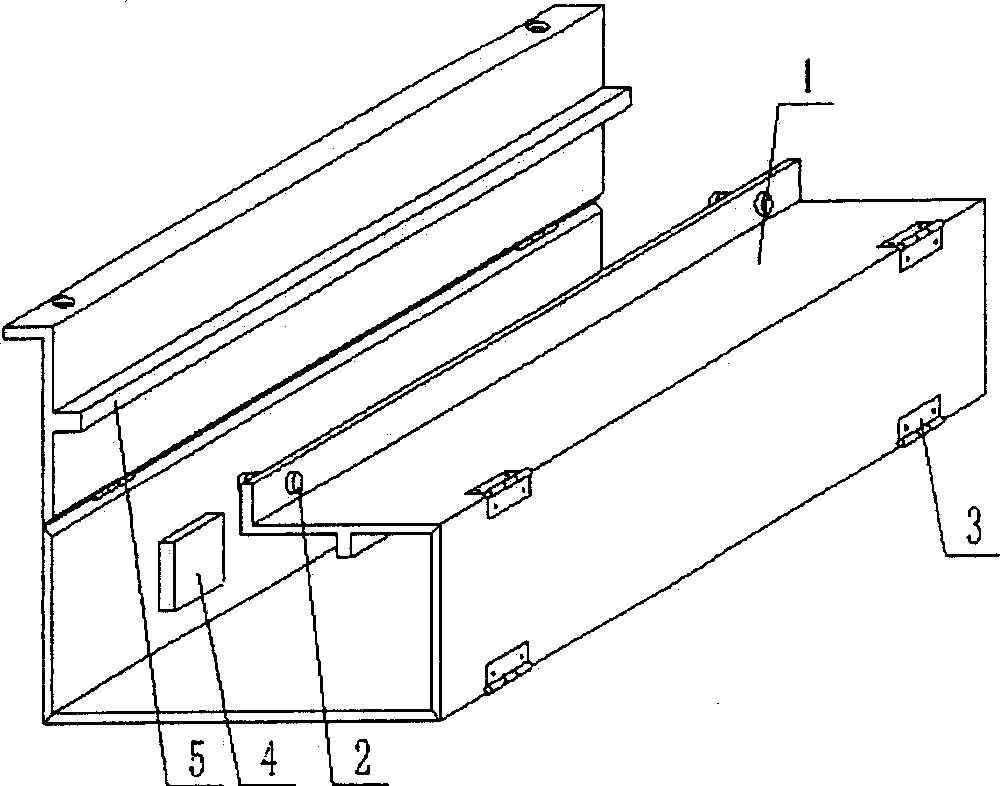

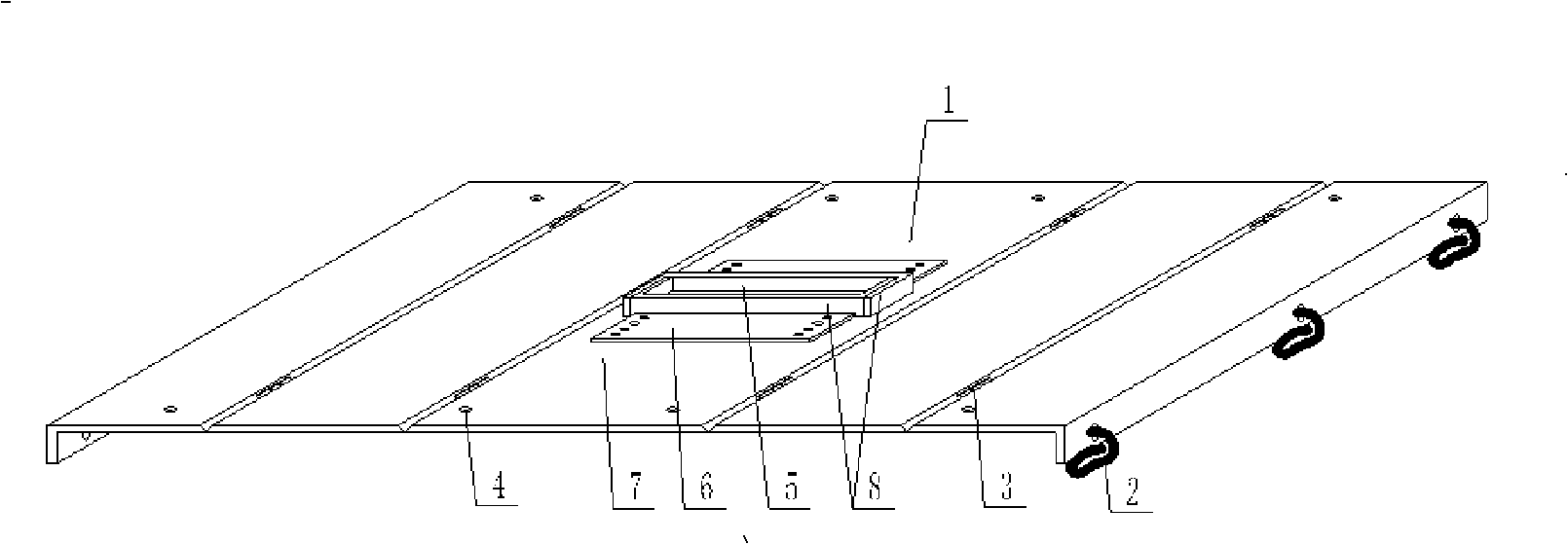

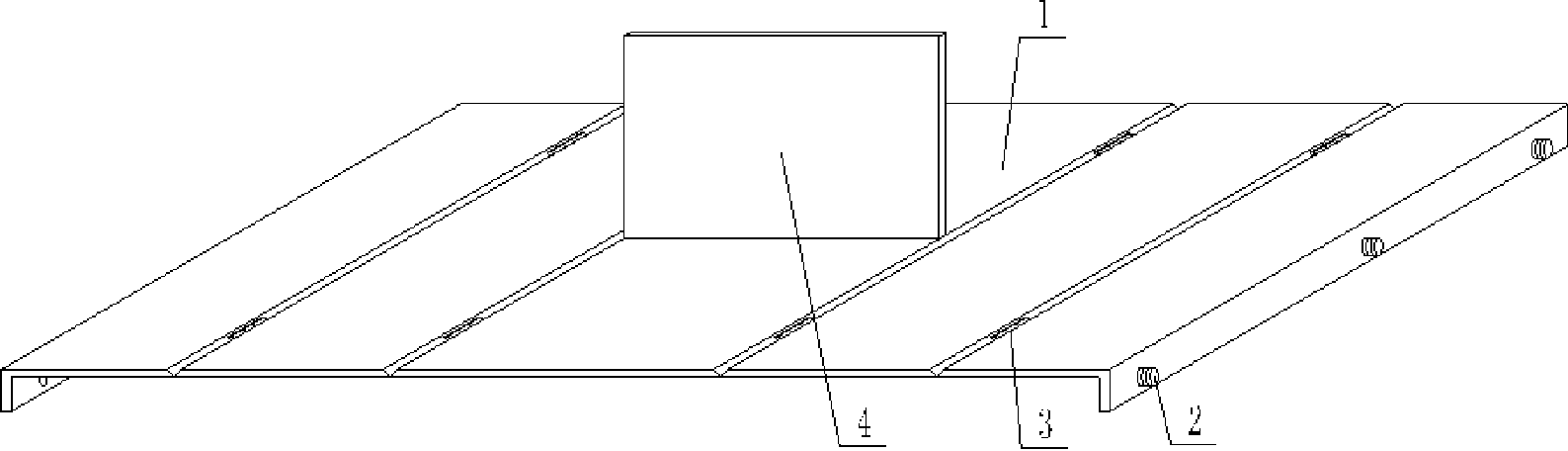

The invention relates to a concrete-filled hollow thin-walled member forming mould which comprises templates (1), a joint and tight piece (2), and rotatable components (3). The templates (1) are connected by the rotatable components (3). The connected templates (1) can relatively rotate. After the templates (1) are folded, the templates are fixed by the joint and tight piece (2). The mould is characterized in that at least three templates (1) are sequentially connected with each other side by side in the mould; wherein, a projection (4) or sand strip (5) protruding the surface of the templates is arranged on at least one of the three templates. The projection (4) or the sand strip (5) and the templates (1) are a whole body integrally formed. At least one of a gemel, a hinge, a bolt hinge, a film, a rotatable tenon, a rotatable slot or a rotatable jack, a rotatable bolt, a rotatable connector pin and a rotatable sliding bush serves as the rotatable components (3). Therefore, a very convenient demoulding can be ensured after the joint and tight piece is loosed; at the same time, a concave structure can be correspondingly formed on the polyhedron members during the production of polyhedron members, thus meeting requirements for a variety of hollow floor systems; furthermore, the mould is characterized by simple structure, easy manufacture, high intensity, low cost, etc., and is suitable for manufacturing a variety of open or closed polyhedral components.

Owner:湖南邱则有专利战略策划有限公司

Polyhedral member shaping mould

InactiveCN102172986AEasy to splitEasy to assembleMould separation apparatusMouldsUltimate tensile strength

