Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73 results about "Zone System" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Zone System is a photographic technique for determining optimal film exposure and development, formulated by Ansel Adams and Fred Archer. Adams described the Zone System as "[...] not an invention of mine; it is a codification of the principles of sensitometry, worked out by Fred Archer and myself at the Art Center School in Los Angeles, around 1939–40."

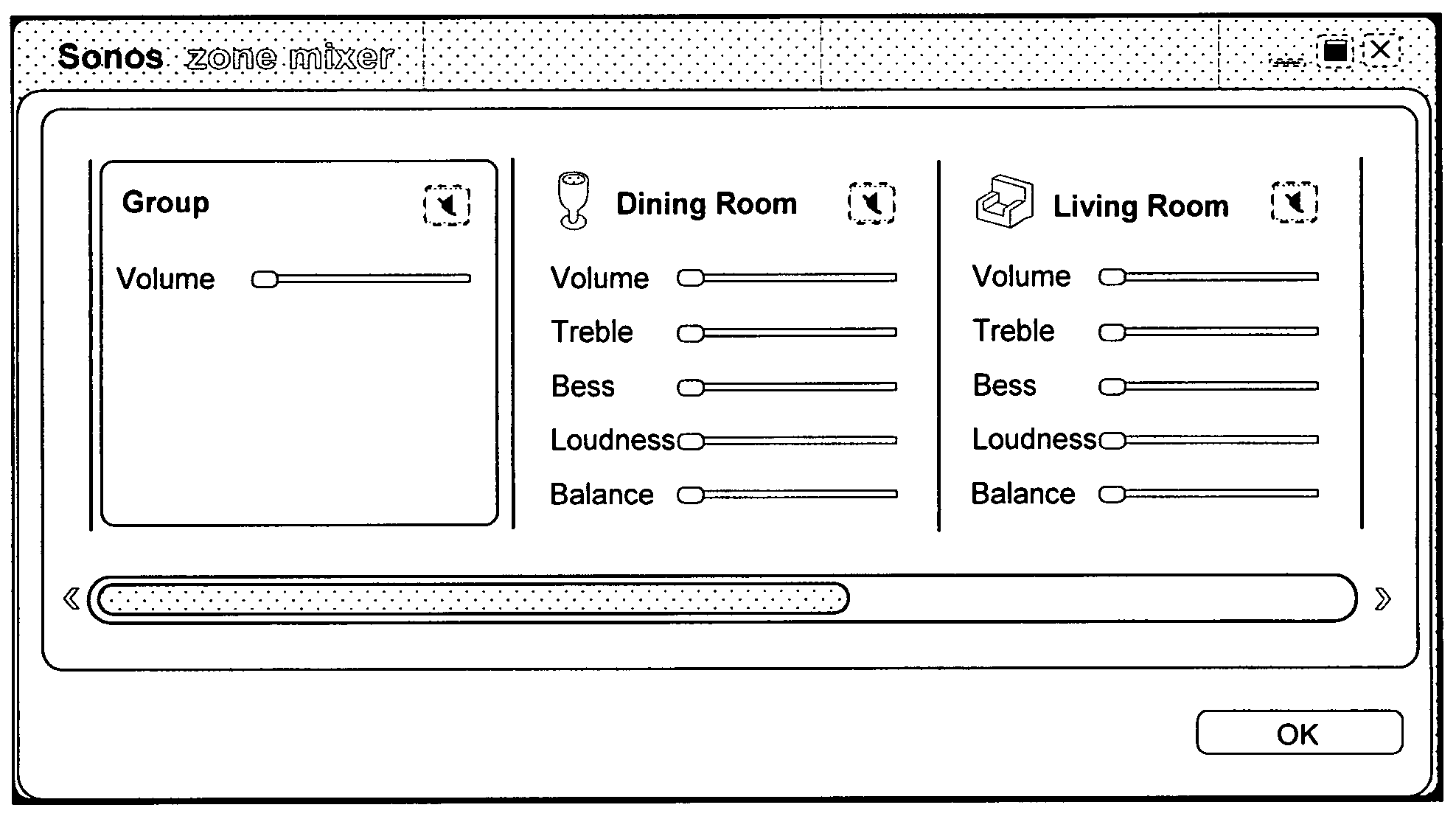

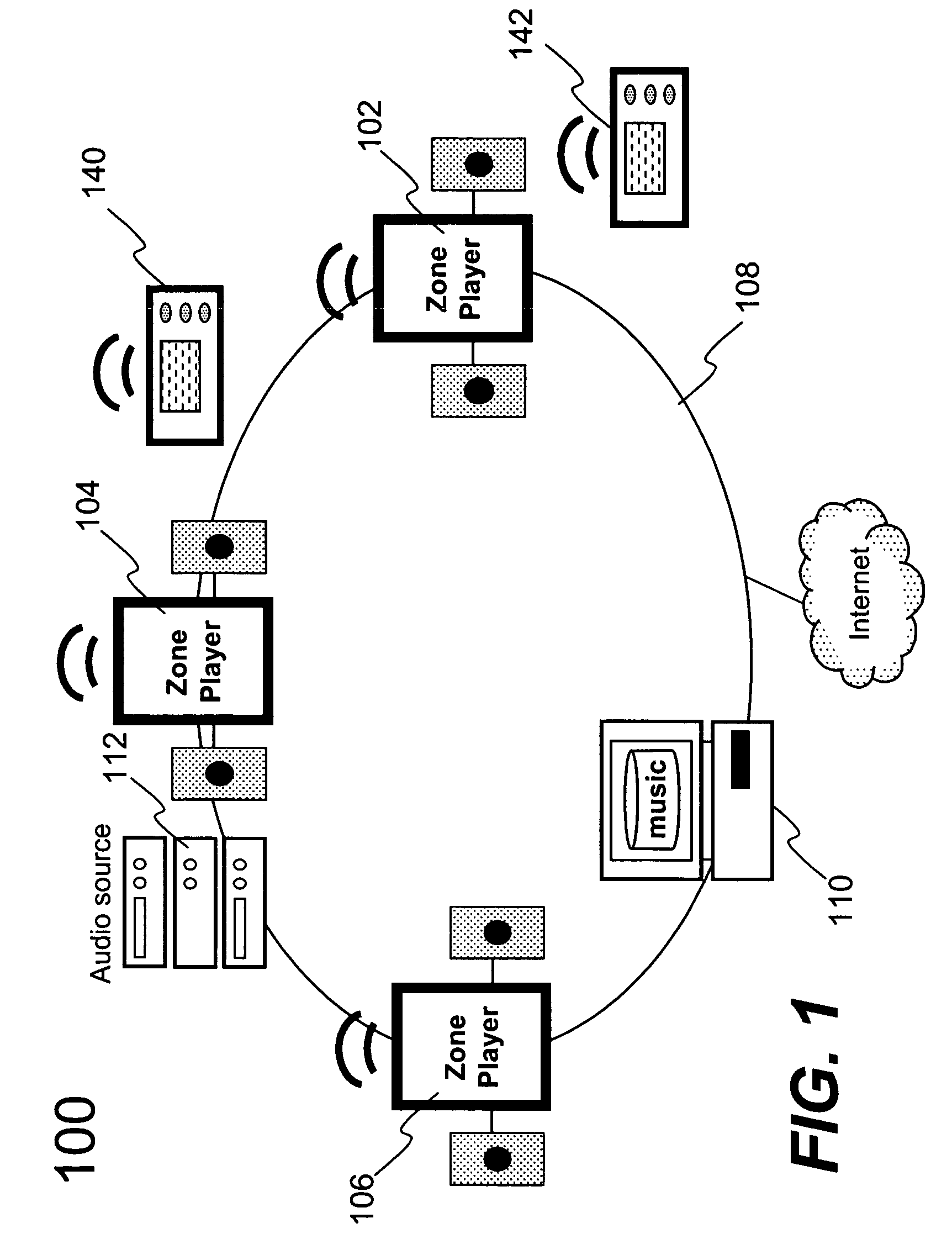

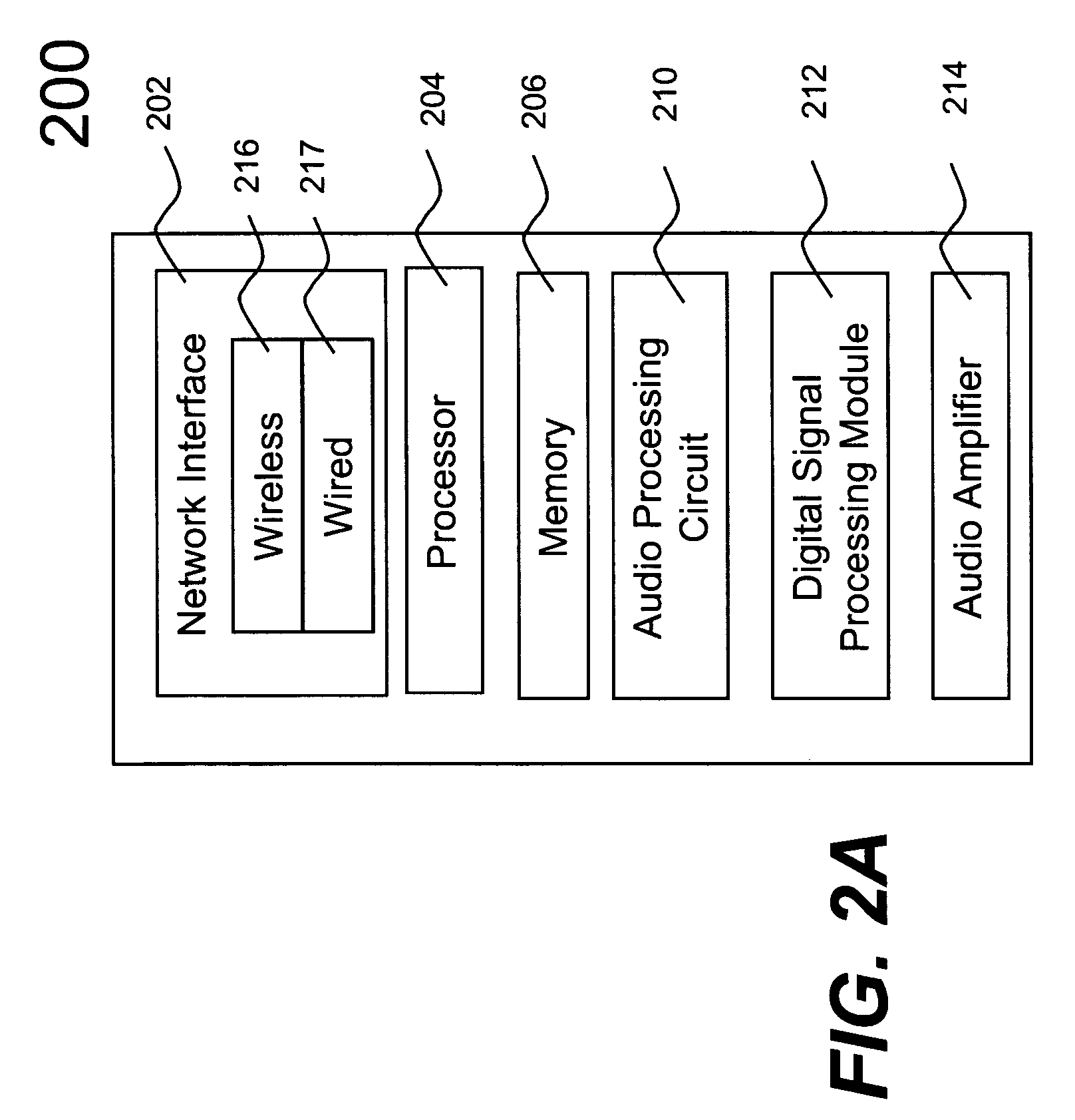

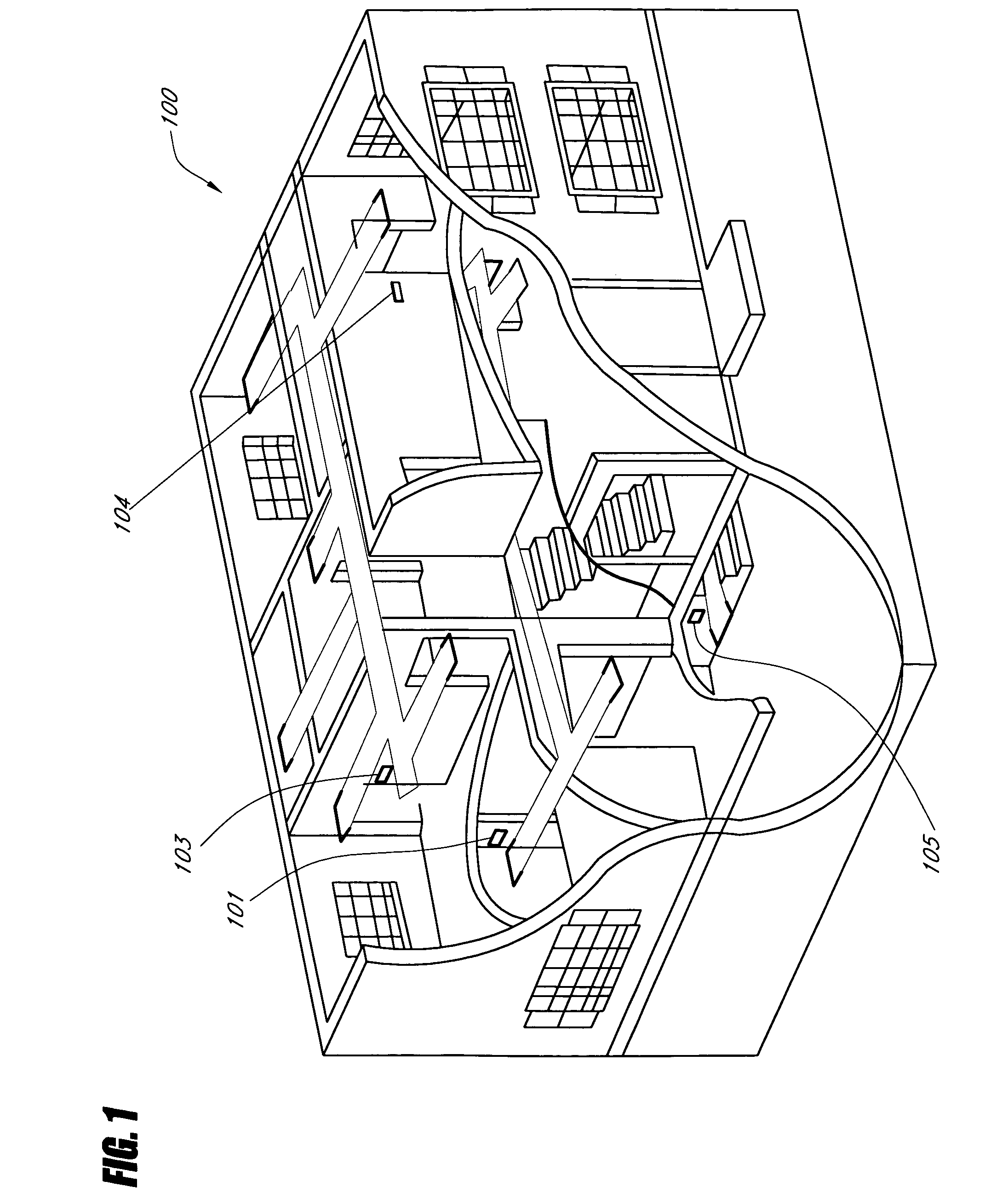

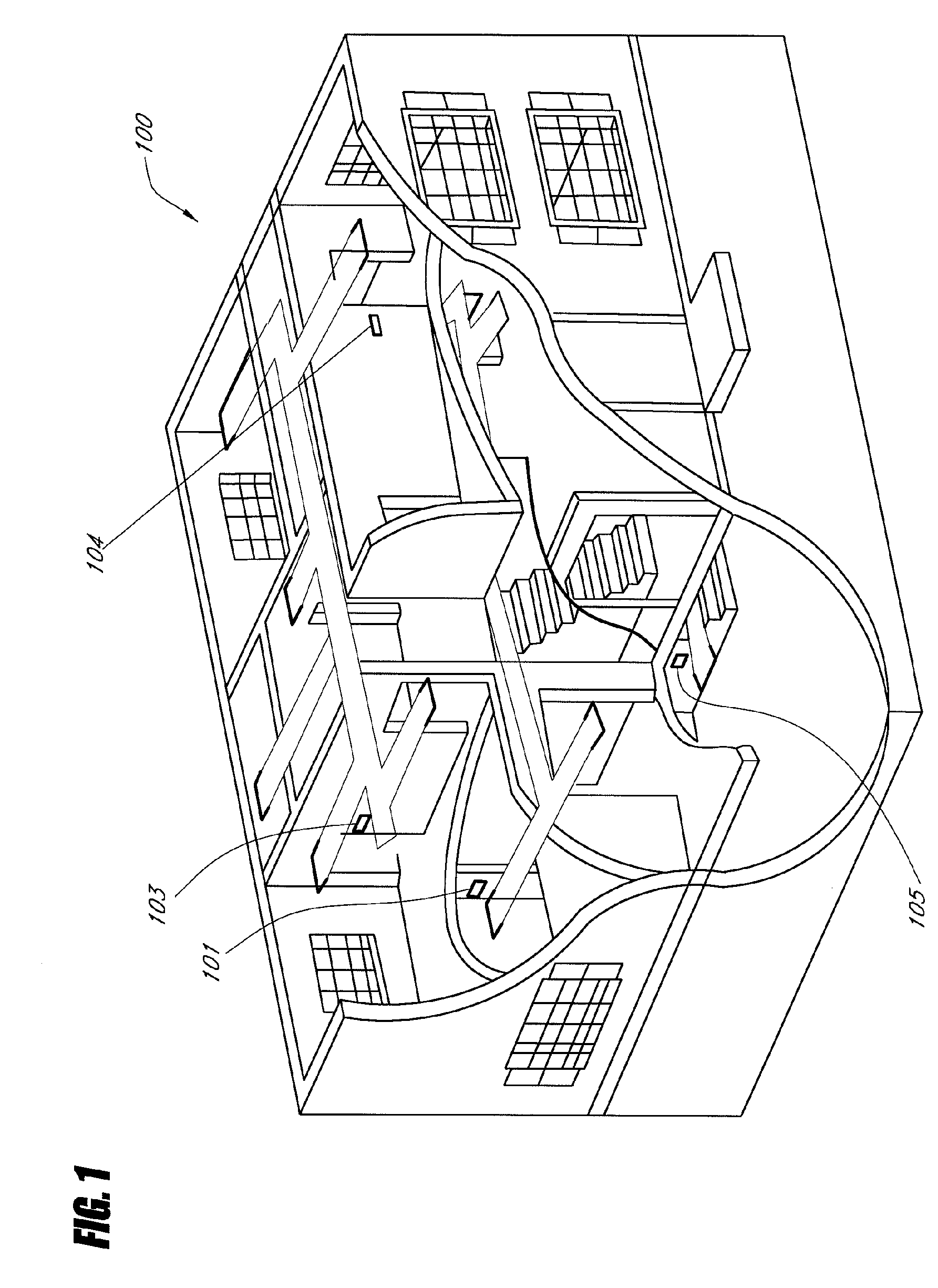

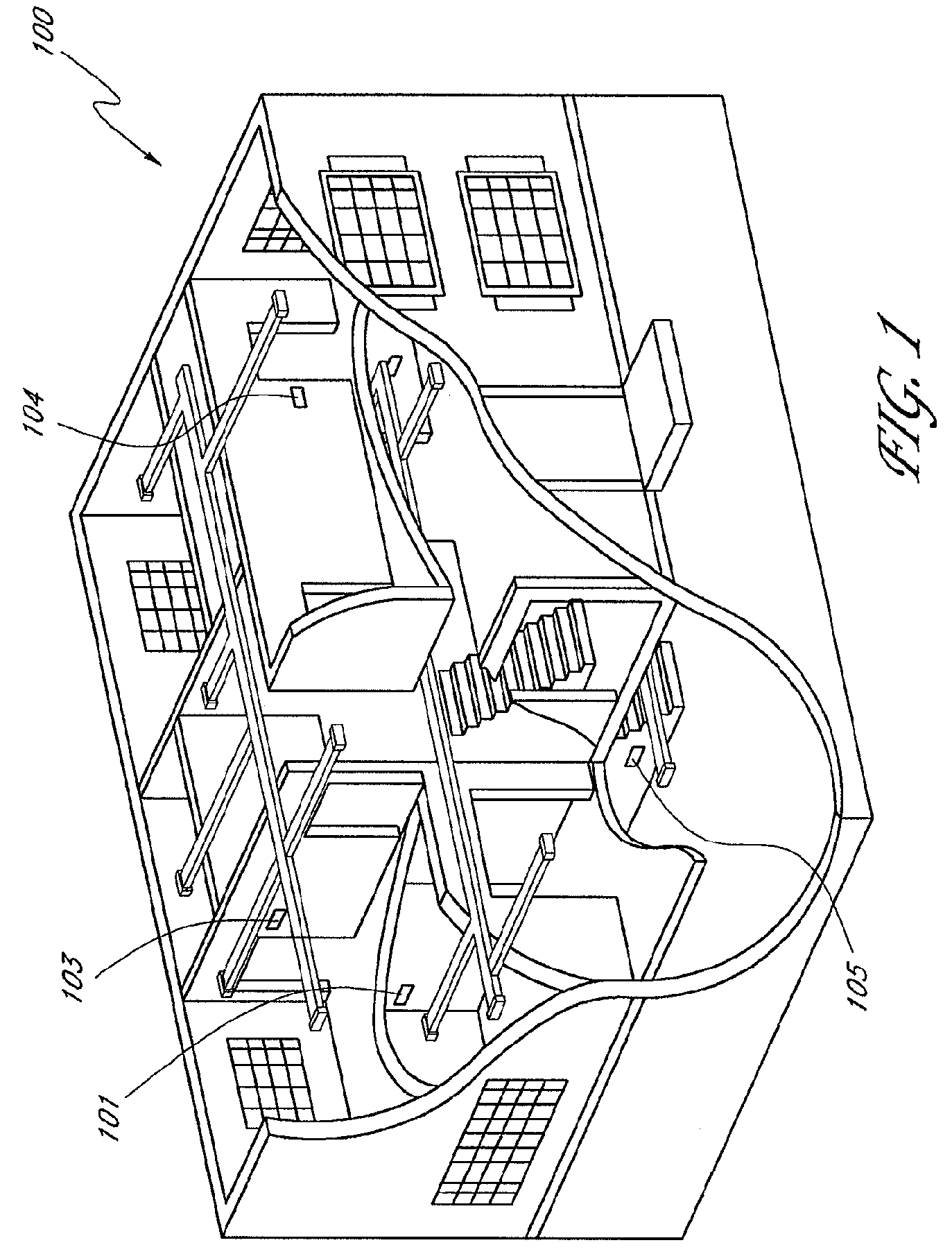

Method and apparatus for controlling multimedia players in a multi-zone system

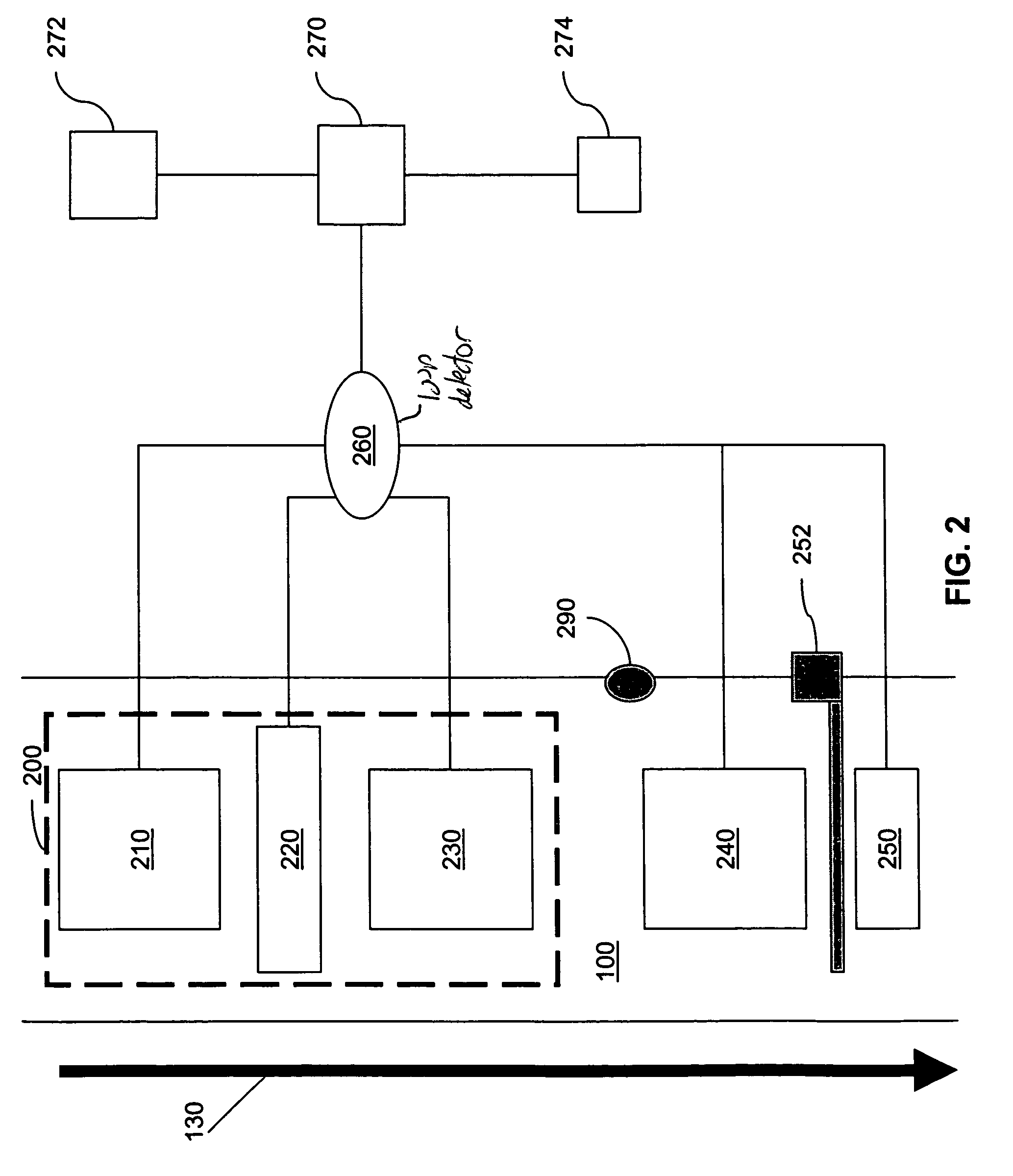

Techniques for controlling zone group and zone group characteristics such as audio volume in a multi-zone system are disclosed. The multi-zone system includes a number of multimedia players, each preferably located in a zone. A controller may control the operations of all of the zone players remotely from any one of the zones. Two or more zone players may be dynamically grouped as a zone group for synchronized operations. According to one aspect of the techniques, a zone group configuration can be managed, updated, modified via an interactive user interface provided in a controlling device. The zone group configuration may be saved in one of zone players. According to another aspect of the techniques, the audio volume control of a zone group can be performed individually or synchronously as a group.

