Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

186results about "Engine with deformable working-chamber walls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

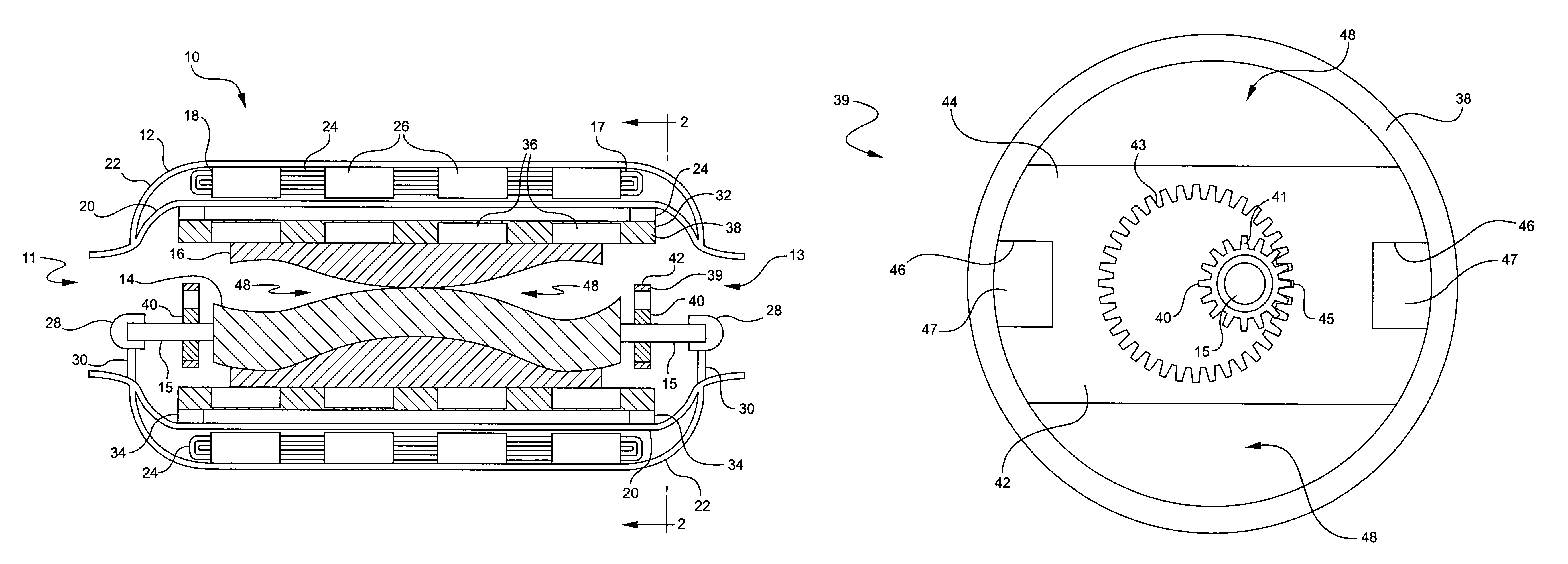

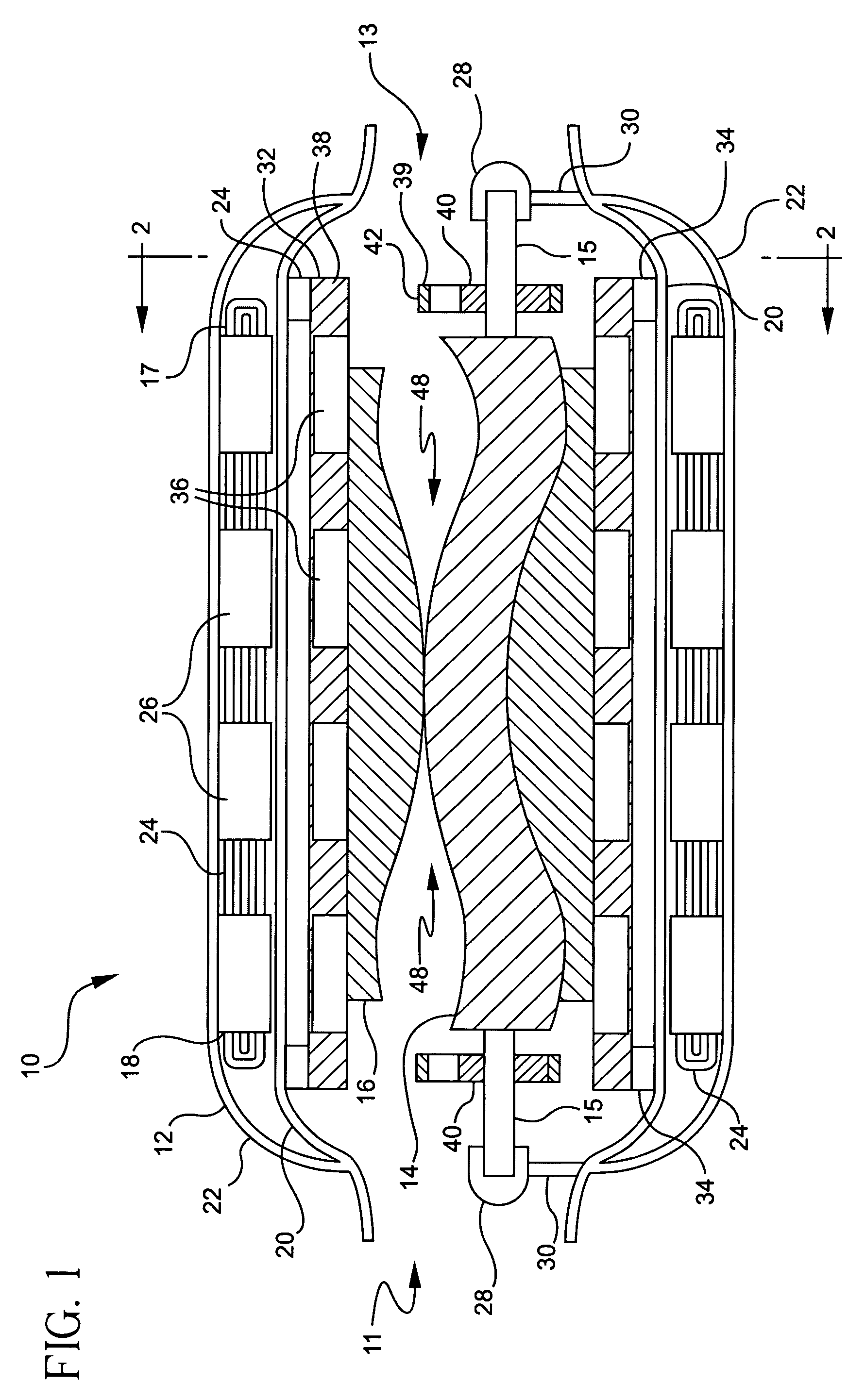

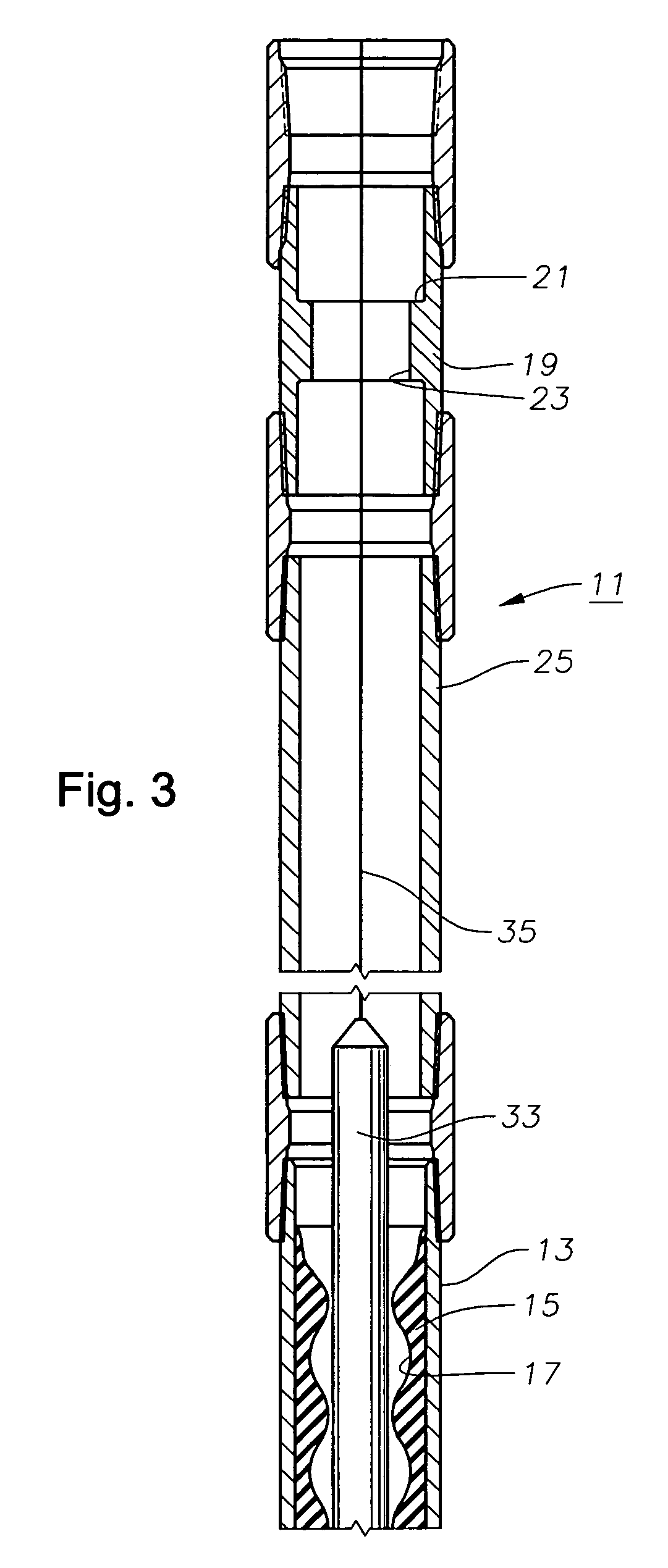

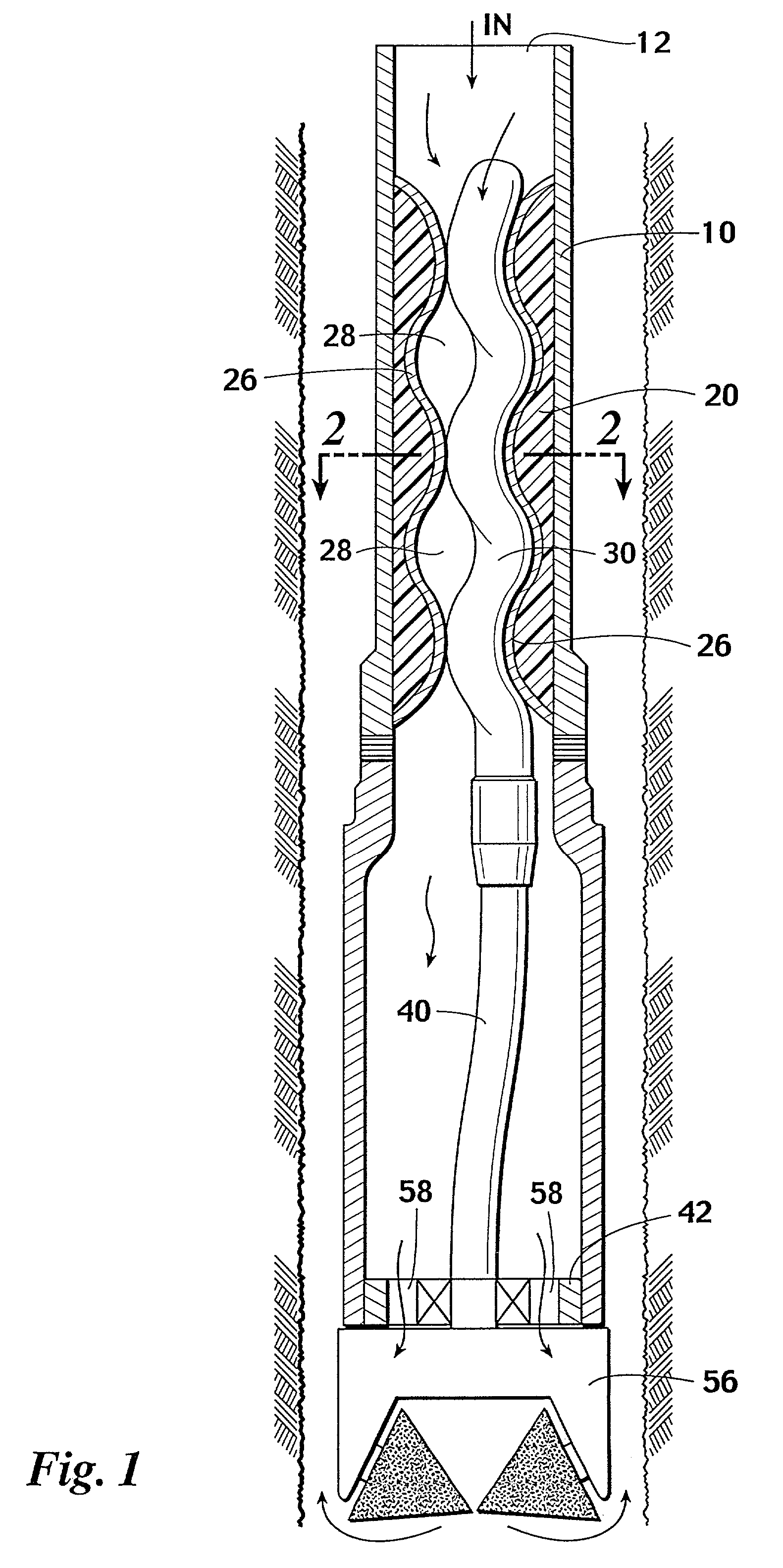

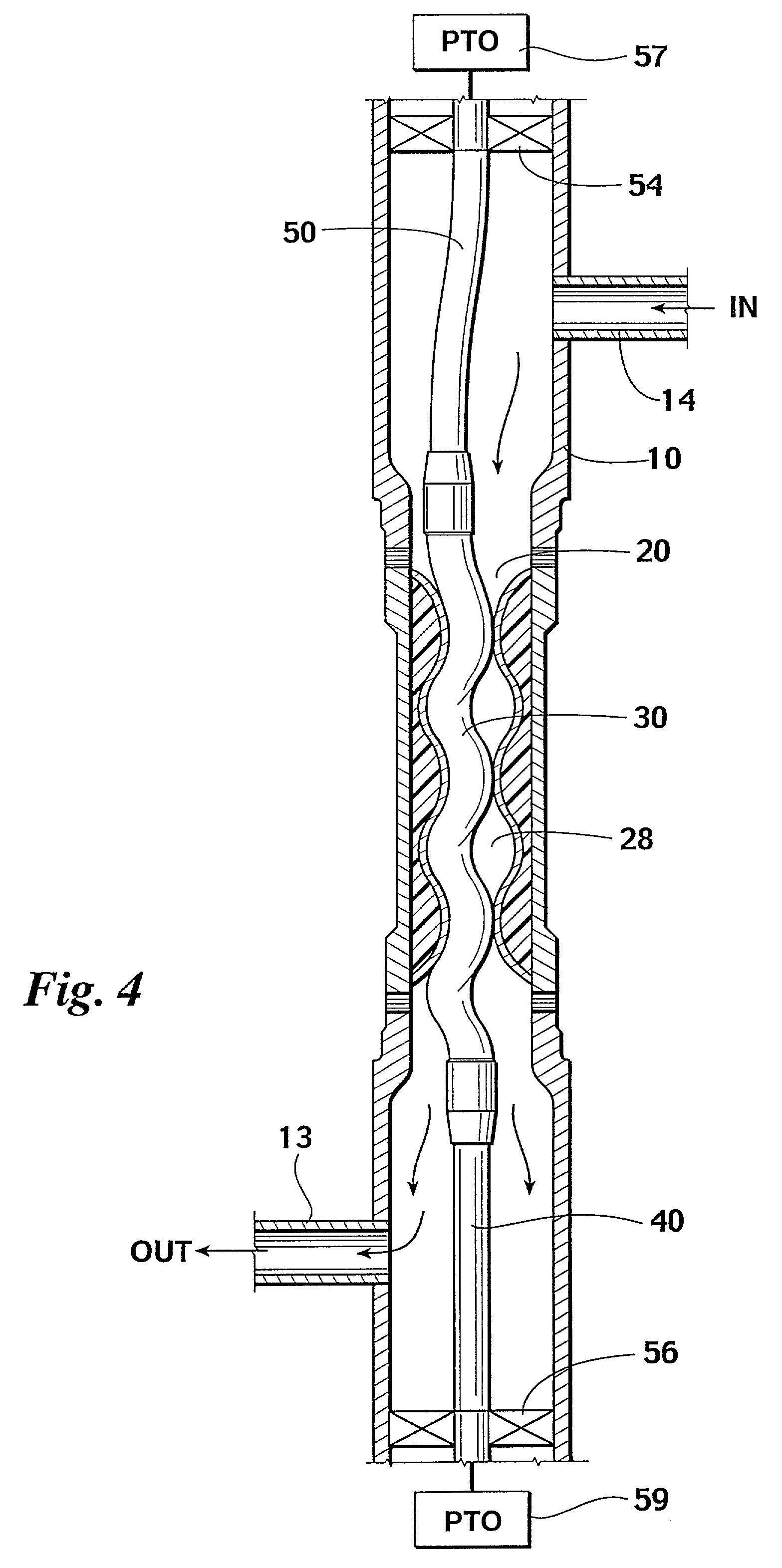

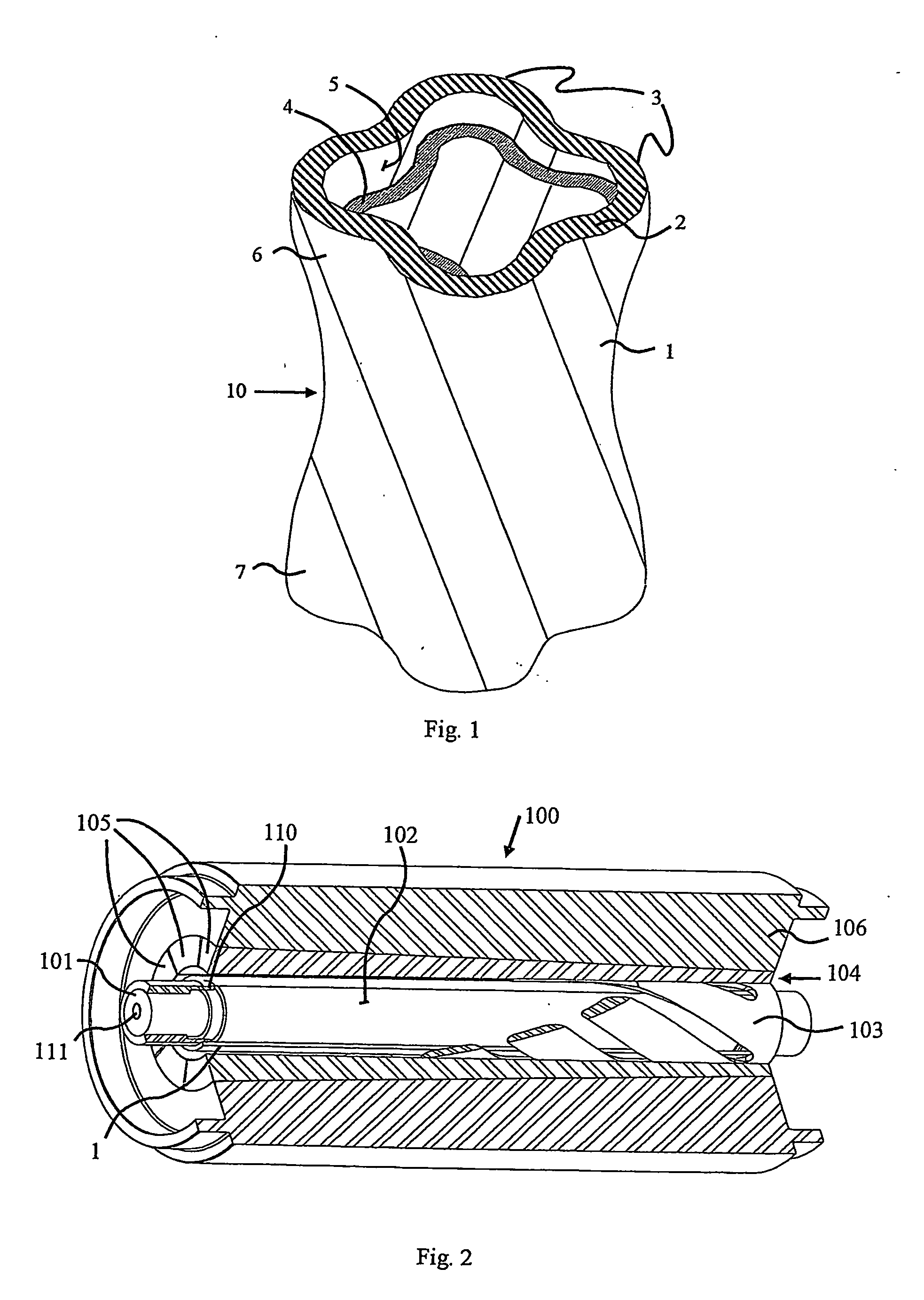

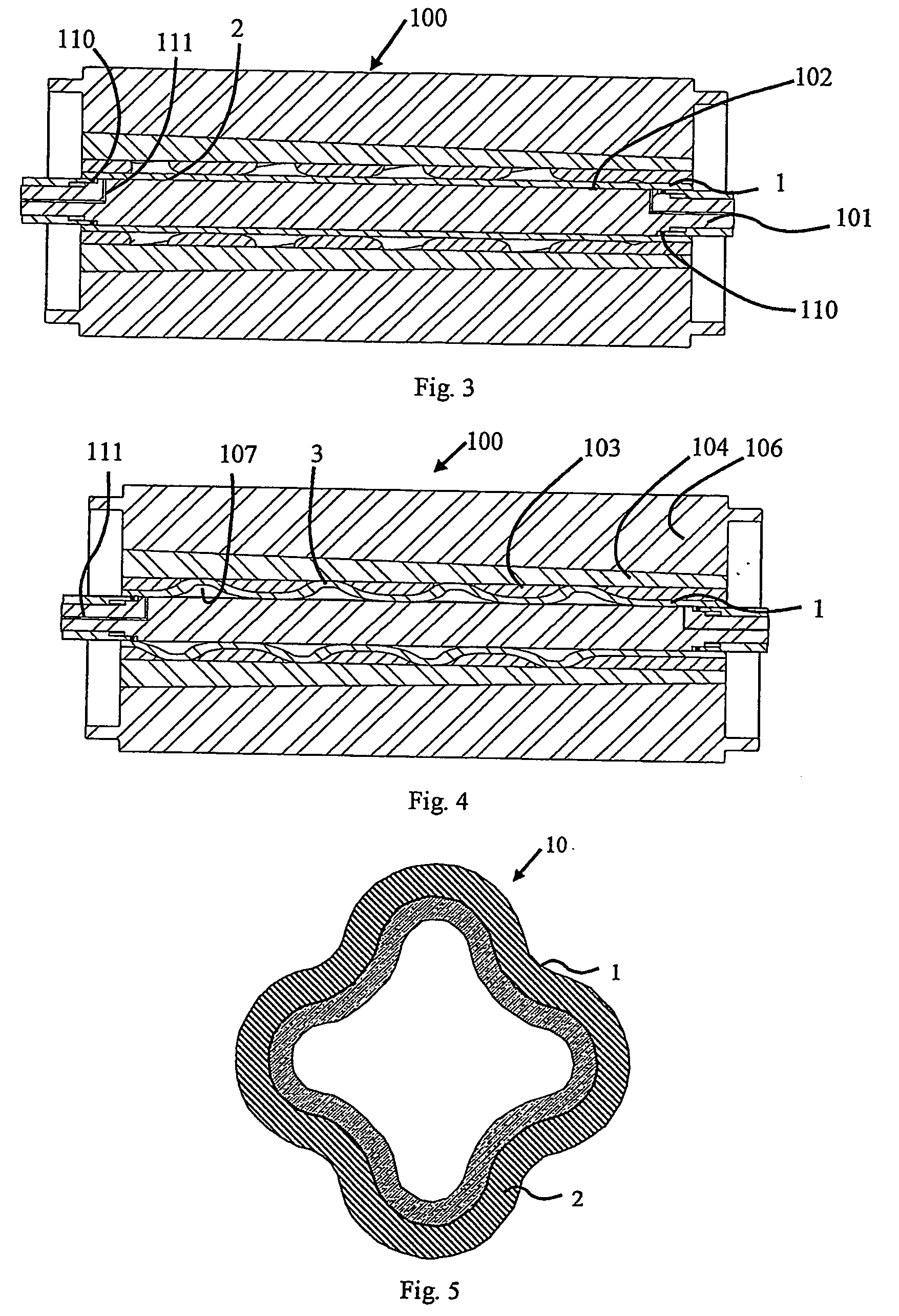

Direct drive linear flow blood pump

A ventricular assistive device (VAD) based on a progressive cavity pump includes a pump housing having an inlet and an outlet, a pump stator contained within the pump housing, a pump rotor rotatably disposed within the pump stator, a motor including a motor rotor contained within the pump housing and a direct drive means connected between the motor rotor and an axial shaft of the pump rotor for rotating the pump rotor. The motor rotates the motor rotor, which in turn rotates the pump rotor through the direct drive means. The rotation of the pump rotor within the pump stator forms a plurality of cavities that carry blood forward through the pump housing from the inlet to the outlet as the motor drives the direct drive means.