Owner:湖南邱则有专利战略策划有限公司

Polyhedron component molding mould

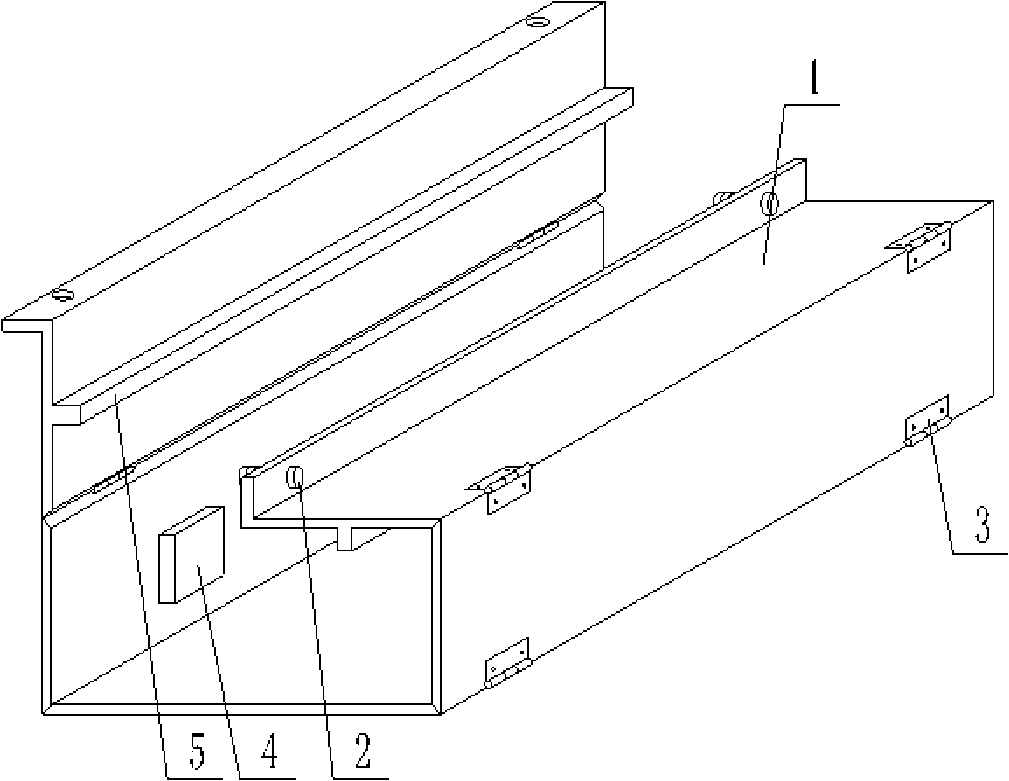

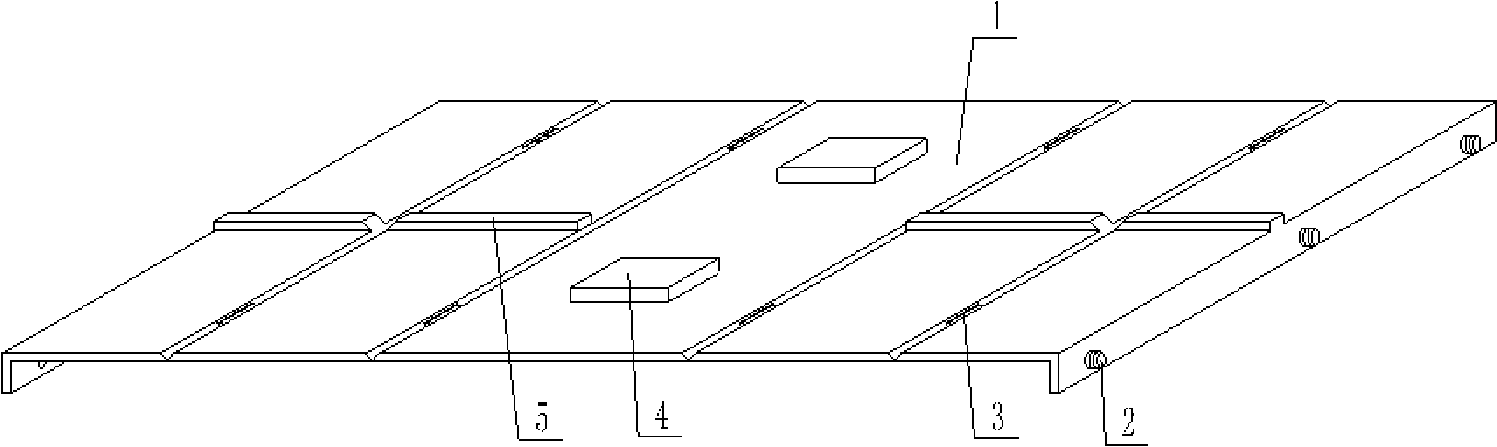

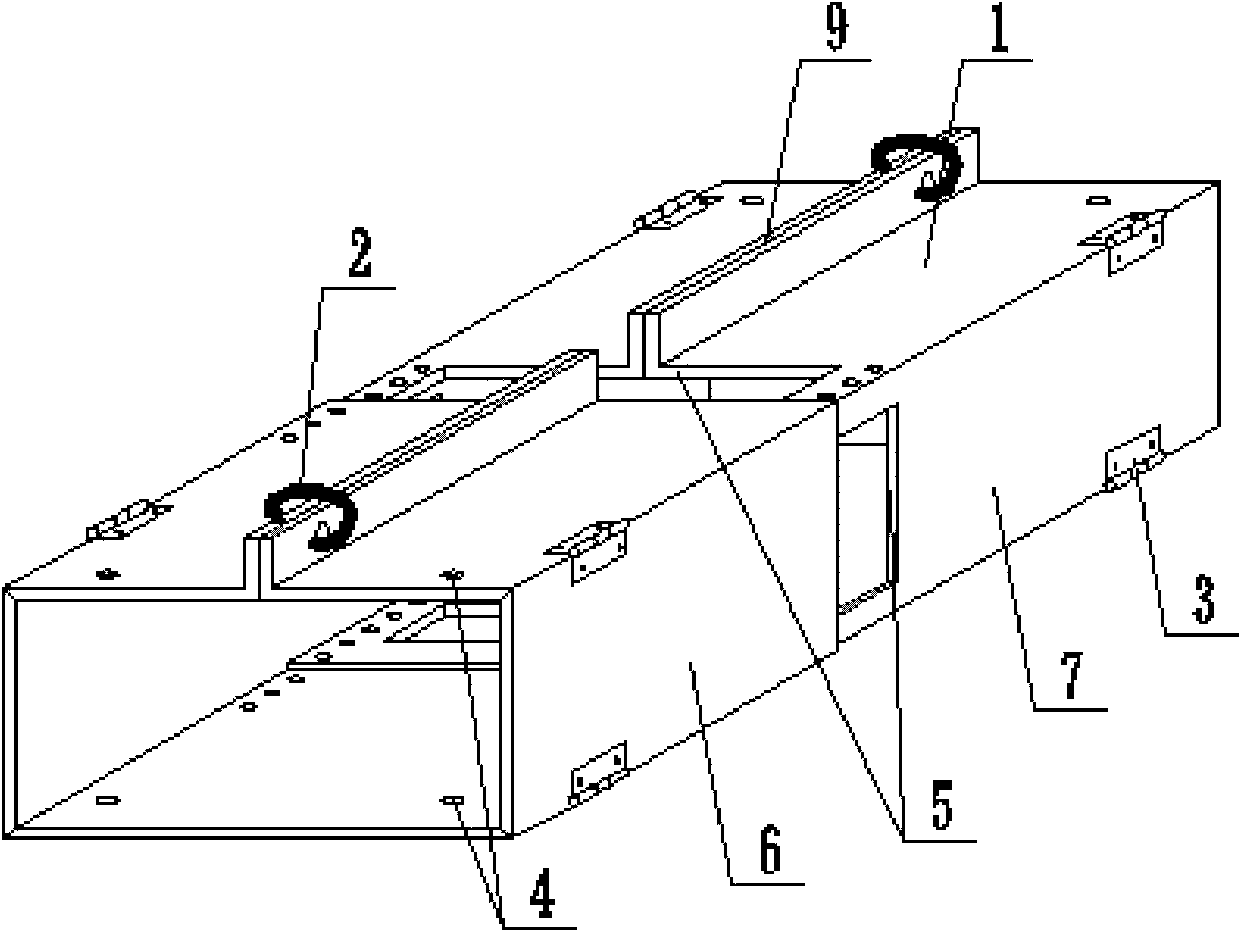

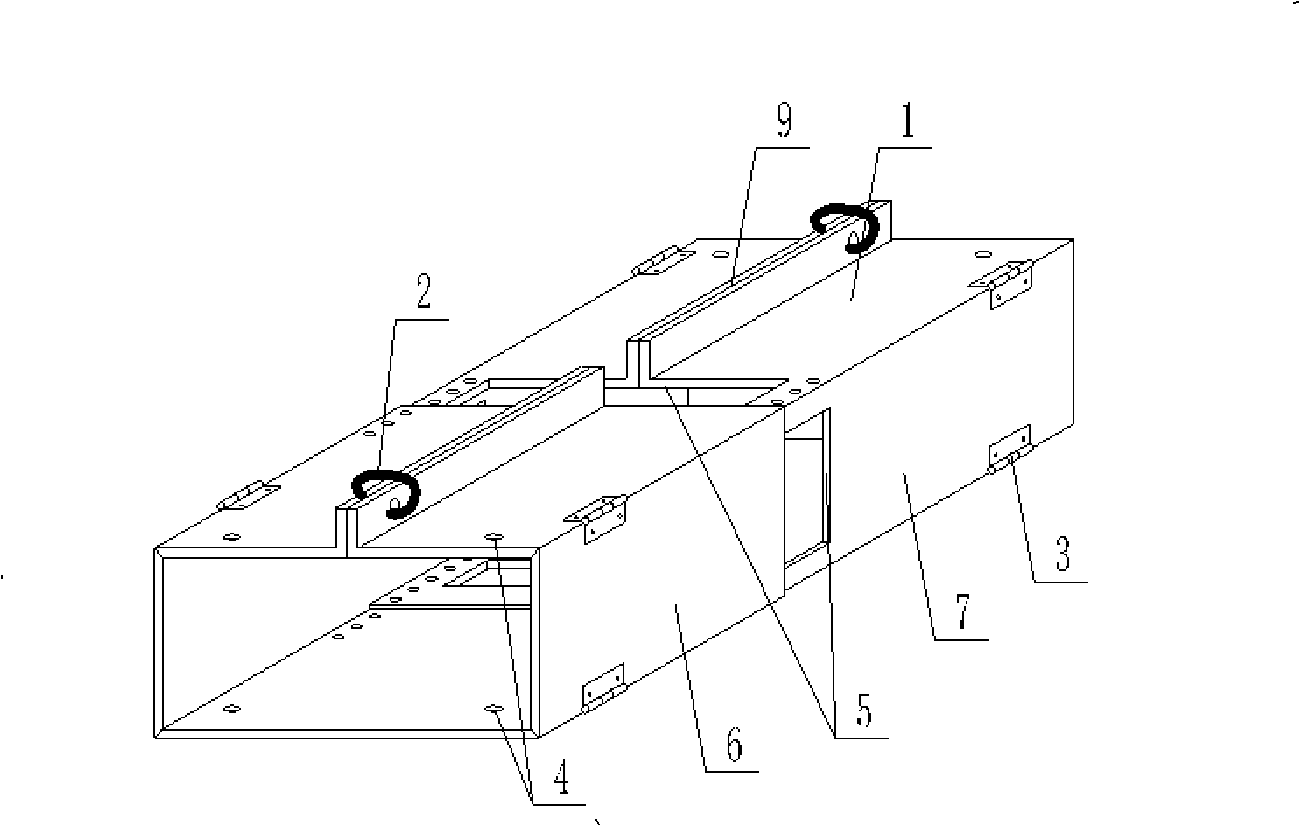

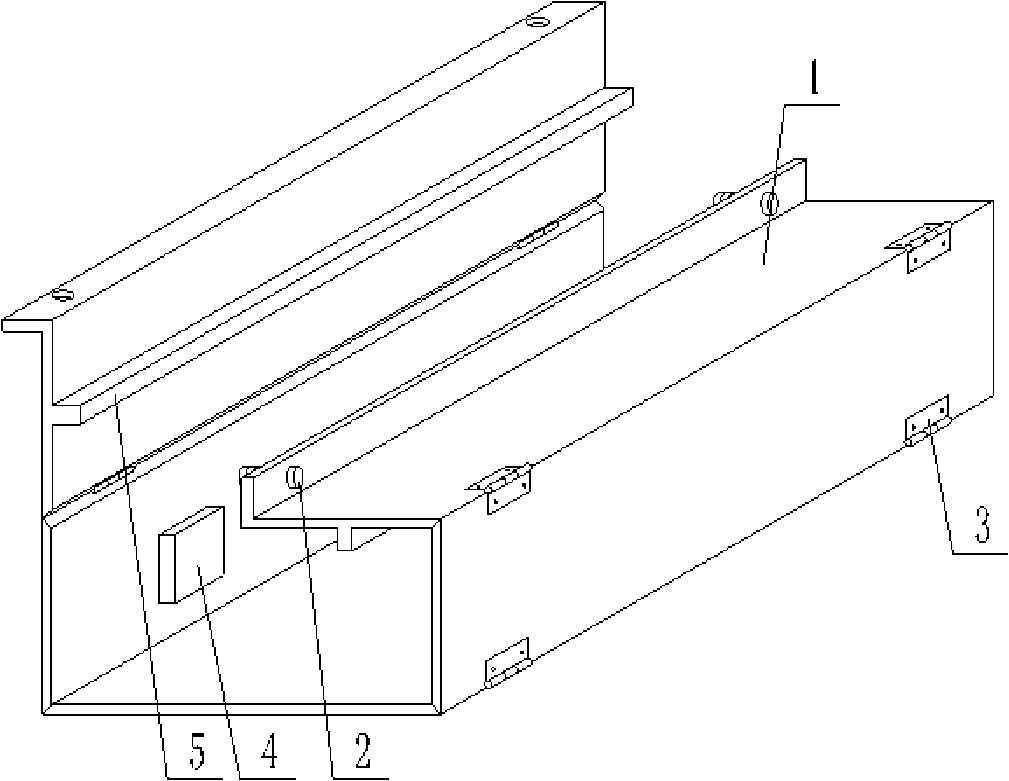

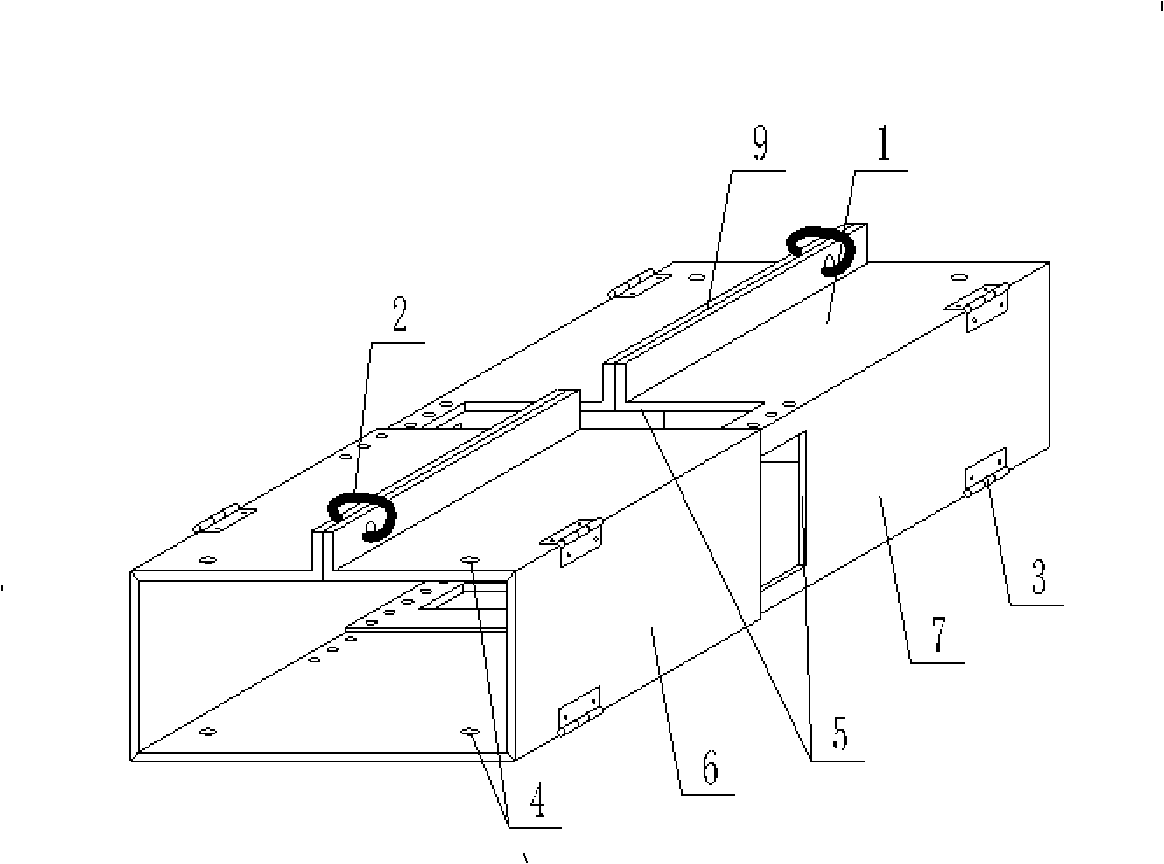

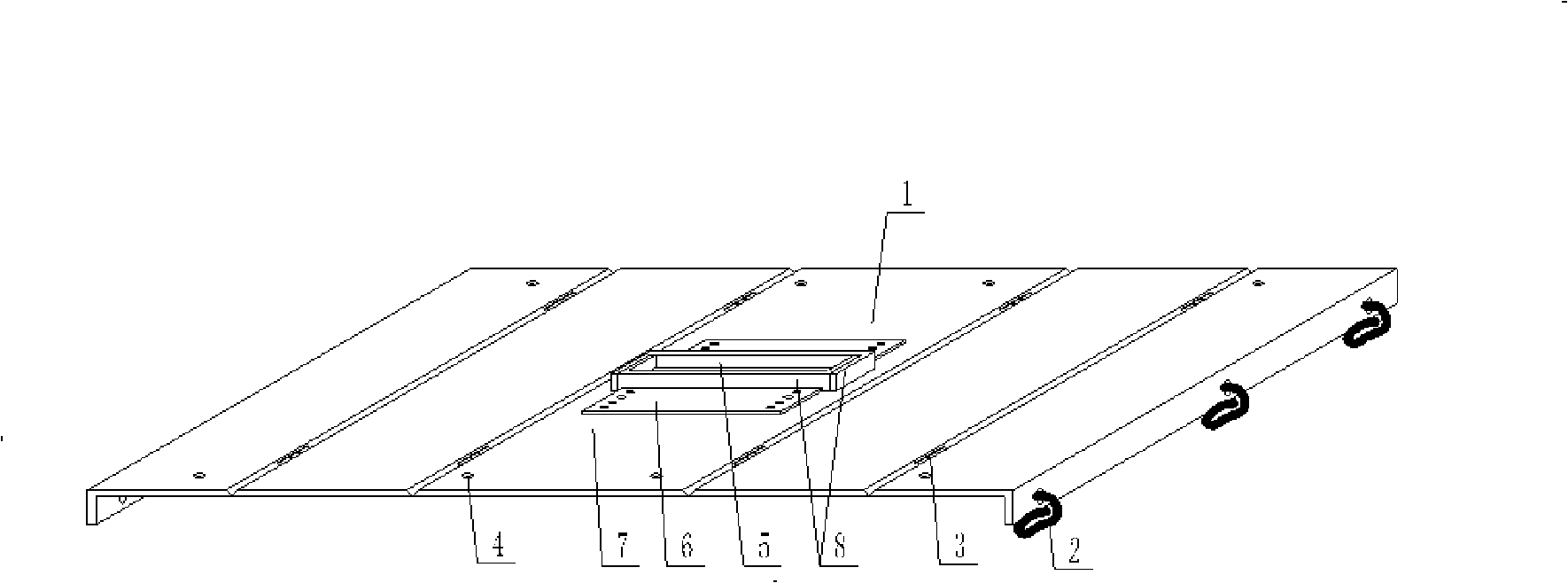

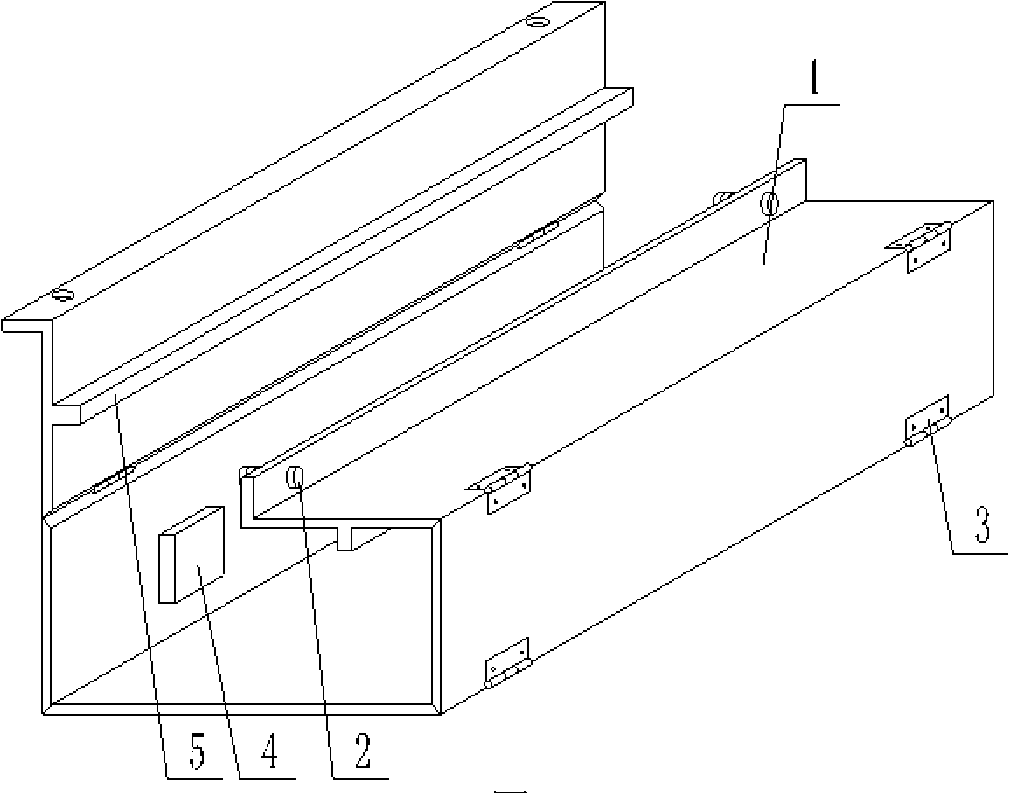

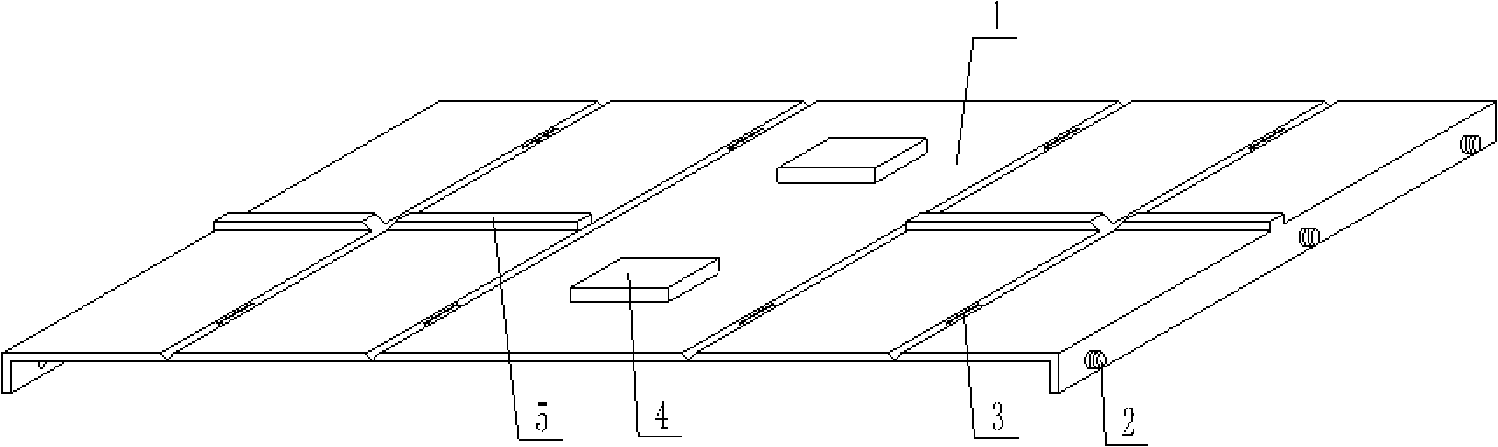

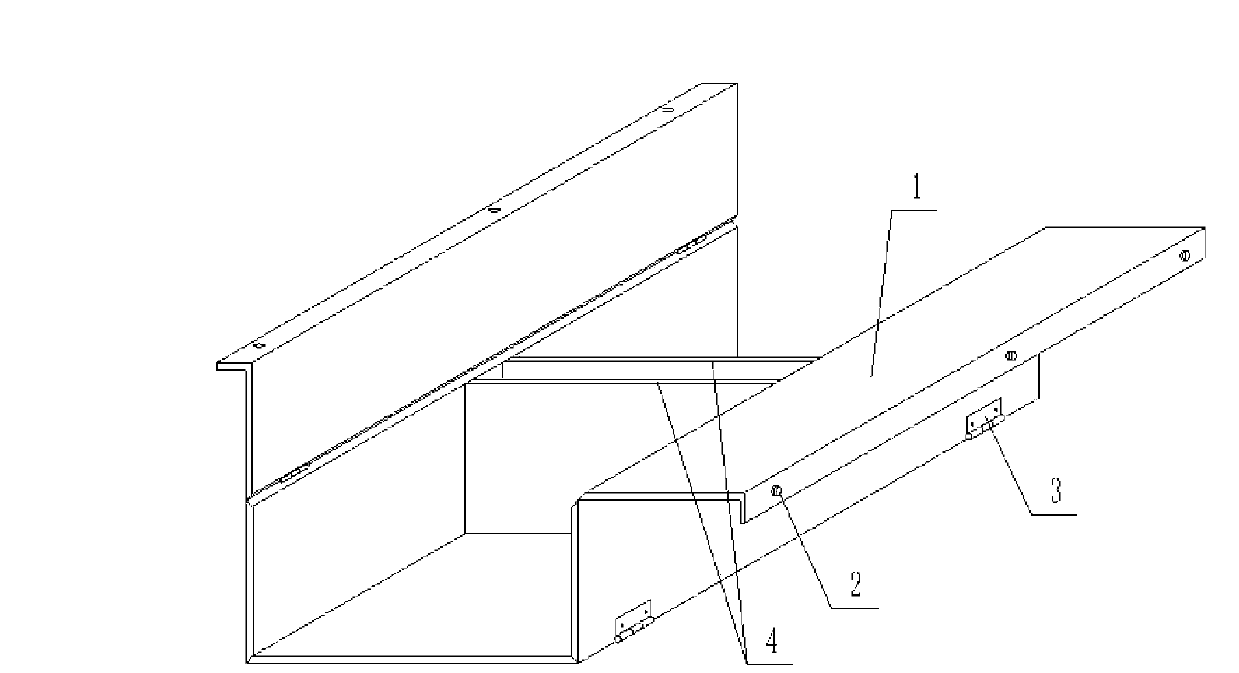

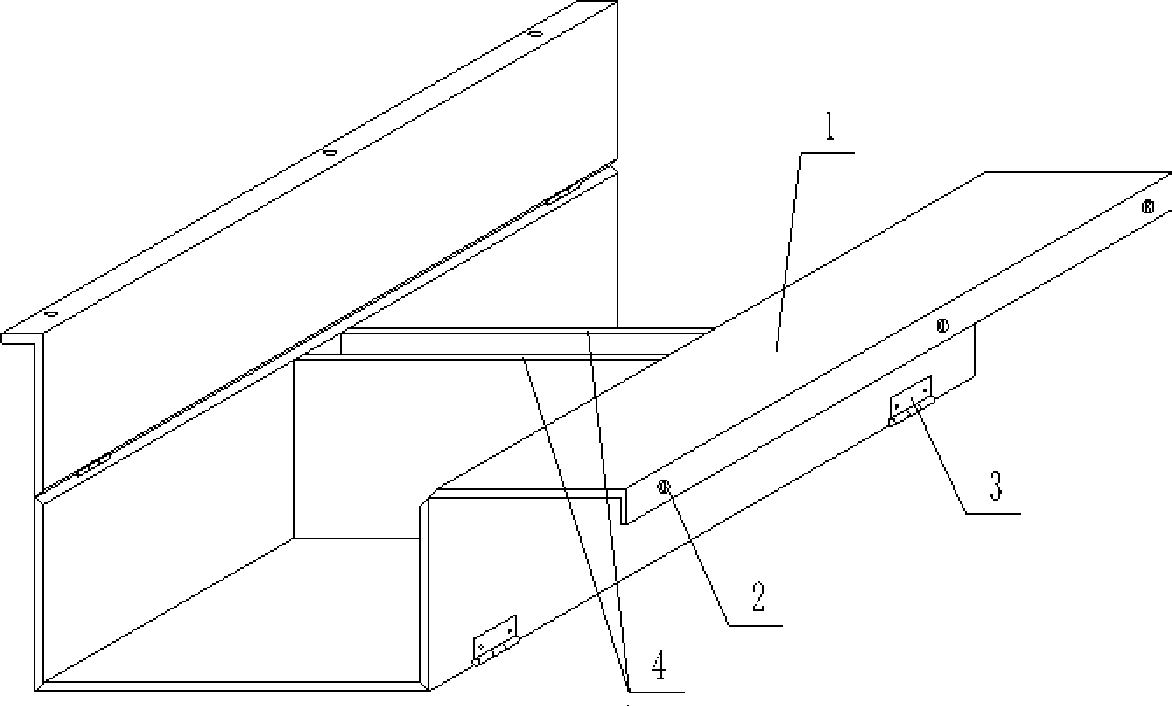

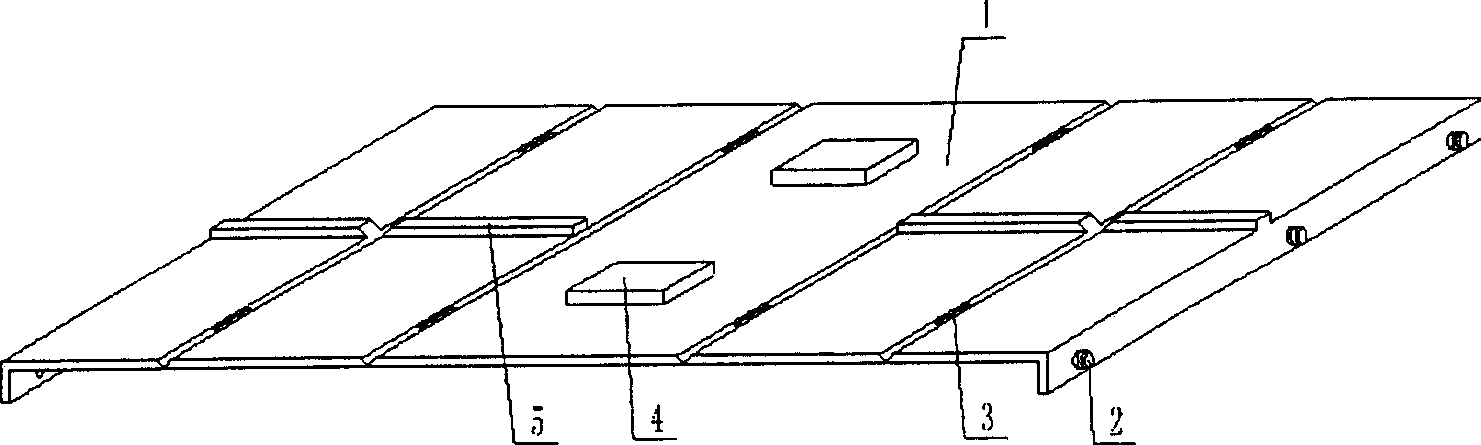

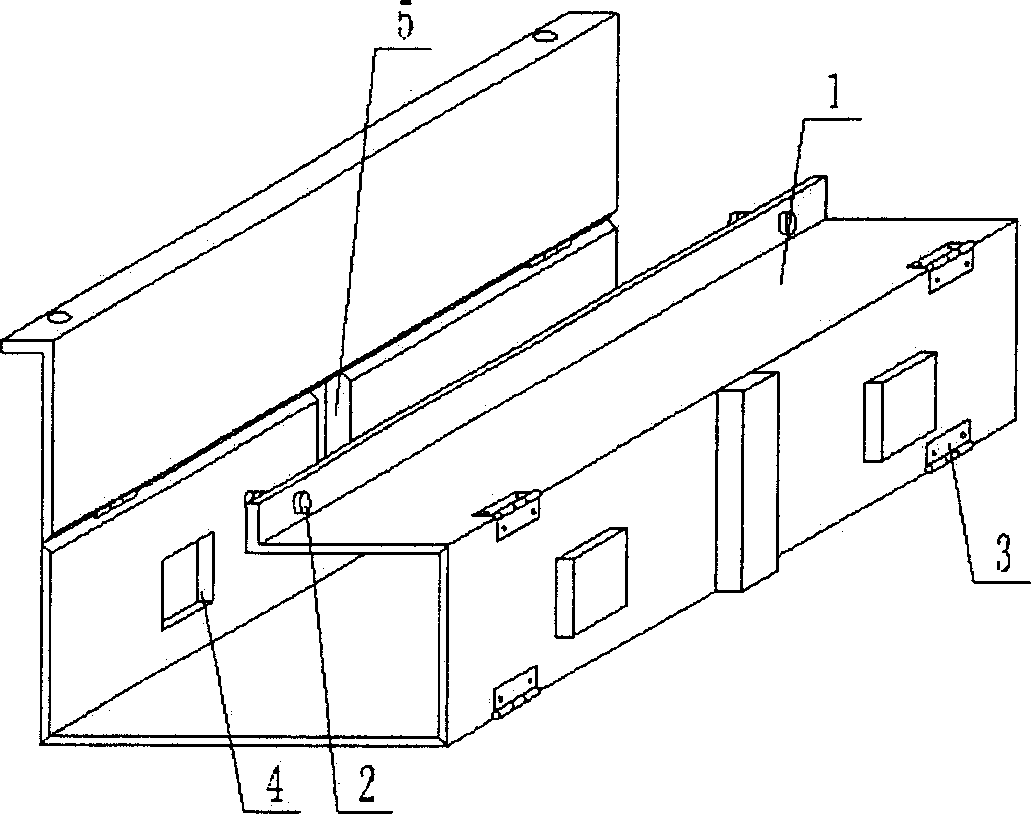

The invention provides a mould for moulding a polyhedral component, which comprises templets (1), fasteners (2) and a rotary component (3). The templets (1) are connected with each other by the rotary component (3); the connected templets (1) can turn relatively; after the templets (1) are folded, the templets are fixed with the fastener (3). The mould is characterized in that at least three templets are connected in turn side by side; at least one templet (1) is provided with a clear opening (4) and / or a continuous groove (5); four templets (1) are connected through hinges in turn side by side. The mould provided by the invention has the characteristics of being unloaded conveniently, simple structure, high strength, low cost and so on.

