Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "F connector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

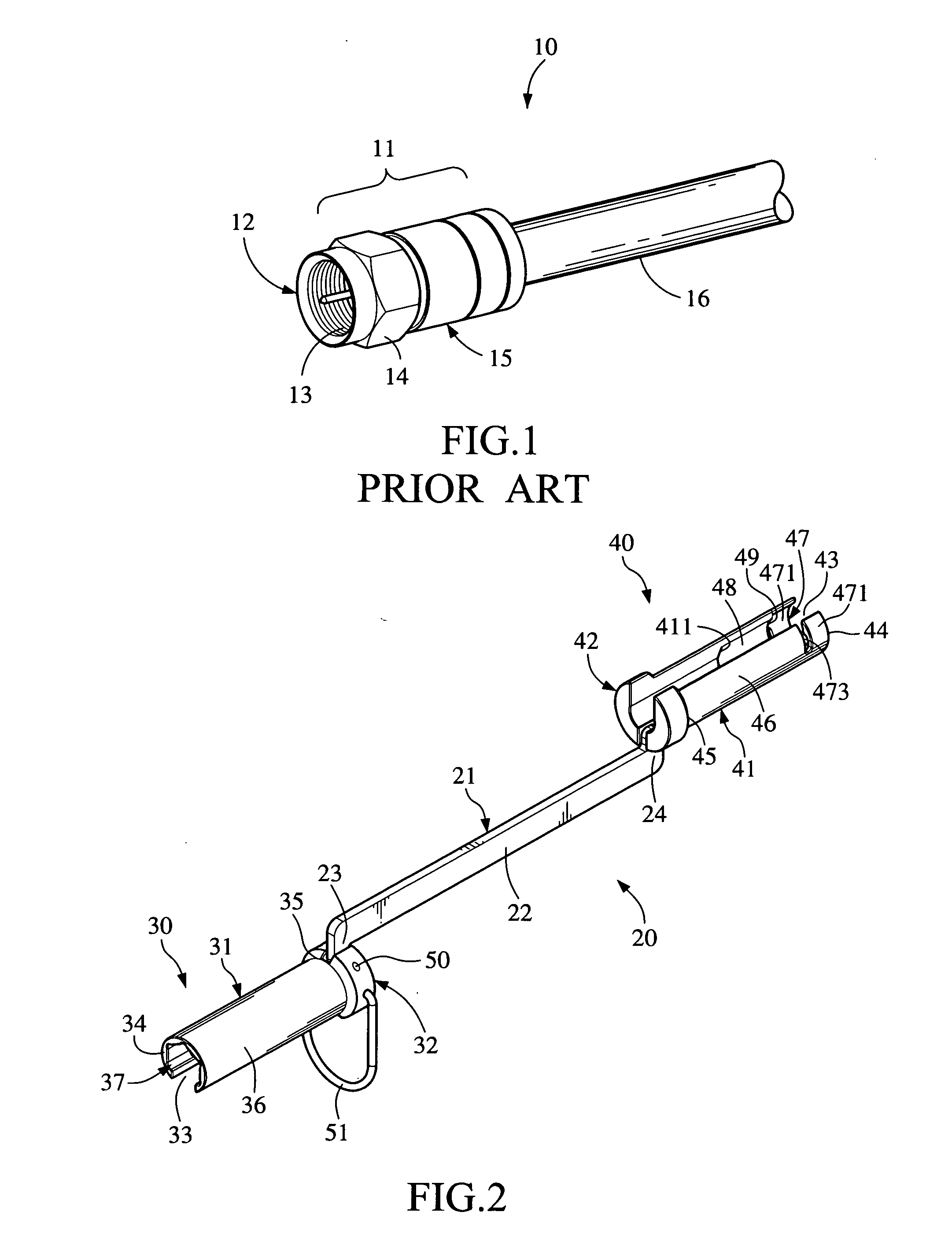

The F connector (also F-type) is a coaxial RF connector commonly used for "over the air" terrestrial television, cable television and universally for satellite television and cable modems, usually with RG-6/U cable or, in older installations, with RG-59/U cable.

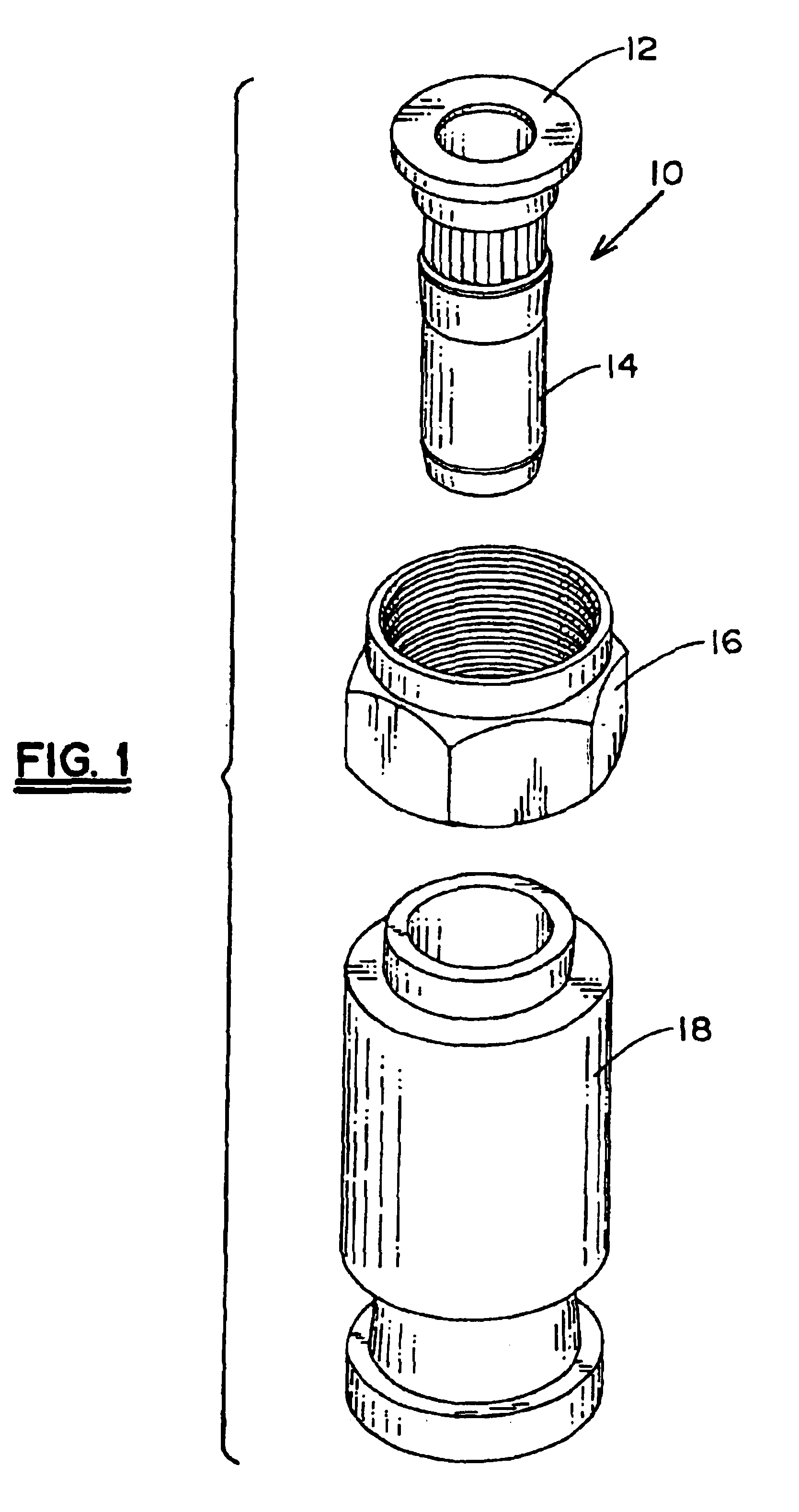

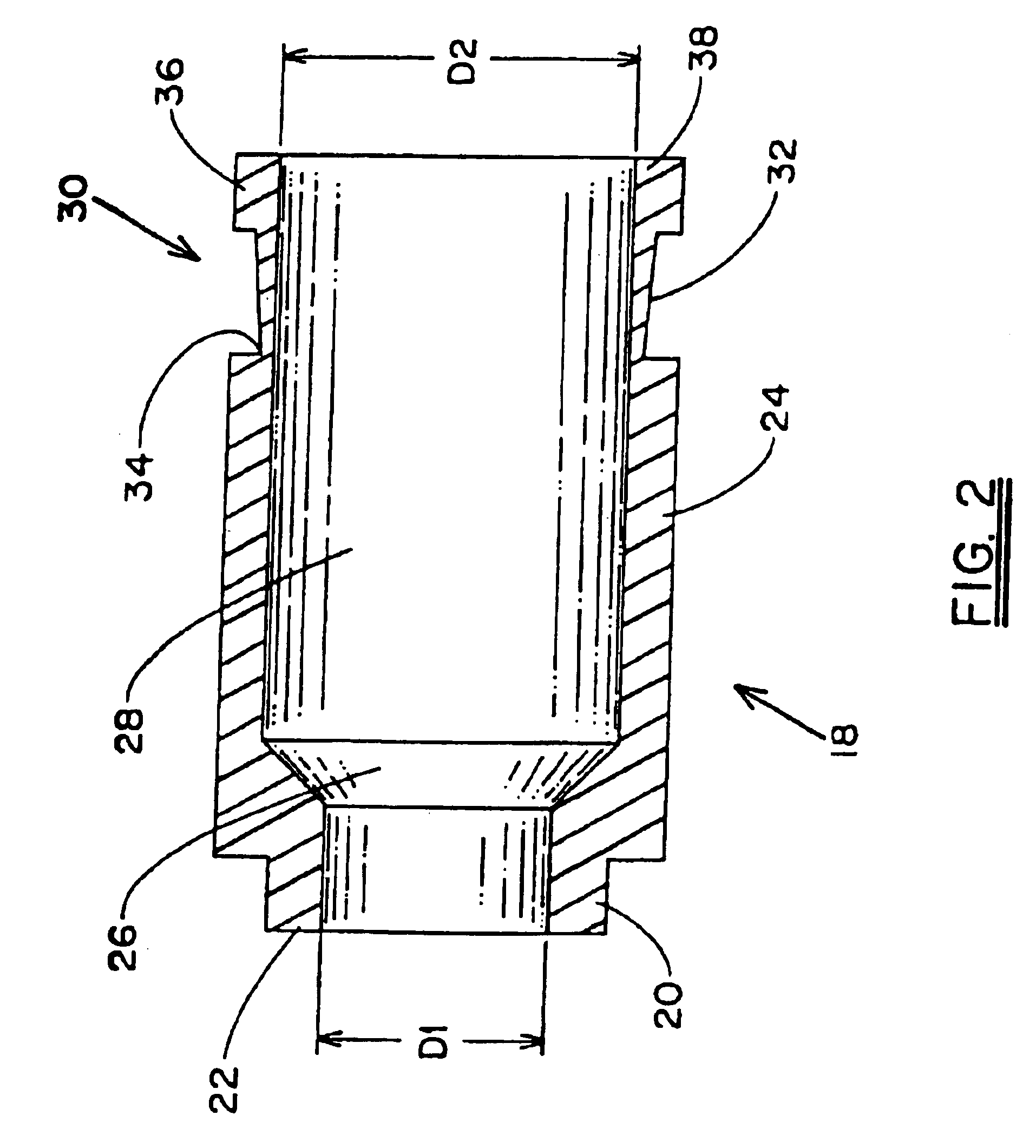

U-Channel Coaxial F-Connector

InactiveUS20130040481A1Well formedEngagement/disengagement of coupling partsContact member manufacturingElectrical conductorEngineering

An F-connector for a coaxial cable comprises a front insulator, a back insulator, a connecting lead, and a locking ring. The connecting lead has an interior portion and an exterior portion. The interior portion is configured with a pair of side wall portions which are parallel to each other, and which together with a bottom portion form a U-shaped channel. The side wall portions each comprise a curved portion that are configured to grip the center conductor of the coaxial cable so as to withstand a certain level of withdrawal force, and such that the F-connector exhibits a desired impedance of 75 Ohms. The connecting lead engages with the front insulator and the back insulator such that the components are held in position within a connector body.