Owner:CHANG SHELDON

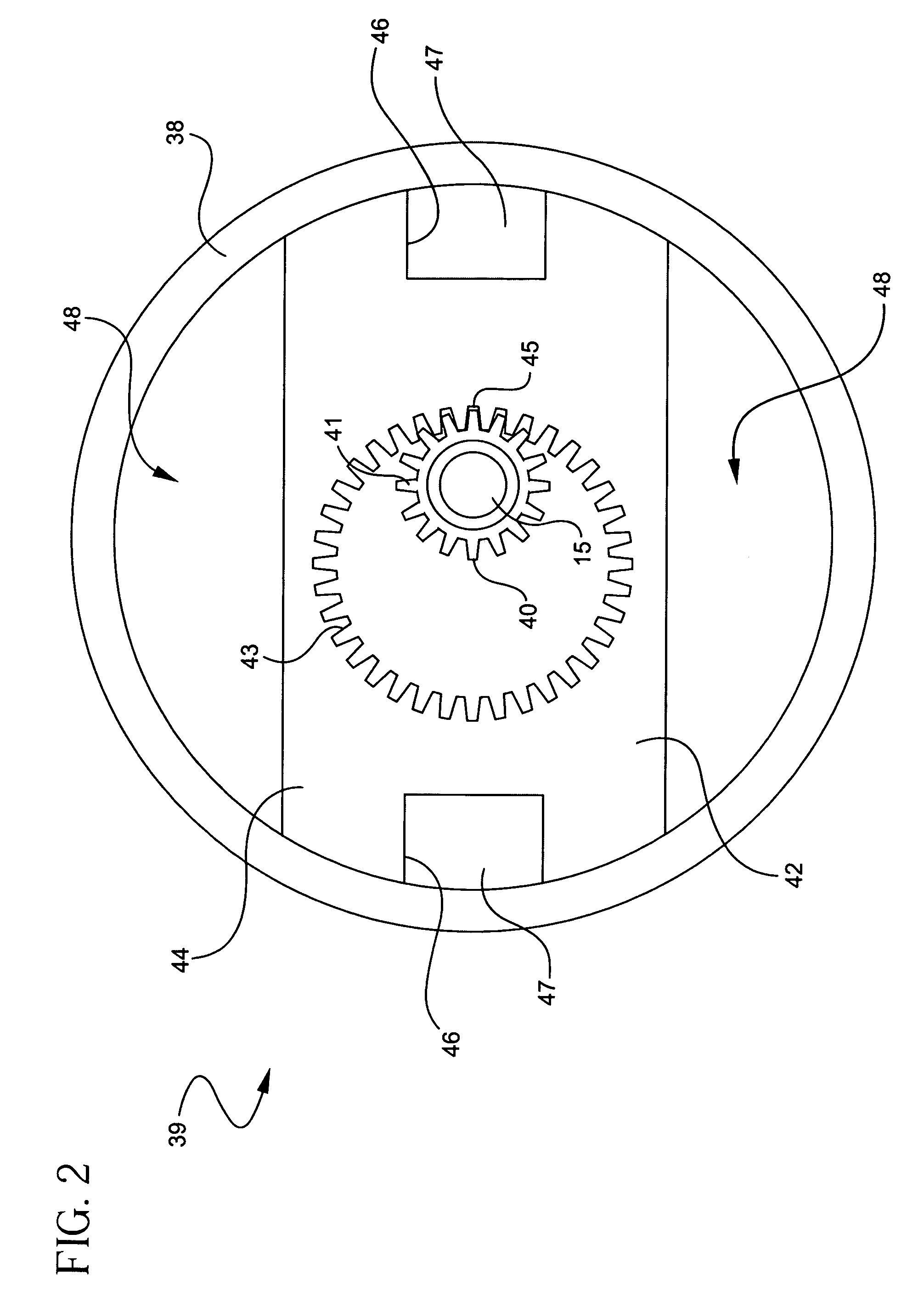

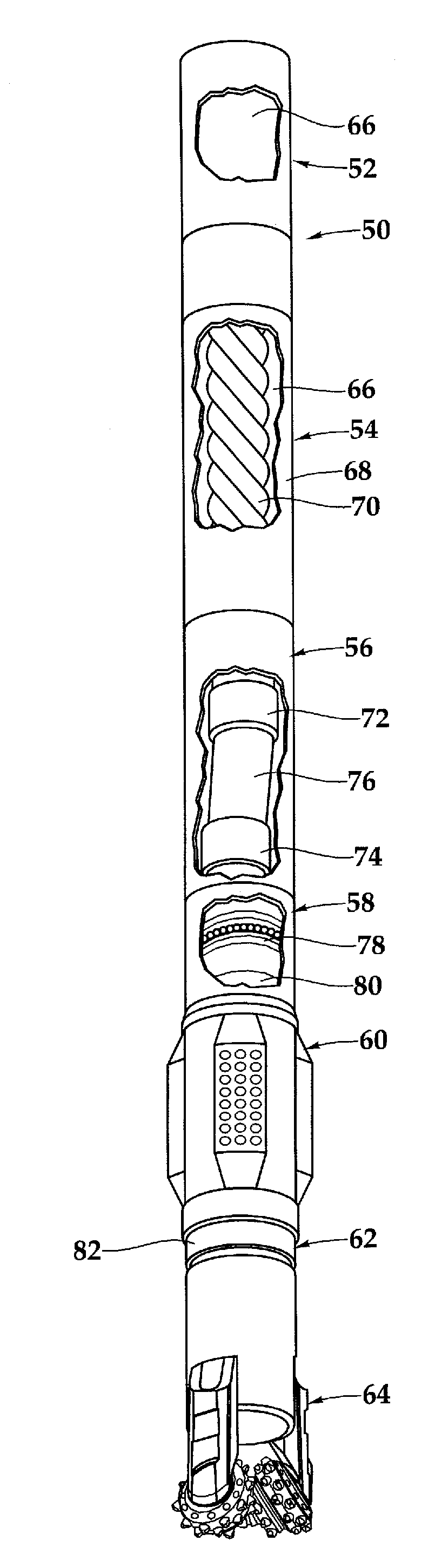

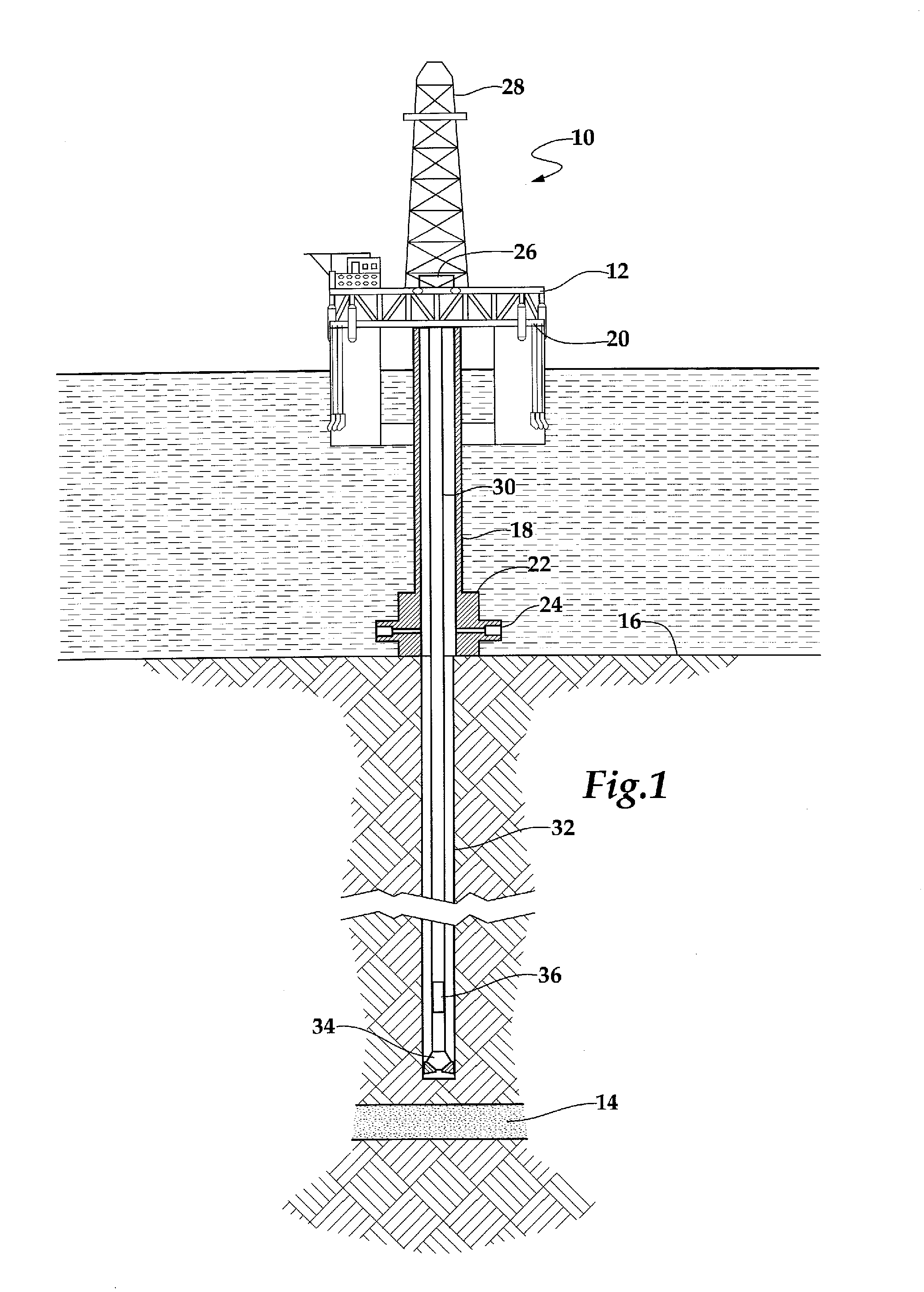

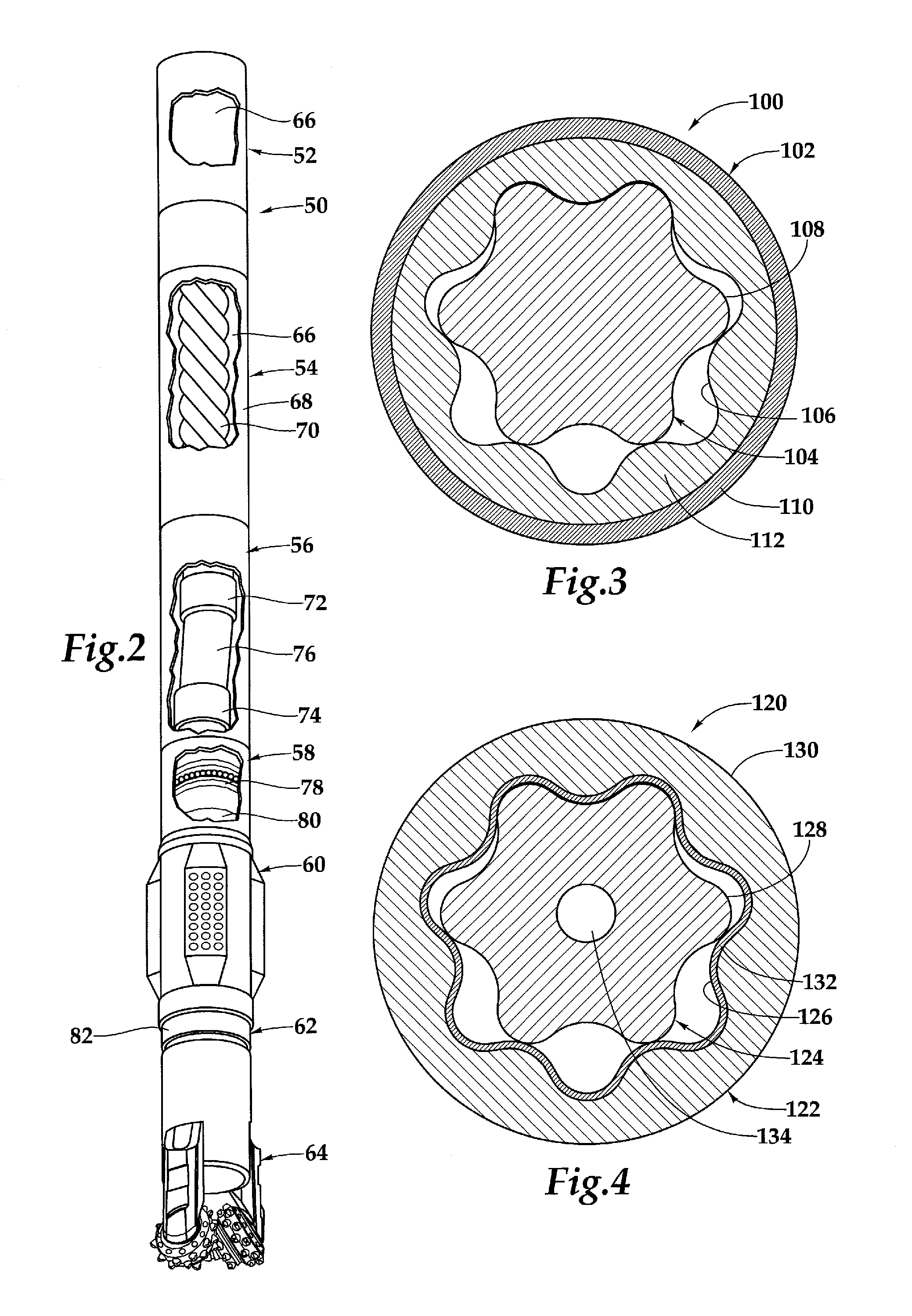

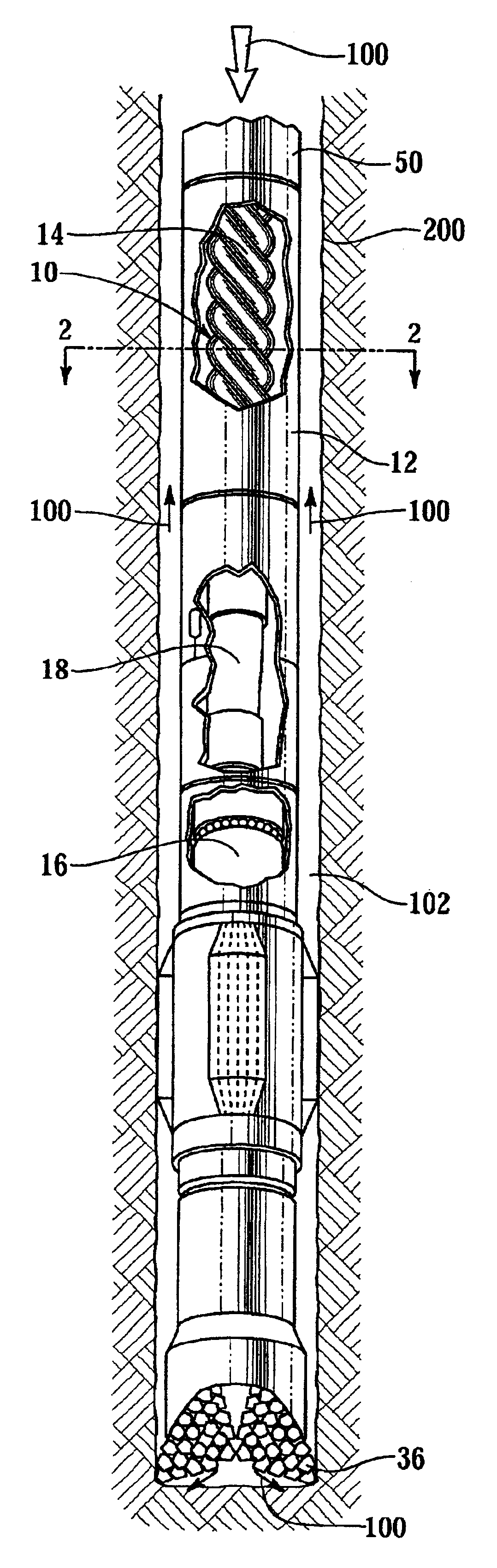

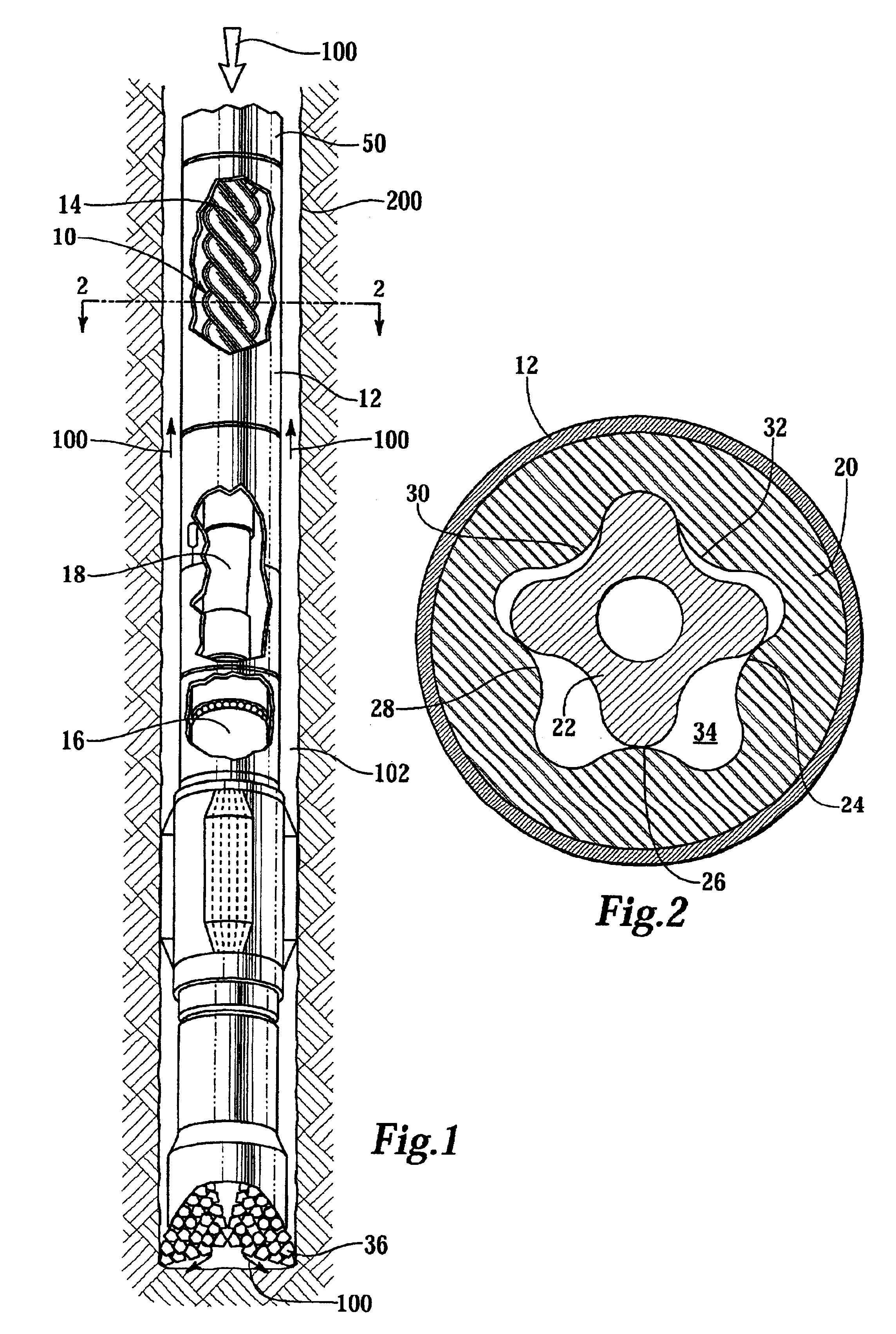

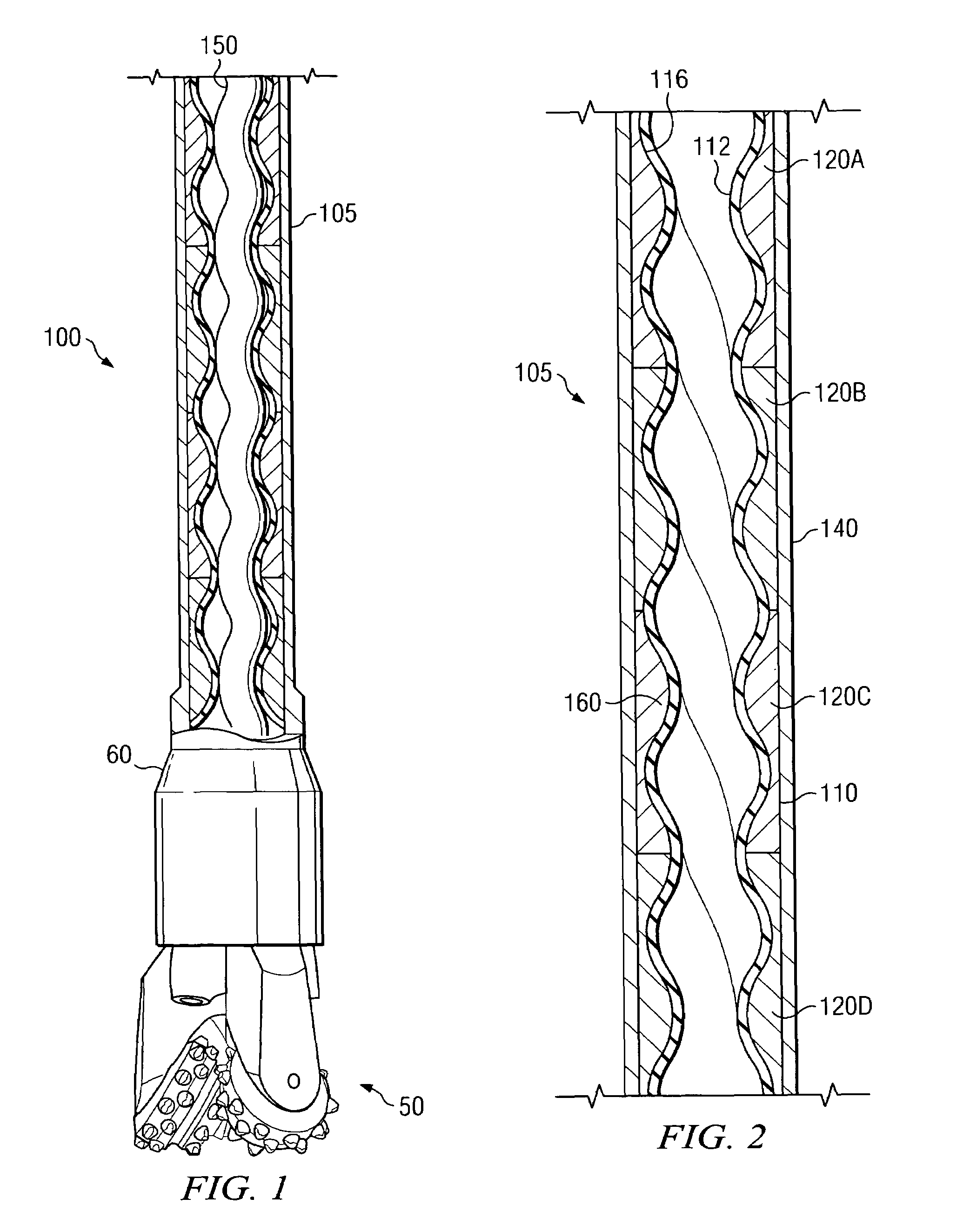

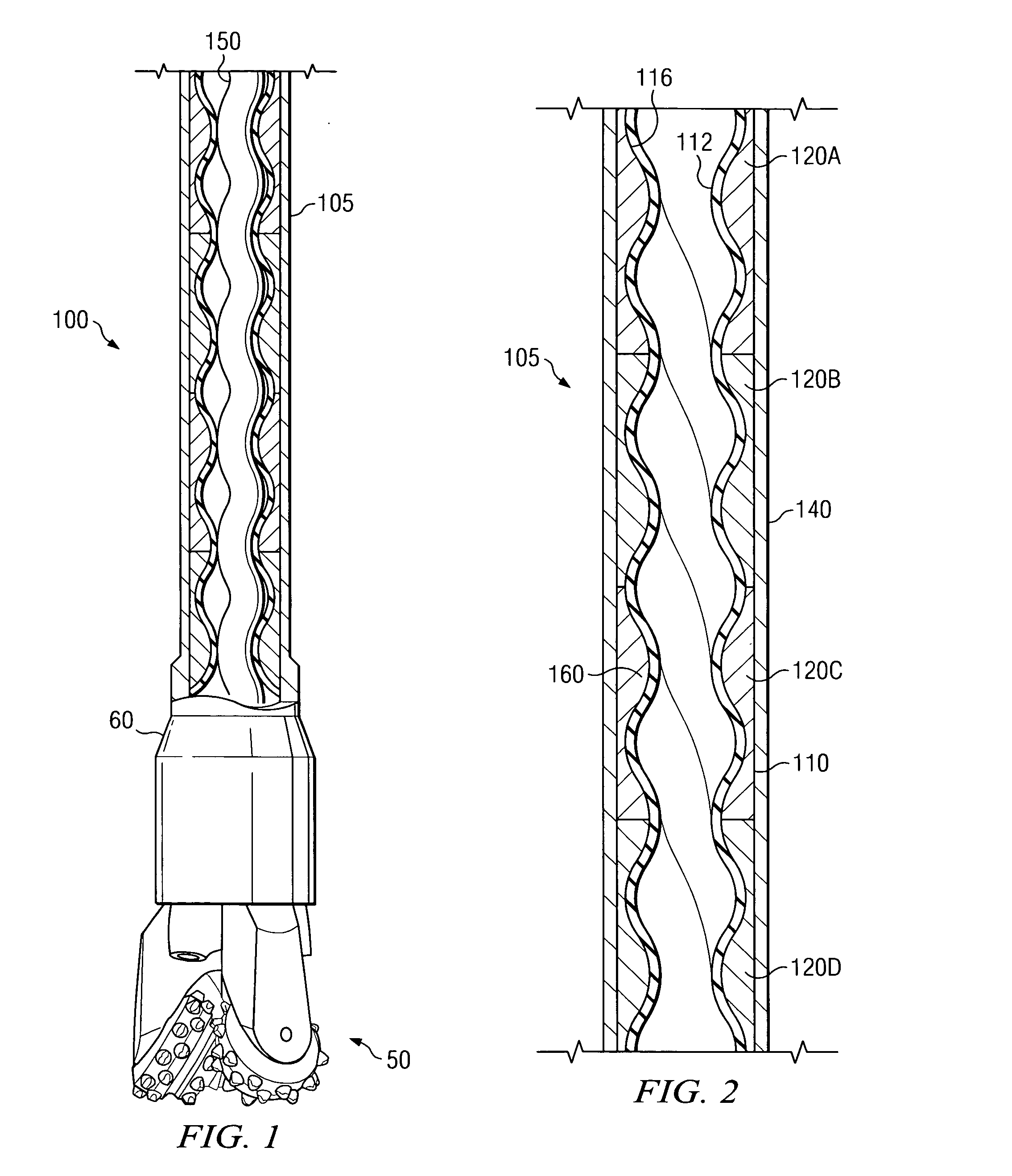

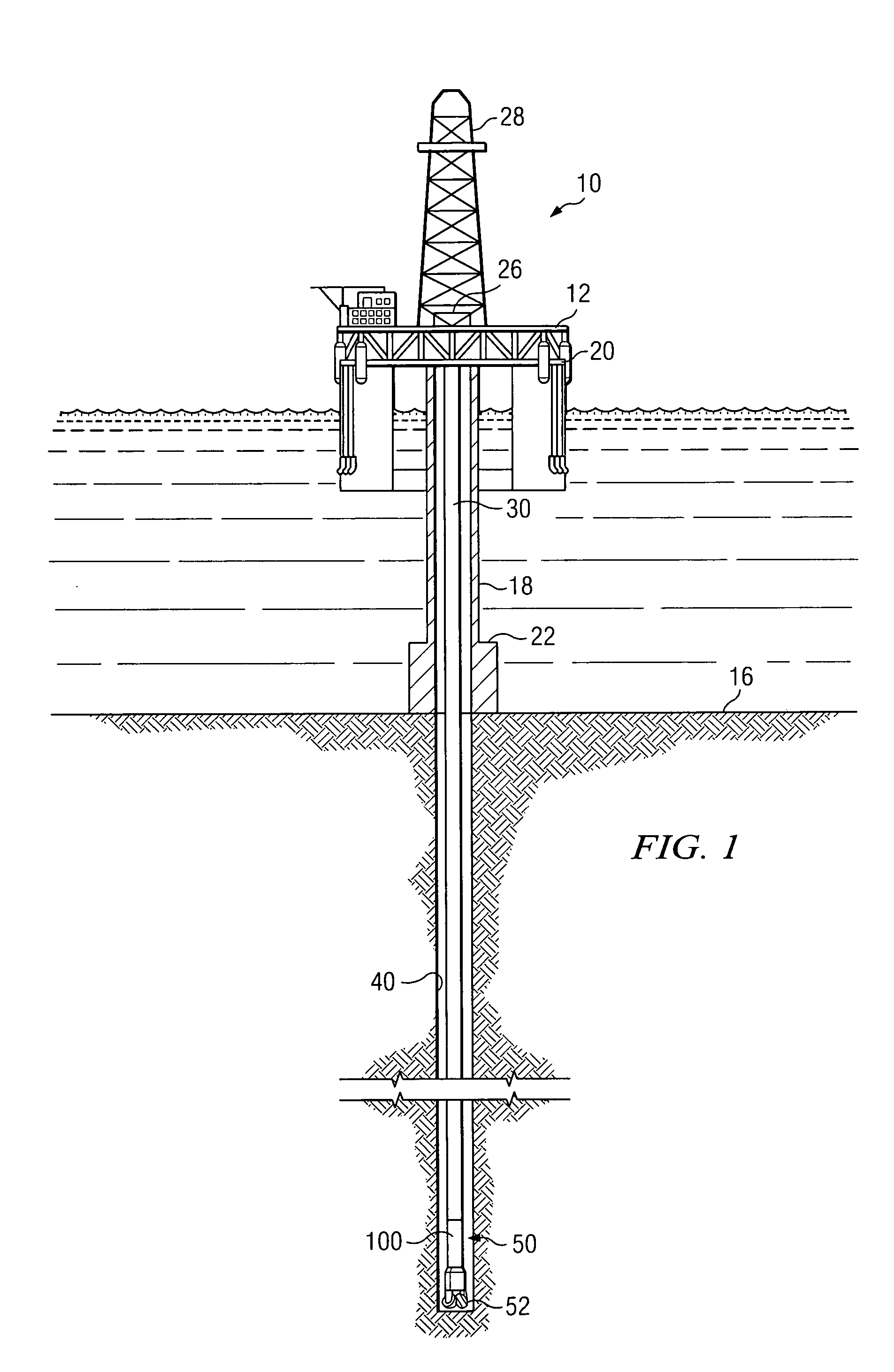

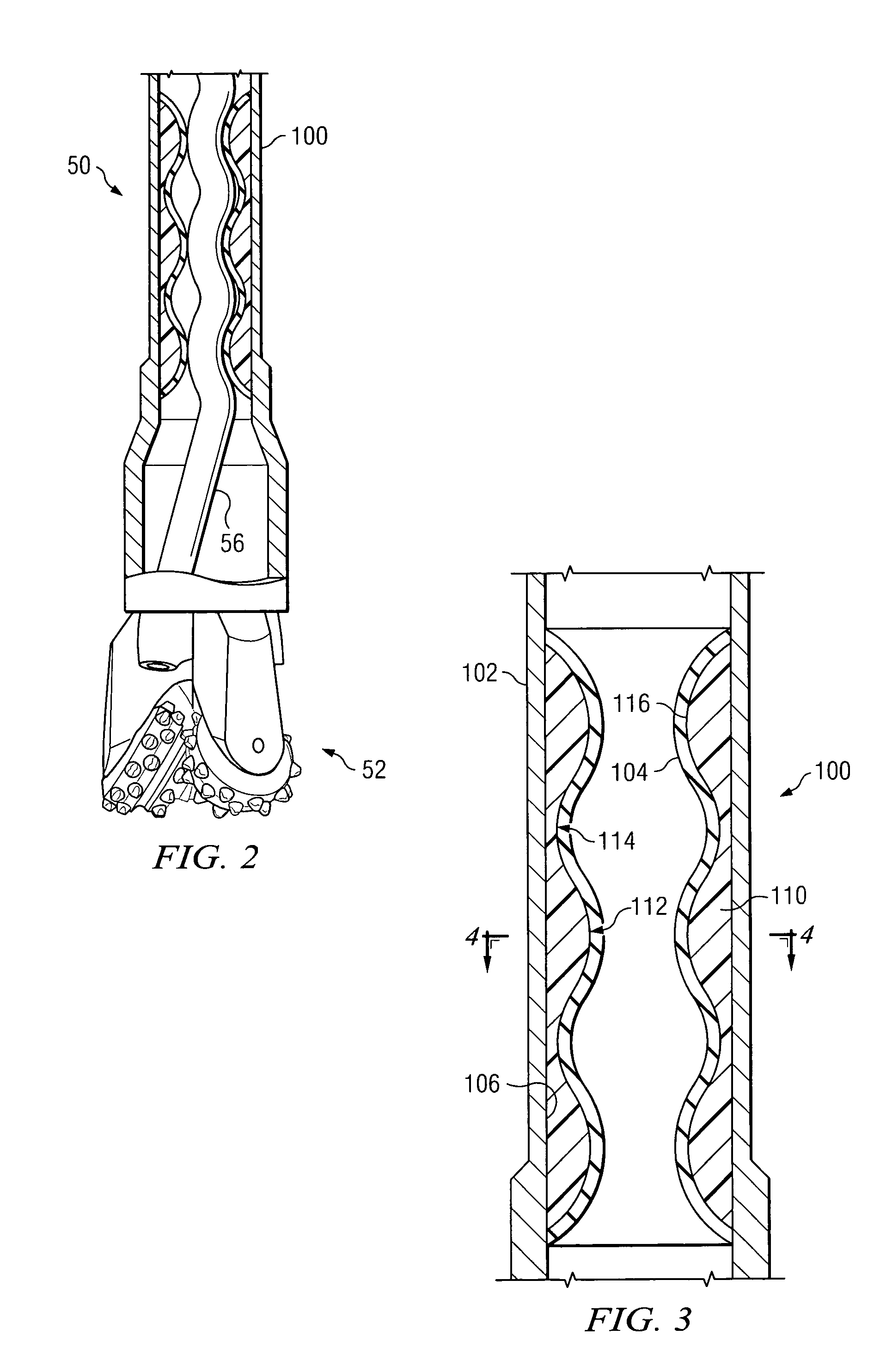

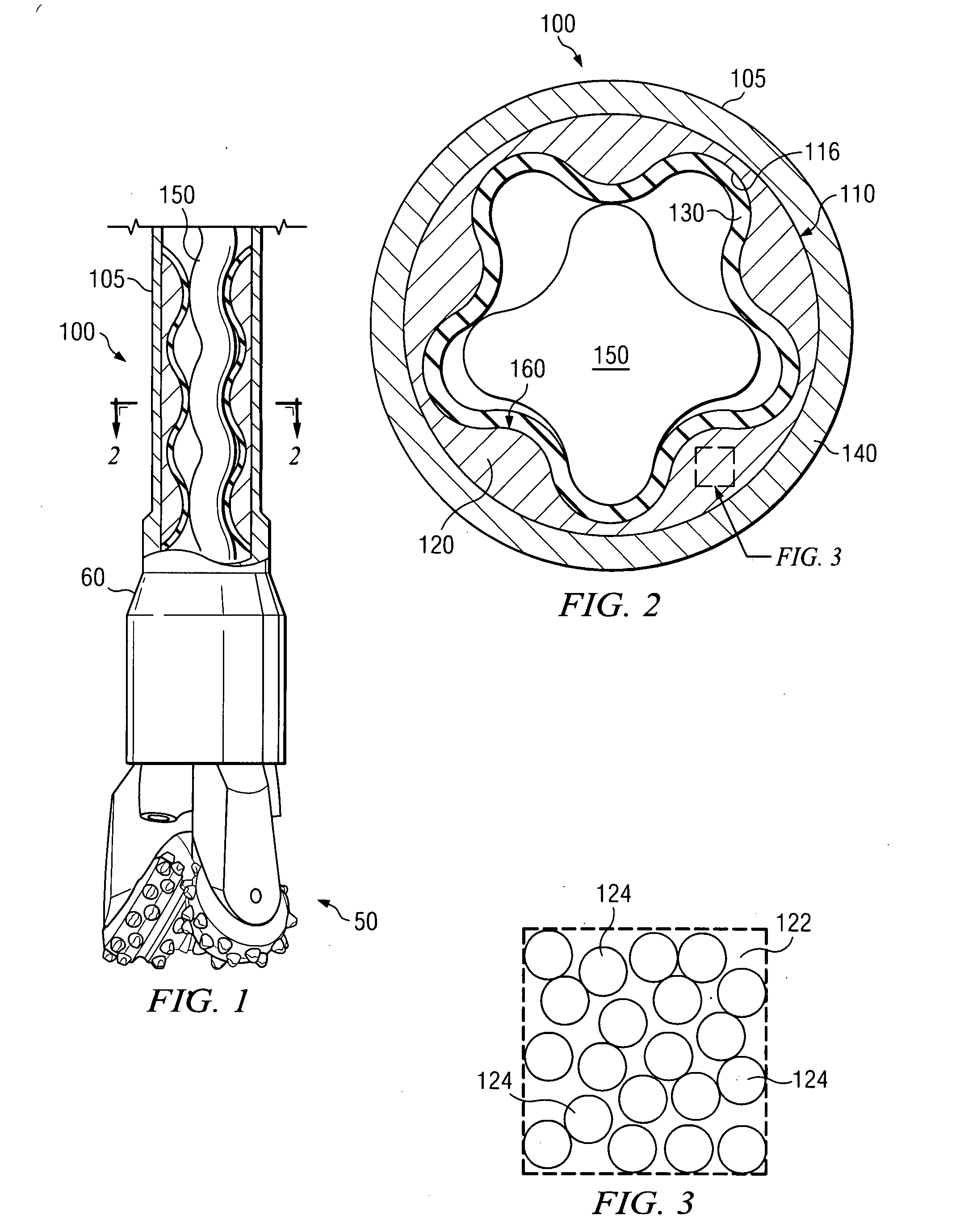

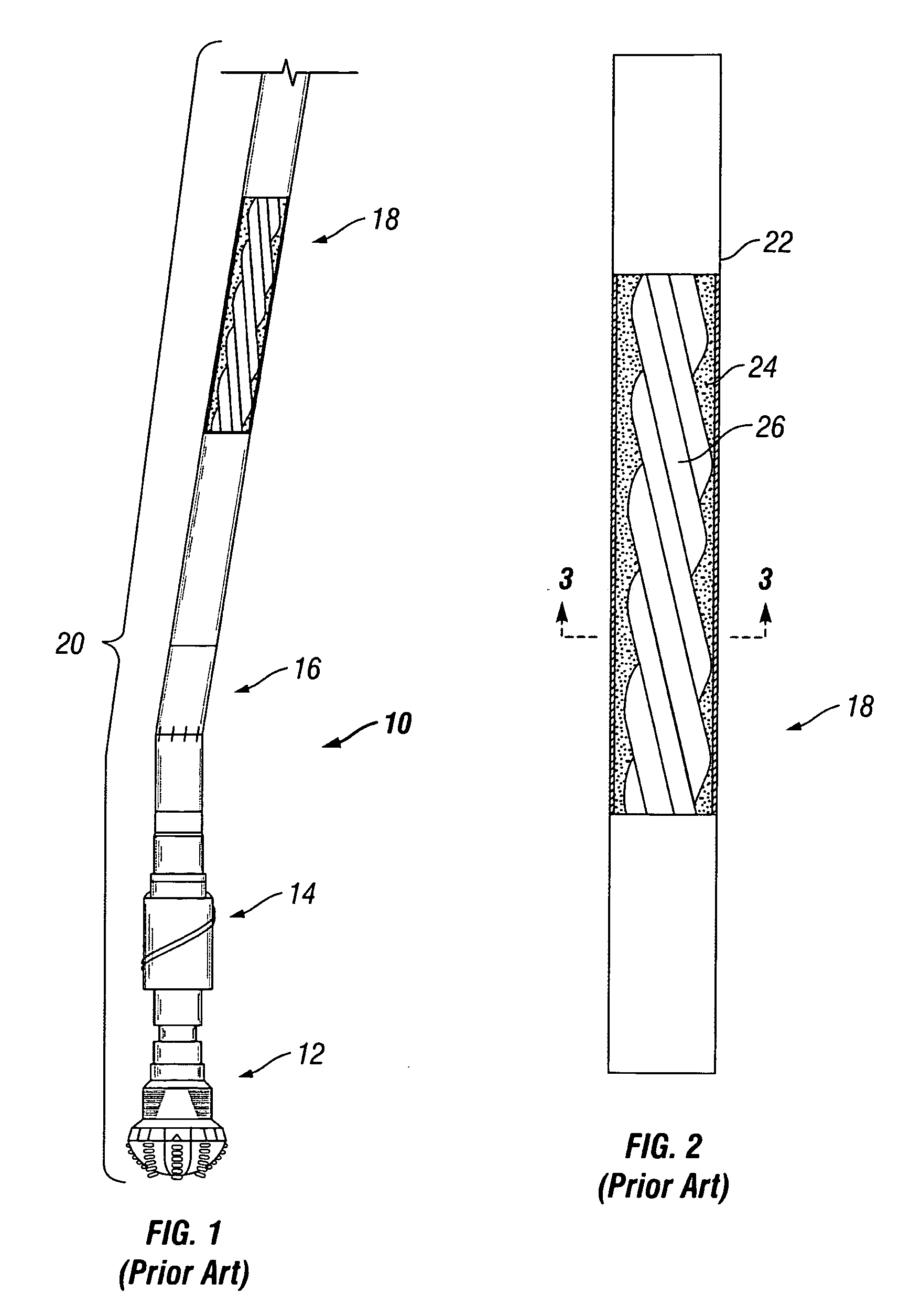

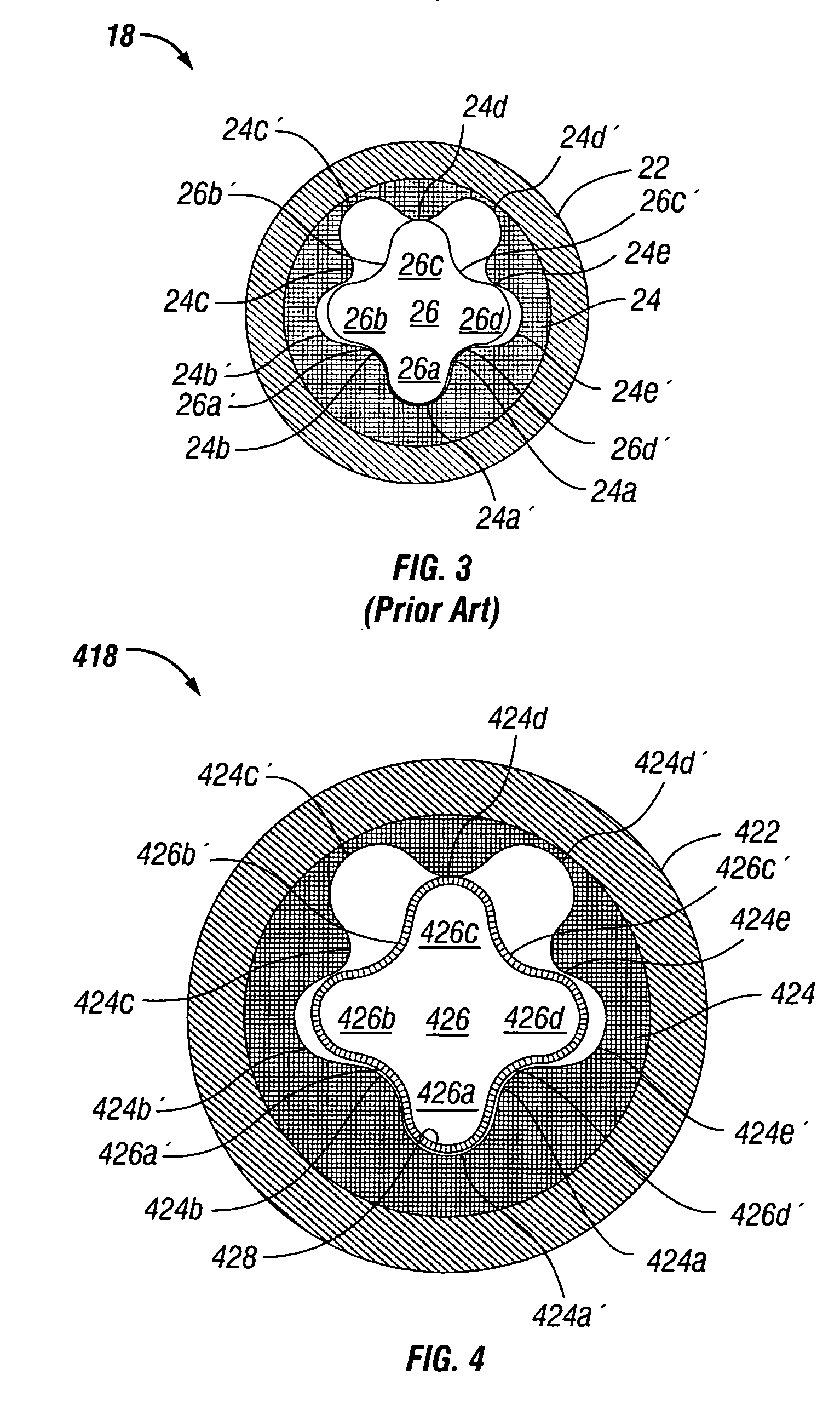

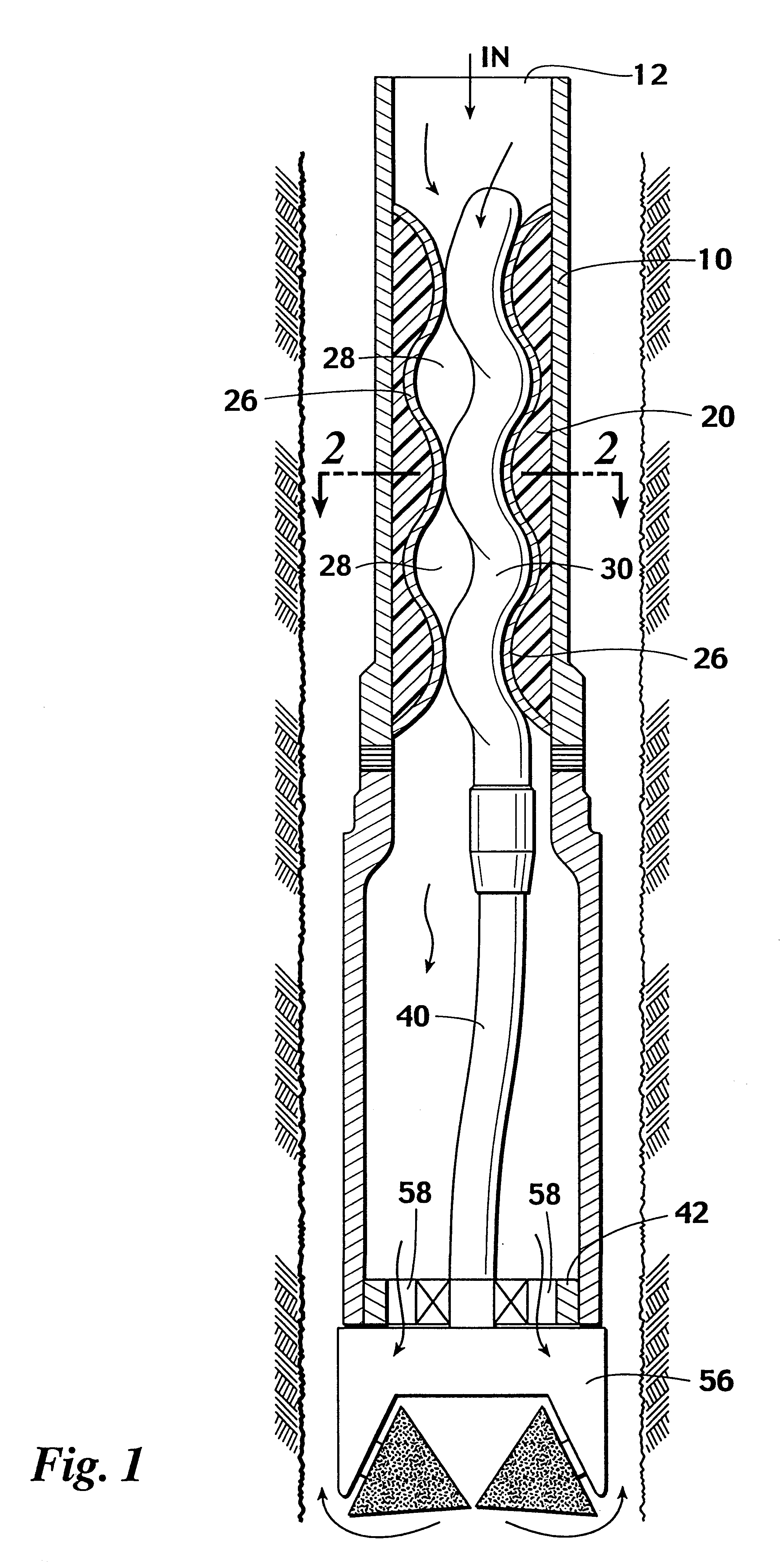

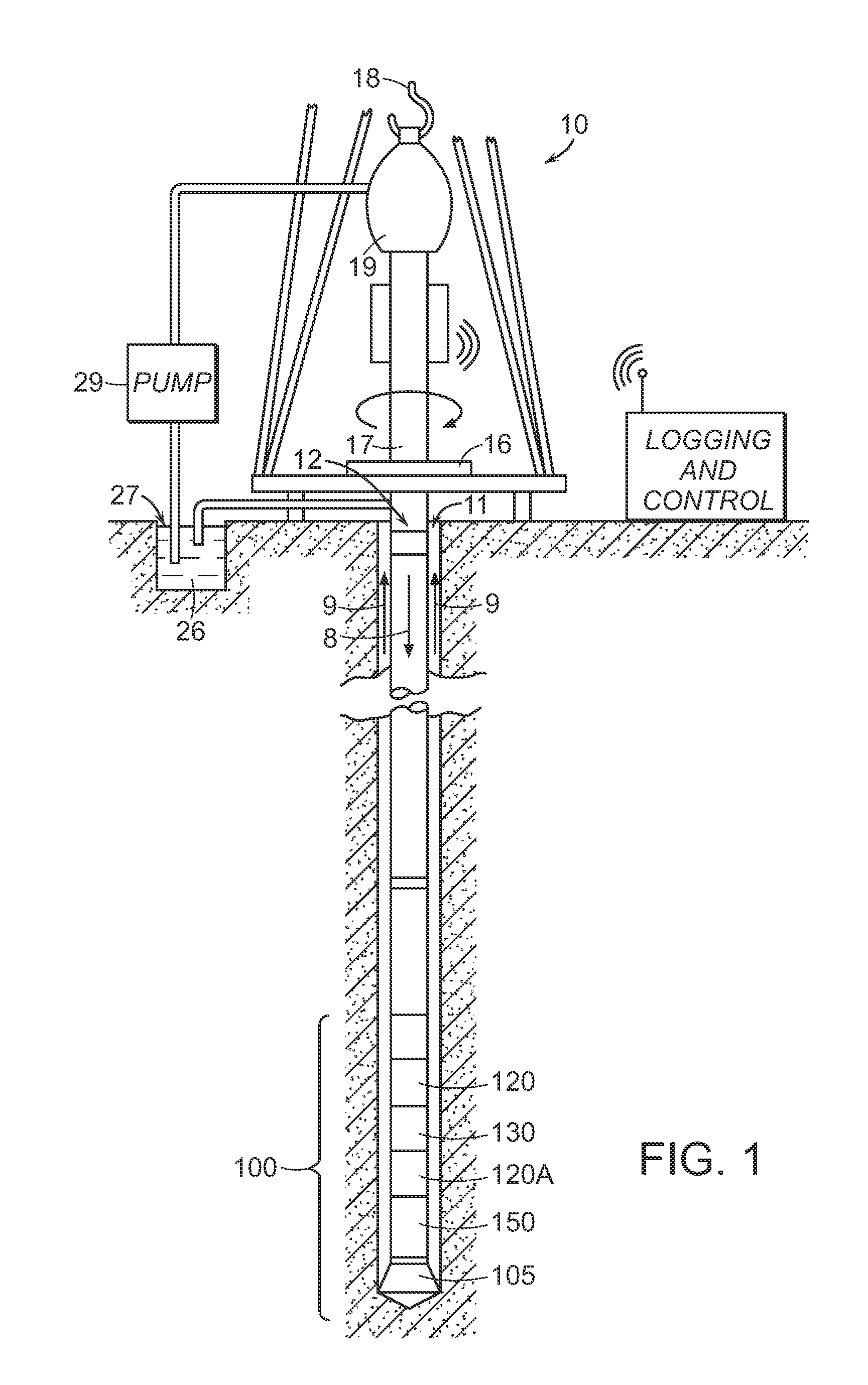

Apparatus and method for high temperature drilling operations

InactiveUS20100038142A1High mechanical loadPump componentsOscillating piston enginesEngineeringWellbore