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

A shaping die for a concrete-filled hollow thin-wall component includes templates (1), fasteners (2) and rotatable parts (3). The templates (1) are connected by the rotatable parts (3); the connected templates (1) can rotate oppositely; the templates (1) after being folded are fixed by the fasteners (2). The invention is characterized in that at least three templates (1) are connected in sequence side by side in the die; at least one template (1) is provided with at least one transverse isolating die (4); the transverse isolating die (4) is formed by joining at least two movable parts (5) together; the transverse isolating die (4) is a clapboard and is a one-off die which is combined with the product to become one part of the product. The shaping die for a concrete-filled hollow thin-wall component is applicable to manufacturing various opened or closed polyhedron components.

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

A shaping die for a concrete-filled hollow thin-wall component includes templates (1), fasteners (2) and rotatable parts (3). The templates (1) are connected by the rotatable parts (3); the connected templates (1) can rotate oppositely; the templates (1) after being folded are fixed by the fasteners (2). The invention is characterized in that at least three templates (1) are connected in sequence in the die side by side; at least one template (1) is provided with at least one transverse isolating die (4) which is a clapboard; the transverse isolating die (4) is a double isolating die. In this way, after the fasteners are loosened, the die is very convenient to be released; simultaneously, when a polyhedron component is produced, a concave structure can be correspondingly formed on the polyhedron component or a conjoined or non-conjoined polyhedron component is manufactured; the production requirements for different polyhedron components can be met; besides, the die is also characterized by simple structure, easy manufacture, high intensity, low cost, and the like. The shaping die for a concrete-filled hollow thin-wall component is suitable for manufacturing various opened or closed polyhedron components.

