Tower foot workpiece automatic welding system and method based on weld joint recognition

An automatic welding and workpiece technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low overall productivity, high labor intensity of workers, and waiting for development, so as to improve welding accuracy and obtain simple methods , The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

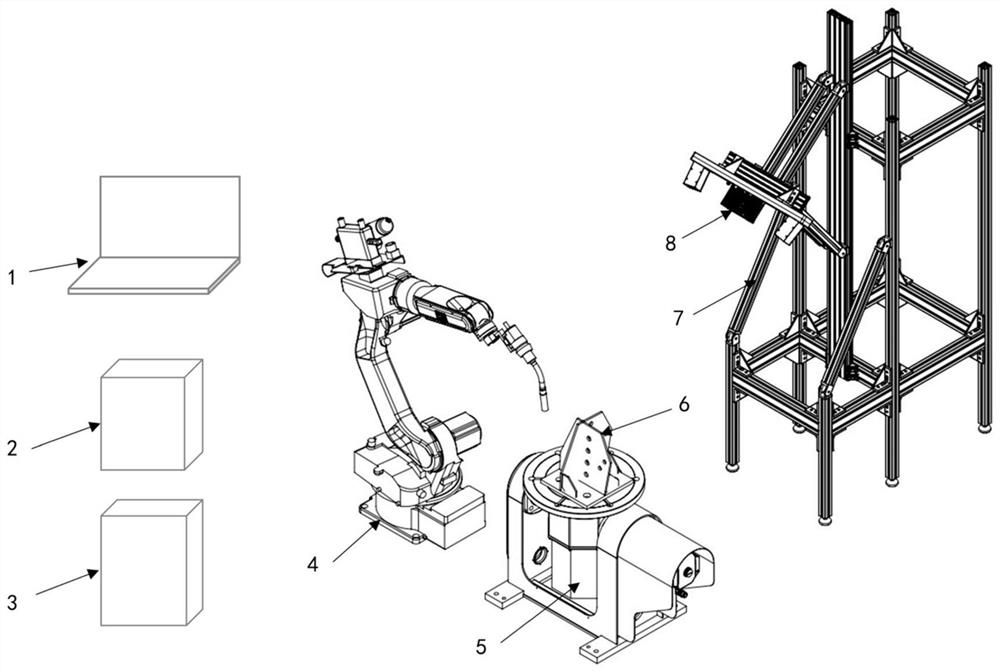

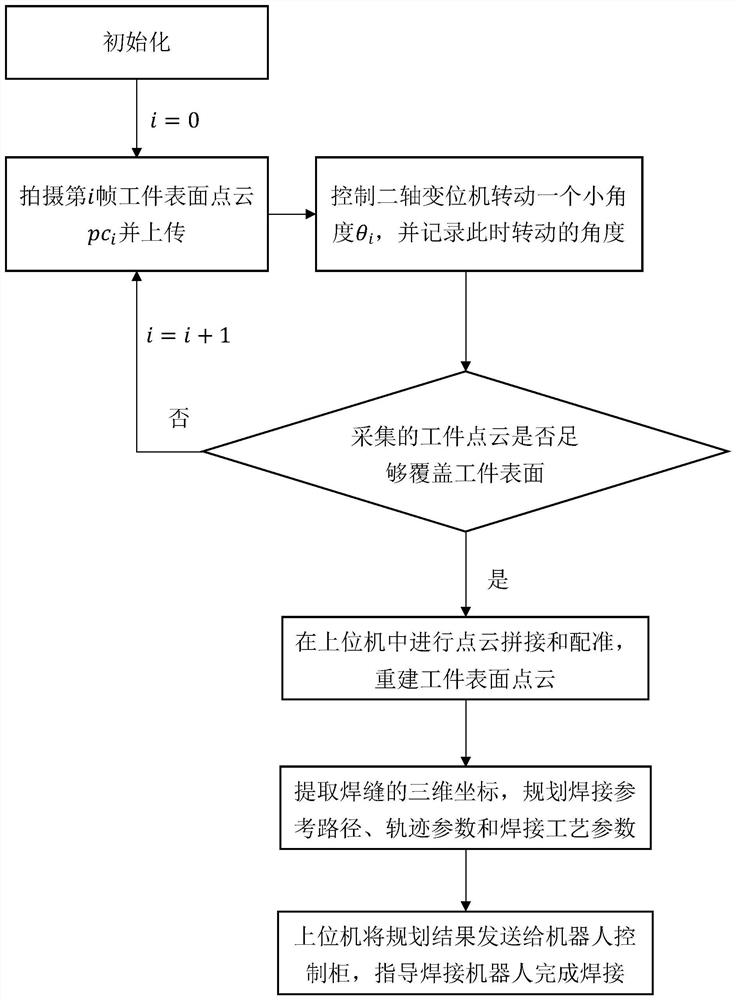

[0034] Such as figure 1 As shown, an automatic welding system for tower foot workpieces based on weld seam recognition includes: host computer 1, welding power