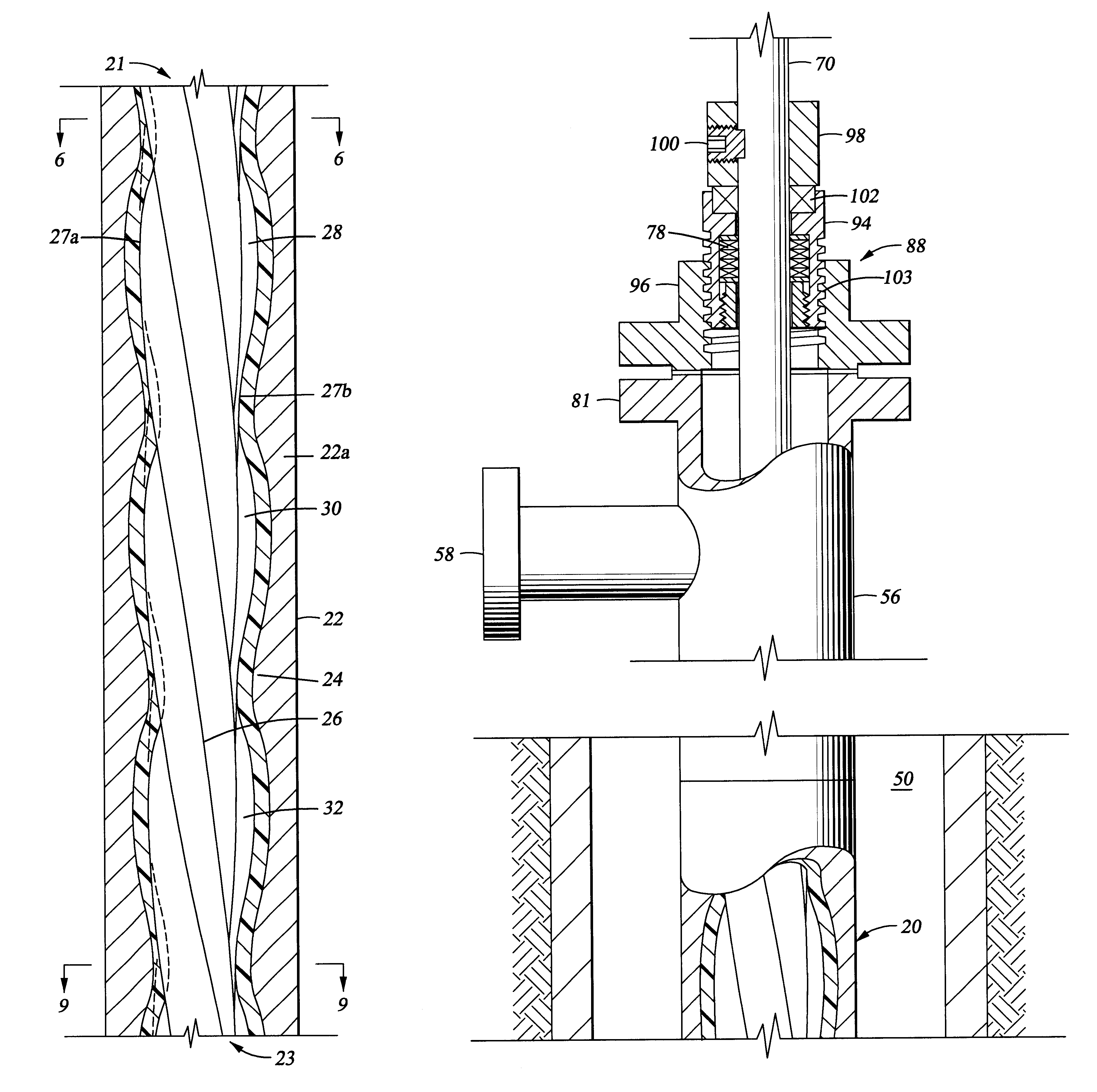

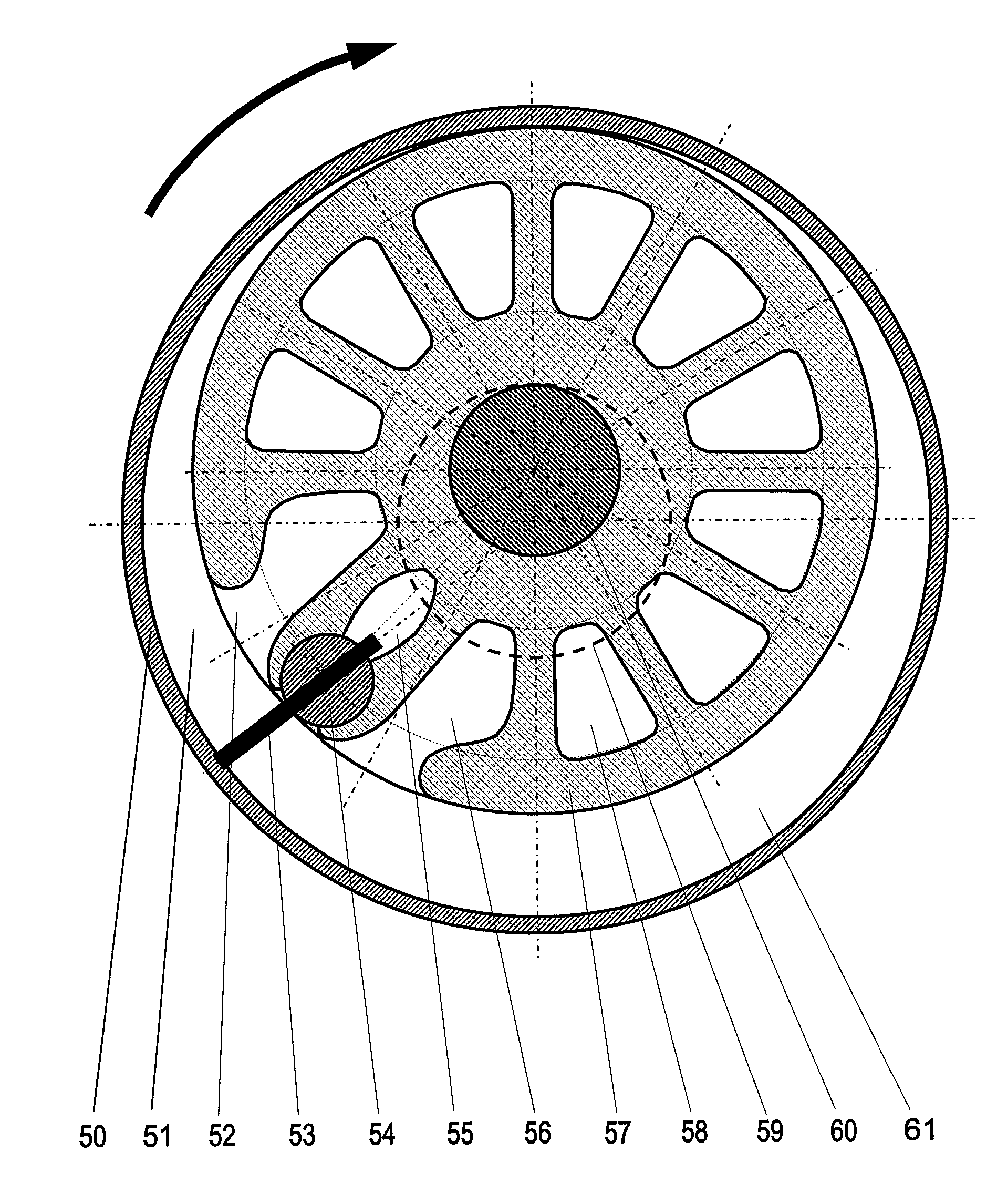

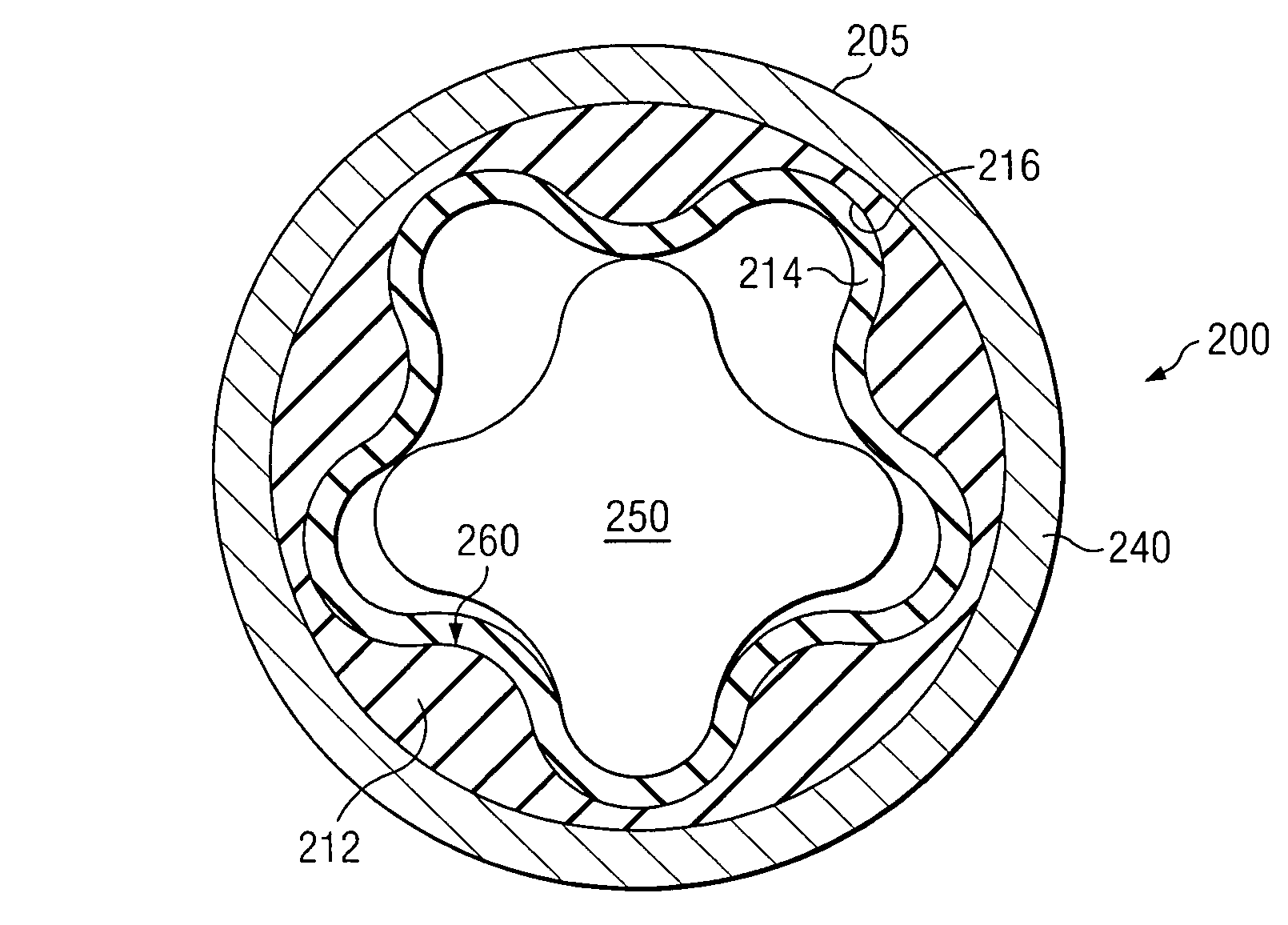

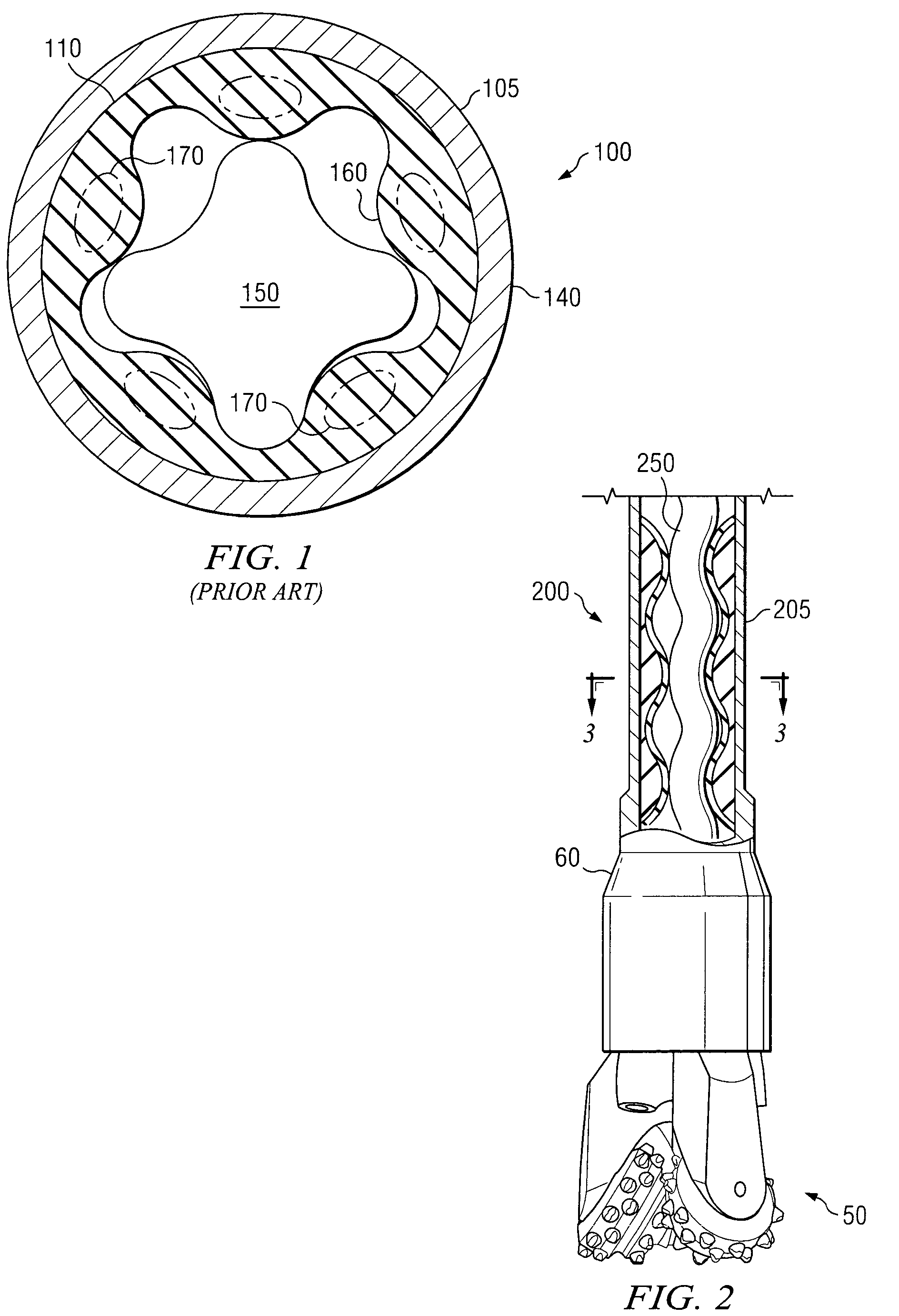

An apparatus (50) for drilling a wellbore that transverses a subterranean hydrocarbon bearing formation. The apparatus (50) includes a drill string (52) having an inner fluid passageway (66). A drill bit (64) is disposed at a distal end of the drill string (52) and is operable to rotate relative to at least a portion of the drill string (52). A fluid motor (54) is disposed within the drill string (52) and is operable to rotate the drill bit (64) in response to a circulating fluid received via the inner fluid passageway (66) of the drill string (52). The fluid motor (54) has a stator (68) with (n) lobes and a rotor (70) with (n−1) lobes. The stator (68) includes an inner surface formed from a first material and the rotor (70) includes an outer surface formed from a second material that is dissimilar to the first material.

Owner:HALLIBURTON ENERGY SERVICES INC

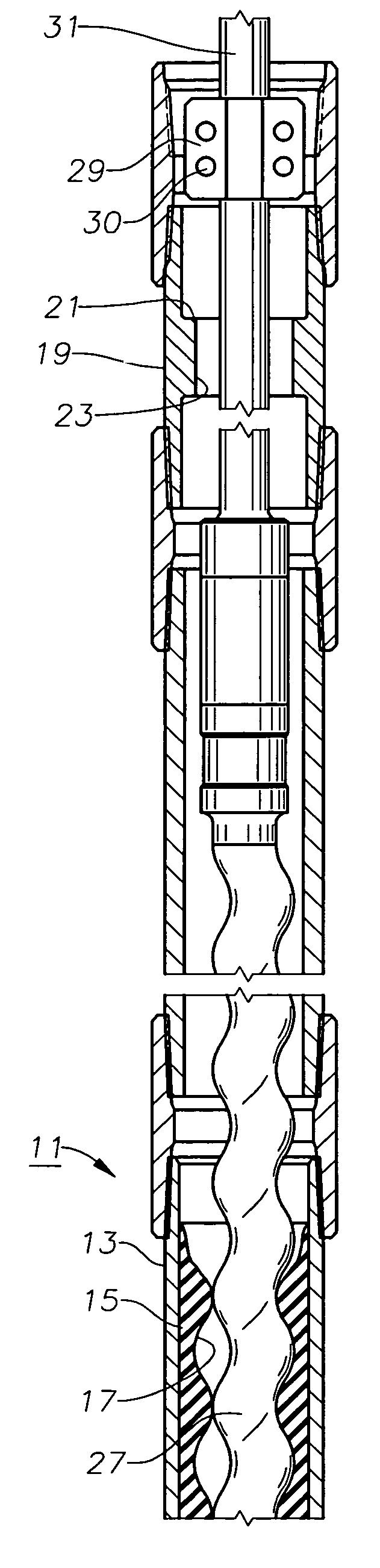

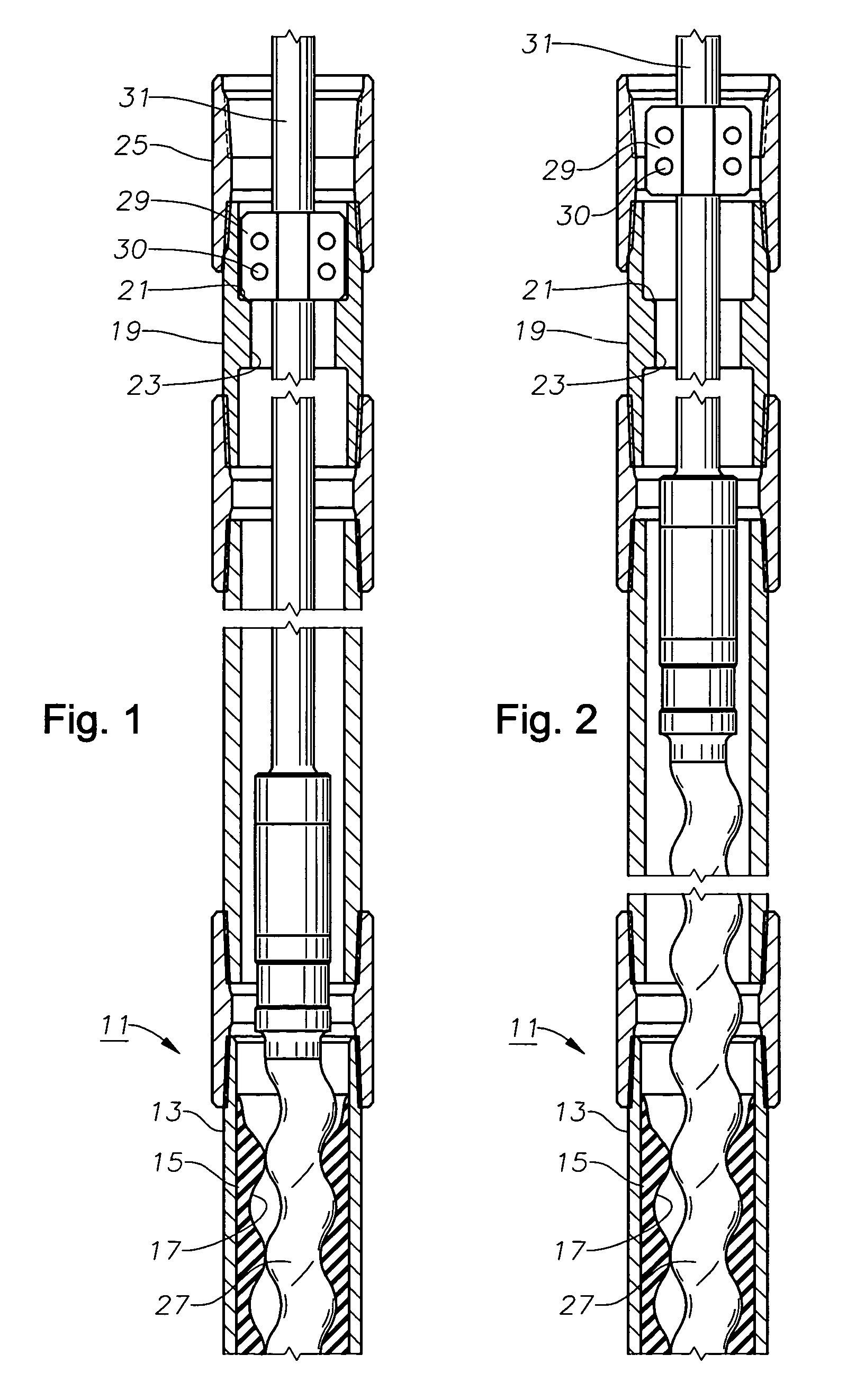

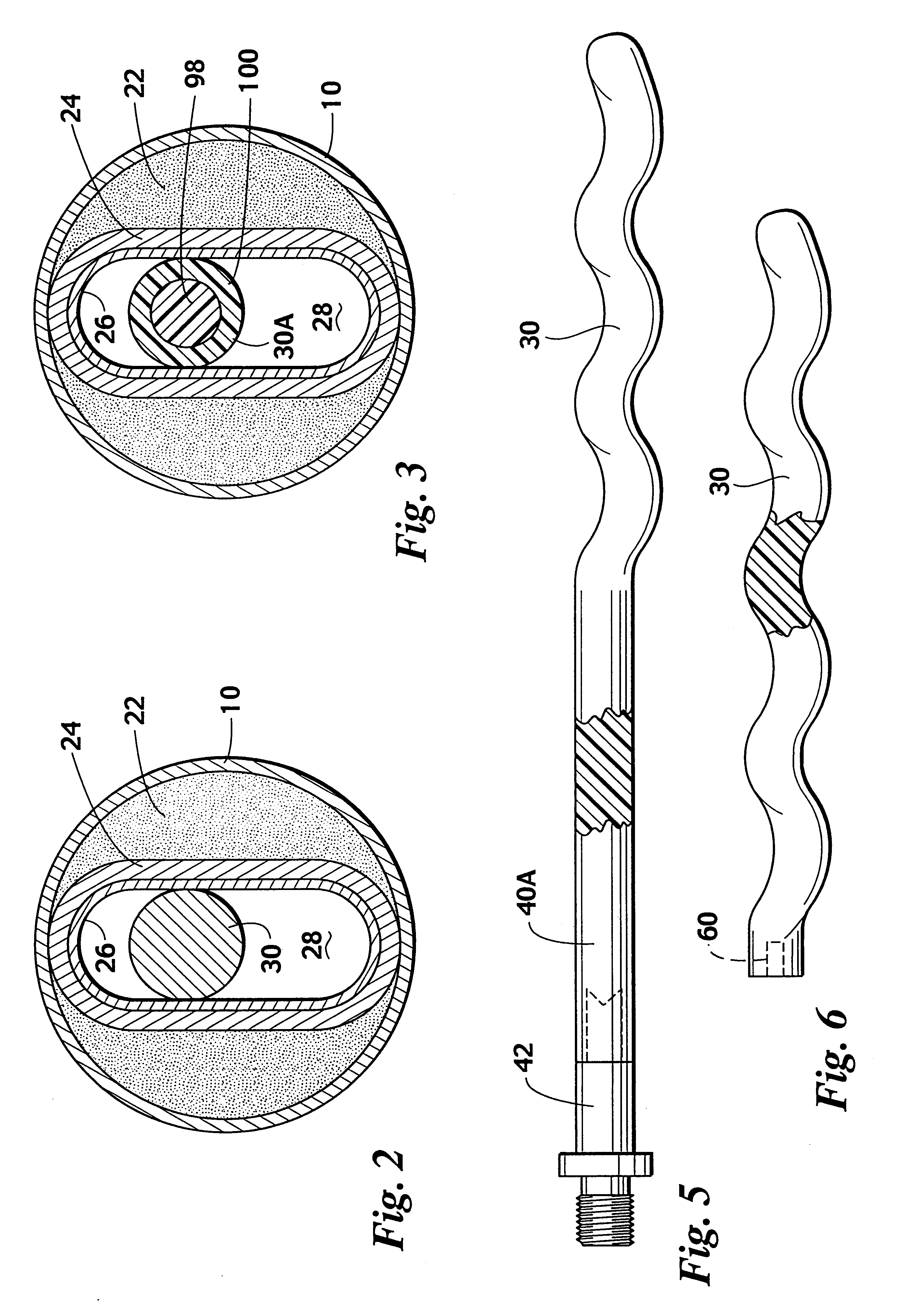

Method and apparatus for aligning rotor in stator of a rod driven well pump

InactiveUS7201222B2Oscillating piston enginesEngine of intermeshing engagement typeMechanical engineeringHelix

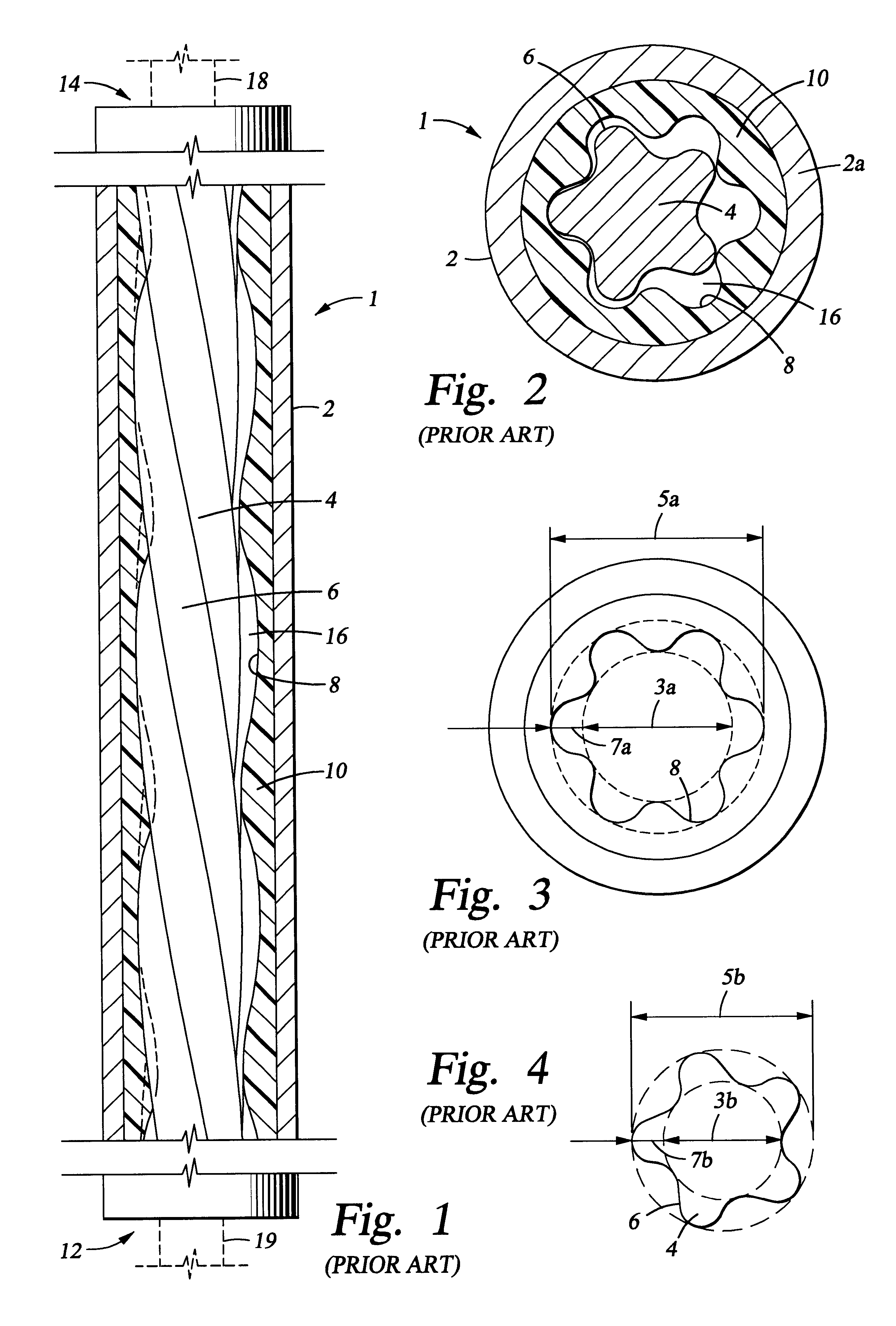

A progressing cavity rod-driven well pump utilizes a tag shoulder above a helical passage of the stator. The pump stator is located at the lower end of a string of tubing. The tag shoulder is more restrictive than a passage through the tubing. A pump rotor is secured to a string of rods and has a stop located above the rotor. The rotor is lowered on the rods until the stop lands on the tag shoulder. Then the operator lifts the rods and the rotor to accommodate for expected stretch during operation. By removing the rods and rotor, monitoring tools can be lowered through the tag shoulder and stator.

Owner:BAKER HUGHES INC

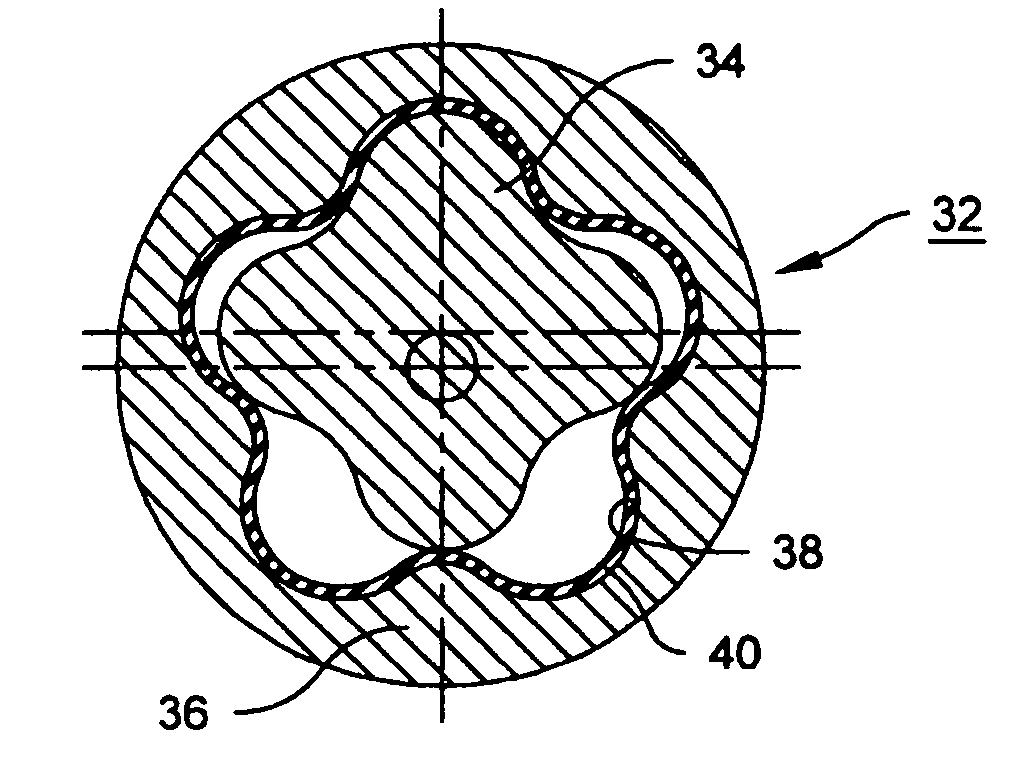

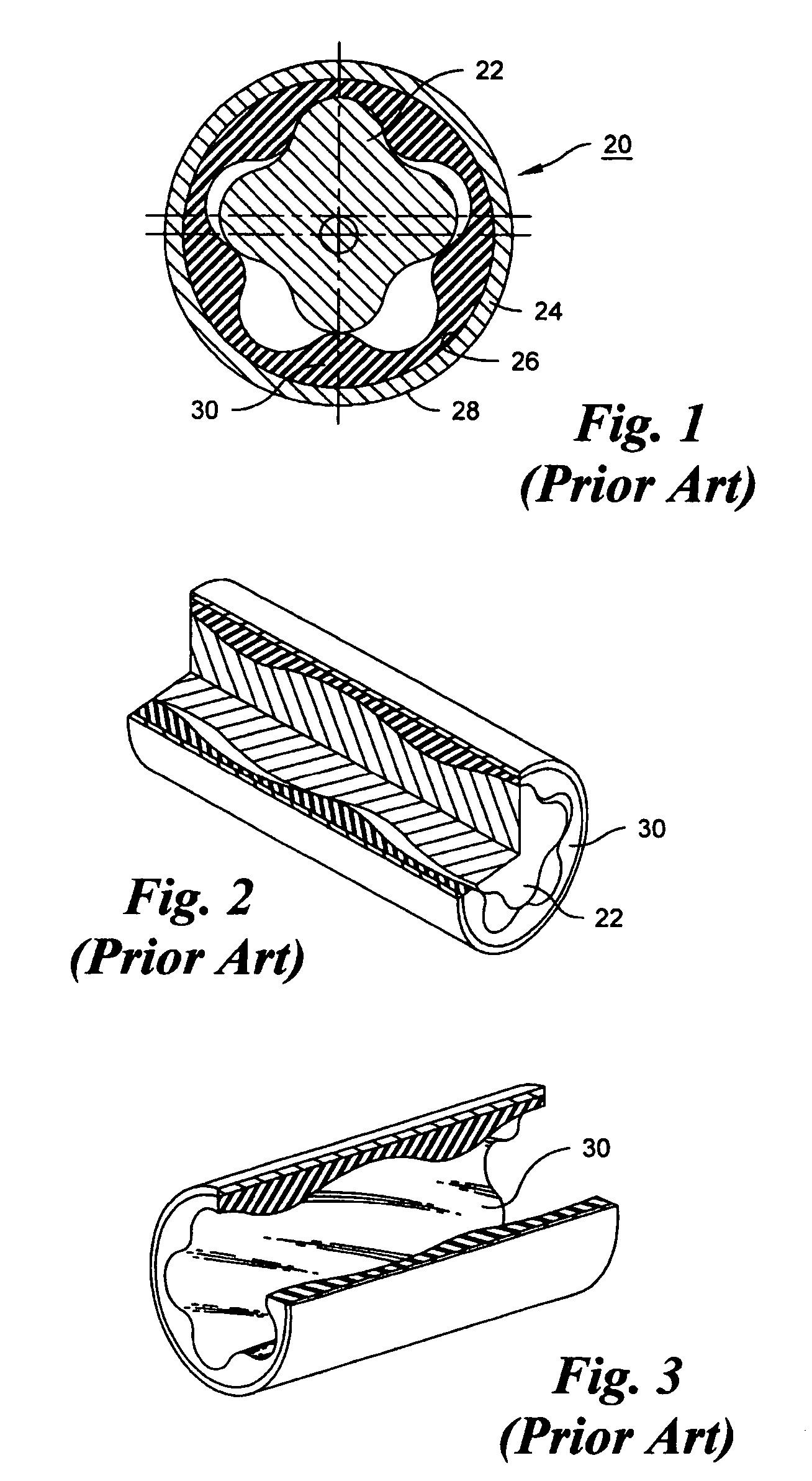

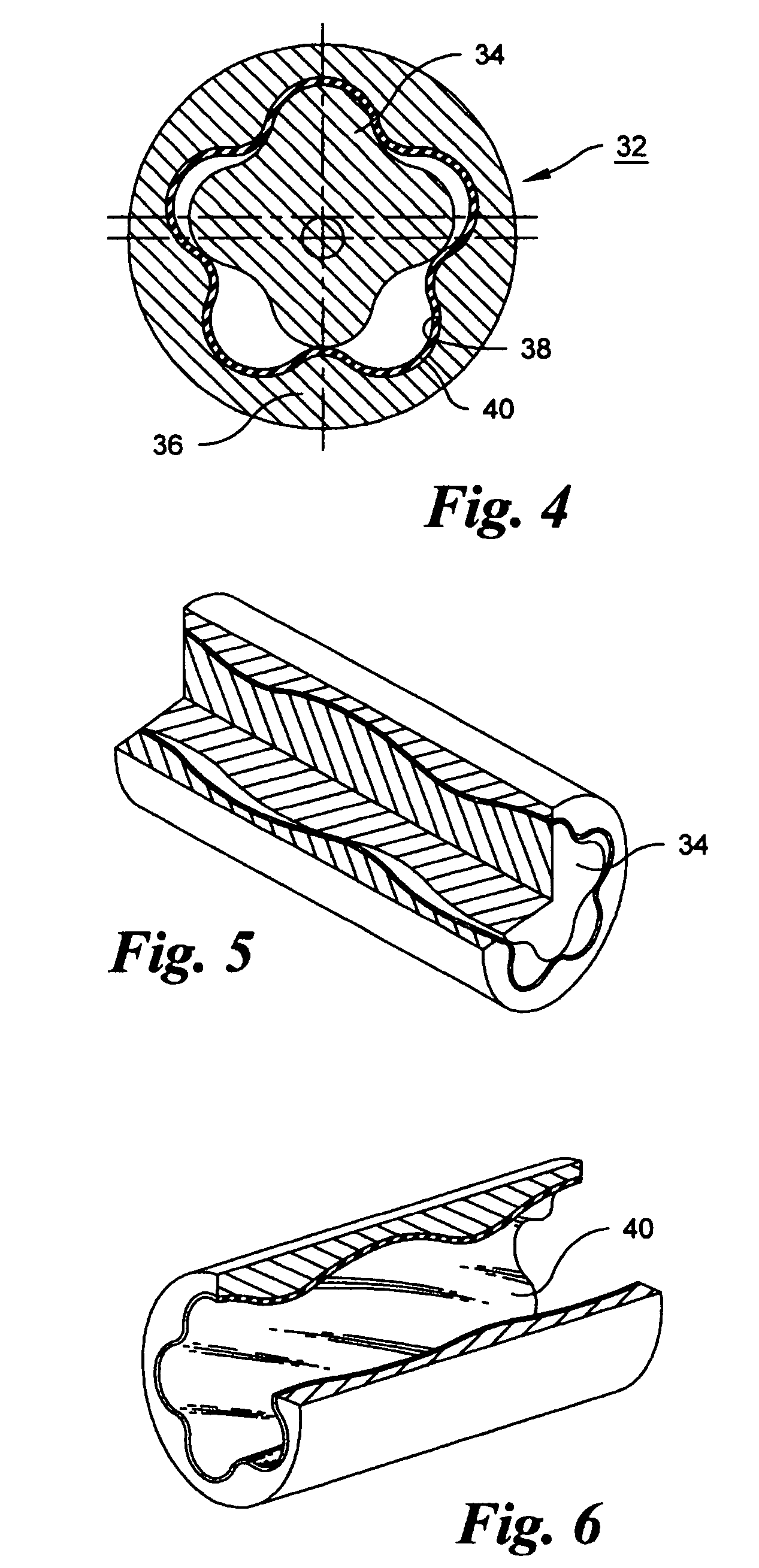

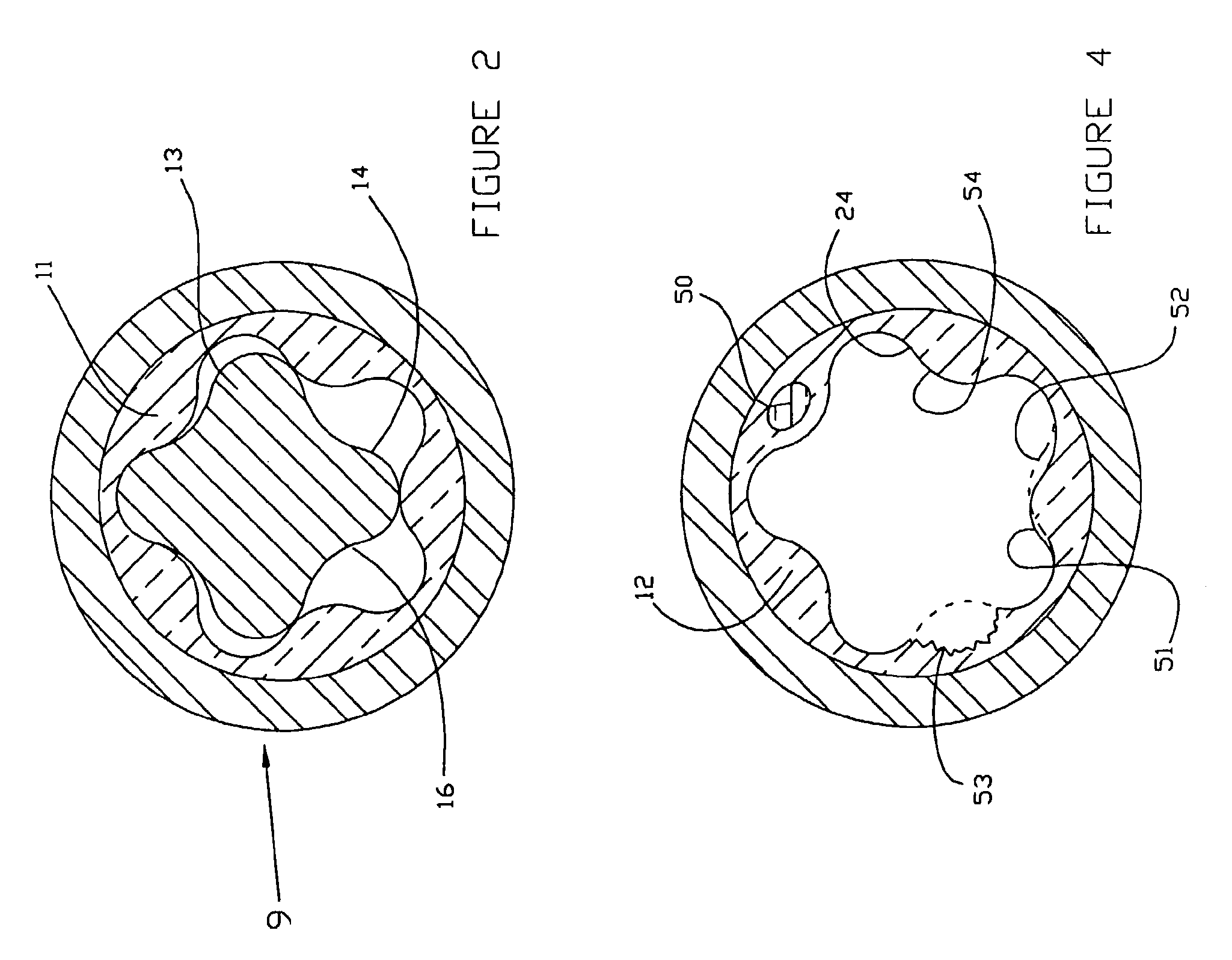

Progressive cavity pump/motor stator, and apparatus and method to manufacture same by electrochemical machining