Owner:湖南邱则有专利战略策划有限公司

Polyhedron component molding mould

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

A shaping die for a concrete-filled hollow thin-wall component includes templates (1), fasteners (2) and rotatable parts (3). The templates (1) are connected by the rotatable parts (3); the connected templates (1) can rotate oppositely; the templates (1) after being folded are fixed by the fasteners (2). The invention is characterized in that at least three templates (1) are connected in sequence side by side in the die; at least one template (1) is provided with at least one transverse isolating die (4); at least one end of at least one of the side-by-side templates (1) is connected with a movable template (1); the surface of the transverse isolating die (4) is a shaping die surface. In this way, after the fasteners are loosened, the die is very convenient to be released; simultaneously, when a polyhedron component is produced, a concave structure can be correspondingly formed on the polyhedron component; the production requirements for different polyhedron components can be met; besides, the die is also characterized by simple structure, easy manufacture, high intensity, low cost, and the like. The shaping die for a concrete-filled hollow thin-wall component is applicable to manufacturing various opened or closed polyhedron components.

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

InactiveCN101347949AQuick assemblyQuick dismantlingMould separation apparatusMouldsEngineeringHigh intensity

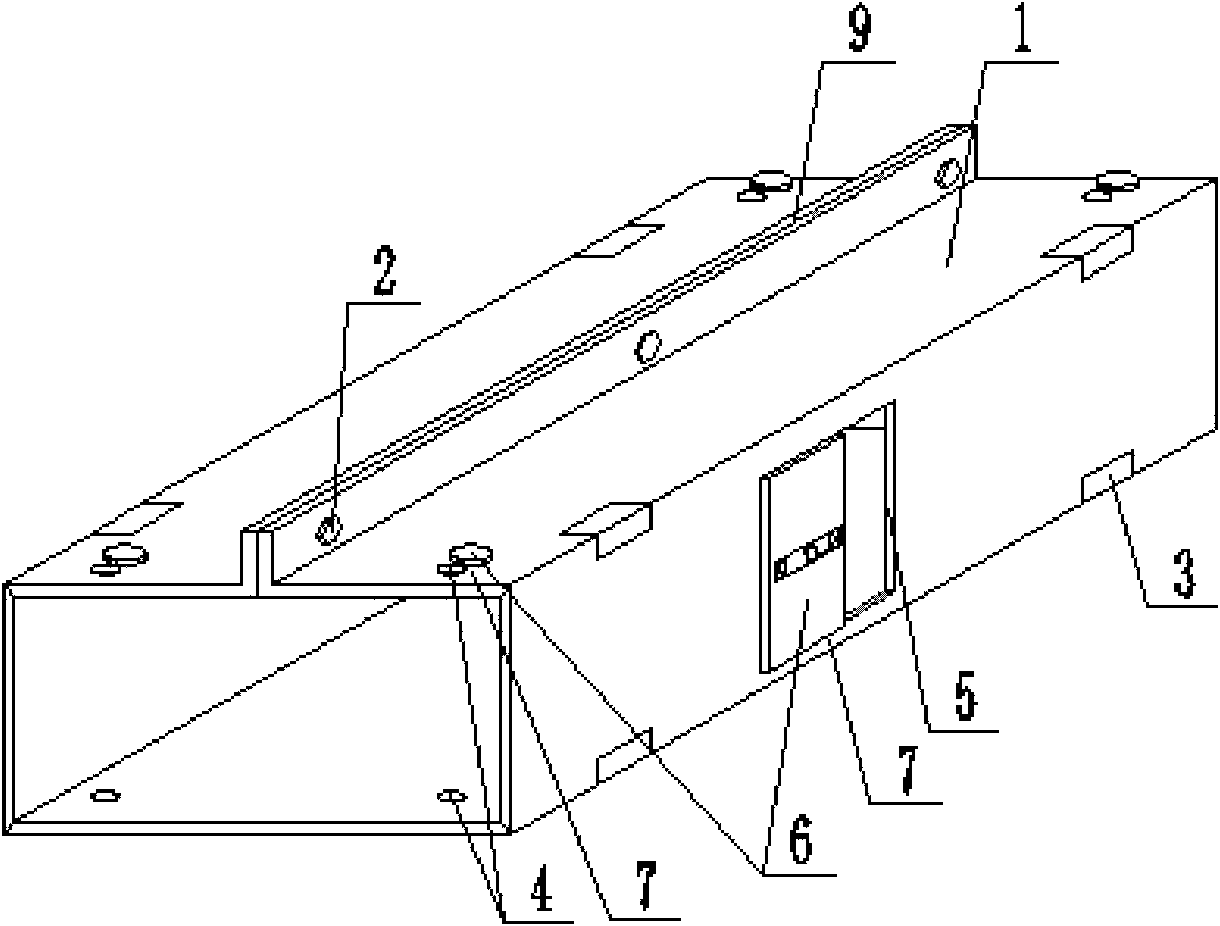

The invention relates to a concrete-filled hollow thin-walled member forming mould which comprises templates (1), a joint and tight piece (2), and rotatable components (3). The templates (1) are connected by the rotatable components (3). The connected templates (1) can relatively rotate. After the templates (1) are folded, the templates are fixed by the joint and tight piece (2). The mould is characterized in that at least three templates (1) are sequentially connected with each other side by side in the mould; wherein, a projection (4) or sand strip (5) protruding the surface of the templates is arranged on at least one of the three templates. The four templates (1) are folded into a tube-shaped mould. At least one of a gemel, a hinge, a bolt hinge, a film, a rotatable tenon, a rotatable slot or a rotatable jack, a rotatable bolt, a rotatable connector pin and a rotatable sliding bush serves as the rotatable components (3). Therefore, a very convenient demoulding can be ensured after the joint and tight piece is loosed; at the same time, a concave structure can be correspondingly formed on the polyhedron members during the production of polyhedron members, thus meeting requirements for a variety of hollow floor systems; furthermore, the mould is characterized by simple structure, easy manufacture, high intensity, low cost, etc., and is suitable for manufacturing a variety of open or closed polyhedral components.