Owner:GENESIS TECH USA

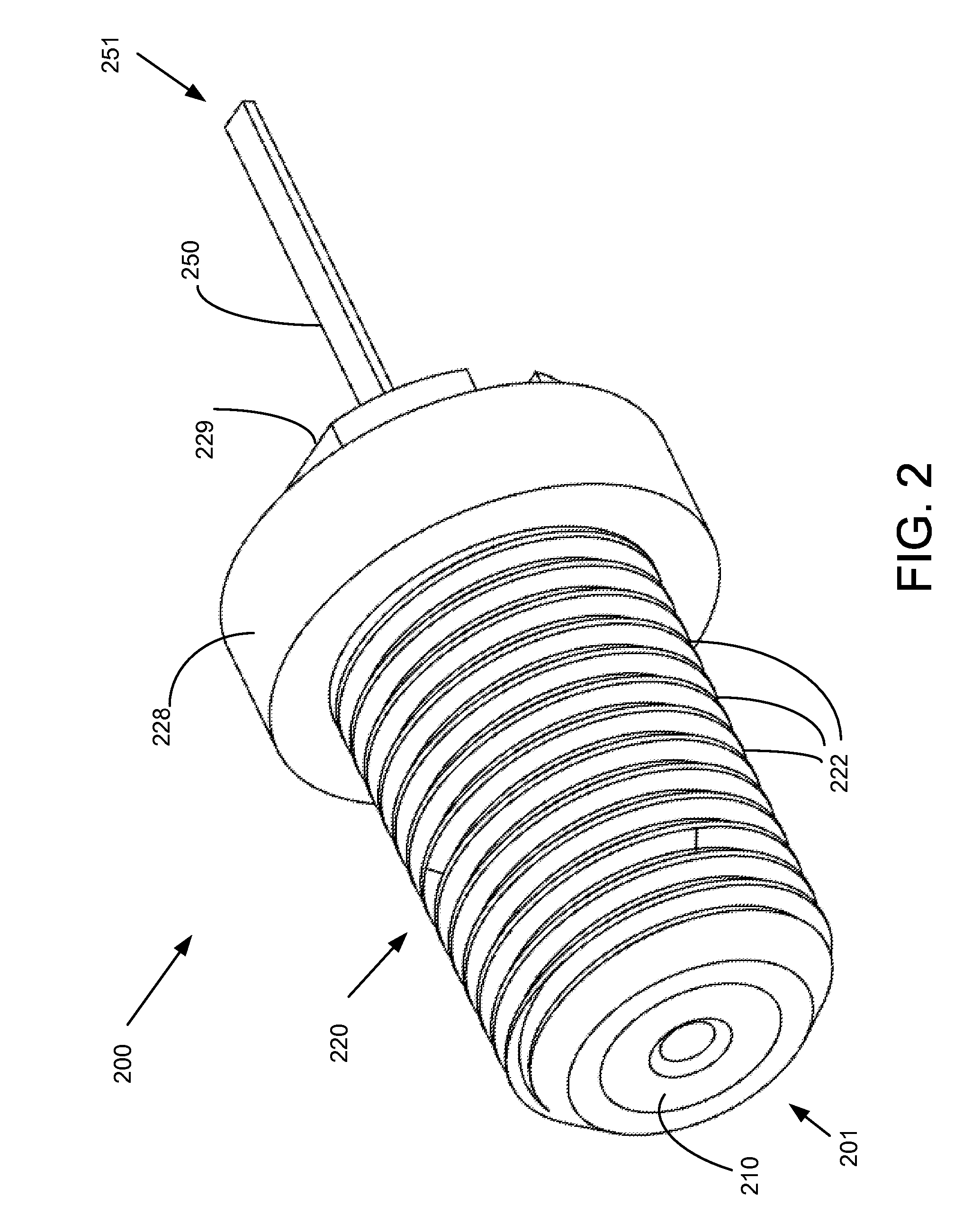

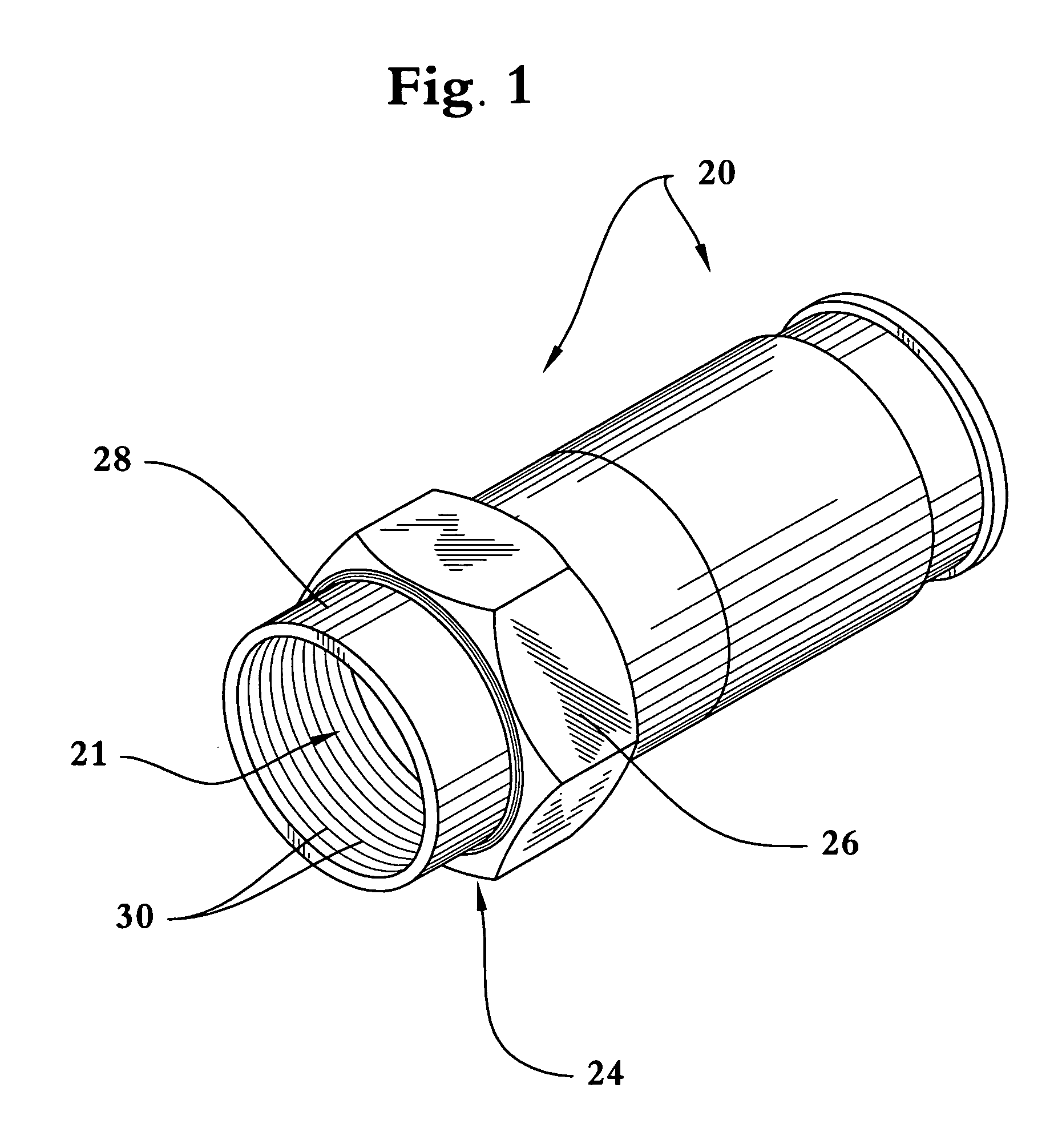

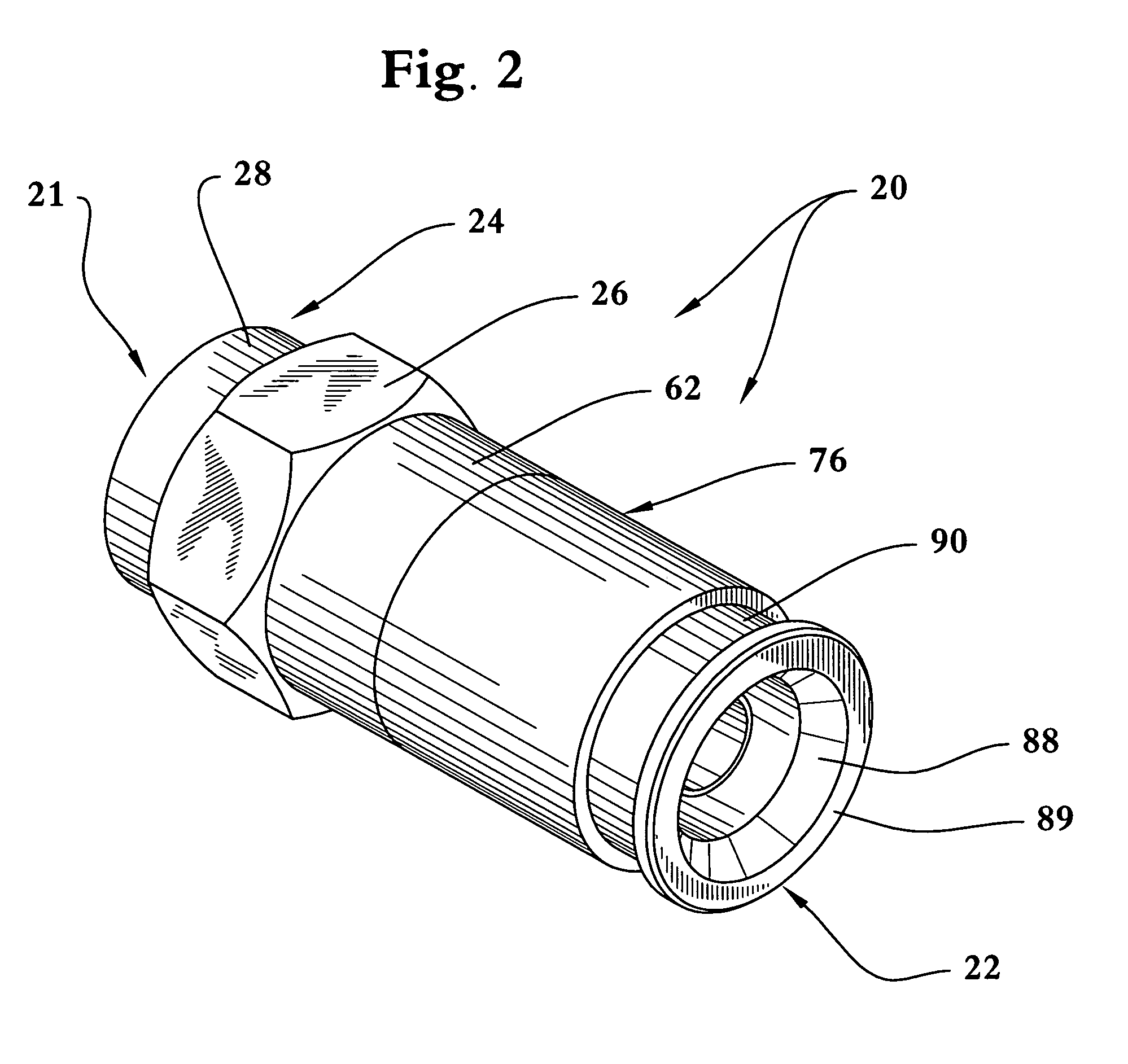

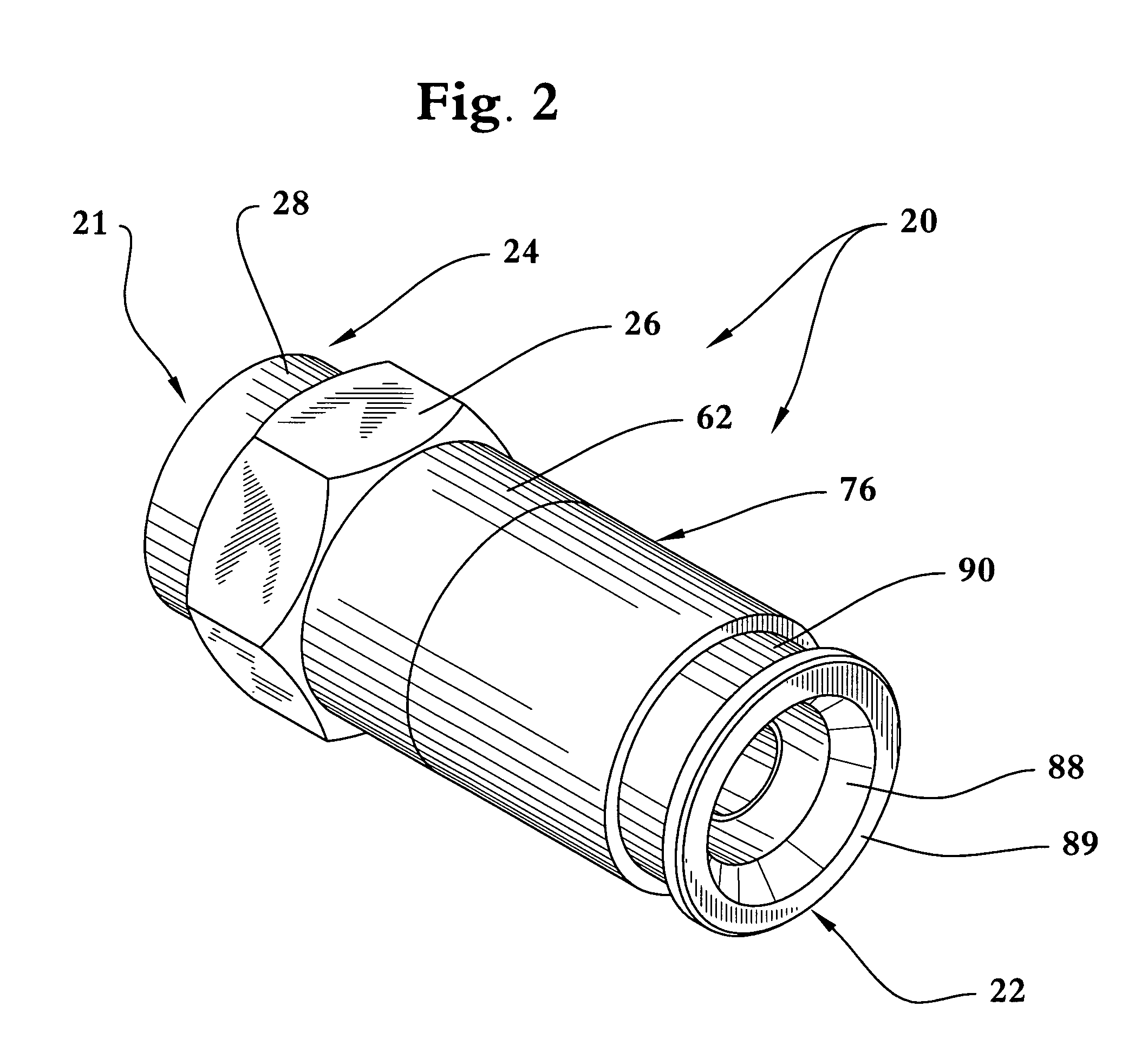

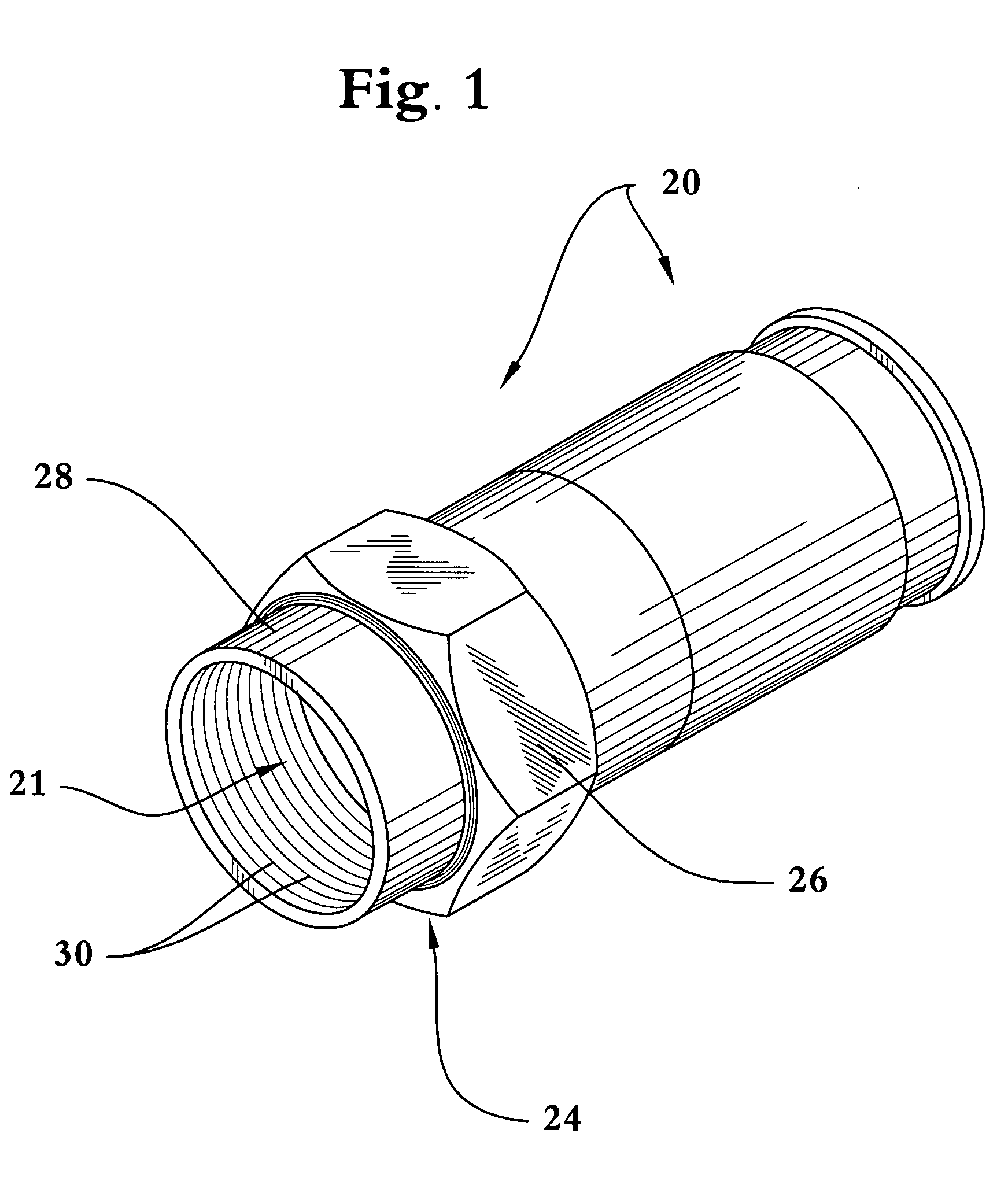

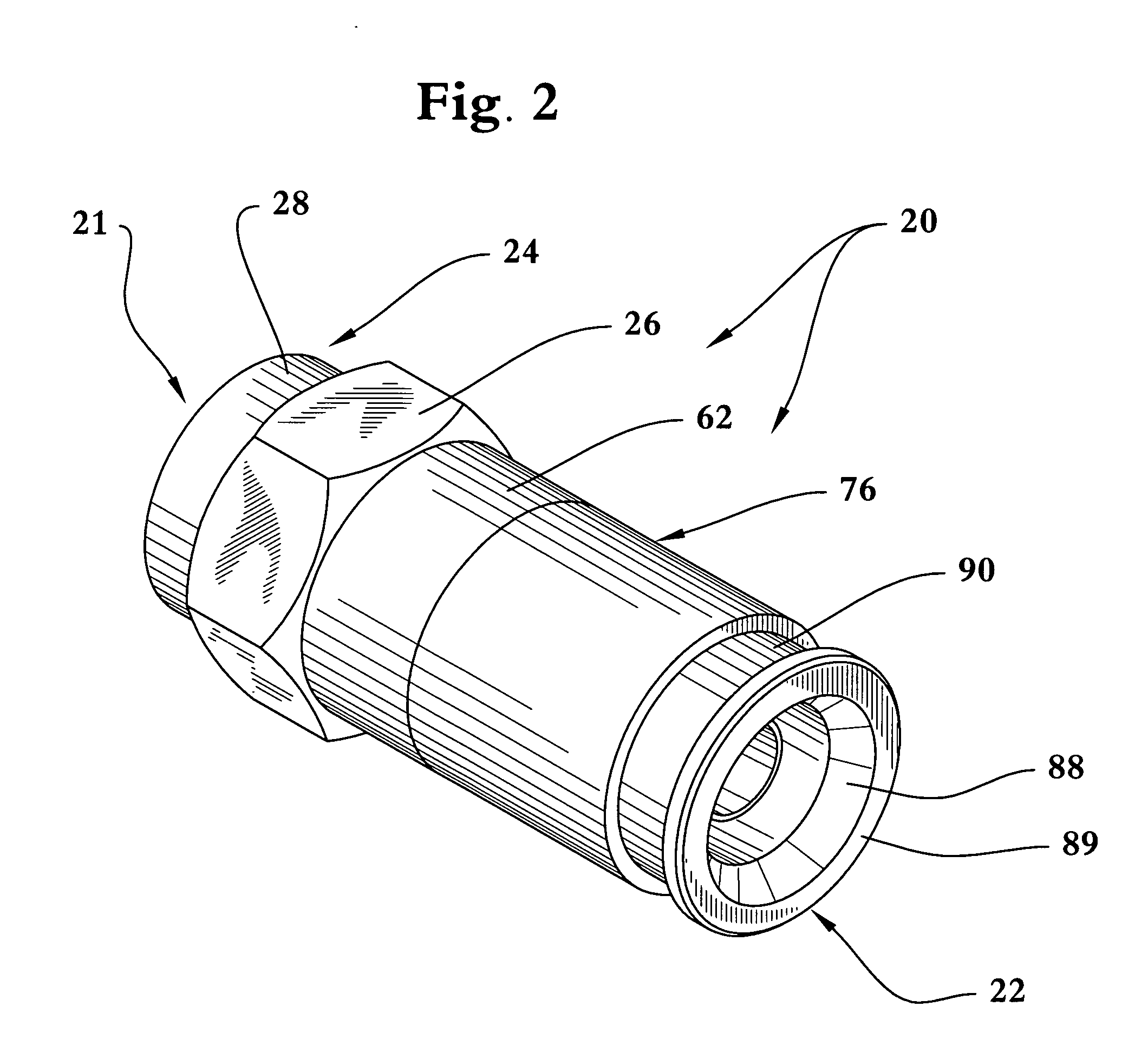

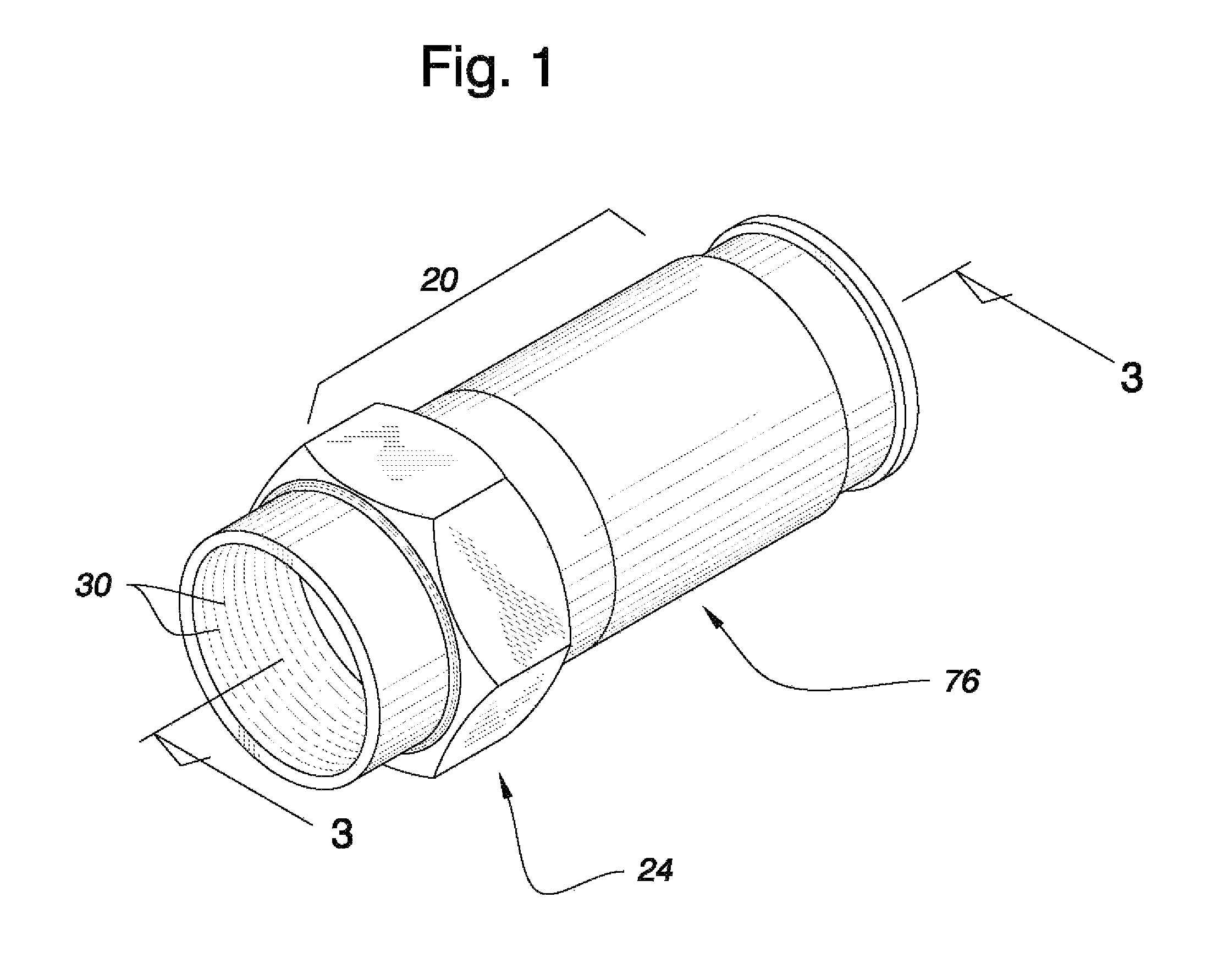