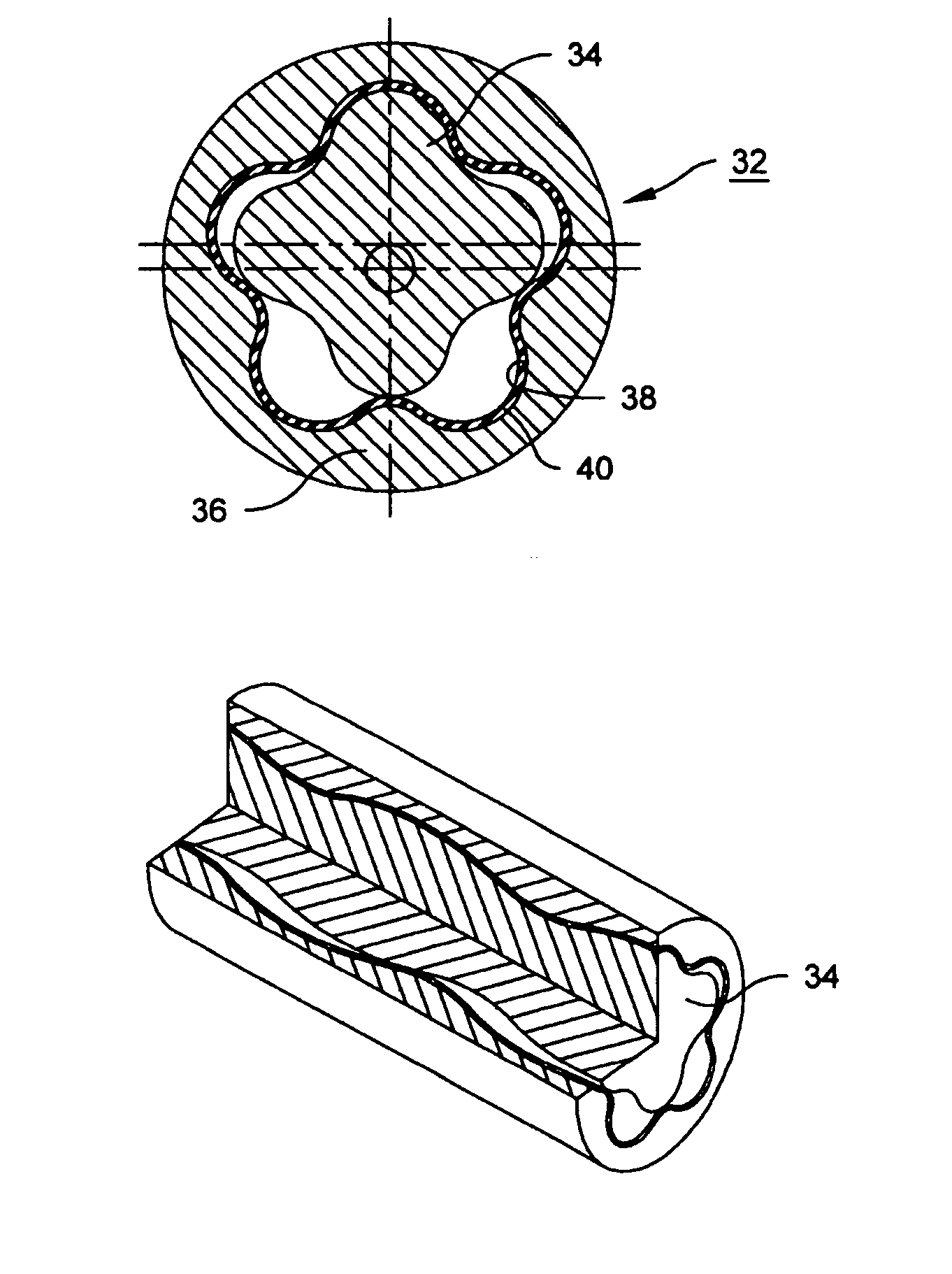

ActiveUS7192260B2Improve heat transfer performanceReduce adverse effectsElectrolysis componentsEngine of intermeshing engagement typeElastomerElectricity

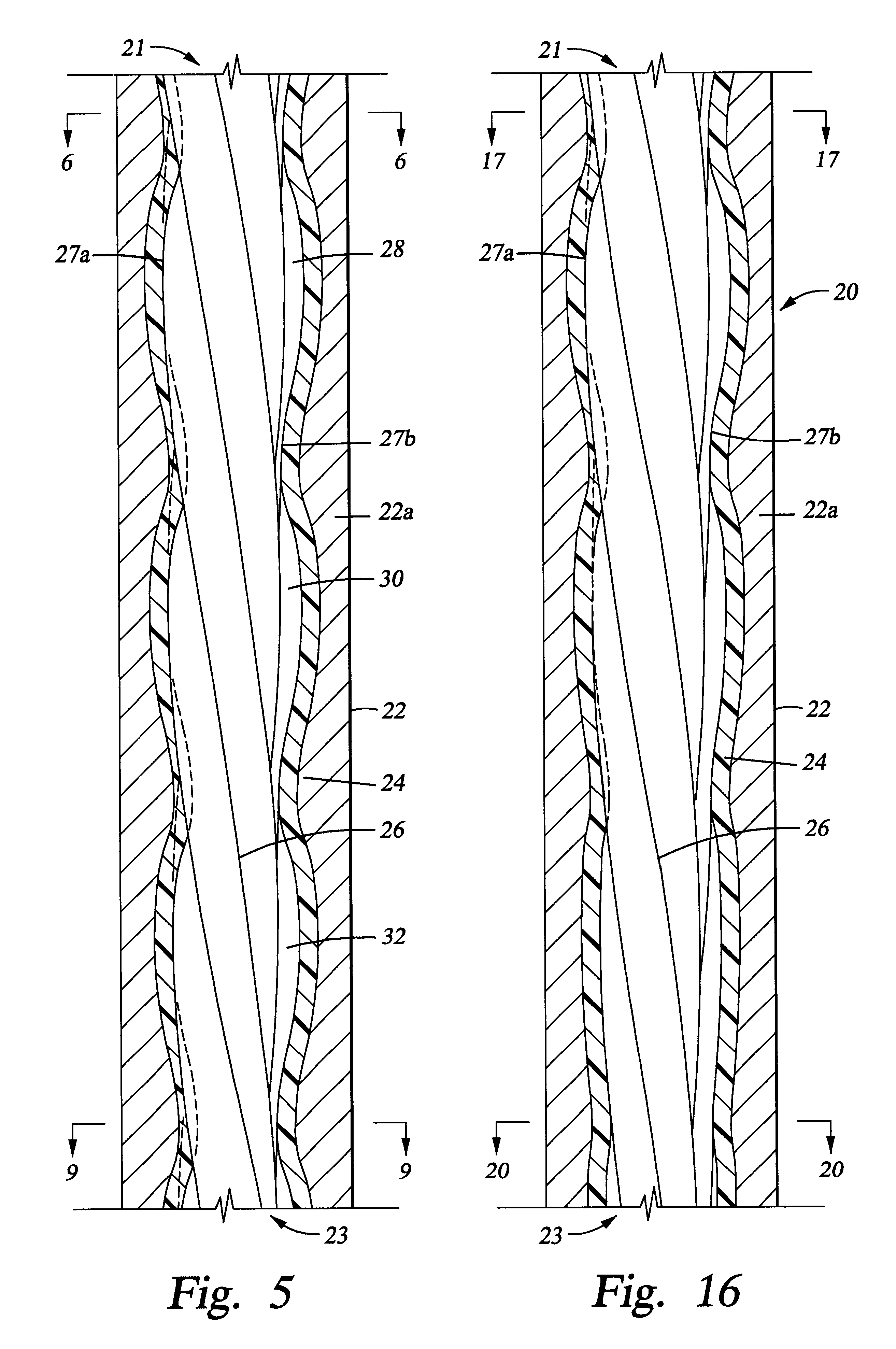

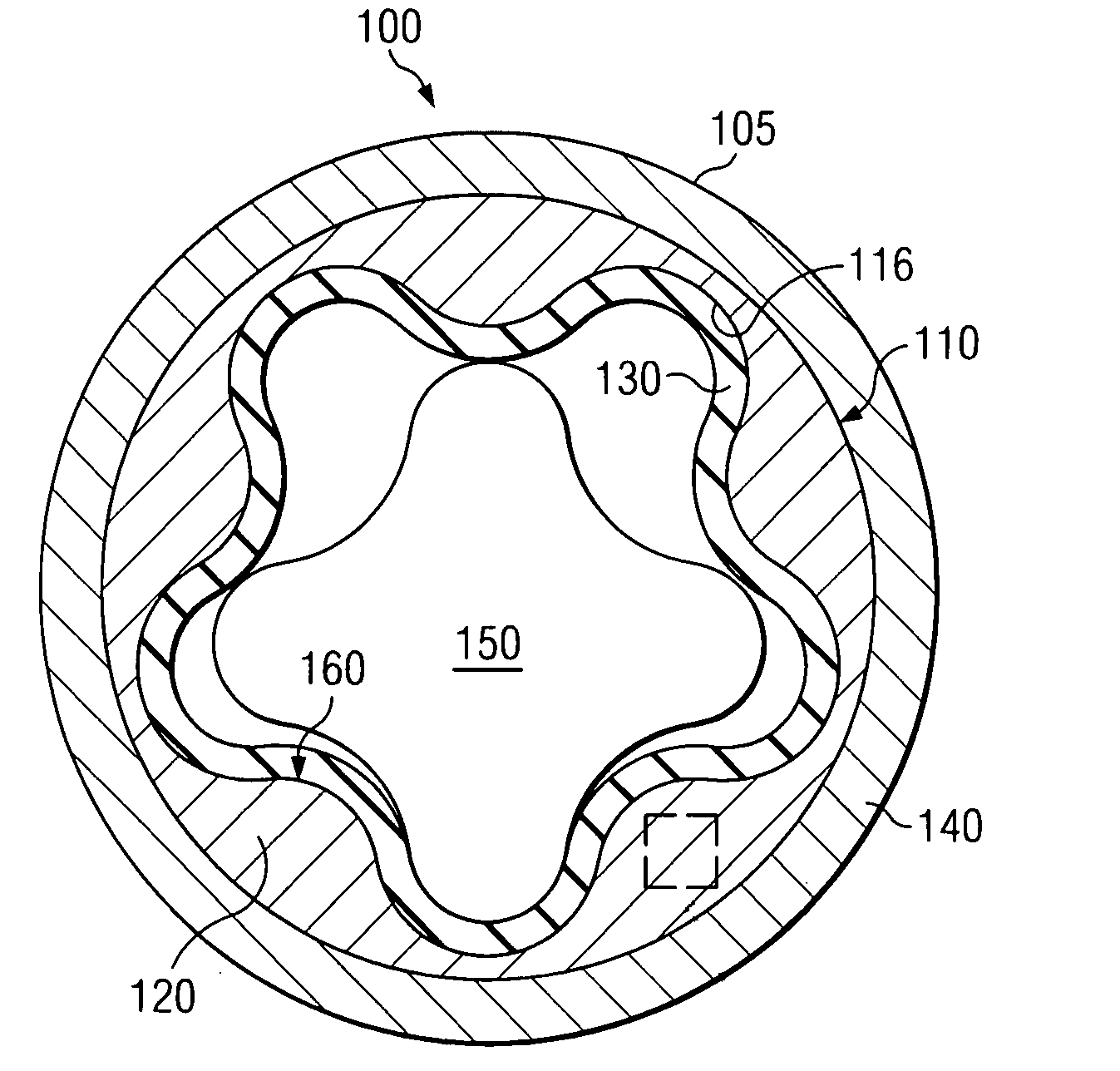

Electrochemical machining is used to generate the helical lobe profiles of the stator of a progressive cavity pump or motor. A thin, elastomeric liner, of uniform thickness is bonded either to the interior of the stator, or to the exterior of the rotor. Where the elastomeric liner is to be bonded to the interior of the stator, bonding is improved by electrically etching the interior of the stator during the electrochemical machining process to produce a roughened surface.

Owner:LEHR PRECISION

Pump with conveying chamber formed in outer rotor surface

ActiveUS7674100B2Avoid flowEngine of arcuate-engagement typeRotary piston pumpsMechanical engineeringMedical treatment

Owner:QUANTEX ARC LTD

Stator for down hole drilling motor

InactiveUS6905319B2Reduced susceptibility to stator damageSufficient wear characteristicOscillating piston enginesEngine of intermeshing engagement typeDrill holePhysics

An improved down hole drilling motor suitable for drilling applications. The down hole drilling motor comprising a stator disposed in the tubular housing. The stator includes an internal cavity having one or more lobes. A rotor operatively positioned in the cavity of the stator is adapted to cooperate with the one or more lobes of the stator. The stator comprising a compound having improved manufacturing and performance characteristics.

Owner:HALLIBURTON ENERGY SERVICES INC

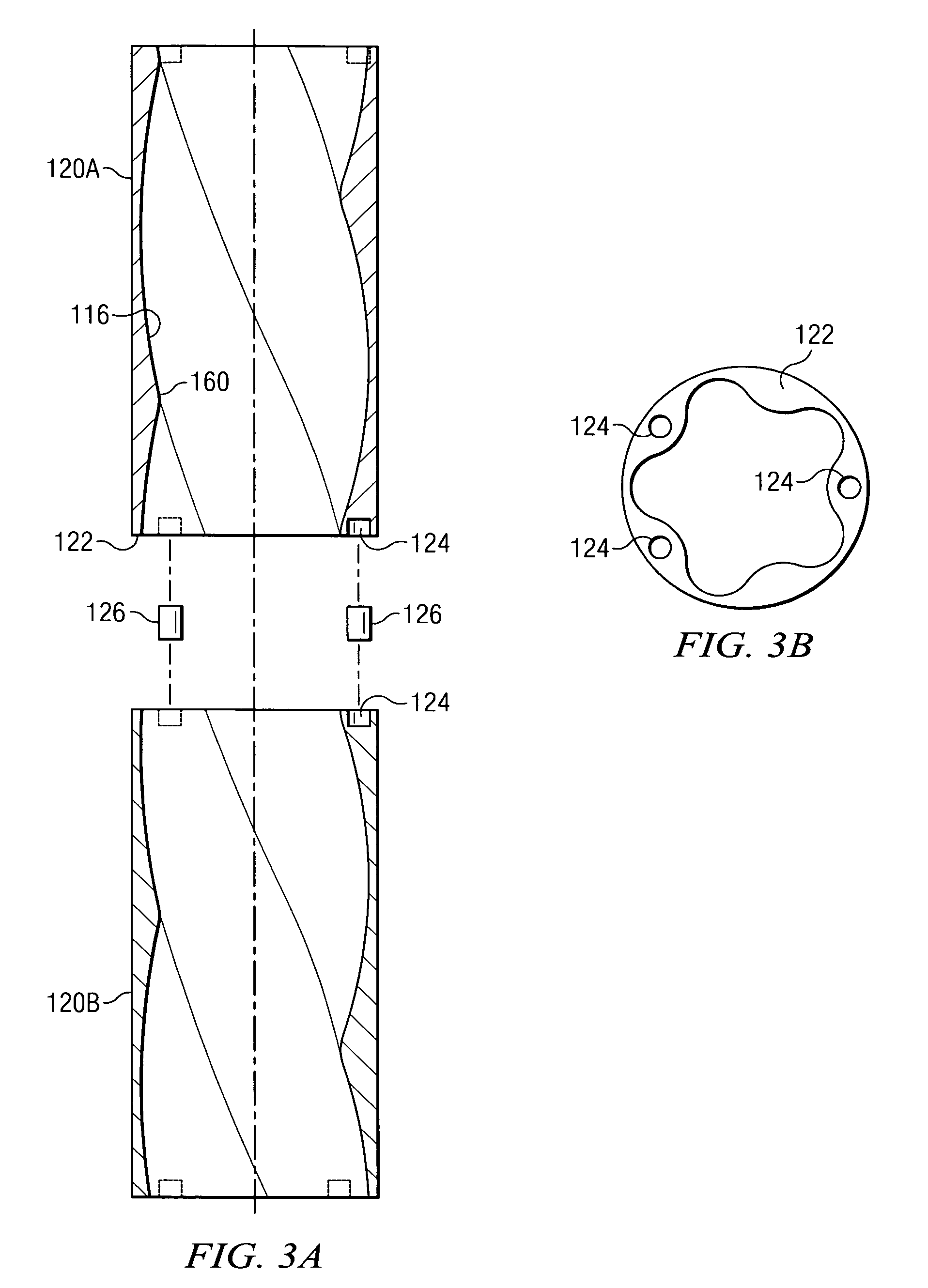

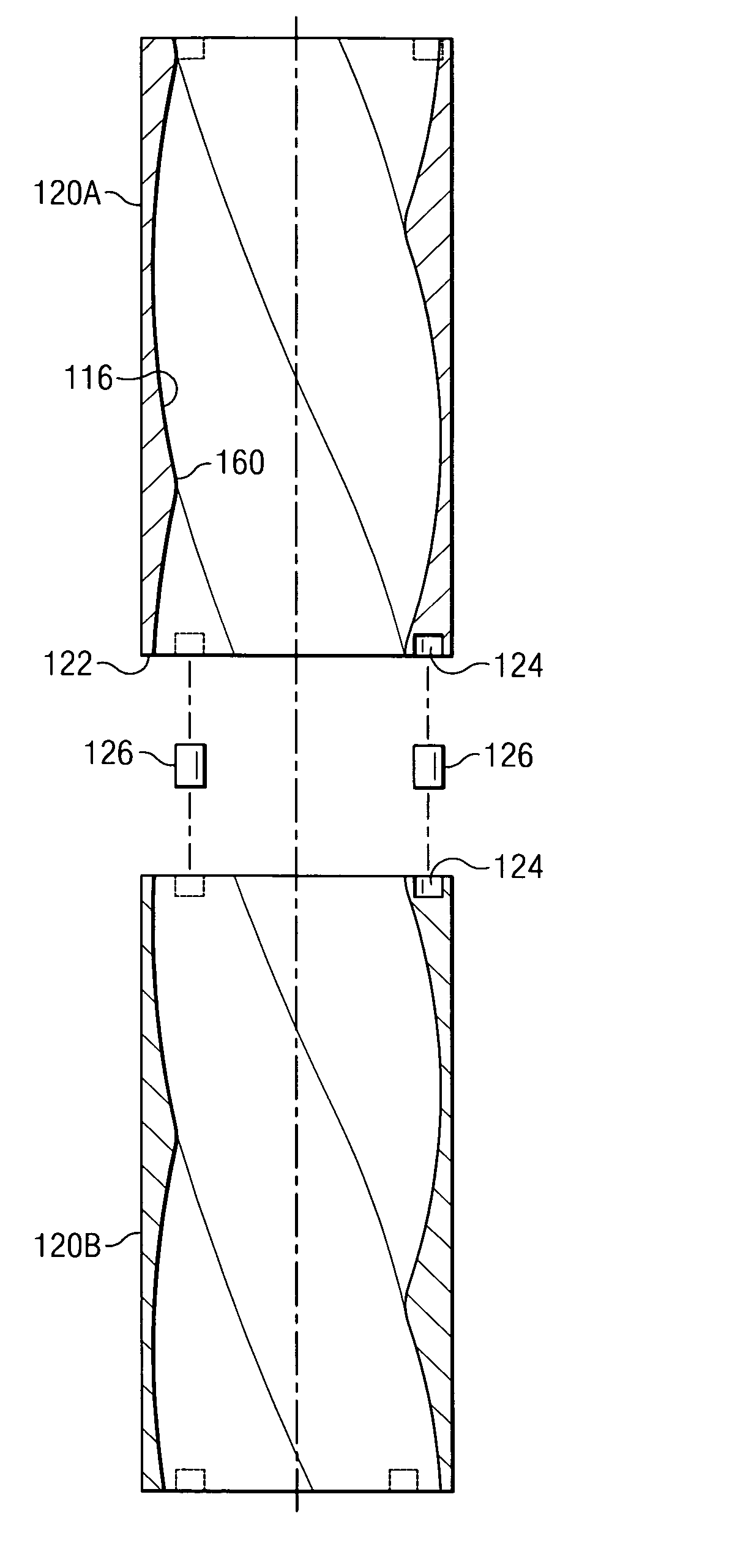

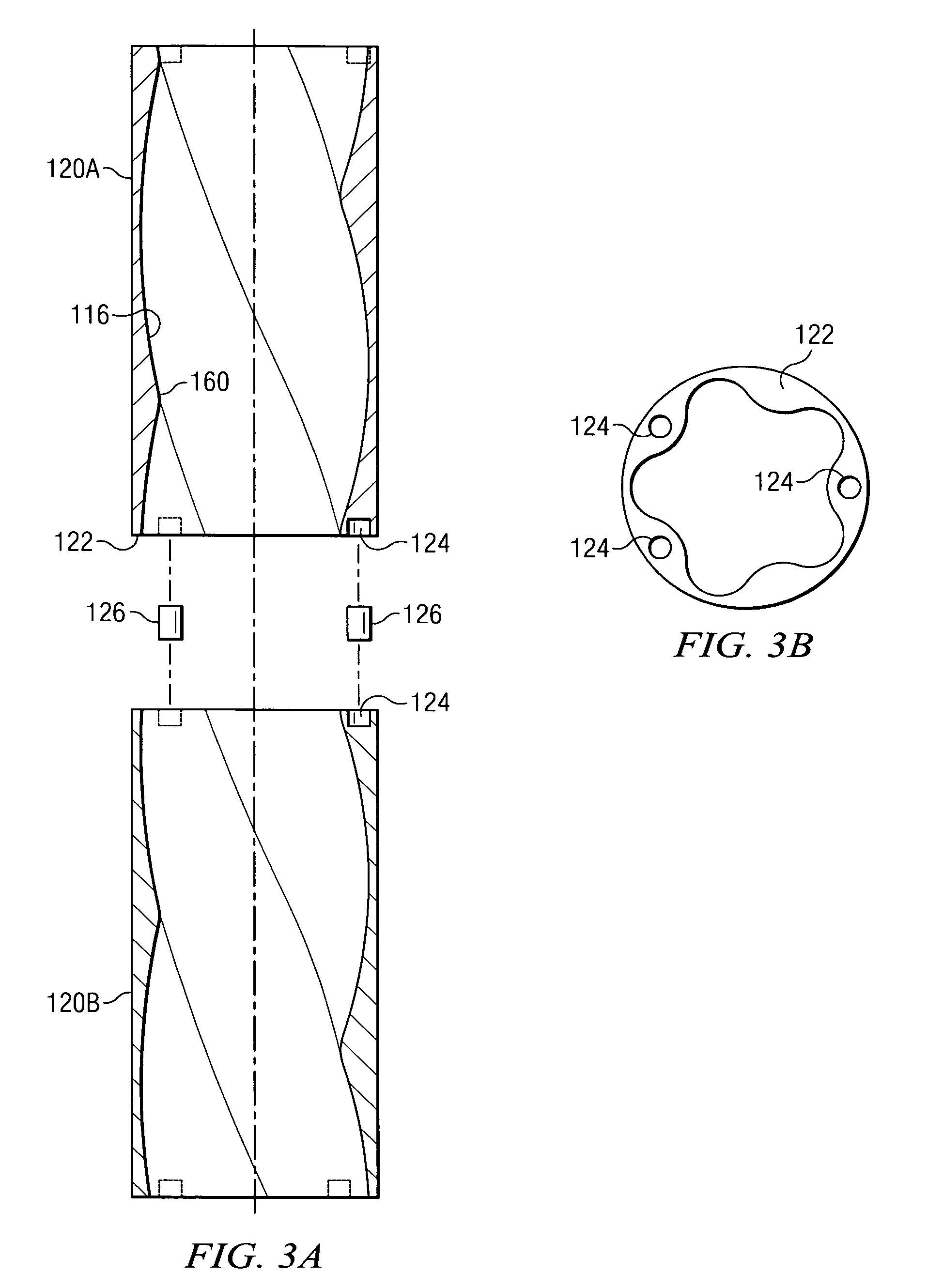

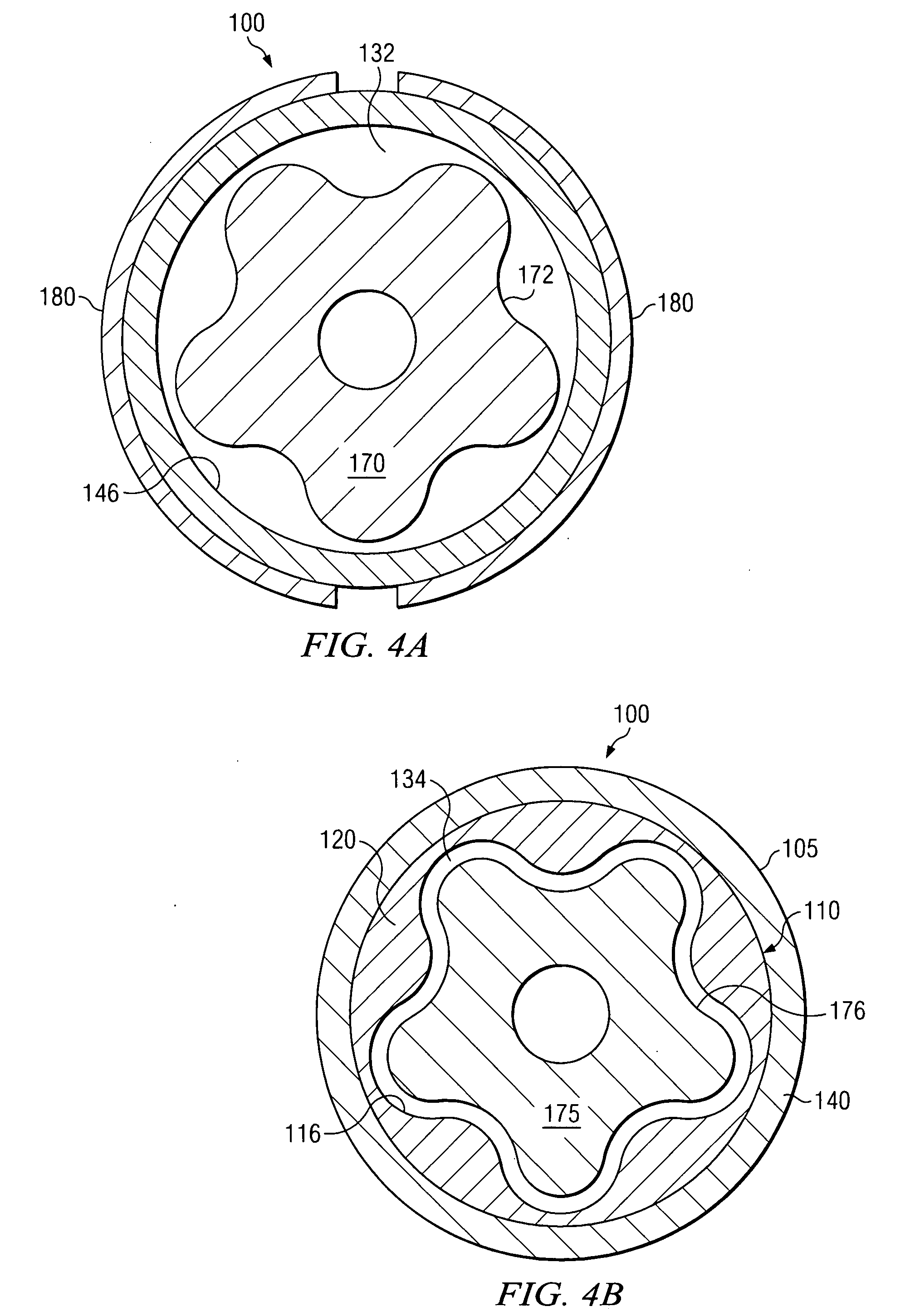

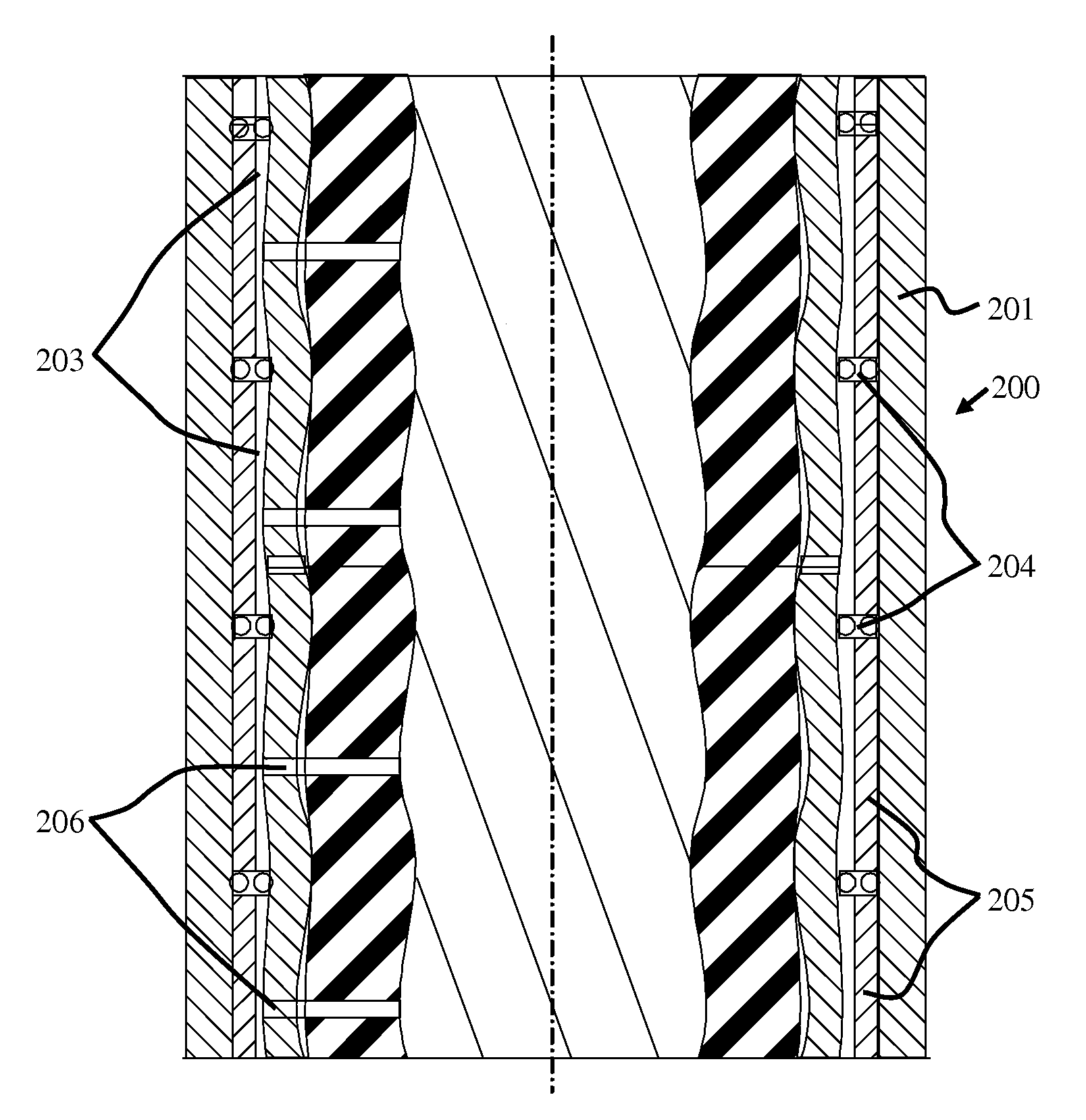

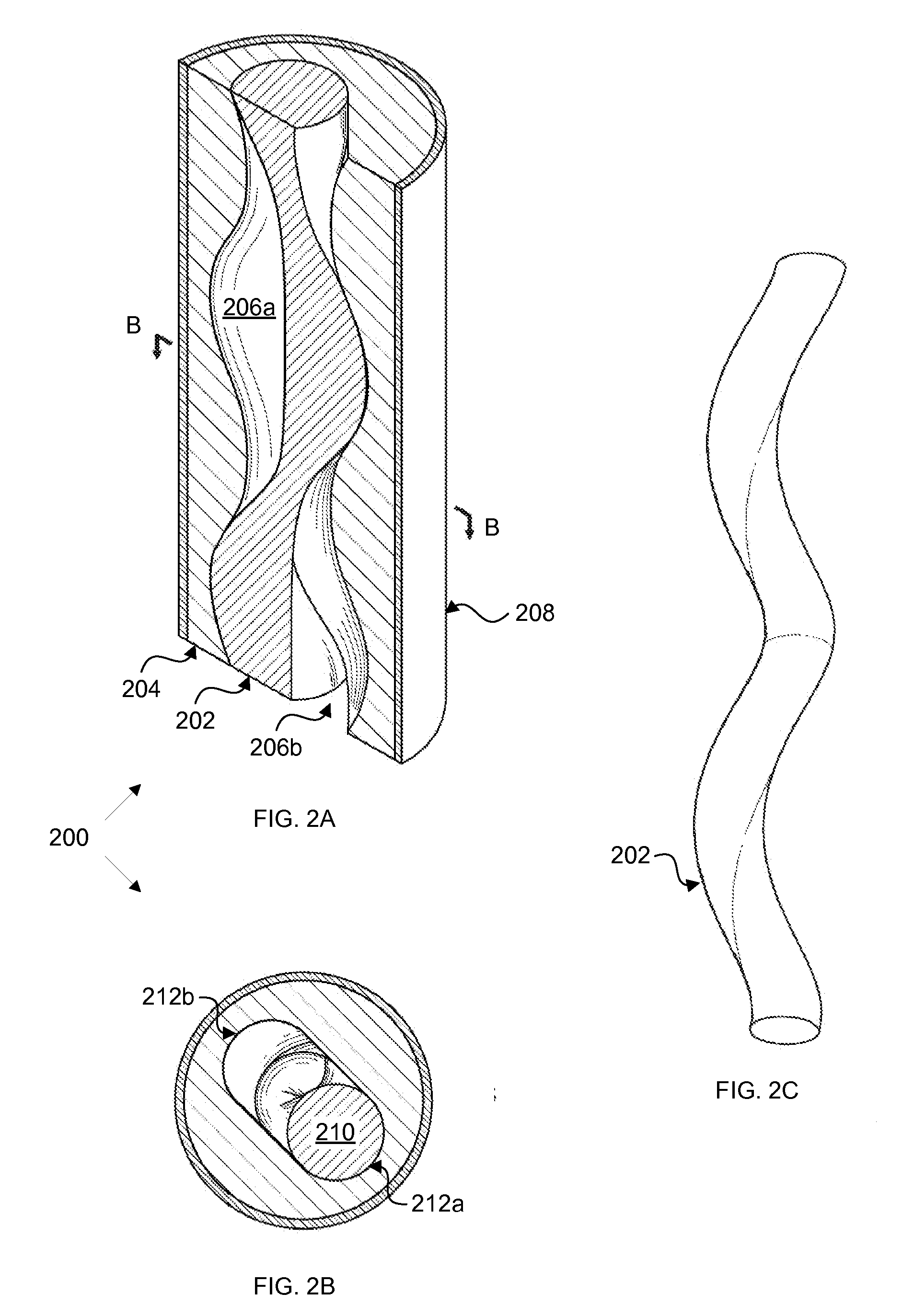

Progressing cavity stator including at least one cast longitudinal section

InactiveUS7396220B2Increased torque outputSimple and inexpensive to manufactureOscillating piston enginesEngine of intermeshing engagement typeElastomerHigh torque

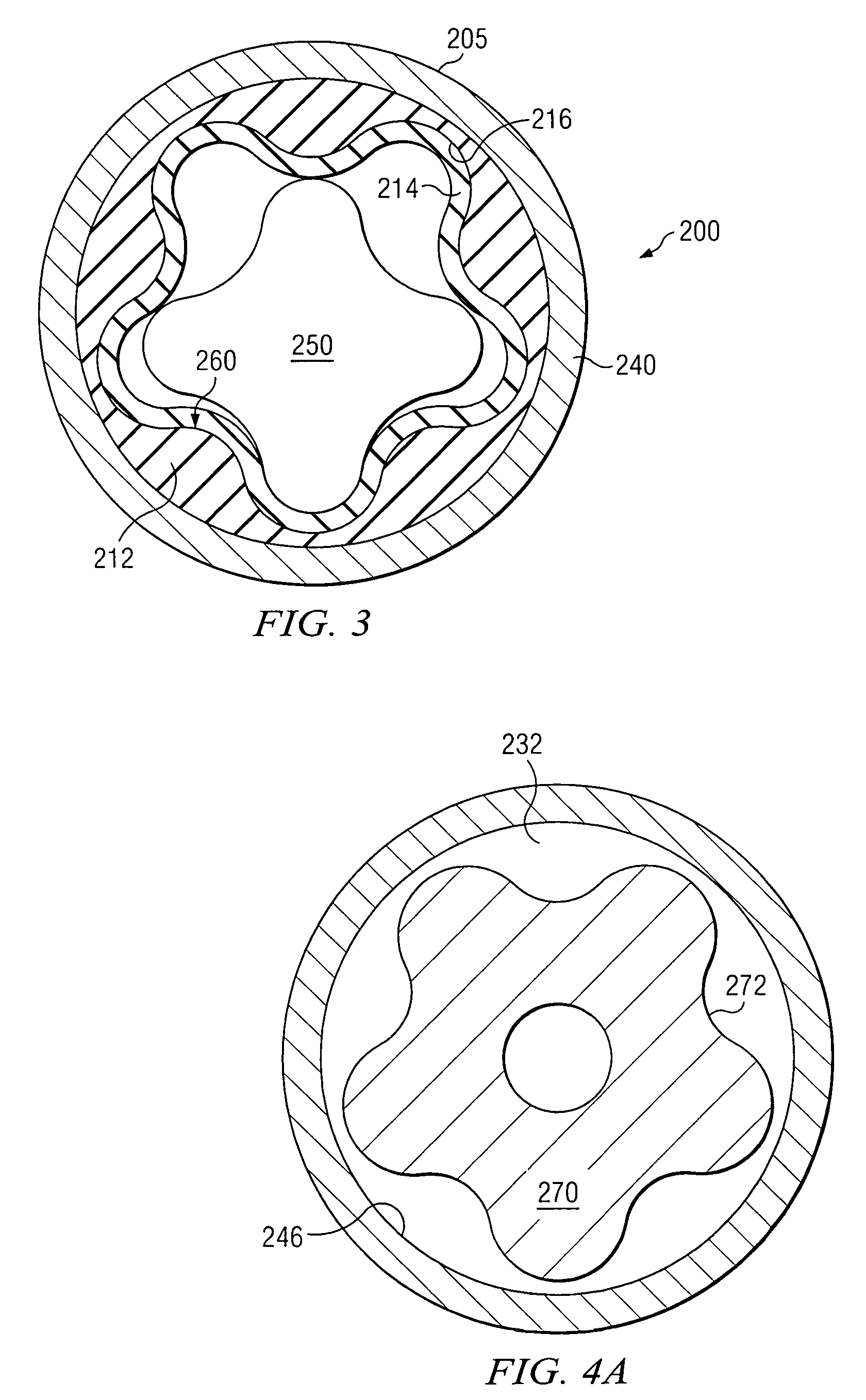

A progressing cavity stator and a method for fabricating such a stator are disclosed. Exemplary embodiments of the progressing cavity stator include a plurality of rigid longitudinal stator sections concatenated end-to-end in a stator tube. The stator sections are rotationally aligned so that each of the internal lobes extends in a substantially continuous helix from one end of the stator to the other. The stator further includes an elastomer liner deployed on an inner surface of the concatenated stator sections. Exemplary embodiments of this invention include a comparatively rigid stator having high torque output and are relatively simple and inexpensive to manufacture as compared to prior art rigid stators.