Owner:SONOS

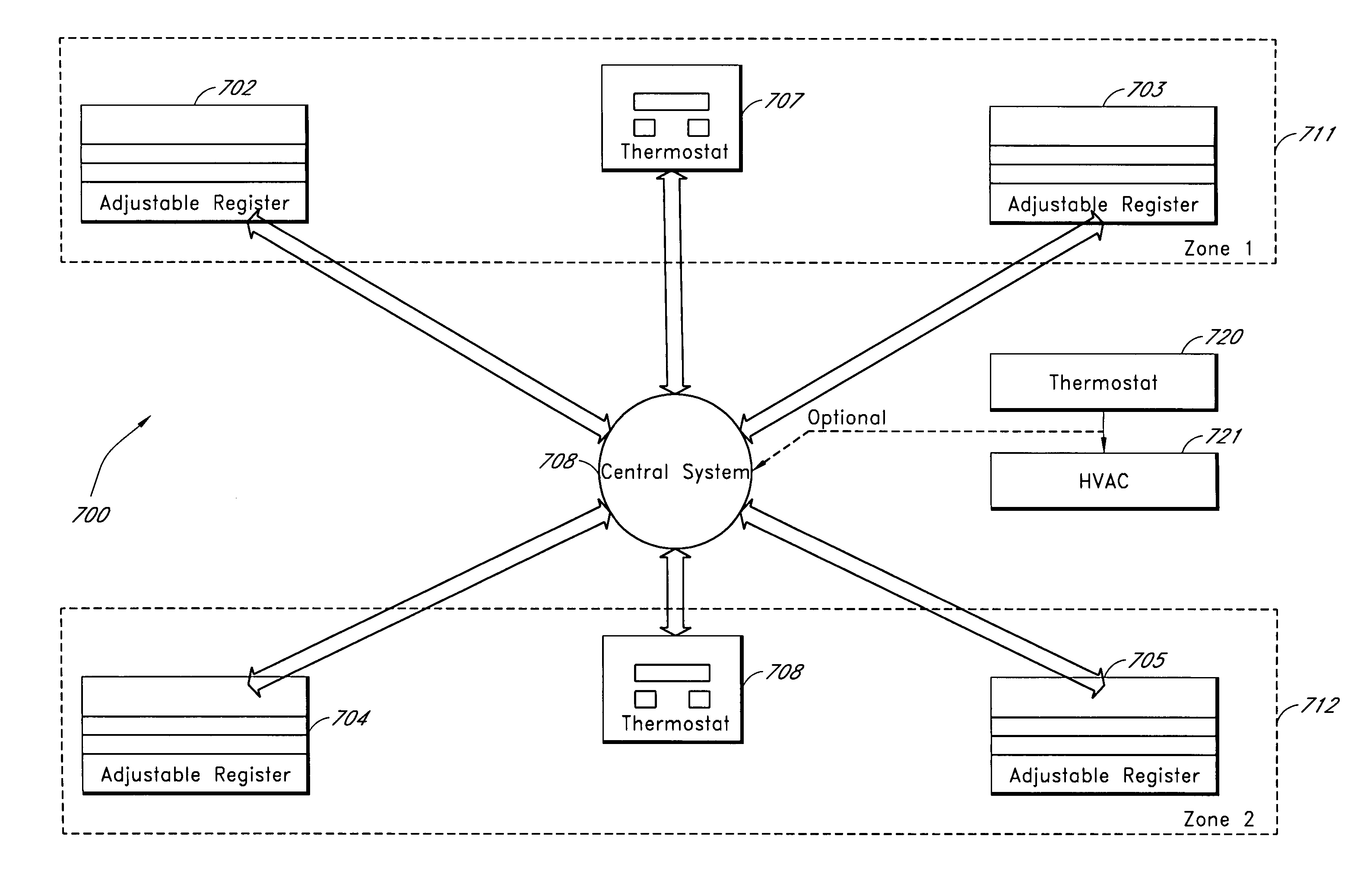

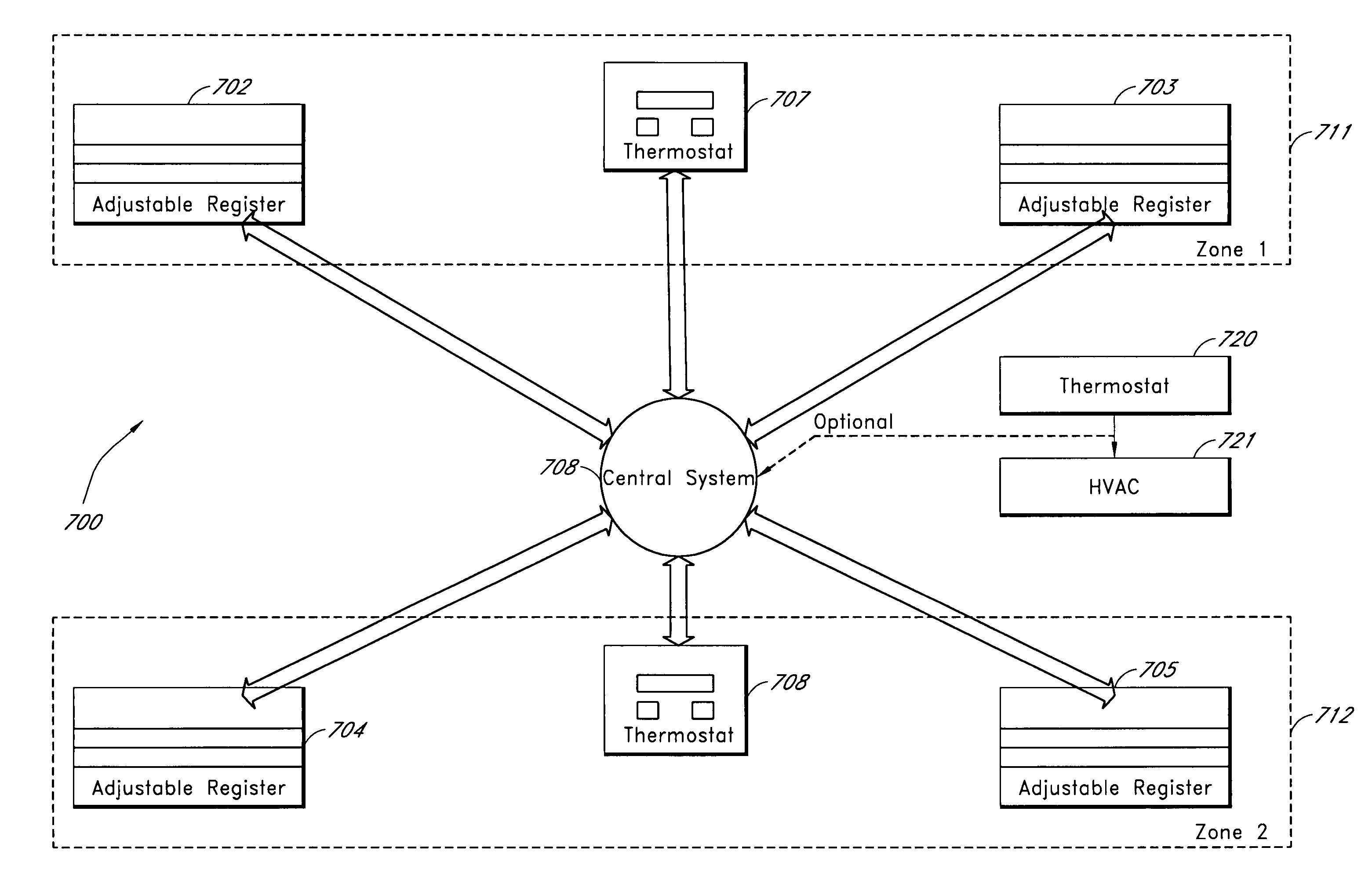

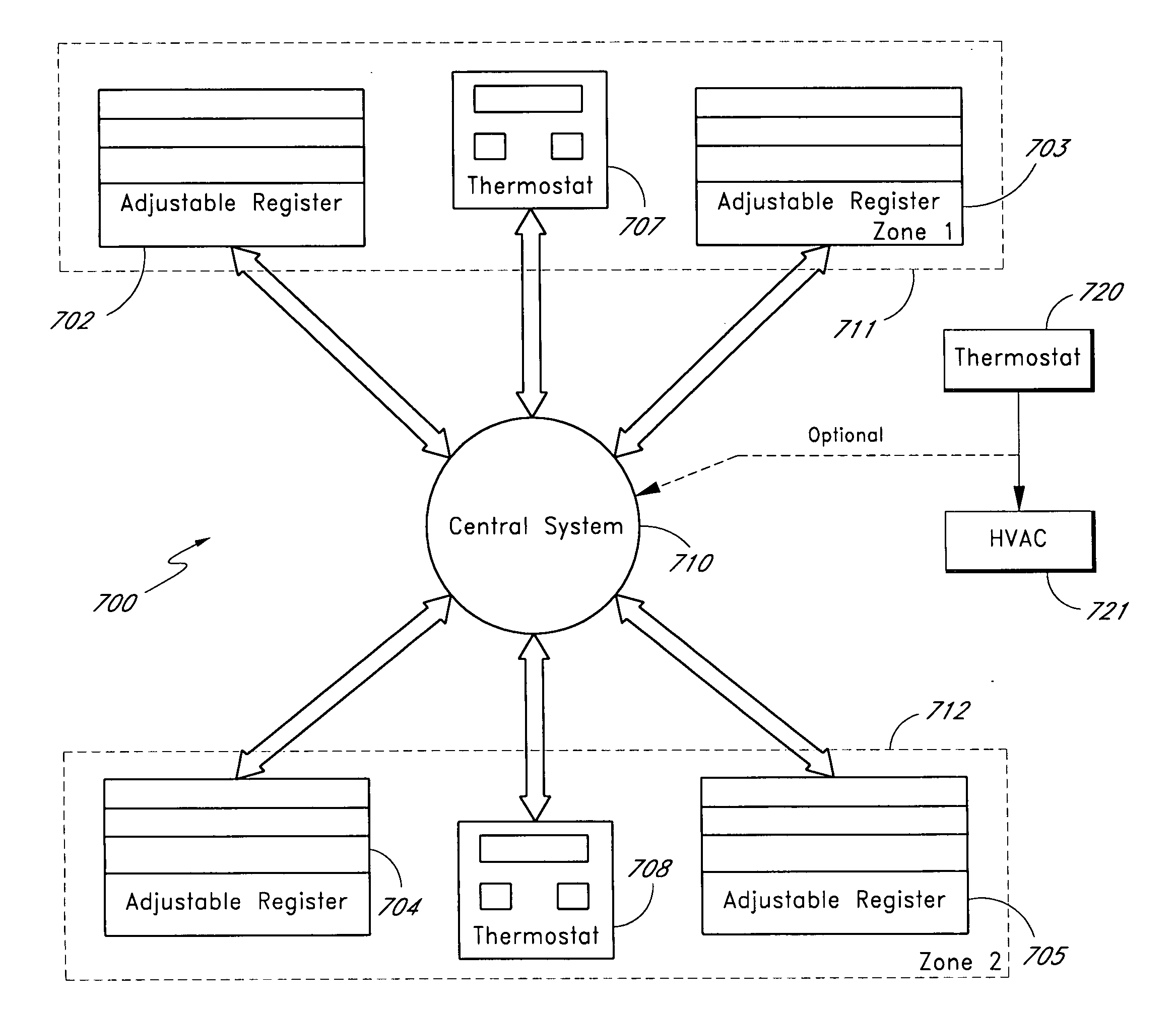

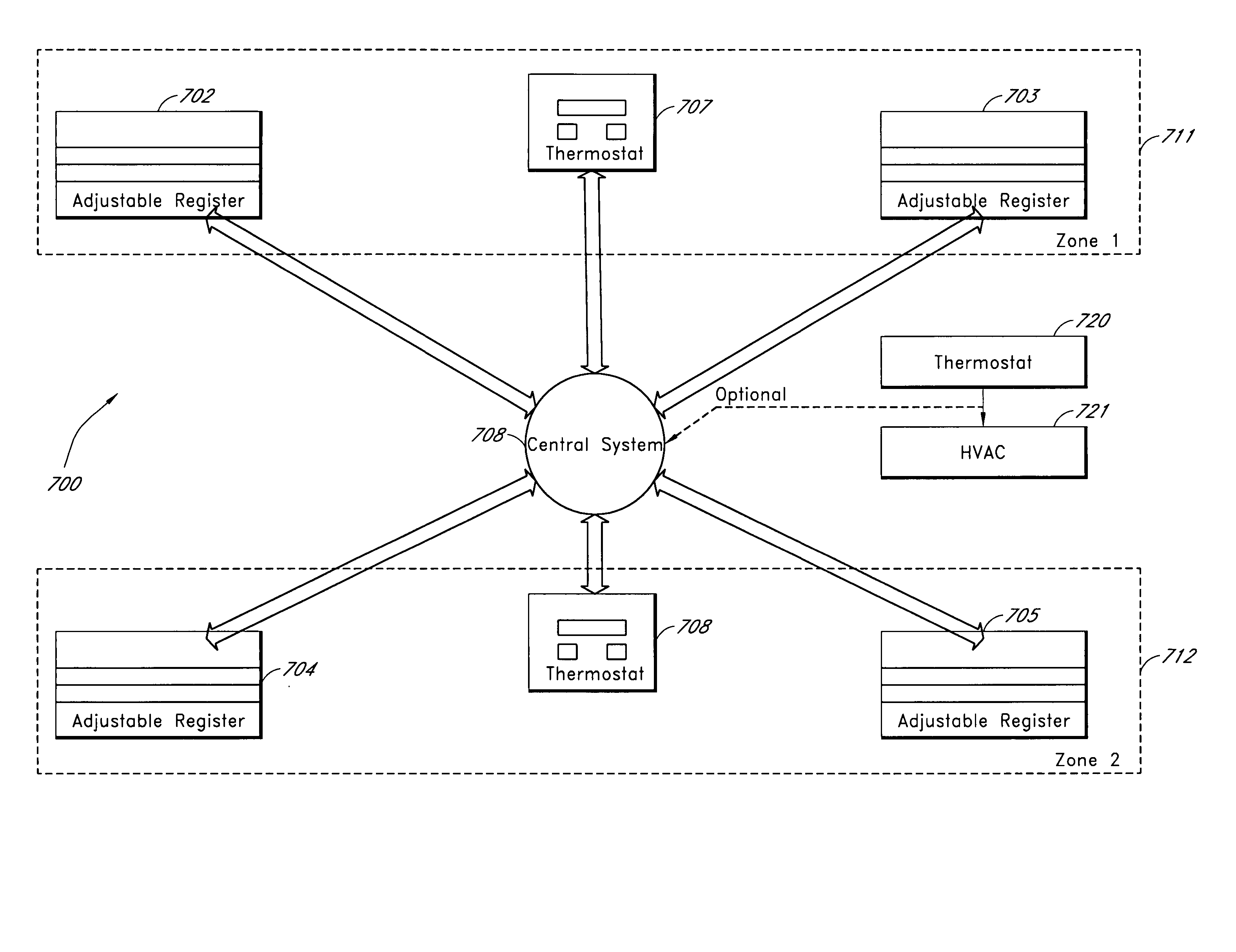

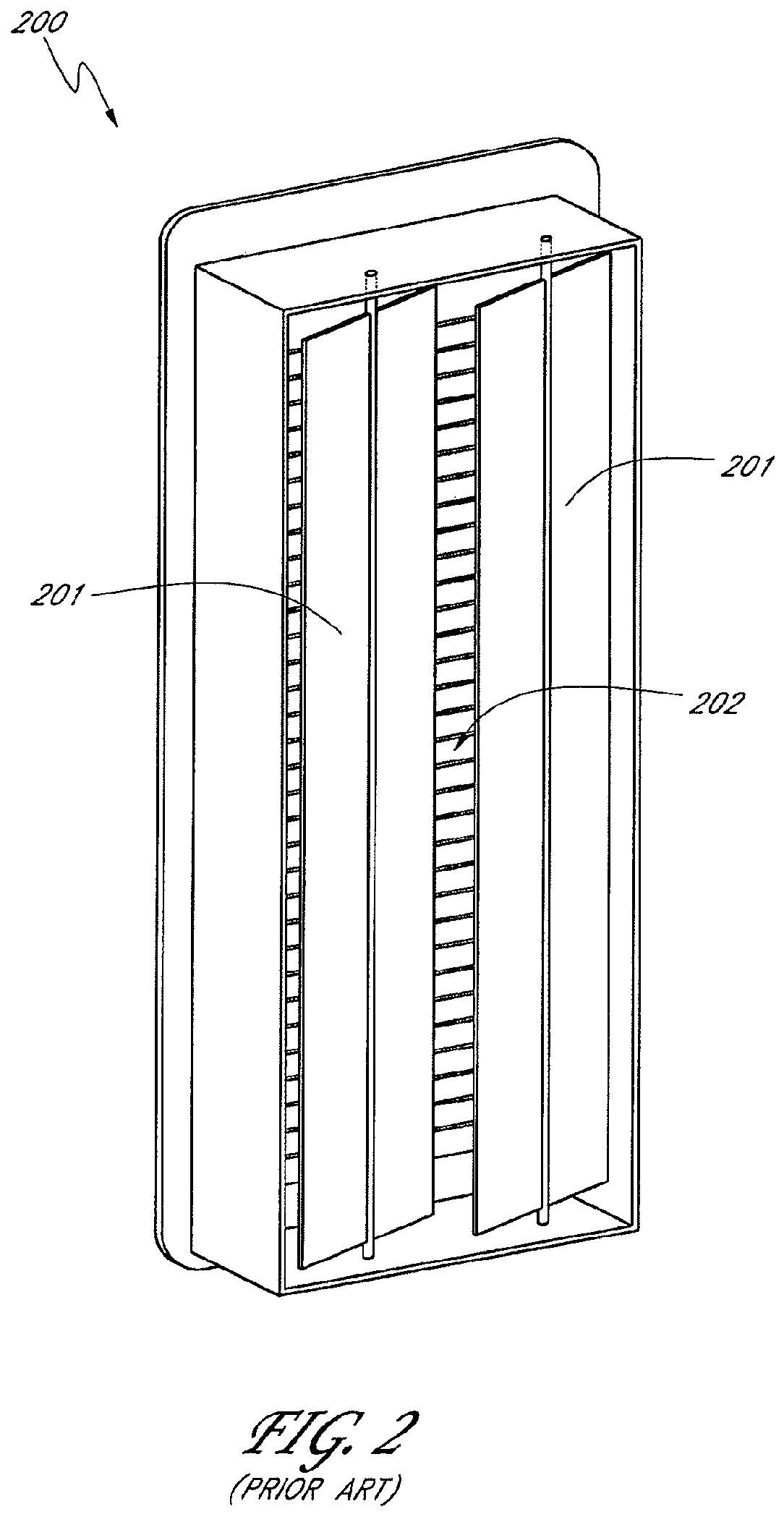

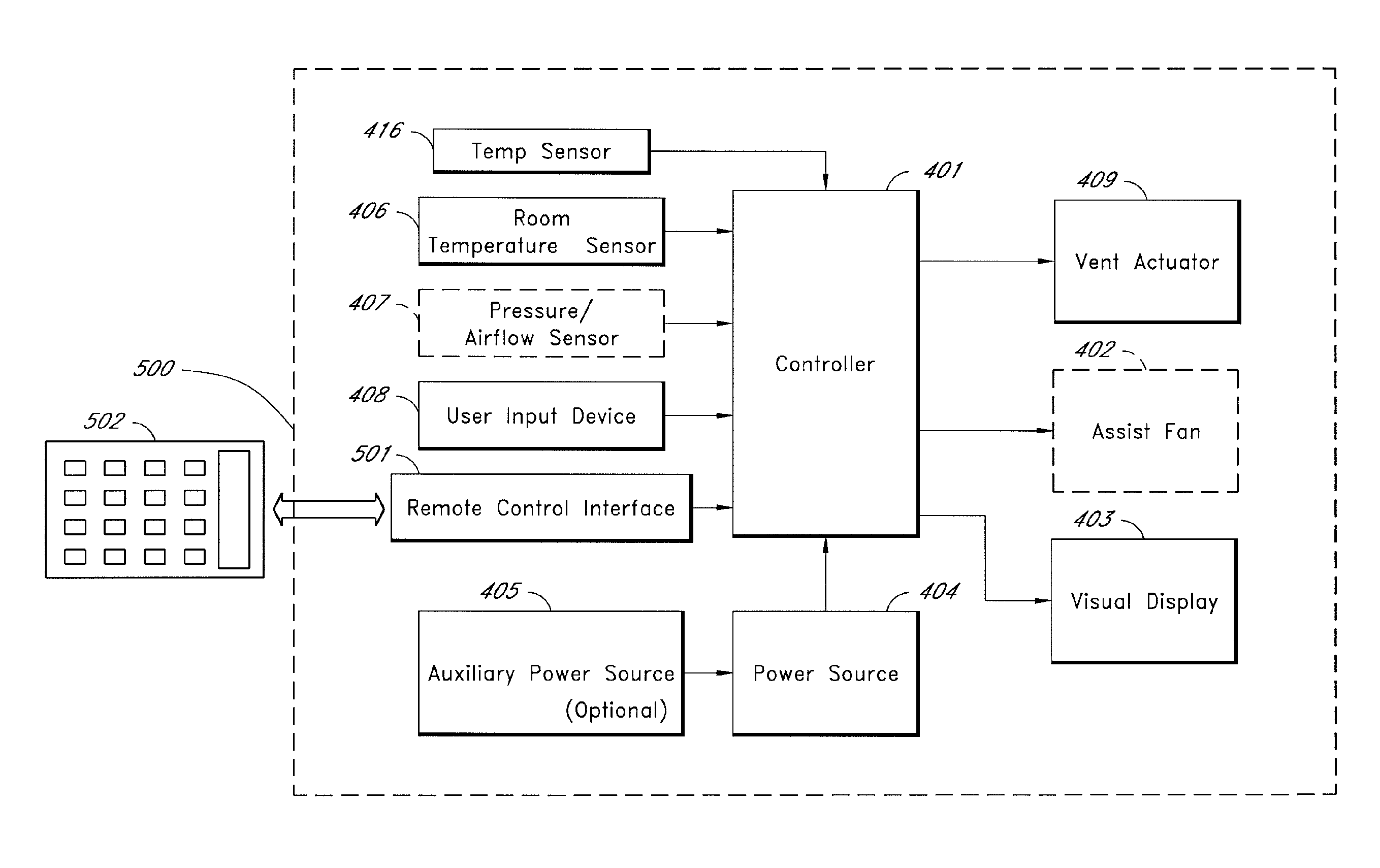

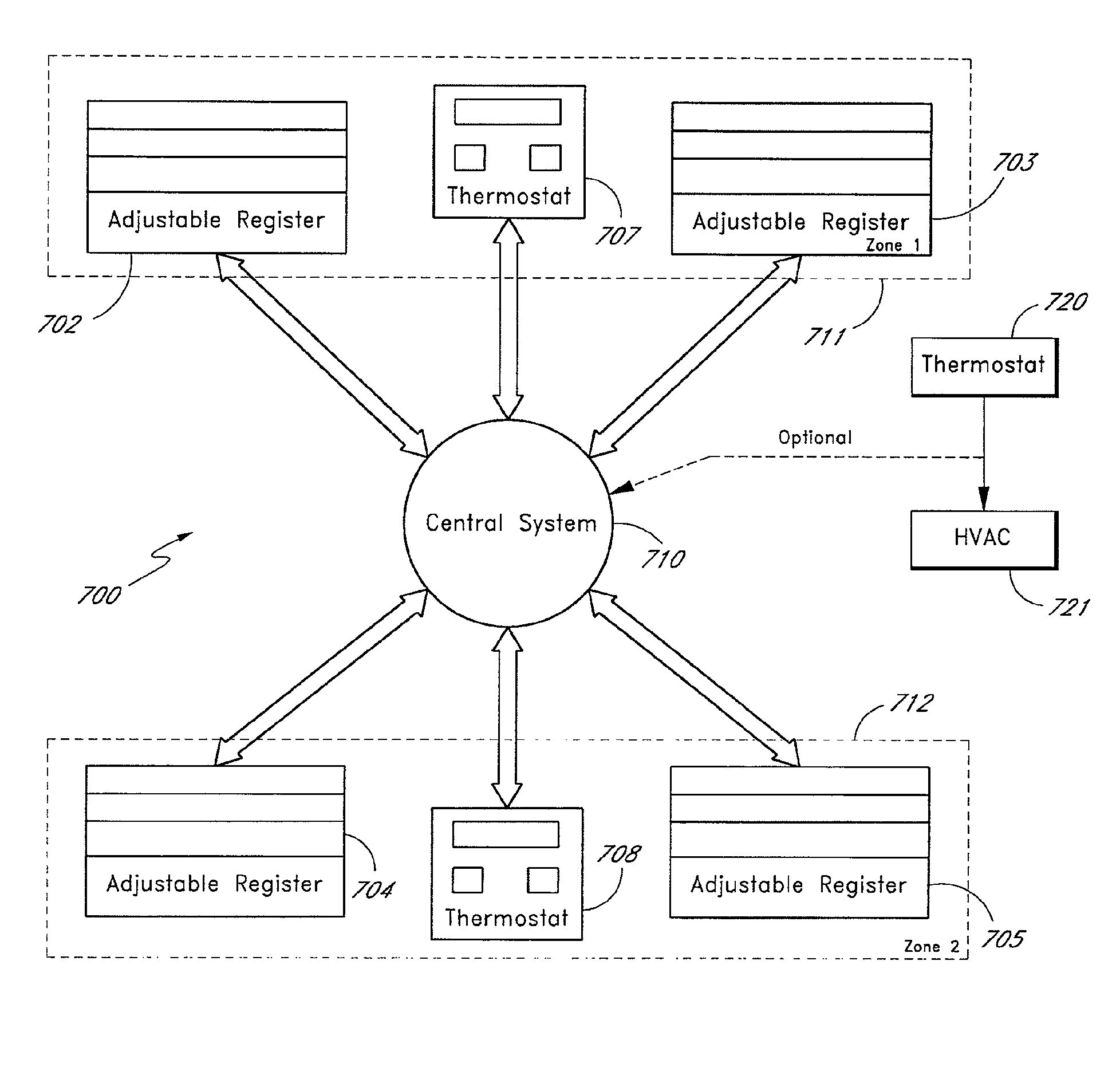

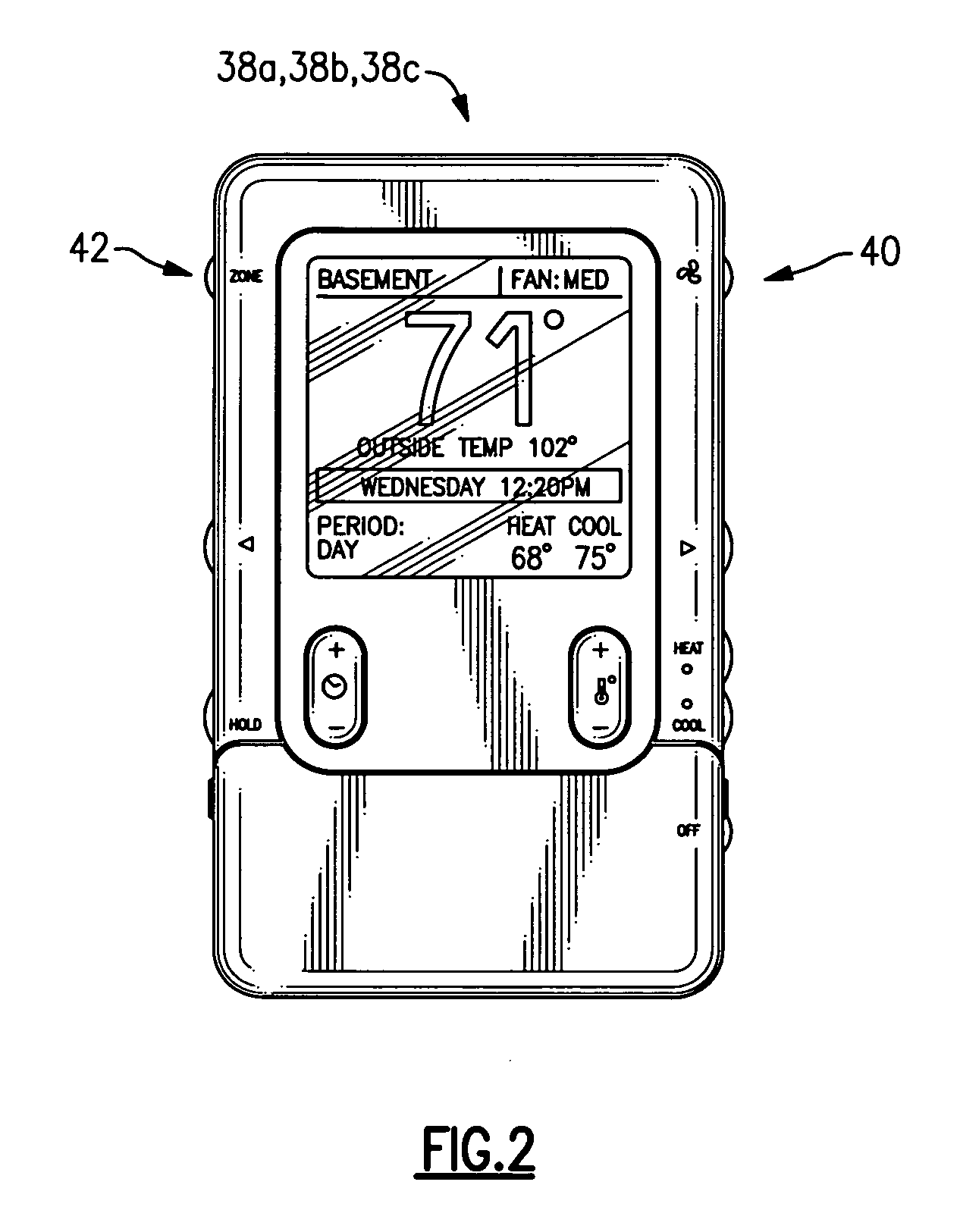

Zone thermostat for zone heating and cooling

A zone thermostat for use in connection with an Electronically-Controlled Register vent (ECRV) that can be easily installed by a homeowner or general handyman is disclosed. The ECRV can be used to convert a non-zoned HVAC system into a zoned system. The ECRV can also be used in connection with a conventional zoned HVAC system to provide additional control and additional zones not provided by the conventional zoned HVAC system. In one embodiment, the ECRV is configured have a size and form-factor that conforms to a standard manually-controlled register vent. In one embodiment, the zone thermostat is configured to provide thermostat information to the ECRV. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones.

Owner:GOOGLE LLC

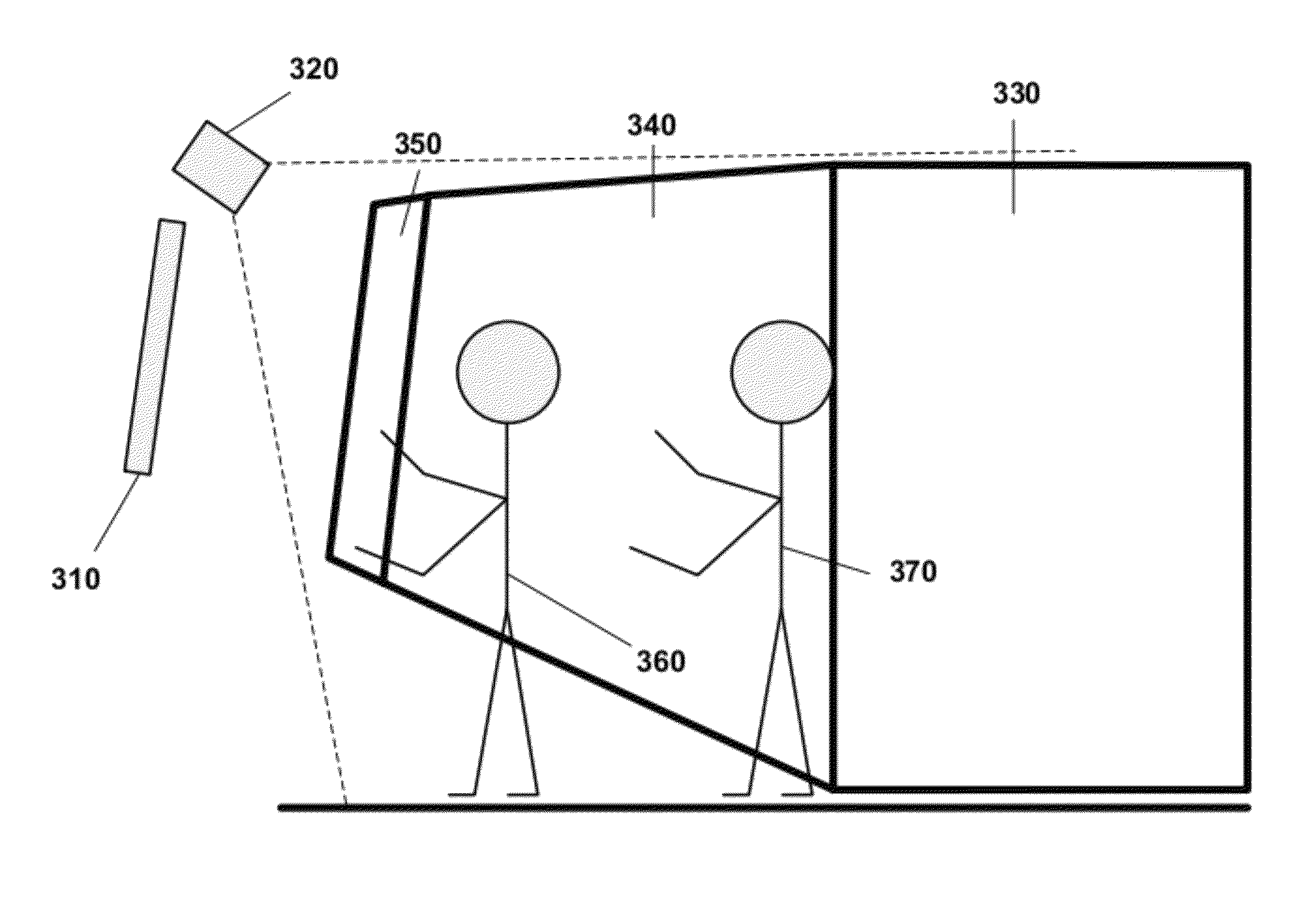

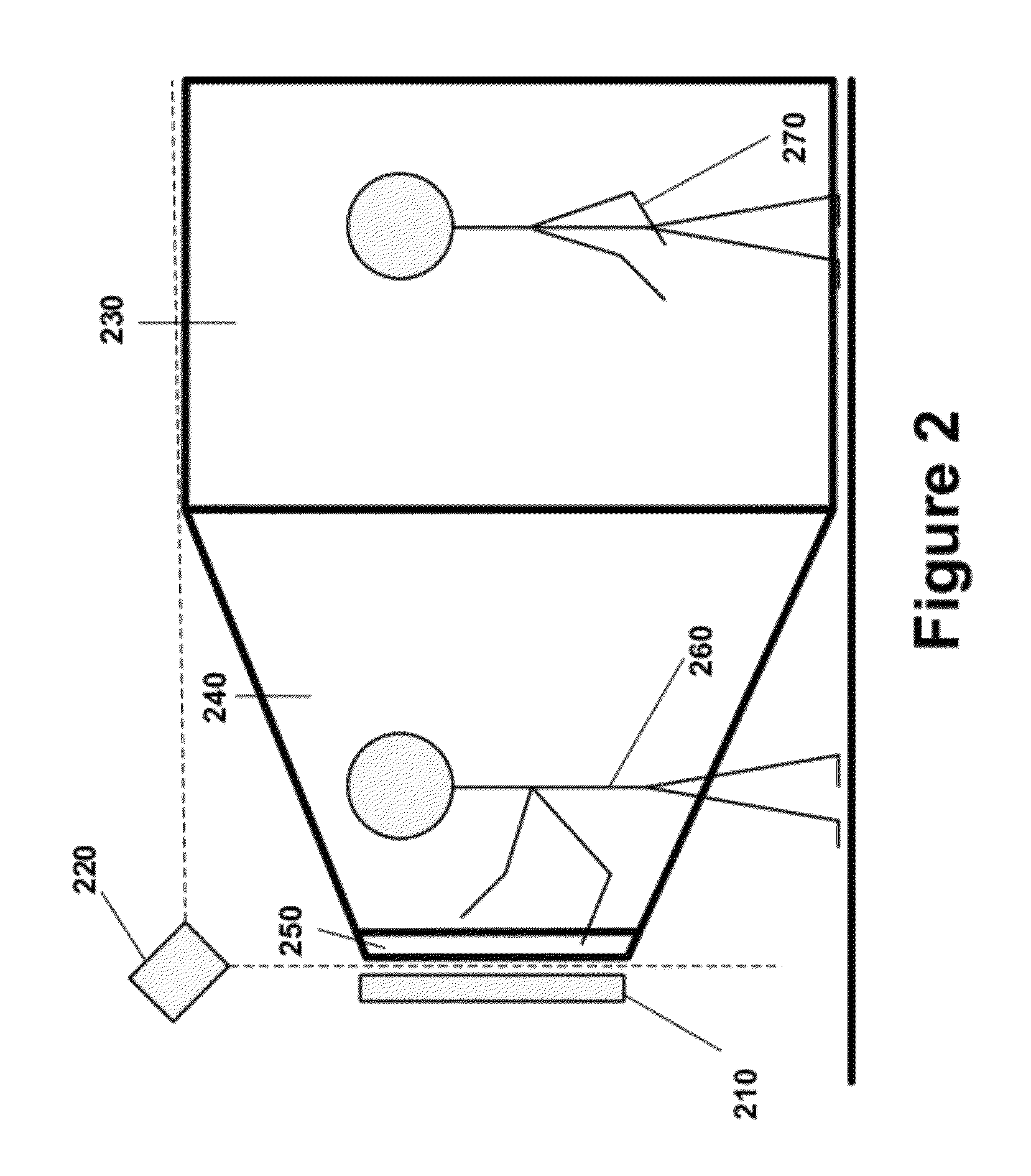

Gesture-based user interactions with status indicators for acceptable inputs in volumetric zones