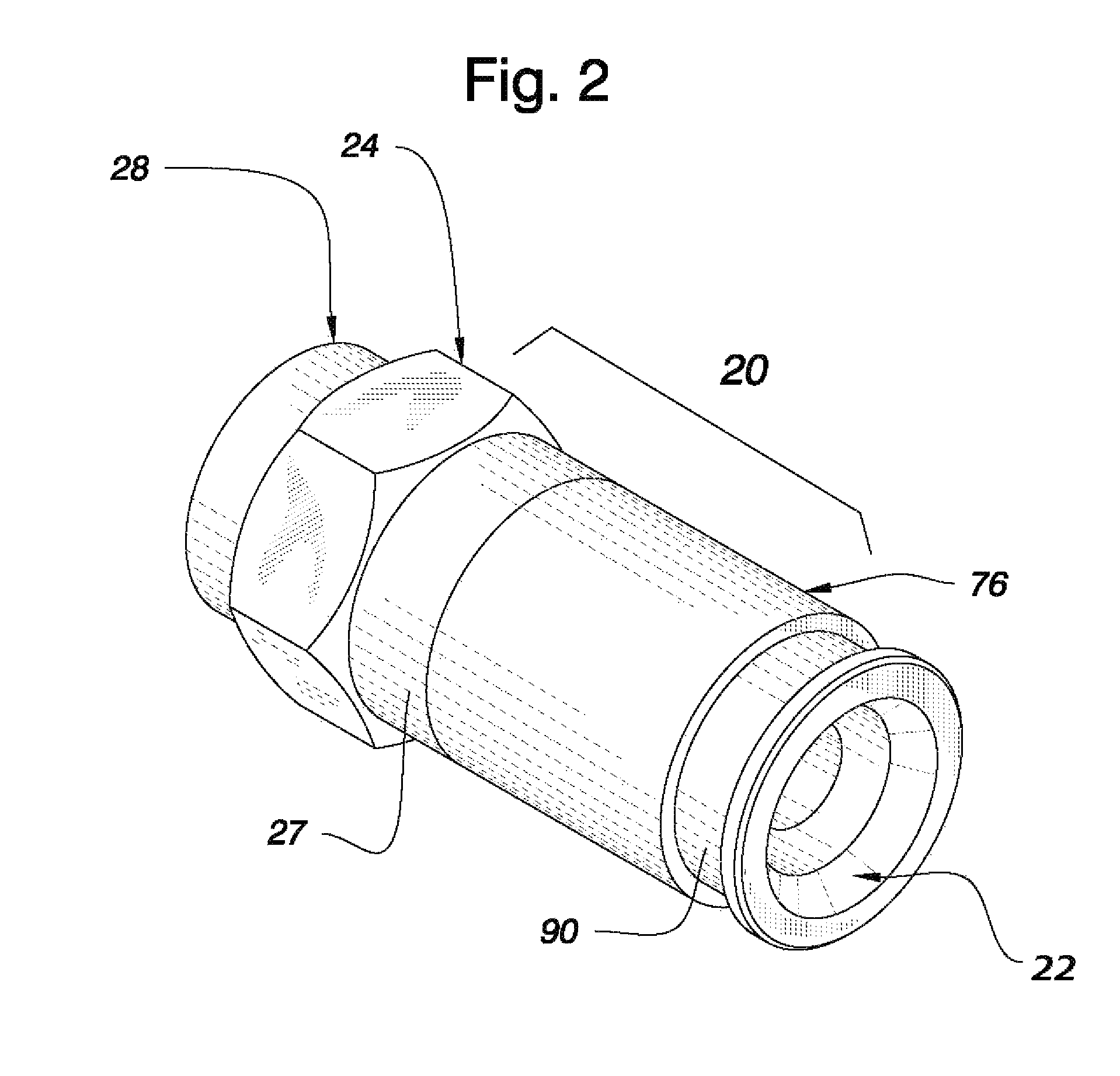

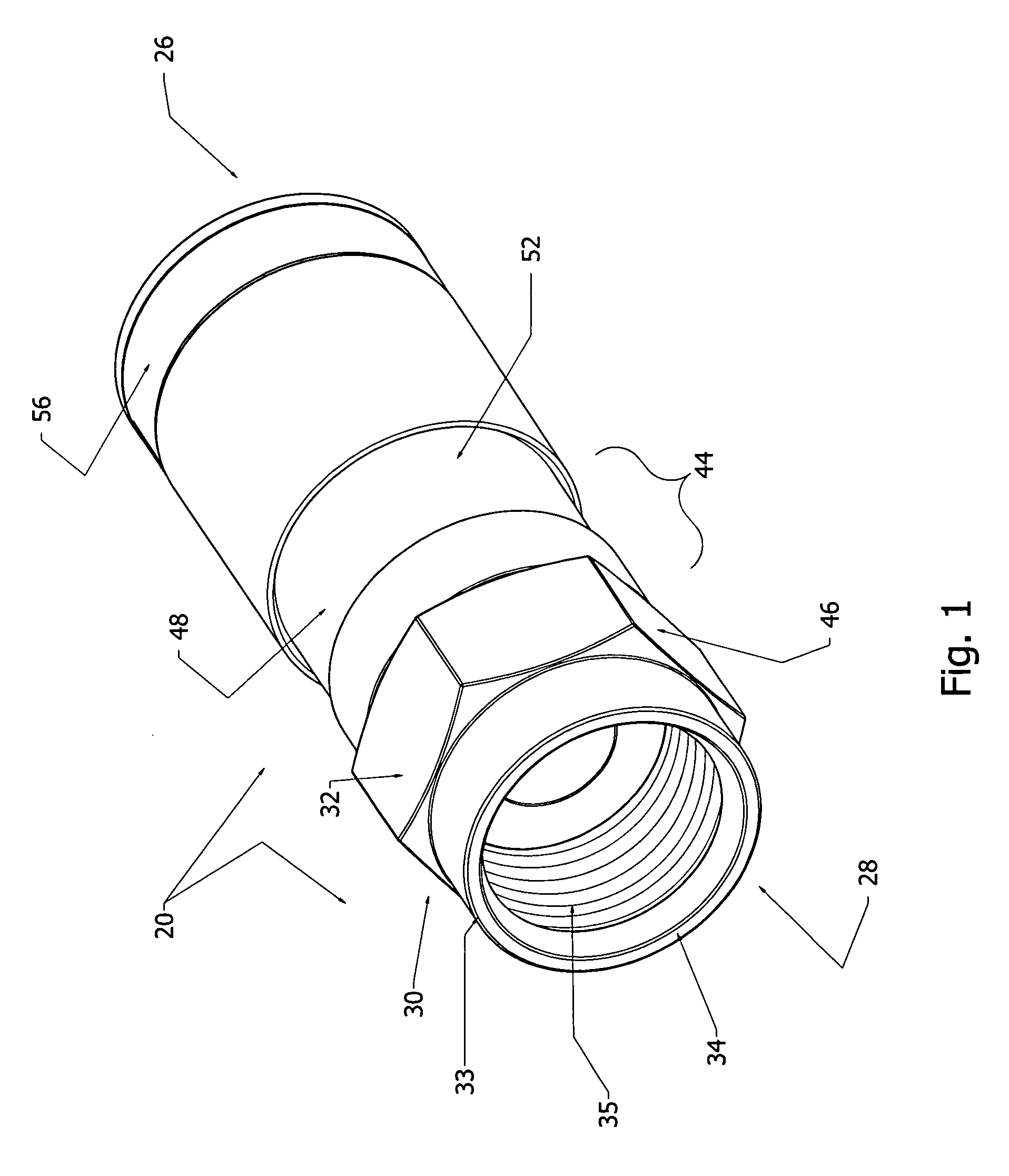

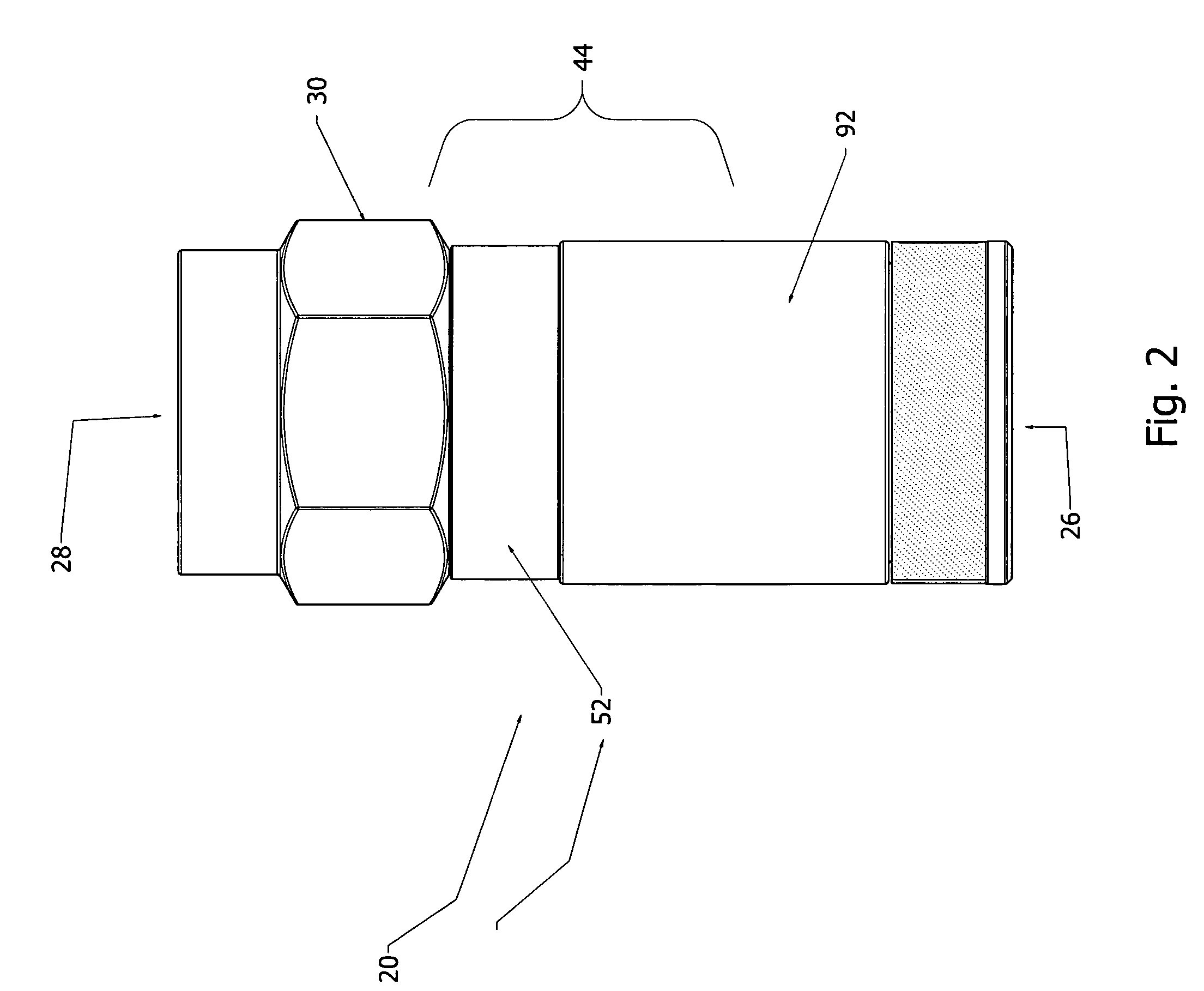

Compression type coaxial cable F-connectors

InactiveUS7513795B1The connection is tight and firmEasy to operate manuallyElectrically conductive connectionsCoupling device detailsHigh bandwidthEngineering