Owner:SMITH INT INC

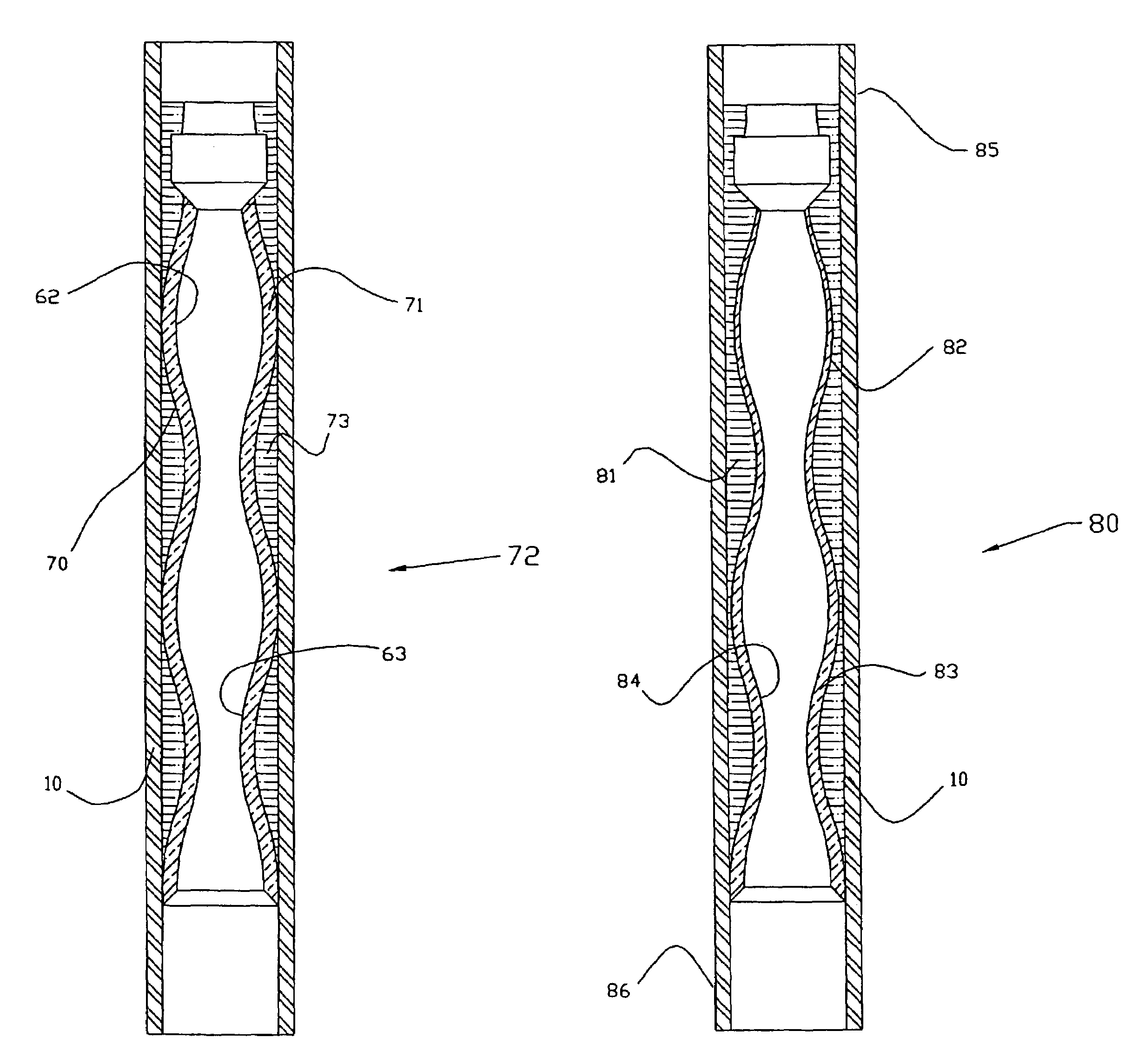

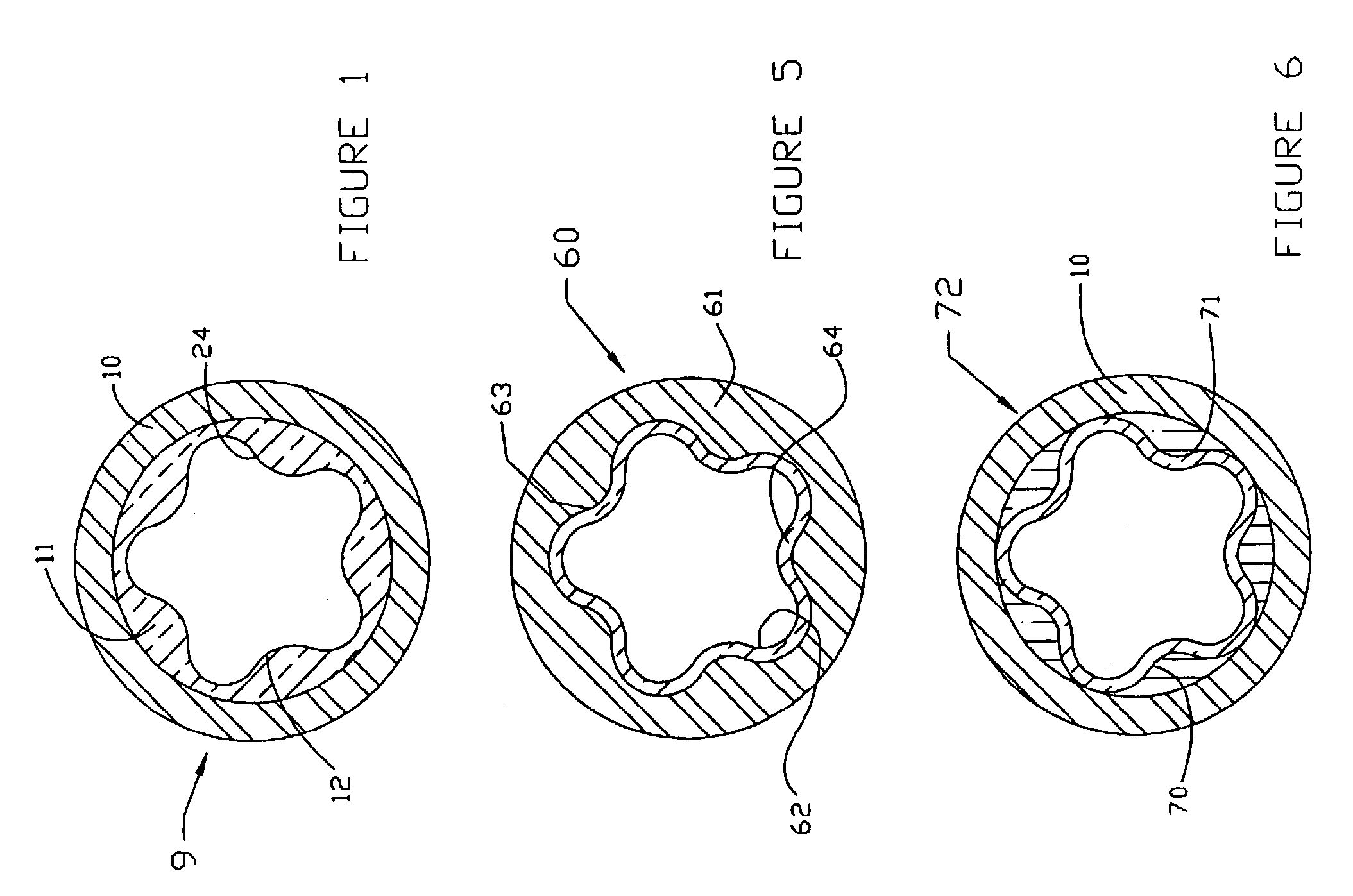

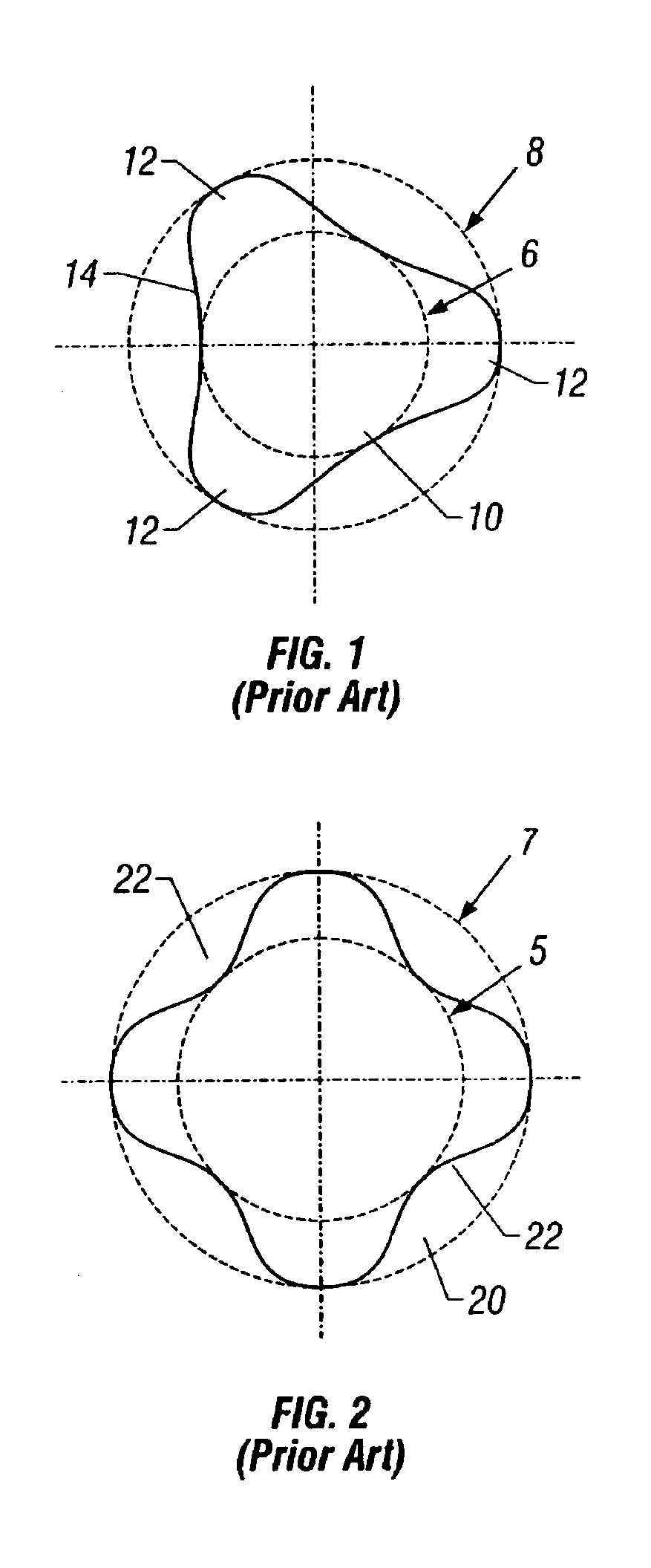

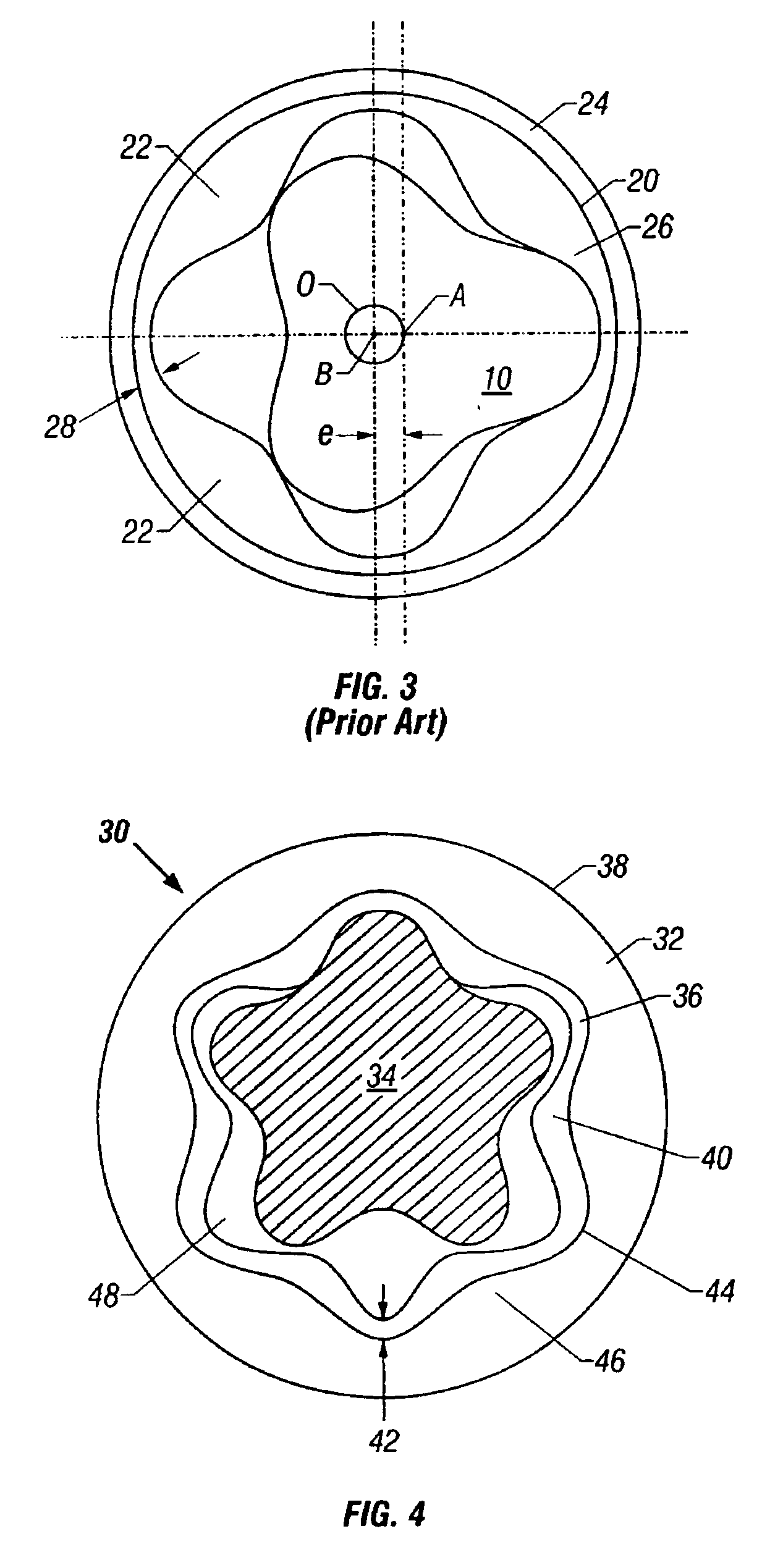

Progressive cavity pump/motor

InactiveUS6881045B2Accurate verificationOscillating piston enginesEngine of intermeshing engagement typeEngineeringDrill bit

A progressive cavity pump or motor, particularly suitable for hydrocarbon recovery operations, includes a rotor 20 and a stator 10. Fluid pressure in cavities between the stator and the rotor create torque which rotates the bit. An interior surface of the stator is rigidly secured to the outer housing of the pump stator and defines an interior profile. A substantially uniform thickness elastomeric layer 62 is supported on the outer housing. The pump rotor has an exterior profile which corresponds with the interior profile of the elastomeric layer.

Owner:ROBBINS & MYERS ENERGY SYST

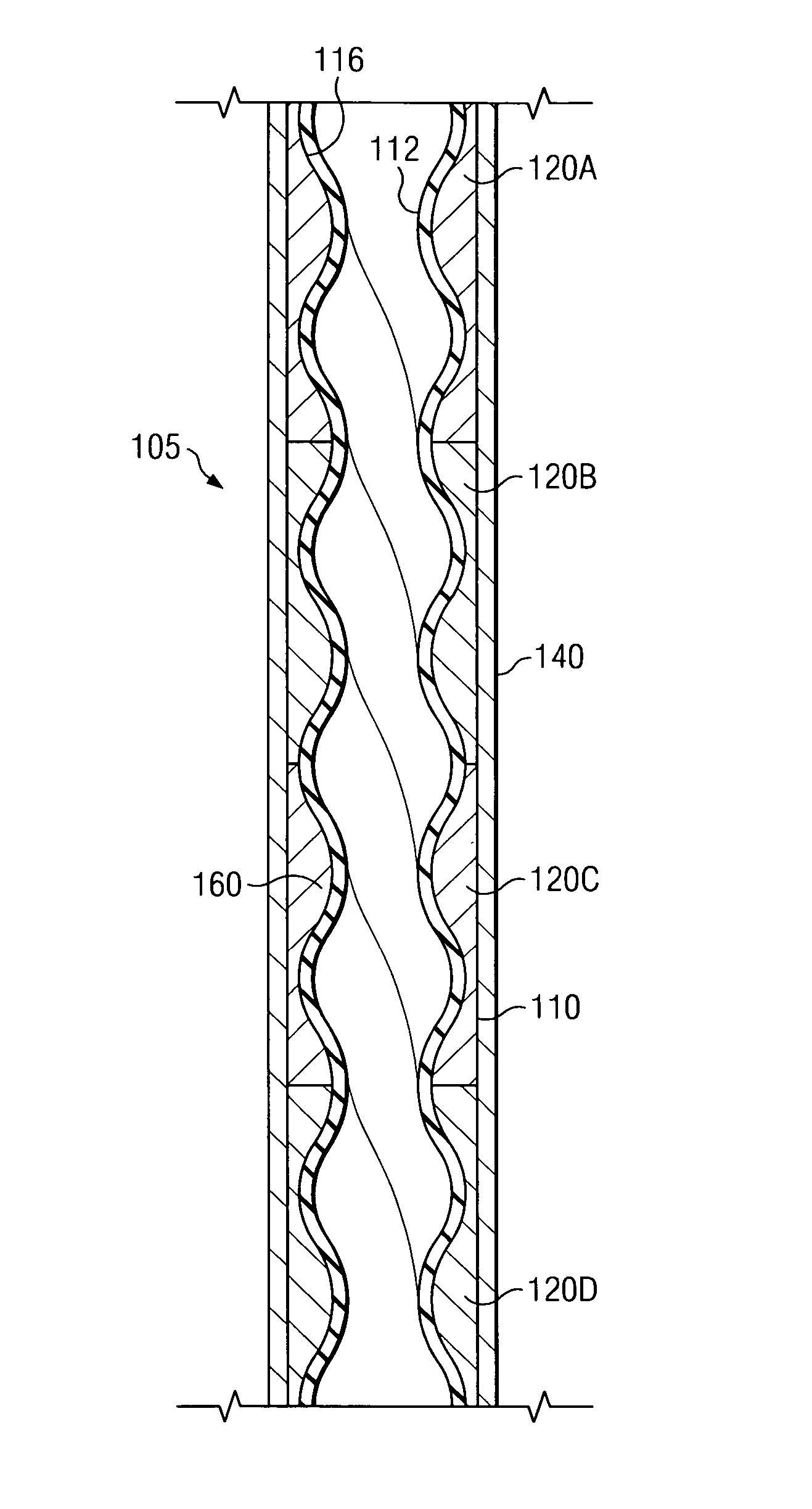

Progressing cavity stator including at least one cast longitudinal section

InactiveUS20060182644A1Prevent rotationIncreased torque outputOscillating piston enginesEngine of intermeshing engagement typeElastomerHigh torque

A progressing cavity stator and a method for fabricating such a stator are disclosed. Exemplary embodiments of the progressing cavity stator include a plurality of rigid longitudinal stator sections concatenated end-to-end in a stator tube. The stator sections are rotationally aligned so that each of the internal lobes extends in a substantially continuous helix from one end of the stator to the other. The stator further includes an elastomer liner deployed on an inner surface of the concatenated stator sections. Exemplary embodiments of this invention include a comparatively rigid stator having high torque output and are relatively simple and inexpensive to manufacture as compared to prior art rigid stators.

Owner:SMITH INT INC

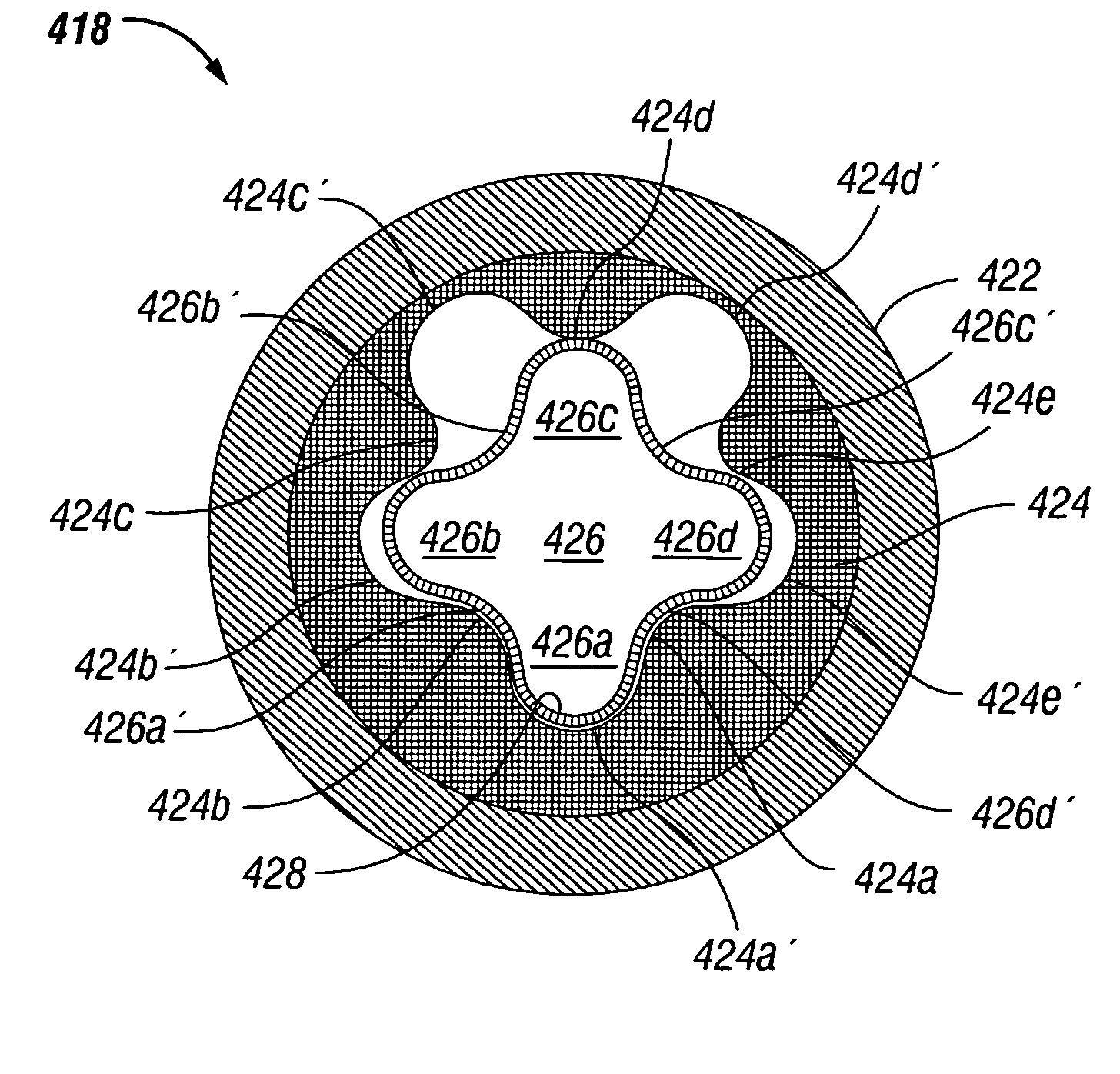

Composite material progressing cavity stators

InactiveUS20050089429A1Extended service lifeImprove reliabilityOscillating piston enginesEngine of intermeshing engagement typeElastomerFiber-reinforced composite

A progressing cavity stator is provided. The progressing cavity stator includes a fiber reinforced composite component providing an internal helical cavity having at least one helical groove and an elastomeric liner disposed on an internal surface of the fiber reinforced composite component. In various exemplary embodiments, the fiber reinforced composite component includes a plurality of fibers disposed in a matrix material, the plurality of fibers being disposed such that distinct portions thereof follow correspondingly distinct directions. Exemplary embodiments of this invention may advantageously exhibit a prolonged service life in downhole applications as compared to conventional progressing cavity stators. A replaceable progressing cavity insert for a stator is also provided. Methods for fabricating progressing cavity stators and progressing cavity inserts are also provided.

Owner:DYNA DRILL TECH

Adjustable fit progressive cavity pump/motor apparatus and method

InactiveUS6358027B1Oscillating piston enginesSealing arrangement for pumpsInterference fitEngineering

The present invention provides an adjustable rotor and / or stator, so that the interference fit and / or clearance can be adjusted. The rotor and / or stator are tapered to provide a difference in fit between the rotor and stator by longitudinal adjustment of their relative position. In one embodiment, the adjustment may occur while the PCP in mounted downhole in a wellbore. In another embodiment, the adjustment may occur automatically depending on sensor input of operating conditions of the PCP.

Owner:WEATHERFORDLAMB

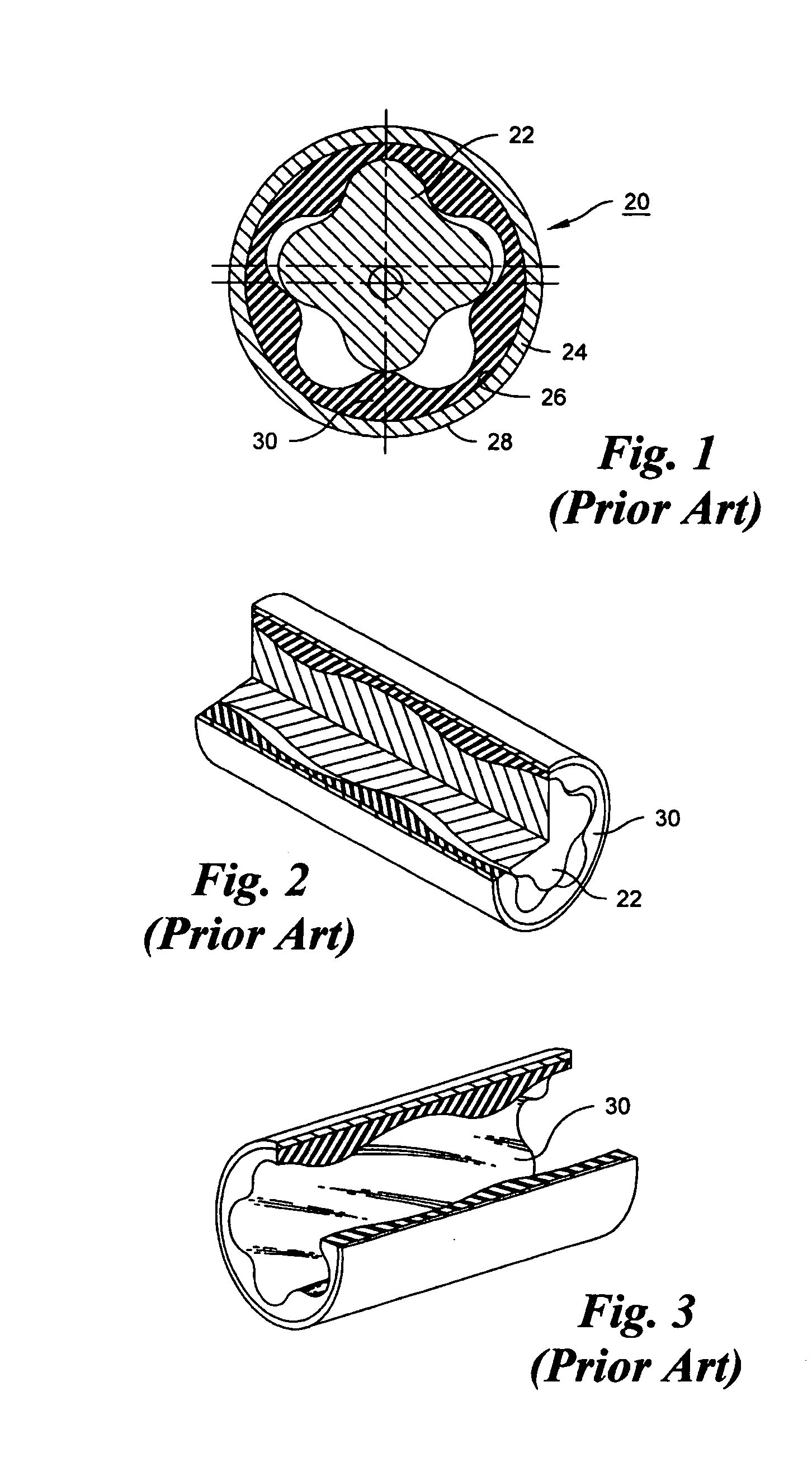

Braze or solder reinforced moineu stator

InactiveUS20080304992A1Extended service lifeImprove efficiencyOscillating piston enginesEngine of intermeshing engagement typeElastomerState of art

A Moineau style stator includes a helical reinforcement component that provides an internal helical cavity. A resilient liner is deployed on an inner surface of the helical reinforcement component. The helical reinforcement component includes a solder or braze material and is typically metallurgically bonded to an inner wall of a stator tube. In exemplary embodiments, the helical reinforcement component includes a composite mixture of solder and aggregate. Exemplary embodiments of this invention address the heat build up and subsequent elastomer breakdown in the lobes of prior arts stators by providing a helical reinforcement component. Solder reinforced stators tend to be less expensive to fabricate than reinforced stators of the prior art.

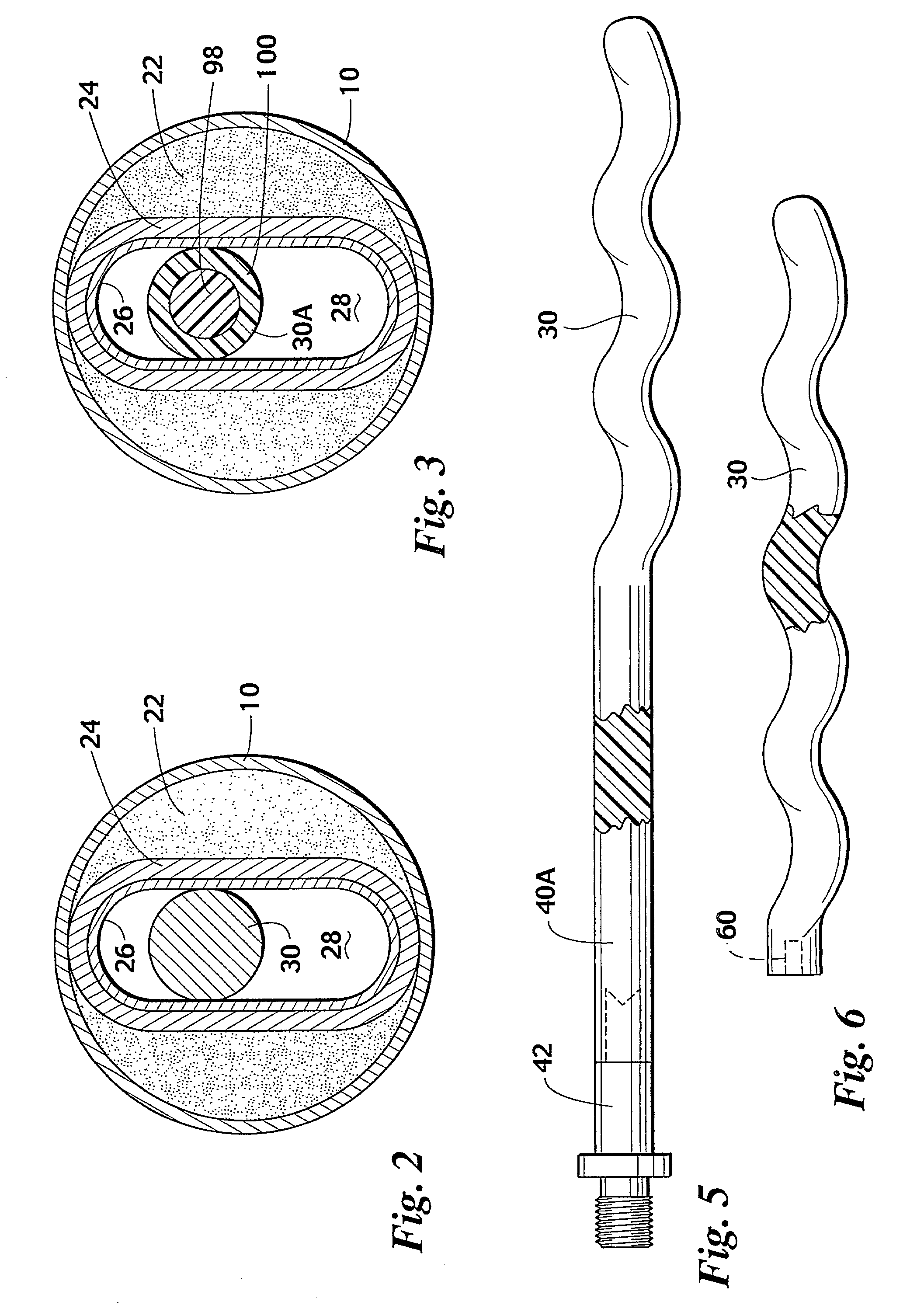

Progressive cavity helical device

InactiveUS20010005486A1Oscillating piston enginesEngine of intermeshing engagement typeBiomedical engineeringHelix

Owner:BICO DRILLING TOOLS

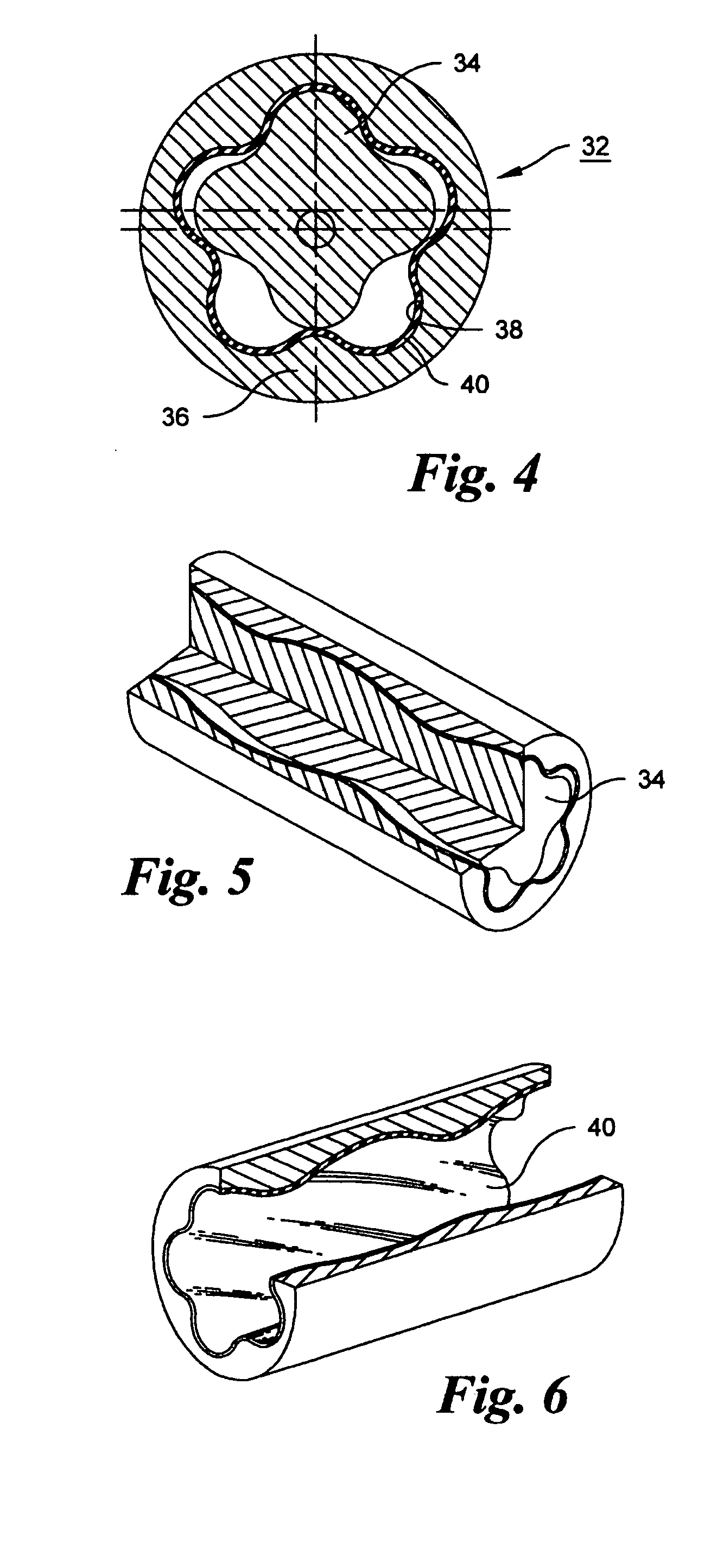

Moineu stator including a skeletal reinforcement

ActiveUS20080304991A1Extended service lifeNot easy to layerOscillating piston enginesEngine of intermeshing engagement typeElastomerInterference fit

A Moineau style stator includes a helical cavity component having reinforced helical lobes. The lobes are reinforced with a three-dimensional network of physically bonded aggregate particles. The network of bonded aggregate provides a porous skeletal-like structural reinforcement. Pore volume between the bonded aggregate particles may optionally be partially or substantially filled with an elastomer. An elastomer liner is typically deployed on an inner surface of the helical lobes to promote a rotational interference fit with a rotor.