Owner:META PLATFORMS INC

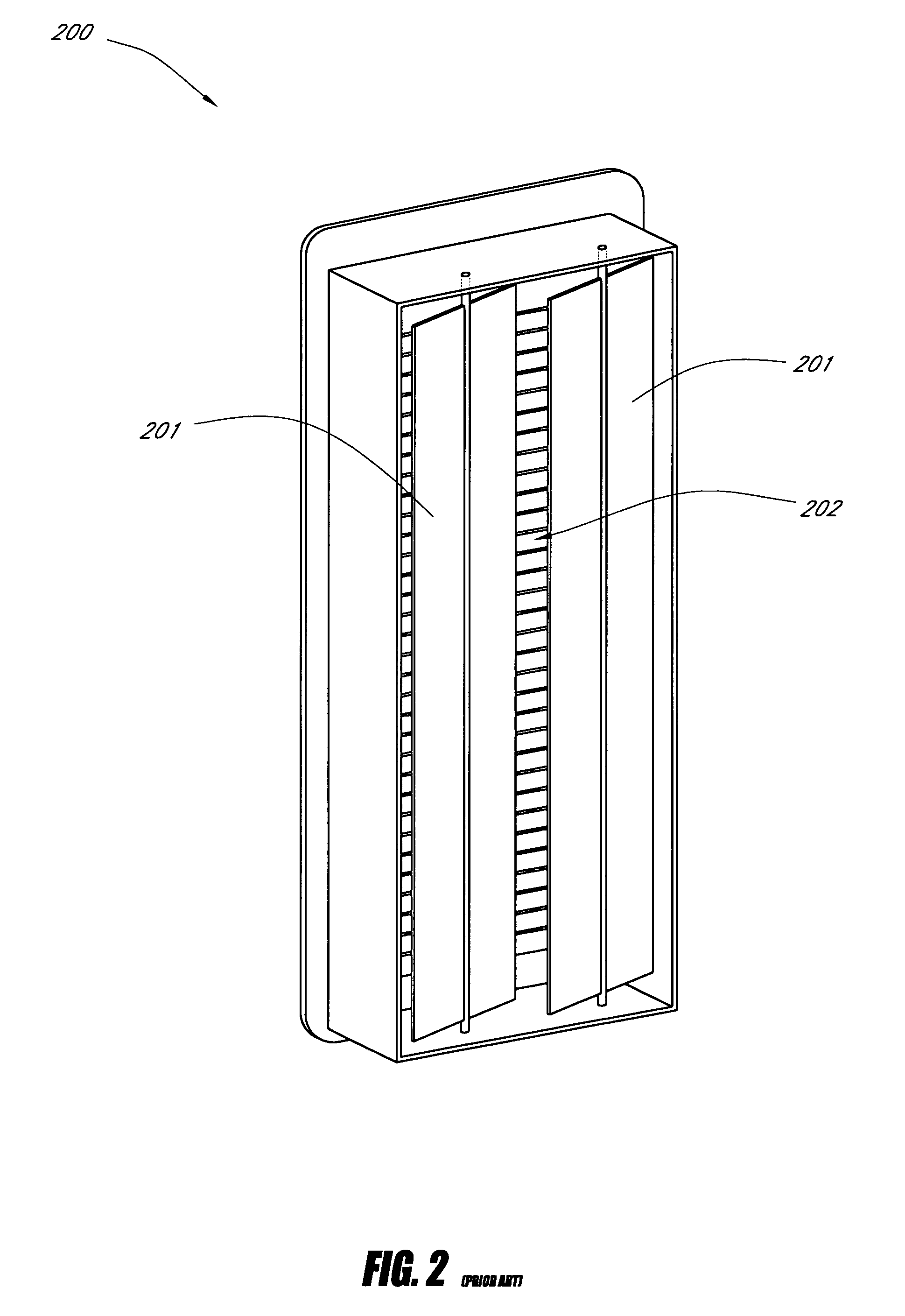

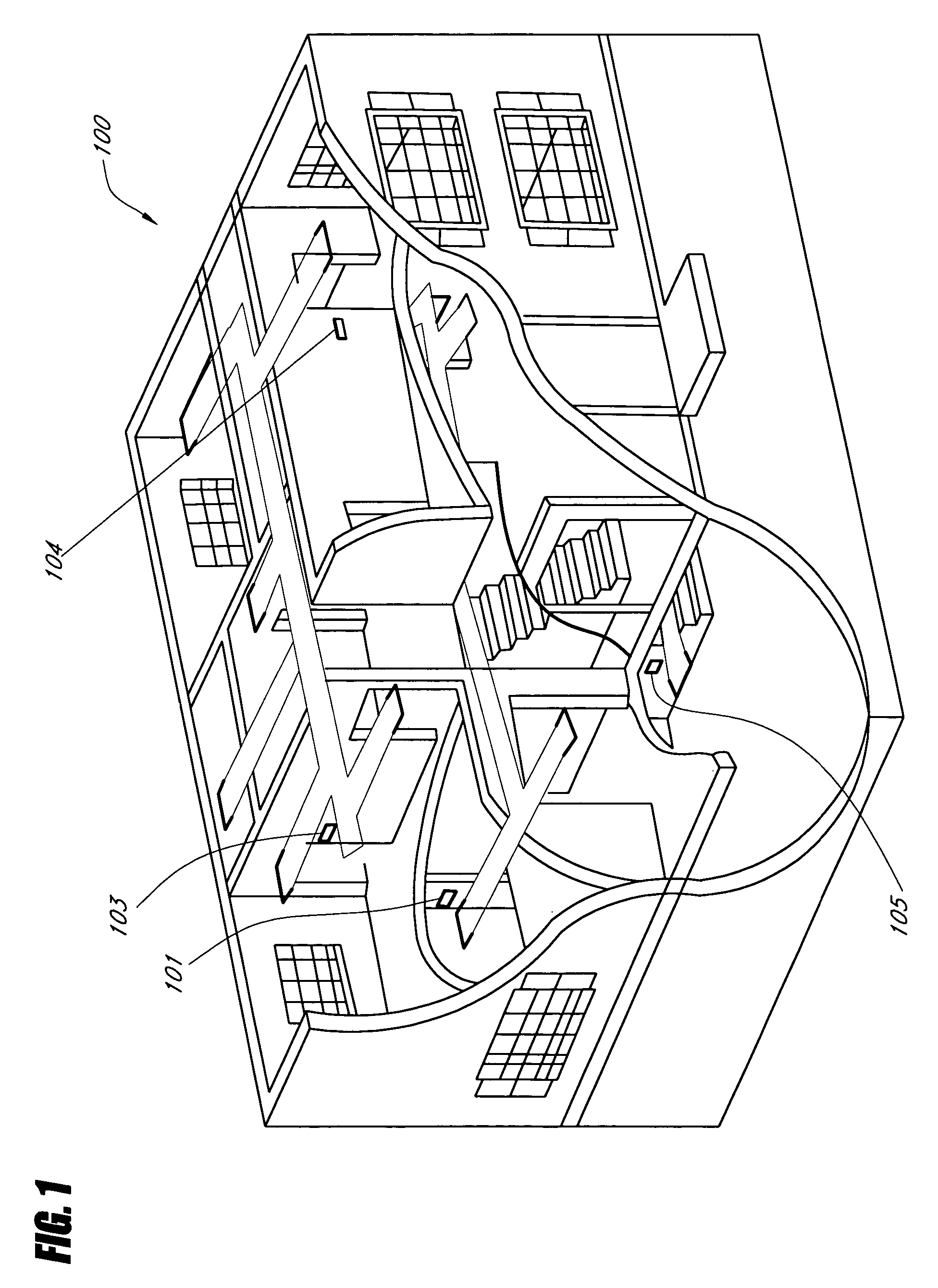

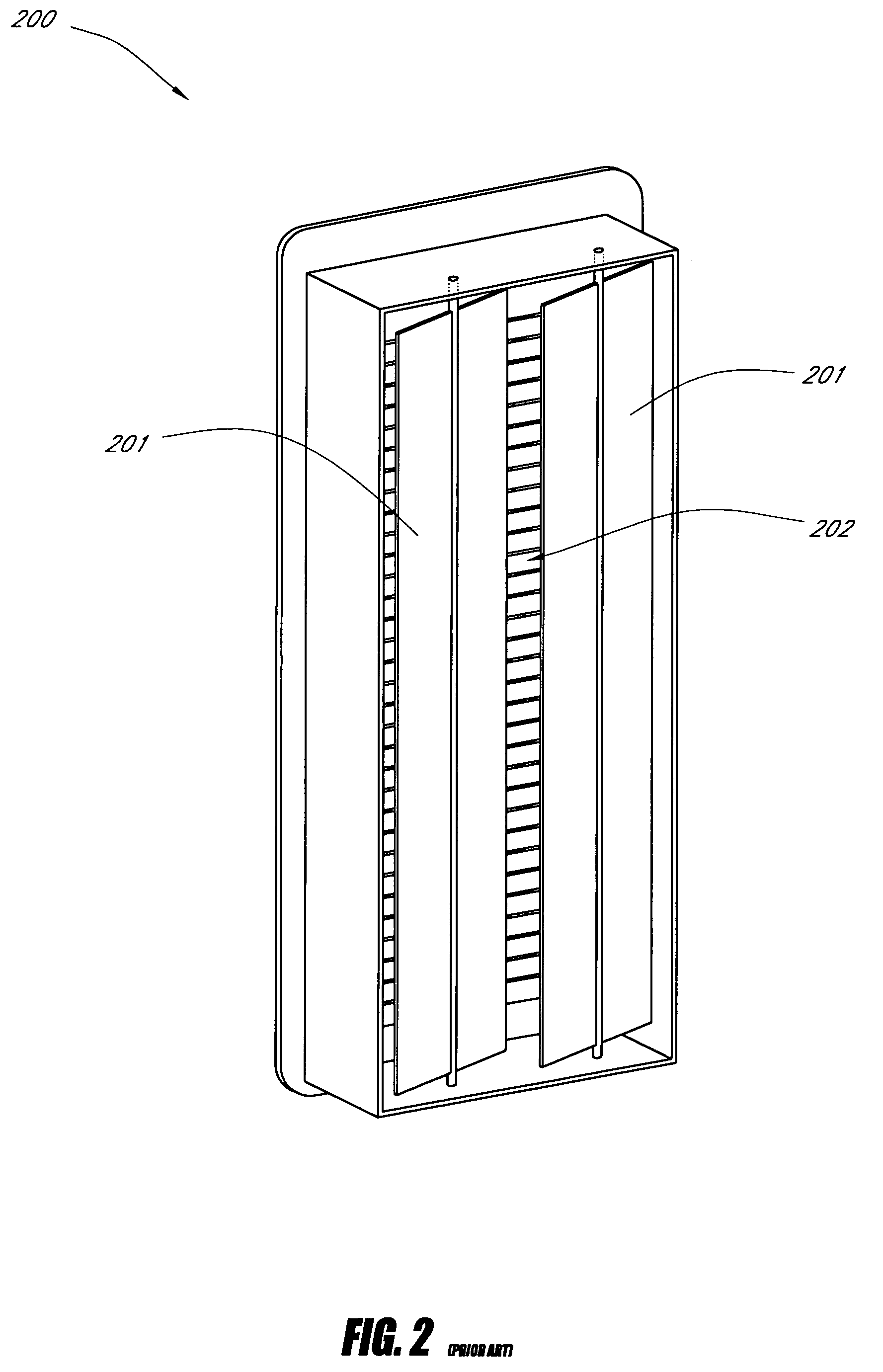

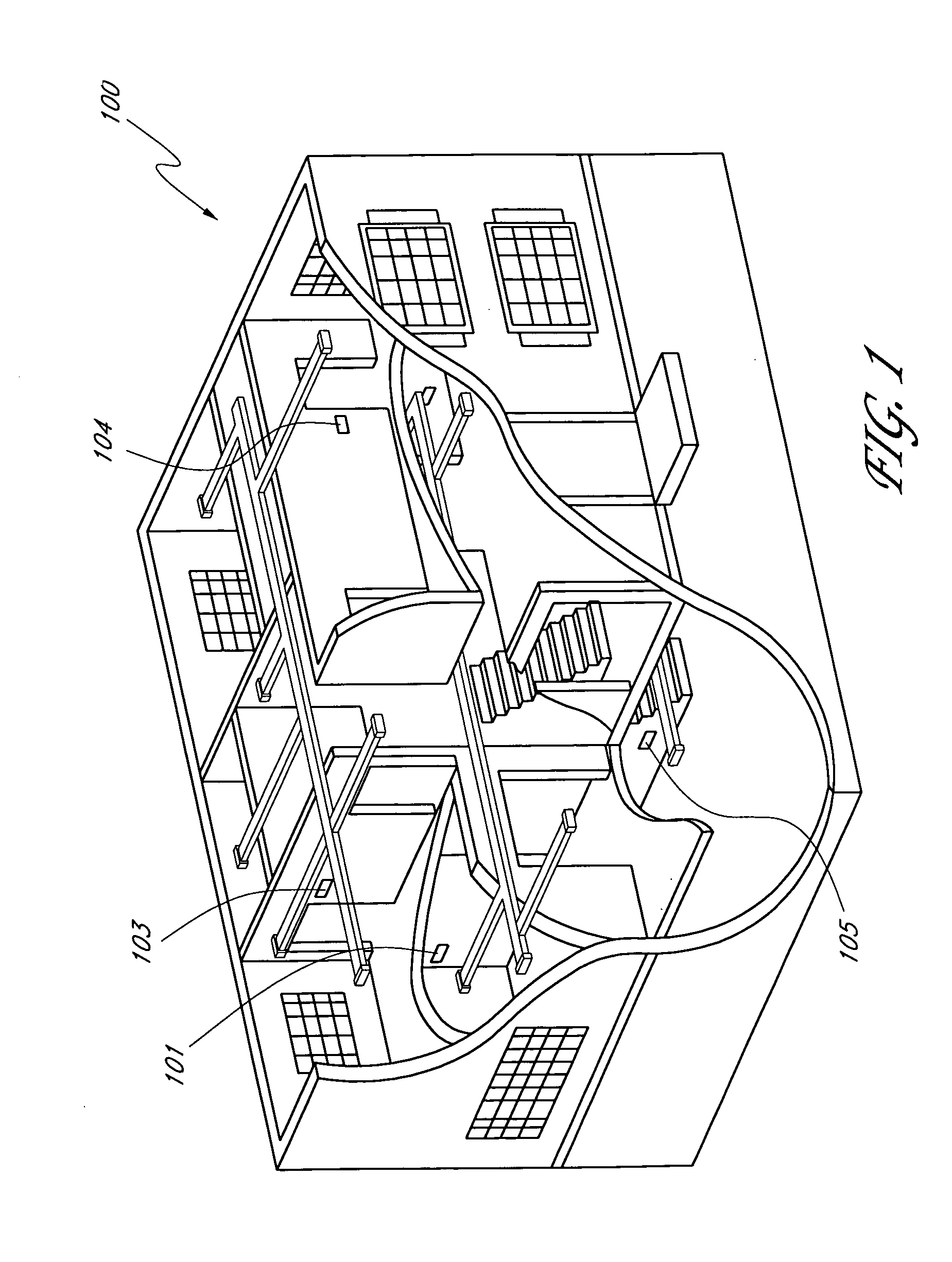

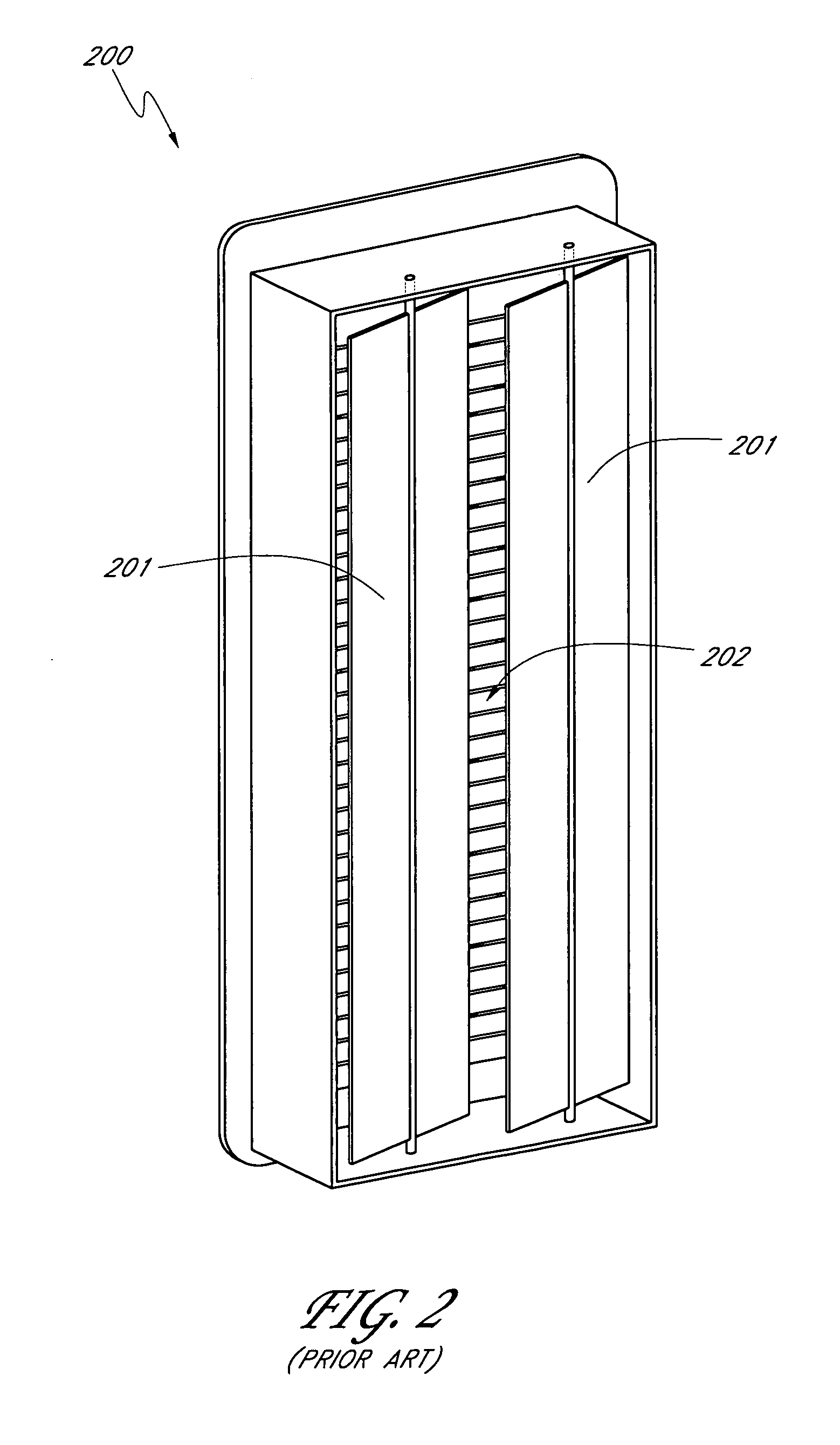

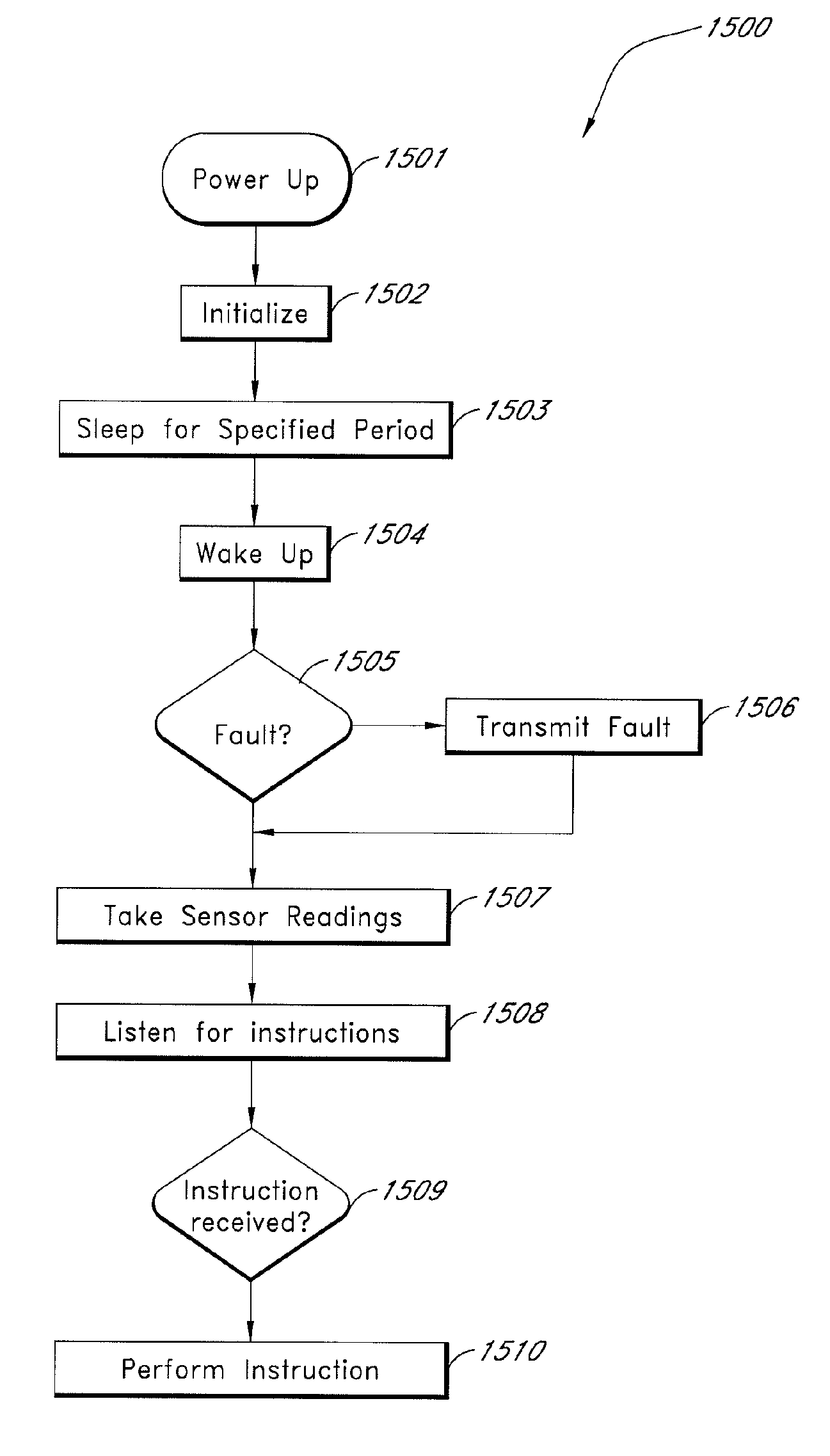

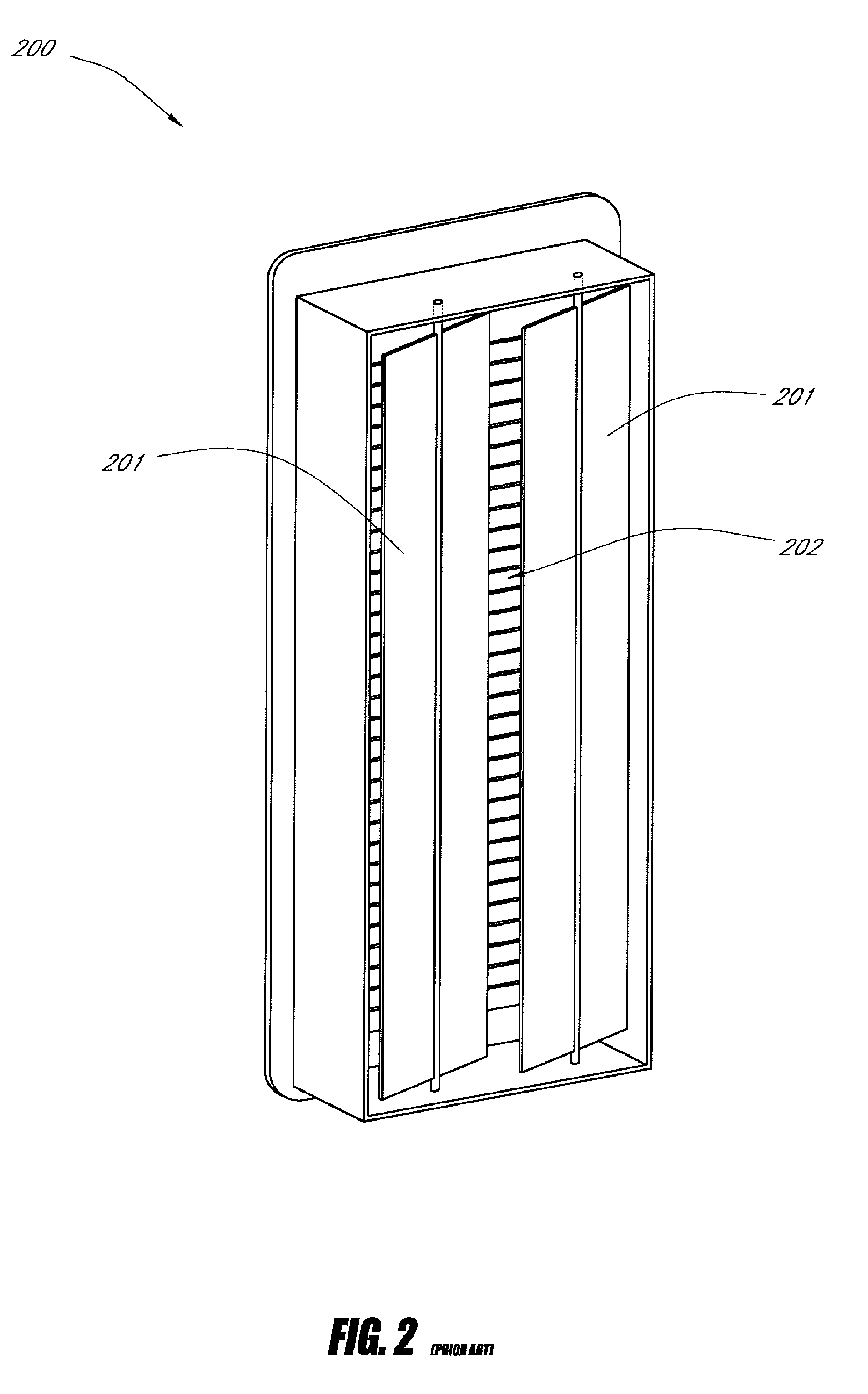

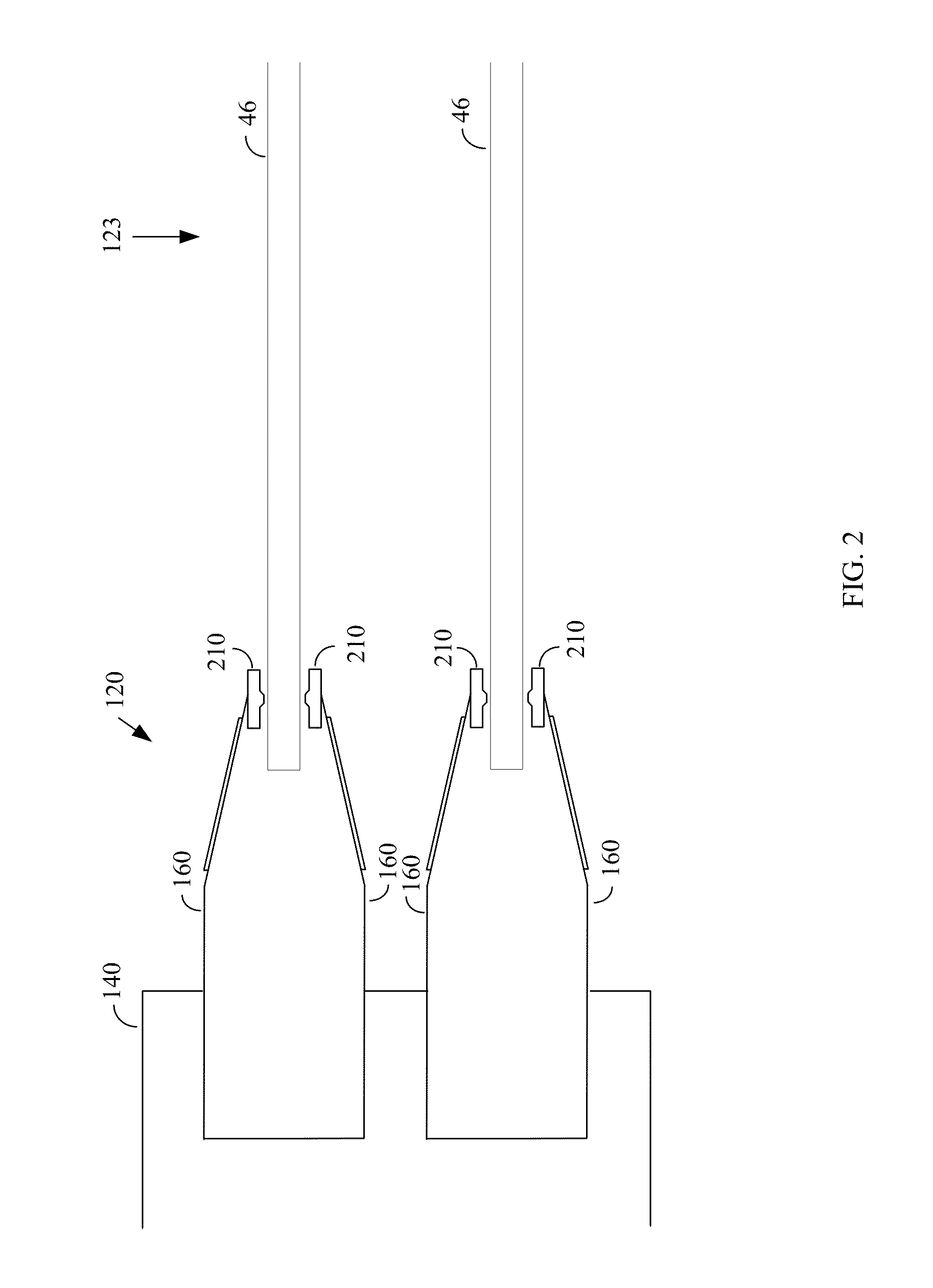

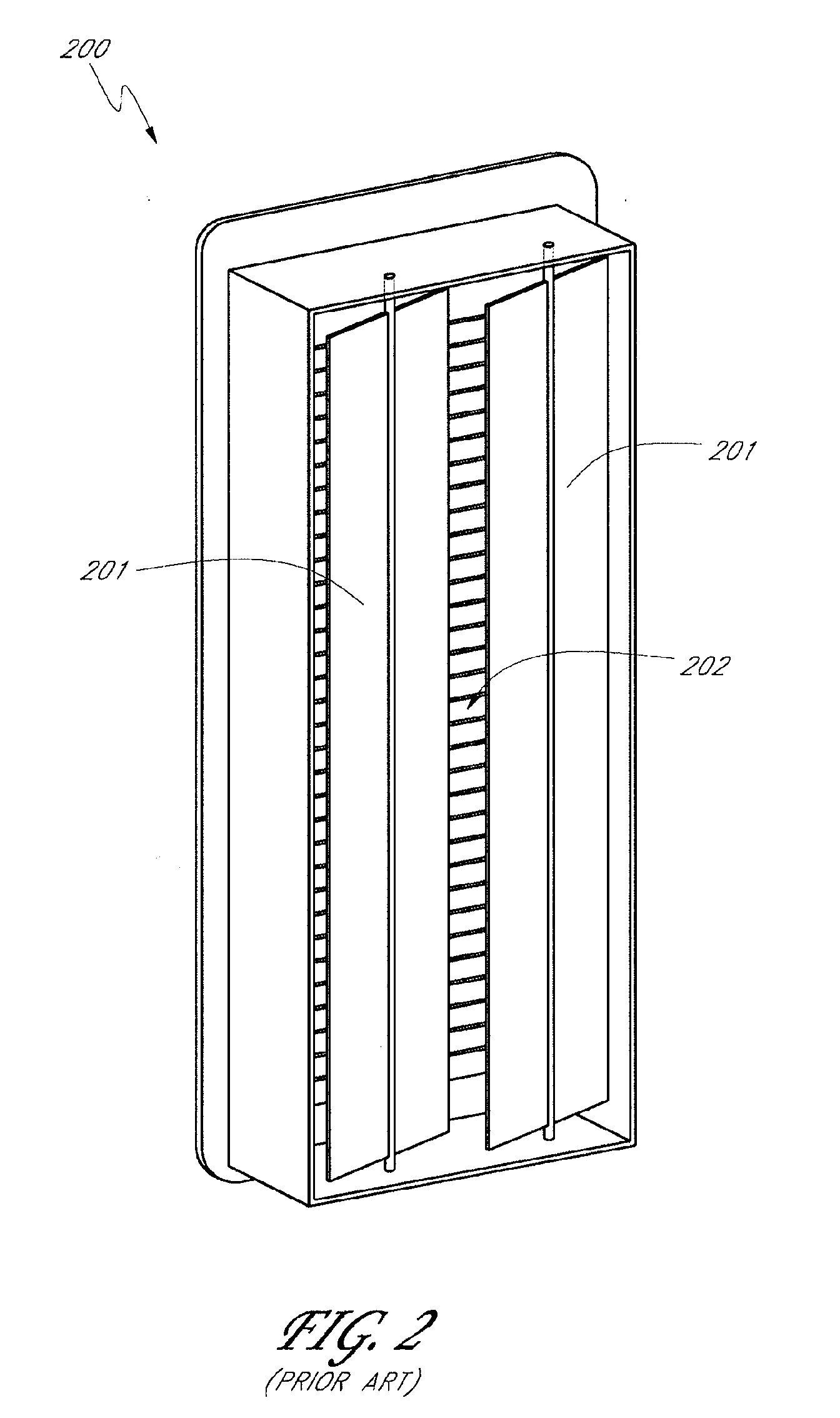

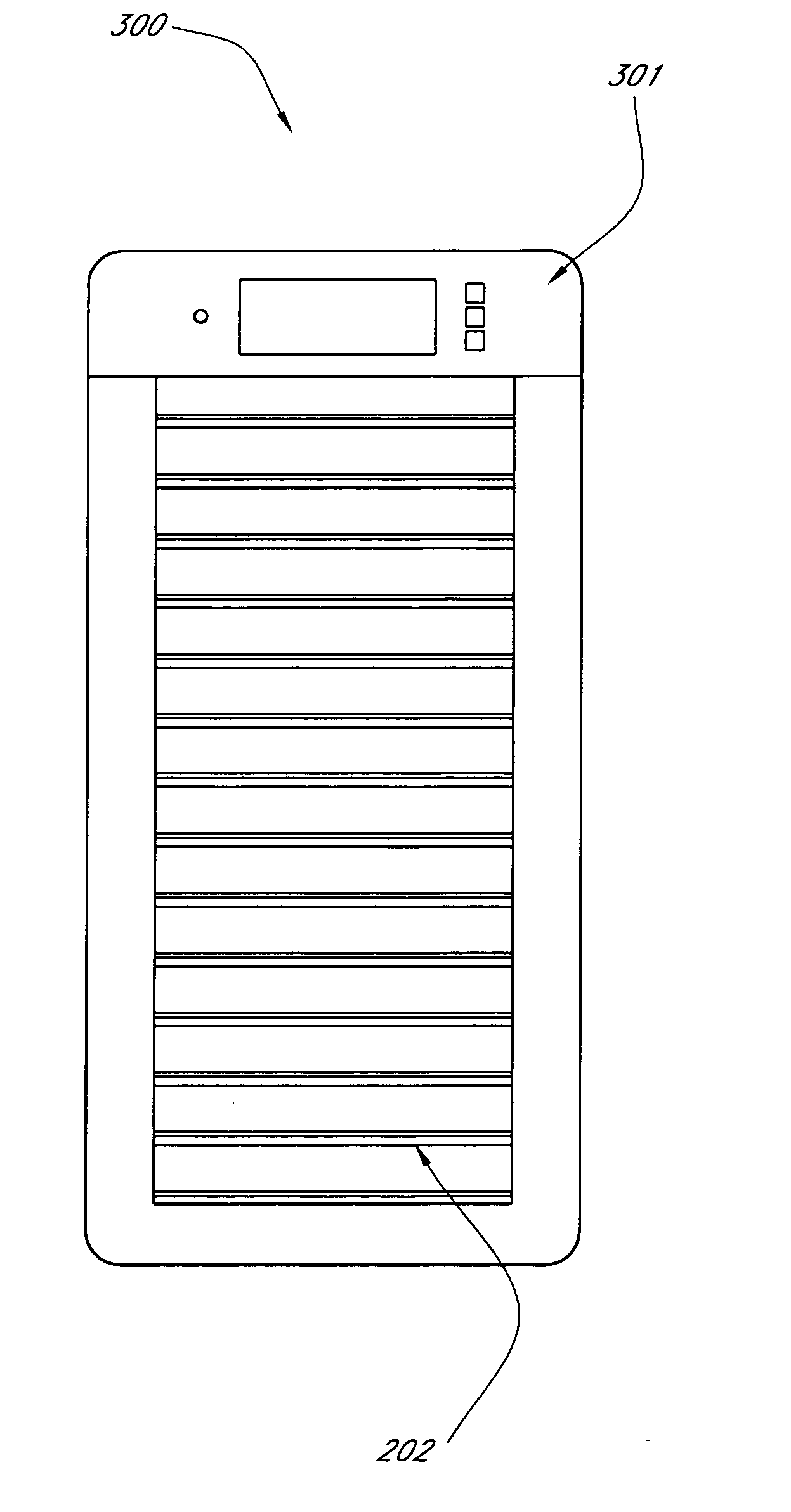

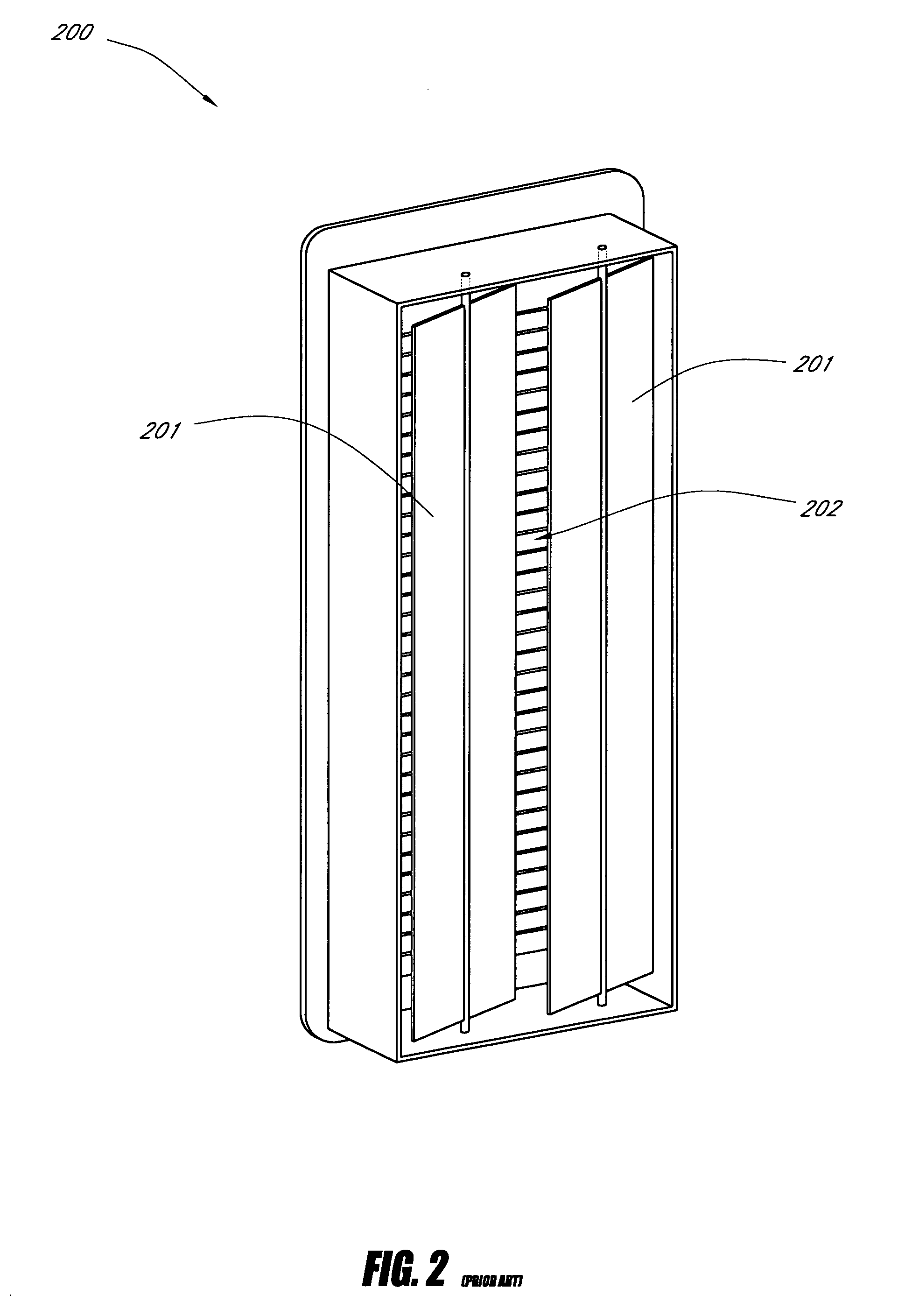

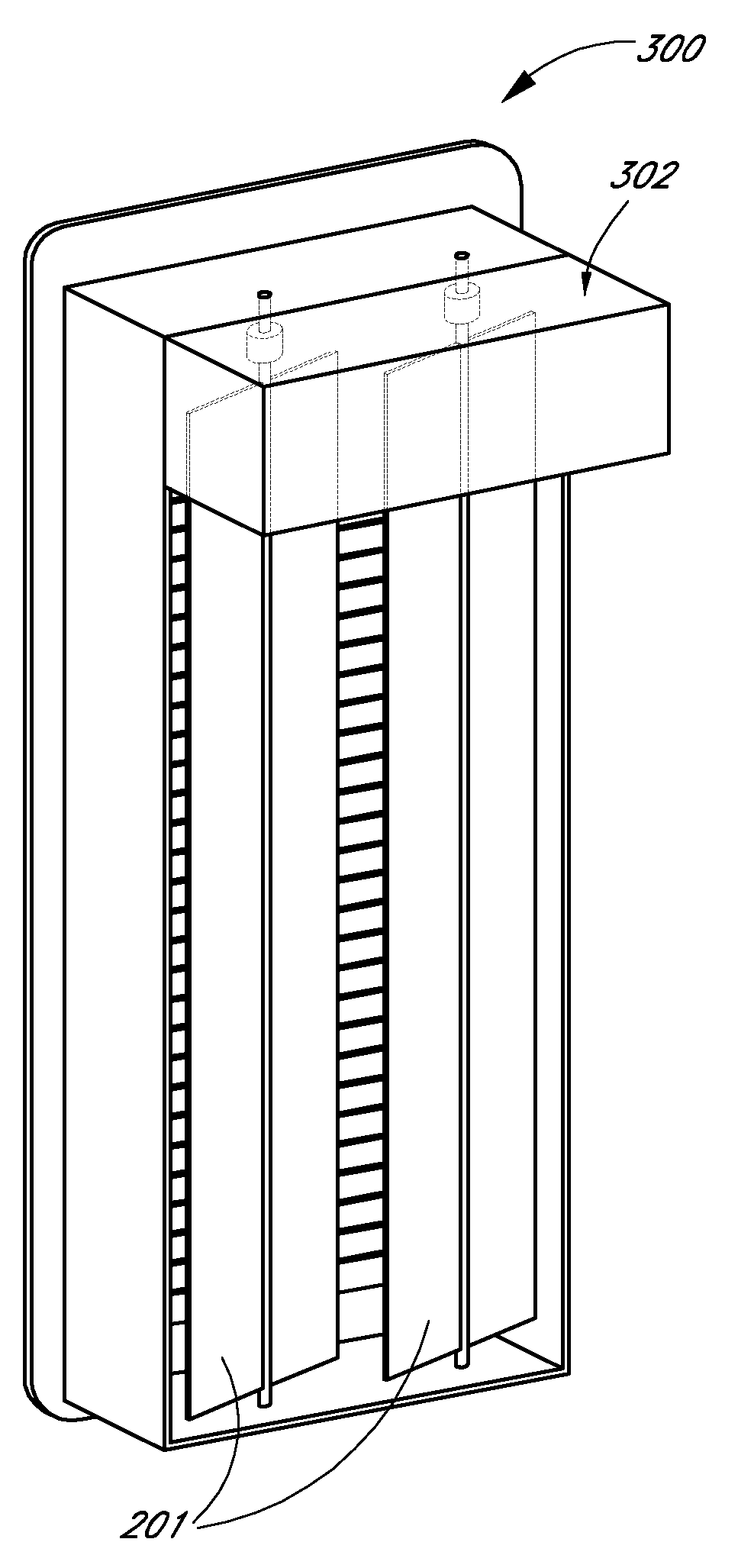

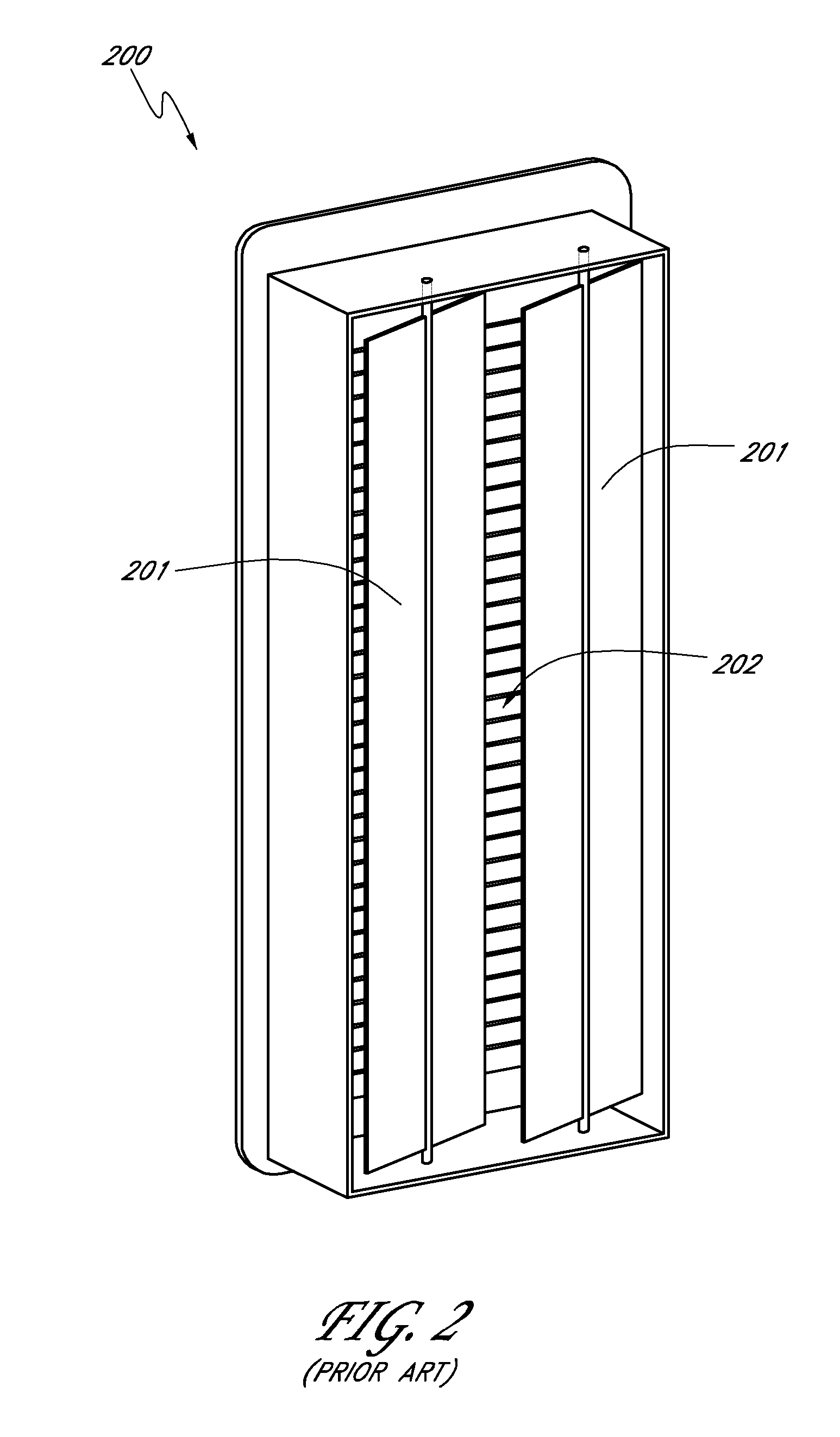

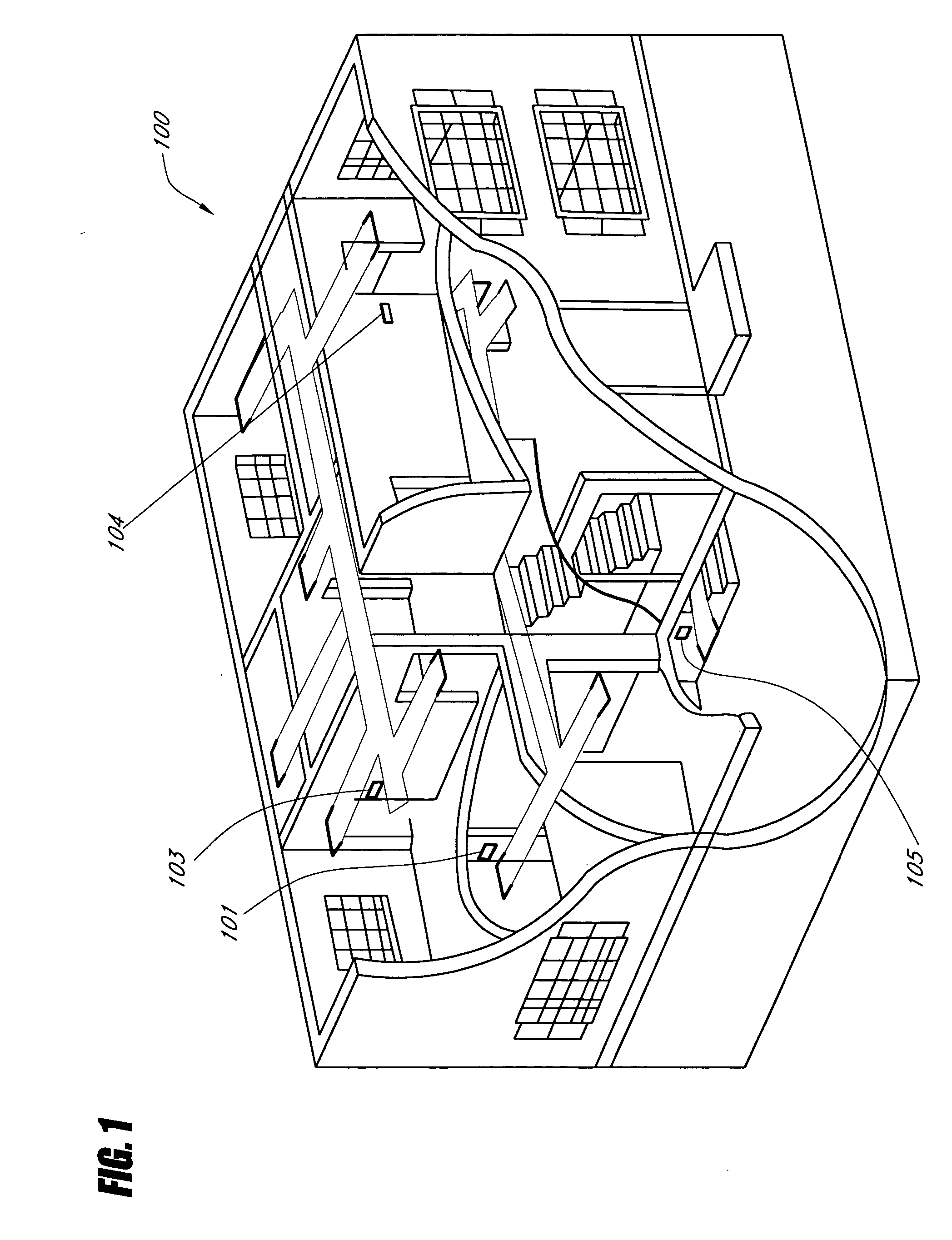

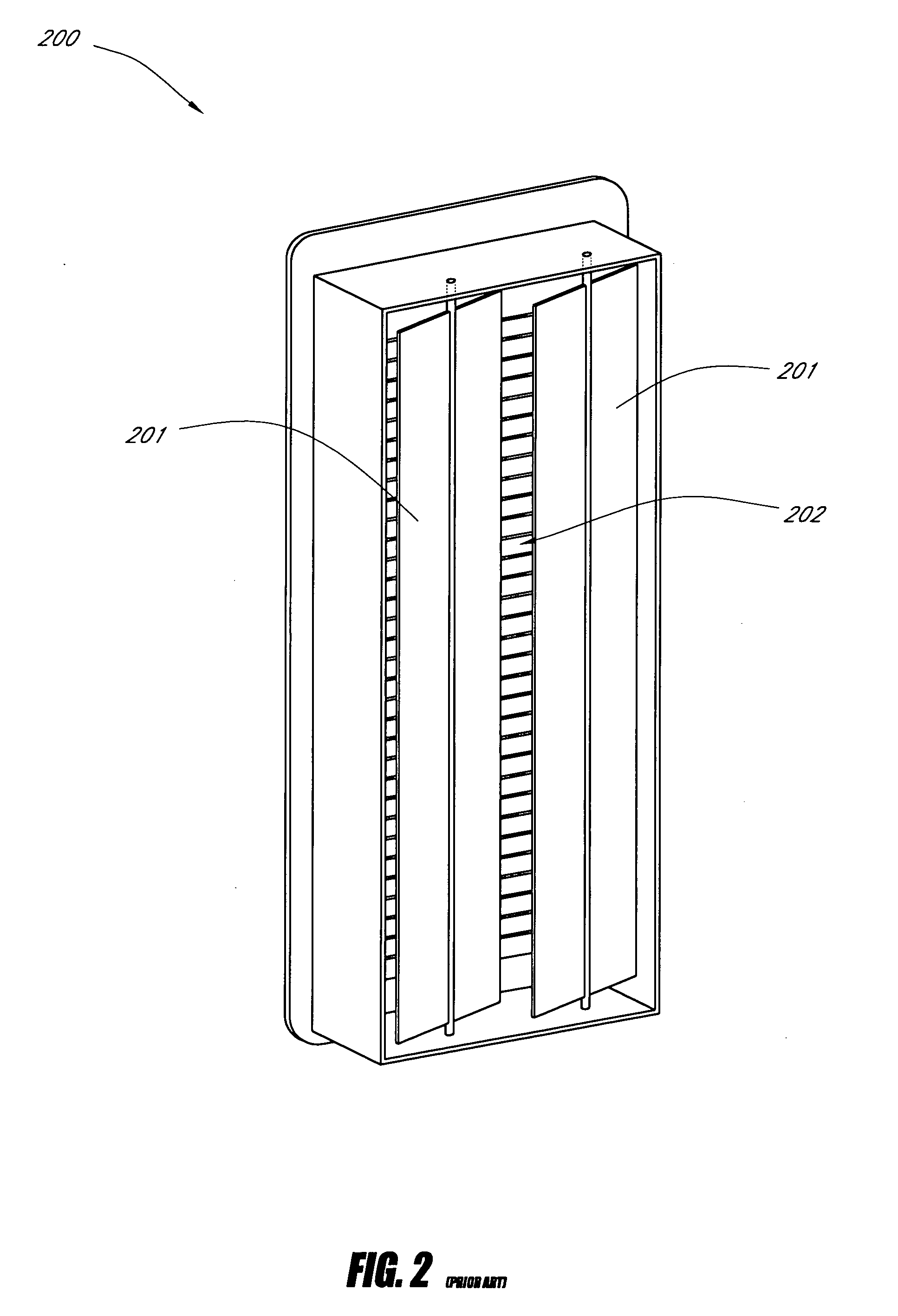

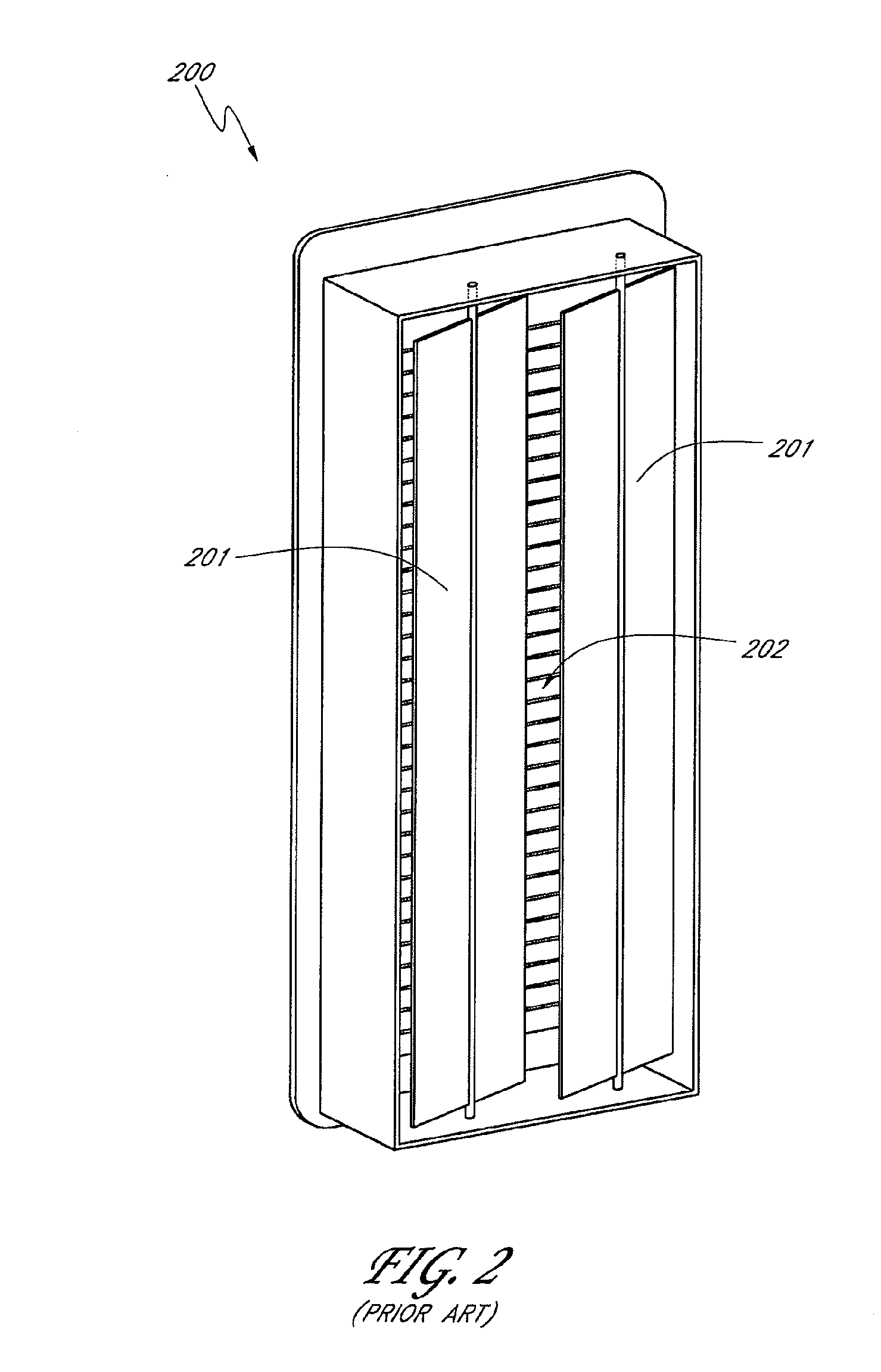

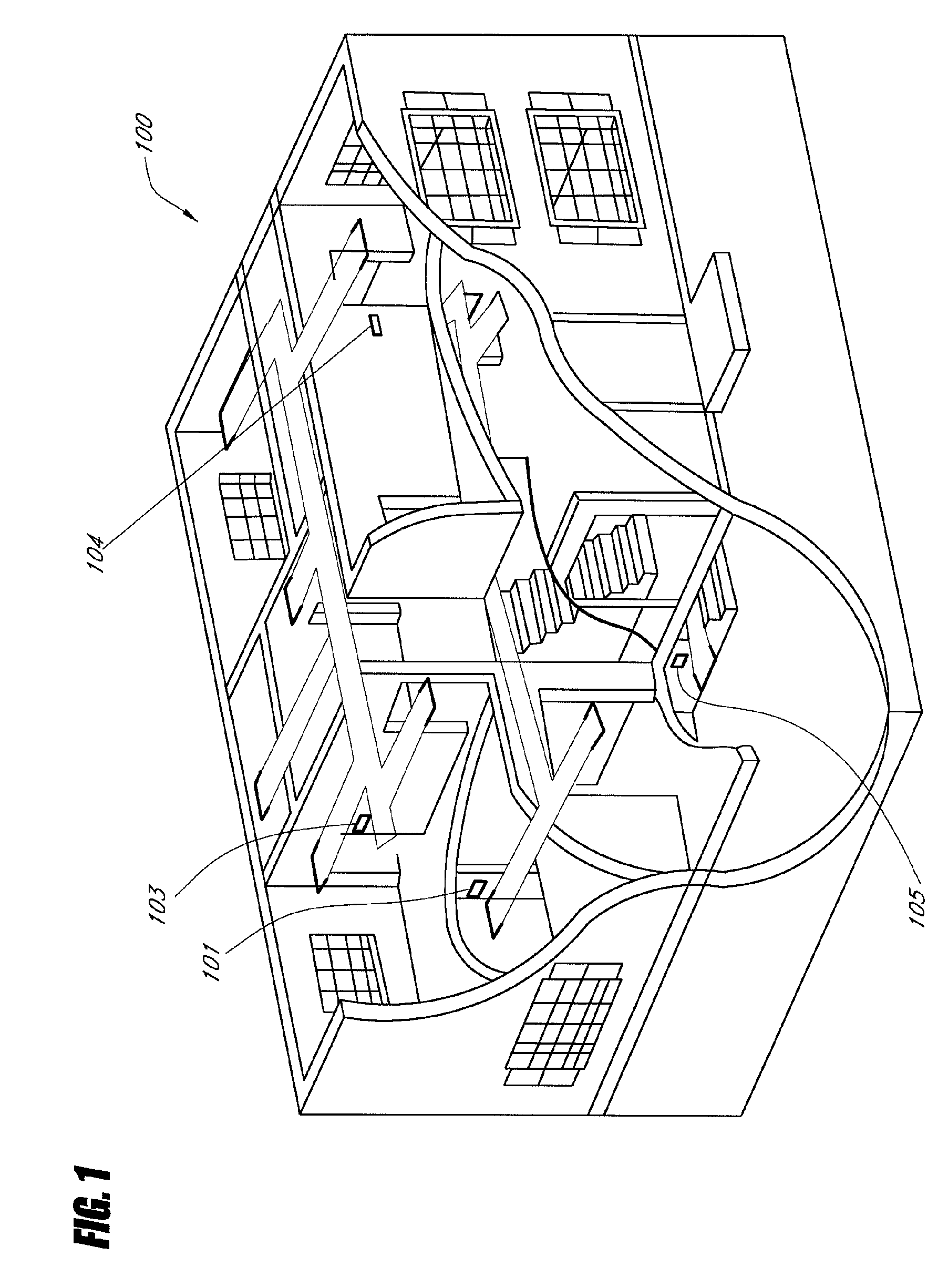

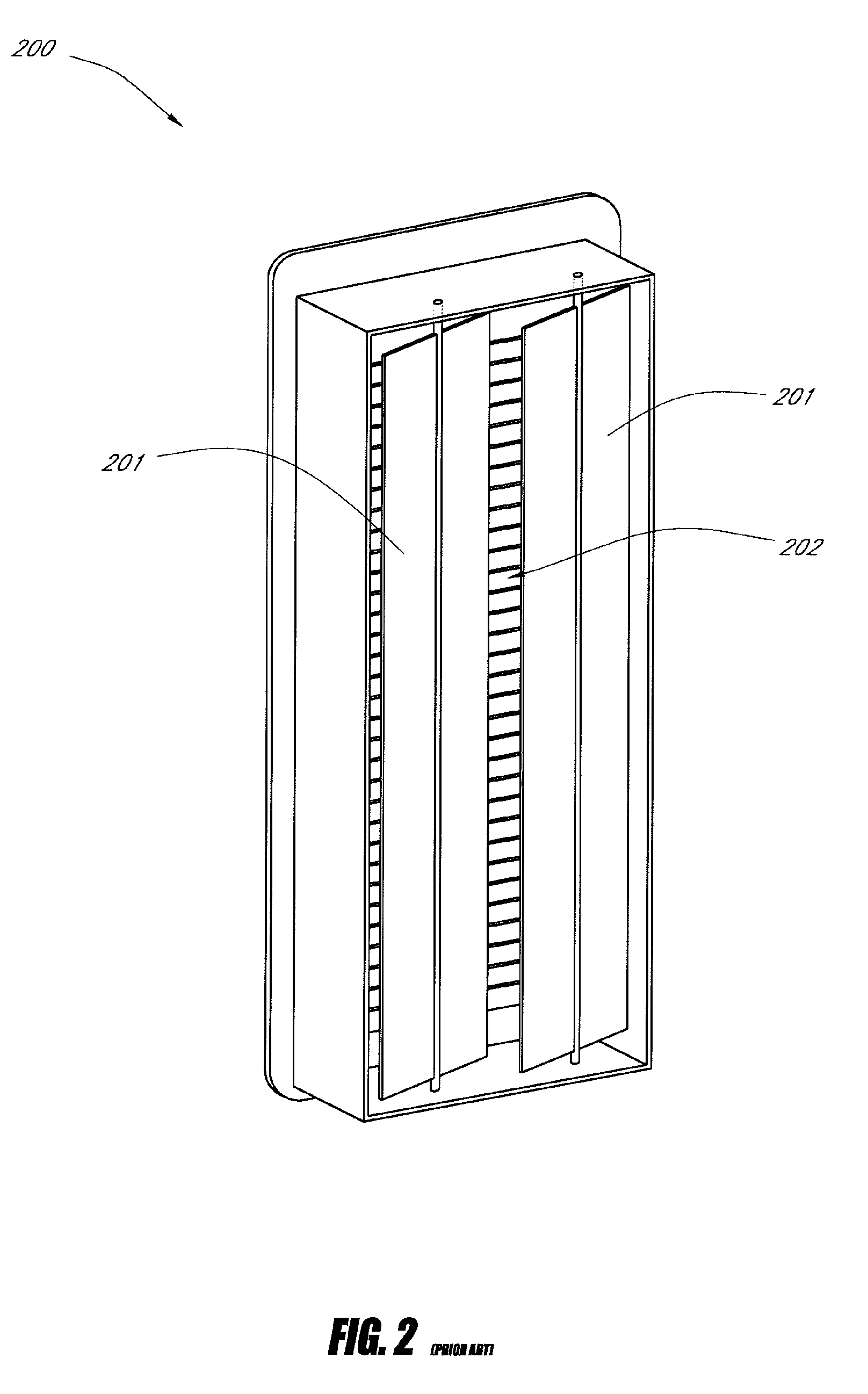

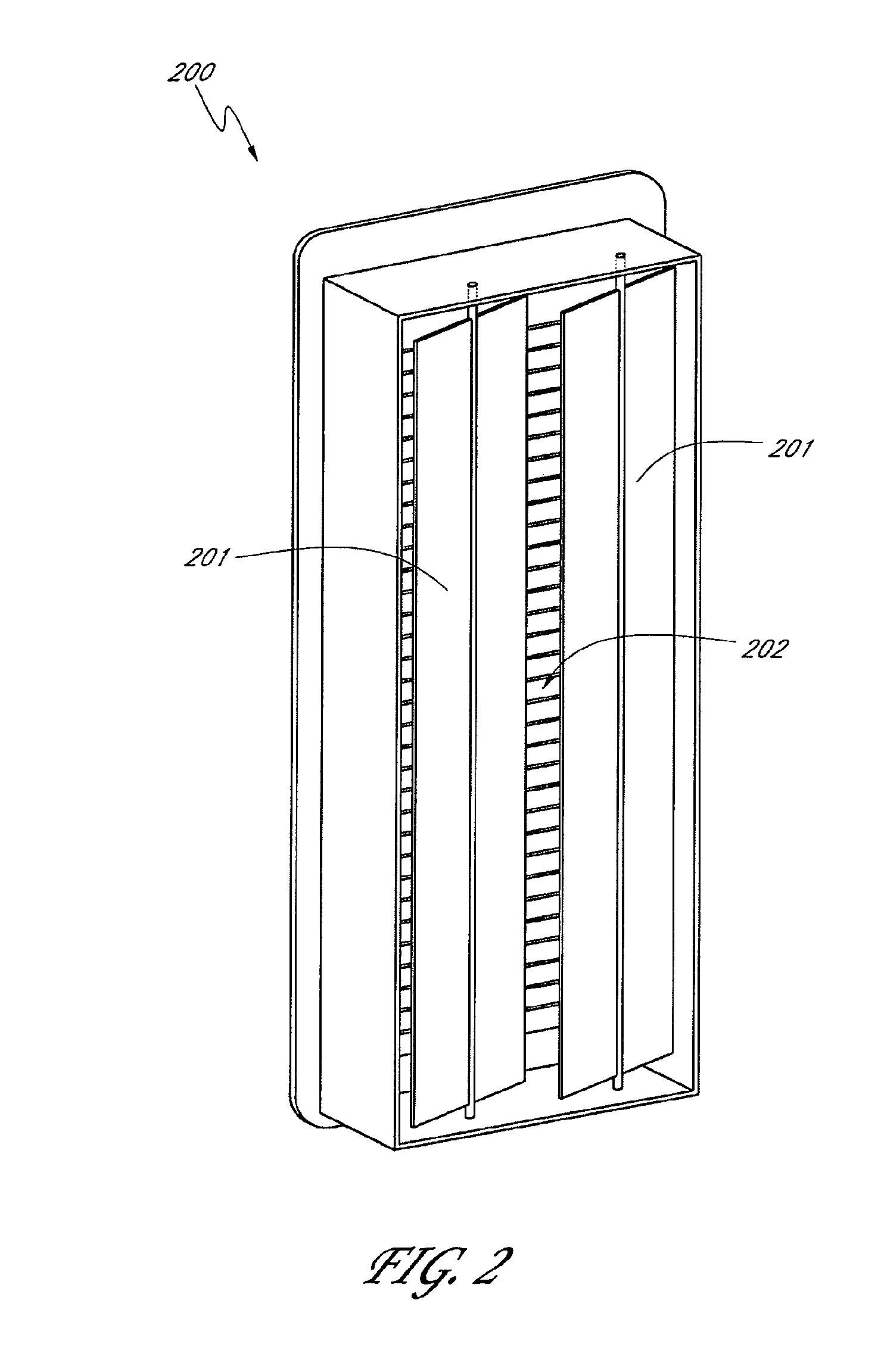

Electronically-controlled register vent for zone heating and cooling

An Electronically-Controlled Register vent (ECRV) that can be easily installed by a homeowner or general handyman is disclosed. The ECRV can be used to convert a non-zoned HVAC system into a zoned system. The ECRV can also be used in connection with a conventional zoned HVAC system to provide additional control and additional zones not provided by the conventional zoned HVAC system. In one embodiment, the ECRV is configured have a size and form-factor that conforms to a standard manually-controlled register vent. In one embodiment, a zone thermostat is configured to provide thermostat information to the ECRV. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones.

Owner:GOOGLE LLC

System and method for zone heating and cooling

ActiveUS7163156B2Easy to installMechanical apparatusLighting and heating apparatusZone SystemMonitoring system

An Electronically-Controlled Register vent (ECRV) that can be easily installed by a homeowner or general handyman is disclosed. The ECRV can be used to convert a non-zoned HVAC system into a zoned system. The ECRV can also be used in connection with a conventional zoned HVAC system to provide additional control and additional zones not provided by the conventional zoned HVAC system. In one embodiment, the ECRV is configured have a size and form-factor that conforms to a standard manually-controlled register vent. In one embodiment, a zone thermostat is configured to provide thermostat information to the ECRV. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones.

Owner:GOOGLE LLC

Electronically-controlled register vent for zone heating and cooling

ActiveUS20070119958A1Difficult to coolHeat is not easyDucting arrangementsMechanical apparatusZone SystemControl register

An Electronically-Controlled Register vent (ECRV) that can be easily installed by a homeowner or general handyman is disclosed. The ECRV can be used to convert a non-zoned HVAC system into a zoned system. The ECRV can also be used in connection with a conventional zoned HVAC system to provide additional control and additional zones not provided by the conventional zoned HVAC system. In one embodiment, the ECRV is configured have a size and form-factor that conforms to a standard manually-controlled register vent. In one embodiment, a zone thermostat is configured to provide thermostat information to the ECRV. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones.

Owner:GOOGLE LLC

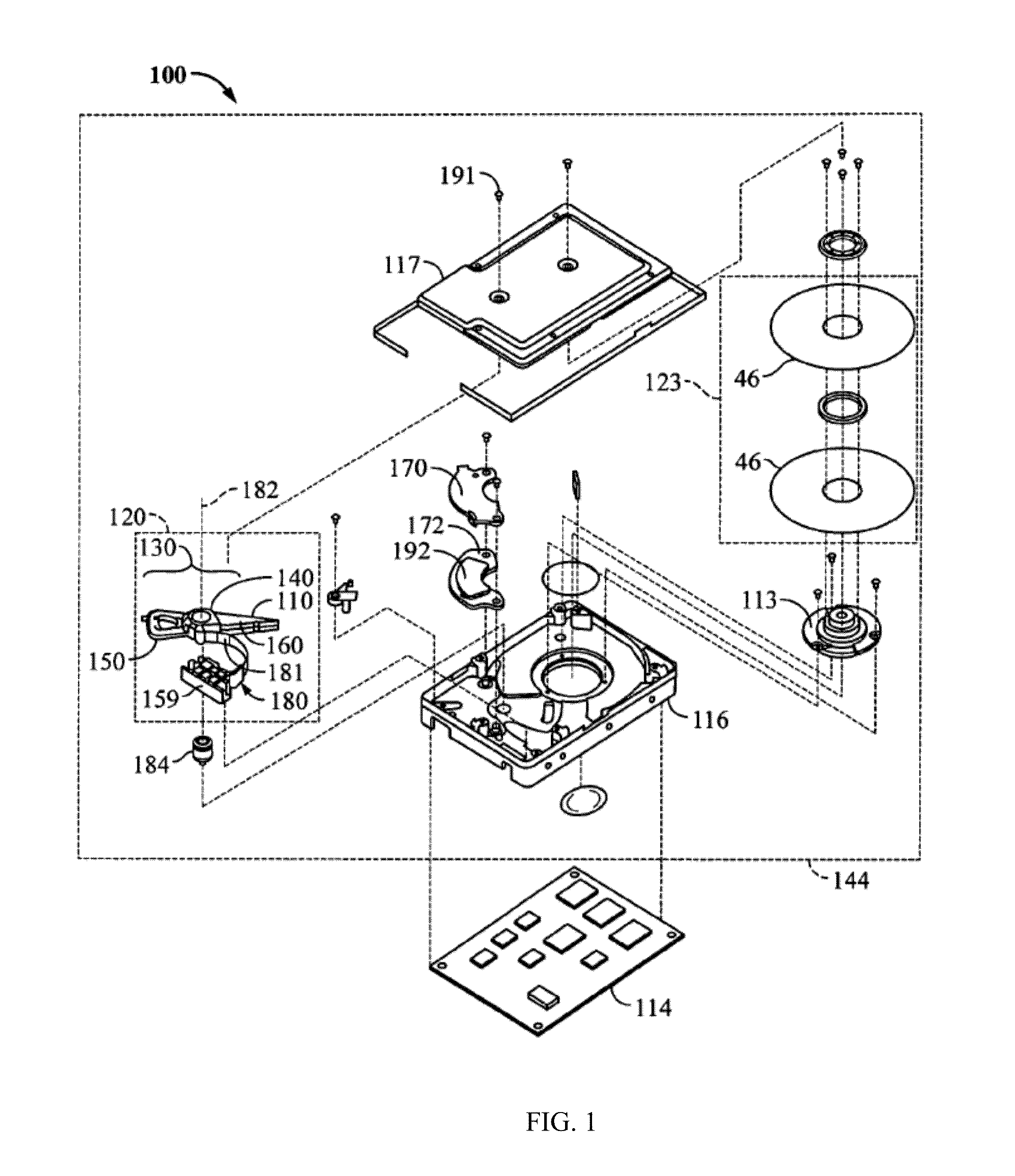

Systems and methods for improving sequential data rate performance using sorted data zones

Systems and methods for writing a sequence of data to a disk drive using sorted data zones are provided. In one embodiment, a multi-head disk drive comprises a plurality of disk surfaces, wherein each disk surface comprises a plurality of data zones, each data zone having a data transfer rate different from the other zones of the respective disk surface. The multi-head disk drive also comprises a head assembly comprising a plurality of heads, wherein each head is configured to write data to a respective one of the disk surfaces, and a controller configured to operate the plurality of heads to sequentially write a sequence of data blocks to the plurality of disk surfaces in accordance with a list of head-zone combinations ordered from highest data rate to lowest data rate, each head-zone combination corresponding to one of the heads and a data zone of the respective disk surface.