Owner:湖南邱则有专利战略策划有限公司

Polyhedron component molding mould

Owner:湖南邱则有专利战略策划有限公司

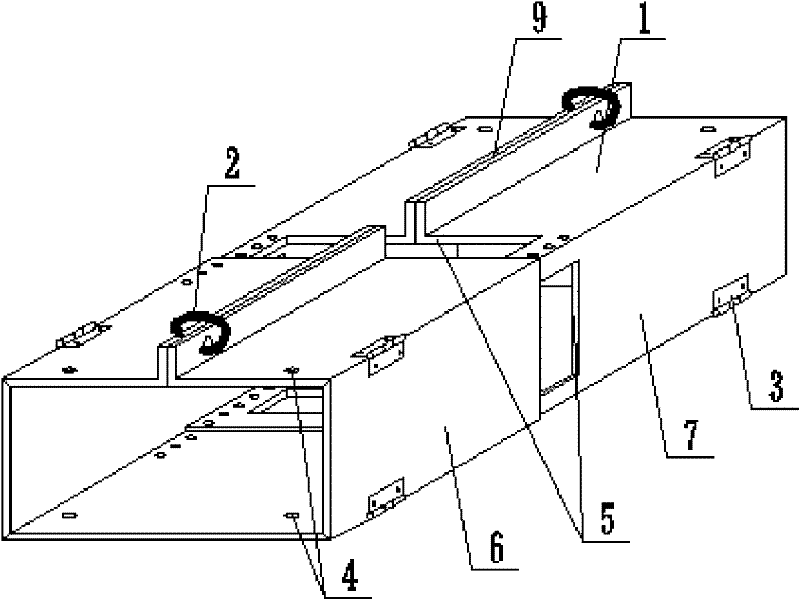

Mould for molding concrete filled hollow thin wall component

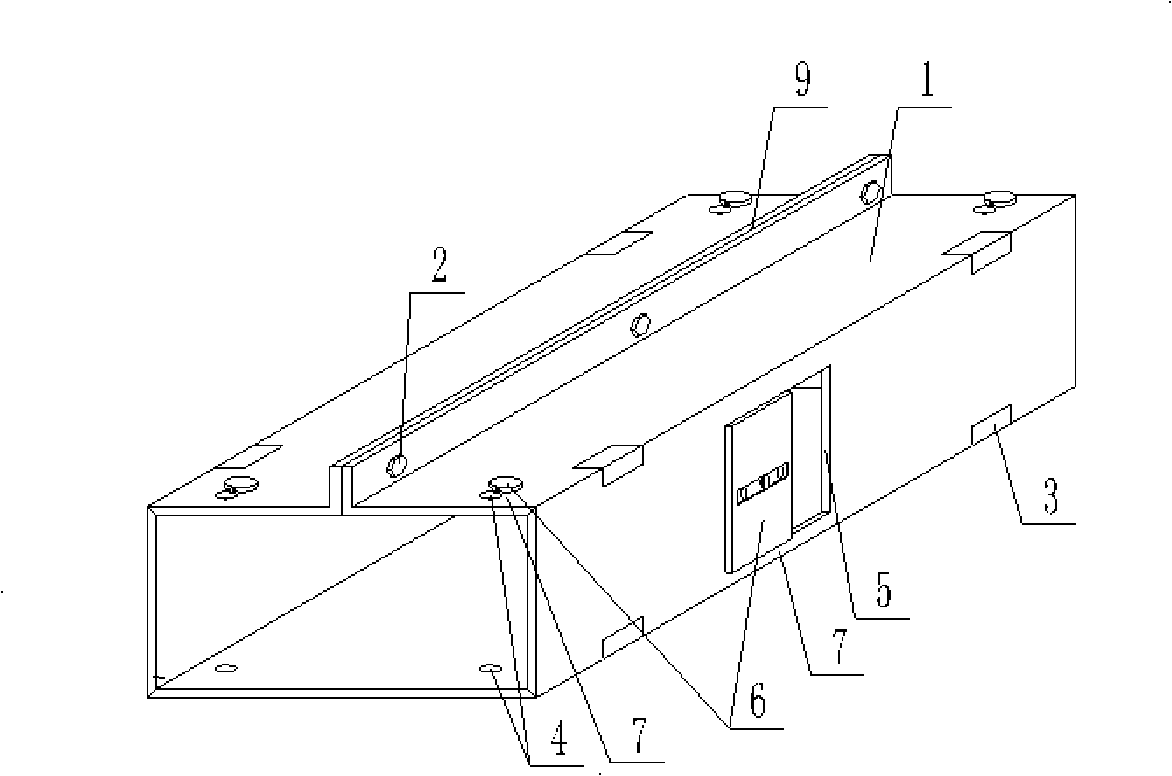

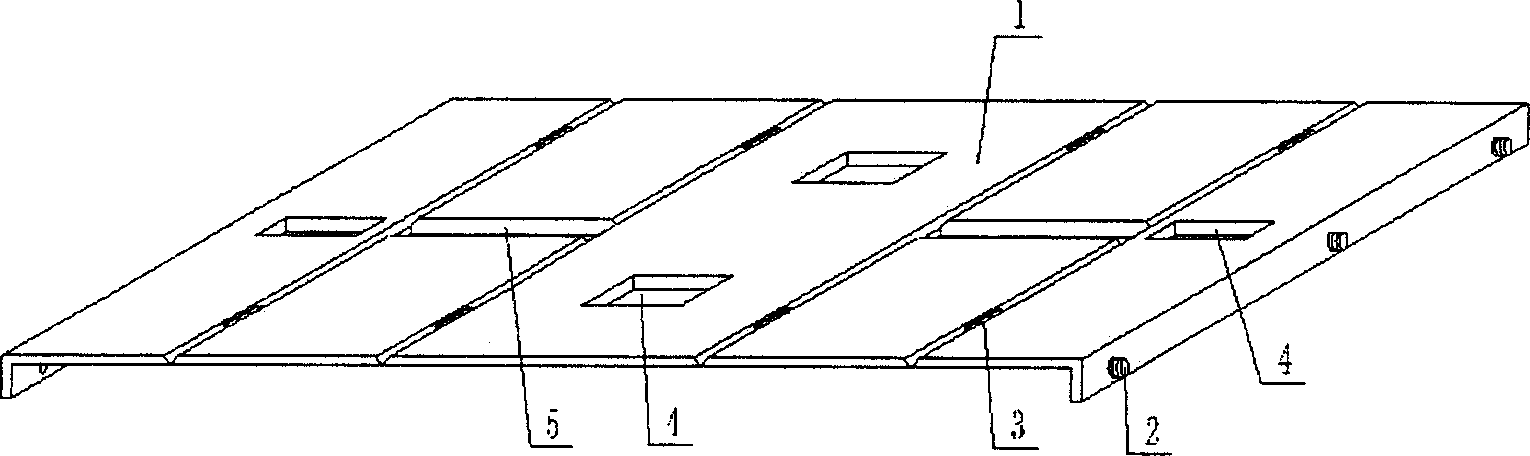

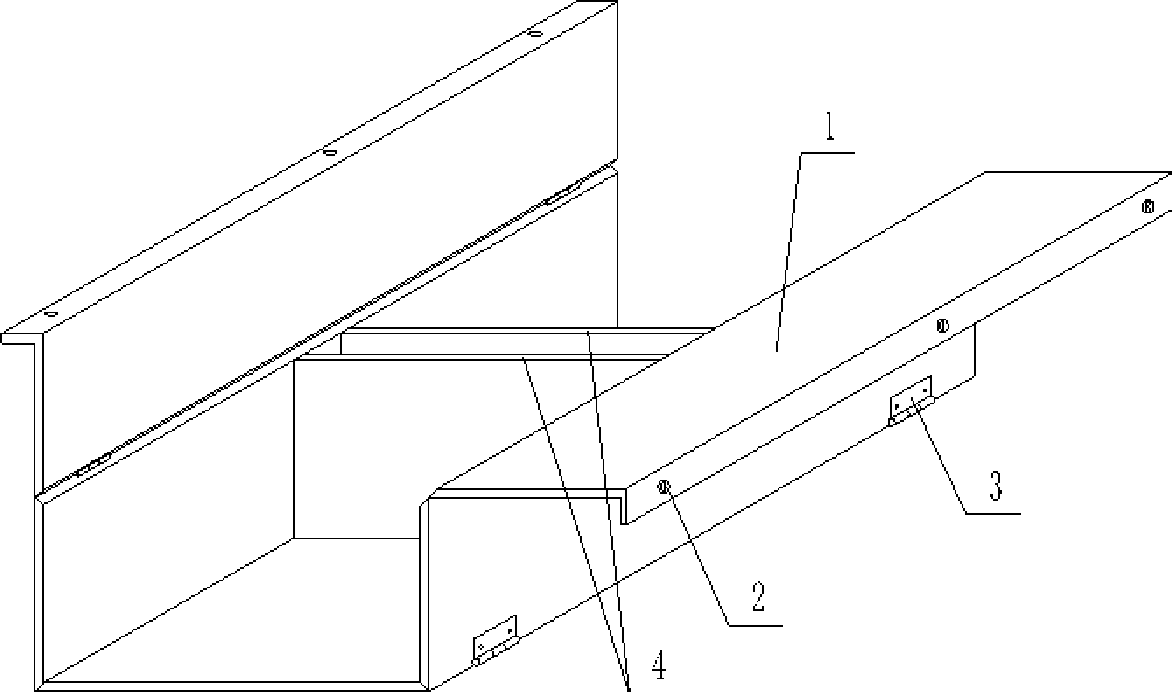

The invention provides a mould for moulding a concrete filled hollow thin wall component, which comprises templets (1), fasteners (2) and rotary components (3). The templets (1) are connected with each other by the rotary components (3); the connected templets (1) can turn relatively; after the templets are folded, the fasteners (2) fix the templets (1). The mould for moulding the concrete filled hollow thin wall component is characterized in that at least three templets in the mould are connected in turn side by side; at least one templet (1) is provided with at least one cross spacing mould (4) which is a movable spacing mould; the surface of the cross spacing mould is a moulding surface. In this way, after the fasteners become loose, the mould can be unloaded conveniently. When polyhedral components are produced, the mould can form concave structures on the polyhedral components, or be used for manufacturing connected or disconnected polyhedral components. Accordingly, the mould meets the requirements for producting various polyhedral components. In addition, the mould has the characteristics of simple structure, being manufactured easily, high strength, low cost and so on, which is applicable for manufacturing various open-end or closed-end polyhedral components.