Owner:SMITH INT INC

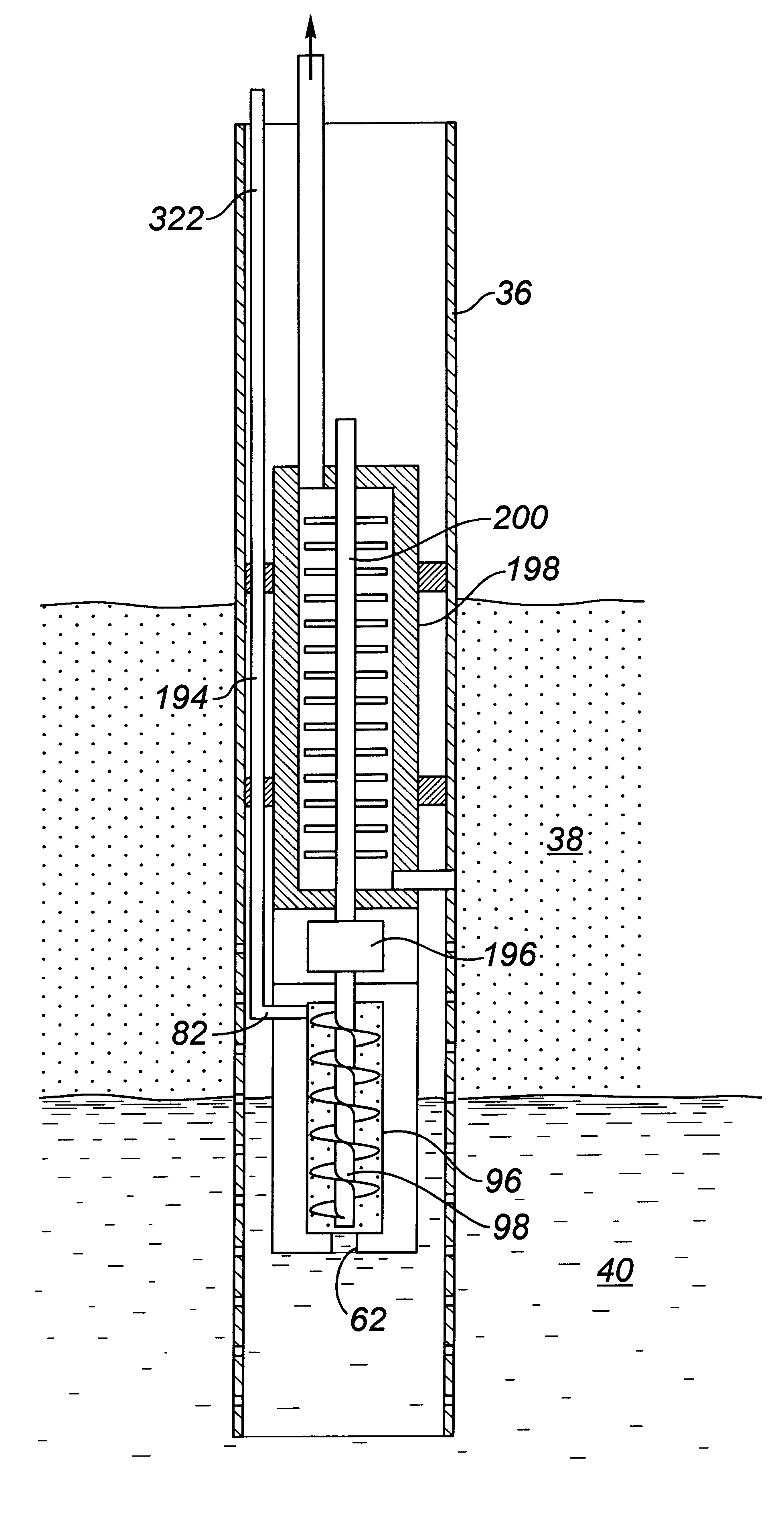

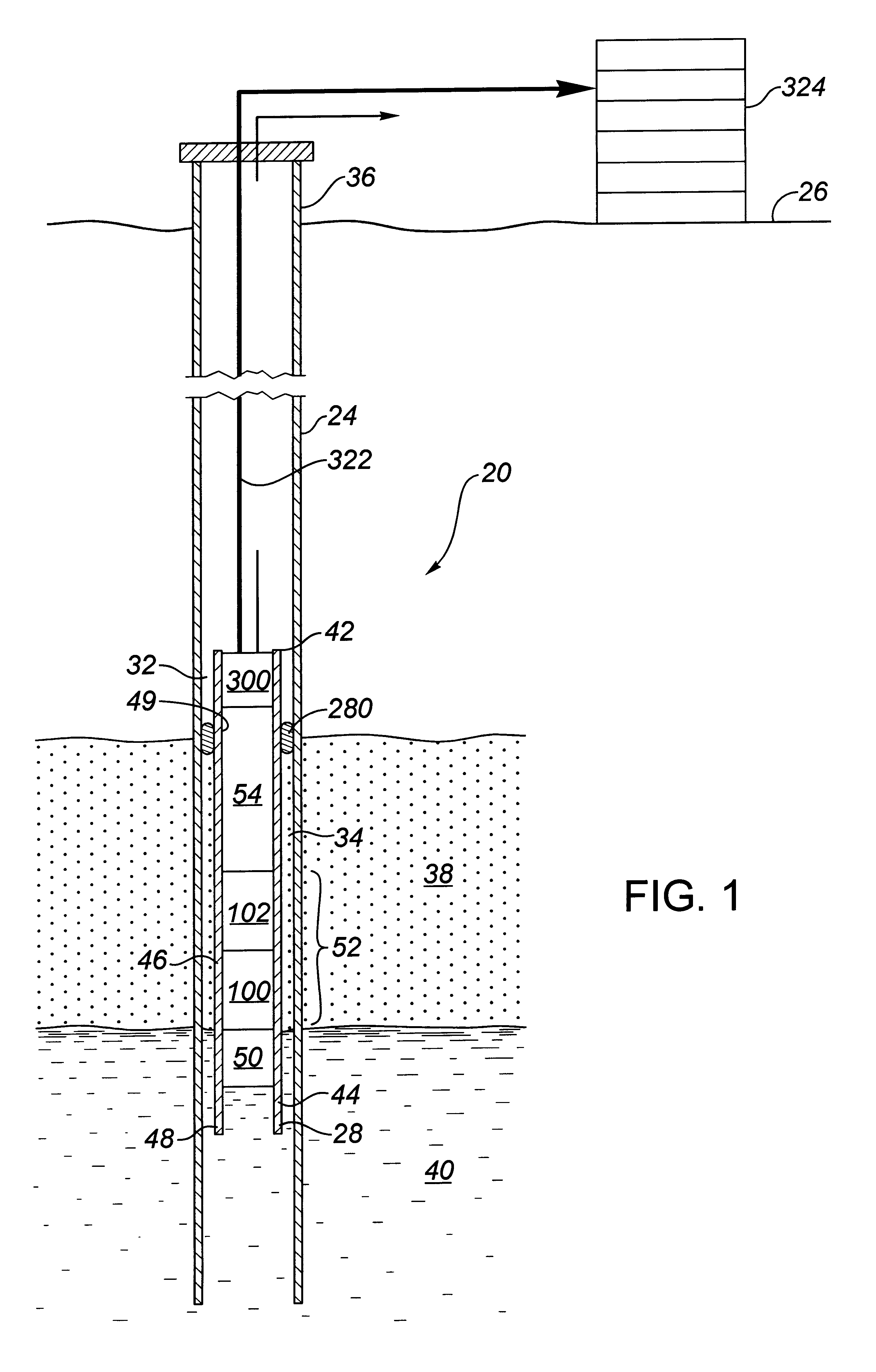

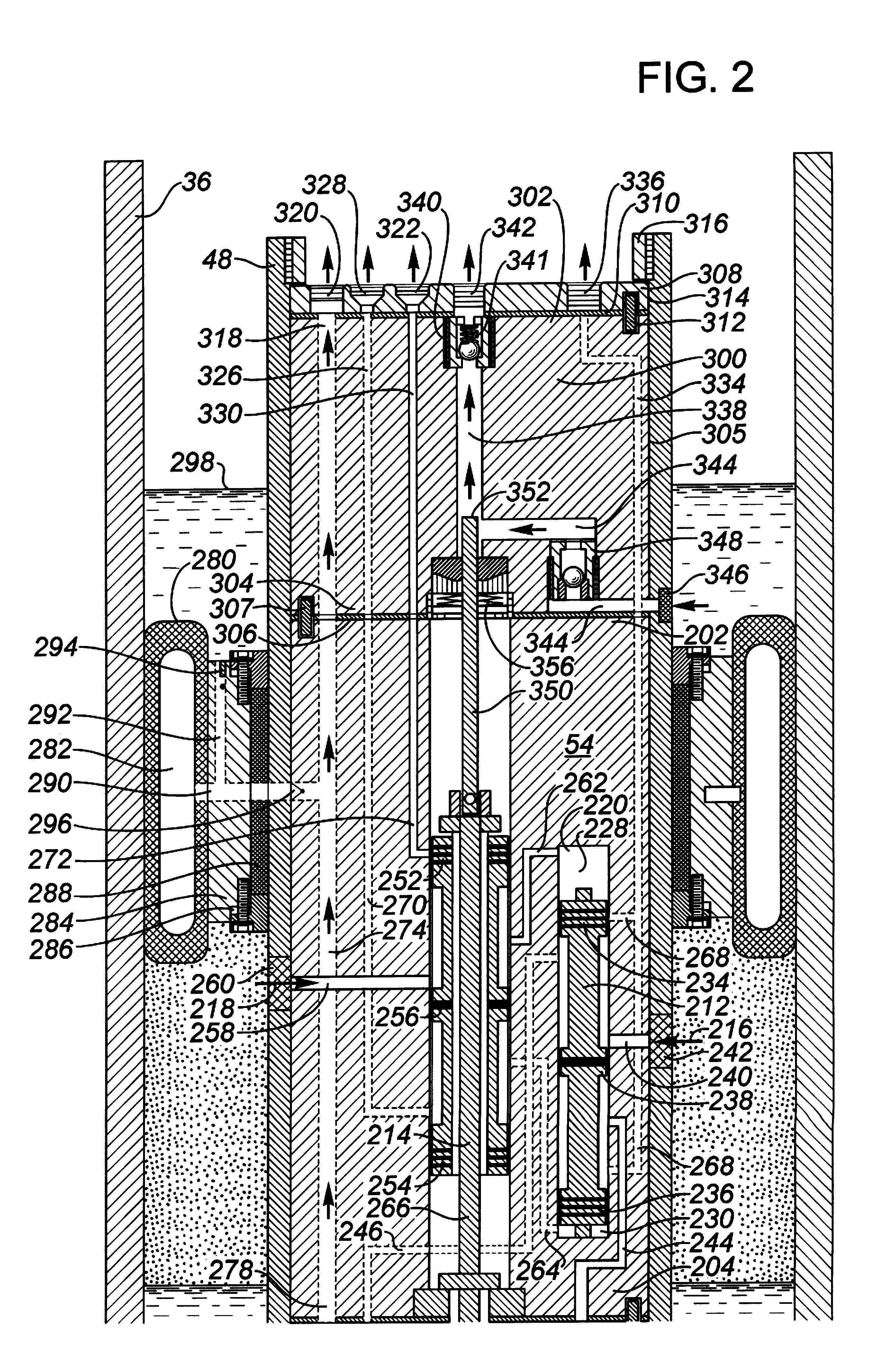

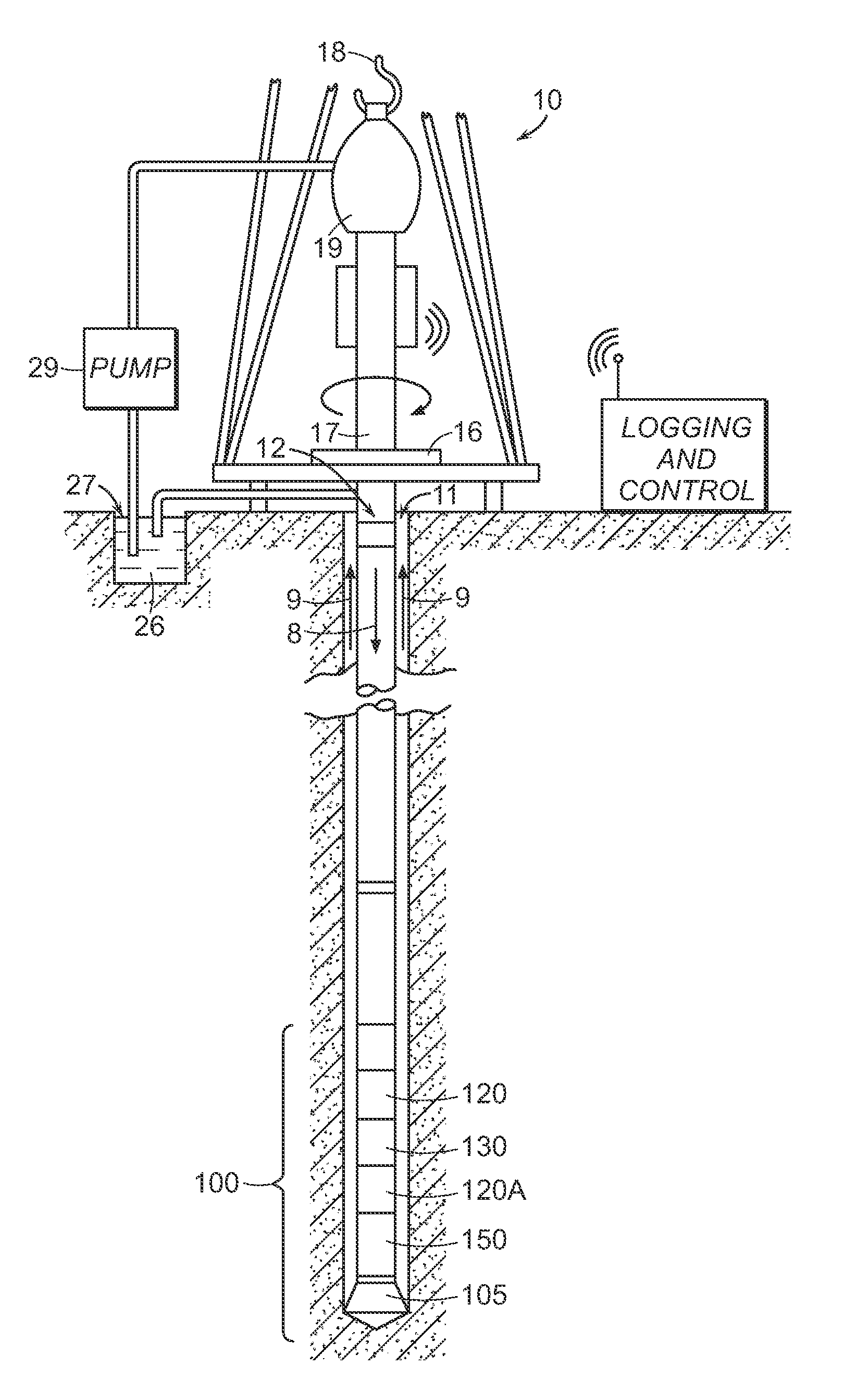

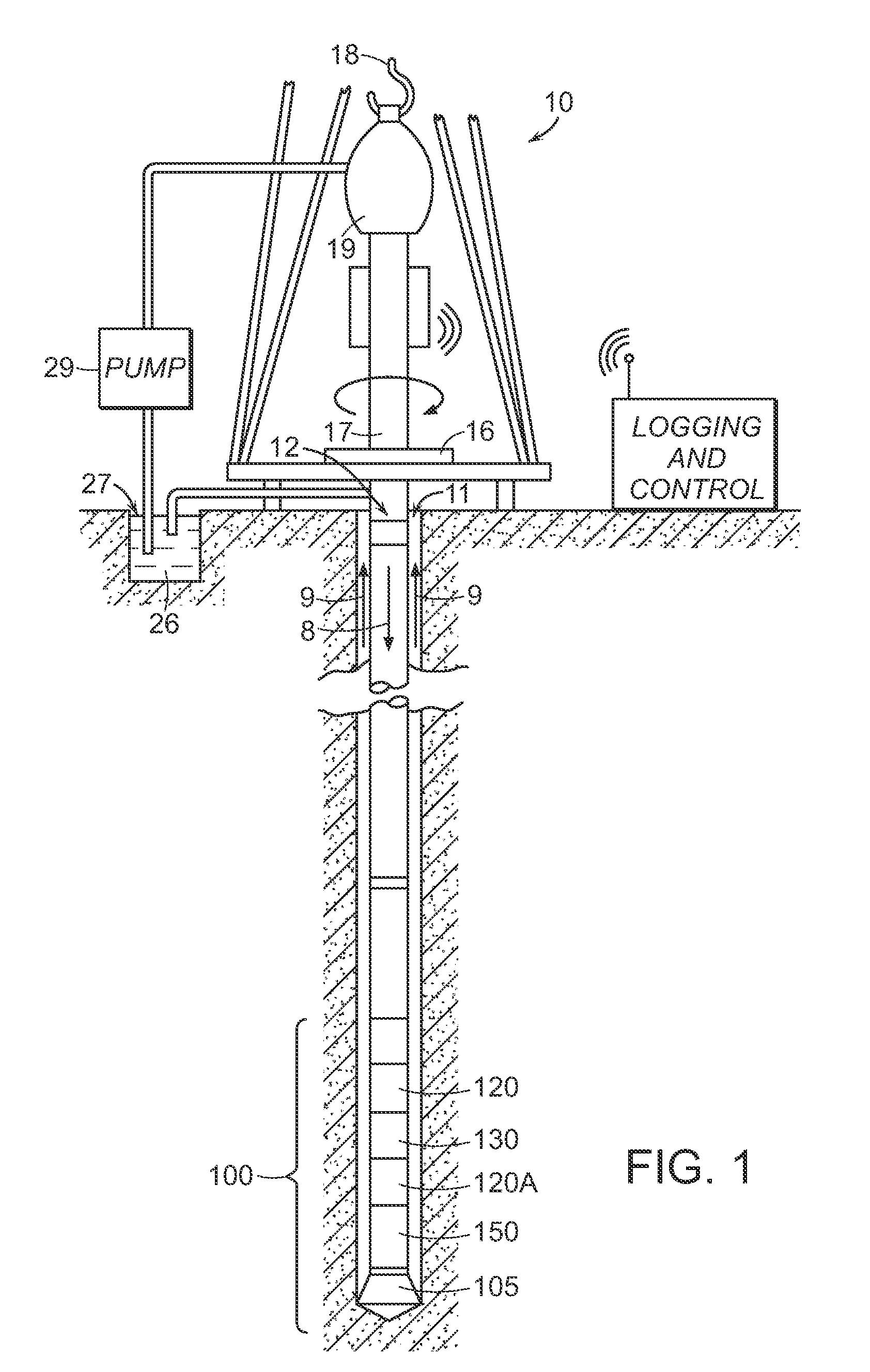

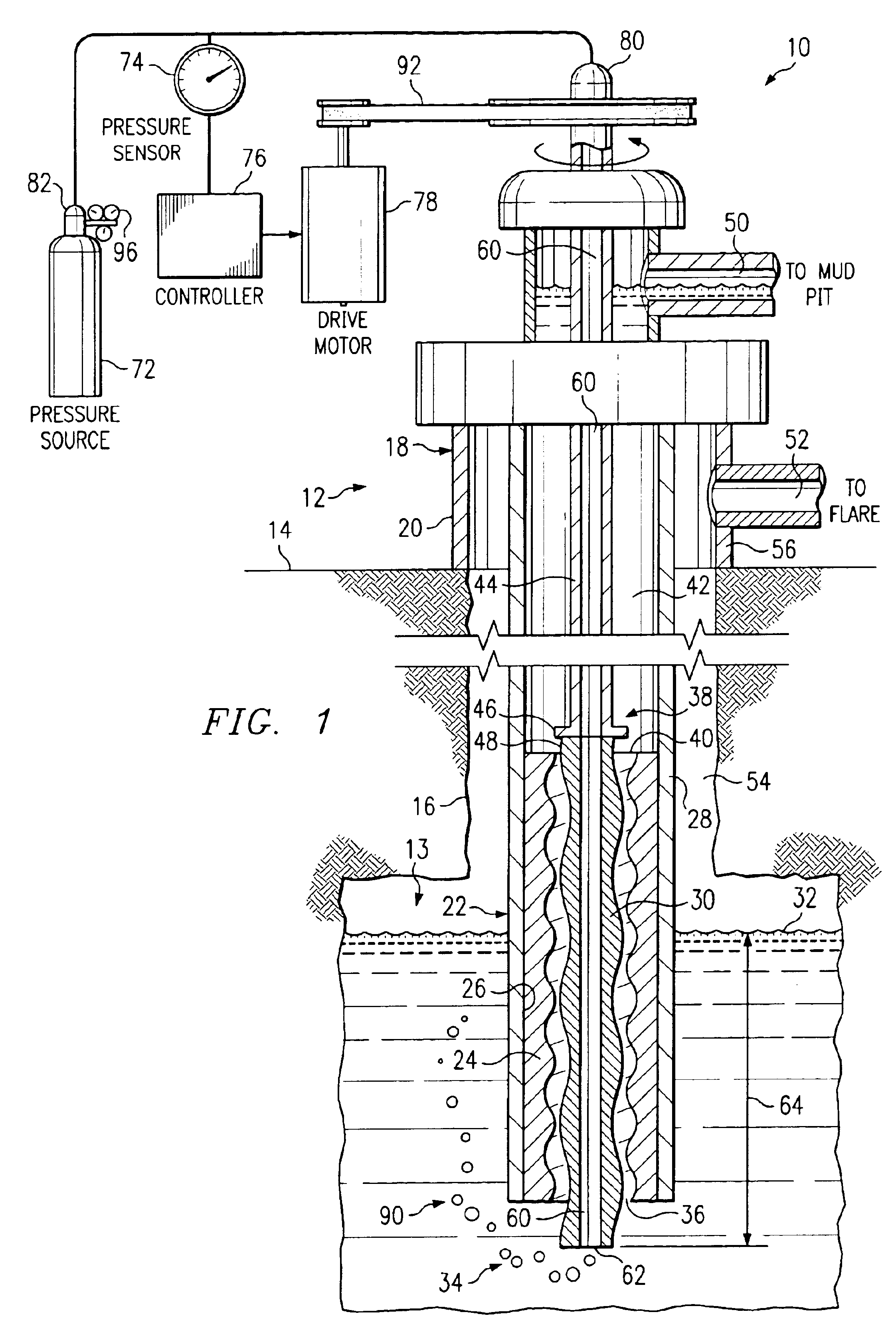

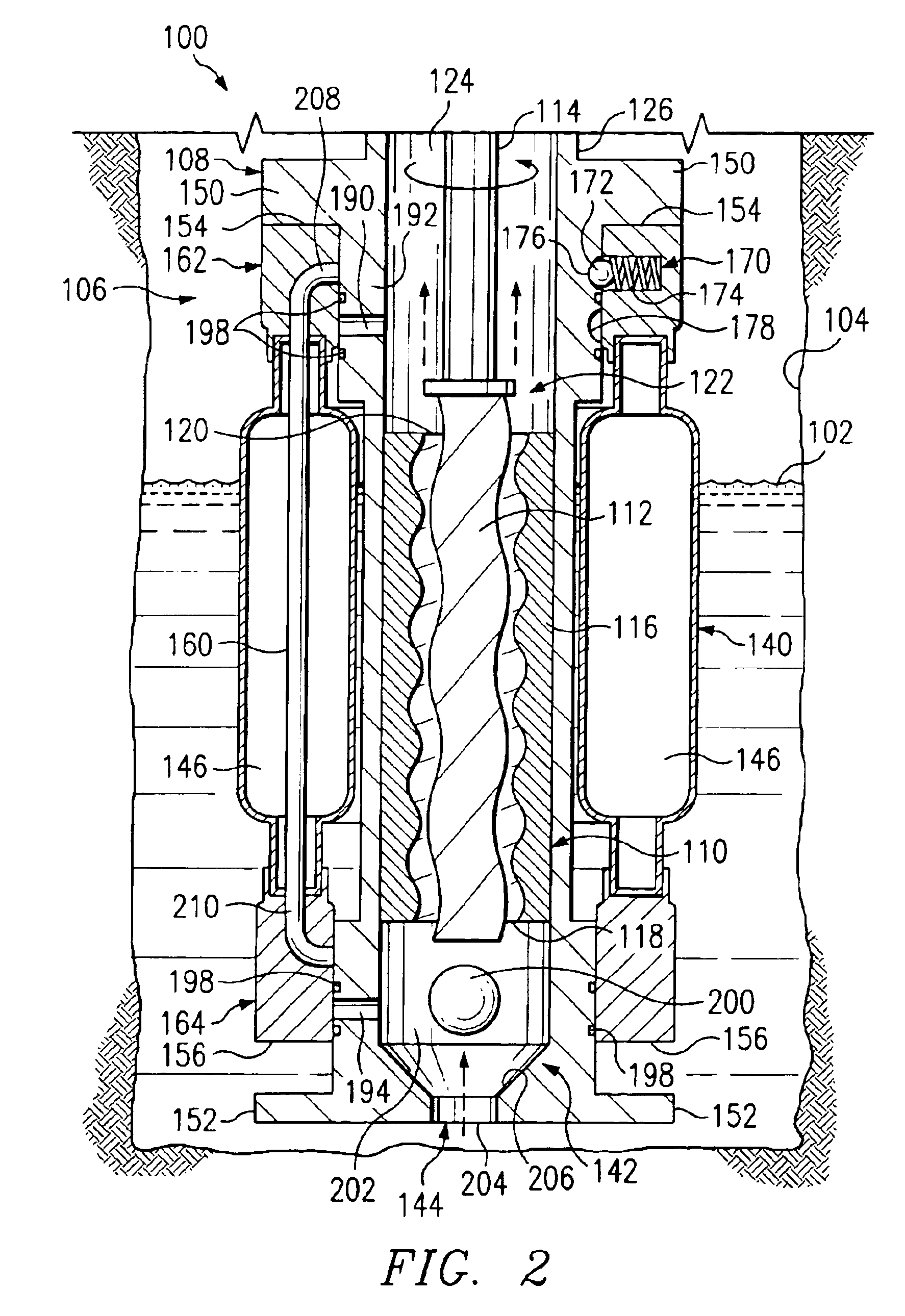

Reservoir fluids production apparatus and method

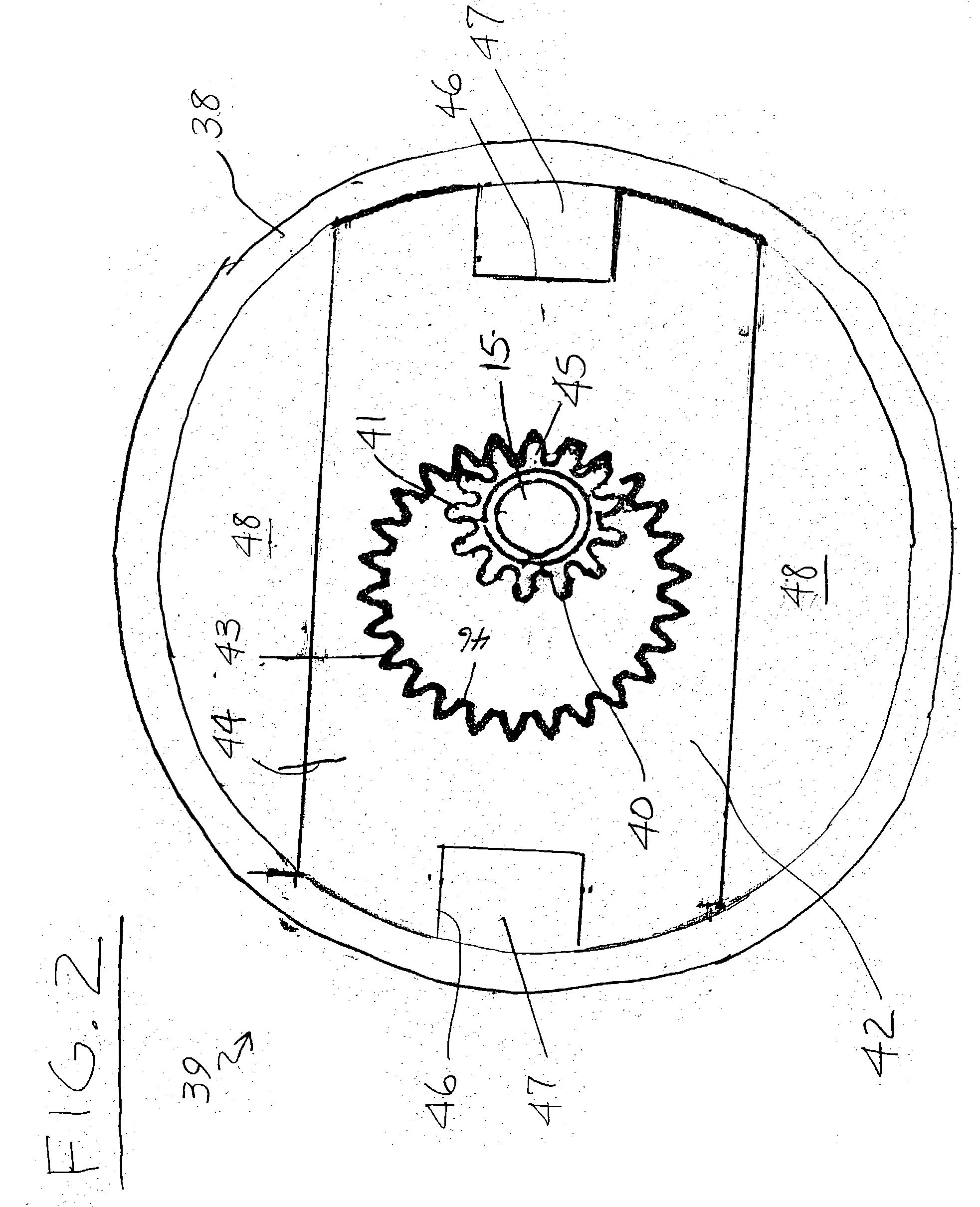

The invention is an apparatus for moving reservoir fluids from an underground reservoir using a wellbore extending from the surface to an end beneath the surface, wherein the wellbore communicates with the reservoir such that reservoir fluids enter the wellbore and separate into a liquid phase and a gas phase at a gas pressure. The apparatus includes a first pump, for containing within the wellbore in communication with the liquid, for pumping the liquid phase. The apparatus further includes a pump drive, for containing within the wellbore, operably connected to the first pump for driving the first pump. The pump drive is powered using the gas pressure of the gas phase in the wellbore. An intake communicates with the gas phase in the wellbore and directs the gas phase to the pump drive in order to power the pump drive, while an exhaust directs the gas phase from the pump drive. Further, the invention is a method for moving reservoir fluids from an underground reservoir using a wellbore. The method includes the steps of intaking the gas phase from the wellbore into the pump drive, powering the pump drive using the gas pressure of the gas phase in the wellbore, pumping the liquid phase from the wellbore by the first pump and exhausting the gas phase from the pump drive.

Owner:ALBERTA INNOVATES TECH FUTURES

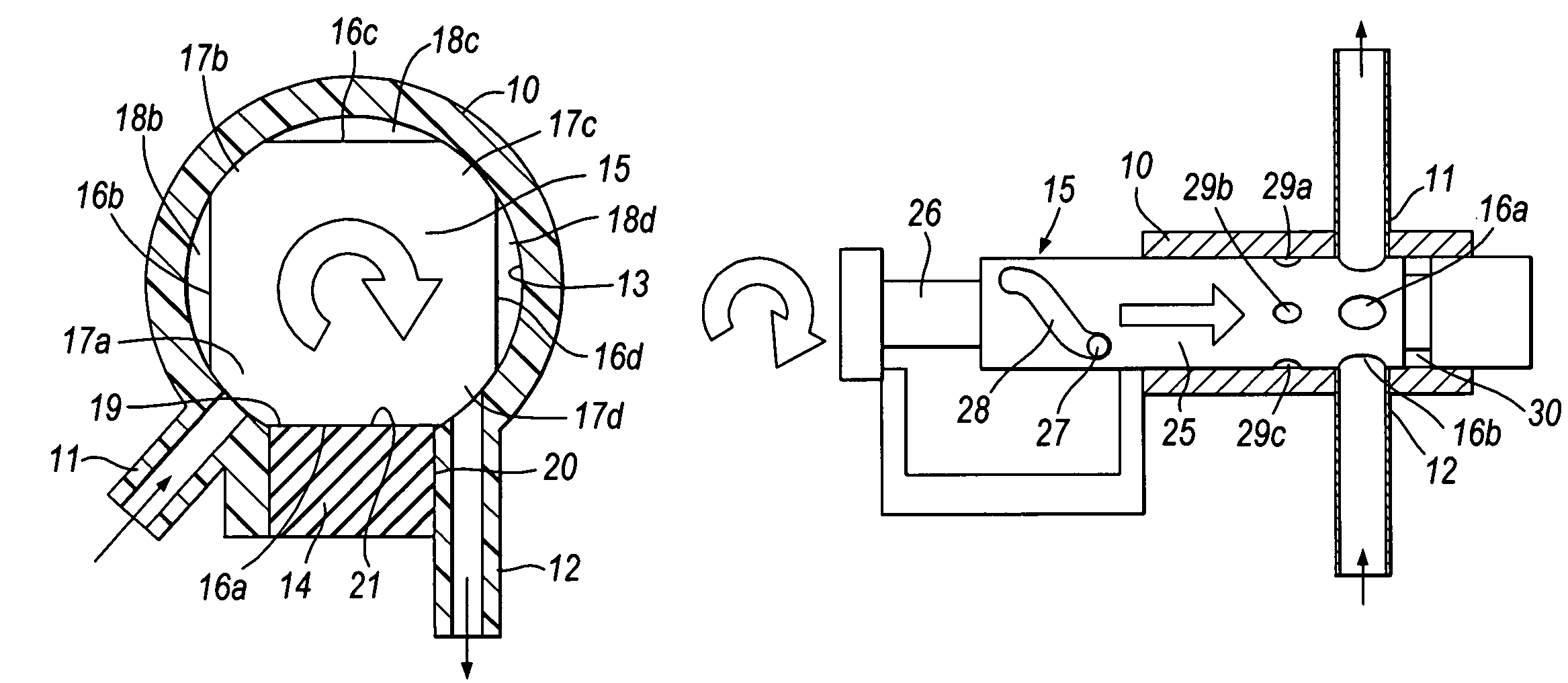

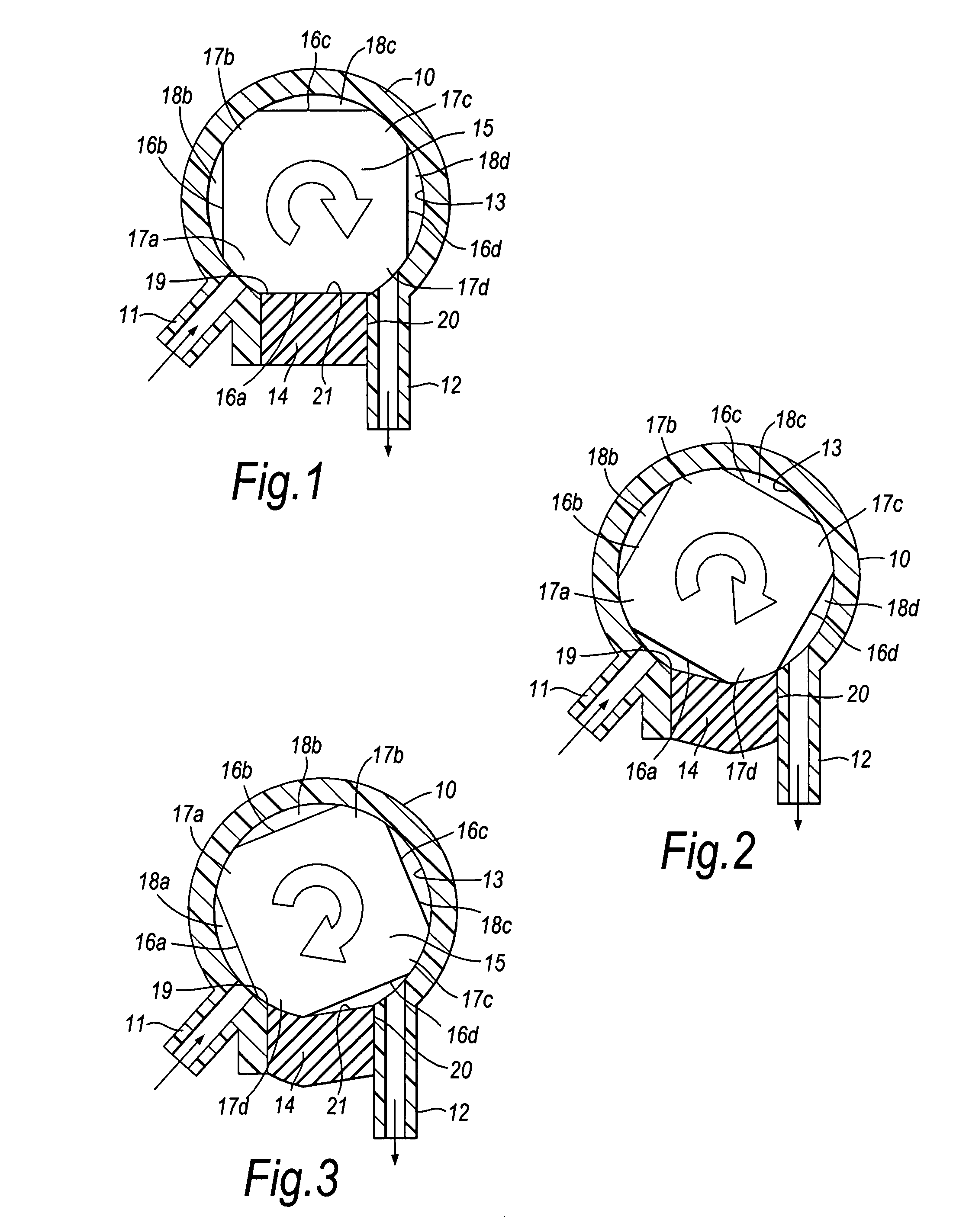

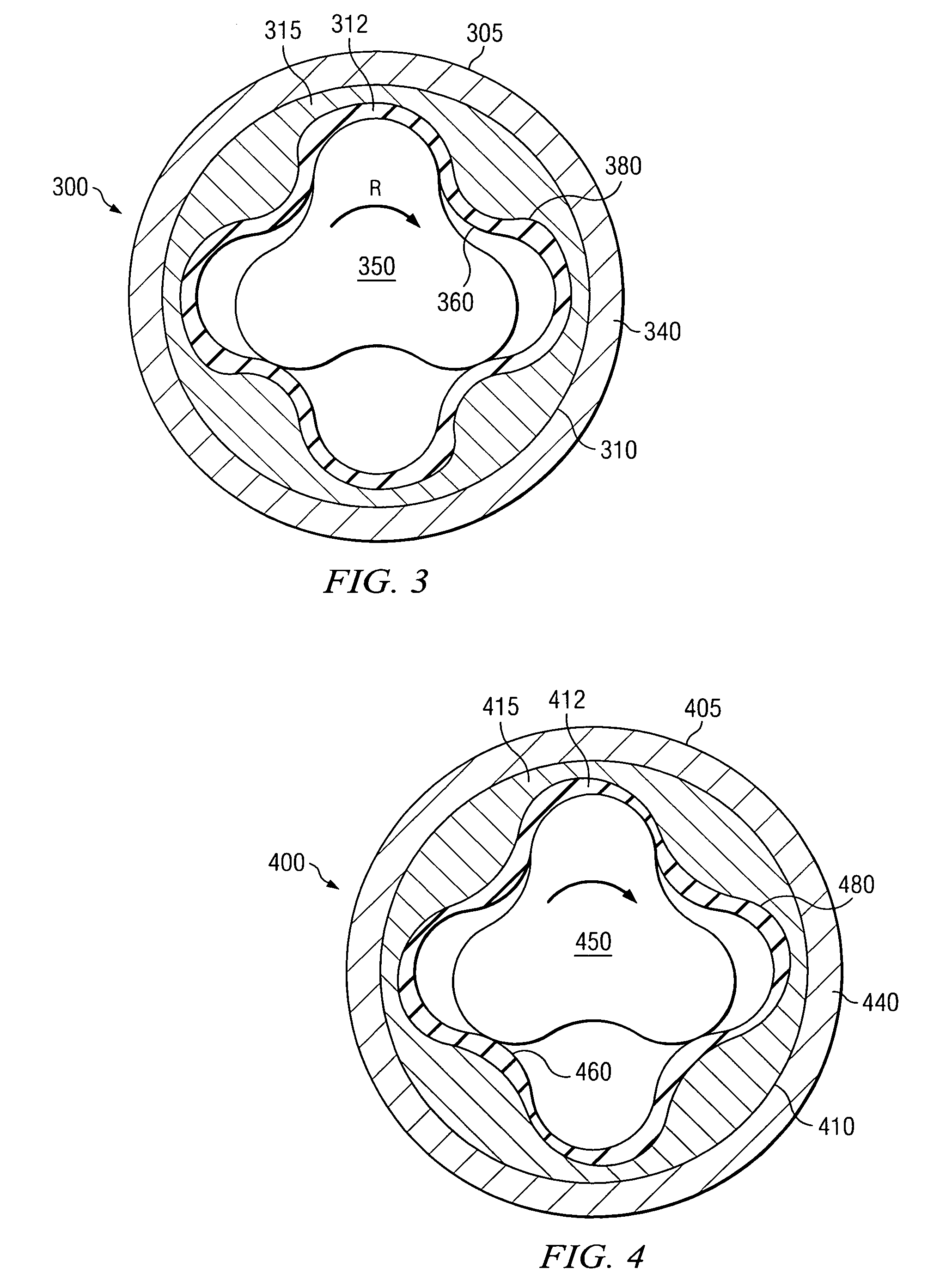

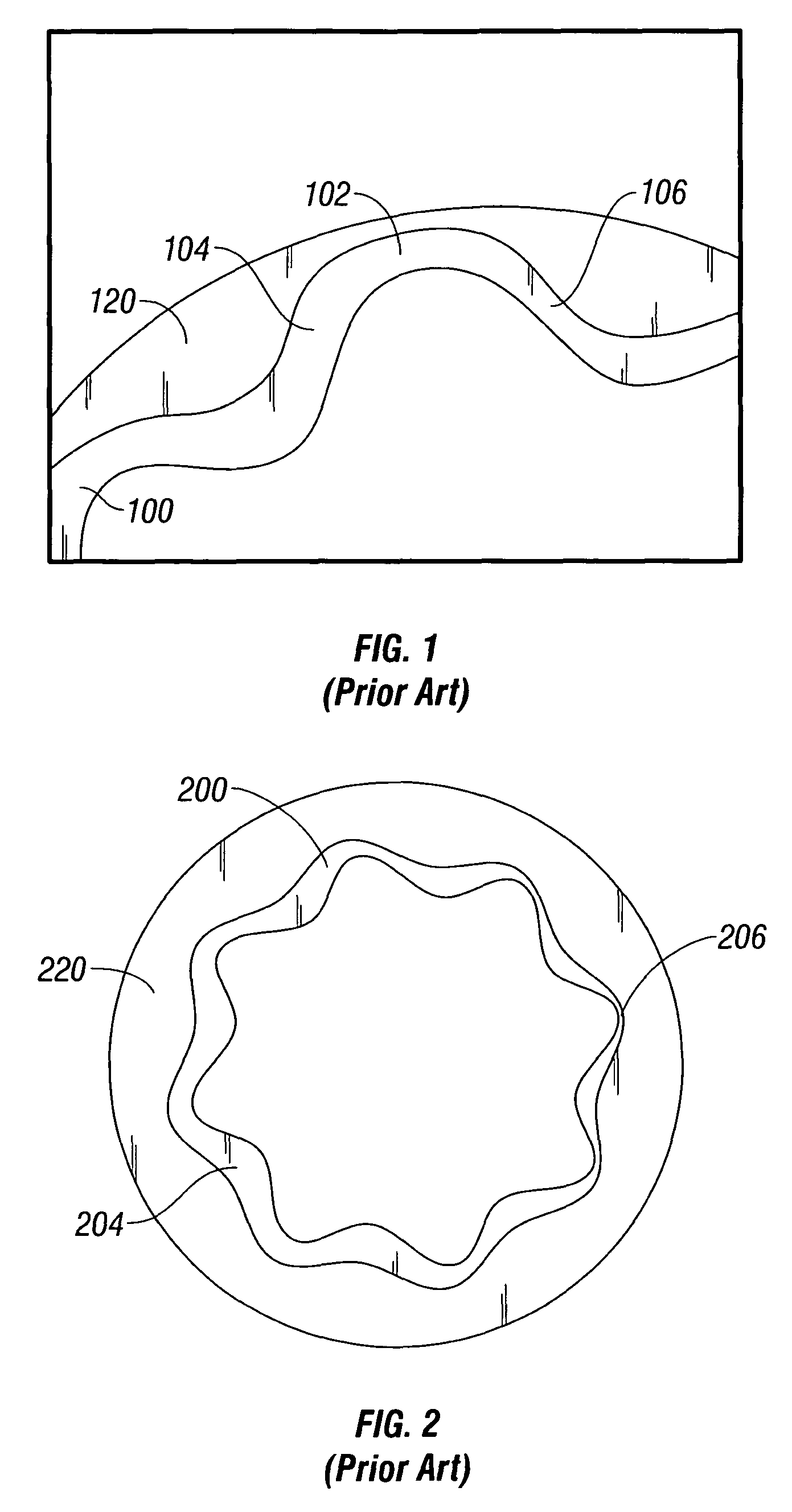

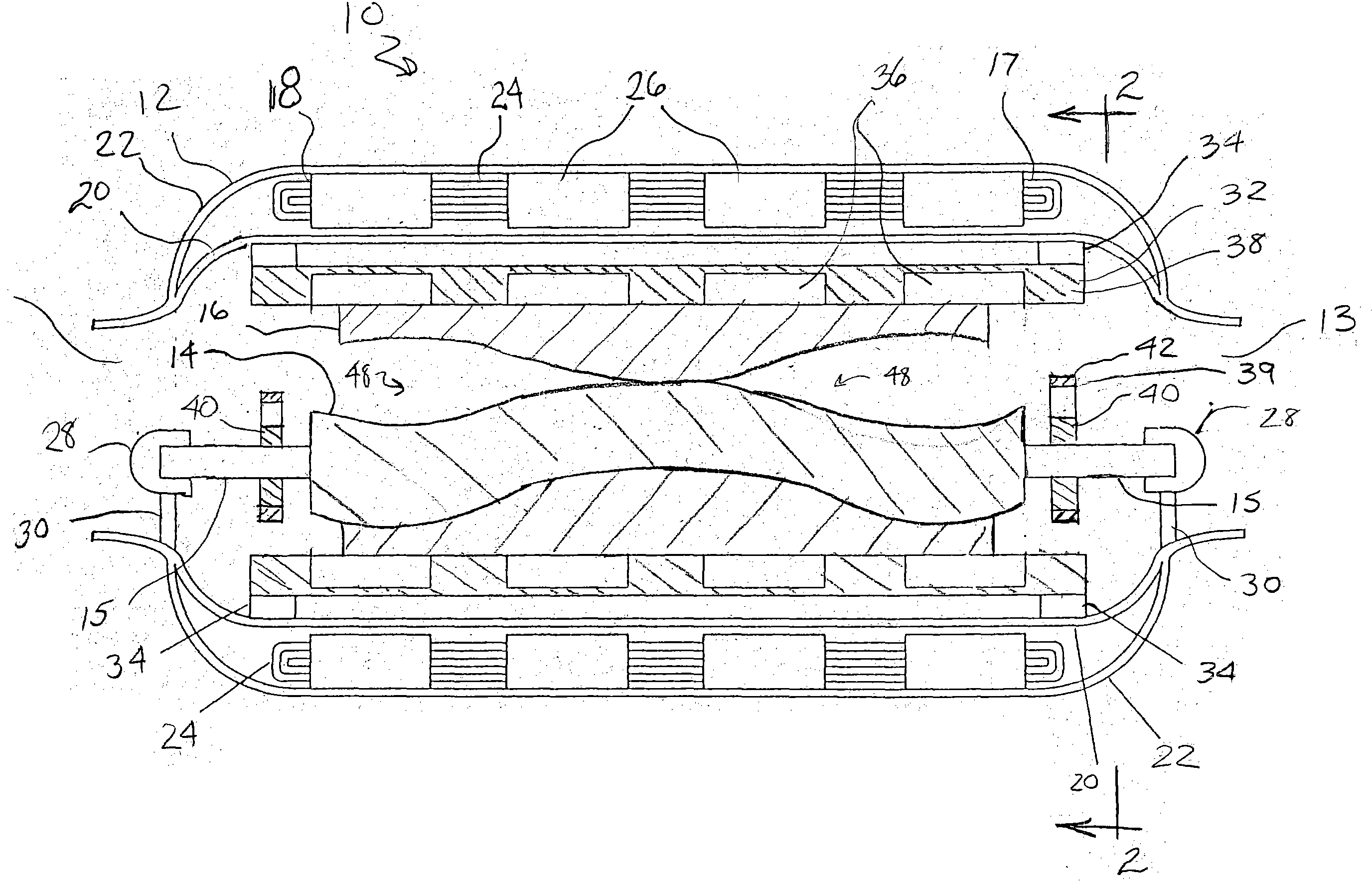

Roudong Volume Variation Method for Fluid Machinery and Its Mechanisms and Applications