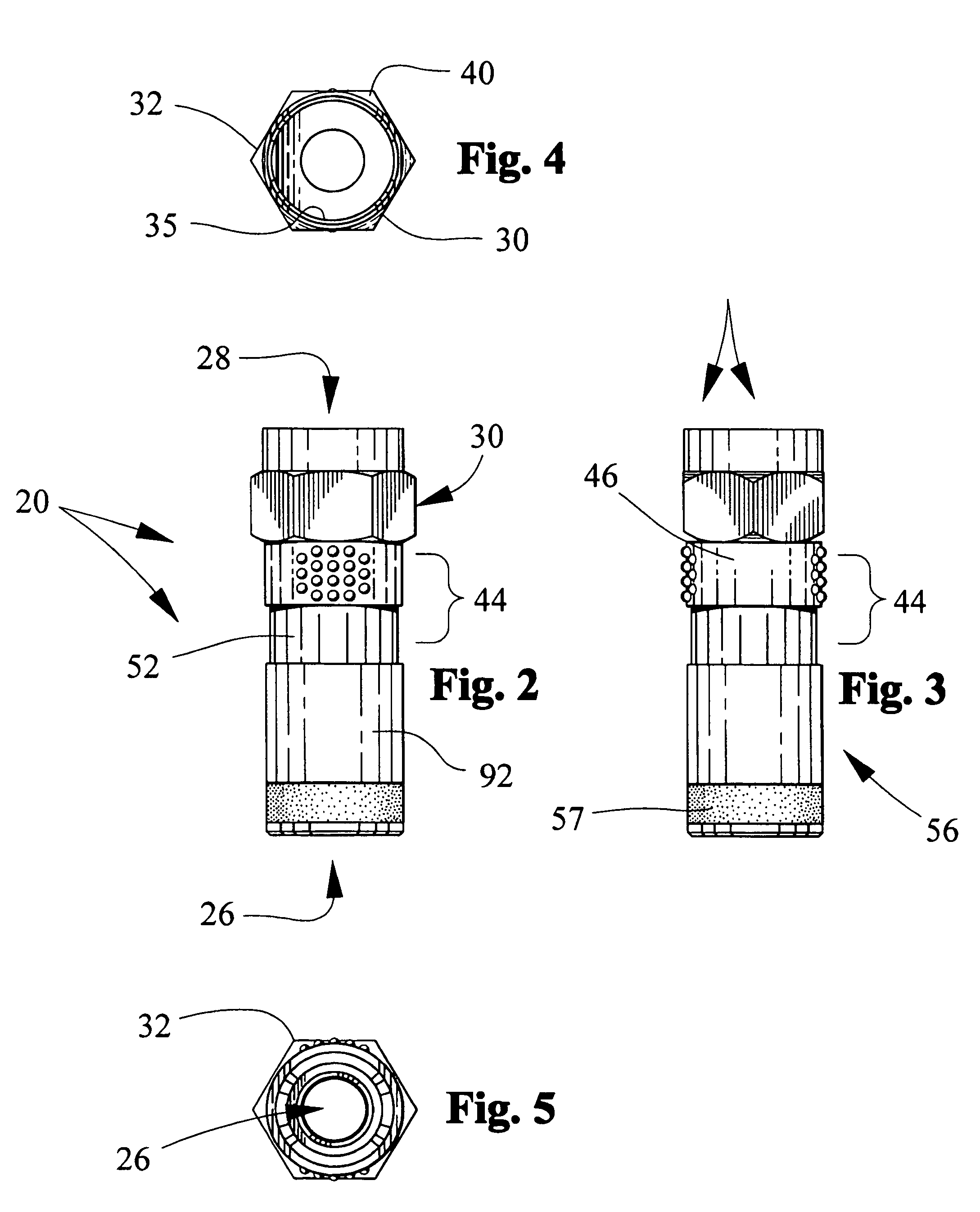

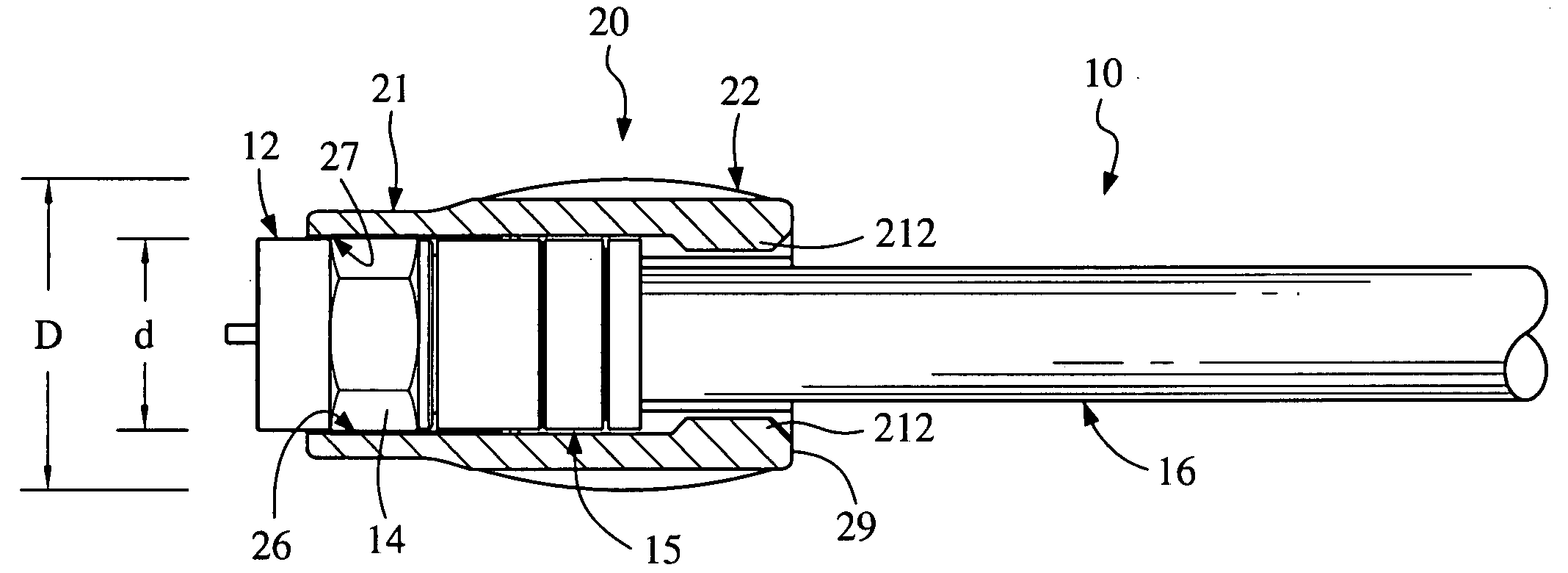

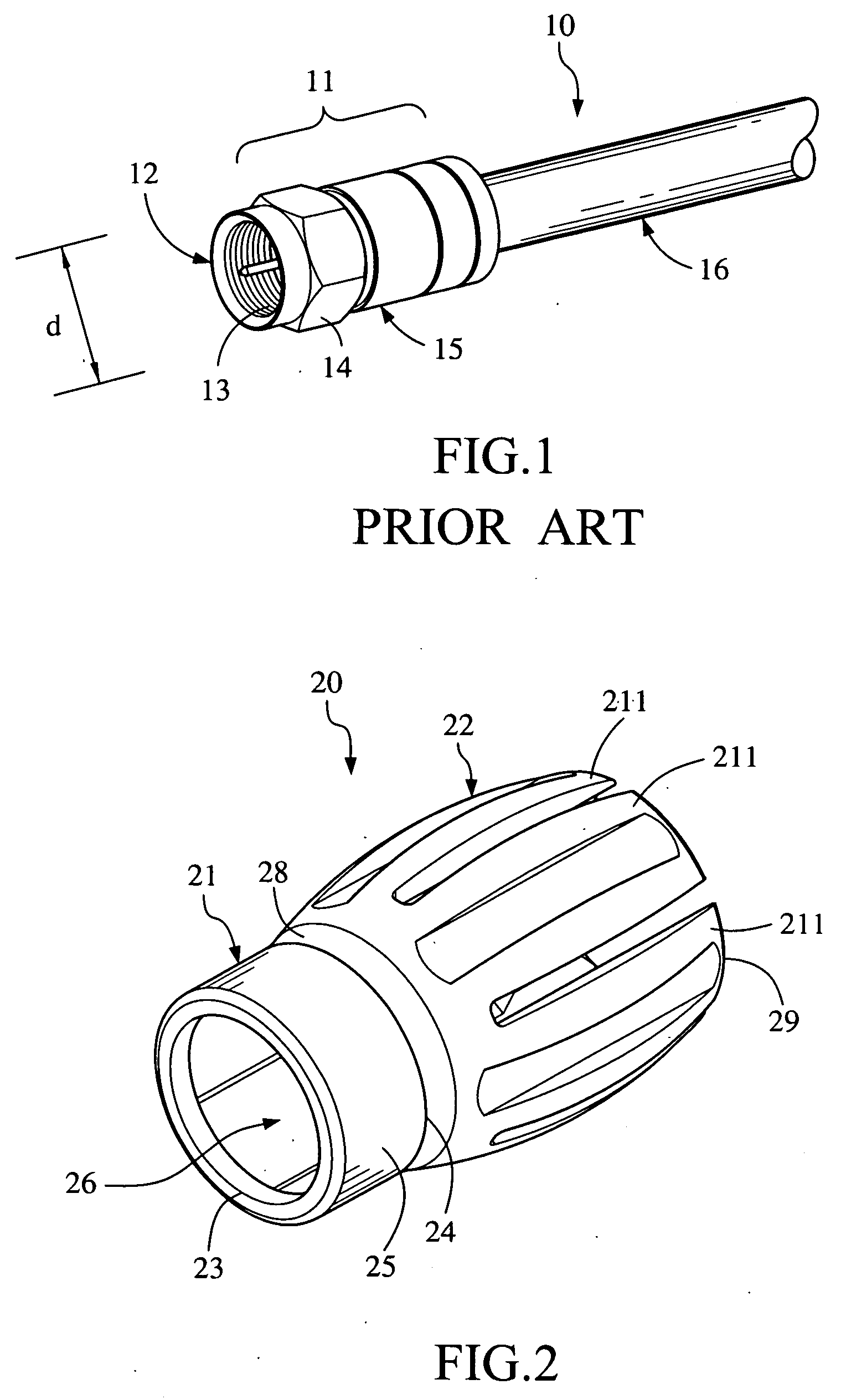

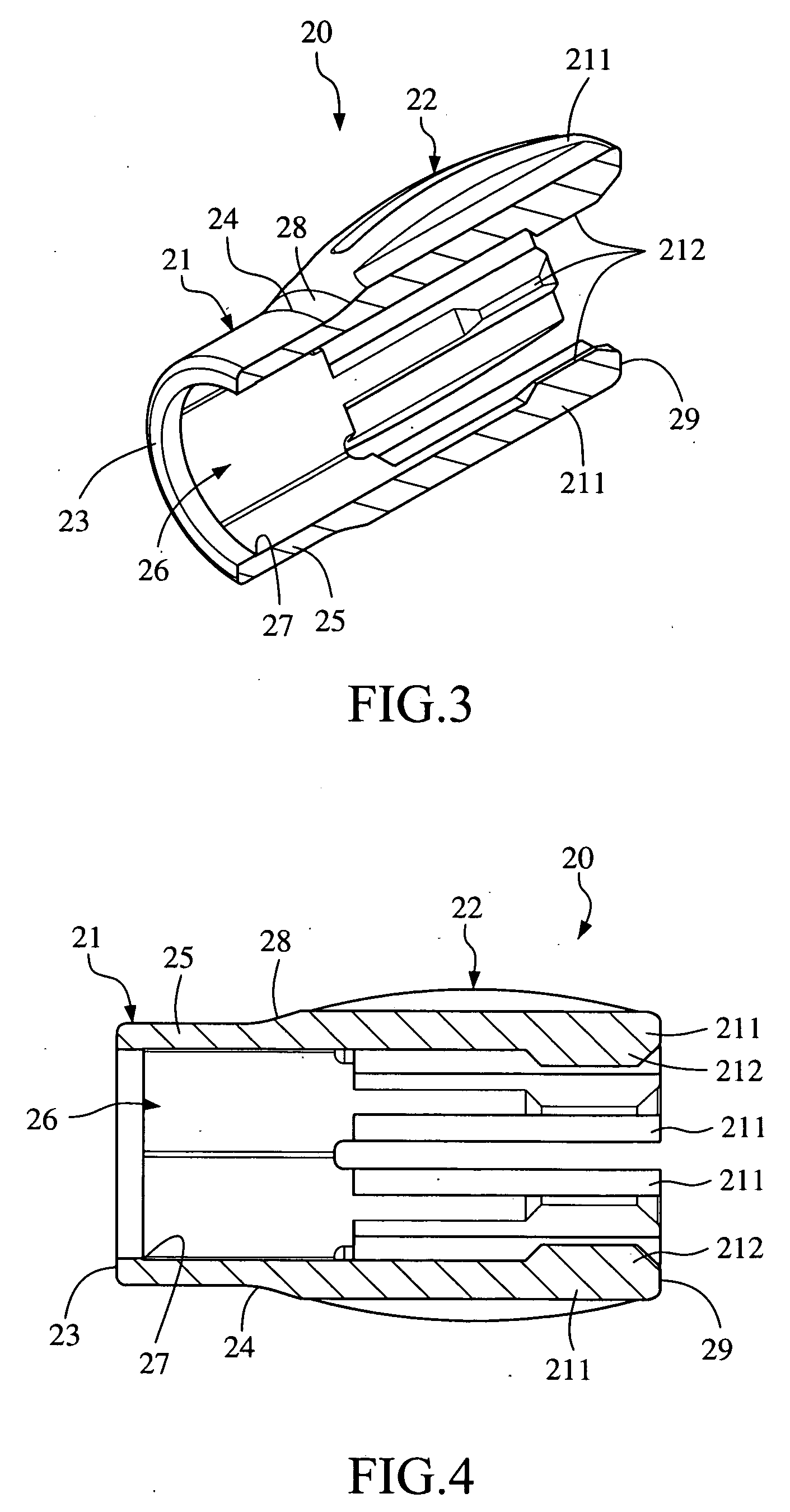

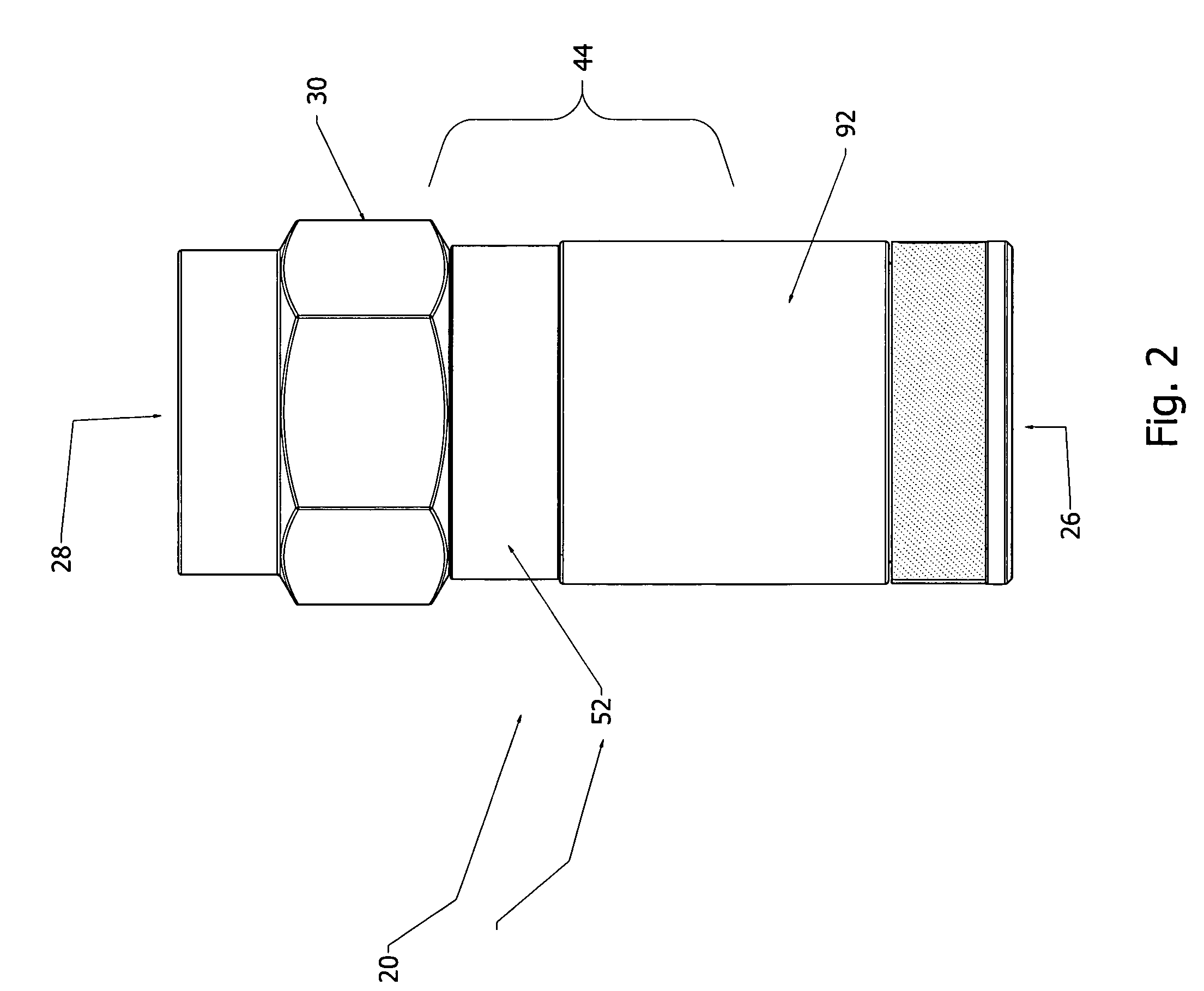

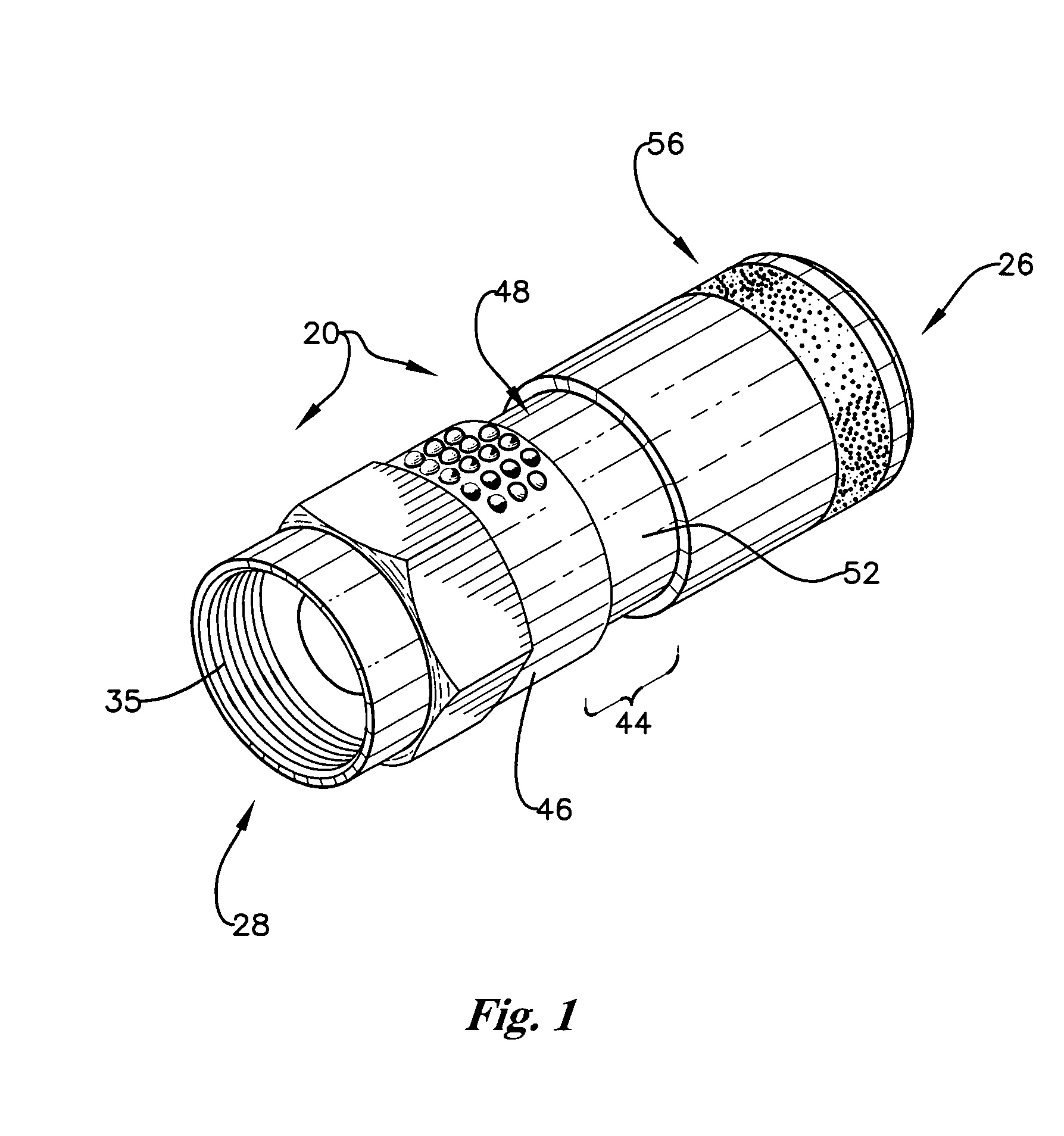

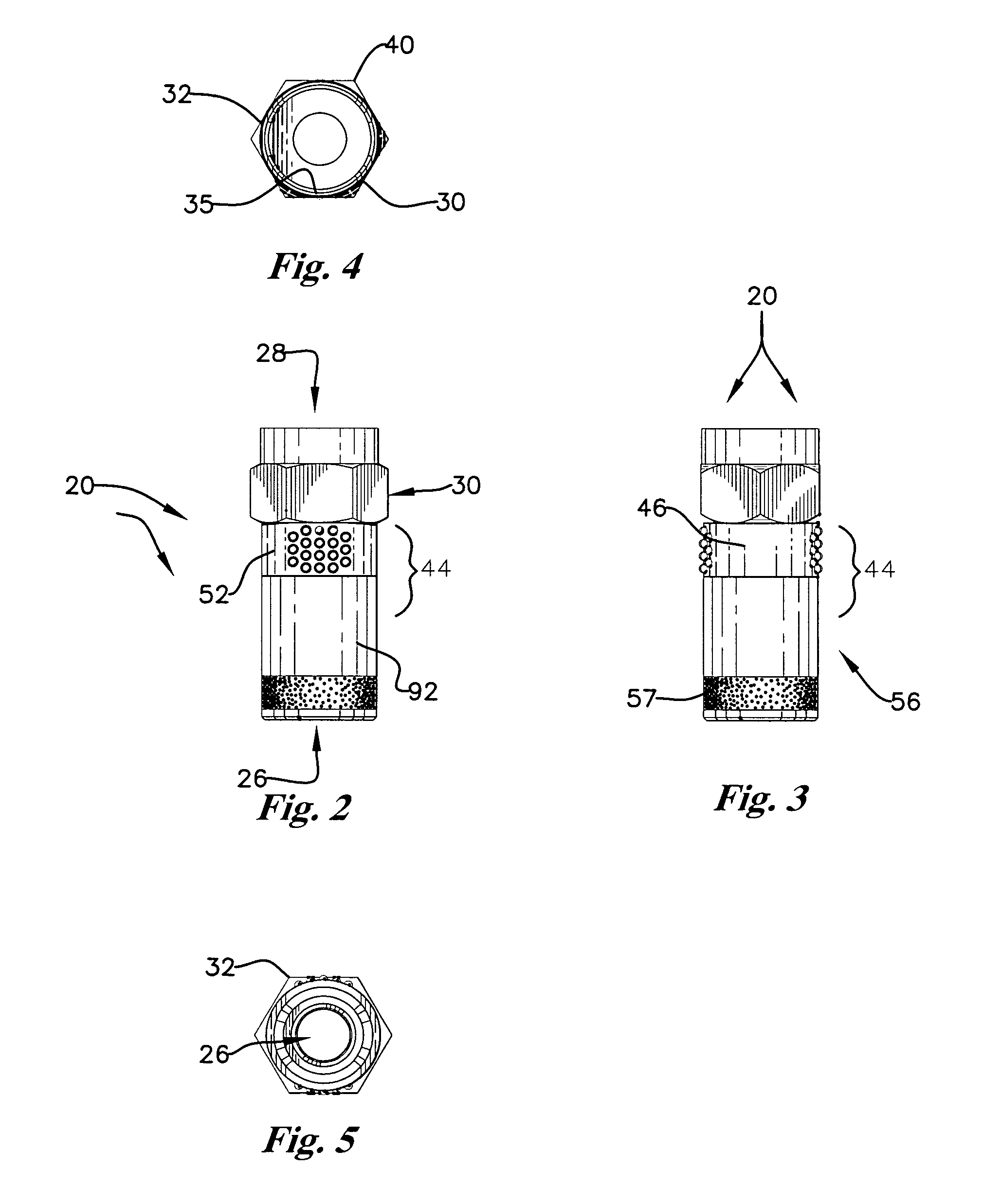

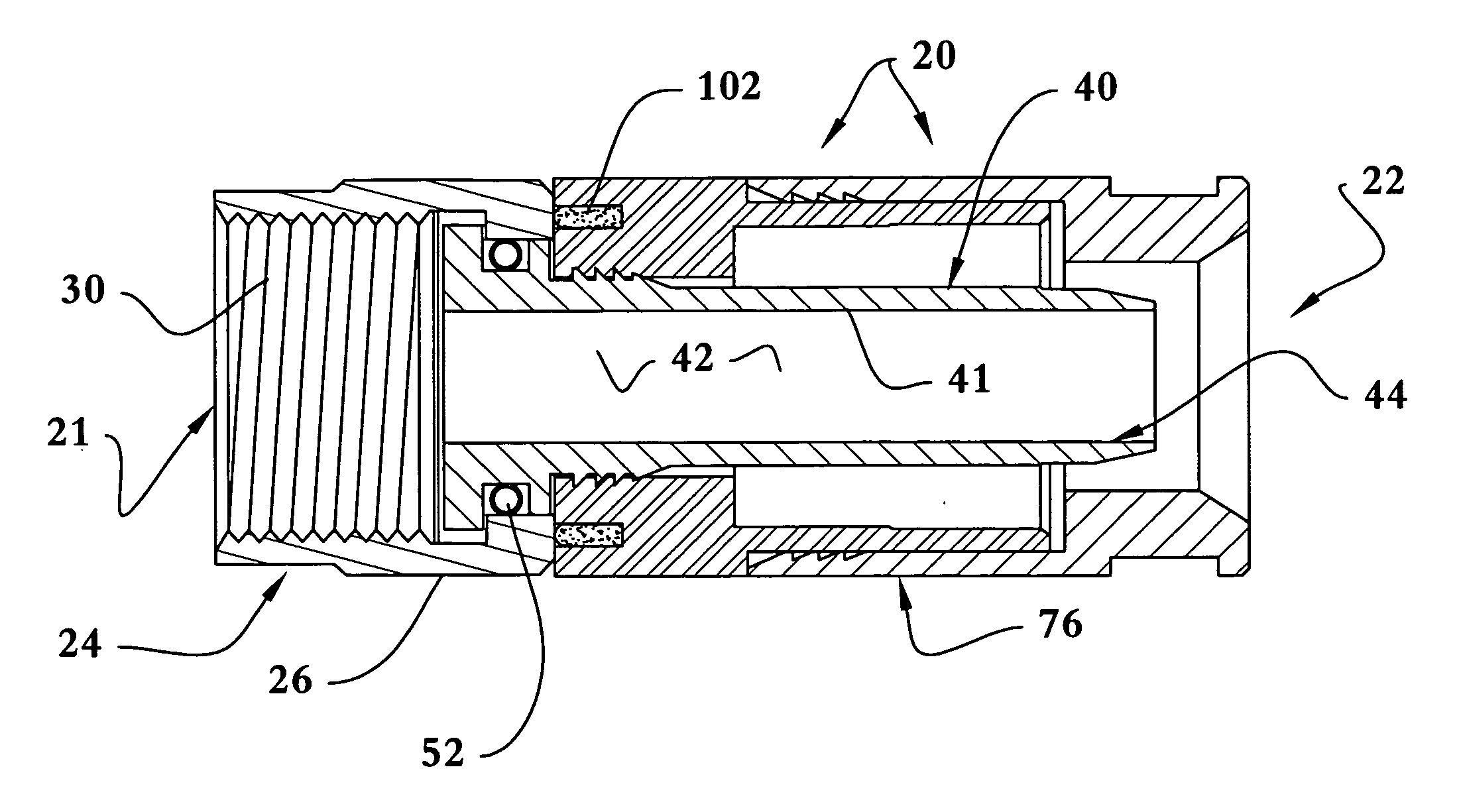

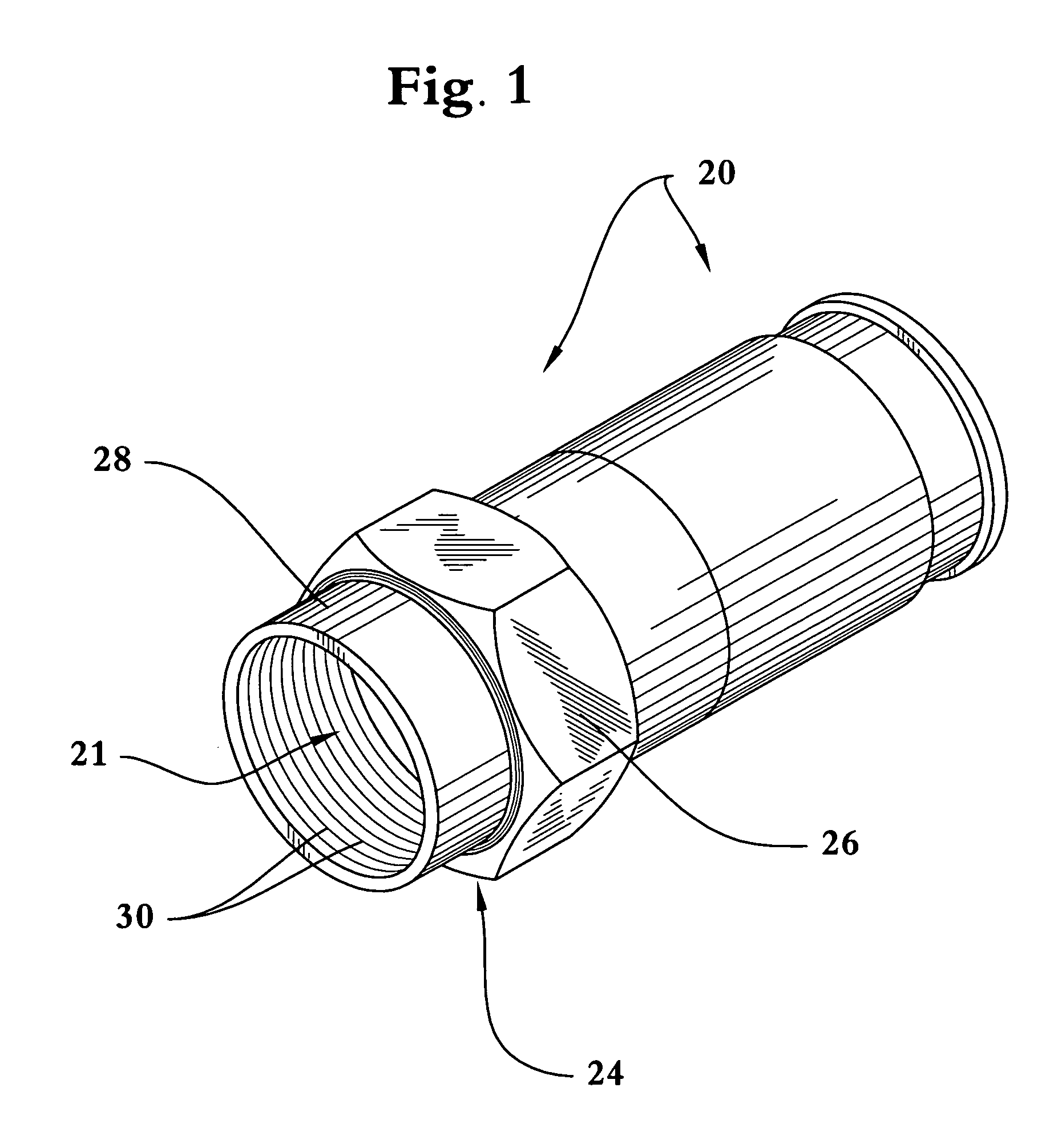

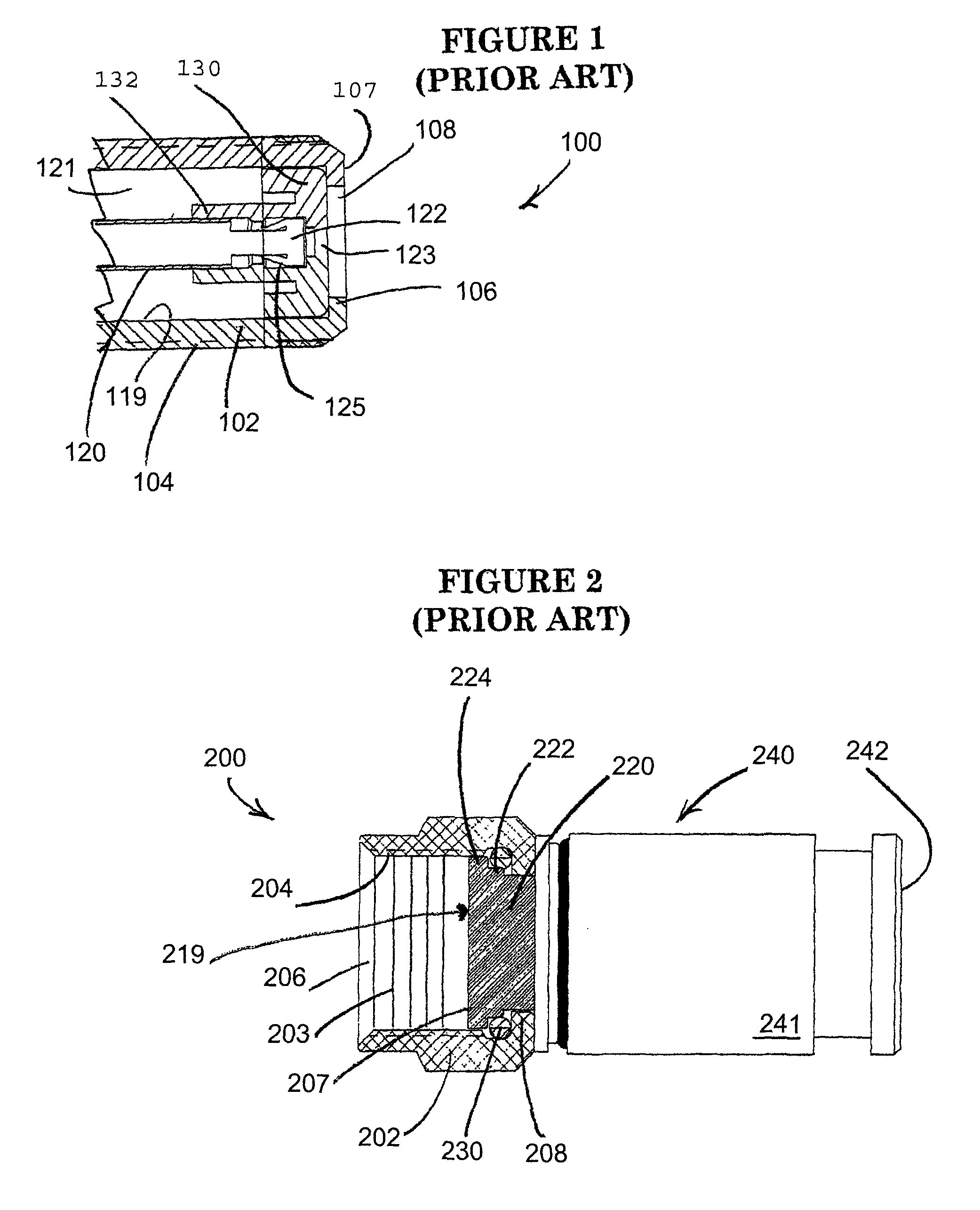

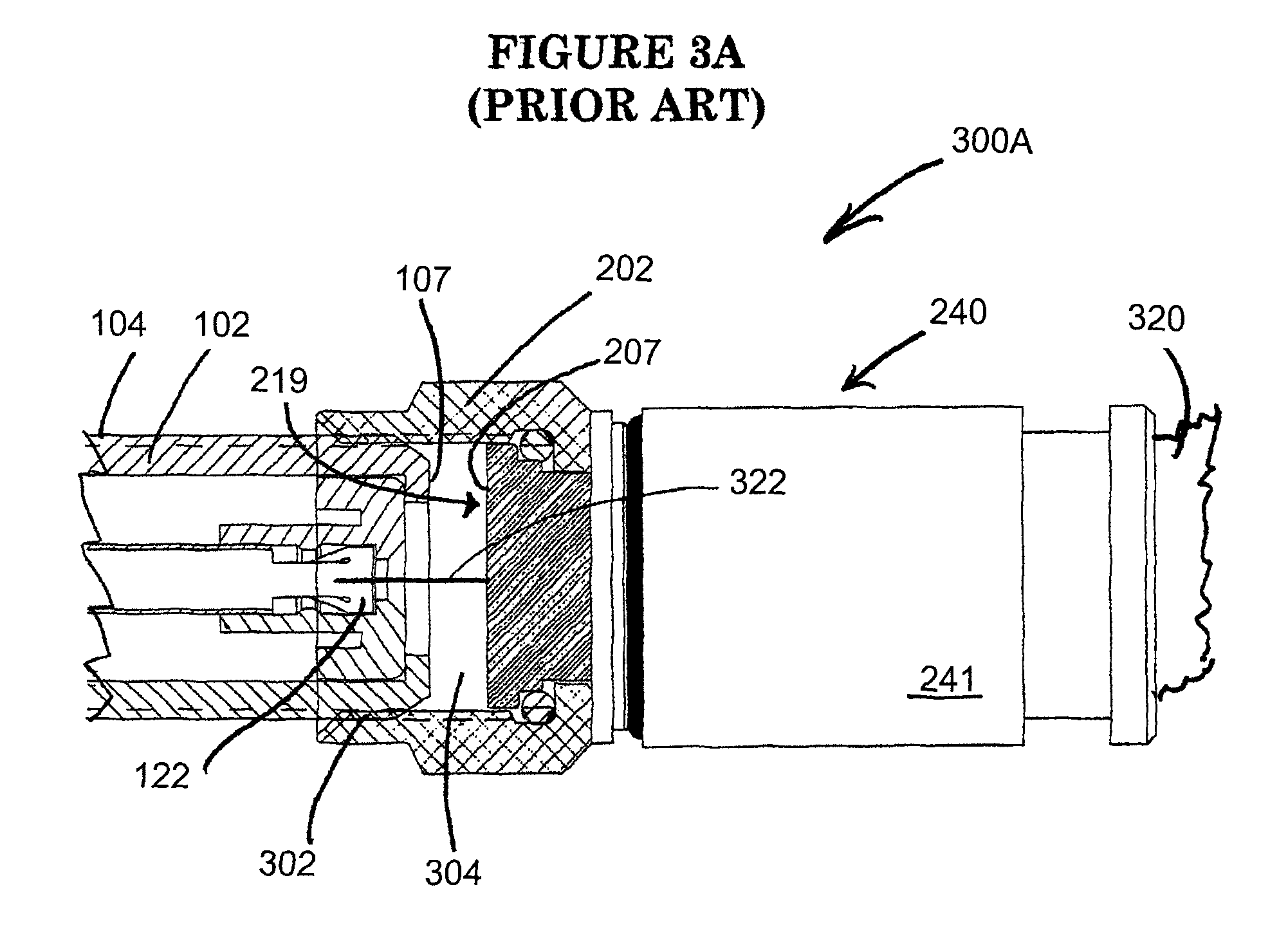

Axially compressible, high bandwidth F-connectors designed for conventional installation hand tools for interconnection with coaxial cable. Each connector has a rigid nut that is axially and rotatably secured to a molded plastic, tubular body. A rigid, conductive post coaxially extends through the connector, linking the nut and body. A post barbed end penetrates the cable within the connector. The body has a tubular shank with an obstruction-free surface and an integral stop ring. A tubular, metallic end cap is slidably fitted to the body shank, and thereafter forcibly compressed lengthwise, with travel limited by the stop ring. No detented structure is formed on the body, and the end cap can irreversibly assume any position, being held by end cap teeth. A tactile system comprising convex projections on the stop ring complemented by a resilient O-ring on the end cap helps installers determine correct placement through the sense of touch.