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

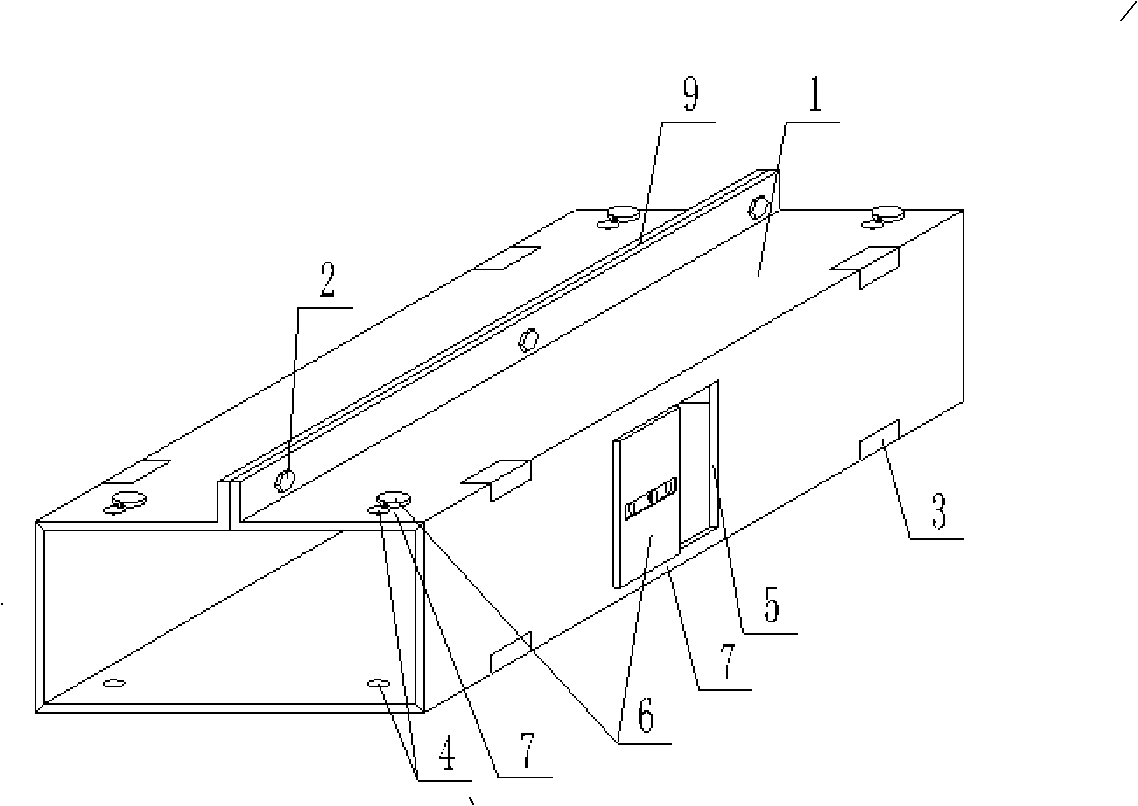

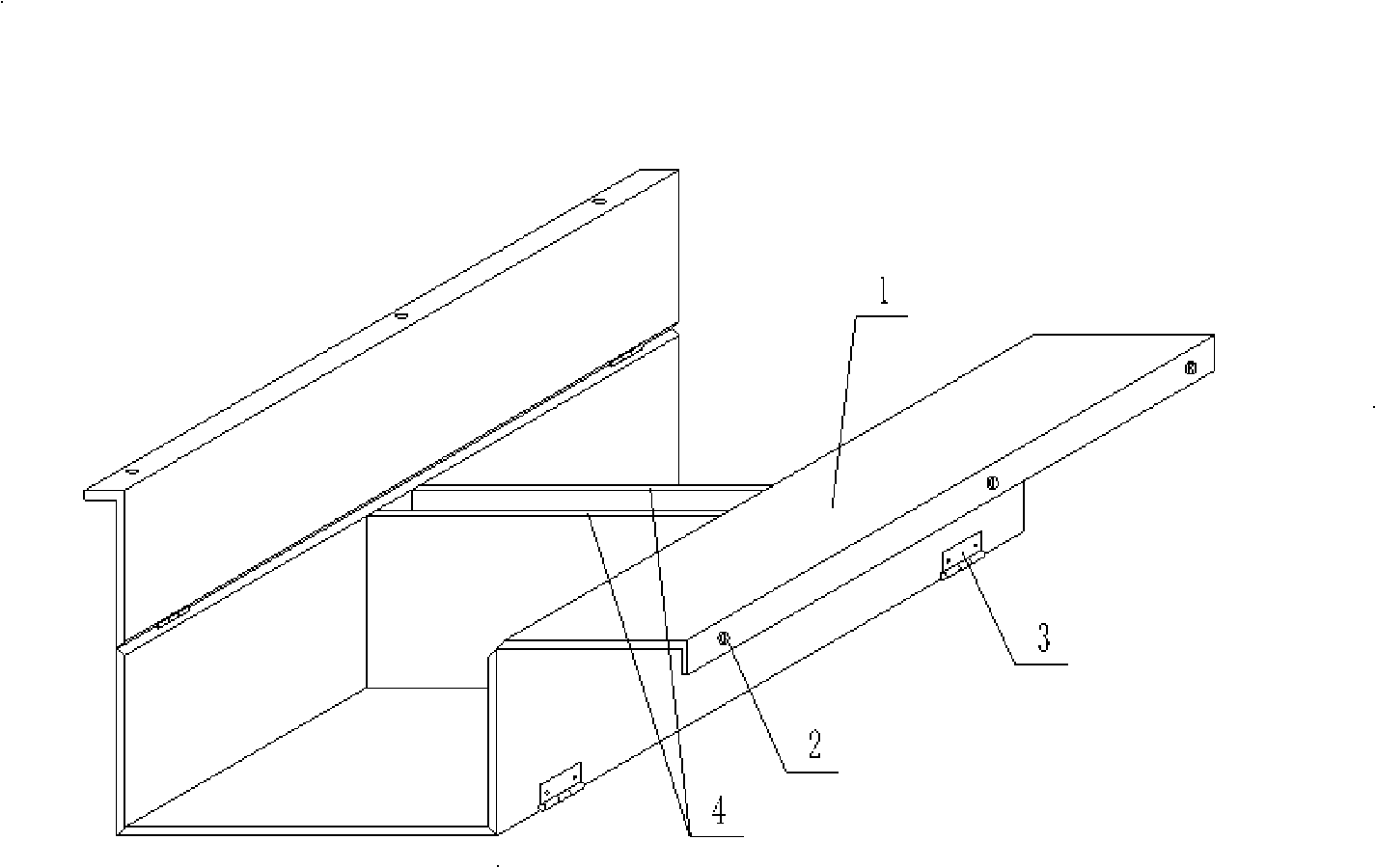

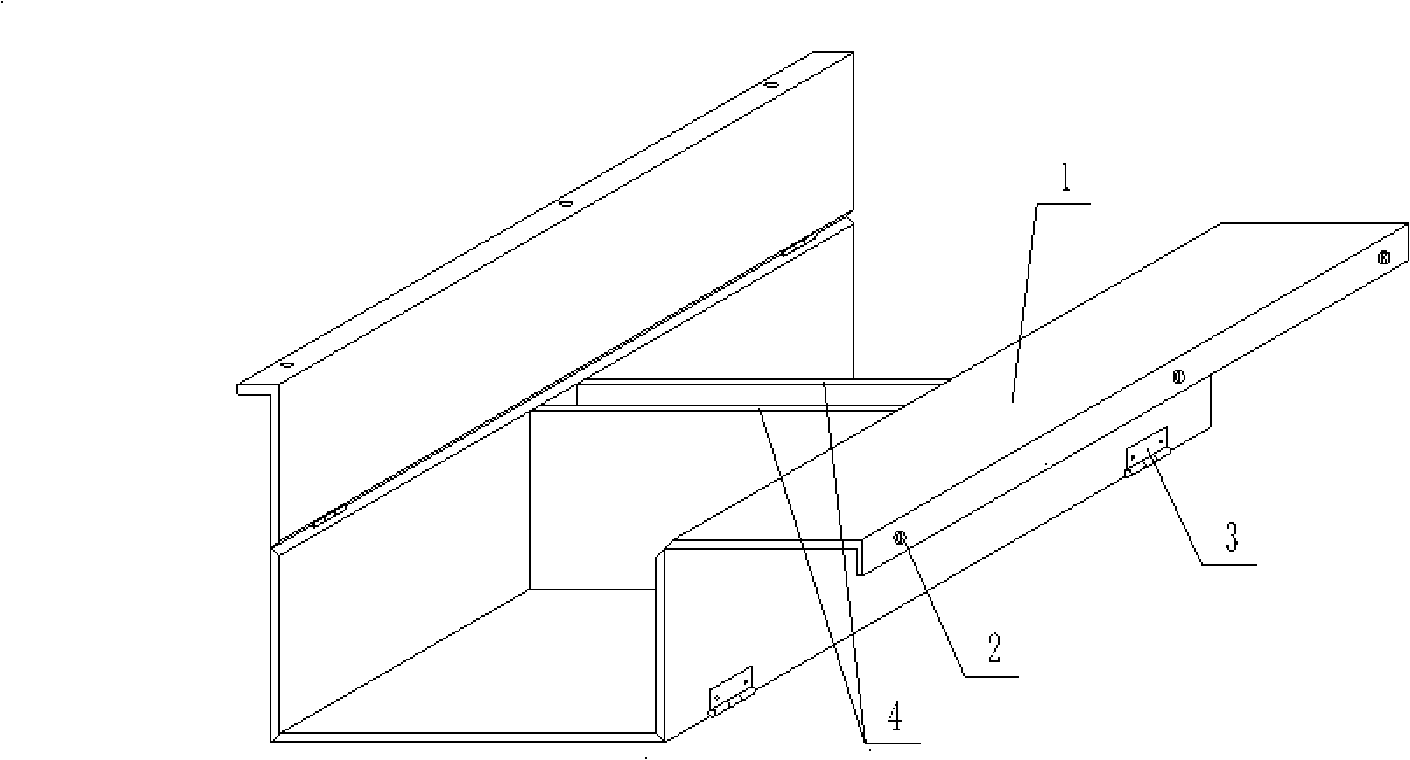

A shaping die for a concrete-filled hollow thin-wall component includes templates (1), fasteners (2) and rotatable parts (3). The templates (1) are connected by the rotatable parts (3); the connected templates (1) can rotate oppositely; the templates (1) after being folded are fixed by the fasteners (2). The invention is characterized in that at least three templates (1) are connected in sequence side by side in the die; at least one template (1) is provided with at least one transverse isolating die (4); the die clamping opening of a cylindrical die formed by folding four templates (1) is arranged at a corner part; the surface of the transverse isolating die (4) is a shaping die surface. In this way, after the fasteners are loosened, the die is very convenient to be released; simultaneously, when a polyhedron component is produced, a concave structure can be correspondingly formed on the polyhedron component or a conjoined or non-conjoined polyhedron component is manufactured; the production requirements for different polyhedron components can be met; besides, the die is also characterized by simple structure, easy manufacture, high intensity, low cost, and the like. The shaping die for a concrete-filled hollow thin-wall component is applicable to manufacturing various opened or closed polyhedron components.

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

A shaping die for a concrete-filled hollow thin-wall component includes templates (1), fasteners (2) and rotatable parts (3). The templates (1) are connected by the rotatable parts (3); the connected templates (1) can rotate oppositely; the templates (1) after being folded are fixed by the fasteners (2). The invention is characterized in that at least three templates (1) are connected in sequence side by side in the die; at least one template (1) is provided with at least one transverse isolating die (4); the transverse isolating die (4) is a clapboard and a one-off die which is combined with the product to become one part of the product; the transverse isolating die (4) is formed by joining at least two movable parts (5) together. The shaping die for a concrete-filled hollow thin-wall component is applicable to manufacturing various opened or closed polyhedron components.

Owner:湖南邱则有专利战略策划有限公司

Mould for molding concrete filled hollow thin wall component

The invention provides a mould for moulding a concrete filled hollow thin wall component, which comprises templets (1), a rotary component (3) and fasteners (2). The templets (1) are connected with each other by the rotary component (3); the connected templets (1) can turn relatively; after the templets (1) are folded, the templets are fixed with the fastener (2). The mould for moulding the concrete filled hollow thin wall component is characterized in that at least three templets in the mould are connected in turn side by side; at least one templet (1) is provided with at least one cross spacing mould (4) which is a partition; the cross partition (4) is connected with the templets in a movable way or detachable way. In this way, after the fasteners become loose, the cylindrical mould can be unloaded conveniently. When polyhedral components are produced, the mould can form concave structures on the polyhedral components, or be used for manufacturing connected or disconnected polyhedral components. Accordingly, the mould meets the requirements for production of various polyhedral components. In addition, the mould has the characteristics of simple structure, being manufactured easily, high strength, low cost and so on, which is applicable for manufacturing various open-end or closed-end polyhedral components.

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

The invention relates to a concrete-filled hollow thin-walled member forming mould which comprises templates (1), a joint and tight piece (2), and rotatable components (3). The templates (1) are connected by the rotatable components (3). The connected templates (1) can relatively rotate. After the templates (1) are folded, the templates are fixed by the joint and tight piece (2). The mould is characterized in that at least three templates (1) are sequentially connected with each other side by side in the mould; wherein, a projection (4) or sand strip (5) protruding the surface of the templates is arranged on at least one of the three templates. A hole or a stitch (7) is arranged on the projection (4) or the sand strip (5). At least one of a gemel, a hinge, a bolt hinge, a film, a rotatable tenon, a rotatable slot or a rotatable jack, a rotatable bolt, a rotatable connector pin and a rotatable sliding bush serves as the rotatable components (3). Therefore, a very convenient demoulding can be ensured after the joint and tight piece is loosed; at the same time, a concave structure can be correspondingly formed on the polyhedron members during the production of polyhedron members, thus meeting requirements for a variety of hollow floor systems; furthermore, the mould is characterized by simple structure, easy manufacture, high intensity, low cost, etc., and is suitable for manufacturing a variety of open or closed polyhedral components.

Owner:湖南邱则有专利战略策划有限公司

Die in user for molding component of concrete filled double thin wall

InactiveCN1727151BQuick assemblyQuick dismantlingMould separation apparatusMouldsEngineeringUltimate tensile strength

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

The invention relates to a concrete-filled hollow thin-walled member forming mould which comprises templates (1), a joint and tight piece (2), and rotatable components (3). The templates (1) are connected by the rotatable components (3). The connected templates (1) can relatively rotate. After the templates (1) are folded, the templates are fixed by the joint and tight piece (2). The mould is characterized in that at least three templates (1) are sequentially connected with each other side by side in the mould; wherein, a projection (4) or sand strip (5) protruding the surface of the templates is arranged on at least one of the three templates. The projection (4) or the sand strip (5) is fixedly or movably connected with the templates (4) or the sand strip (5) is parallel to or vertical to the rotatable axes of the rotatable components (3). At least one of a gemel, a hinge, a bolt hinge, a film, a rotatable tenon, a rotatable slot or a rotatable jack, a rotatable bolt, a rotatable connector pin and a rotatable sliding bush serves as the rotatable components (3). Therefore, a very convenient demoulding can be ensured after the joint and tight piece is loosed; at the same time, a concave structure can be correspondingly formed on the polyhedron members during the production of polyhedron members, thus meeting requirements for a variety of hollow floor systems; furthermore, the mould is characterized by simple structure, easy manufacture, high intensity, low cost, and the like, and is suitable for manufacturing a variety of open or closed polyhedral components.

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

Owner:湖南邱则有专利战略策划有限公司

Die in user for molding component of concrete filled double thin wall

InactiveCN1727151AQuick assemblyQuick dismantlingMould separation apparatusMouldsEngineeringThin walled

Owner:湖南邱则有专利战略策划有限公司

Mold for molding hollow thin wall component for filling concrete

Owner:湖南邱则有专利战略策划有限公司

Die in use for molding component of concrete filled double thin wall

InactiveCN1727156AQuick assemblyQuick dismantlingMould separation apparatusMouldsEngineeringThin walled