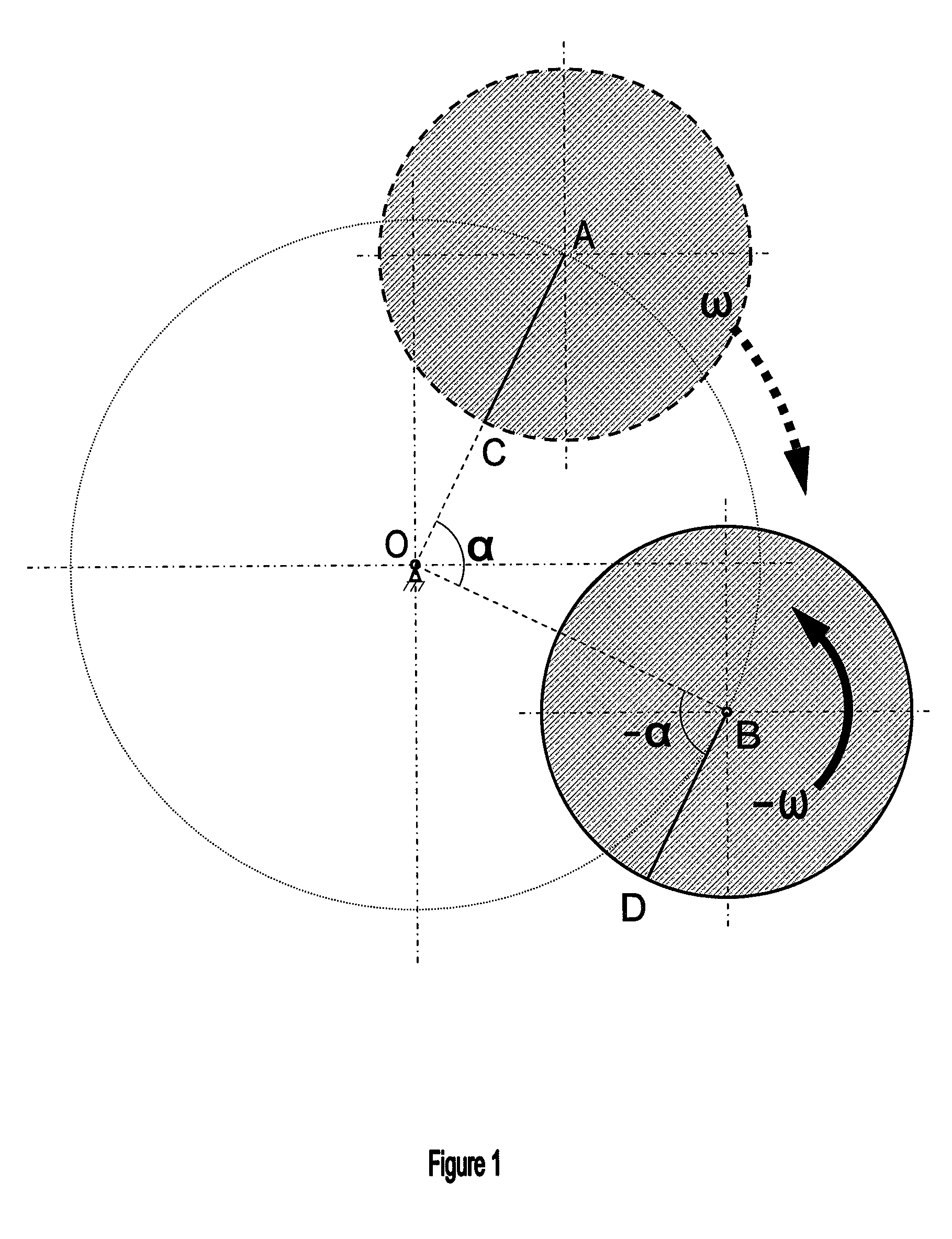

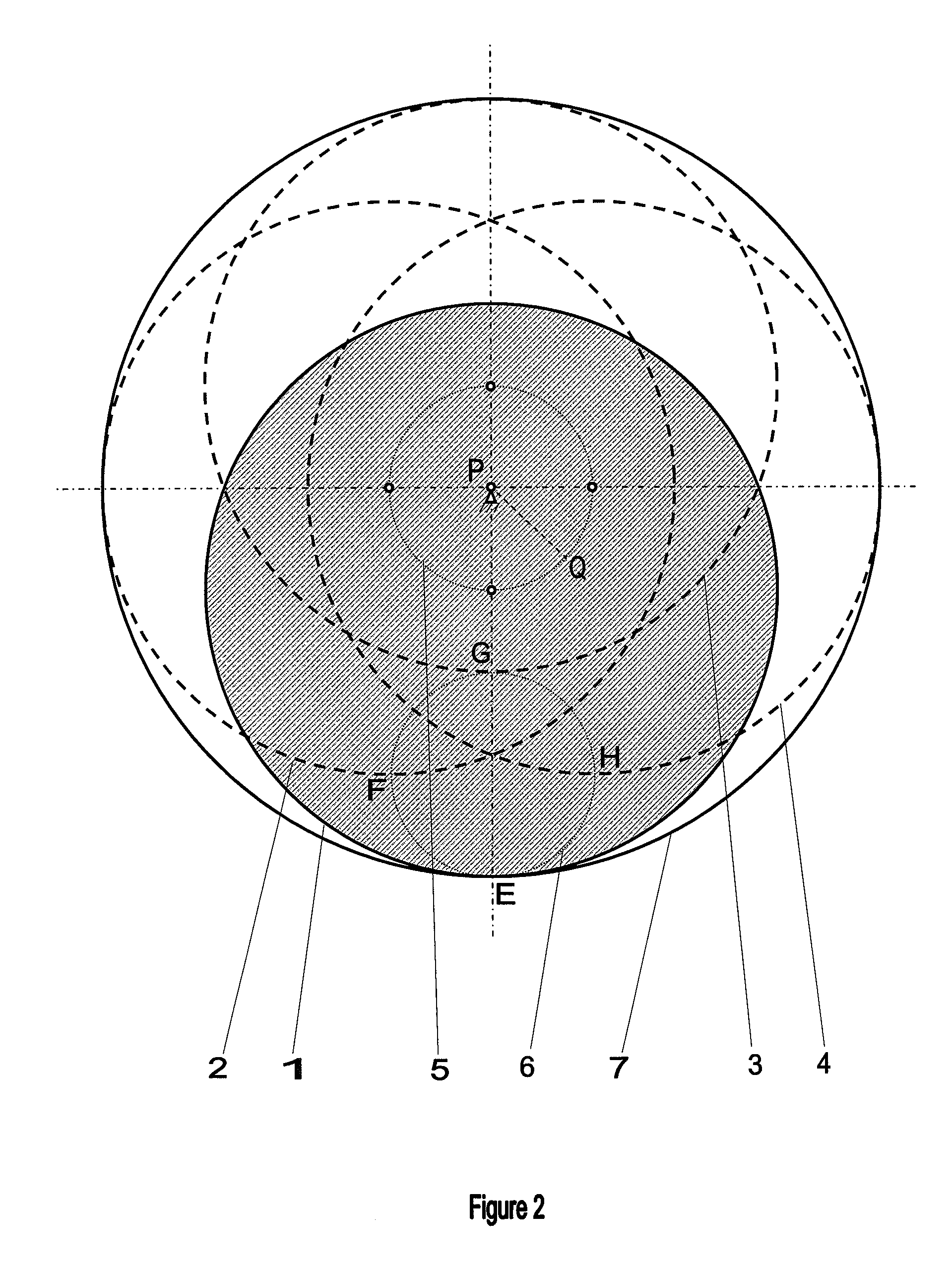

InactiveUS20080095652A1Wide range of applicationsSignificant positive effectInternal combustion piston enginesOscillating piston enginesMomentumVolume variation

The invention relates to a roudong volume variation method for fluid machinery and its mechanisms and applications, which is suitable to be used in internal combustion engine, pump, compressor, motor, transmission, refrigeration, metering, etc. In the roudong volume variation method, a roudong volume variation motion can be produced by the combination of a revolution of a roudong rotor in a roudong cavity and a rotation of the same in an inverse direction, causing speed, moment of momentum and loss to be reduced by 90%˜99% in comparison with a rotor with the same ratio. A roudong internal combustion engine has an efficiency increase of 25% and is free from lubrication. A roudong pump has an efficiency as high as 90%. Roudong isothermal compression can reduce 39%˜67% work, while roudong refrigeration can reduce 50% work. Roudong general fluid machinery has the functions of pump and motor, and also has such functions as metering, control, etc. Roudong general fluid machinery, which can be operated with gas, liquid and two-phase flow, can be provided with a flow rate as desired. It has good pressure self-adaptability, versatility and high efficiency.

Owner:JIANG ZIGANG

Progressive cavity pump/motor stator, and apparatus and method to manufacture same by electrochemical machining

ActiveUS20050079083A1Improve heat transfer performanceReduce adverse effectsOscillating piston enginesEngine of intermeshing engagement typeRough surfaceElectricity

Electrochemical machining is used to generate the helical lobe profiles of the stator of a progressive cavity pump or motor. A thin, elastomeric liner, of uniform thickness is bonded either to the interior of the stator, or to the exterior of the rotor. Where the elastomeric liner is to be bonded to the interior of the stator, bonding is improved by electrically etching the interior of the stator during the electrochemical machining process to produce a roughened surface.

Owner:LEHR PRECISION

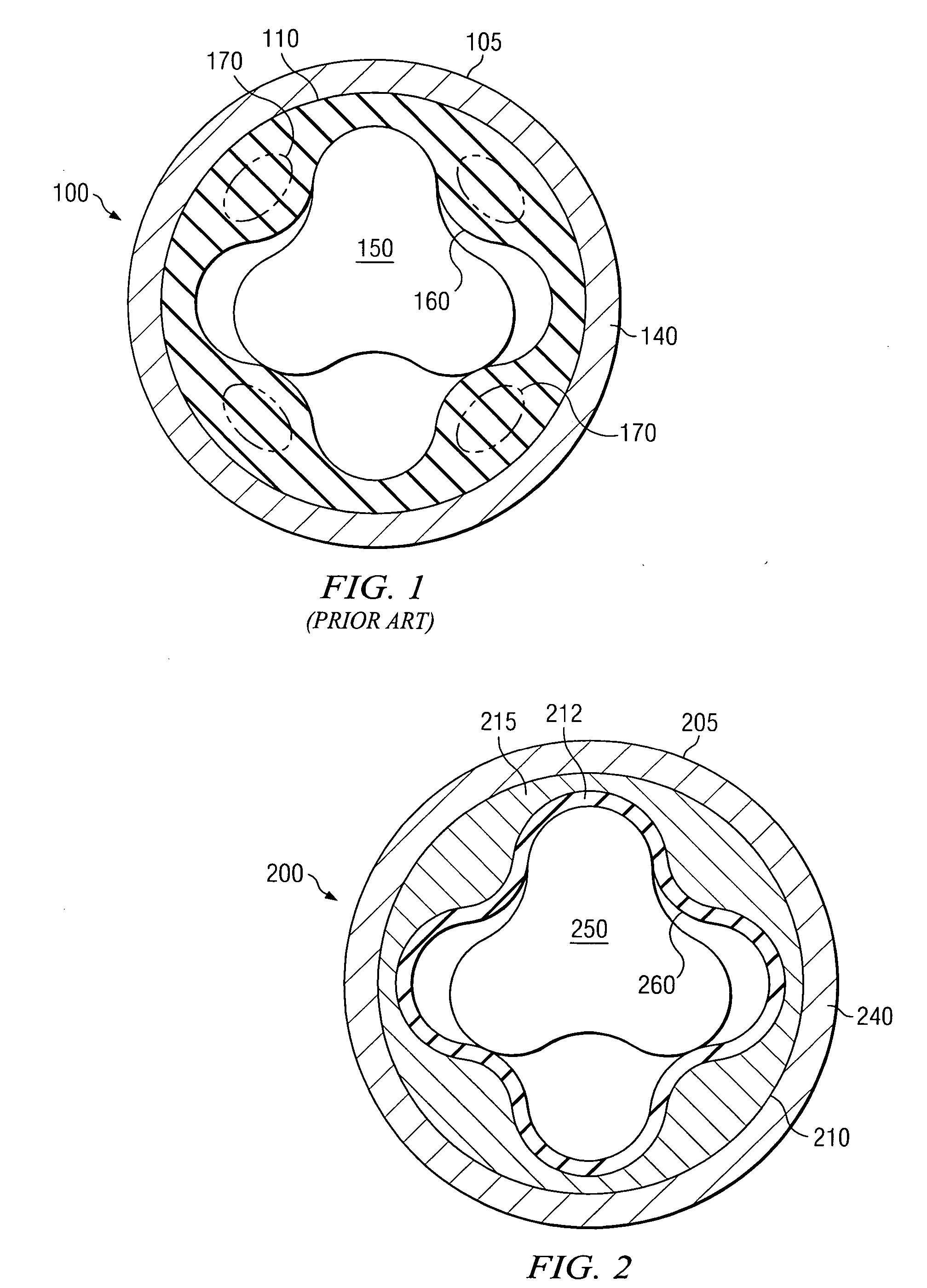

Asymmetric contouring of elastomer liner on lobes in a Moineau style power section stator

ActiveUS7083401B2Increasing the thicknessIncrease elasticityOscillating piston enginesEngine of intermeshing engagement typeElastomerEngineering

The inventive stator includes a helical cavity component made from a material chosen to reinforce an elastomer liner deployed thereon. The contouring of the elastomer liner is asymmetrical, such that the elastomer liner is relatively thick on the loaded side of a lobe as compared to its thickness on the unloaded side of the lobe.

Owner:SMITH INT INC

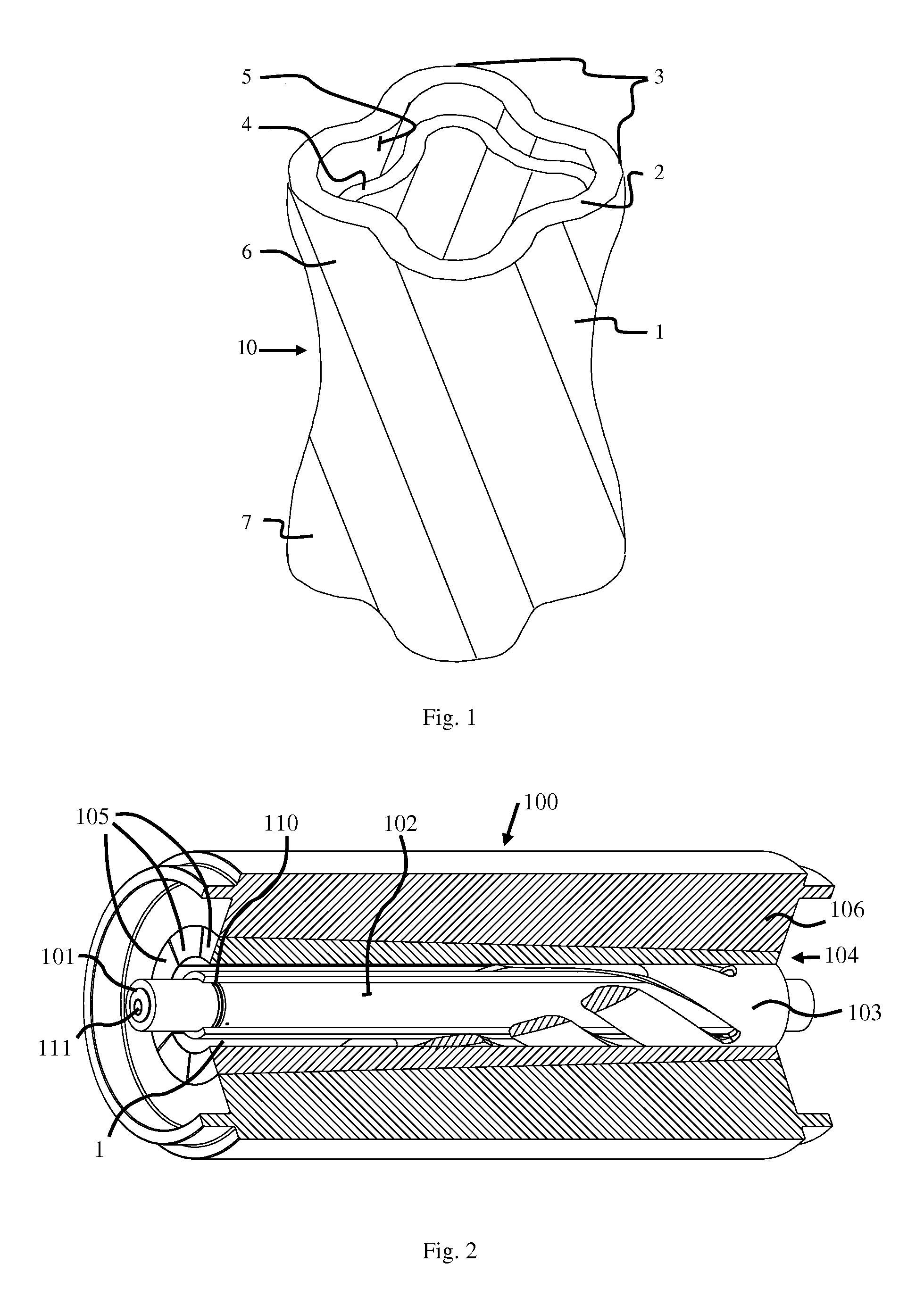

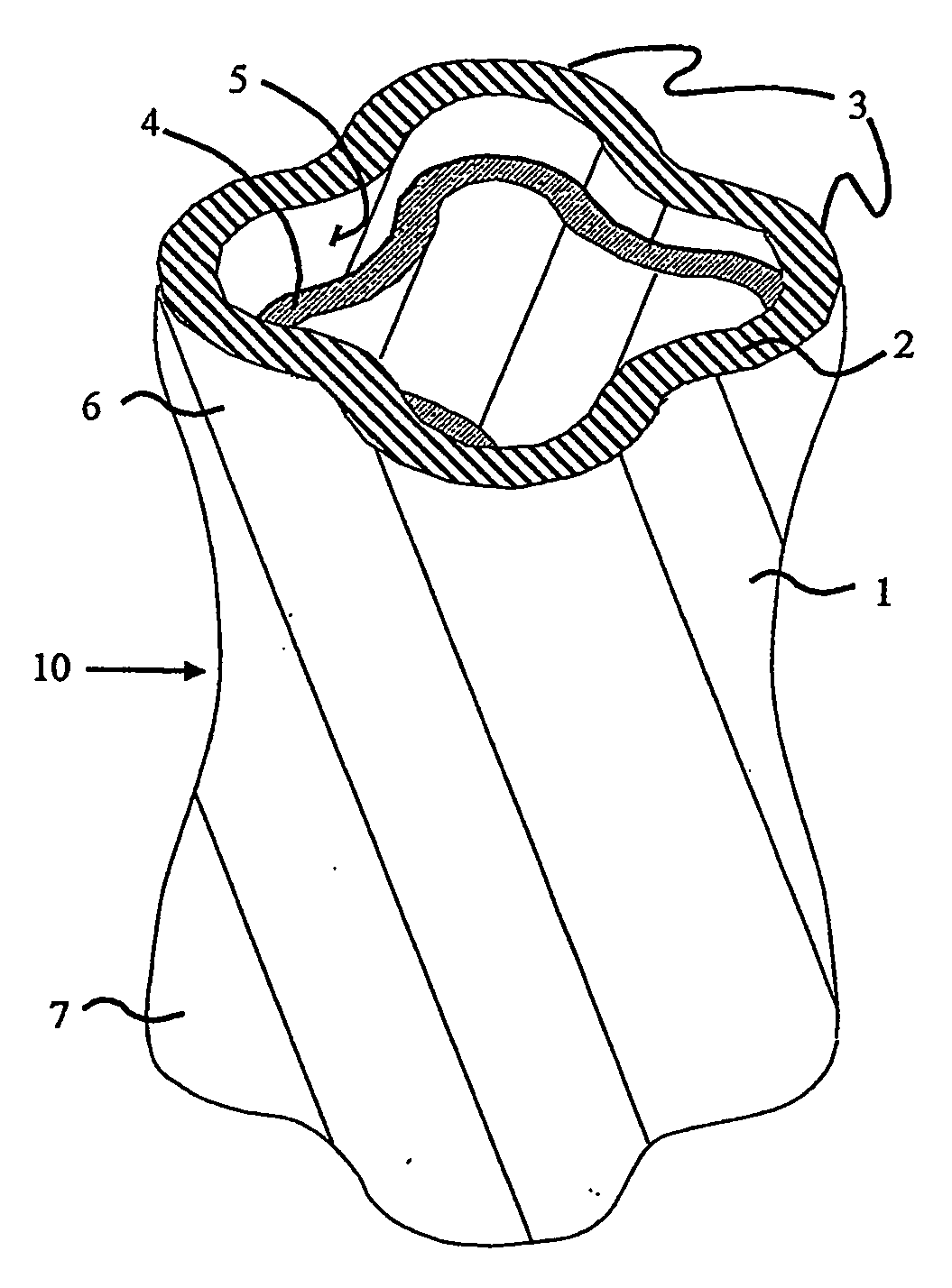

Stator of a moineau-pump

InactiveUS7442019B2Improve rigidityHigh strengthOscillating piston enginesEngine of intermeshing engagement typeEngineeringMechanical engineering

A Moineau stator includes a tube (10) having lobes (3) arranged in a configuration which is adapted to interact with a rotor and formed through a hydroforming process.

Owner:NOETIC TECH INC

Downhole motor seal and method

InactiveUS20060216178A1Improved frictional engagementEasy to operateOscillating piston enginesEngine of intermeshing engagement typeEngineeringMechanical engineering

Owner:SCHLUMBERGER TECH CORP

Method of forming an optimized fiber reinforced liner on a rotor with a motor

InactiveUS6944935B2Engine of intermeshing engagement typeRotary piston pumpsEngineeringMechanical engineering

Owner:SCHLUMBERGER TECH CORP

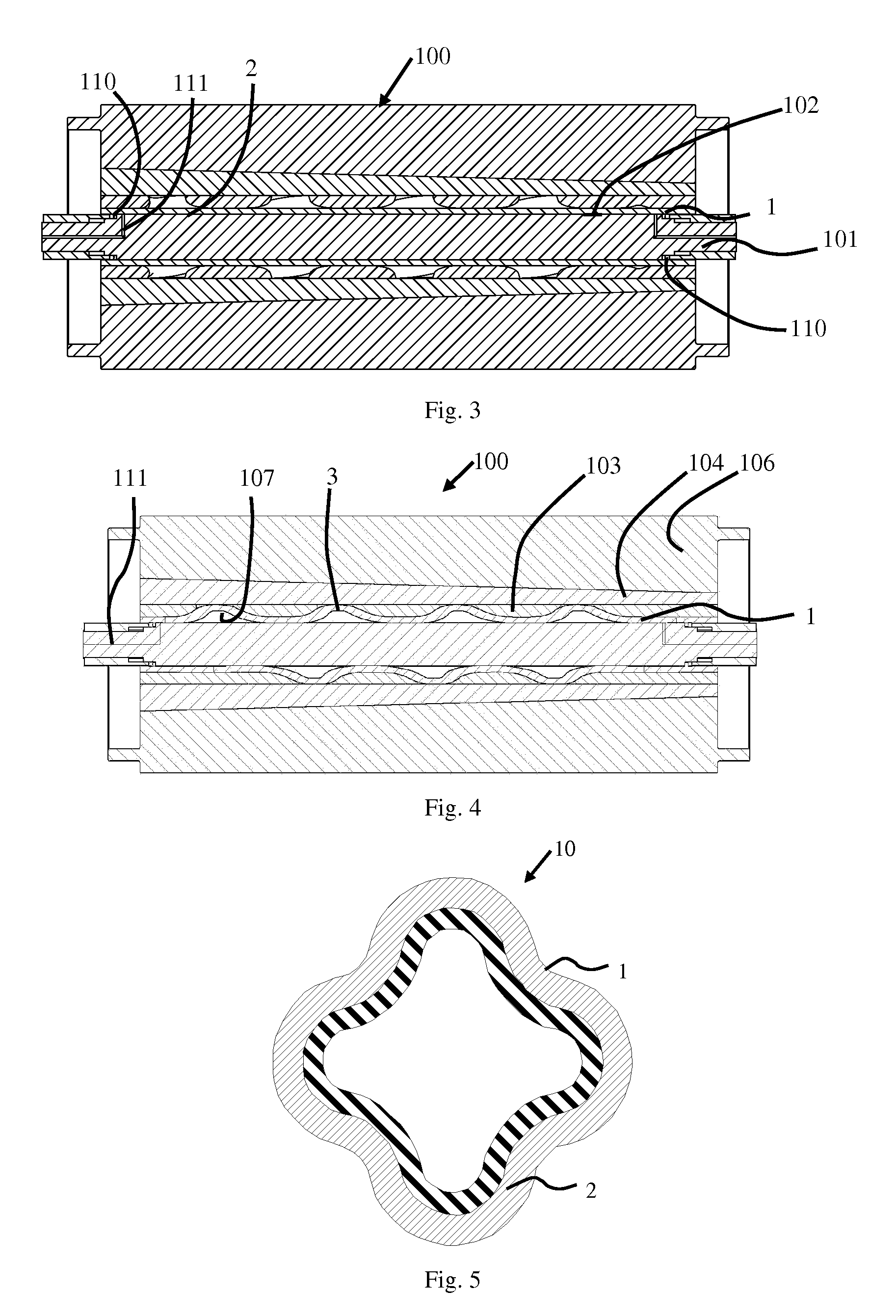

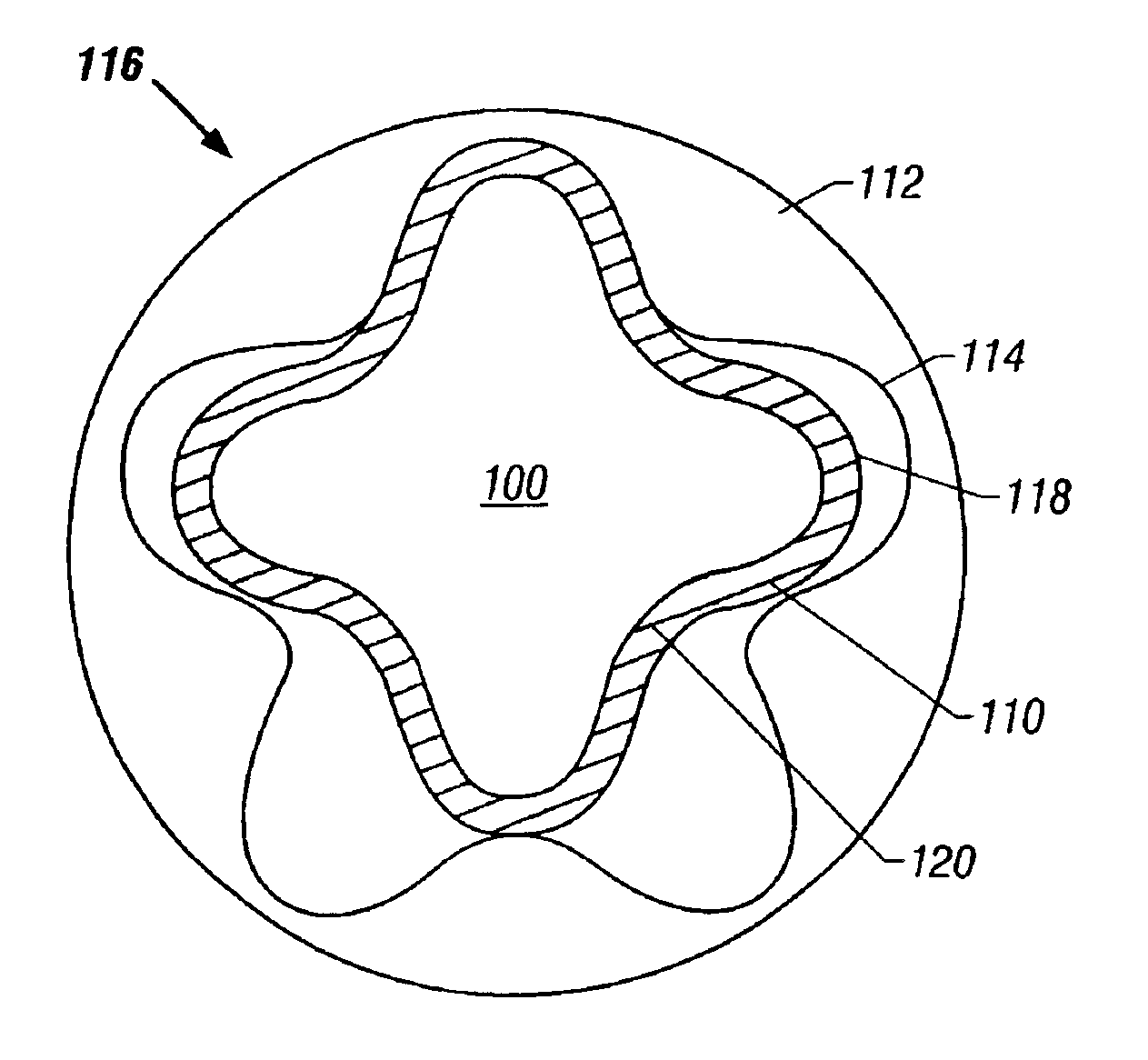

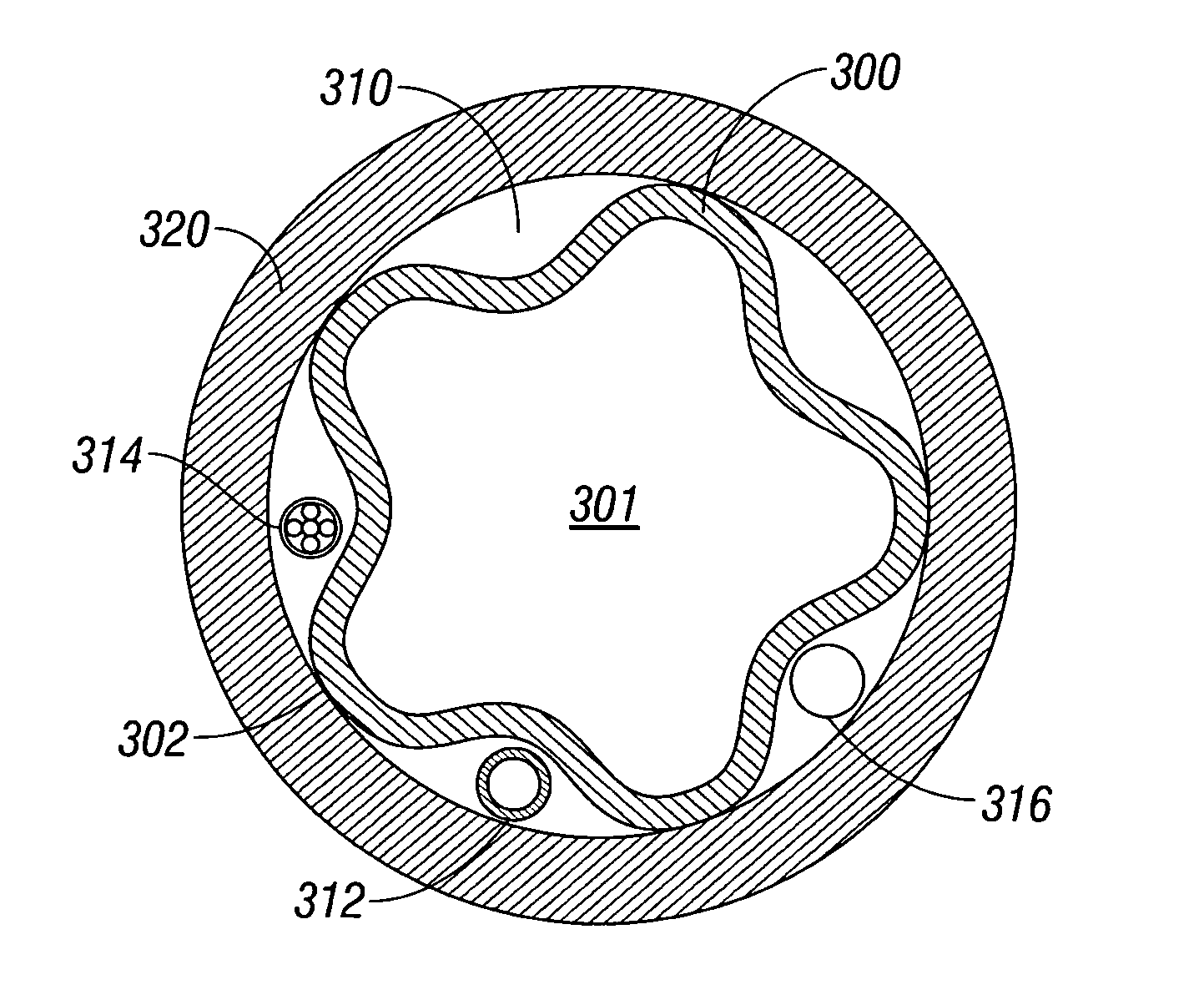

Method of forming controlled thickness resilient material lined stator

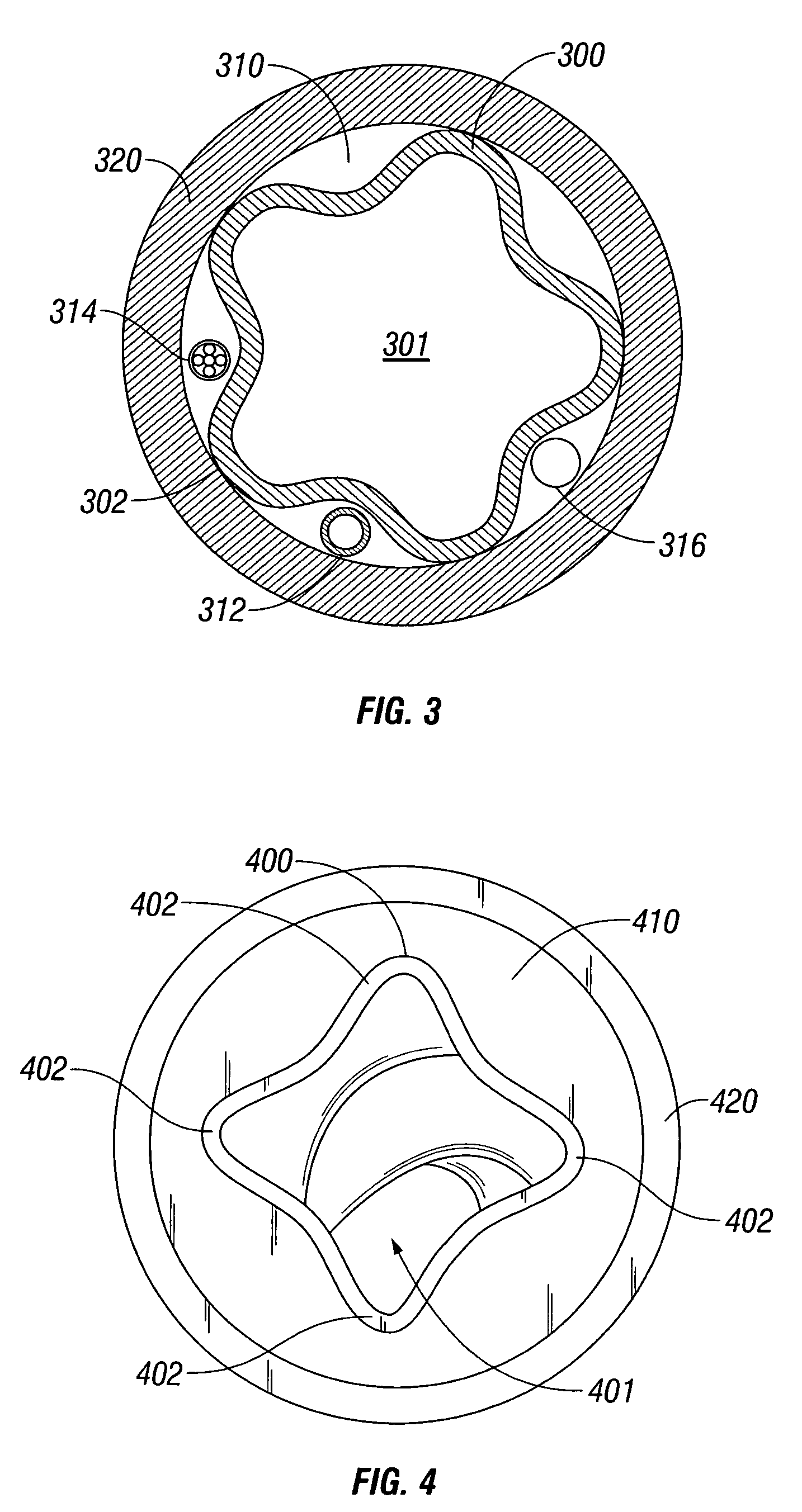

InactiveUS7739792B2Oscillating piston enginesEngine of intermeshing engagement typeElastomerElectrical conductor

The present invention relates to a resilient material lined stator and method of forming. A method of forming a resilient material lined stator can include disposing a resilient material tube 400 with a profiled helical inner surface 401 into the bore of a body 420. A cast material 410 can be disposed therebetween. The cast material 410 can bond to the body 420 to form a resilient material lined stator or the body 420 can be removed. The cast material 310 can include a conduit 312 or conductor 314 extending therethrough. The cast material 310 can include a pathway 316 formed therethrough. The resilient material can be an elastomer.