Owner:PERFECTVISION MFG

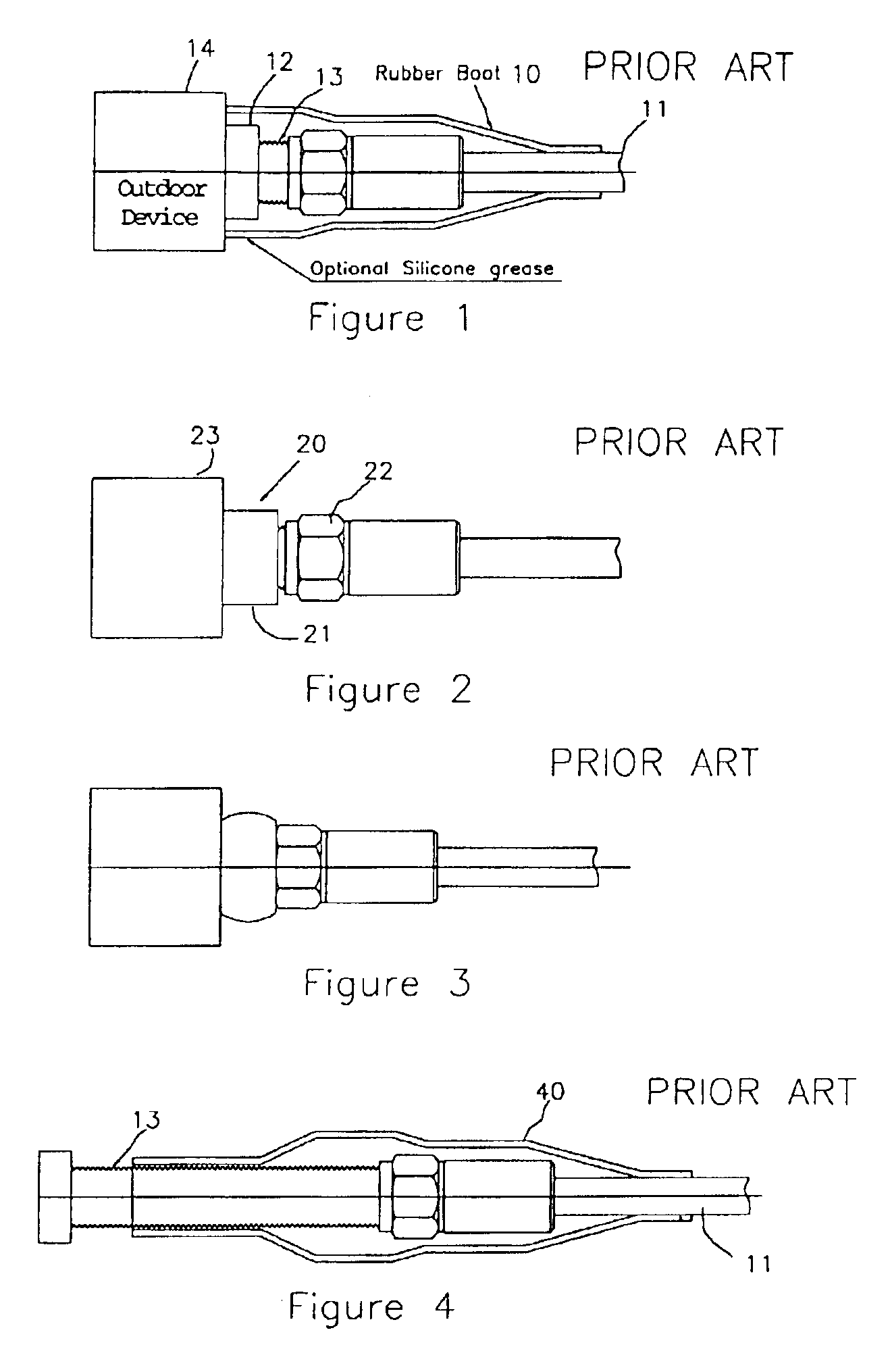

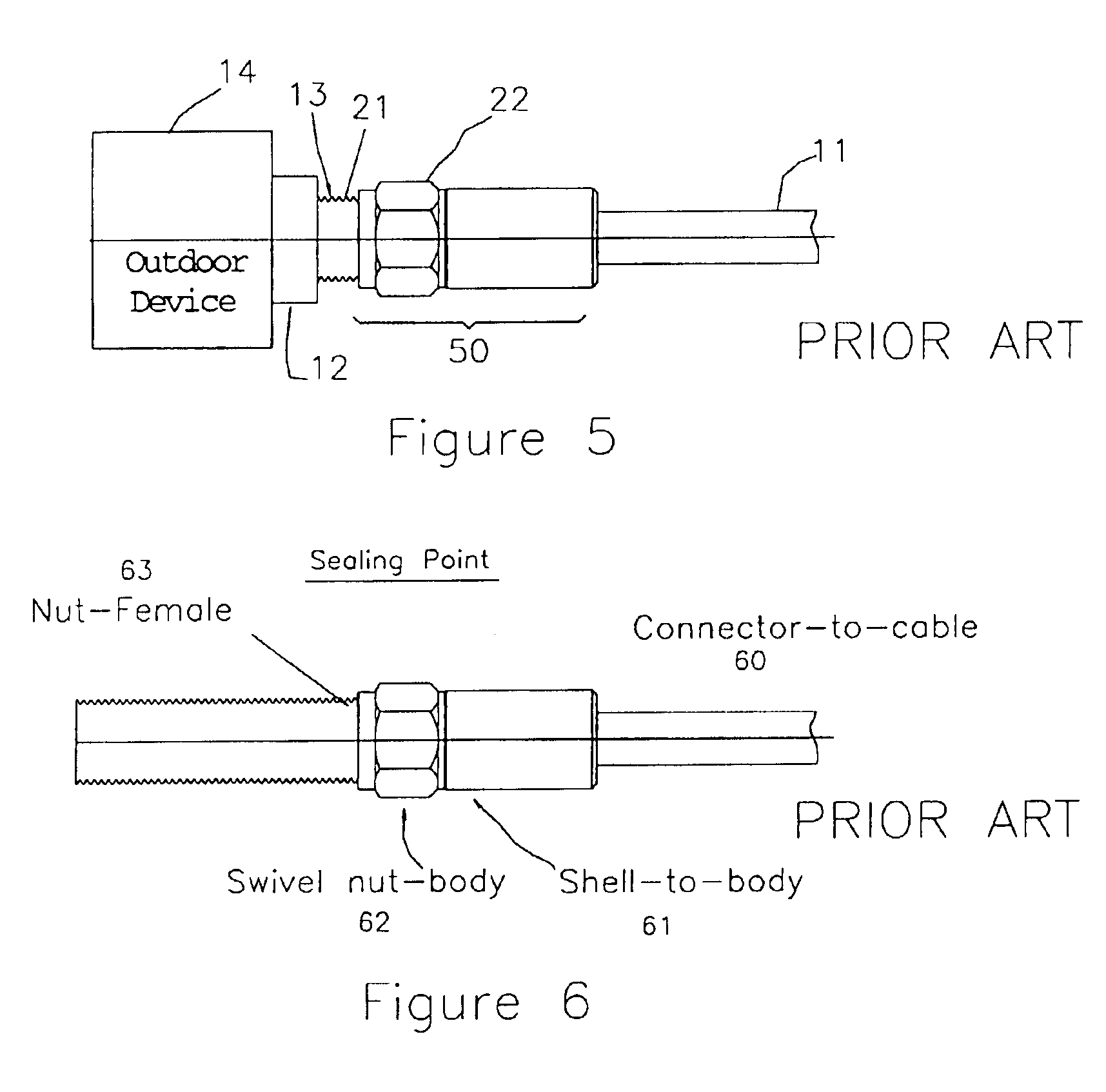

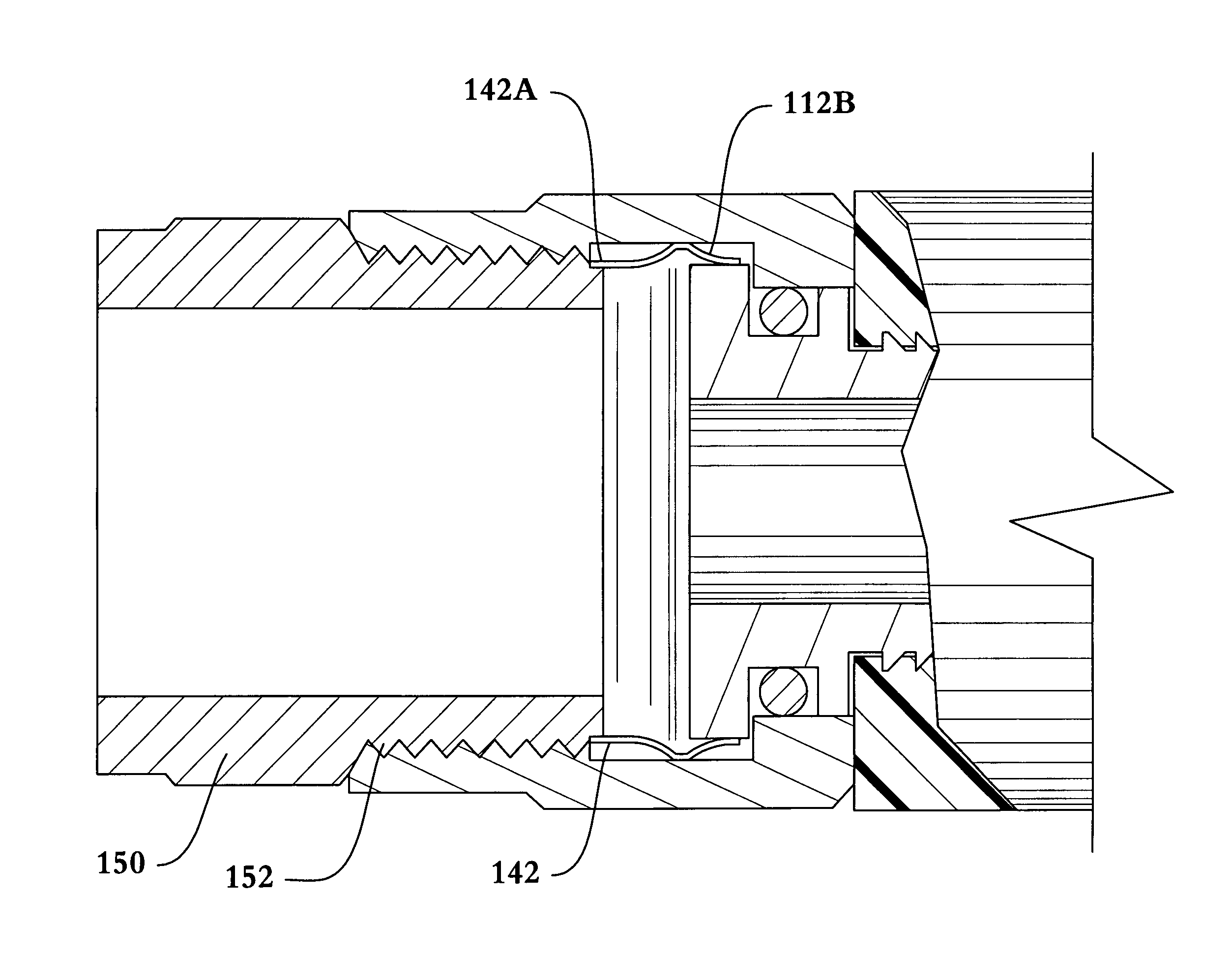

Moisture seal for an F-Type connector

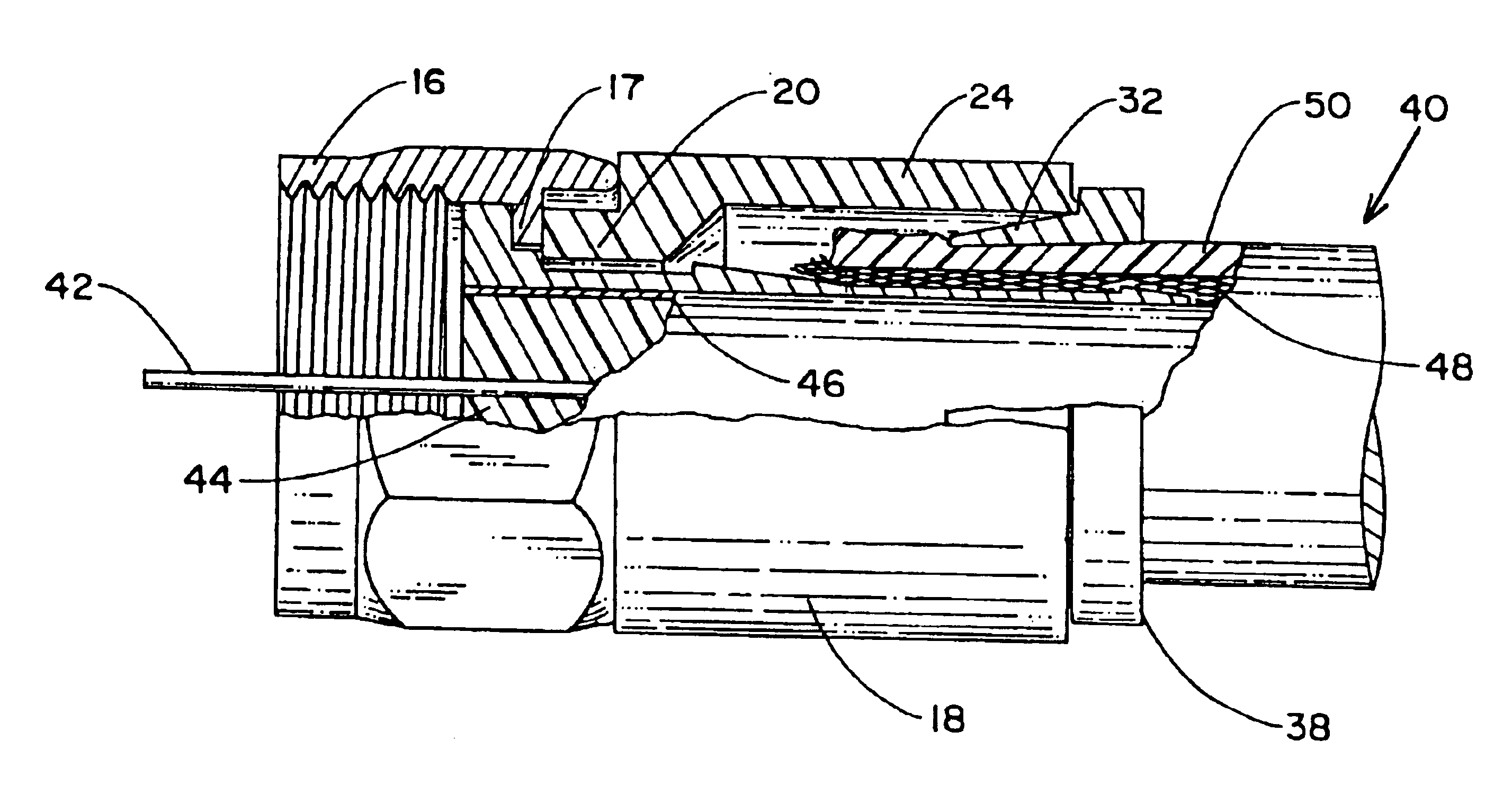

The invention provides a method for moisture sealing the interface between a nut on the leading end of a male F-Type connector and the threaded tubular shaft of the female F connector. The male connector is attached to a coaxial cable and the female is mounted to an outdoor device such as a cable TV splitter, grounding device, satellite dish, or distribution device, amplifier or group. The sealing device includes a compressible portion comprising an elastically compressible member having a cylindrical bore and a conical outer surface. An annular compression ring overlies a portion of the conical outer surface of the compressible portion. The compressible portion is compressed radially inwardly against the shaft of the female F-Type connector as the leading edge of the male F nut is screwed onto the female threaded shaft of the female F-Type connector, providing a pressurized moisture ingress barrier. The compressible portion may have internal 3 / 8-32 threads to mate with threads on the shaft for a more secure seal.