Owner:邱则有

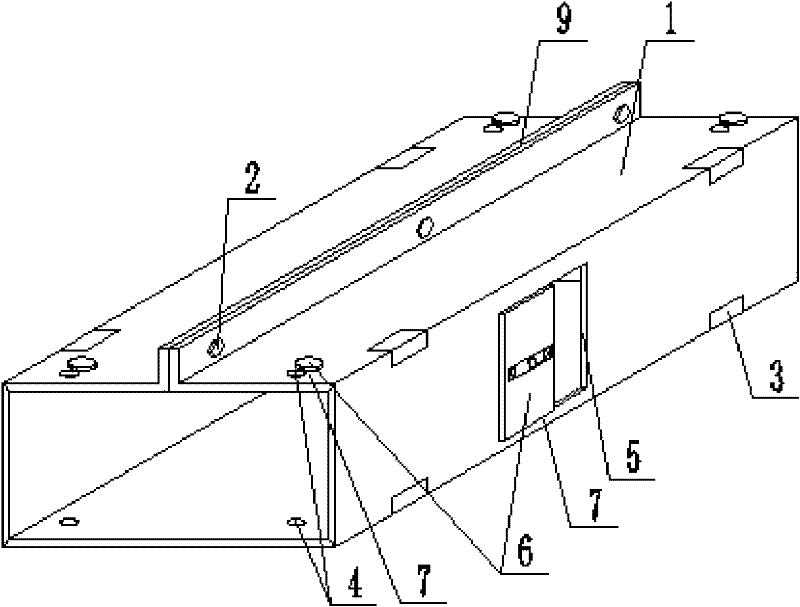

Mould for molding concrete filled hollow thin wall component

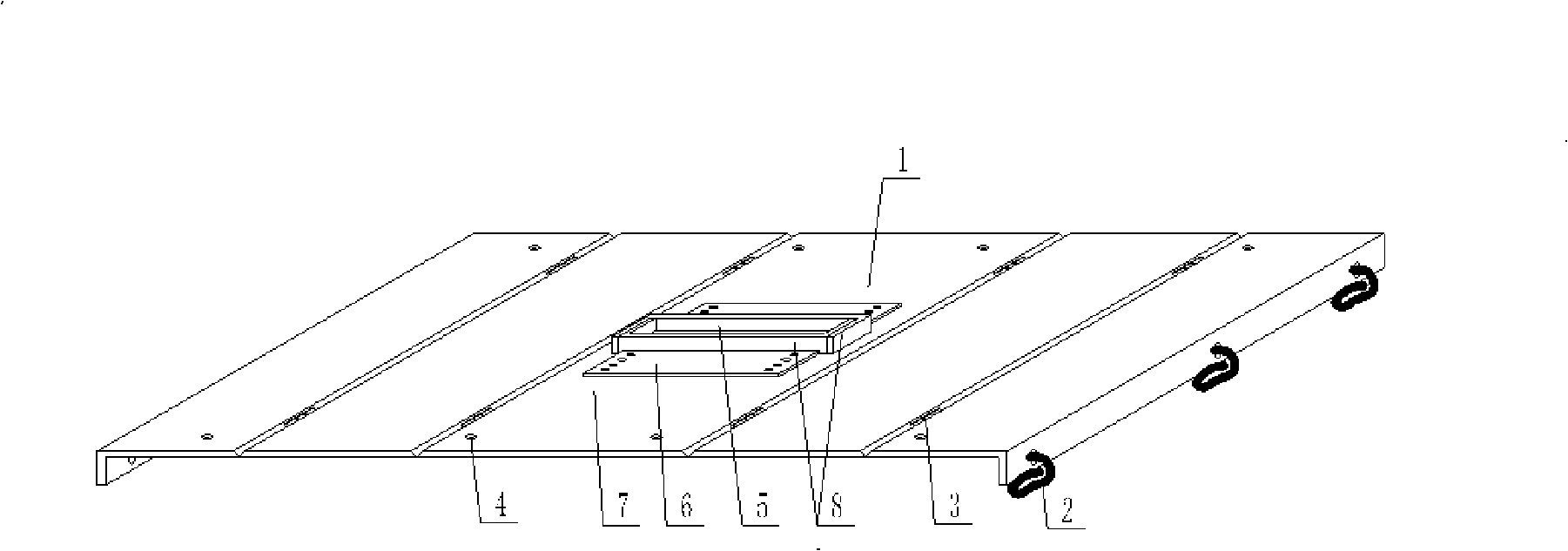

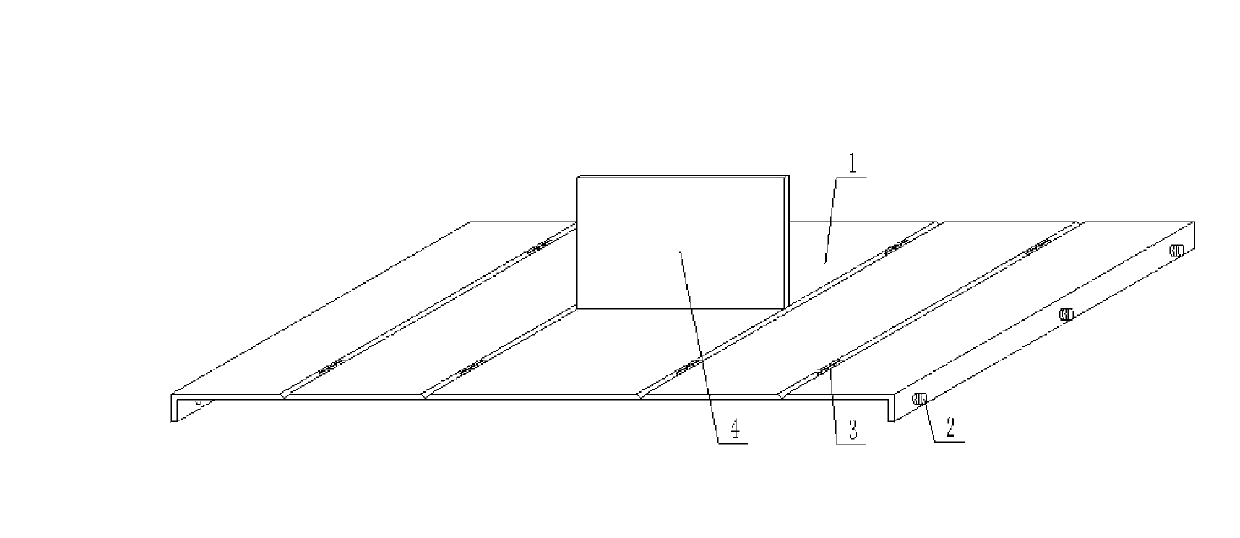

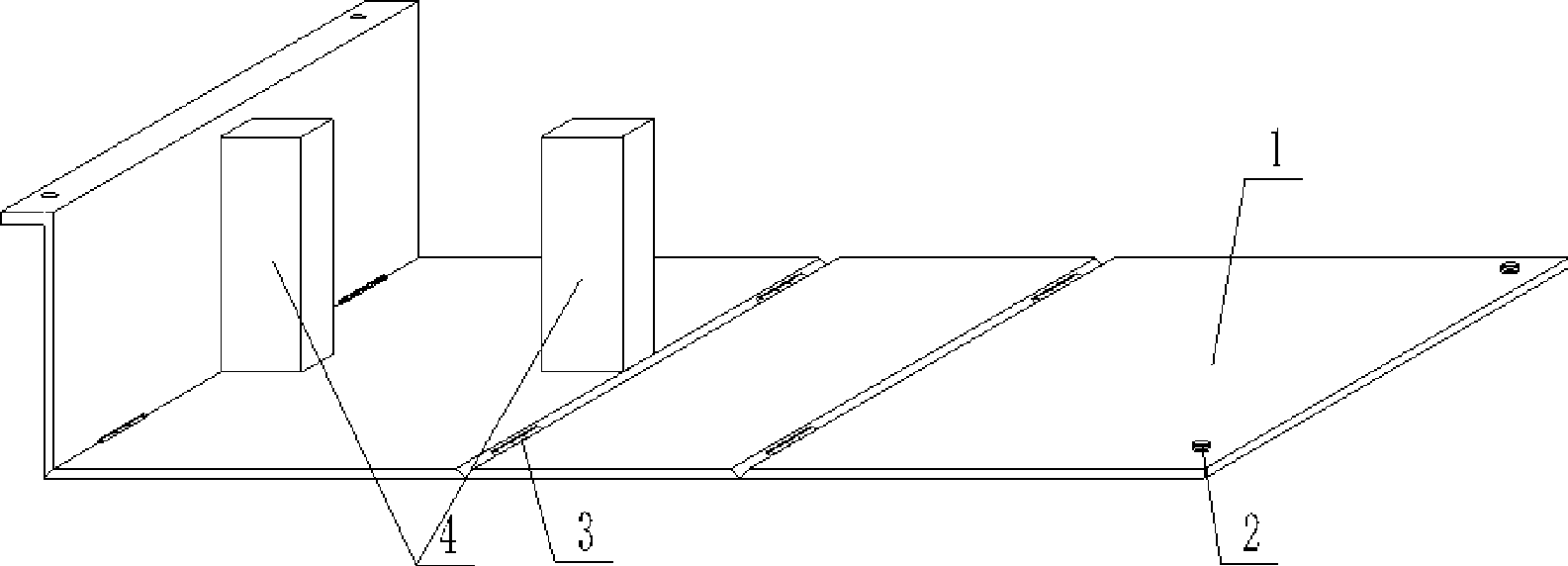

The invention provides a mould for moulding a concrete filled hollow thin wall component, which comprises templets (1), fasteners (2) and rotary components (3). The templets (1) are connected with each other by the rotary components (3); the connected templets (1) can turn relatively; after the templets are folded, the fasteners (2) fix the templets (1). The mould for moulding the concrete filled hollow thin wall component is characterized in that at least three templets in the mould are connected in turn side by side; at least one templet (1) is provided with at least one cross spacing mould (4) which consists of at least two movable components (5) through assembly; the surface of the cross spacing mould is a moulding surface. In this way, after the fasteners become loose, the mould can be unloaded conveniently. When polyhedral components are produced, the mould can form concave structures on the polyhedral components, or be used for manufacturing connected or disconnected polyhedral components. Accordingly, the mould meets the requirements for producing various polyhedral components. In addition, the mould has the characteristics of simple structure, being manufactured easily, high strength, low cost and so on, which is applicable for manufacturing various open-end or closed-end polyhedral components.

Owner:湖南邱则有专利战略策划有限公司

Polyhedral member shaping mould

InactiveCN102172986BEasy to splitEasy to assembleMould separation apparatusMouldsComposite materialHinge angle

Owner:湖南邱则有专利战略策划有限公司

Polyhedron component molding mould

Owner:湖南邱则有专利战略策划有限公司

Die in use for molding component of concrete filled double thin wall

InactiveCN1727157AQuick assemblyQuick dismantlingMould separation apparatusMouldsConvex structureEngineering

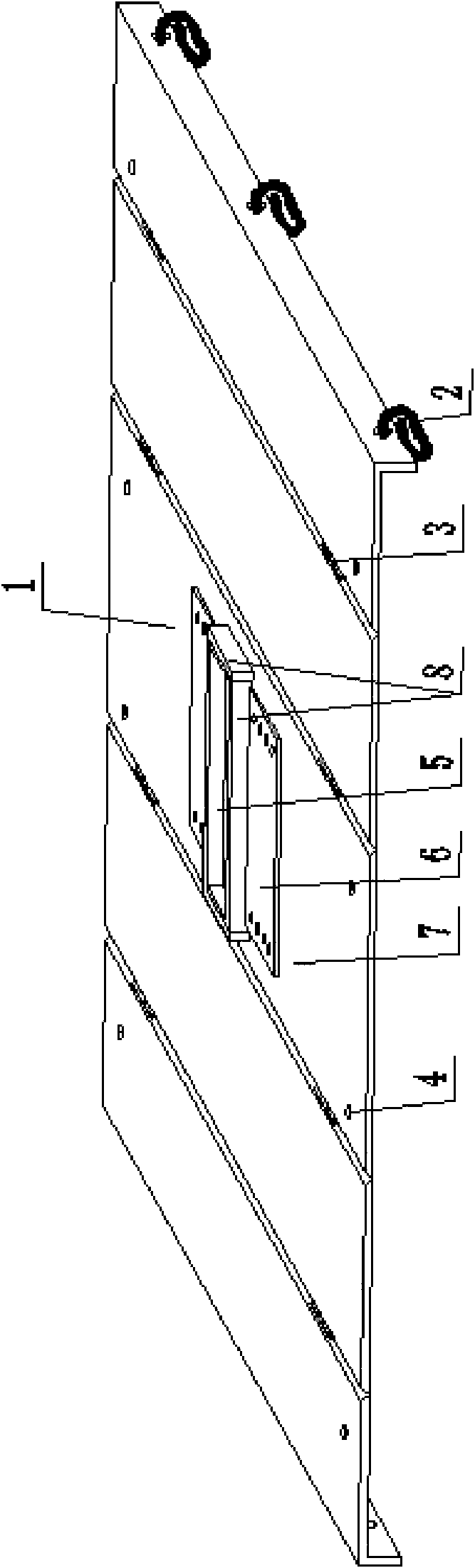

A mould for forming the thin-wall hollow concrete member is composed of the form boards, the turnable parts for connecting the form boards in turnable mode, and the fasteners for fastening the closed form boards. It features that at least 3 form boards are sequentially connected and at least one form board has the concave block or strip for generating convex structure on the product. Its advantages are convenient demoulding and high strength.

Owner:邱则有

Mold for molding hollow thin wall component for filling concrete

A shaping die for a concrete-filled hollow thin-wall component includes templates (1), fasteners (2) and rotatable parts (3). The templates (1) are connected by the rotatable parts (3); the connected templates (1) can rotate oppositely; the templates (1) after being folded are fixed by the fasteners (2). The invention is characterized in that at least three templates (1) are connected in sequence side by side in the die; at least one template (1) is provided with at least one transverse isolating die (4); a hole (3) or a gap (7) is formed on the transverse isolating die (4); the surface of the transverse isolating die (4) is a shaping die surface. In this way, after the fasteners are loosened, the die is very convenient to be released; simultaneously, when a polyhedron component is produced, a concave structure can be correspondingly formed on the polyhedron component or a conjoined or non-conjoined polyhedron component is manufactured; the production requirements for different polyhedron components can be met; besides, the die is also characterized by simple structure, easy manufacture, high intensity, low cost, and the like. The shaping die for a concrete-filled hollow thin-wall component is applicable to manufacturing various opened or closed polyhedron components.

Owner:湖南邱则有专利战略策划有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com