Owner:SCHLUMBERGER TECH CORP

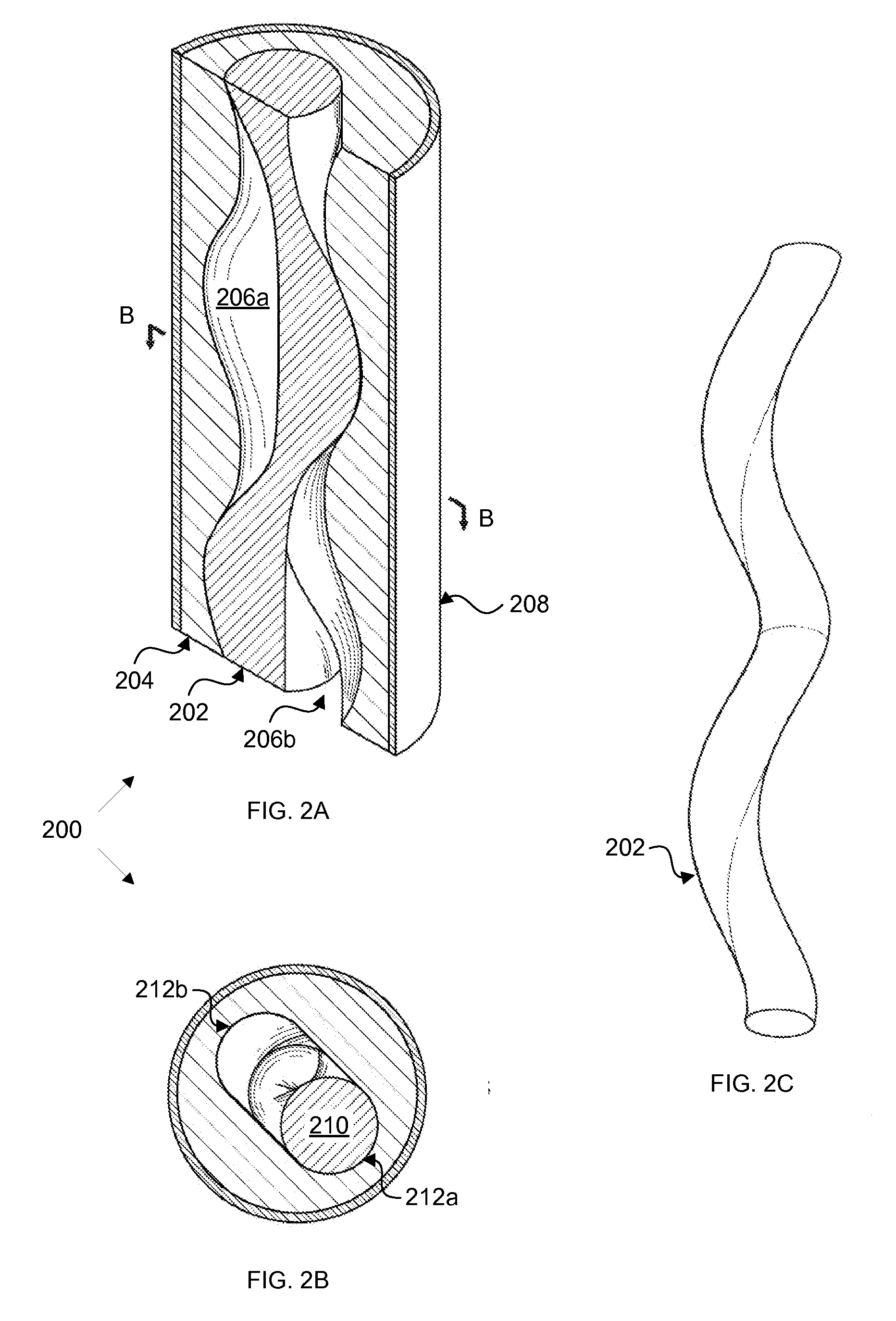

Stators for downwhole motors, methods for fabricating the same, and downhole motors incorporating the same

ActiveUS20110116959A1Oscillating piston enginesEngine of intermeshing engagement typeElectric motorStator

The present invention recites a method of fabricating a stator for a downhole motor, the method comprising the steps of providing a stator tube having an interior surface and applying a bonding agent to the interior surface of the stator tube. Additionally, a mandrel is positioned within the stator tube, the mandrel having an outer geometry that is complimentary to a desired inner geometry for the stator. Furthermore, a reinforcing material is introduced into the stator tube to fill space between the mandrel and the interior surface of the stator tube and subsequently solidified to bond the reinforcing material to the interior surface of the stator tube, The mandrel is then removed from the bonded stator tube and reinforcing material such that a stator is fabricated.

Owner:SCHLUMBERGER TECH CORP

Stator of a moineau-pump

InactiveUS20060029507A1Improve rigidityHigh strengthOscillating piston enginesEngine of intermeshing engagement typeHydroformingStator

Owner:NOETIC TECH INC

Progressive cavity helical device

InactiveUS6461128B2Oscillating piston enginesEngine of intermeshing engagement typeBiomedical engineeringHelix

Owner:BICO DRILLING TOOLS

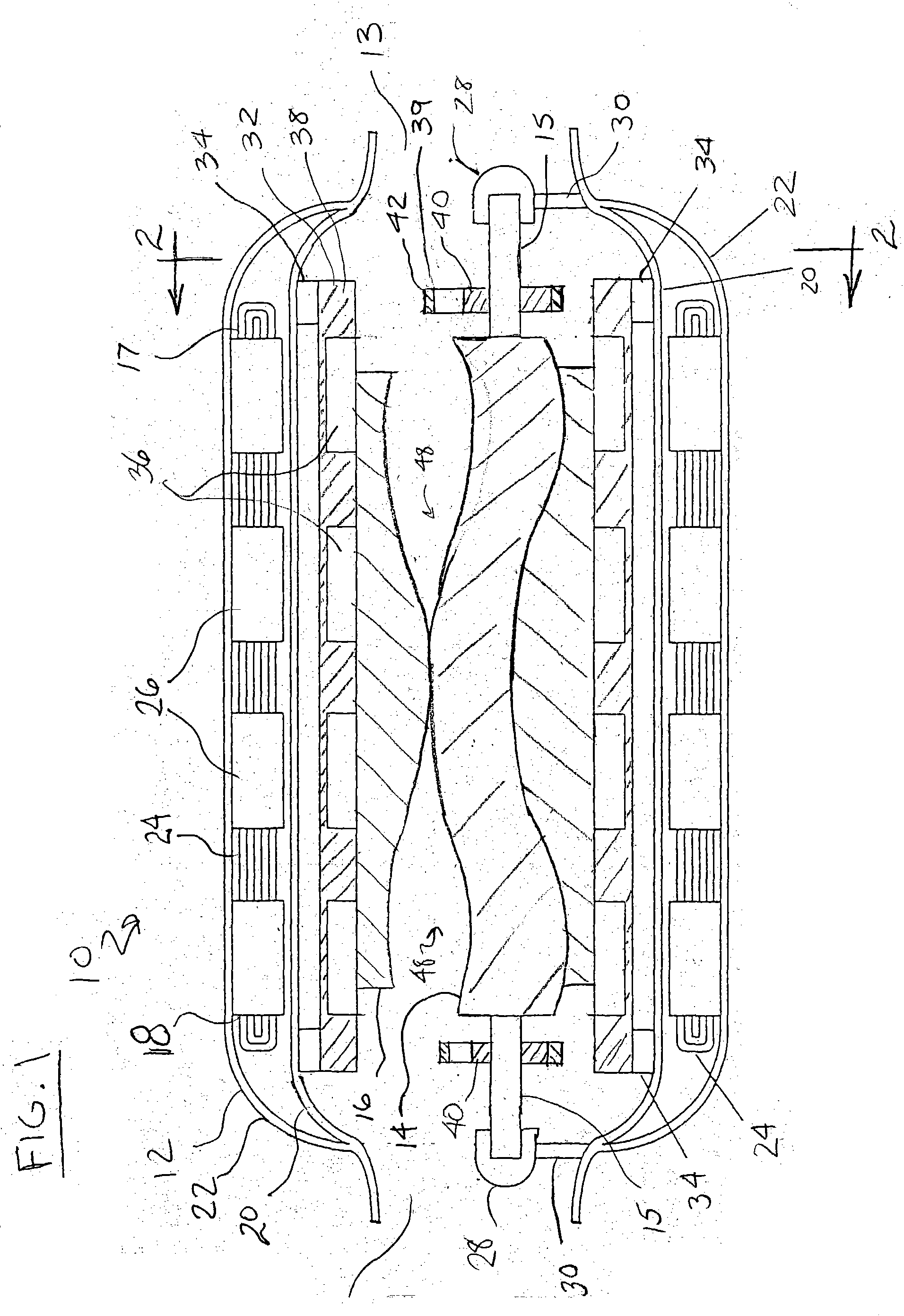

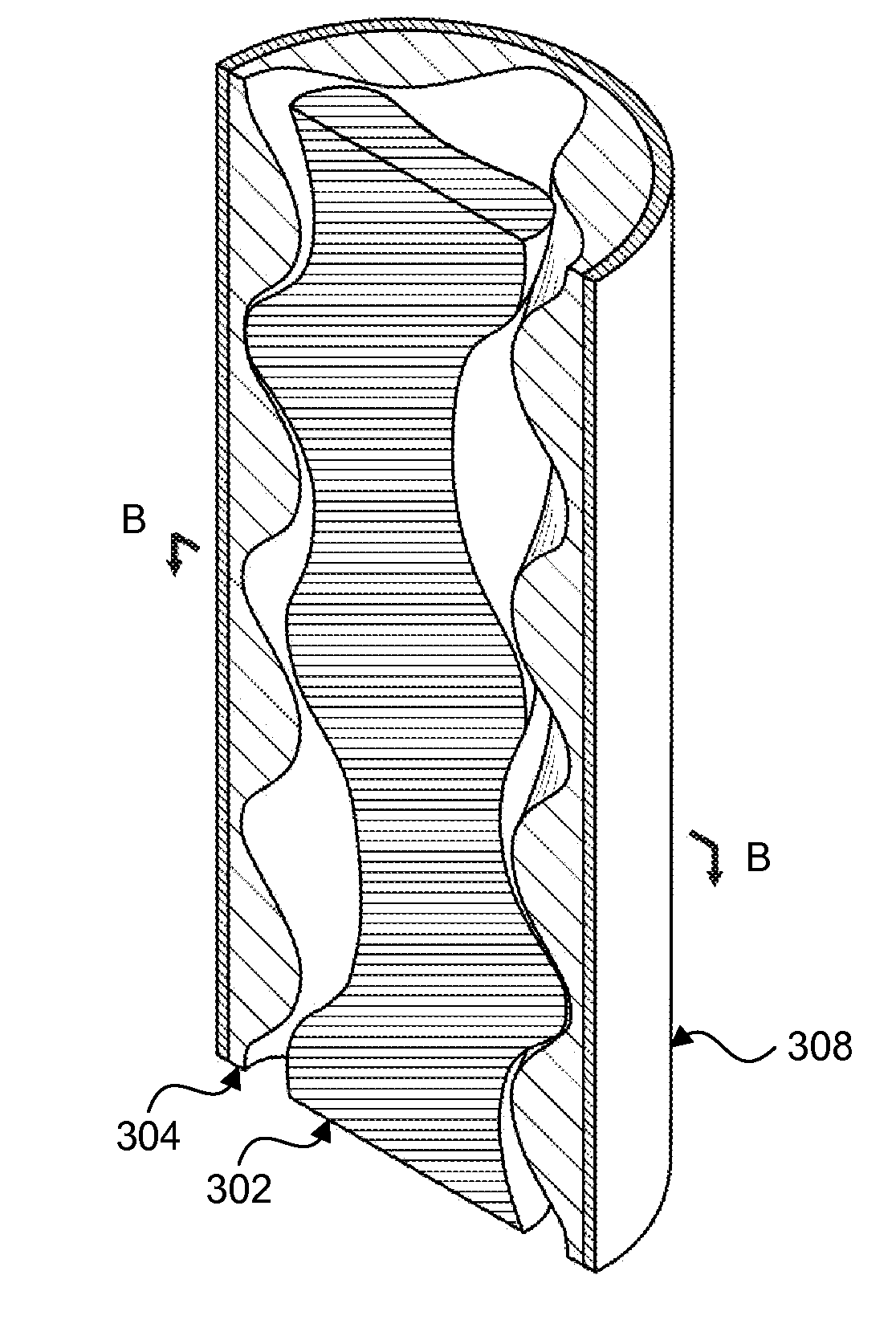

Direct drive linear flow blood pump

InactiveUS20050008509A1Reduce unbalanced magnetic forceReduce magnetic forceOscillating piston enginesBlood pumpsMotor driveBlood pump

A ventricular assistive device (VAD) based on a progressive cavity pump includes a pump housing having an inlet and an outlet, a pump stator contained within the pump housing, a pump rotor rotatably disposed within the pump stator, a motor including a motor rotor contained within the pump housing and a direct drive means connected between the motor rotor and an axial shaft of the pump rotor for rotating the pump rotor. The motor rotates the motor rotor, which in turn rotates the pump rotor through the direct drive means. The rotation of the pump rotor within the pump stator forms a plurality of cavities that carry blood forward through the pump housing from the inlet to the outlet as the motor drives the direct drive means.

Owner:CHANG SHELDON

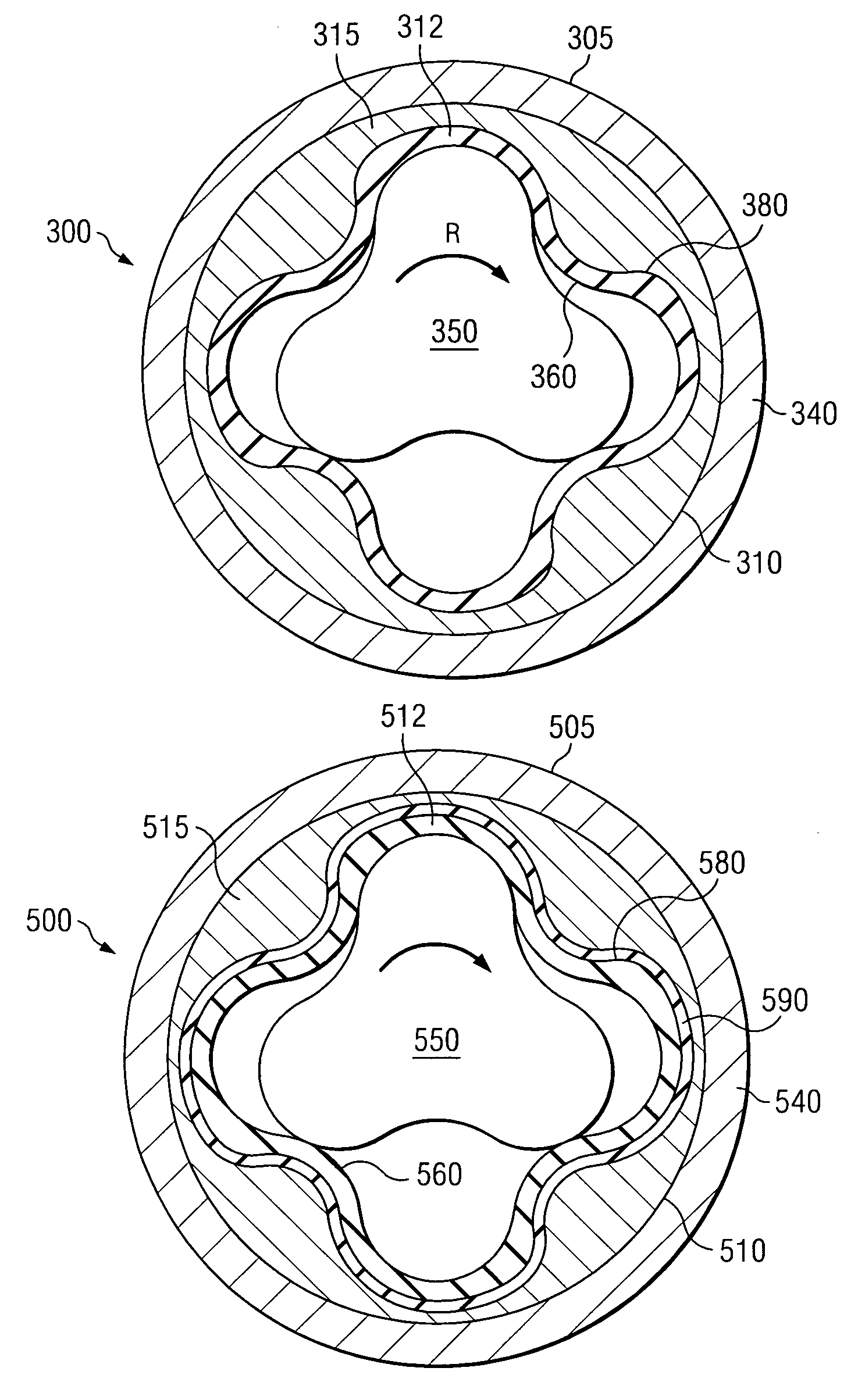

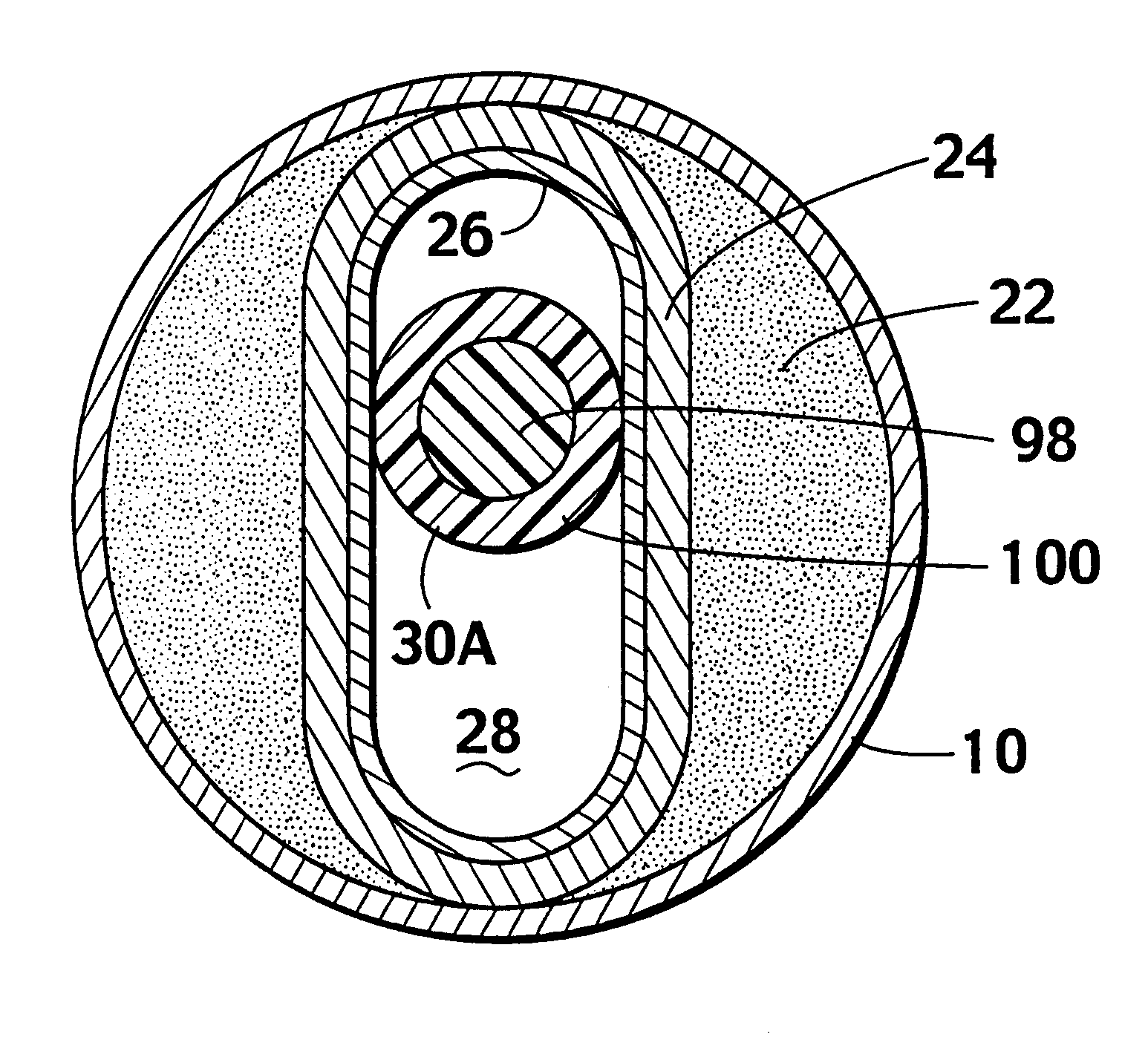

Multiple elastomer layer progressing cavity stators

InactiveUS7517202B2Improve performanceReducing tradeoffs associatedOscillating piston enginesEngine of intermeshing engagement typeElastomerPolymer science

A progressing cavity stator and a method for fabricating such a stator are disclosed. The progressing cavity stator includes first and second elastomer layers fabricated from corresponding first and second elastomer materials. The first and second elastomer materials are selected to have at least one distinct material property. Exemplary embodiments of this invention may reduce tradeoffs associated with elastomer material selection and may further address the heat build up and subsequent elastomer breakdown in the lobes of prior art stators.

Owner:SMITH INT INC

Fluid controlled pumping system and method

InactiveUS6945755B2Improve reliabilityLower the liquid levelSurveyConstructionsFluid controlEngineering

A fluid level controlled pumping system includes a pumping unit disposed within a fluid cavity. The pumping unit includes an inlet operable to receive a fluid to be pumped from the fluid cavity. The system also includes a valve slidably coupled to the pumping unit. The valve includes a passage for receiving pumped fluid from an outlet of the pumping unit. In response to a decreasing fluid level within the fluid cavity, movement of the valve relative to the pumping unit aligns the passage with a port of the pumping unit to recirculate the pumped fluid from the outlet to the inlet.

Owner:EFFECTIVE EXPLORATION

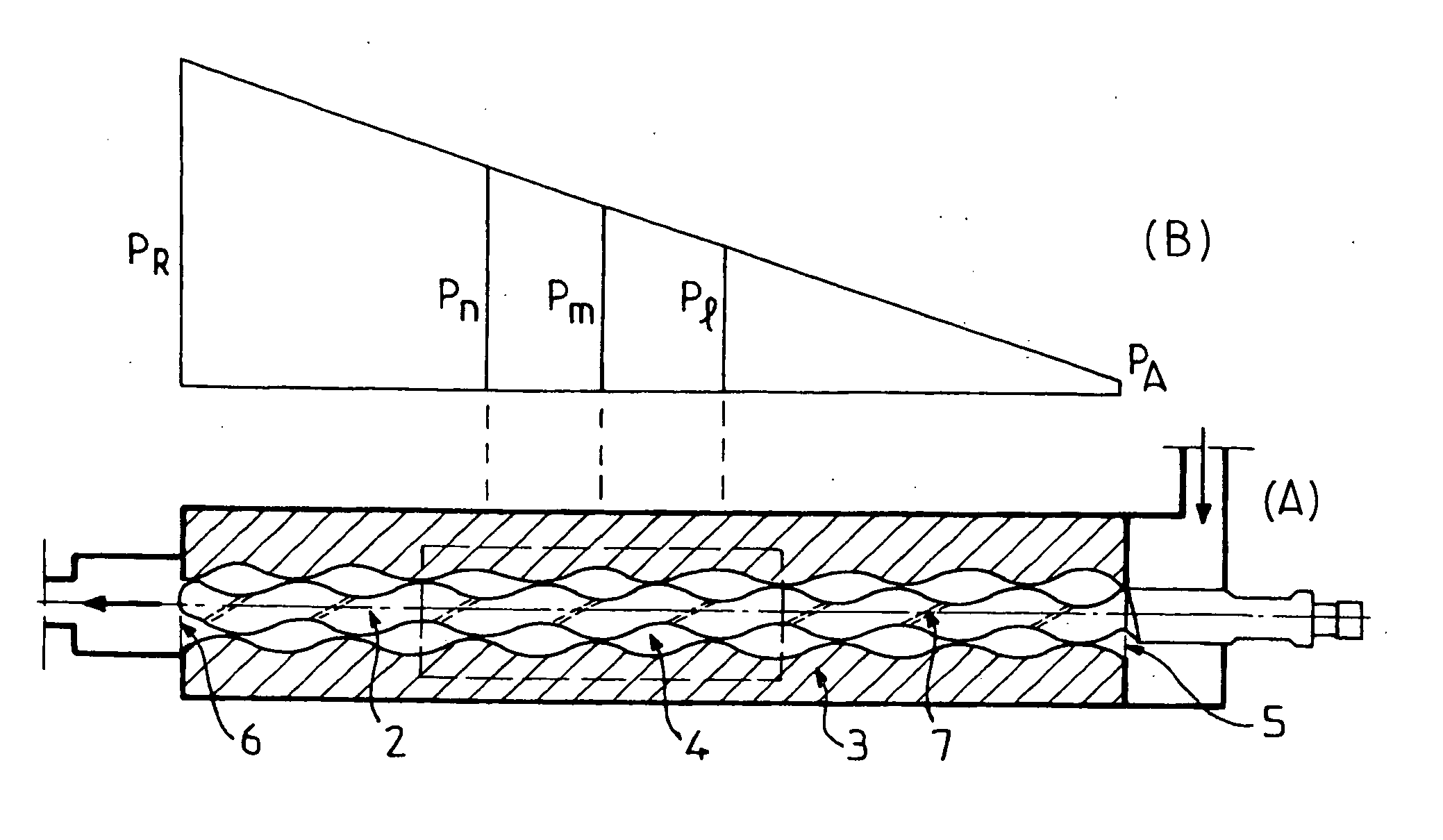

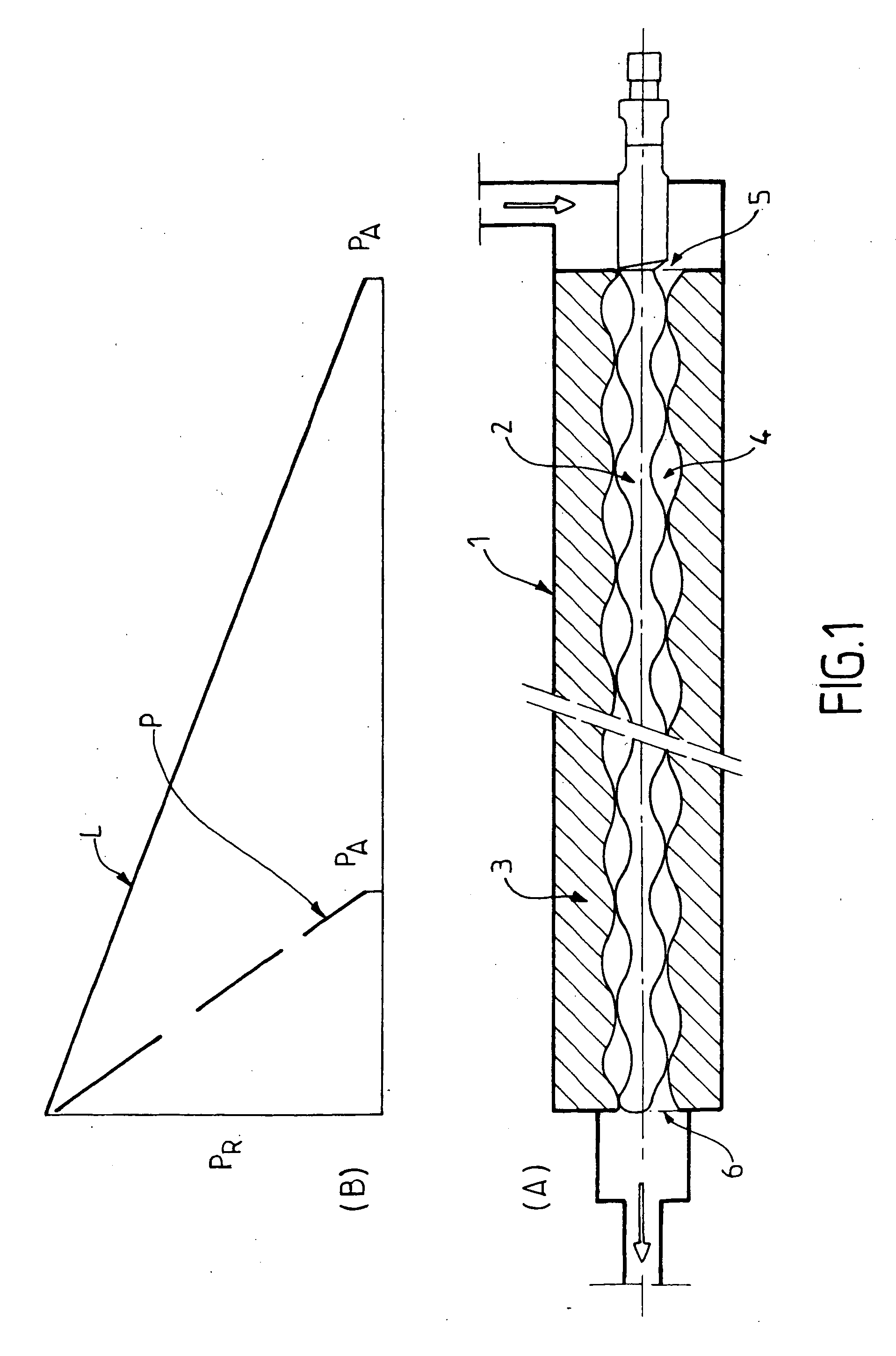

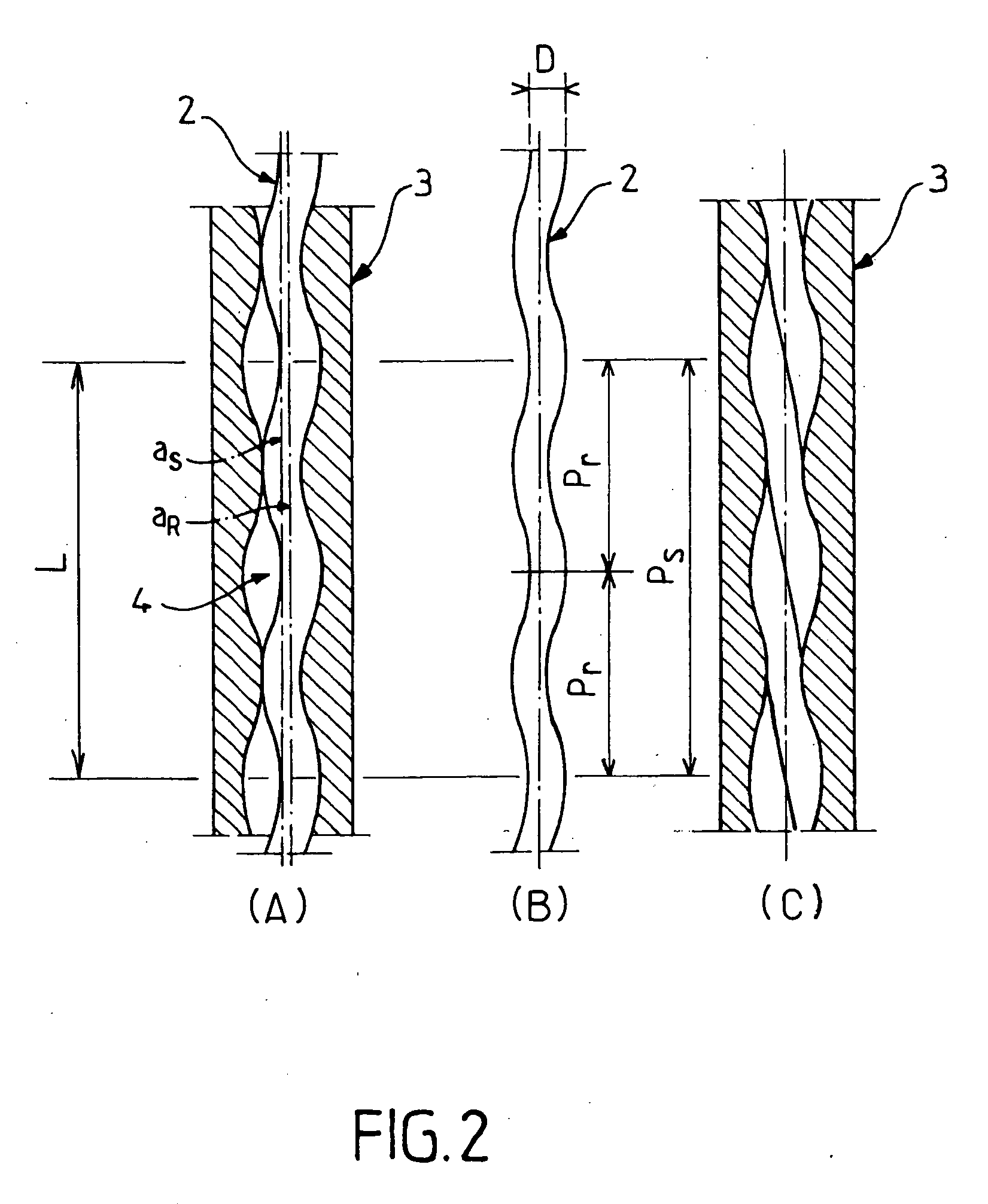

Progressing cavity pump

ActiveUS20050169779A1Improve system reliabilityImprove reliabilityPump componentsOscillating piston enginesTemperature controlEngineering

This progressing cavity pump including a helical rotor (2) mounted to turn inside a helical stator (3), said stator (3) and said rotor (2) being disposed such that the cavities (4) formed between said rotor (2) and said stator (3) move from the inlet (5) towards the outlet (6), is characterized by the fact that hydraulic regulation (HR) means are provided for obtaining internal recirculation of the pumped fluid between at least two of said cavities (4) under conditions capable of performing at least one function selected from: achieving the desired pressure distribution along the pump, stabilizing the temperatures, controlling the leakage flow rates, and compensating for the volumes of compressed gas.

Owner:PC MALL INC

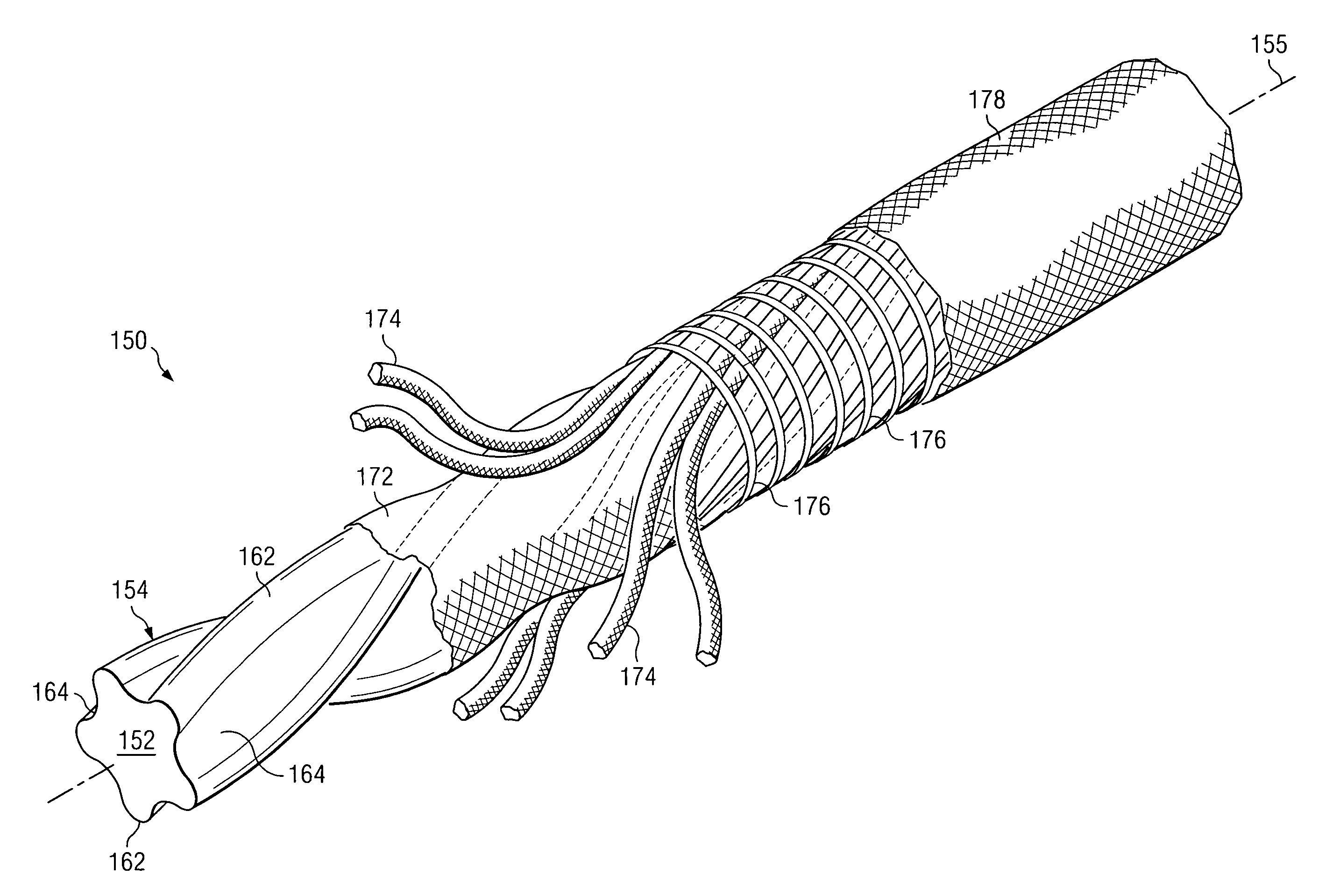

Stator inserts, methods of fabricating the same, and downhole motors incorporating the same

The present invention recites a downhole motor and method of manufacture wherein a mandrel having an outer geometry that is complimentary to a desired inner geometry for the stator is provided. A flexible sleeve is provided over the mandrel and the flexible sleeve and the mandrel are provided into a mold. Additionally, a reinforcing material is introduced into the mold to fill space between the flexible sleeve and the mold. Said material is then solidified to bond the reinforcing material and the flexible sleeve. The solidified reinforcing material and flexible sleeve are then removed from the mold such that a stator insert is fabricated.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com