Owner:WESTERN DIGITAL TECH INC

System and method for zone heating and cooling using controllable supply and return vents

InactiveUS20090065595A1Mechanical apparatusSpace heating and ventilation safety systemsZone SystemControl register

An Electronically-Controlled Register Vent (ECRV) that can be easily installed by a homeowner or general handyman is disclosed. The ECRV can be used to convert a non-zoned HVAC system into a zoned system. The ECRV can also be used in connection with a conventional zoned HVAC system to provide additional control and additional zones not provided by the conventional zoned HVAC system. In one embodiment, the ECRV is configured have a size and form-factor that conforms to a standard manually-controlled register vent. In one embodiment, a zone thermostat is configured to provide thermostat information to the ECRV. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones and the opening of an ECRV provided to a supply vent and the opening of an ECRV provided to a return vent.

Owner:KATES LAWRENCE

Zone thermostat for zone heating and cooling

ActiveUS20060071089A1Easy to installDucting arrangementsMechanical apparatusZone SystemMonitoring system

A zone thermostat for use in connection with an Electronically-Controlled Register vent (ECRV) that can be easily installed by a homeowner or general handyman is disclosed. The ECRV can be used to convert a non-zoned HVAC system into a zoned system. The ECRV can also be used in connection with a conventional zoned HVAC system to provide additional control and additional zones not provided by the conventional zoned HVAC system. In one embodiment, the ECRV is configured have a size and form-factor that conforms to a standard manually-controlled register vent. In one embodiment, the zone thermostat is configured to provide thermostat information to the ECRV. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones.

Owner:GOOGLE LLC

Modular register vent for zone heating and cooling

InactiveUS20100012737A1Difficult to coolHeat is not easyMechanical apparatusSpace heating and ventilation safety systemsZone SystemMonitoring system

A modular Electronically-Controlled Register Vent (ECRV) that can be easily installed by a homeowner or general handyman is disclosed. The ECRV can be used to convert a non-zoned HVAC system into a zoned system. The ECRV can also be used in connection with a conventional zoned HVAC system to provide additional control and additional zones not provided by the conventional zoned HVAC system. In one embodiment, the modular ECRV can be configured to various sizes and form-factors that conform to a standard manually-controlled register vent. In one embodiment, a zone thermostat is configured to provide thermostat information to the ECRV. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones and provides heating and cooling to the various zones according to a cost budget.

Owner:KATES LAWRENCE

Electronically-controlled register vent for zone heating and cooling

ActiveUS20060071087A1Difficult to coolHeat is not easyMechanical apparatusLighting and heating apparatusZone SystemControl register

An Electronically-Controlled Register vent (ECRV) that can be easily installed by a homeowner or general handyman is disclosed. The ECRV can be used to convert a non-zoned HVAC system into a zoned system. The ECRV can also be used in connection with a conventional zoned HVAC system to provide additional control and additional zones not provided by the conventional zoned HVAC system. In one embodiment, the ECRV is configured have a size and form-factor that conforms to a standard manually-controlled register vent. In one embodiment, a zone thermostat is configured to provide thermostat information to the ECRV. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones.