supply 2, robot control cabinet 3, welding robot 4, two-axis positioner 5, welding workpiece 6, and scanning frame 7 and a 3D structured light camera8.

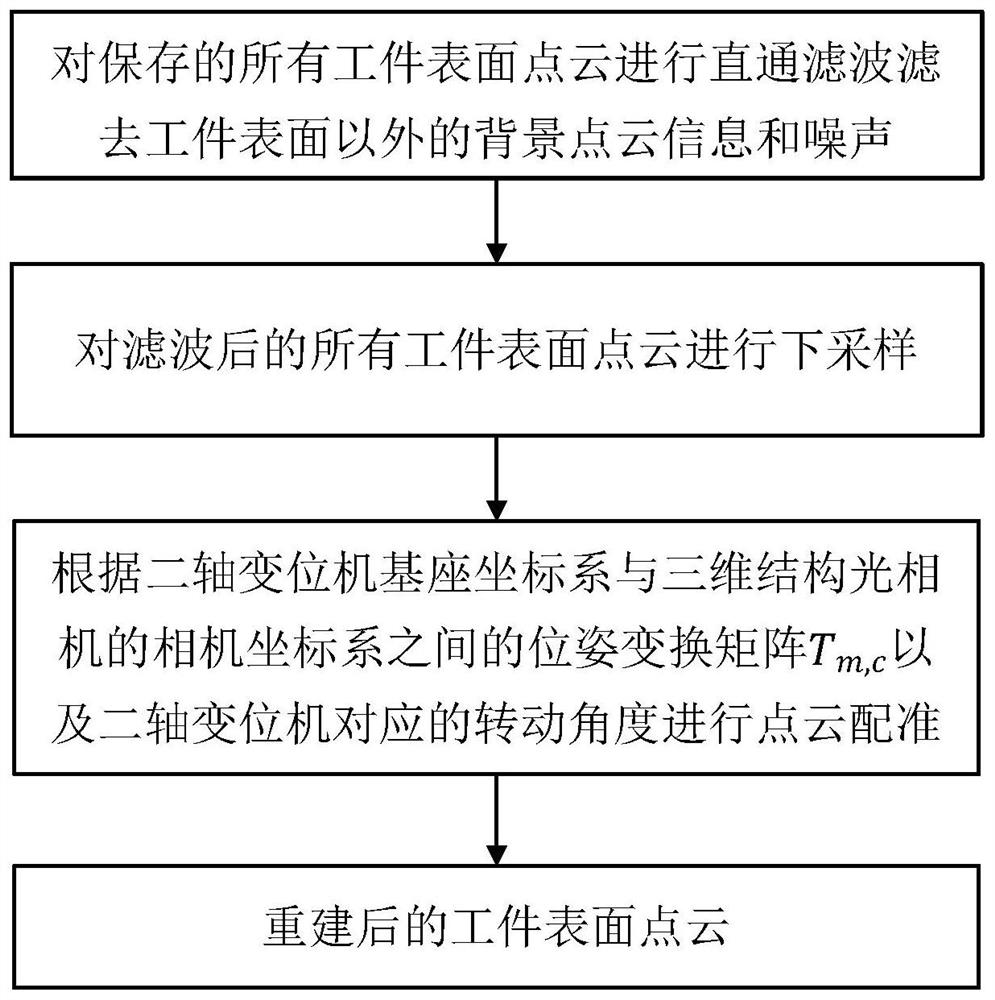

[0035] The host computer 1 is used to receive point cloud information of the workpiece surface captured by the three-dimensional structured light camera 8, perform point cloud stitching and workpiece surface reconstruction, and complete weld seam extraction and welding path planning of the welding robot 4. The welding power source 2 provides power for the robot control cabinet 3, the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com