Owner:GOOGLE LLC

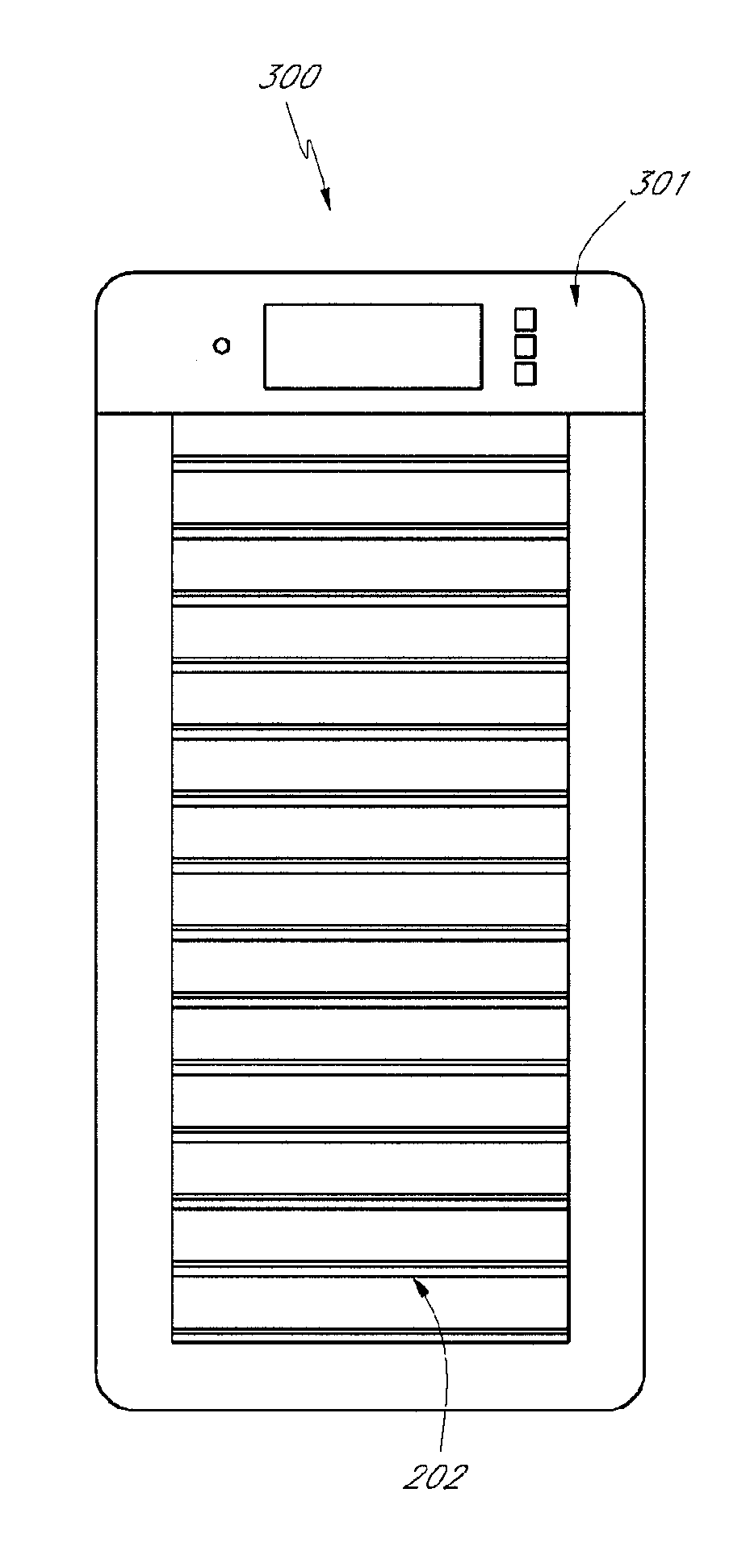

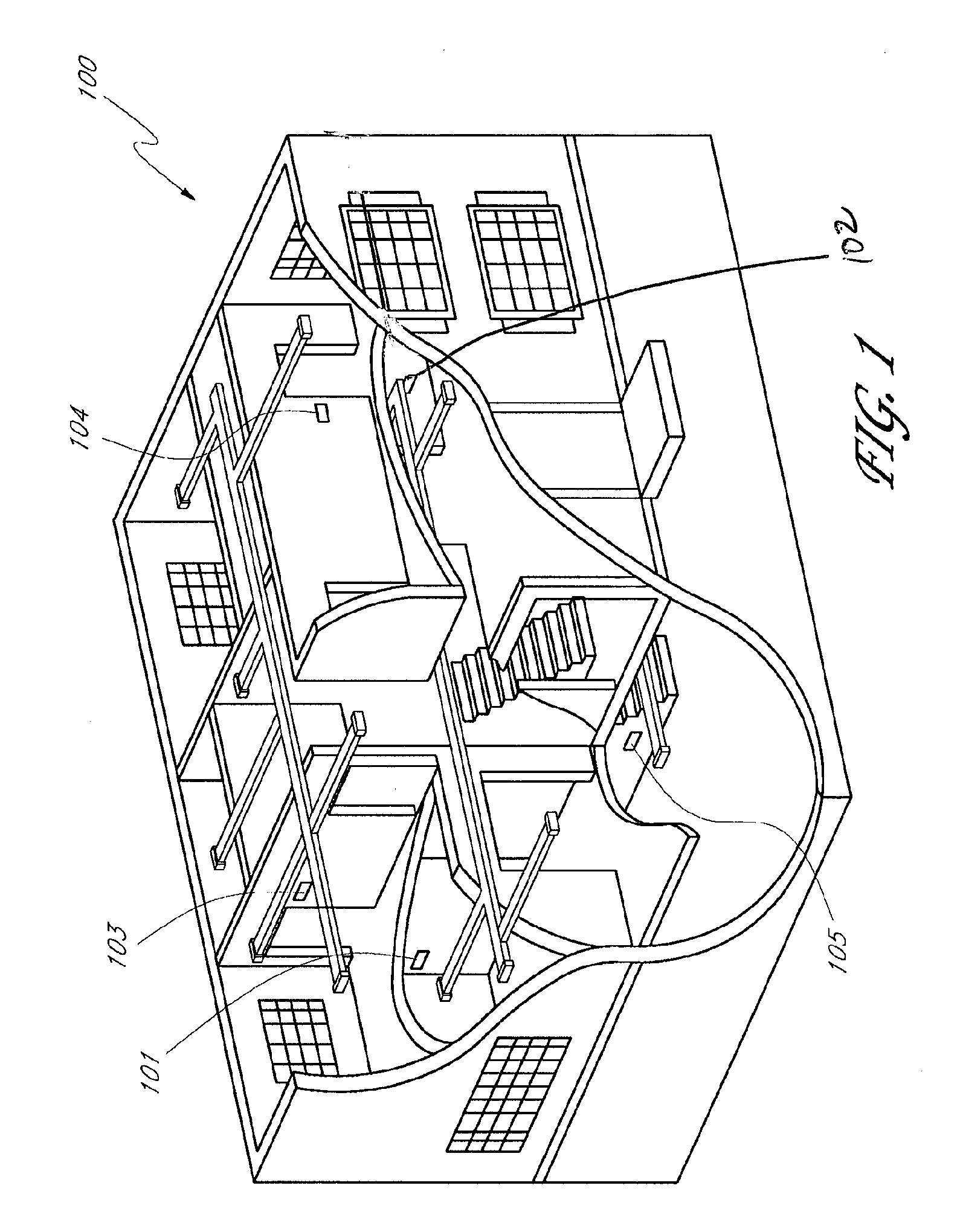

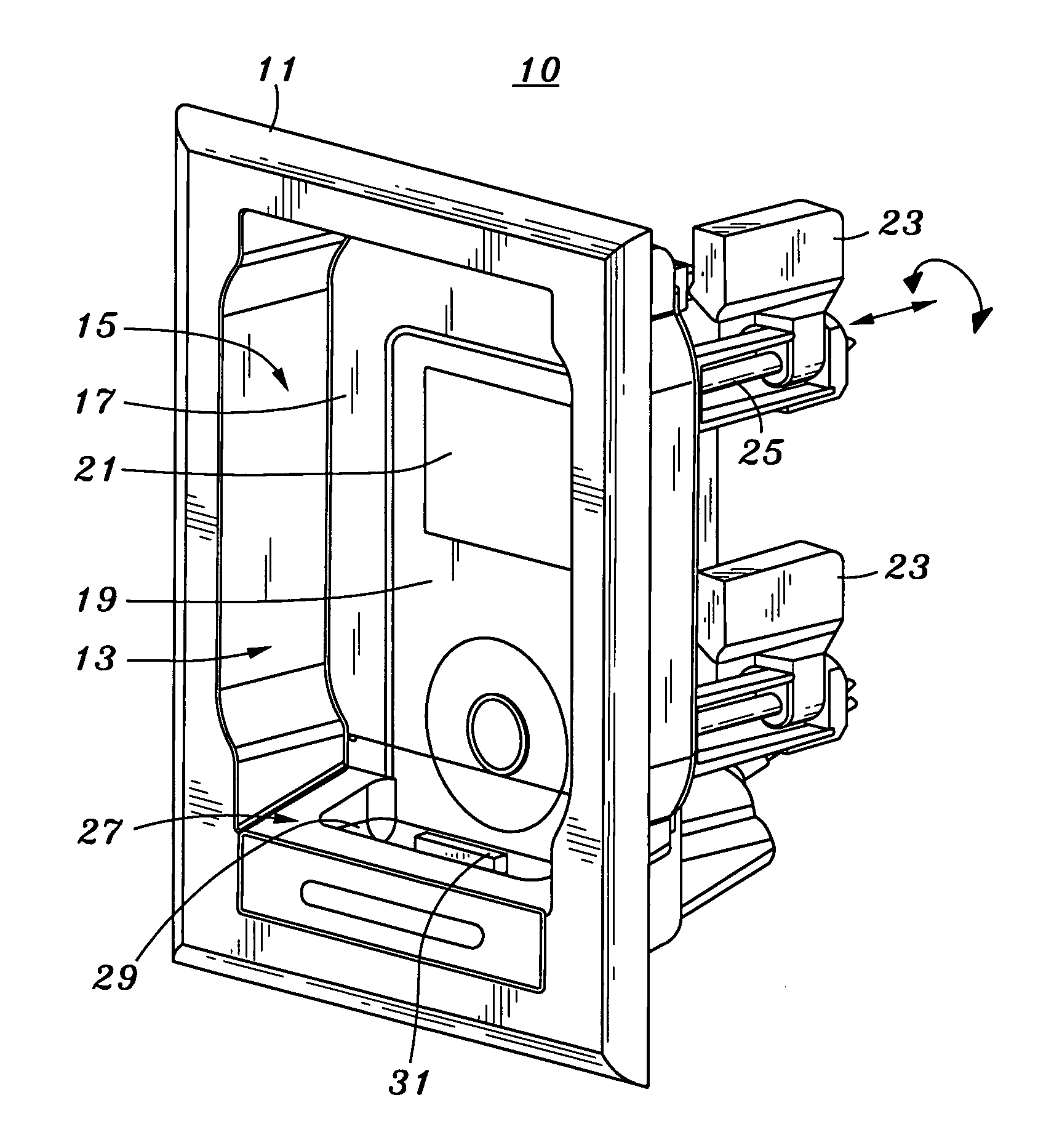

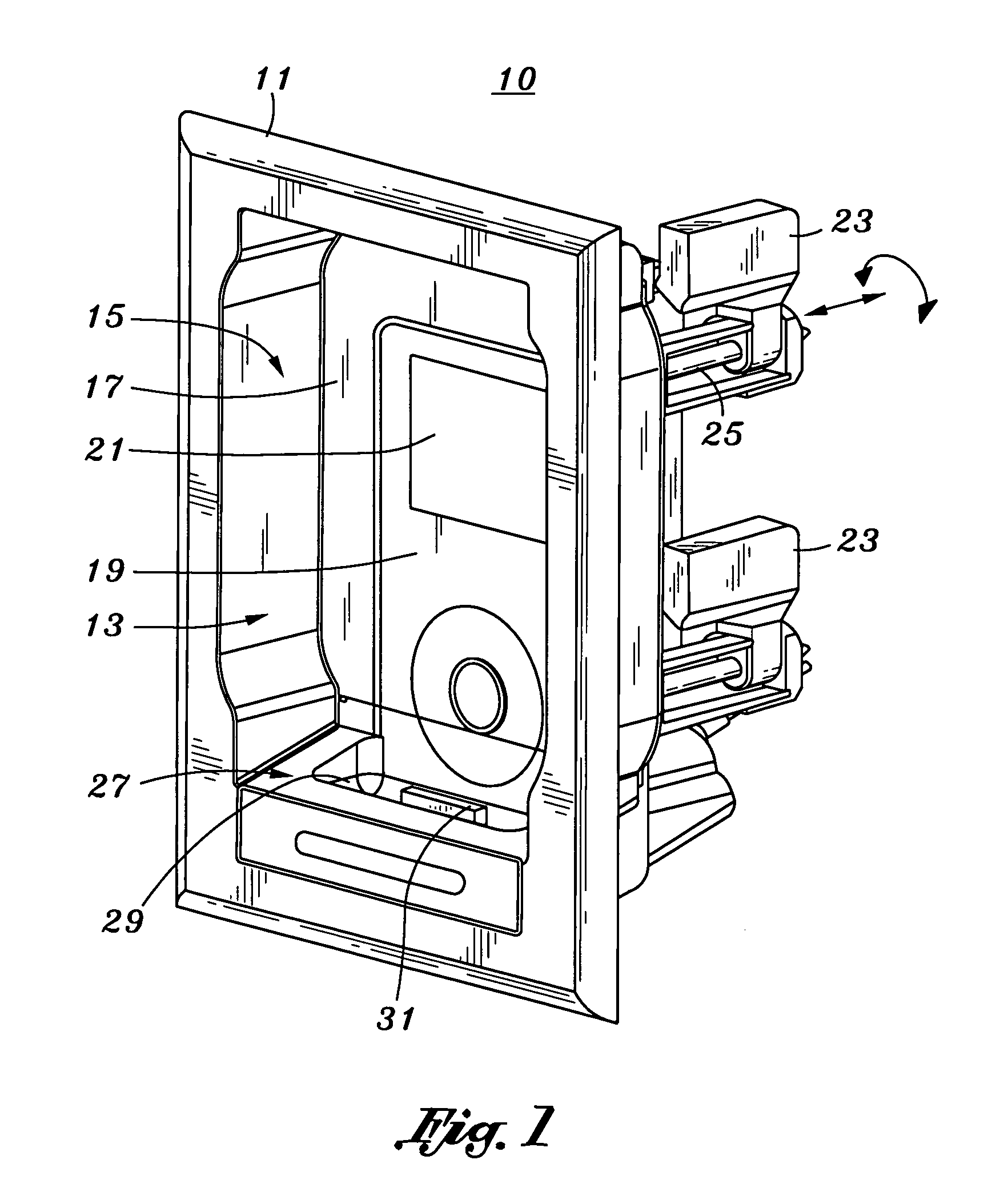

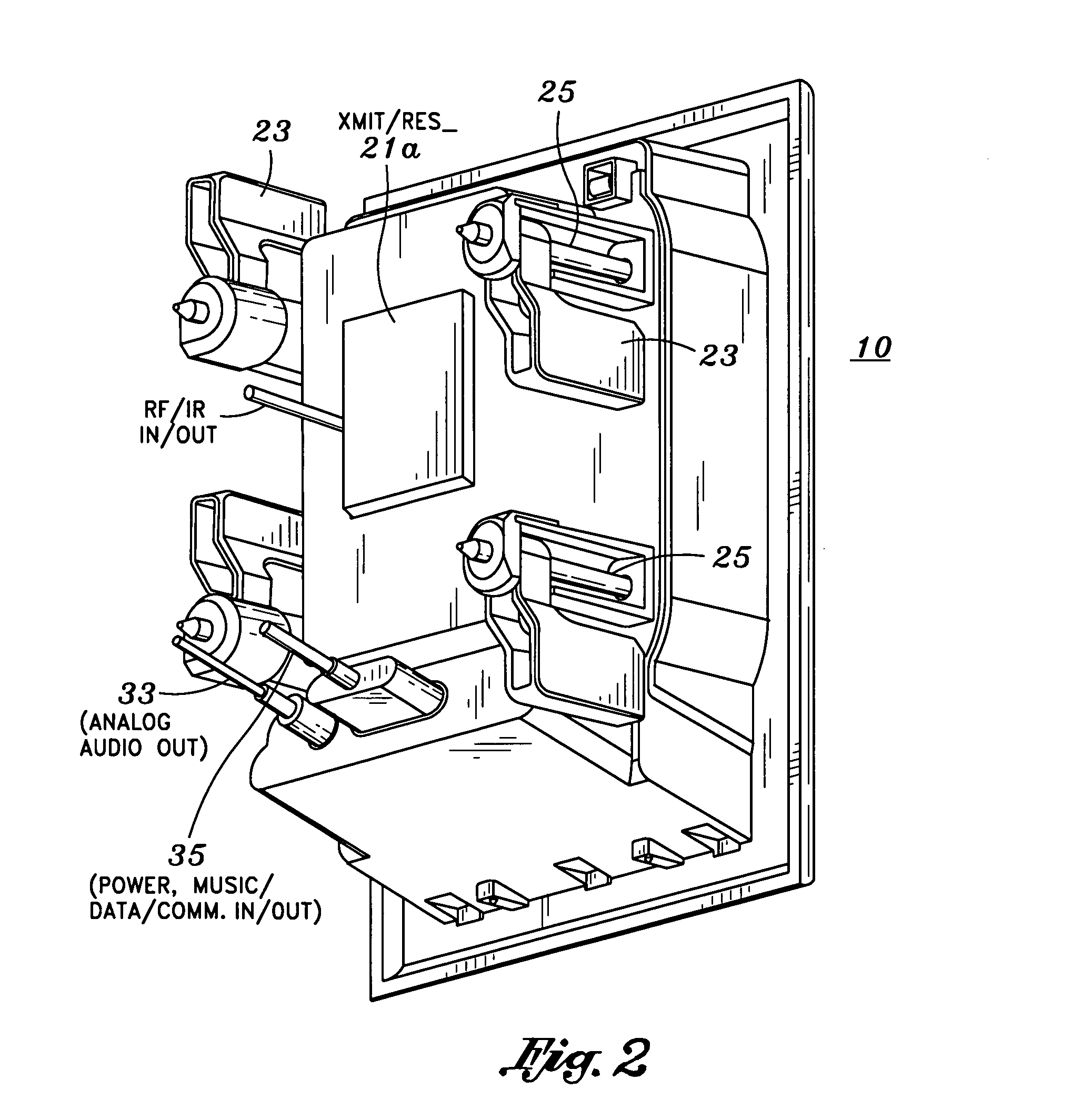

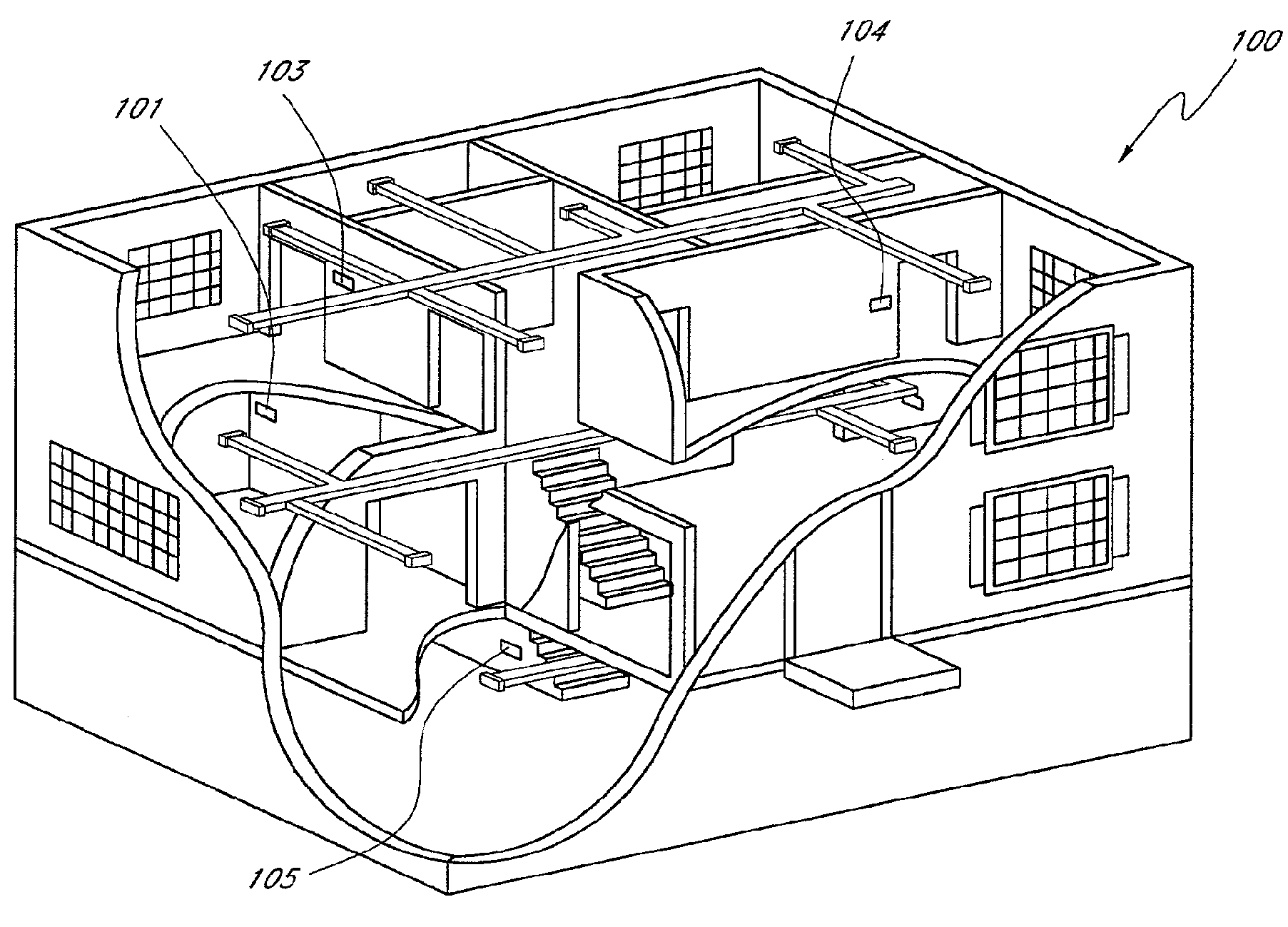

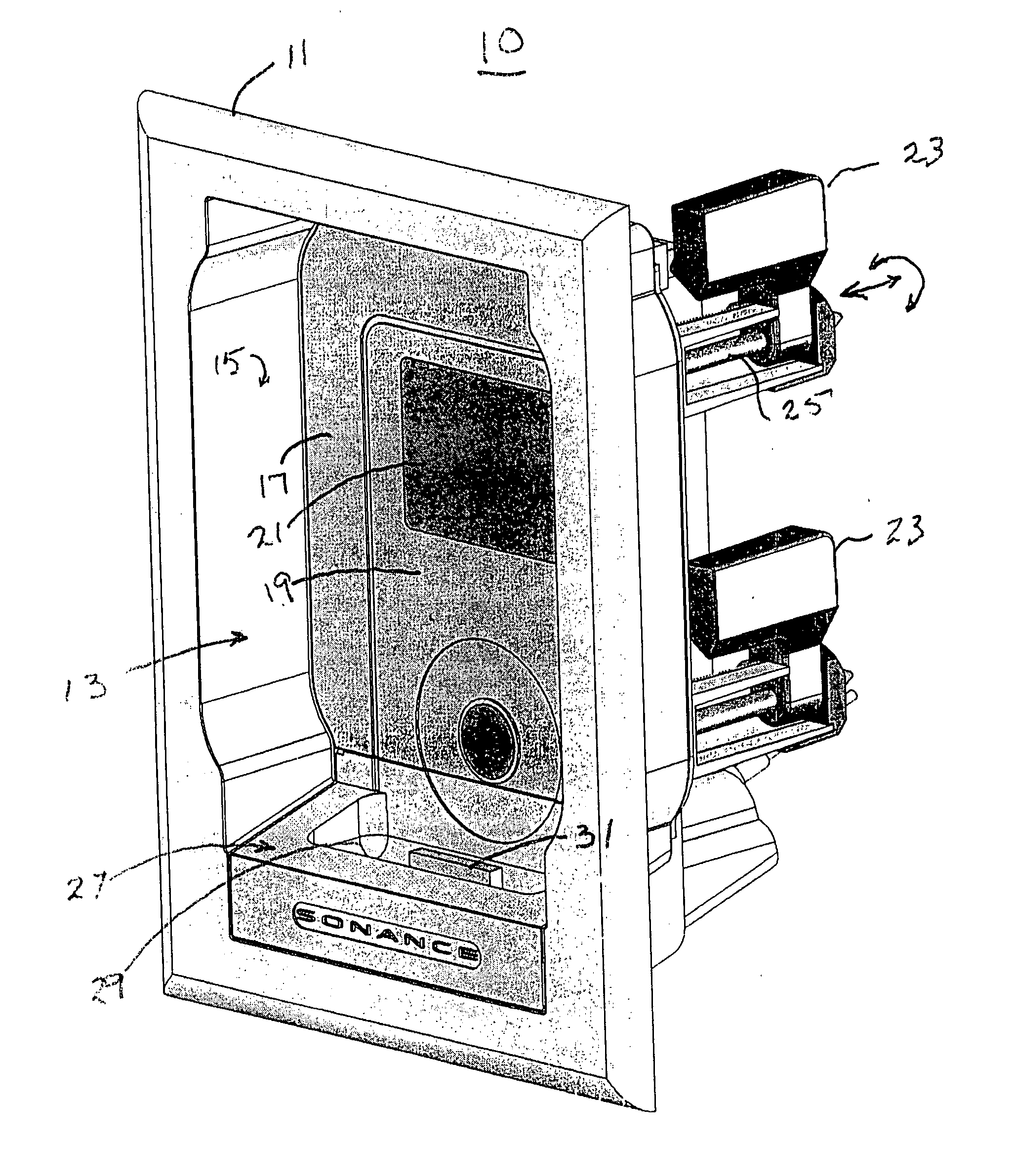

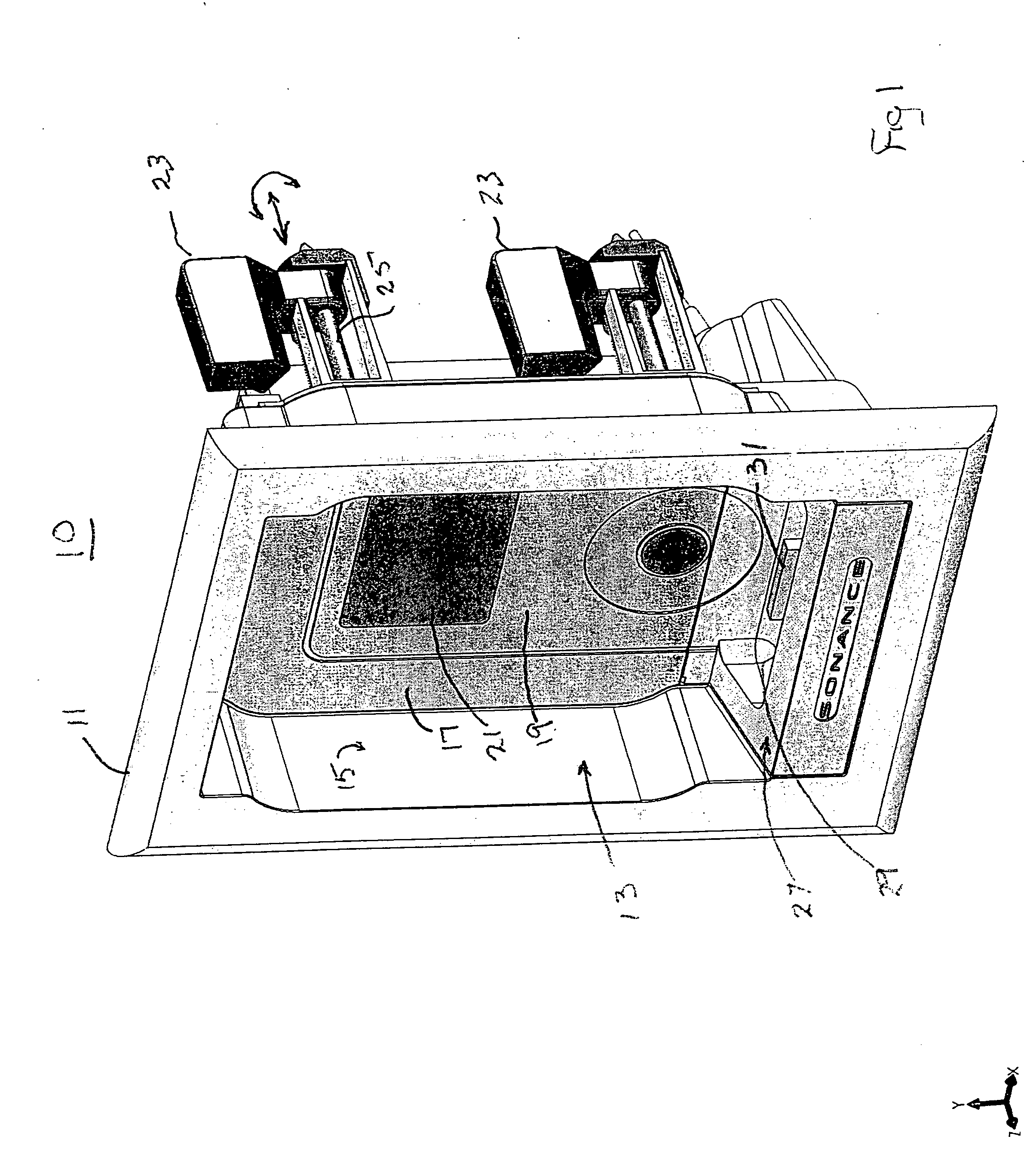

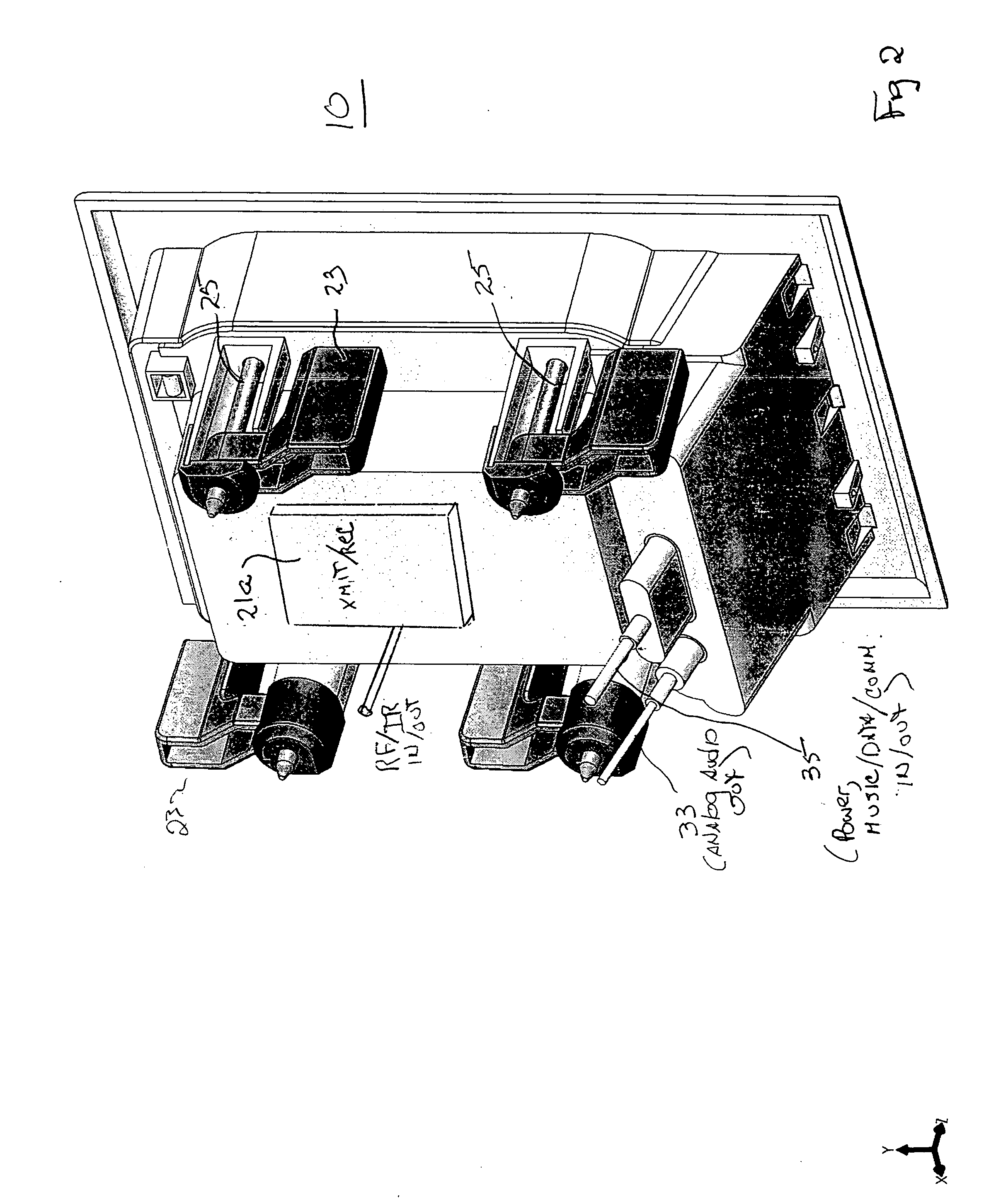

I-port controller

InactiveUS7155214B2Docking-station type assembliesBroadcast specific applicationsZone SystemEngineering

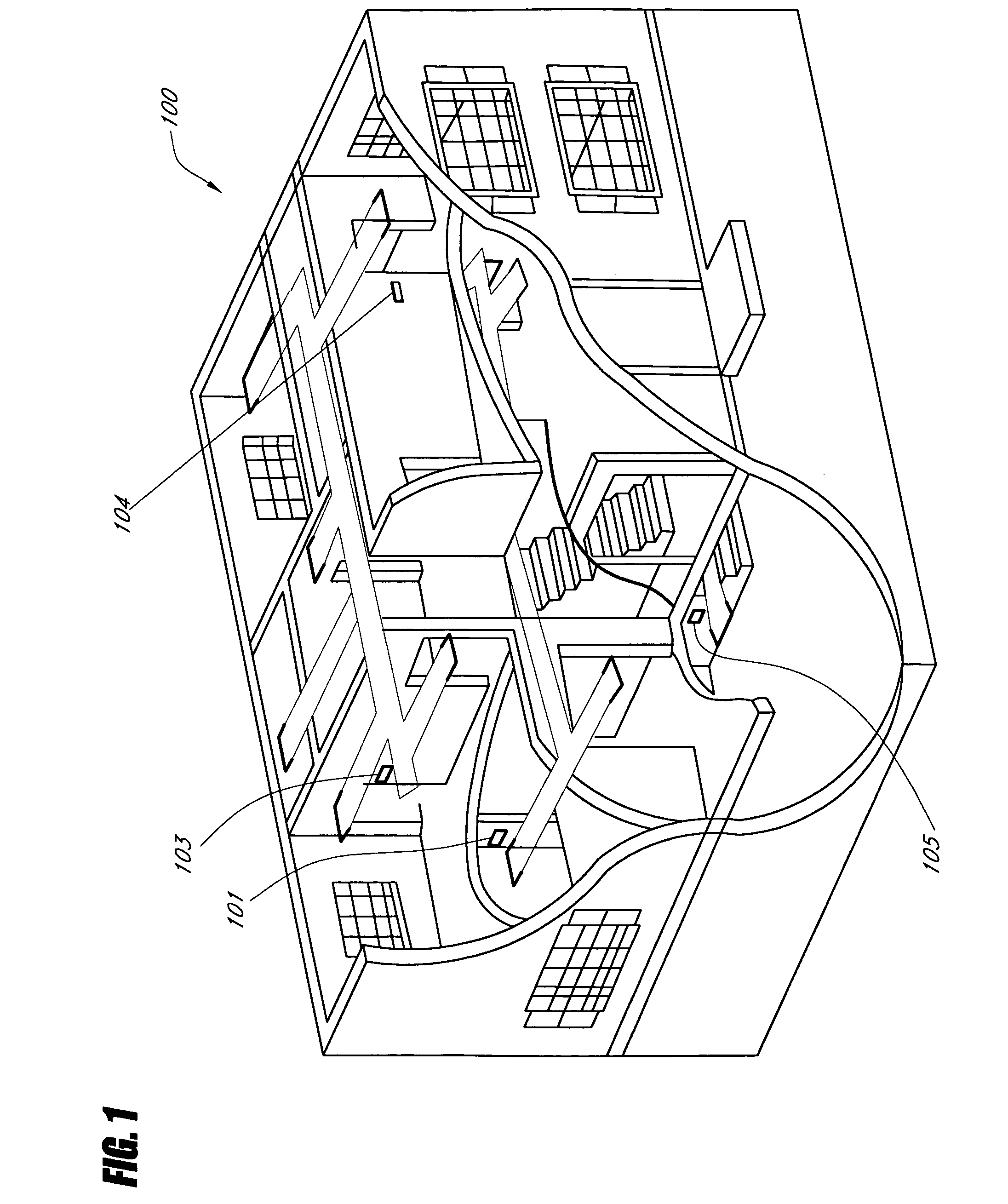

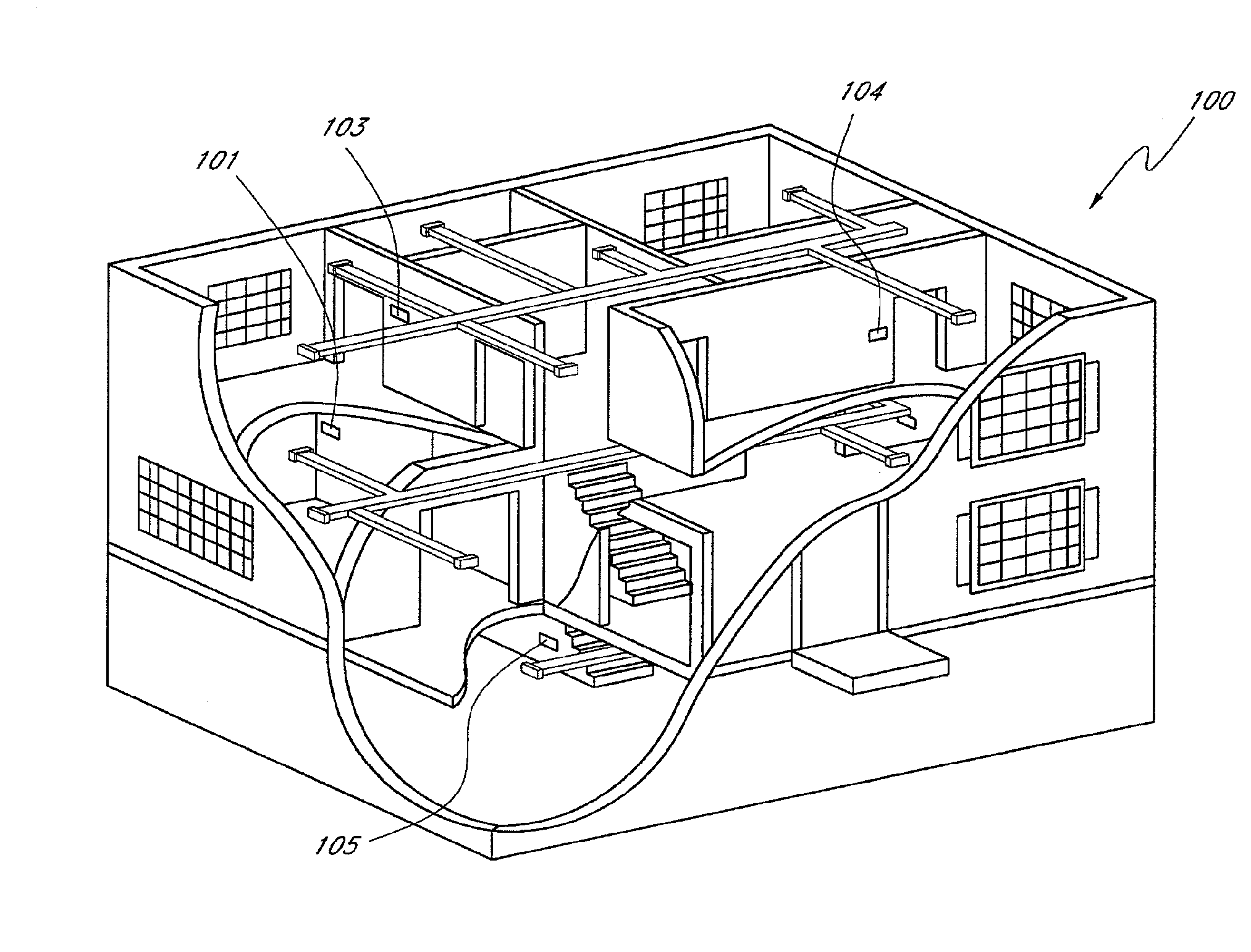

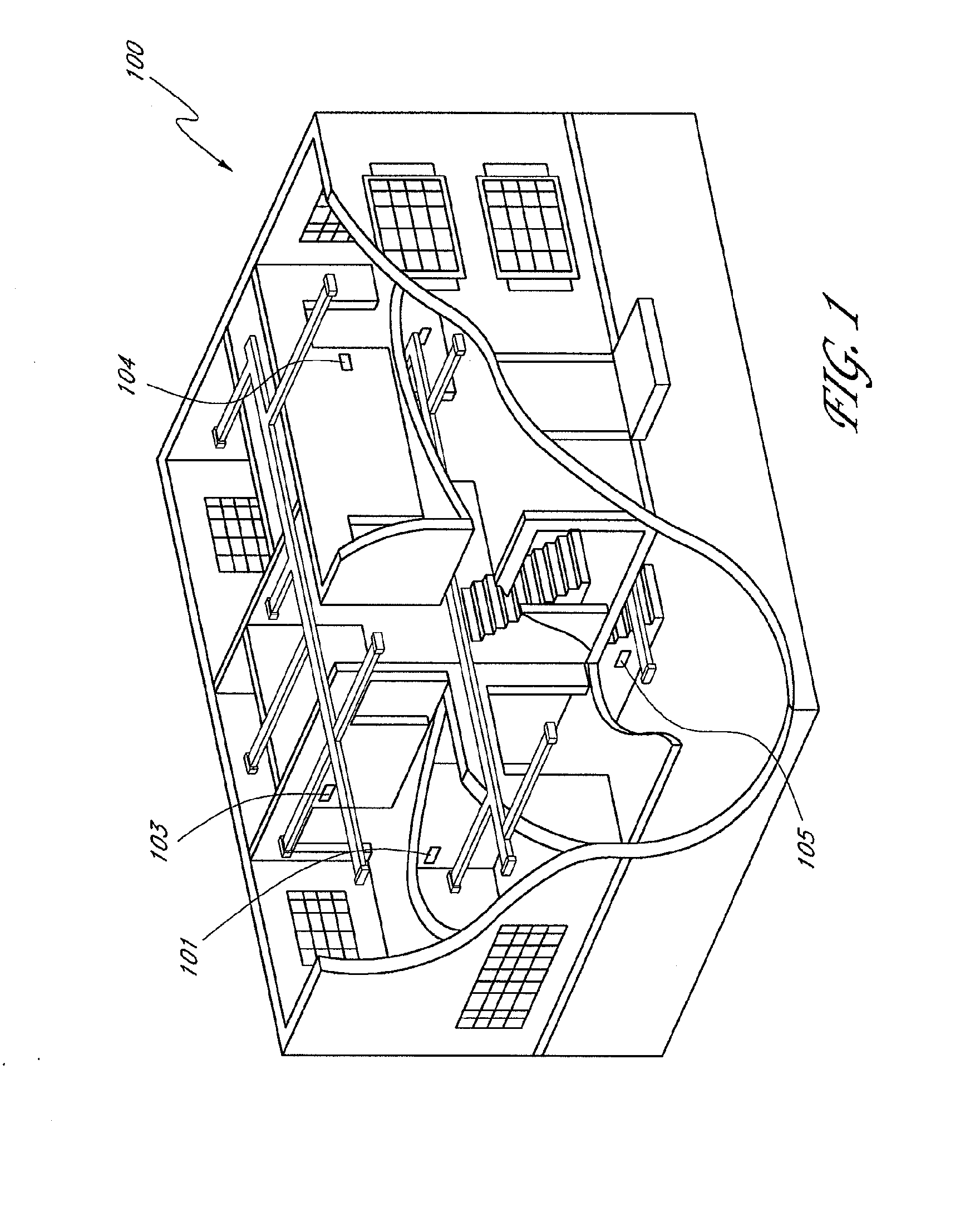

A multi-zone audio system is provided that is portable to a handheld audio device at a plurality of locations. The system includes a multi-zone audio system controller having an audio input / output selection circuit for selectively regulating the source and distribution of audio signals. A plurality of handheld connector docks are distributed about the multi-zone system. Each connector dock is in communication with the audio system controller. The connector docks include a connector port, engagable to the handheld device, for communicating music / data / commands between the handheld device and the system controller. A plurality in-wall audio controllers are also distributed about the multi-zone system. Each in-wall controller is in communication with the audio system controller, and includes an input circuit for selective input of commands to regulate operation of the system controller and / or the handheld device. The handheld connector docks are operative to transfer music / data / commands between the audio system controller and a handheld device disposed within the connector dock.

Owner:DANA INNOVATIONS

System and method for zone thermostat budgeting

InactiveUS20080179053A1Difficult to coolHeat is not easyMechanical apparatusSpace heating and ventilation safety systemsZone SystemControl register

A zone thermostat for use in connection with an Electronically-Controlled Register vent (ECRV) that can be easily installed by a homeowner or general handyman is disclosed. The ECRV can be used to convert a non-zoned HVAC system into a zoned system. The ECRV can also be used in connection with a conventional zoned HVAC system to provide additional control and additional zones not provided by the conventional zoned HVAC system. In one embodiment, the ECRV is configured have a size and form-factor that conforms to a standard manually-controlled register vent. In one embodiment, the zone thermostat is configured to provide thermostat information to the ECRV. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones and provides heating and cooling to the various zones according to a cost budget.

Owner:NEST LABS

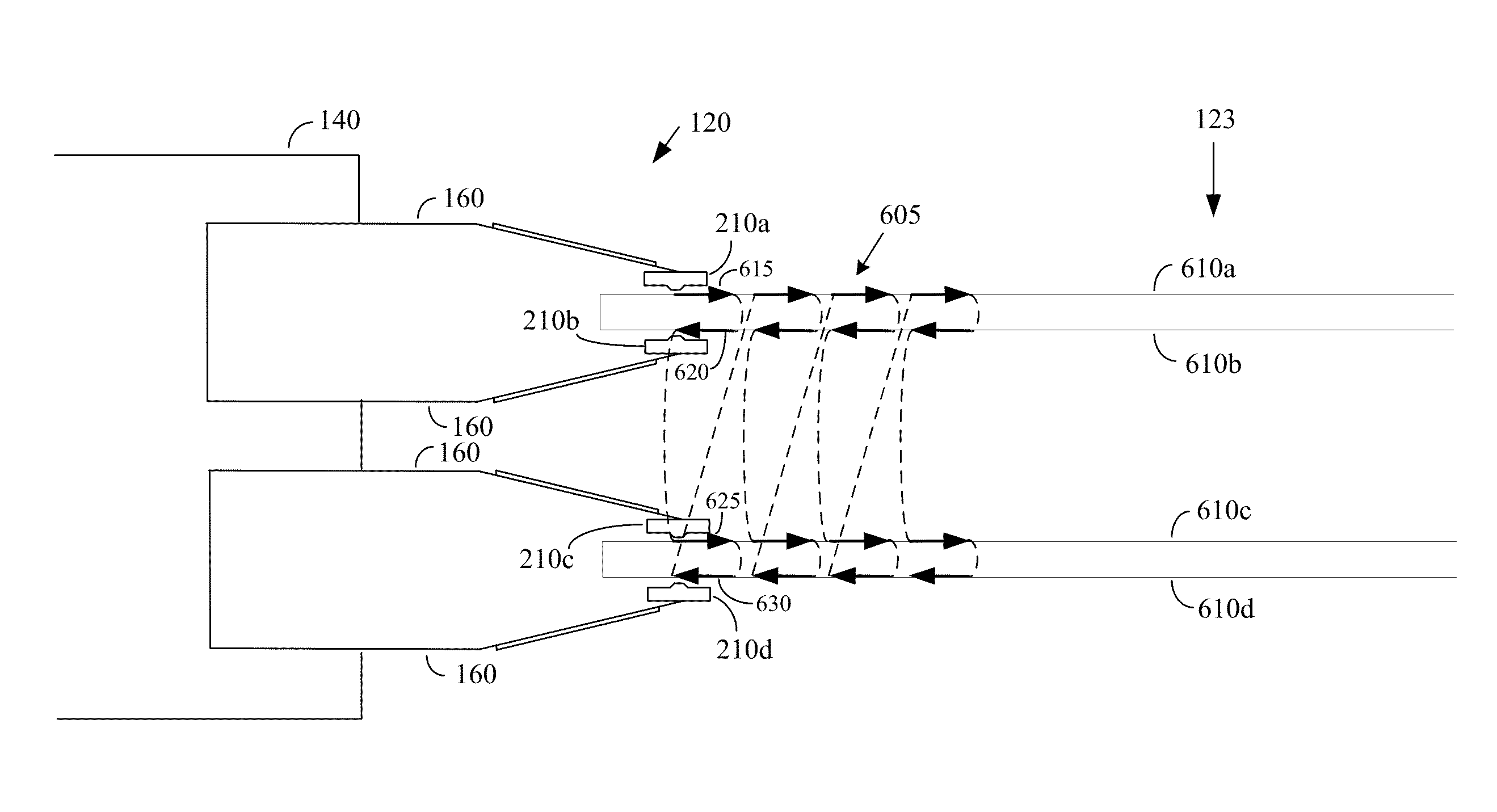

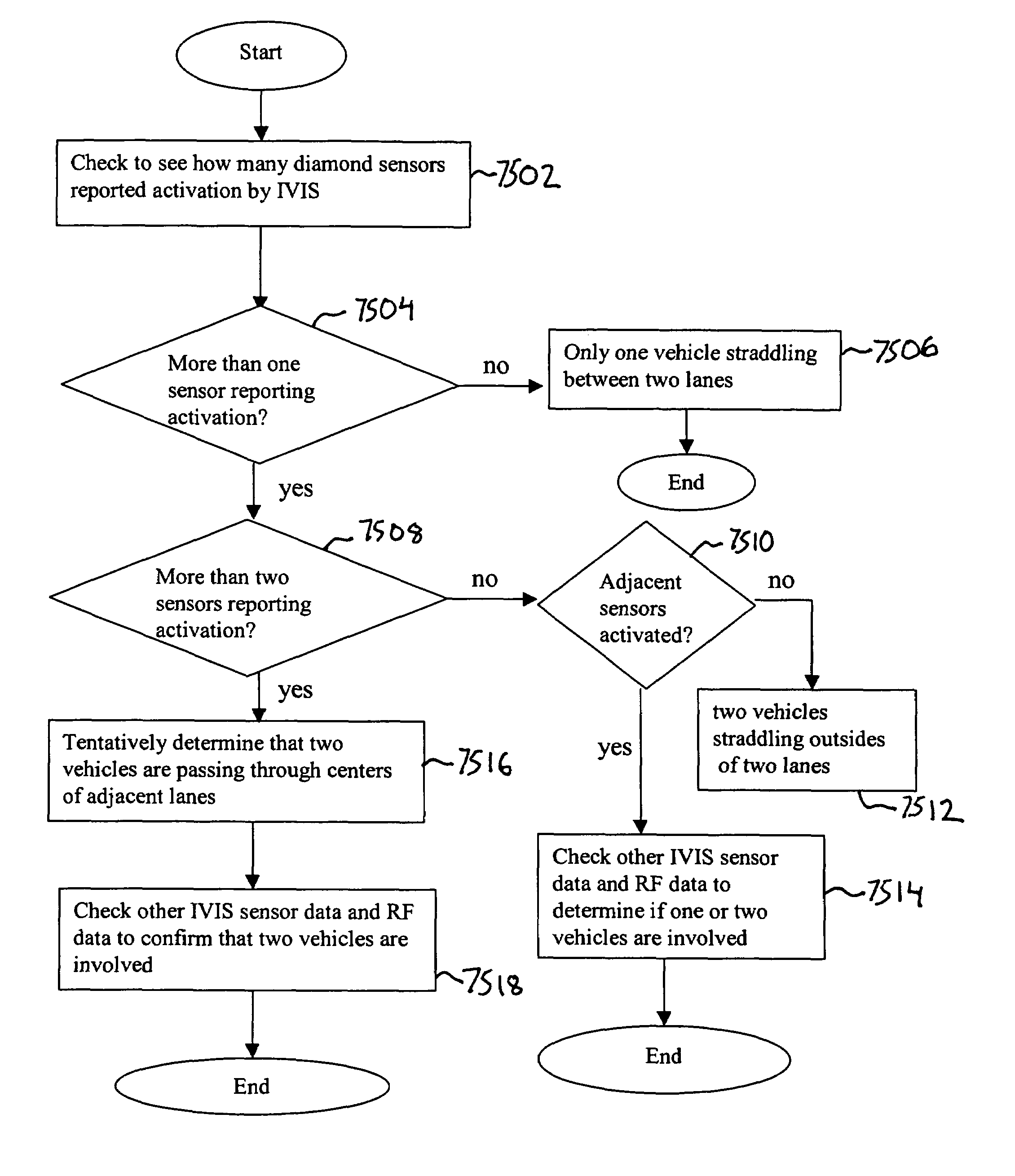

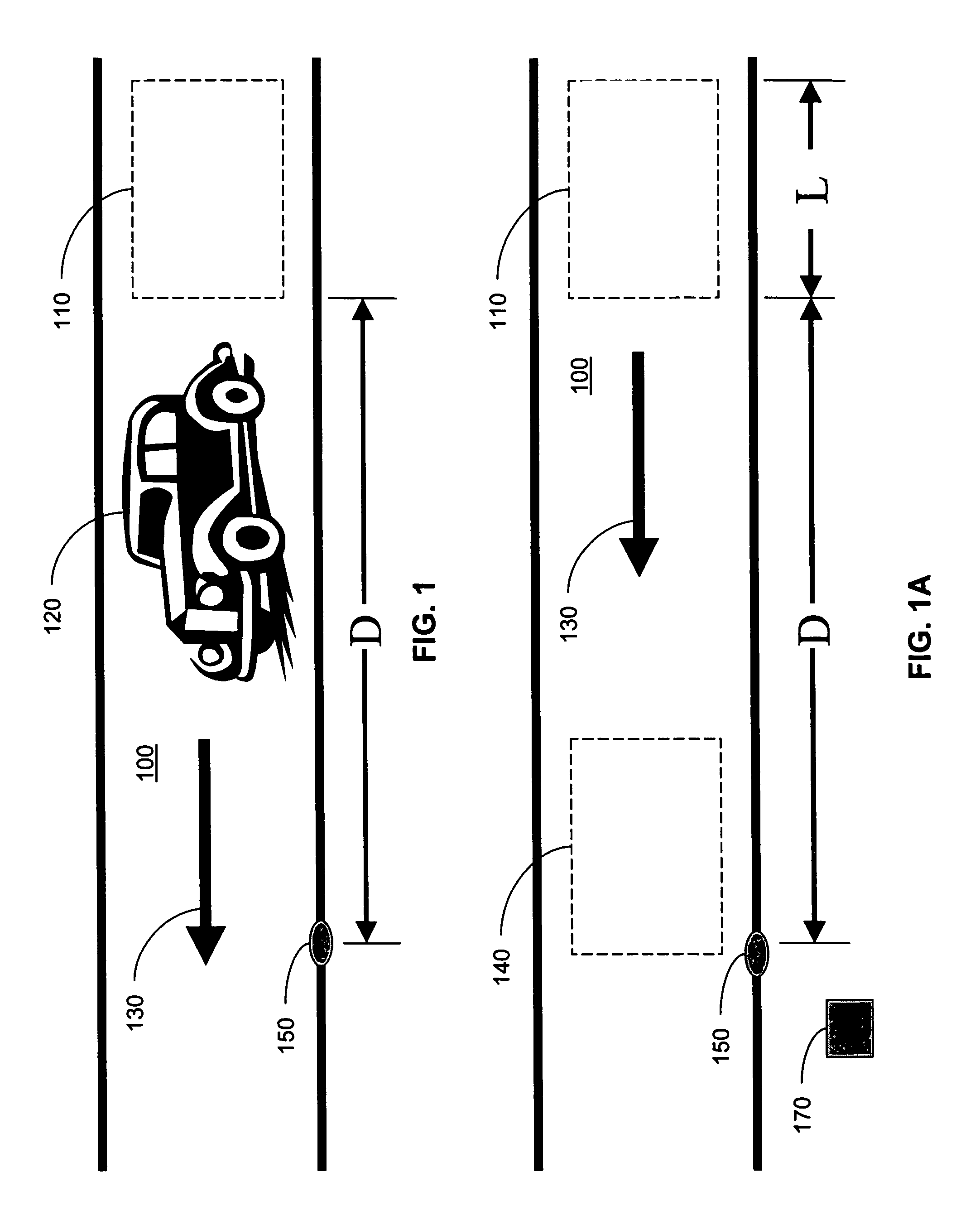

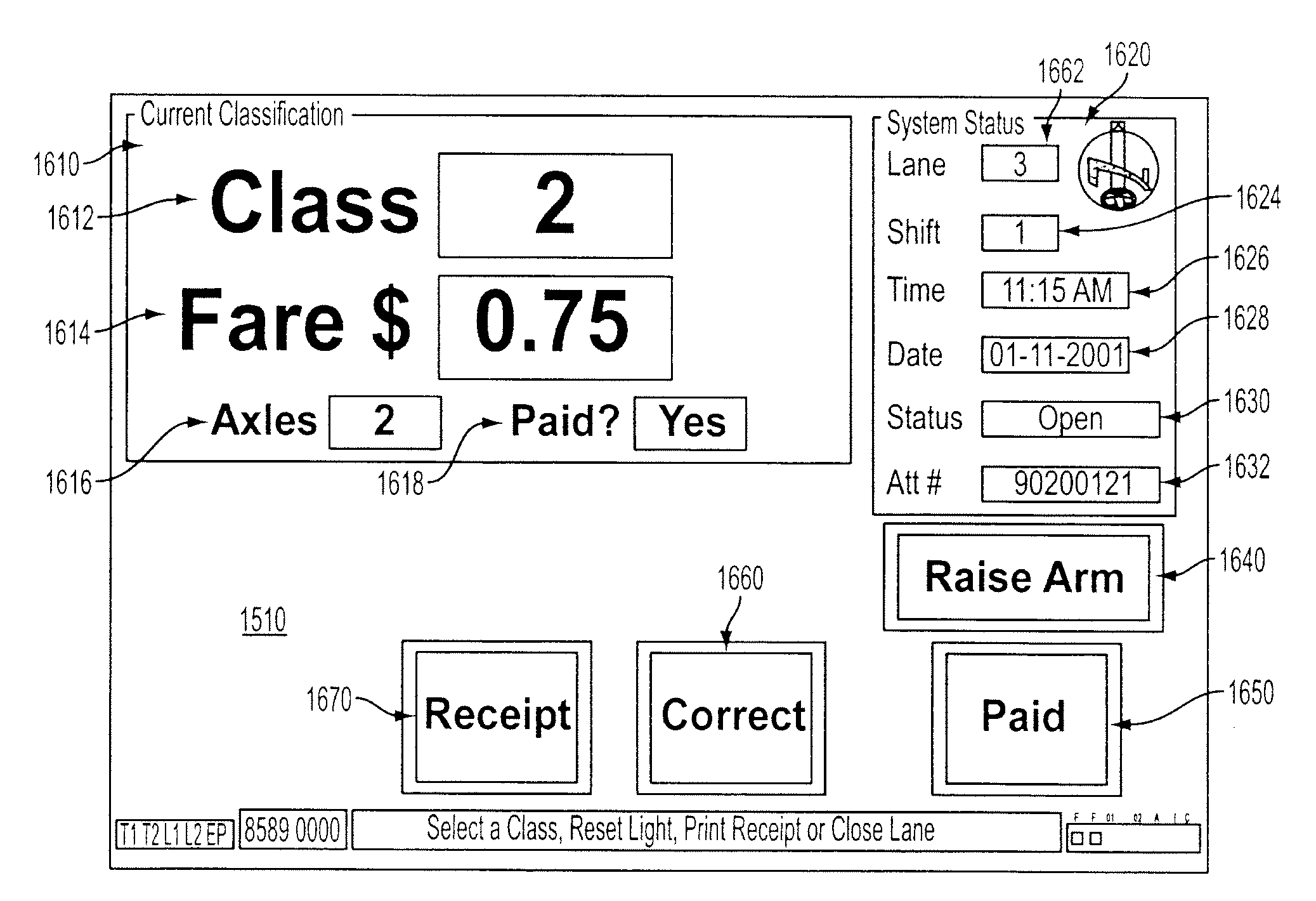

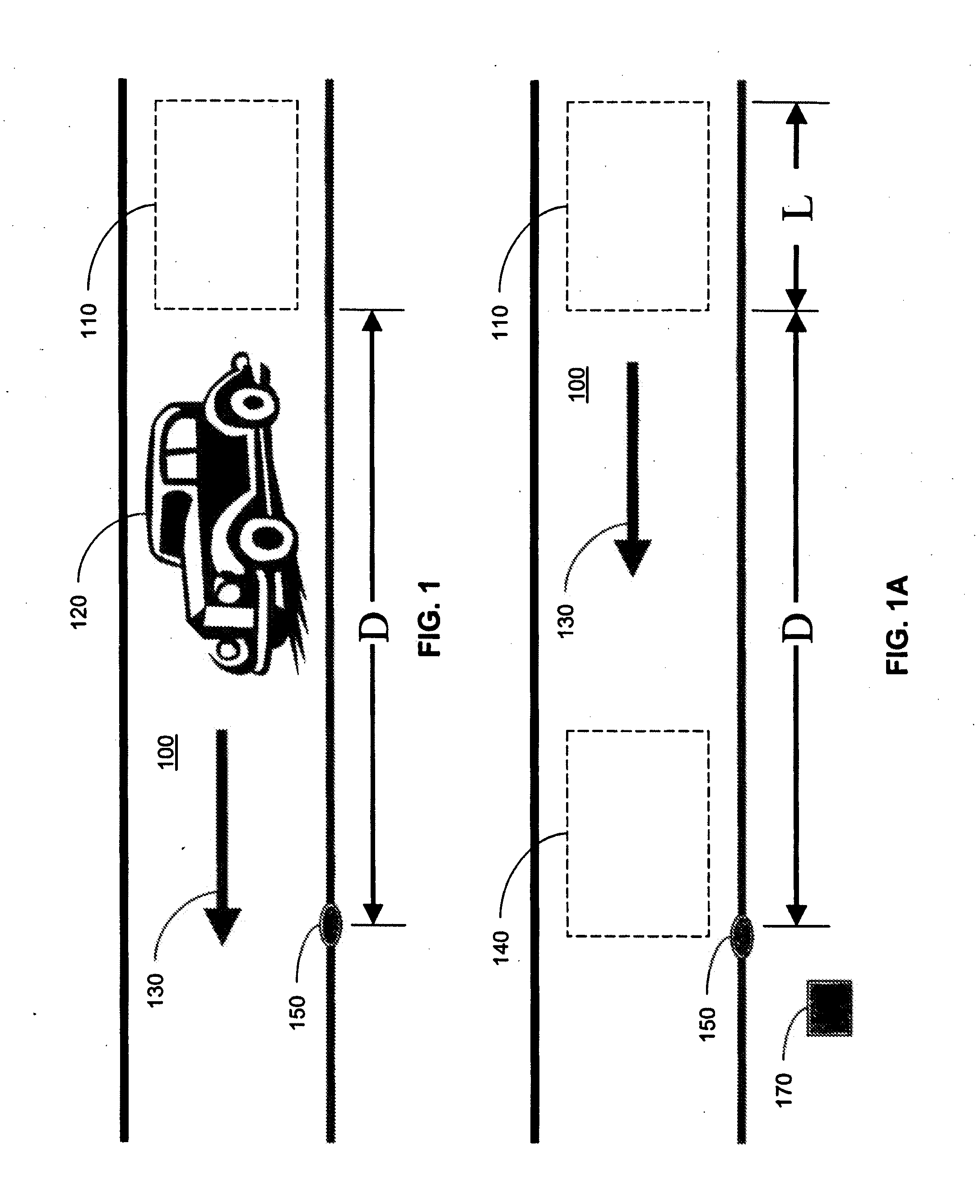

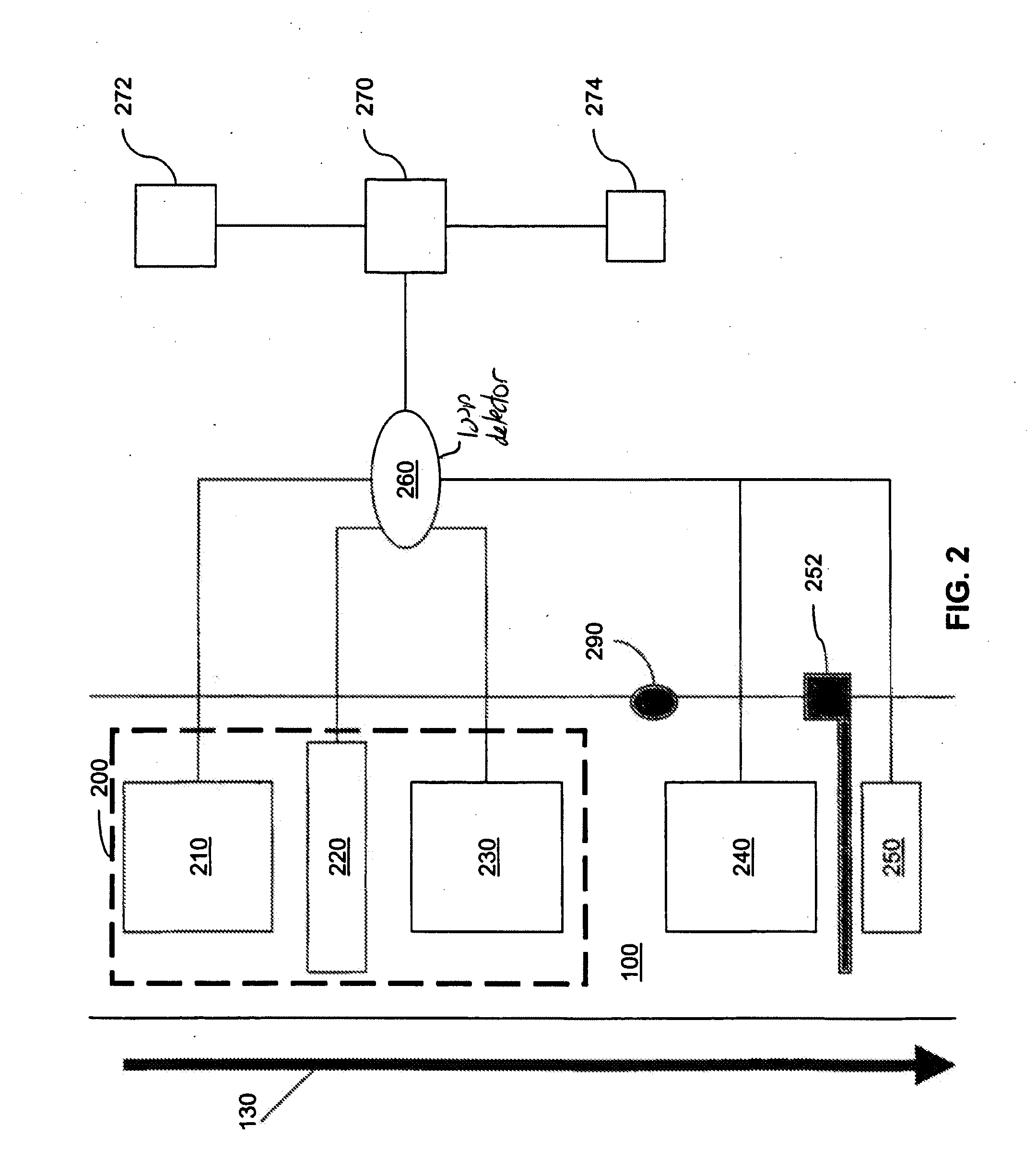

Multiple RF read zone system

A multizone RF read / write system for conducting transactions with vehicles traveling at high speeds. A first RF read zone is created, preferably by use of a first gantry that extends over at least one lane and contains at least one RF source that creates a large powerful RF read zone for reading or reading and writing to a transponder on a passing vehicle. Additional RF read zones arranged in tandem with the first RF read zone are created by at least one additional RF source that is located on an additional gantry extending over at least one lane, or located on the first gantry. Accordingly, multiple RF read zones are created to conduct transactions with passing vehicles. In one aspect, the multiple RF read zones can be used to ensure that tolling transactions with a single vehicle are more likely to be completed and have a higher degree of accuracy. In another aspect, the multiple RF read zones each employ a different RF technology so that multiple types of RF toll tags can be read and written.

Owner:TRANSCORE

System and method for budgeted zone heating and cooling

ActiveUS20080179052A1Difficult to coolHeat is not easyMechanical apparatusAir-treating devicesZone SystemMonitoring system

An Electronically-Controlled Register vent (ECRV) that can be easily installed by a homeowner or general handyman is disclosed. The ECRV can be used to convert a non-zoned HVAC system into a zoned system. The ECRV can also be used in connection with a conventional zoned HVAC system to provide additional control and additional zones not provided by the conventional zoned HVAC system. In one embodiment, the ECRV is configured to have a size and form-factor that conforms to a standard manually-controlled register vent. In one embodiment, a zone thermostat is configured to provide thermostat information to the ECRV. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones and provides heating and cooling to the various zones according to a cost budget.

Owner:GOOGLE LLC

Electronically-controlled register vent for zone heating and cooling

An Electronically-Controlled Register vent (ECRV) that can be easily installed by a homeowner or general handyman is disclosed. The ECRV can be used to convert a non-zoned HVAC system into a zoned system. The ECRV can also be used in connection with a conventional zoned HVAC system to provide additional control and additional zones not provided by the conventional zoned HVAC system. In one embodiment, the ECRV is configured have a size and form-factor that conforms to a standard manually-controlled register vent. In one embodiment, a zone thermostat is configured to provide thermostat information to the ECRV. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones.

Owner:GOOGLE LLC

Multiple RF read zone system

InactiveUS20100274641A1Data processing applicationsTicket-issuing apparatusZone SystemSingle vehicle

A multizone RF read / write system for conducting transactions with vehicles traveling at high speeds. A first RF read zone is created, preferably by use of a first gantry that extends over at least one lane and contains at least one RF source that creates a large powerful RF read zone for reading or reading and writing to a transponder on a passing vehicle. Additional RF read zones arranged in tandem with the first RF read zone are created by at least one additional RF source that is located on an additional gantry extending over at least one lane, or located on the first gantry. Accordingly, multiple RF read zones are created to conduct transactions with passing vehicles. In one aspect, the multiple RF read zones can be used to ensure that tolling transactions with a single vehicle are more likely to be completed and have a higher degree of accuracy. In another aspect, the multiple RF read zones each employ a different RF technology so that multiple types of RF toll tags can be read and written.

Owner:TRANSCORE

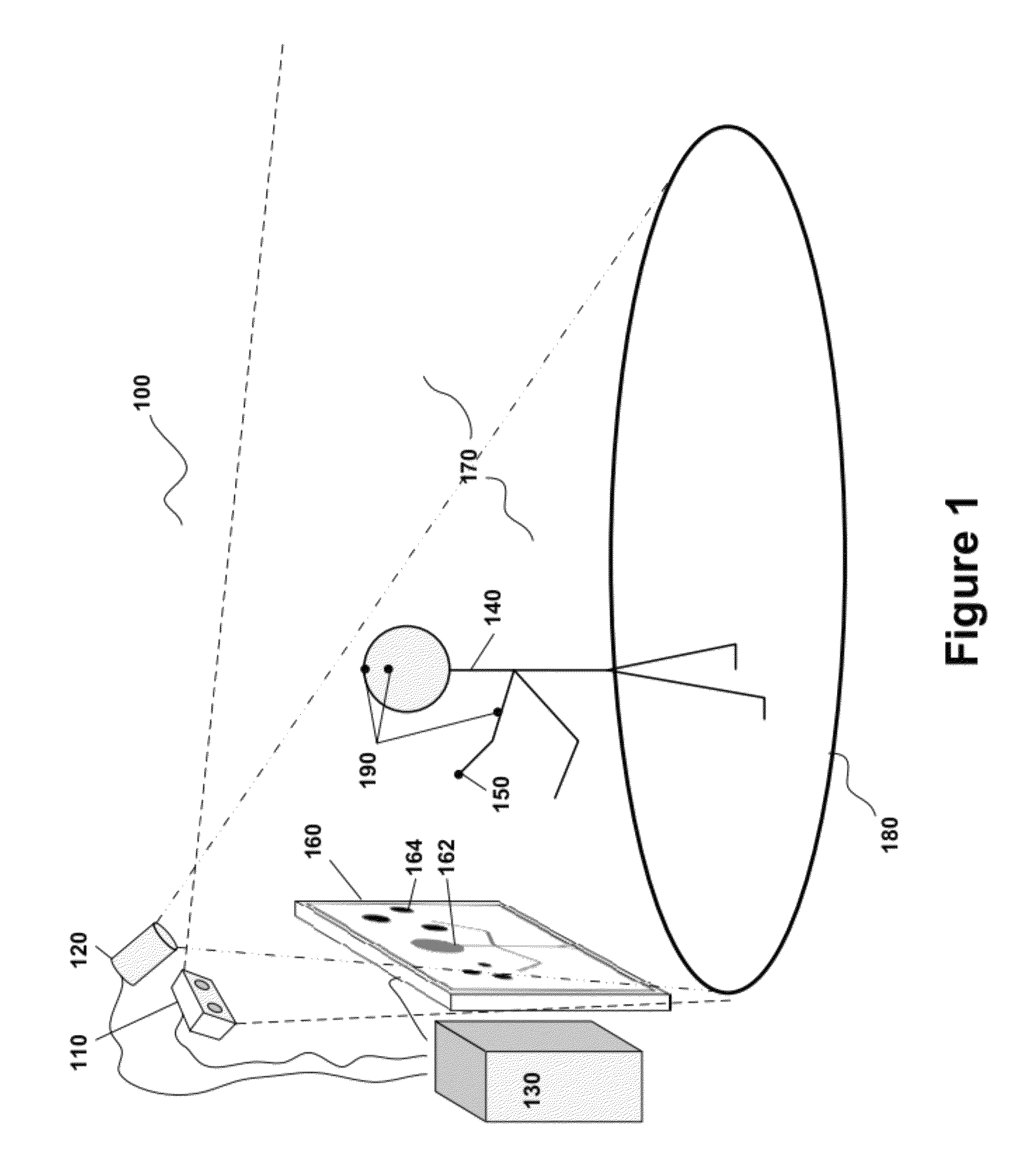

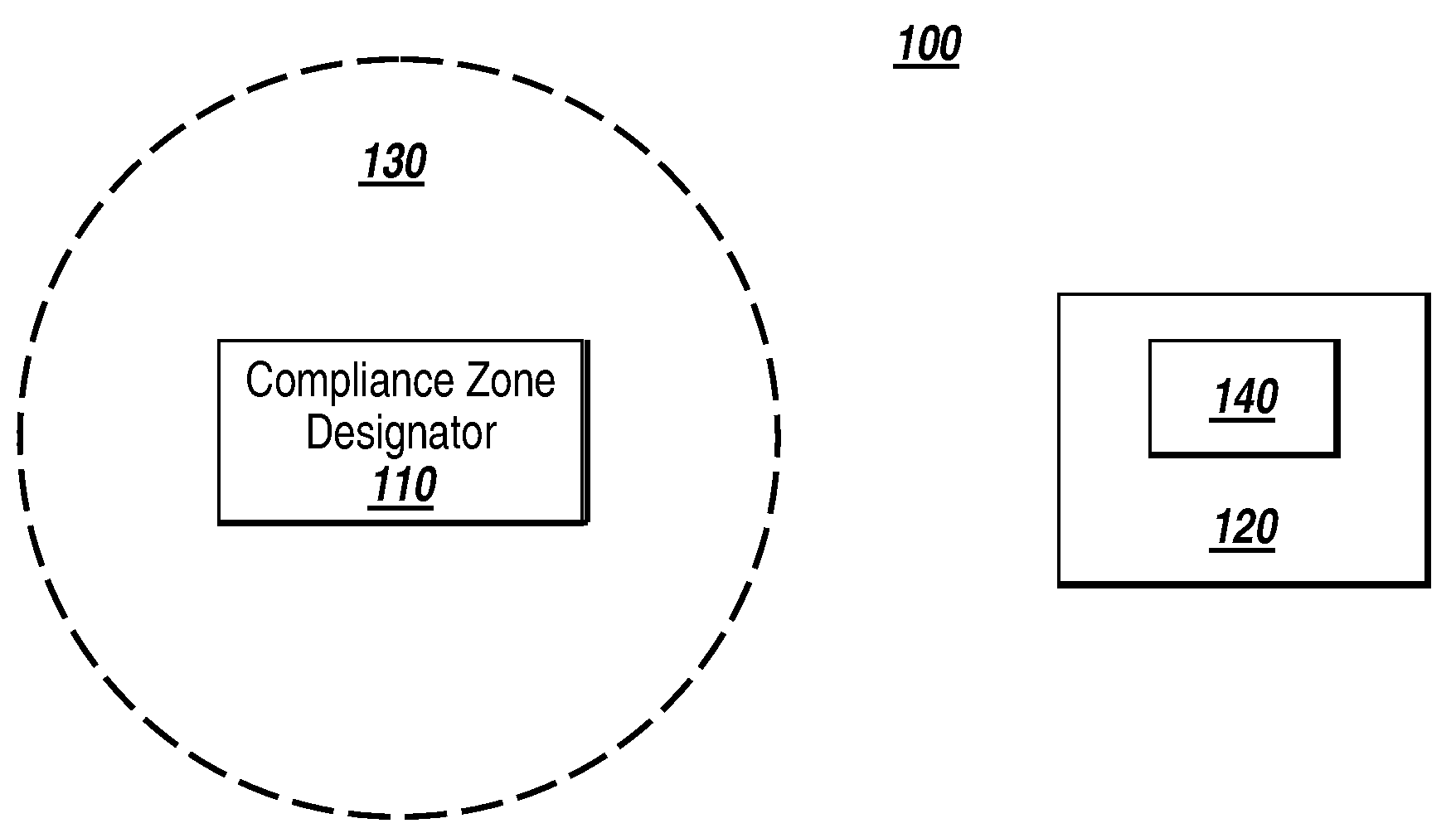

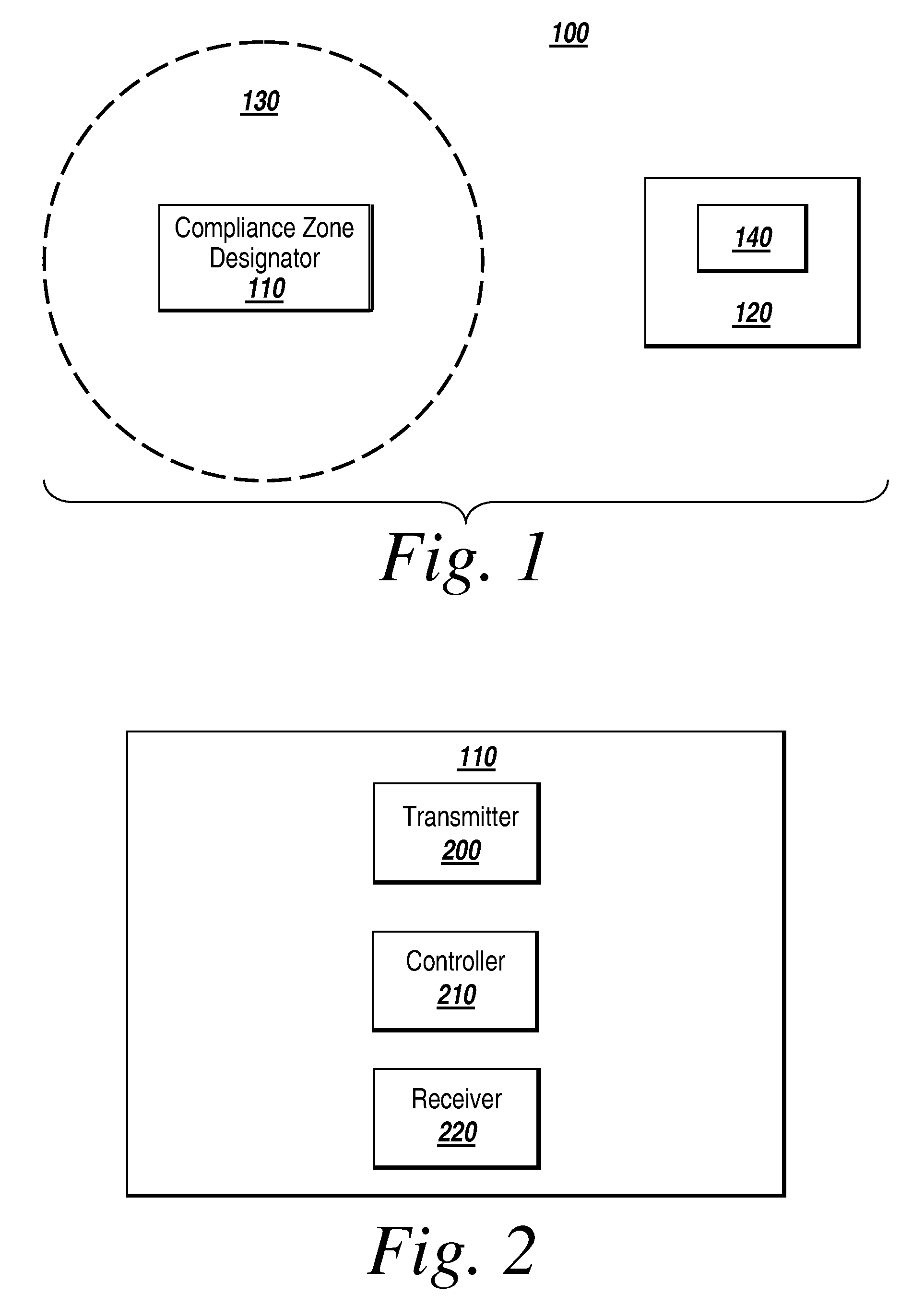

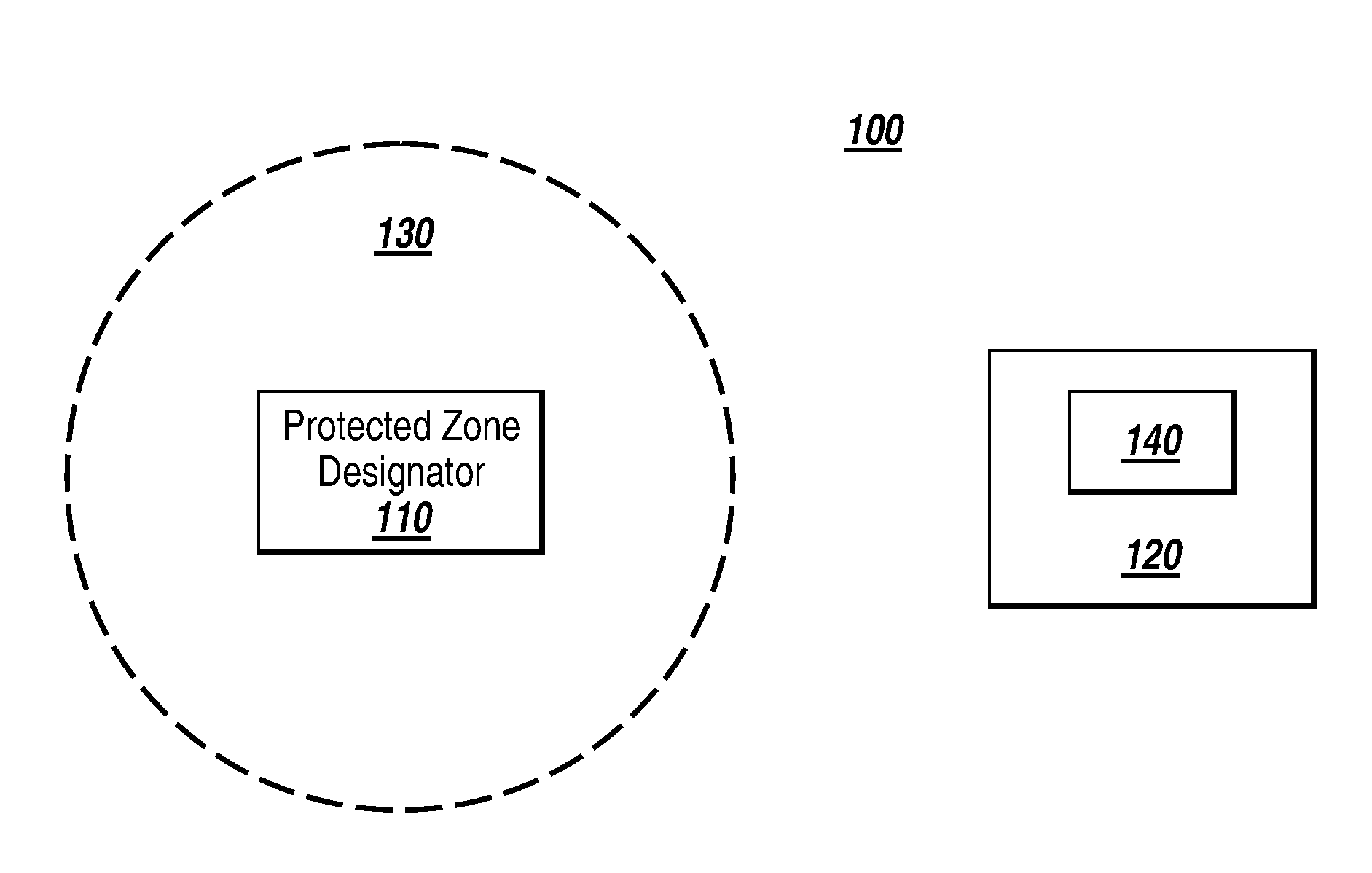

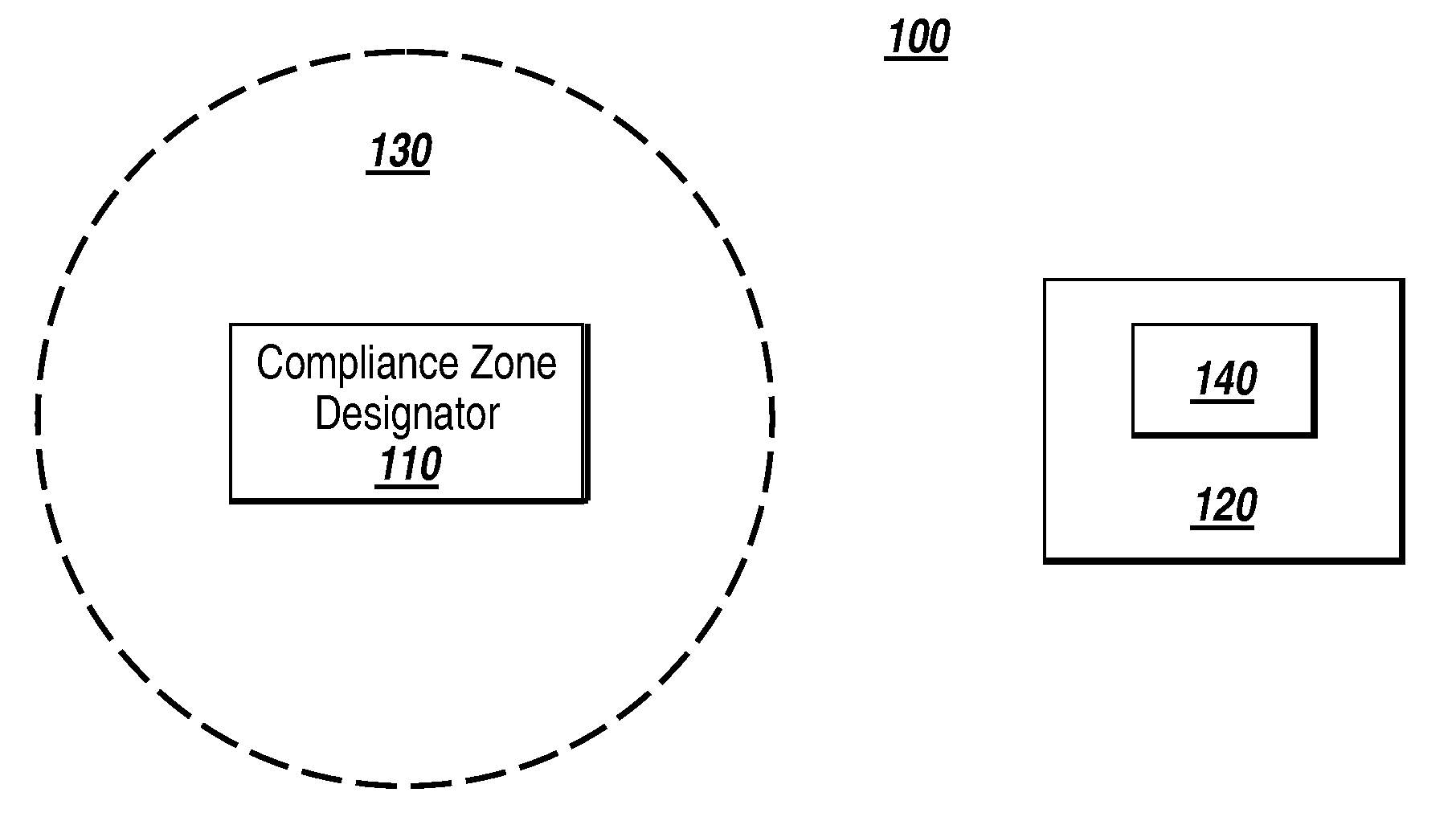

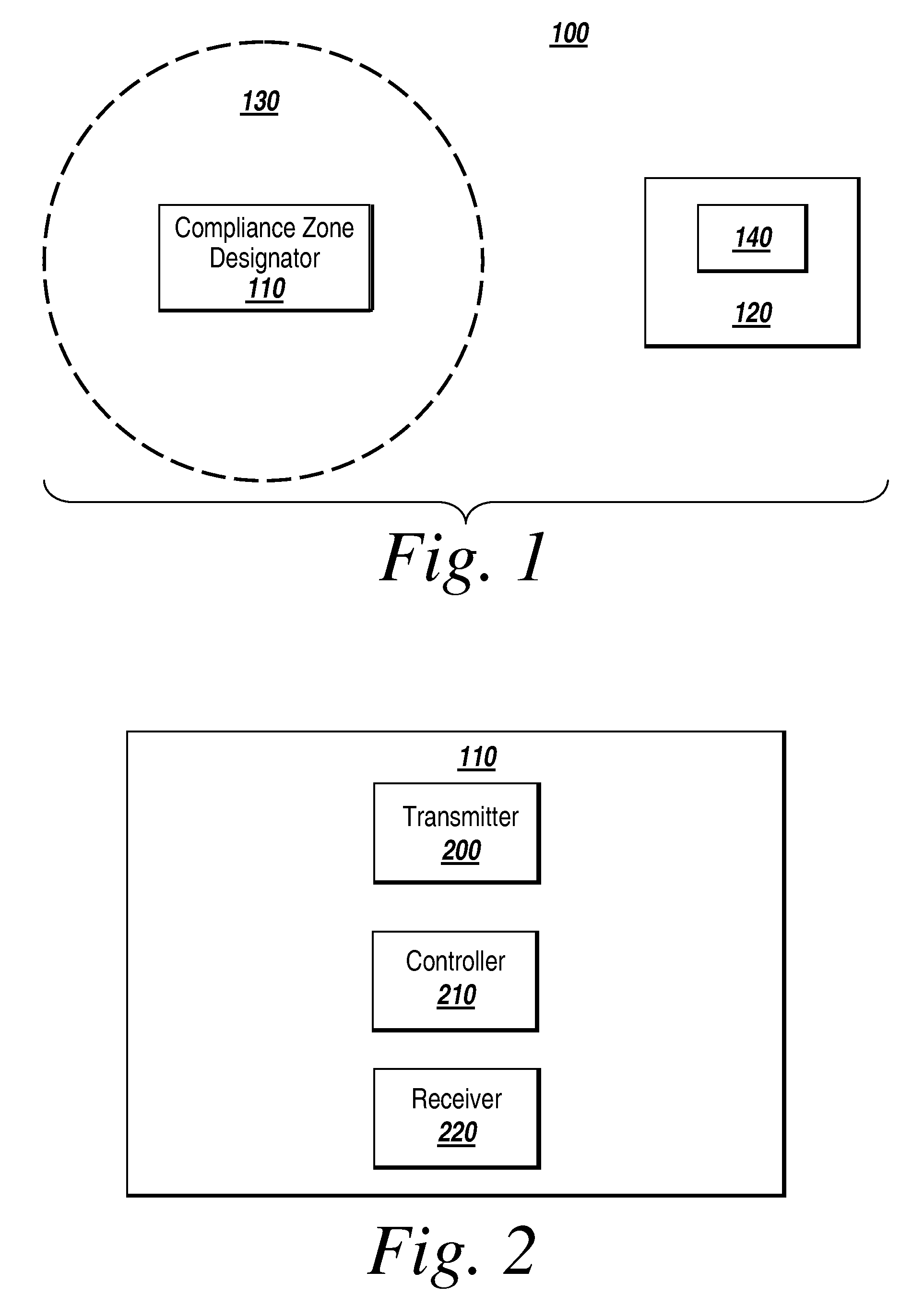

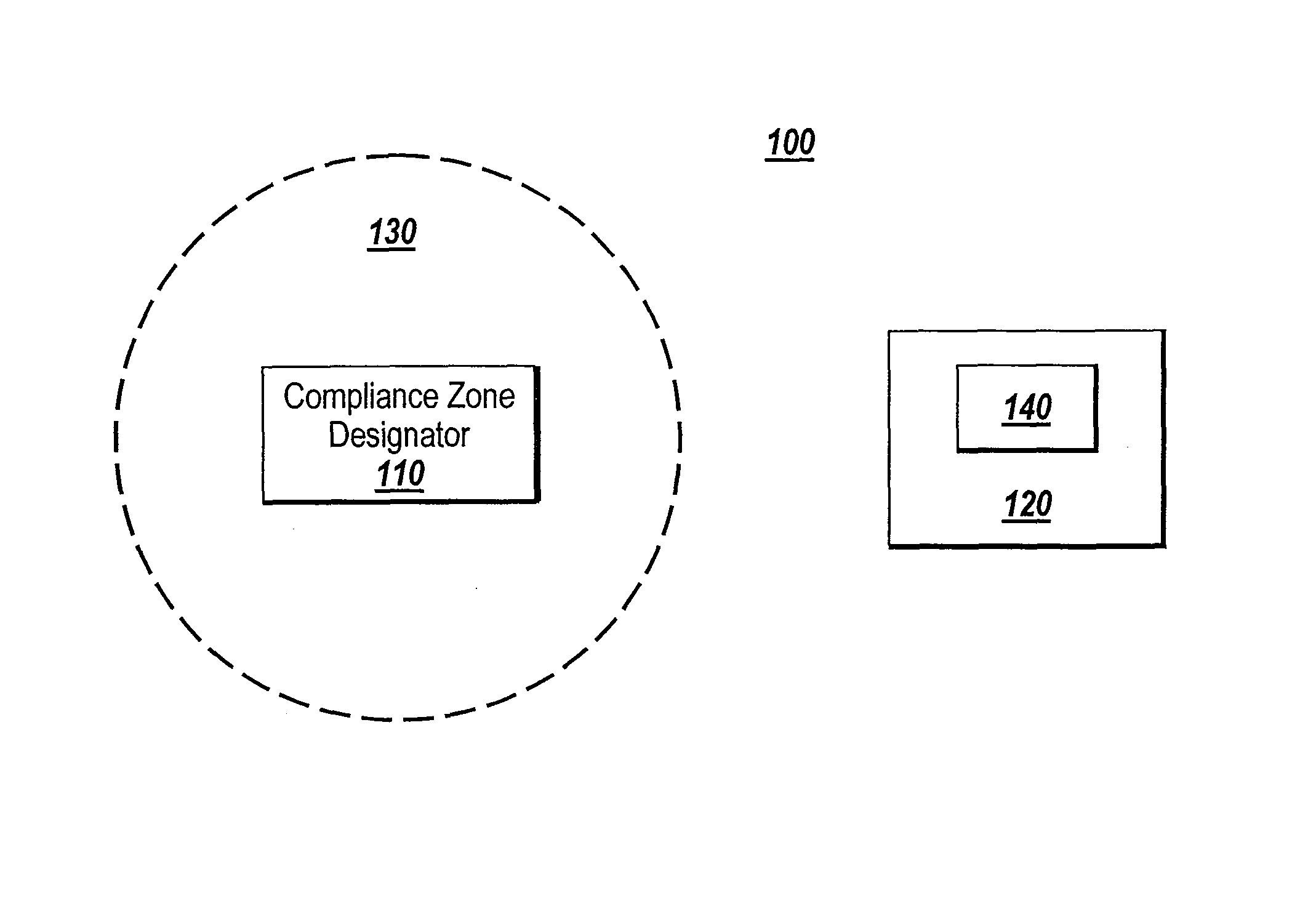

Ultrasonic compliance zone system

ActiveUS20100321180A1Reduce decreaseReliable communicationDetection of traffic movementHealthcare resources and facilitiesZone SystemSonification

A system is provided for establishing a compliance zone and monitoring interactions therewith. The system includes a compliance zone designator and a wearable device. The compliance zone designator transmits an ultrasound signal to establish the compliance zone. The ultrasound signal may be encoded with information on the compliance zone. The compliance zone designator is configured for placement at a location in which the compliance zone is desired. The wearable device is separate from the compliance zone designator. The wearable device includes a compliance zone recognition component configured to recognize the compliance zone and identify one or more pre-defined interaction criteria for the compliance zone. When the wearable device is within the compliance zone, the compliance zone recognition component recognizes the compliance zone and identifies the interaction criteria of the compliance zone. Based on the interaction criteria the wearable device determines and records compliance with the interaction criteria. The recorded data is optionally used to set off real-time alerts. The recorded data is also optionally used in subsequent analysis and documentation of compliance with protocols.

Owner:THE GENERAL HOSPITAL CORP

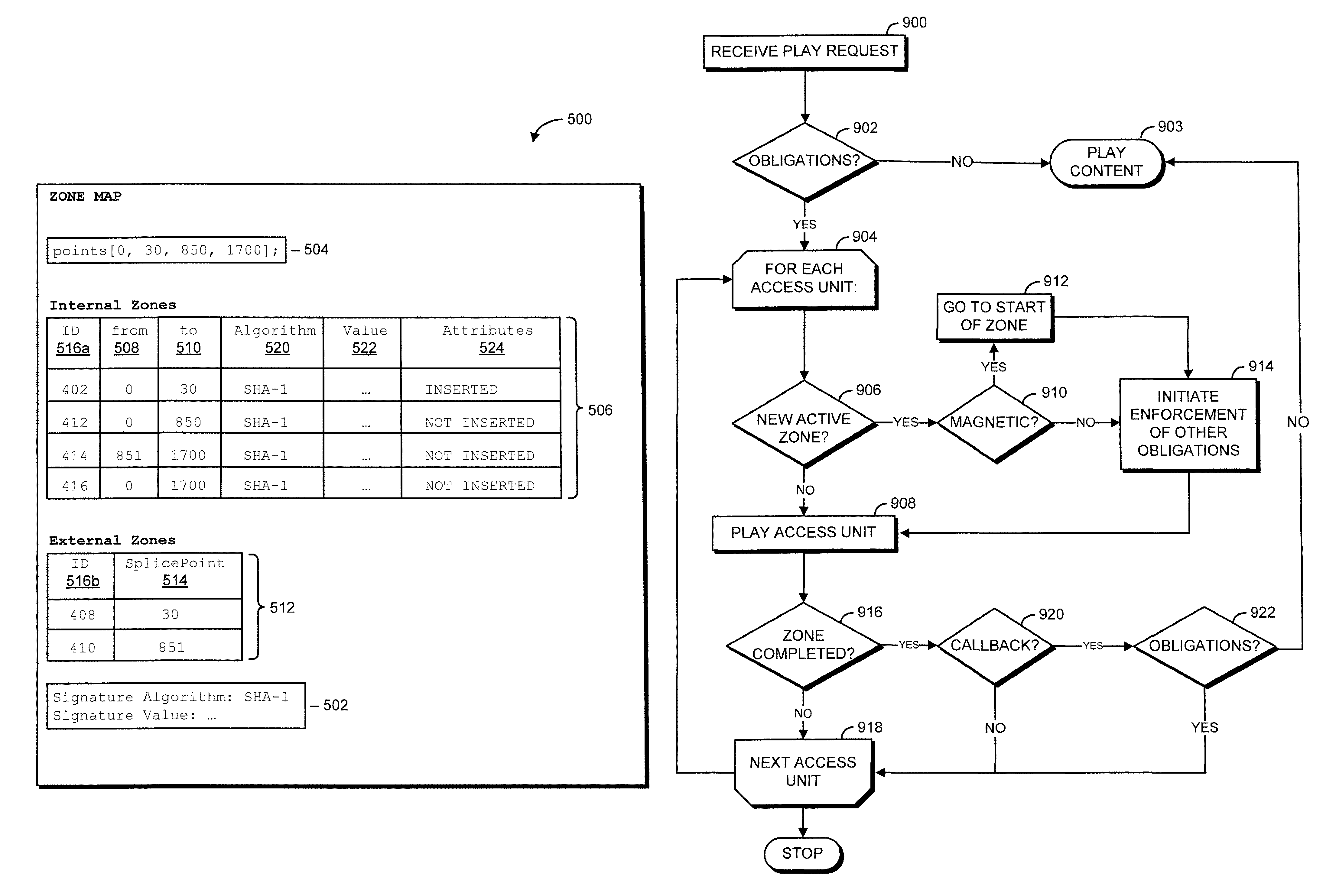

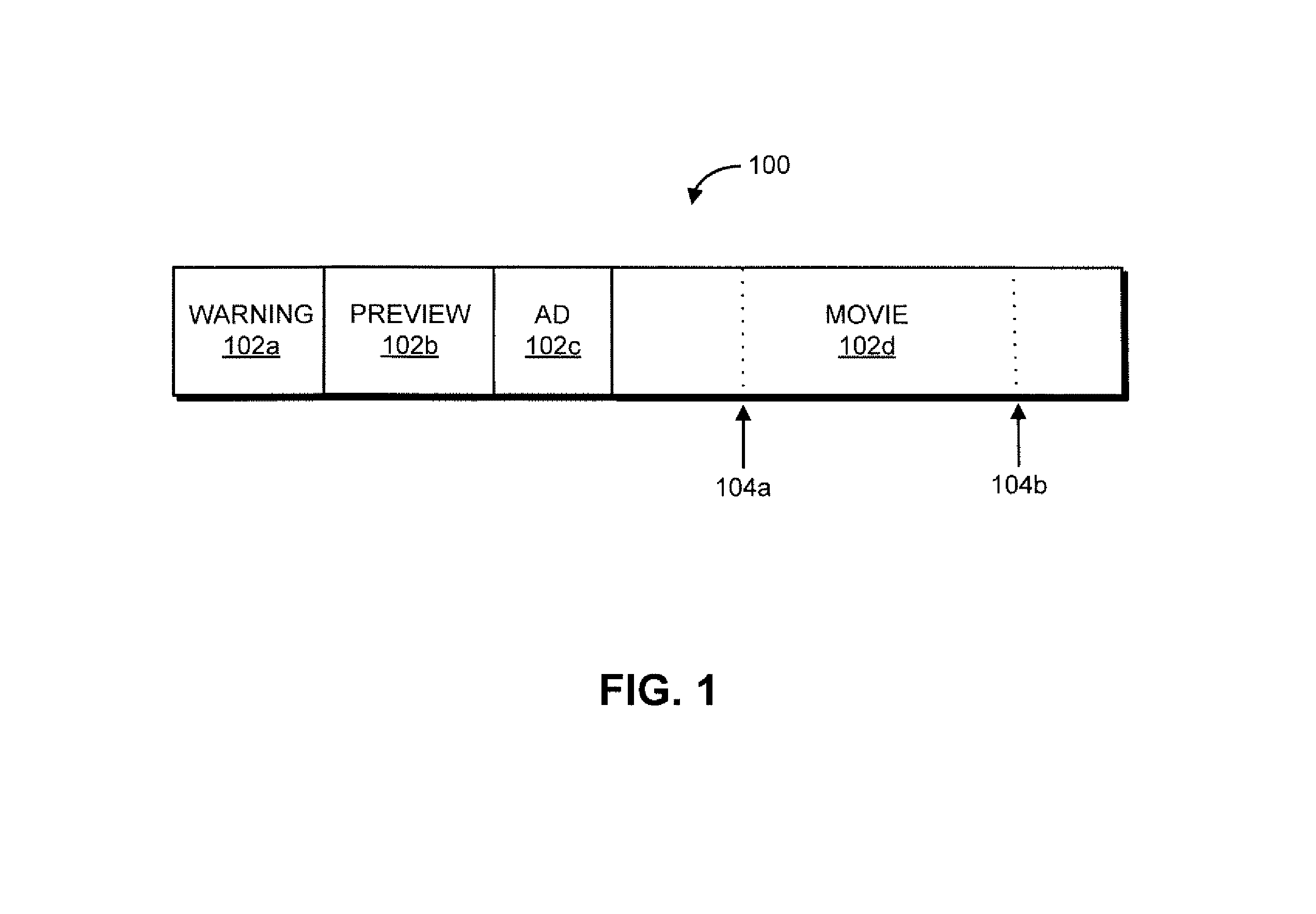

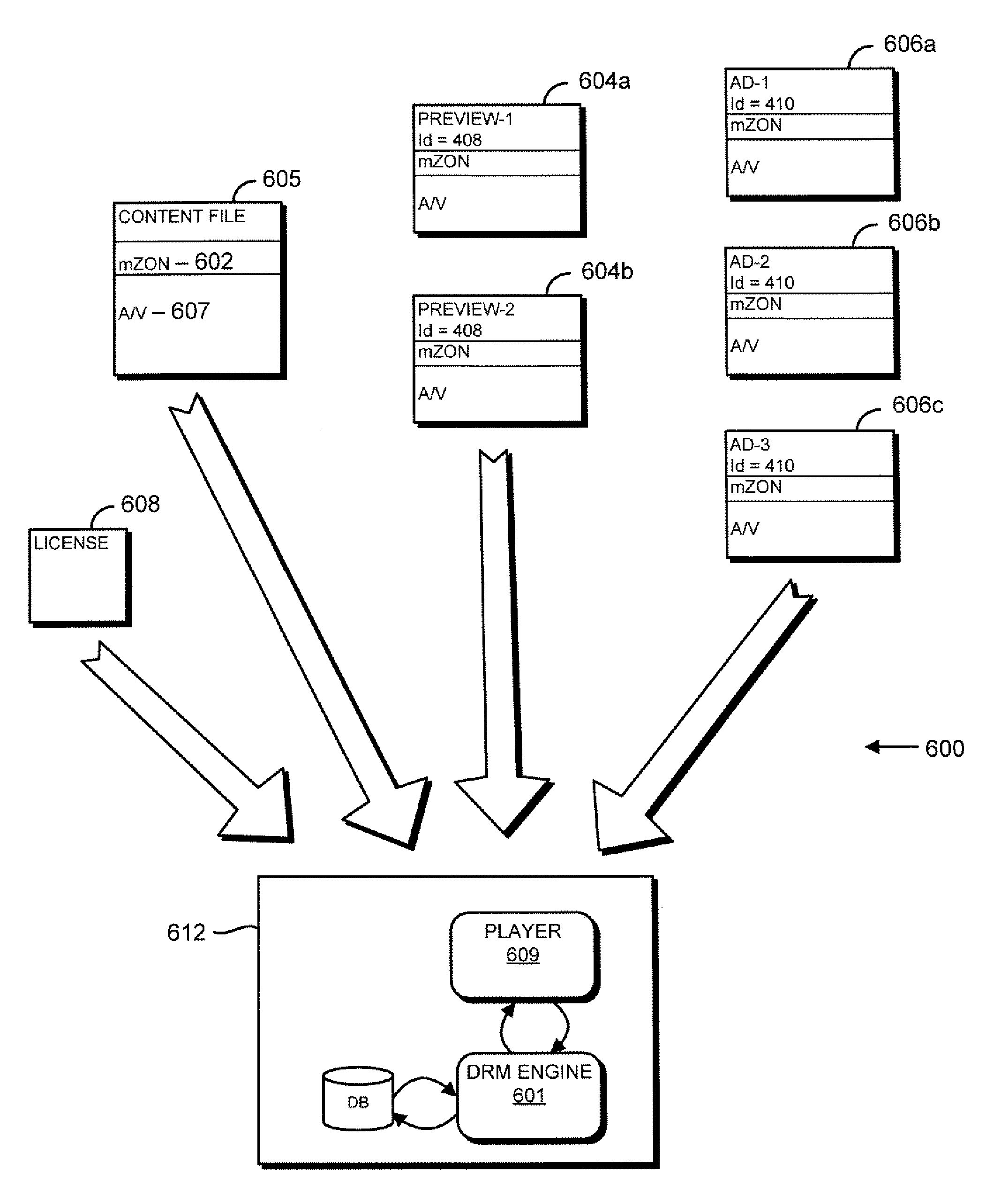

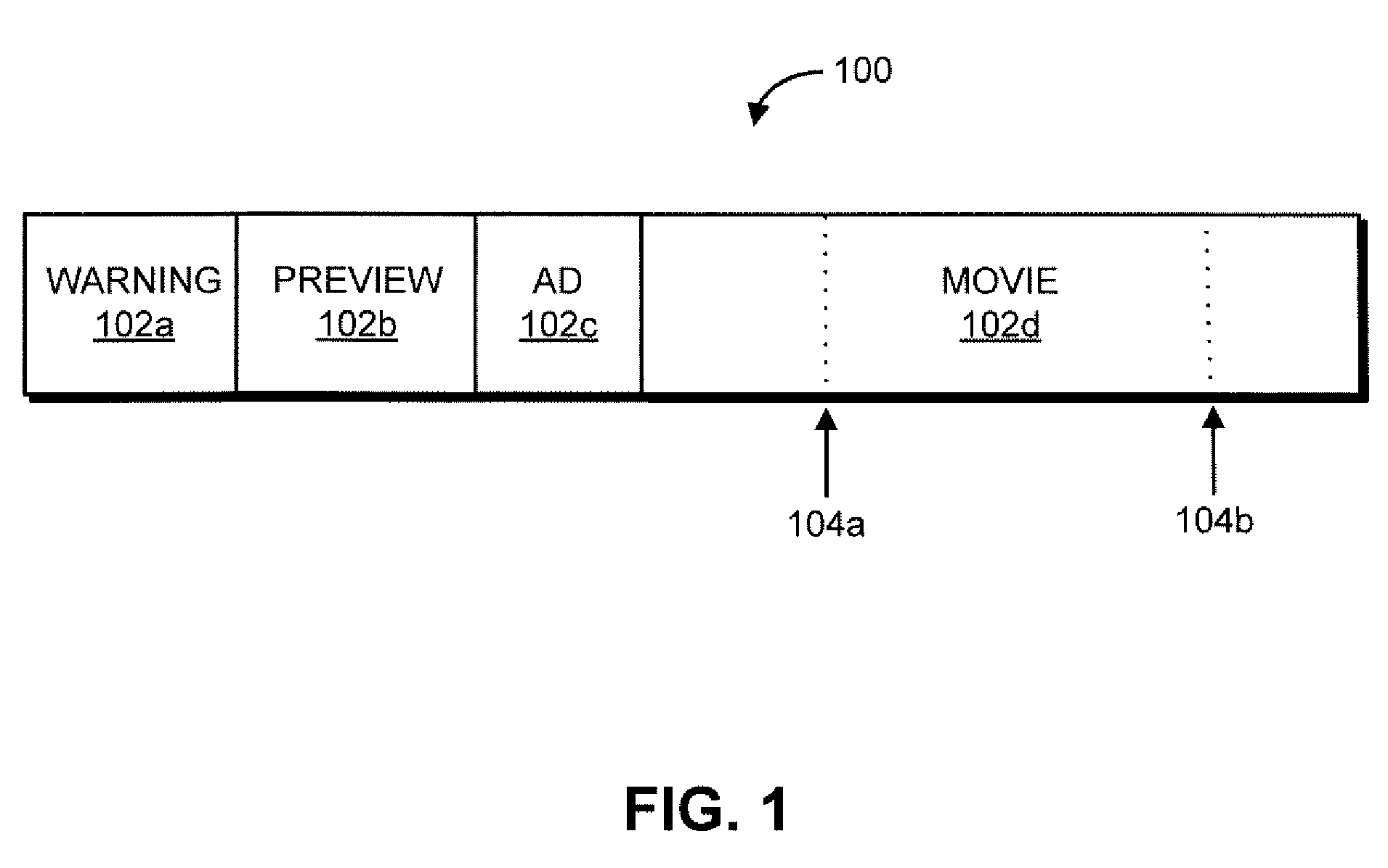

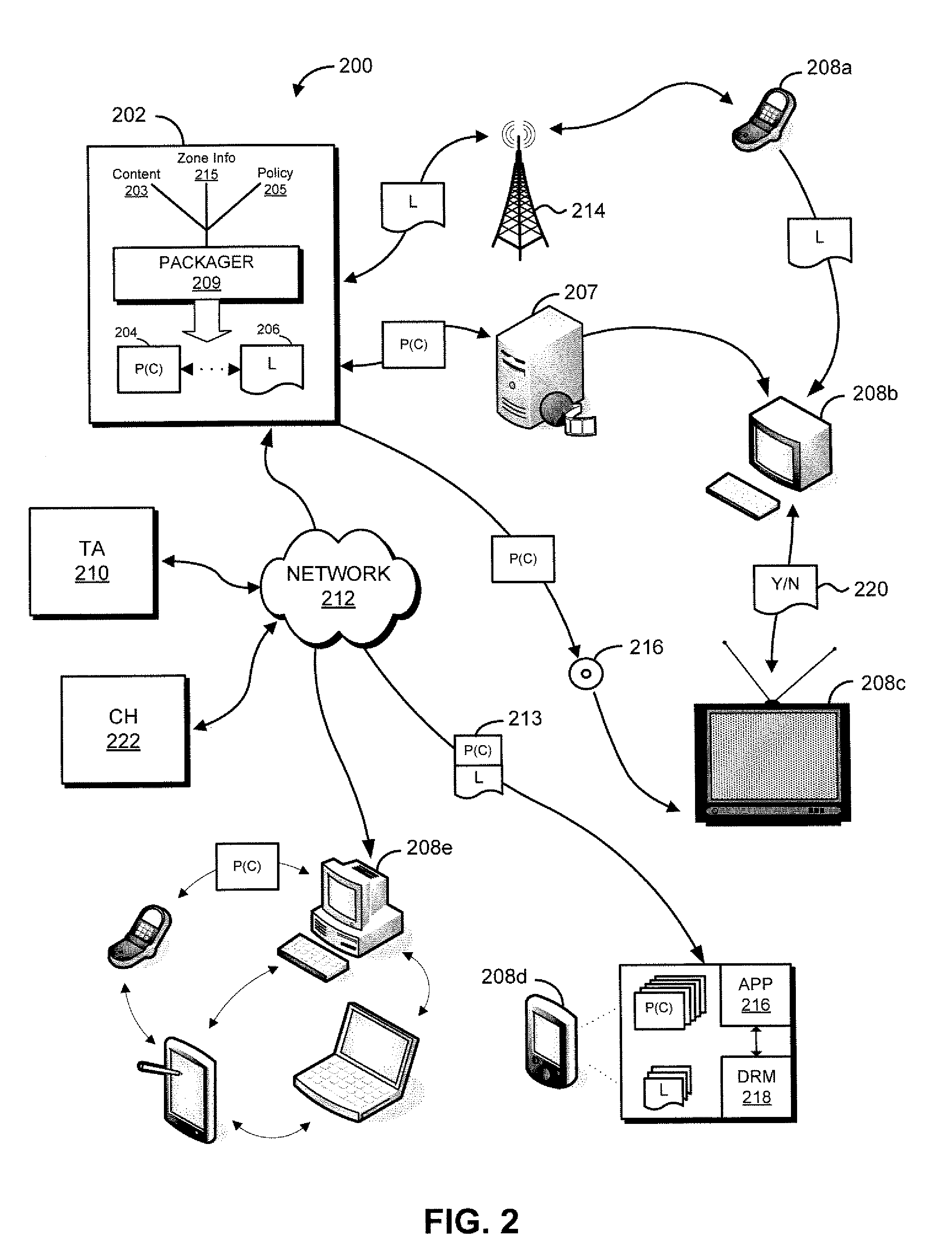

Dynamic media zones systems and methods

ActiveUS8793808B2Digital data processing detailsRecord information storageZone SystemRights management

Systems and methods are described for applying digital rights management techniques to manage zones in electronic content. In one embodiment, zones are defined in a piece of electronic content, and a license is associated with the electronic content that indicates how the zones are to be accessed or otherwise used. A digital rights management engine governs access to or other use of the zoned content in accordance with the license.

Owner:INTERTRUST TECH CORP

Dynamic media zones systems and methods

ActiveUS20090031431A1Limited accessEasy to manageDigital data processing detailsAnalogue secracy/subscription systemsZone SystemDigital rights management

Systems and methods are described for applying digital rights management techniques to manage zones in electronic content. In one embodiment, zones are defined in a piece of electronic content, and a license is associated with the electronic content that indicates how the zones are to be accessed or otherwise used. A digital rights management engine governs access to or other use of the zoned content in accordance with the license.

Owner:INTERTRUST TECH CORP

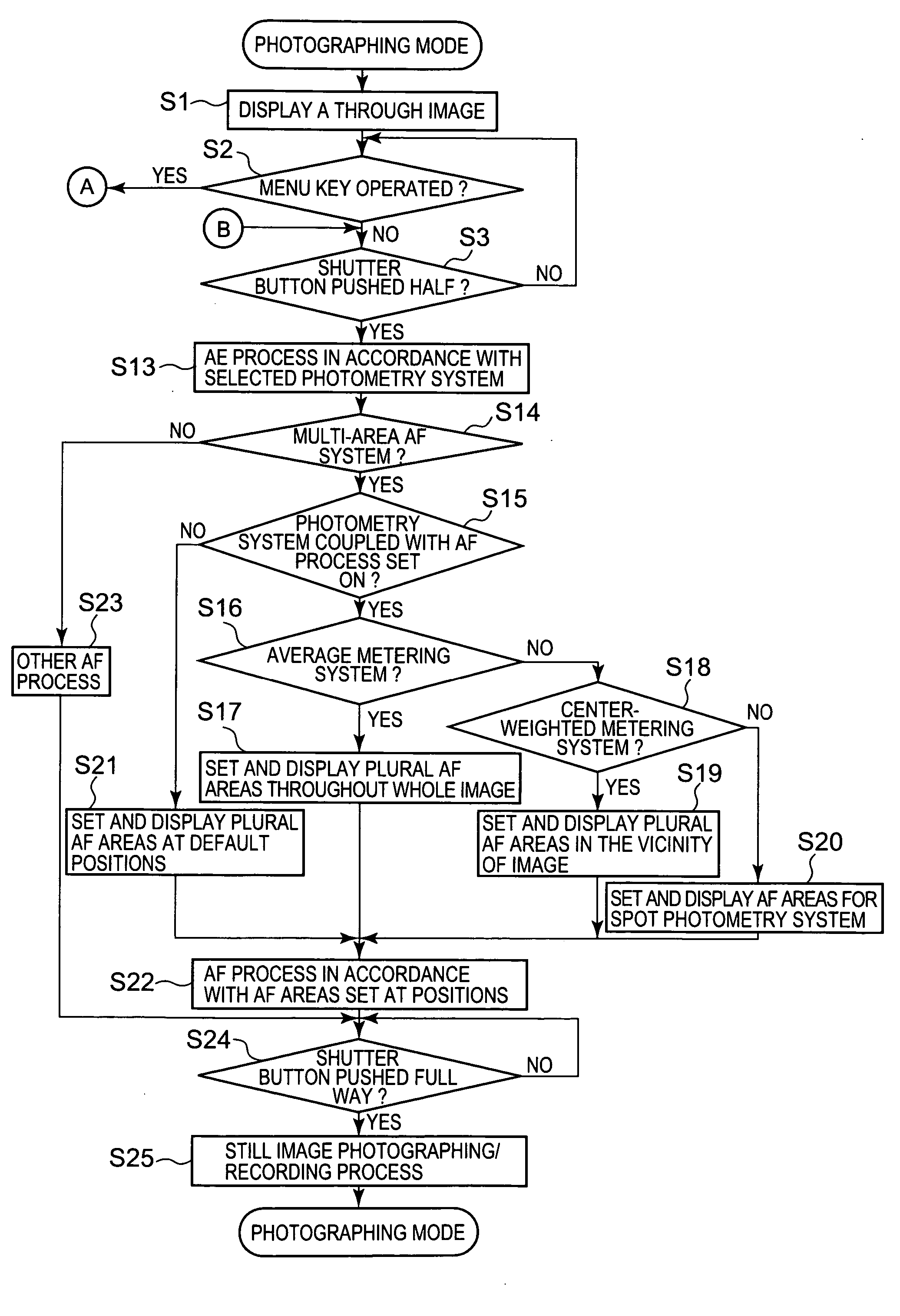

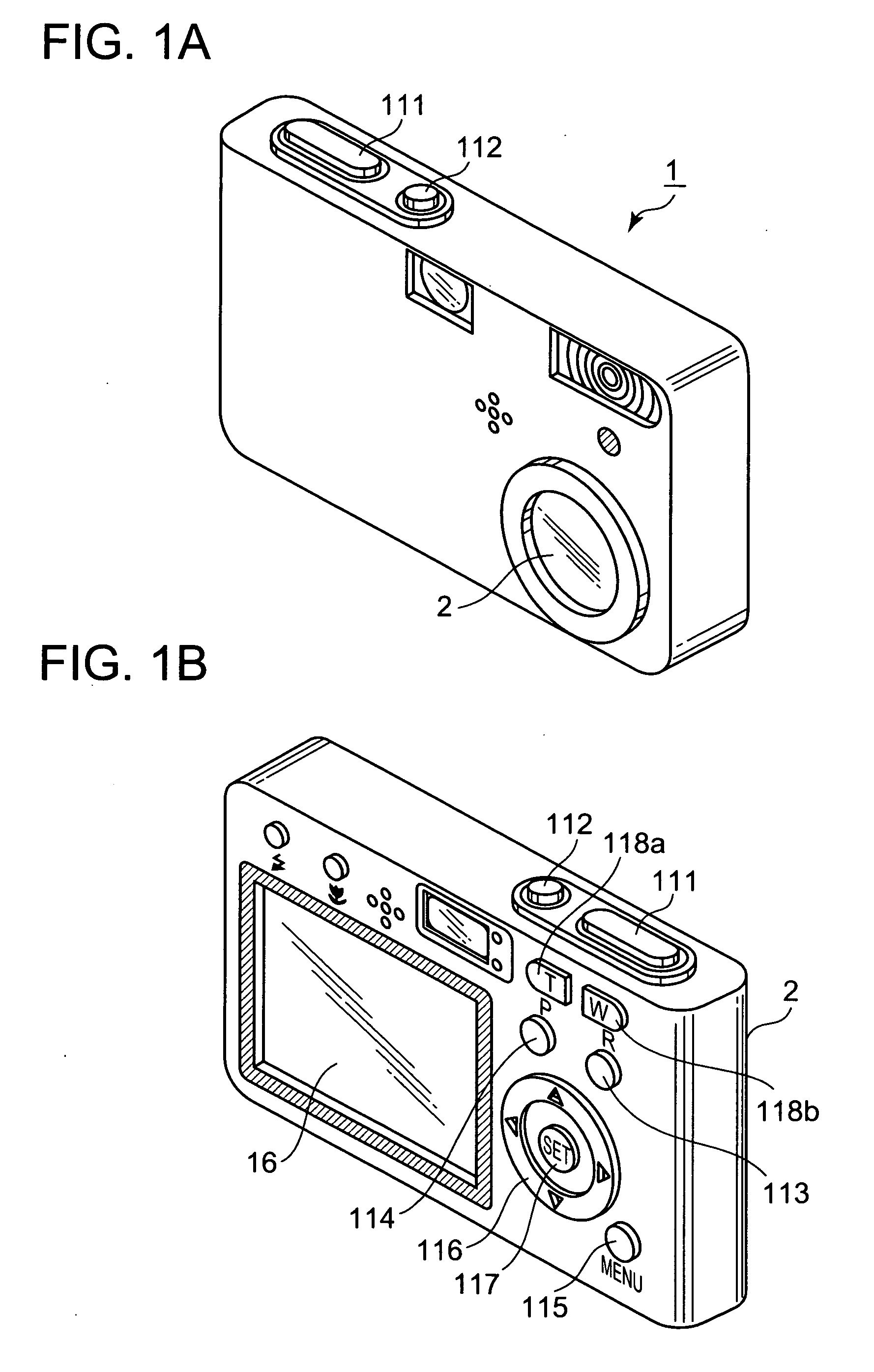

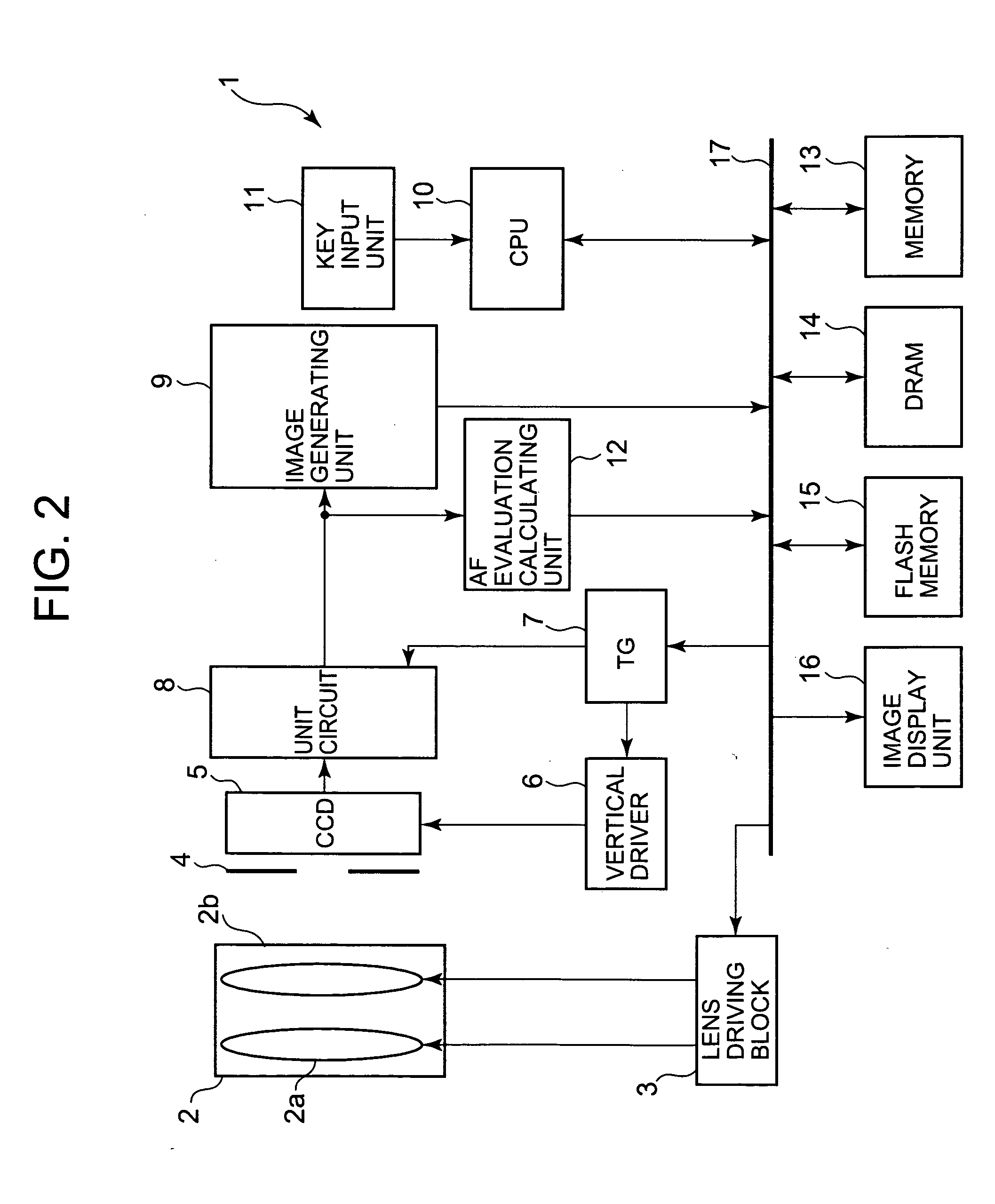

Image pick-up apparatus with a multi-area AF function

InactiveUS20070160359A1Television system detailsProjector focusing arrangementZone SystemImage formation

In an image forming apparatus, the auto-focusing process and the photometry system may be coupled such that when a multi-area AF system is set, the setting of the auto-focusing areas of the multi-area AF system is performed in accordance with a selected photometry system. More specifically, when an average metering system is selected as the photometry system, nine AF areas are set such that the AF areas are distributed throughout the whole image. When a center-weighted metering system is selected as the photometry system, four AF areas are set in the vicinity of the middle of the image. When a spot metering system is selected as the photometry system, one AF area is set in the vicinity of the middle of the image.

Owner:CASIO COMPUTER CO LTD

System and method for budgeted zone heating and cooling

An Electronically-Controlled Register vent (ECRV) that can be easily installed by a homeowner or general handyman is disclosed. The ECRV can be used to convert a non-zoned HVAC system into a zoned system. The ECRV can also be used in connection with a conventional zoned HVAC system to provide additional control and additional zones not provided by the conventional zoned HVAC system. In one embodiment, the ECRV is configured to have a size and form-factor that conforms to a standard manually-controlled register vent. In one embodiment, a zone thermostat is configured to provide thermostat information to the ECRV. In one embodiment, the zone thermostat communicates with a central monitoring system that coordinates operation of the heating and cooling zones and provides heating and cooling to the various zones according to a cost budget.

Owner:GOOGLE LLC

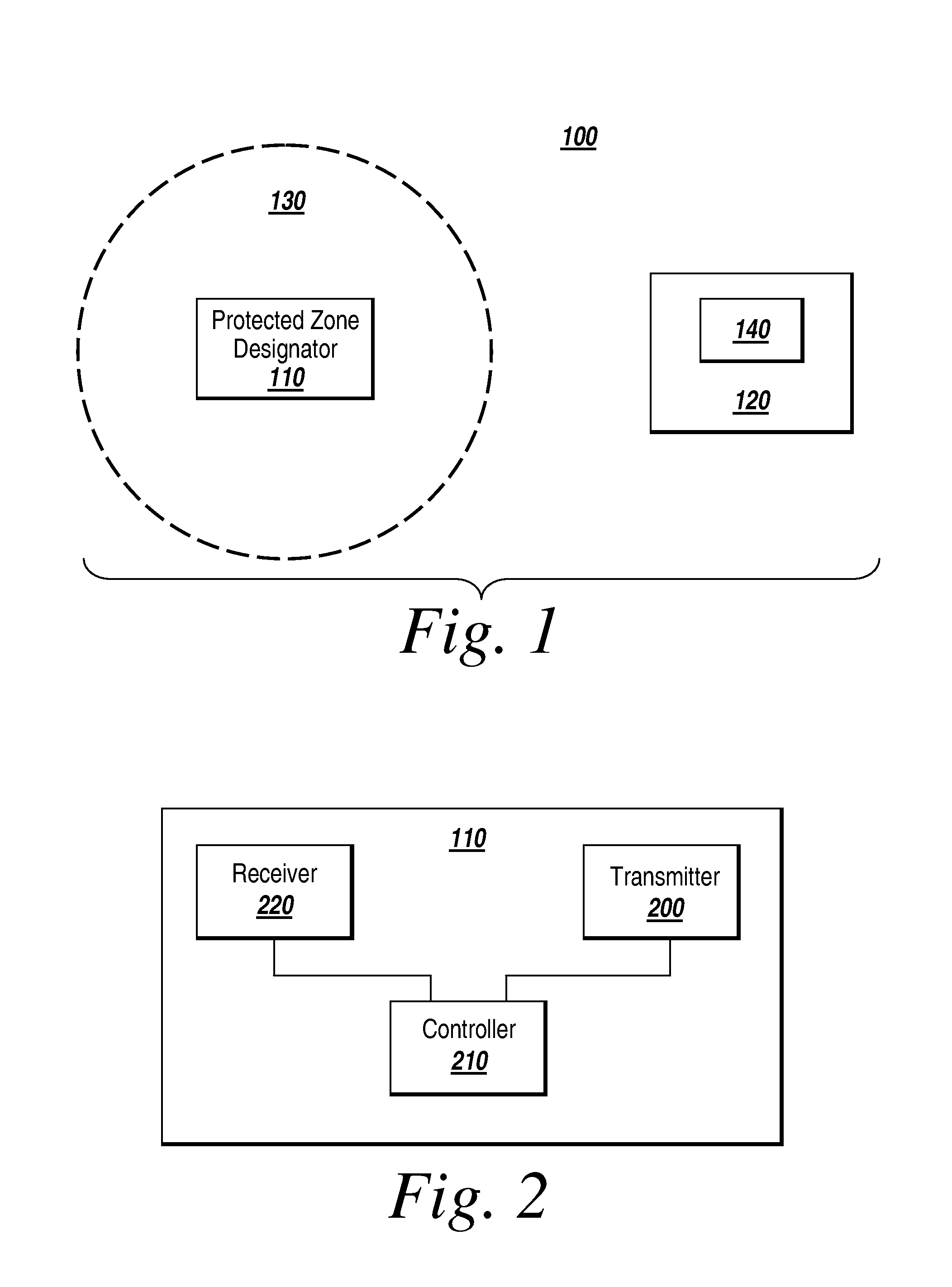

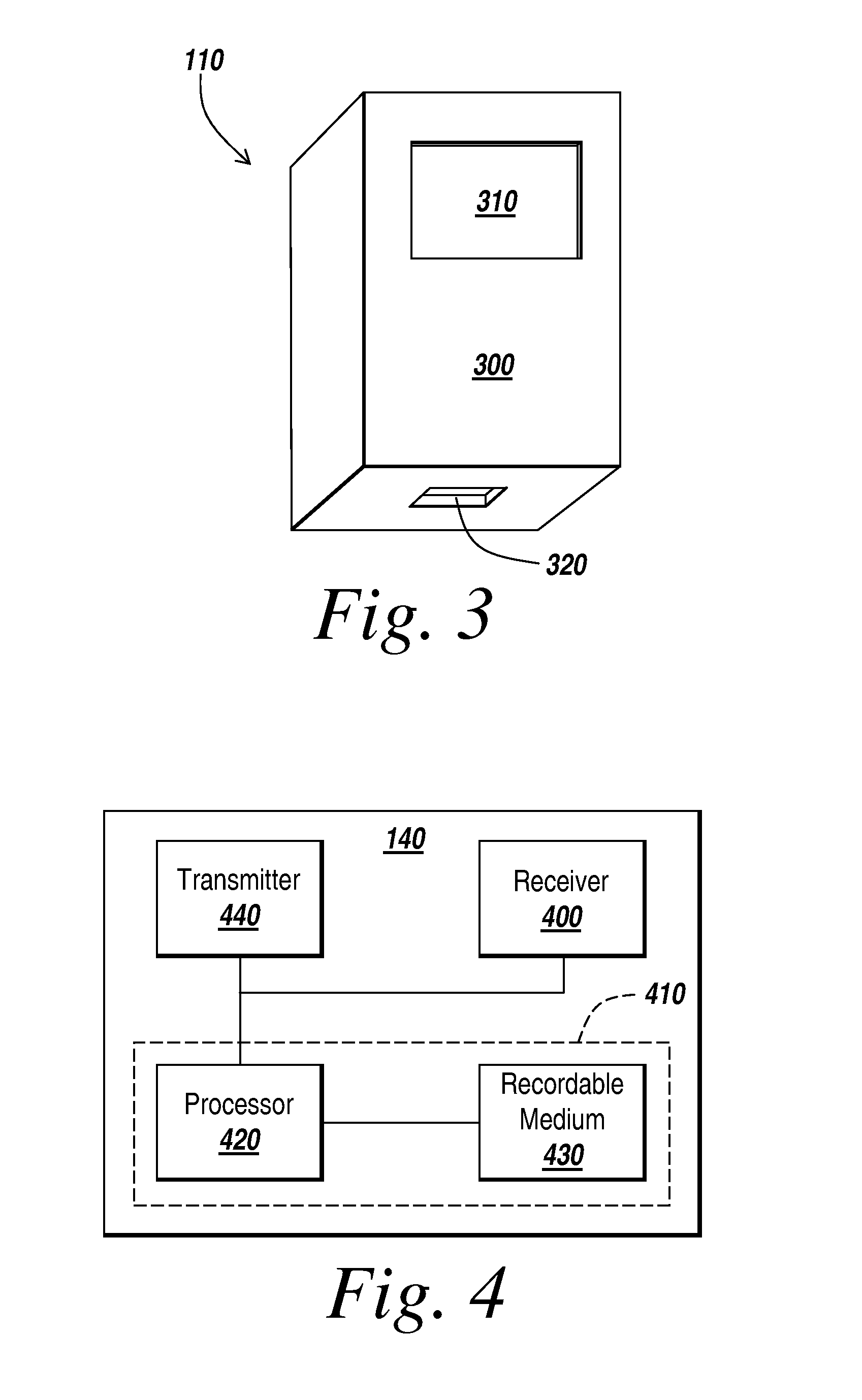

Protected zone system

A system is provided for establishing a protected zone and monitoring interactions therewith. The system includes a protected zone designator and a wearable device. The protected zone designator establishes the protected zone. The protected zone designator is configured for placement at a location in which the protected zone is desired. The wearable device is separate and distal from the protected zone designator. The wearable device includes a protected zone recognition component configured to recognize the protected zone and identify pre-defined interaction criteria for the protected zone. Upon the wearable device entering the protected zone, the protected zone recognition component recognizes the protected zone and identifies the interaction criteria of the protected zone. Based on the interaction criteria the wearable device determines and records compliance with the interaction criteria.

Owner:THE GENERAL HOSPITAL CORP

Ultrasonic compliance zone system

ActiveUS8164439B2Reduce decreaseReliable communicationDetection of traffic movementResourcesZone SystemDocumentation procedure

A system is provided for establishing a compliance zone and monitoring interactions therewith. The system includes a compliance zone designator and a wearable device. The compliance zone designator transmits an ultrasound signal to establish the compliance zone. The ultrasound signal may be encoded with information on the compliance zone. The compliance zone designator is configured for placement at a location in which the compliance zone is desired. The wearable device is separate from the compliance zone designator. The wearable device includes a compliance zone recognition component configured to recognize the compliance zone and identify one or more pre-defined interaction criteria for the compliance zone. When the wearable device is within the compliance zone, the compliance zone recognition component recognizes the compliance zone and identifies the interaction criteria of the compliance zone. Based on the interaction criteria the wearable device determines and records compliance with the interaction criteria. The recorded data is optionally used to set off real-time alerts. The recorded data is also optionally used in subsequent analysis and documentation of compliance with protocols.

Owner:THE GENERAL HOSPITAL CORP

Ultrasonic compliance zone system

ActiveUS8547220B1Short travel timeReduce decreaseDetection of traffic movementSound producing devicesZone SystemDocumentation procedure

A system is provided for establishing a compliance zone and monitoring interactions therewith. The system includes a compliance zone designator and a wearable device. The compliance zone designator transmits an ultrasound signal to establish the compliance zone. The ultrasound signal may be encoded with information on the compliance zone. The compliance zone designator is configured for placement at a location in which the compliance zone is desired. The wearable device is separate from the compliance zone designator. The wearable device includes a compliance zone recognition component configured to recognize the compliance zone and identify one or more pre-defined interaction criteria for the compliance zone. When the wearable device is within the compliance zone, the compliance zone recognition component recognizes the compliance zone and identifies the interaction criteria of the compliance zone. Based on the interaction criteria the wearable device determines and records compliance with the interaction criteria. The recorded data is optionally used to set off real-time alerts. The recorded data is also optionally used in subsequent analysis and documentation of compliance with protocols.

Owner:THE GENERAL HOSPITAL CORP

I-Port controller

InactiveUS20060052097A1Docking-station type assembliesBroadcast specific applicationsZone SystemEngineering

A multi-zone audio system is provided that is portable to a handheld audio device at a plurality of locations. The system includes a multi-zone audio system controller having an audio input / output selection circuit for selectively regulating the source and distribution of audio signals. A plurality of handheld connector docks are distributed about the multi-zone system. Each connector dock is in communication with the audio system controller. The connector docks include a connector port, engagable to the handheld device, for communicating music / data / commands between the handheld device and the system controller. A plurality in-wall audio controllers are also distributed about the multi-zone system. Each in-wall controller is in communication with the audio system controller, and includes an input circuit for selective input of commands to regulate operation of the system controller and / or the handheld device. The handheld connector docks are operative to transfer music / data / commands between the audio system controller and a handheld device disposed within the connector dock.

Owner:DANA INNOVATIONS

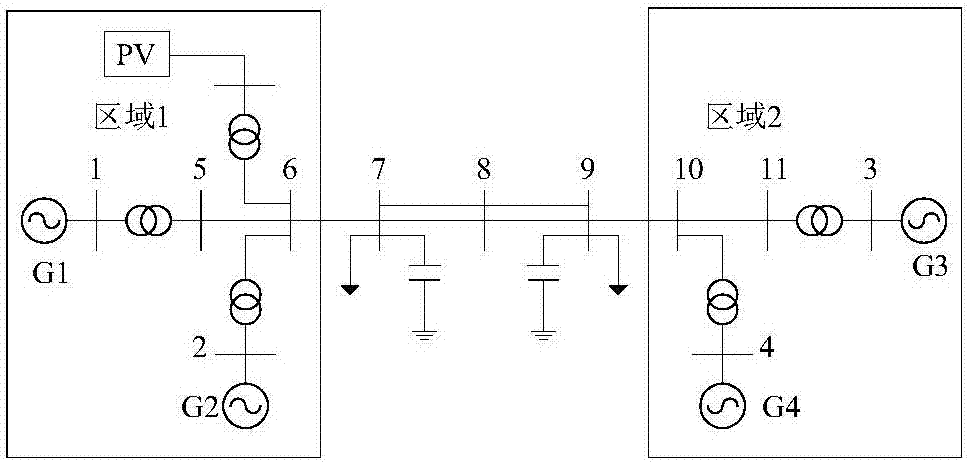

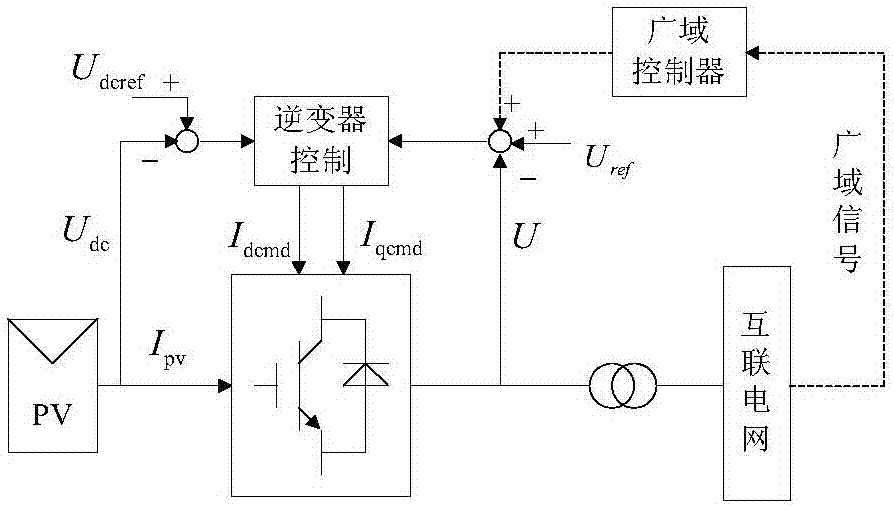

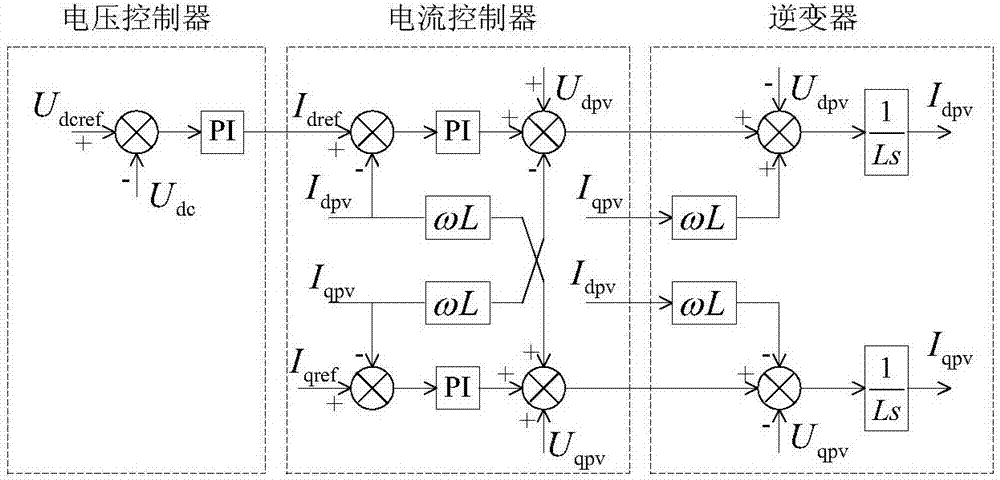

Pattern analysis-based photovoltaic power station multi-unit system low-frequency oscillation suppressing method

InactiveCN107579541ASuppress low frequency oscillationReduce complexitySingle network parallel feeding arrangementsPhotovoltaic energy generationZone SystemWide area

The invention discloses a pattern analysis-based photovoltaic power station multi-unit system low-frequency oscillation suppressing method. The pattern analysis-based photovoltaic power station multi-unit system low-frequency oscillation suppressing method comprises the steps of 1) establishing a grid-connected photovoltaic power station dynamic model comprising a photovoltaic array, an inverter and a control module of the inverter; 2) establishing a photovoltaic power station-contained multi-unit power system state equation and a linearized model of the photovoltaic power station-contained multi-unit power system state equation; 3) taking a four-unit two-area system as an analyzing example to perform pattern analysis on the linearized model; 4) designing a photovoltaic wide-area damping controller. The pattern analysis-based photovoltaic power station multi-unit system low-frequency oscillation suppressing method can effectively achieve damping control of a photovoltaic power generation system, reduce negative effects on system safety and stability levels which are possibly led to by photovoltaic grid connection, and improve receptivity of an interconnected electric power system to the photovoltaic power generation system.

Owner:NANJING UNIV OF SCI & TECH

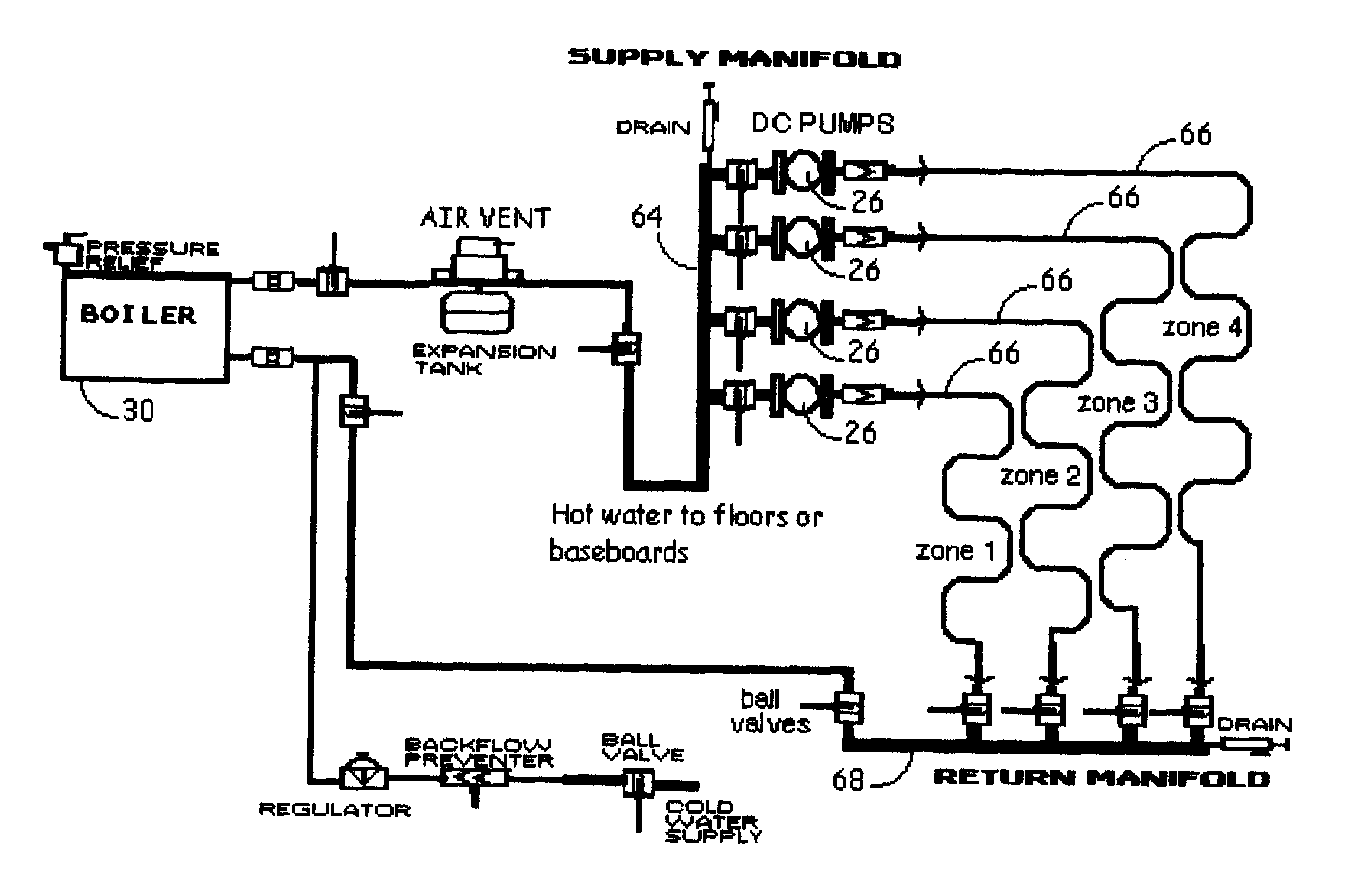

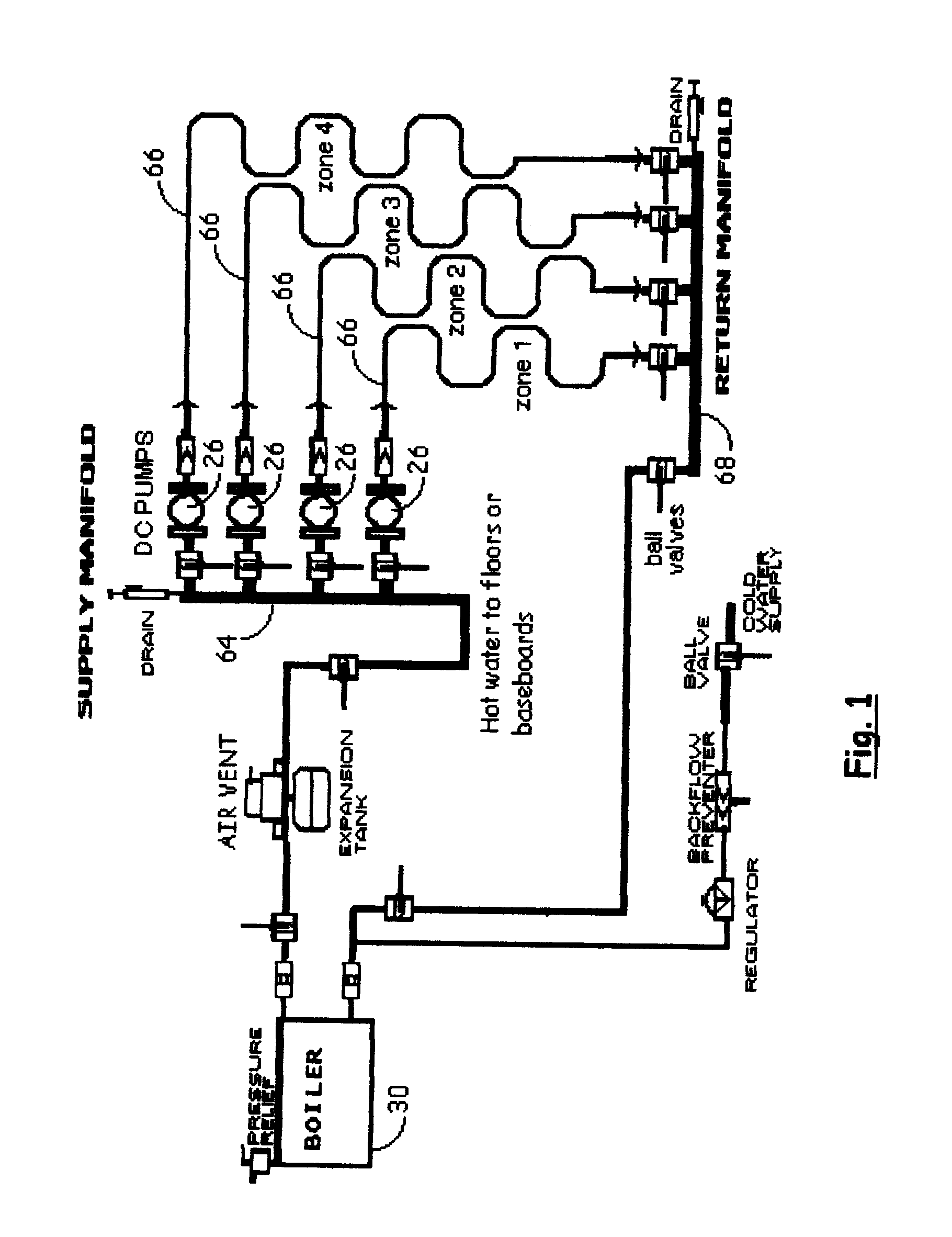

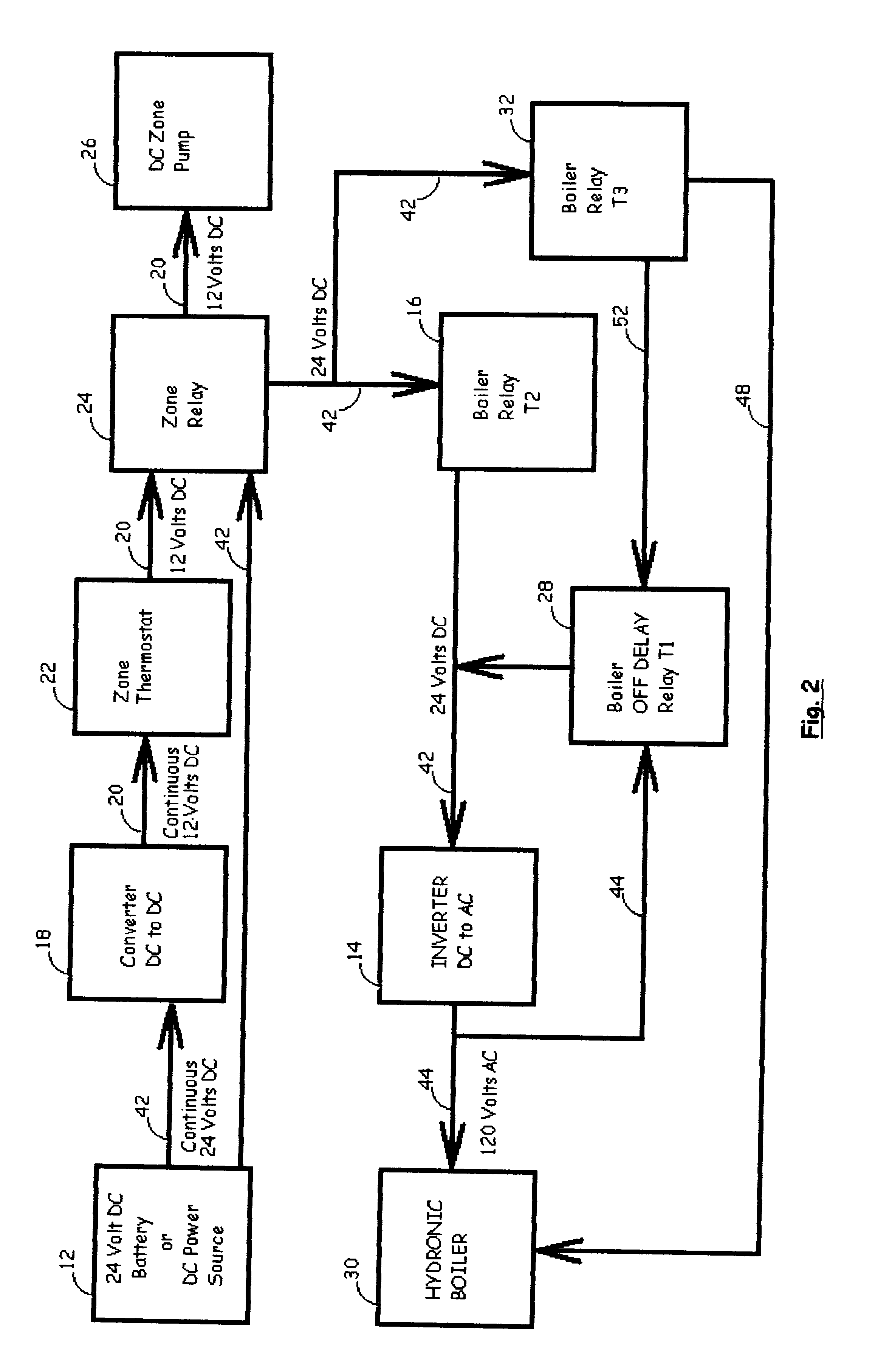

Direct current electrical controls for heating systems

InactiveUS6237855B1Extend battery lifeReduce eliminateAir-treating devicesLighting and heating apparatusZone SystemElectrical battery

A method and apparatus for controlling the normal operation of a hydronic heating system, (including AC powered, gas-burning hot water boiler, multi-zone systems) using a DC power source, such as battery power, as the primary continuous source of electricity. Control functions minimize the consumption of electric power during normal operation, and eliminate standby electric consumption in order to extend the life of the batteries and maximize the run-time of the heating system. A DC to DC converter supplies low voltage DC power to the zone thermostats, and also supplies the proper voltage through zone relays to operate DC zone pumps. By allowing the use of DC power for the thermostats and zone pumps, the system eliminates the need for transformers, zone valves, and AC circulators, resulting in a large savings in electrical consumption and the elimination of the standby electric demand ("phantom load") common in conventional hydronic heating systems. A DC to AC inverter is dedicated to supply AC power for a hydronic (hot water) boiler. The inverter is switched on by relays only when needed, thereby eliminating the "phantom electric load" consumed by most boilers when standing by. A time delay relay circuit allows the boiler to go through its proper shutdown sequence before power is removed. This control system does not require any internal modification to the other heating system components.

Owner:STICKNEY BRISTOL L +1

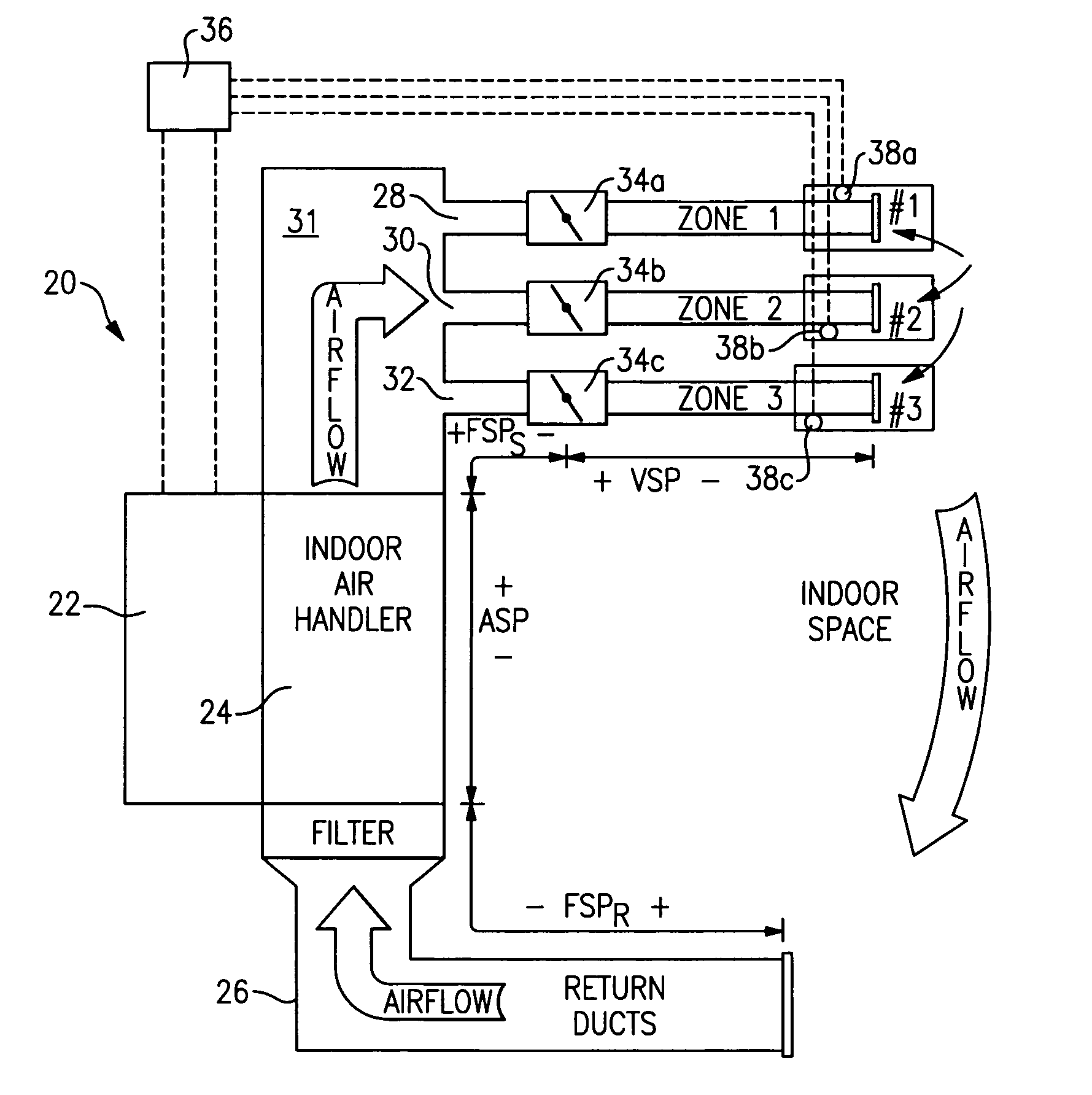

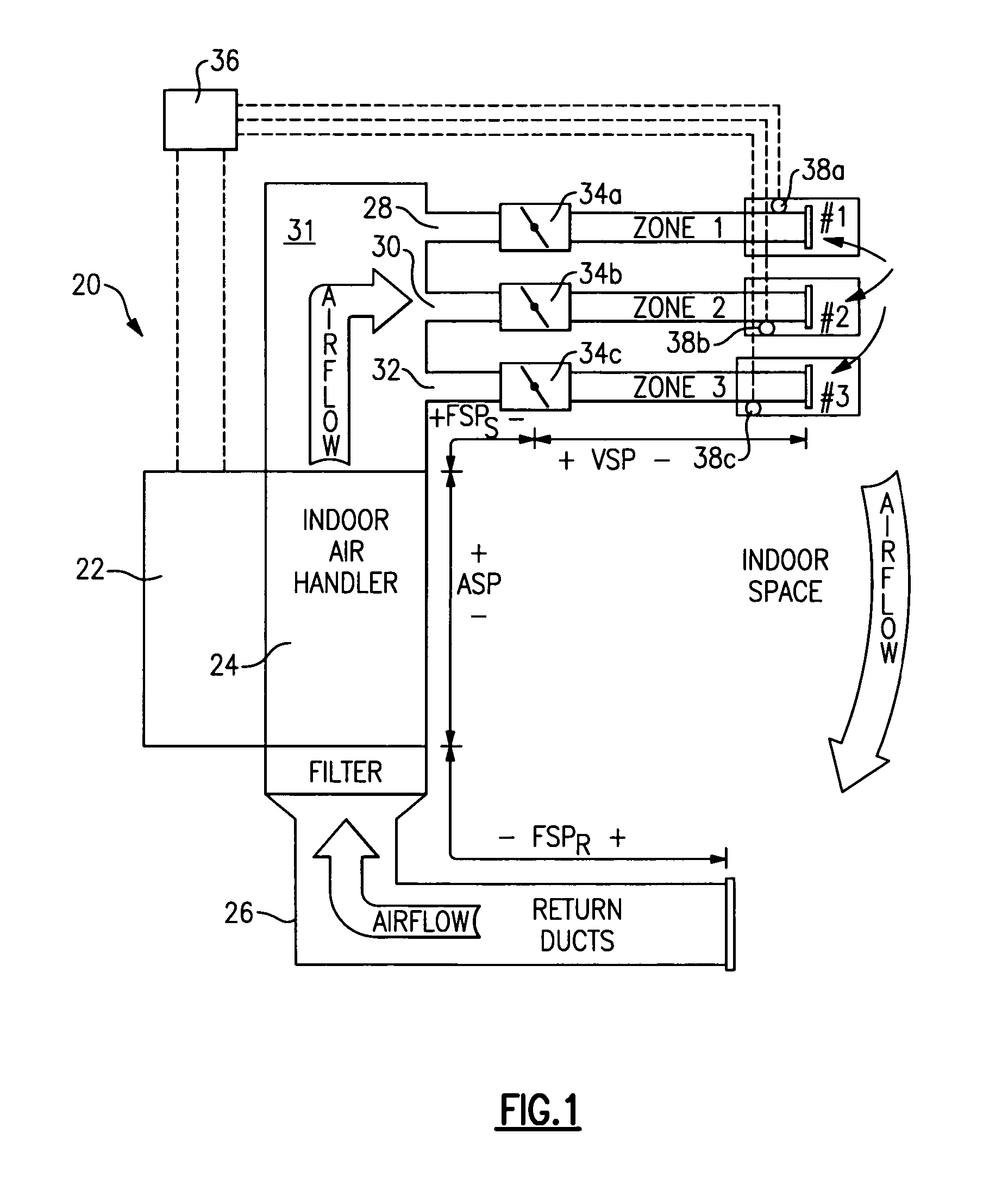

Continuous fan control in a multi-zone HVAC system

ActiveUS20050156054A1Mechanical apparatusSpace heating and ventilation safety systemsSize differenceZone System

A multi-zoned HVAC system includes a control for independently determining the amount of airflow delivered to each zone within the HVAC system. The control determines nominal zone airflow and continuous fan airflow levels for each zone based upon a user selected fan airflow level and the relative size of each zone in the HVAC system. The control determines the desired system airflow for the entire system once the continuous fan airflow levels for each zone are determined. The HVAC system provides a continuous fan airflow to each zone independently of the continuous fan airflow delivered to any other zone and irrespective of the relative size difference of the zones.

Owner:CARRIER CORP

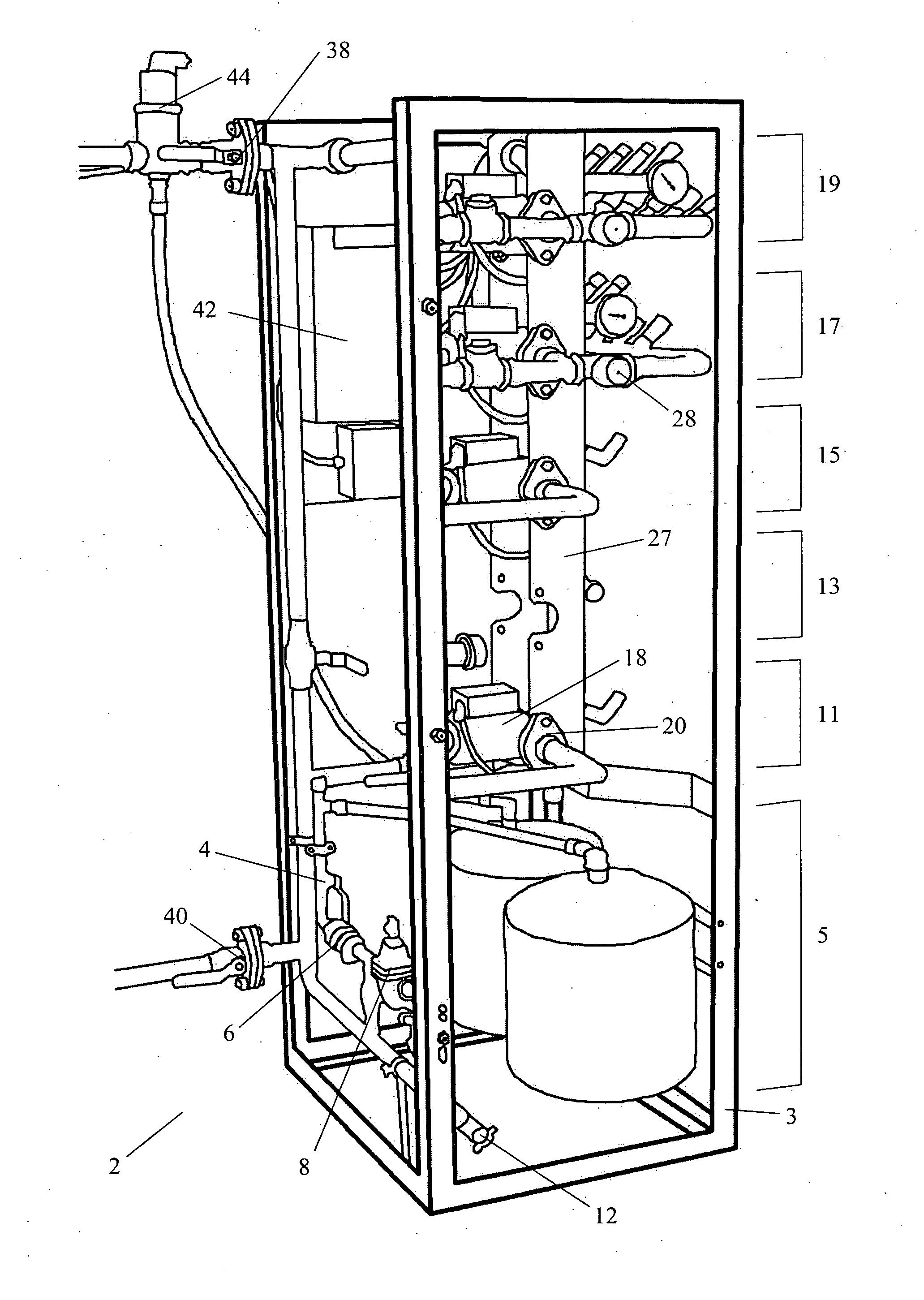

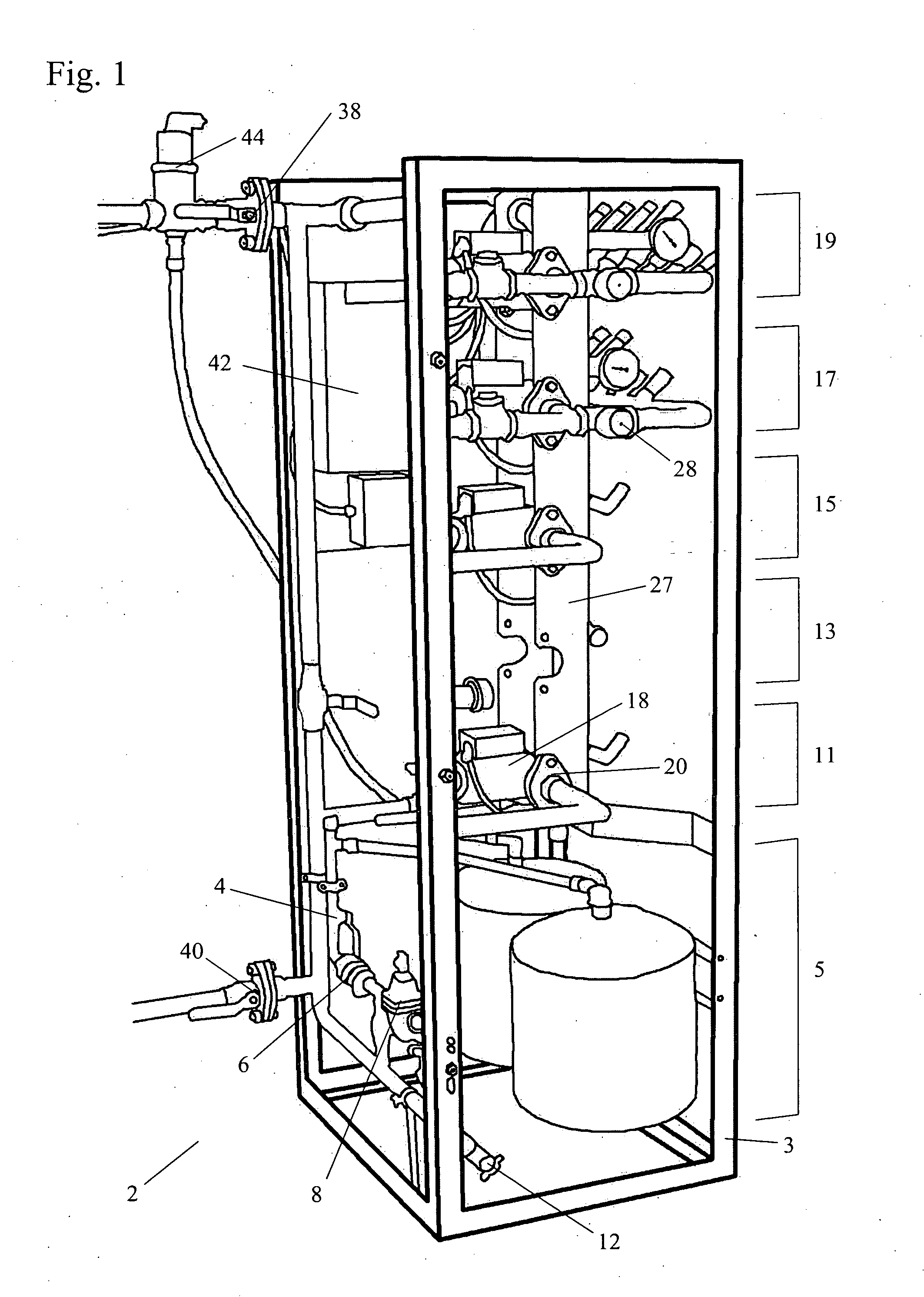

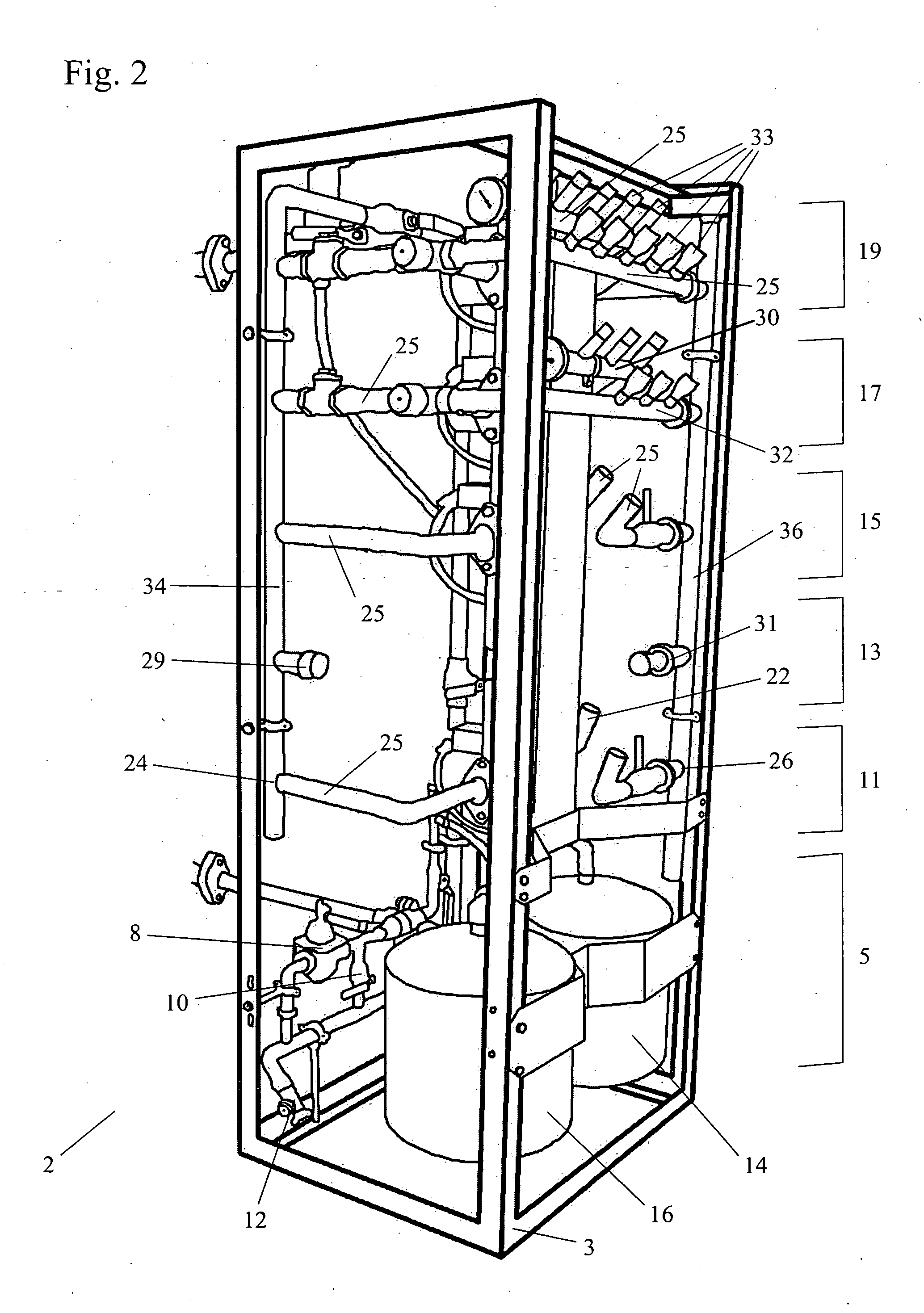

Modular heat distribution unit for hydronic heating systems

A compact modular heat distribution unit for a hydronic heating system connects to a hot water source, to supply and return pipes that lead to heating zones of the building, and, optionally, to an indirect water heater. The module is preferably assembled off-site in a factory setting to contain all components of a typical hydronic heating system except for a hot water source and the building heating pipes. The module includes heating zone distribution sub-modules for the different heating zones of the building. A three-dimensional frame supports the heating zone distribution sub-modules. The module may be used in any multi-zone system including hot water baseboards, hydronic radiant heat floor pipes, swimming pool heaters, ice melt systems or in any combination of these zones.

Owner:WAWAK RYSZARD J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com