Owner:HOLLAND ELECTRONICS

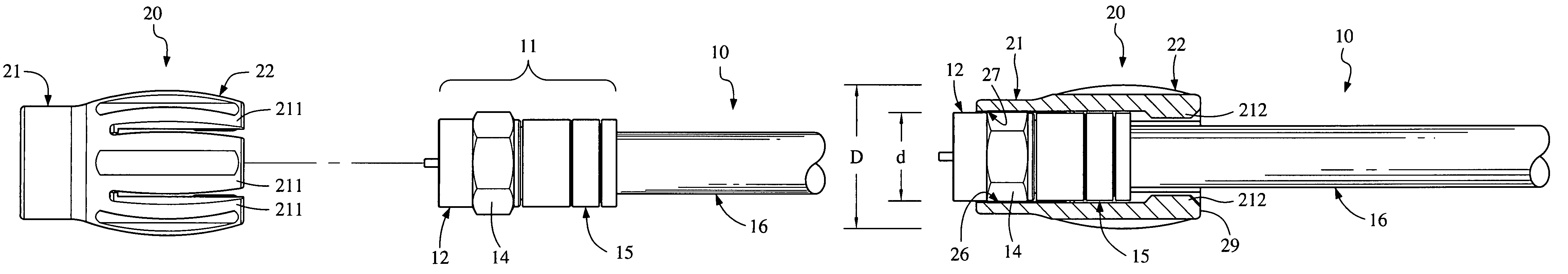

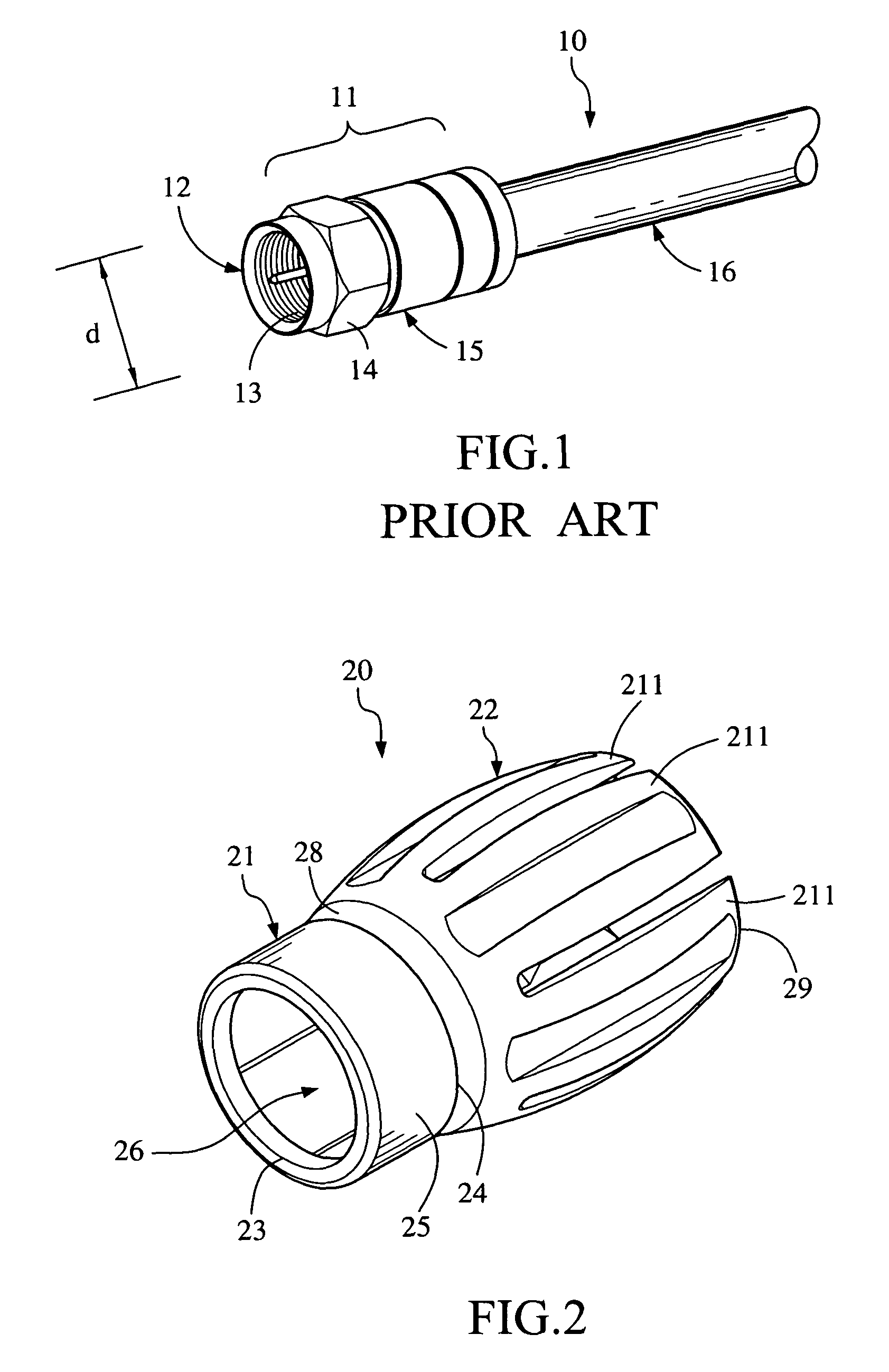

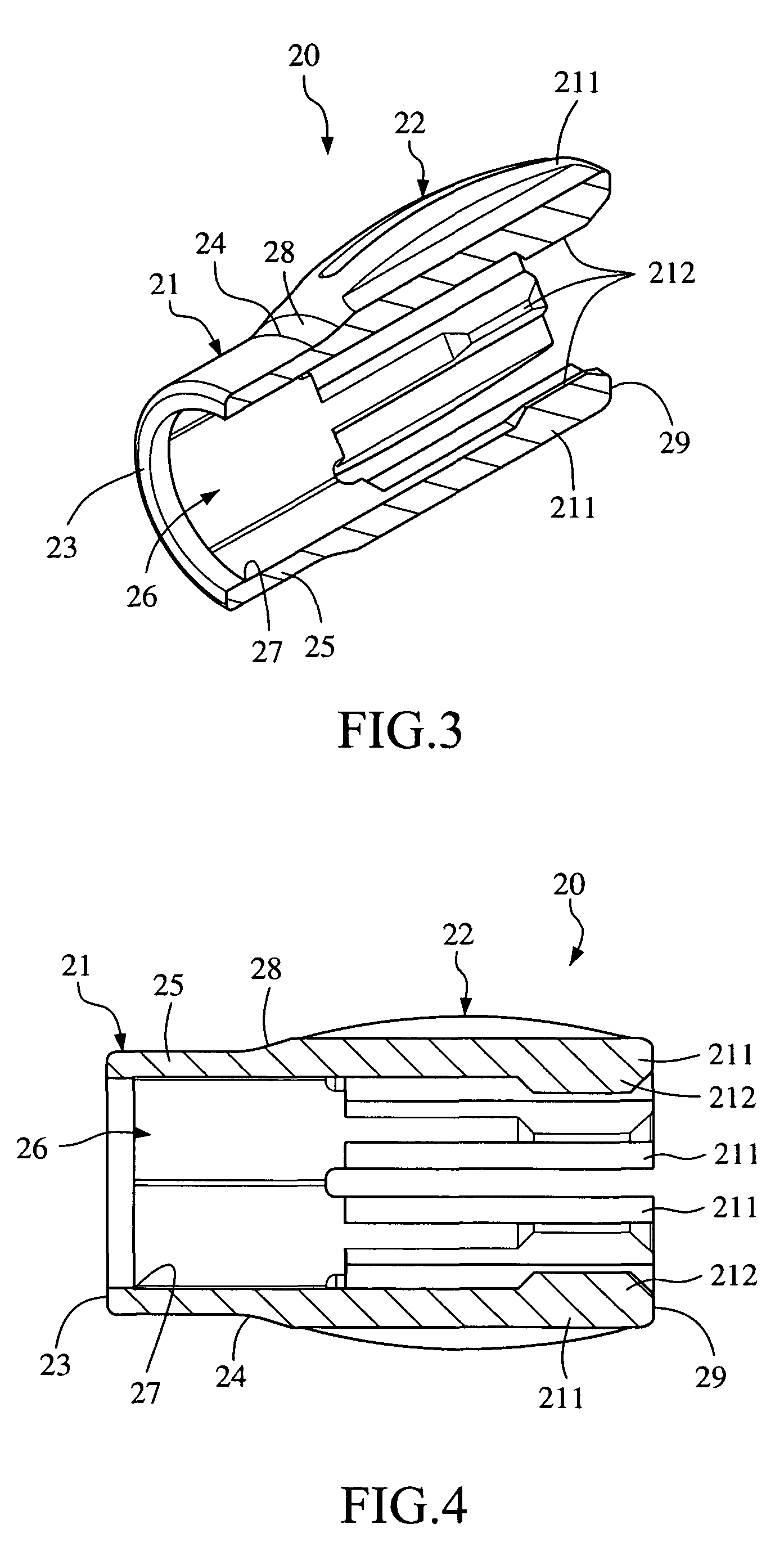

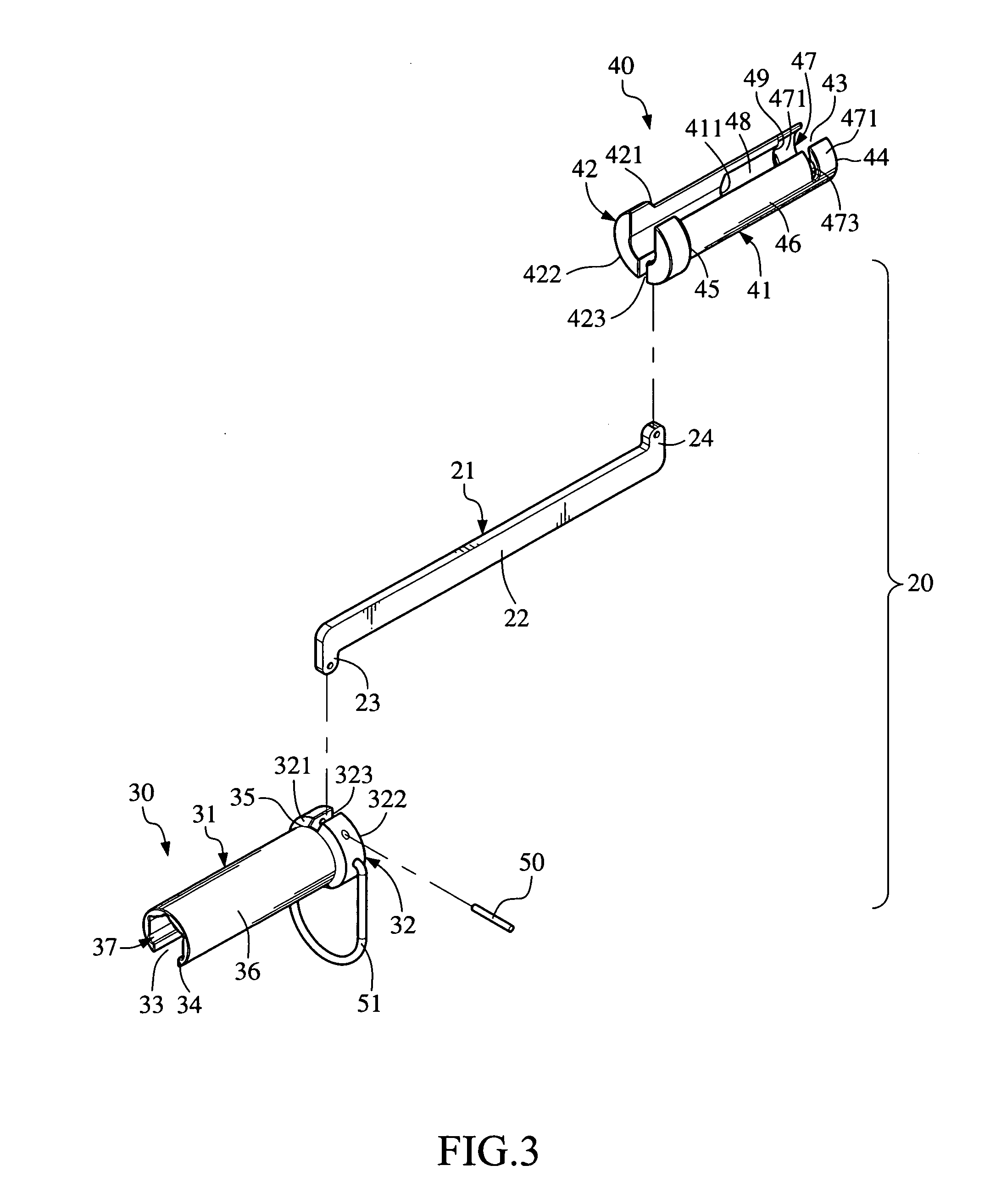

Jumper sleeve for connecting and disconnecting male f connector to and from female f connector

ActiveUS20100233902A1Firmly connectedElectrically conductive connectionsTwo pole connectionsEngineeringMechanical advantage

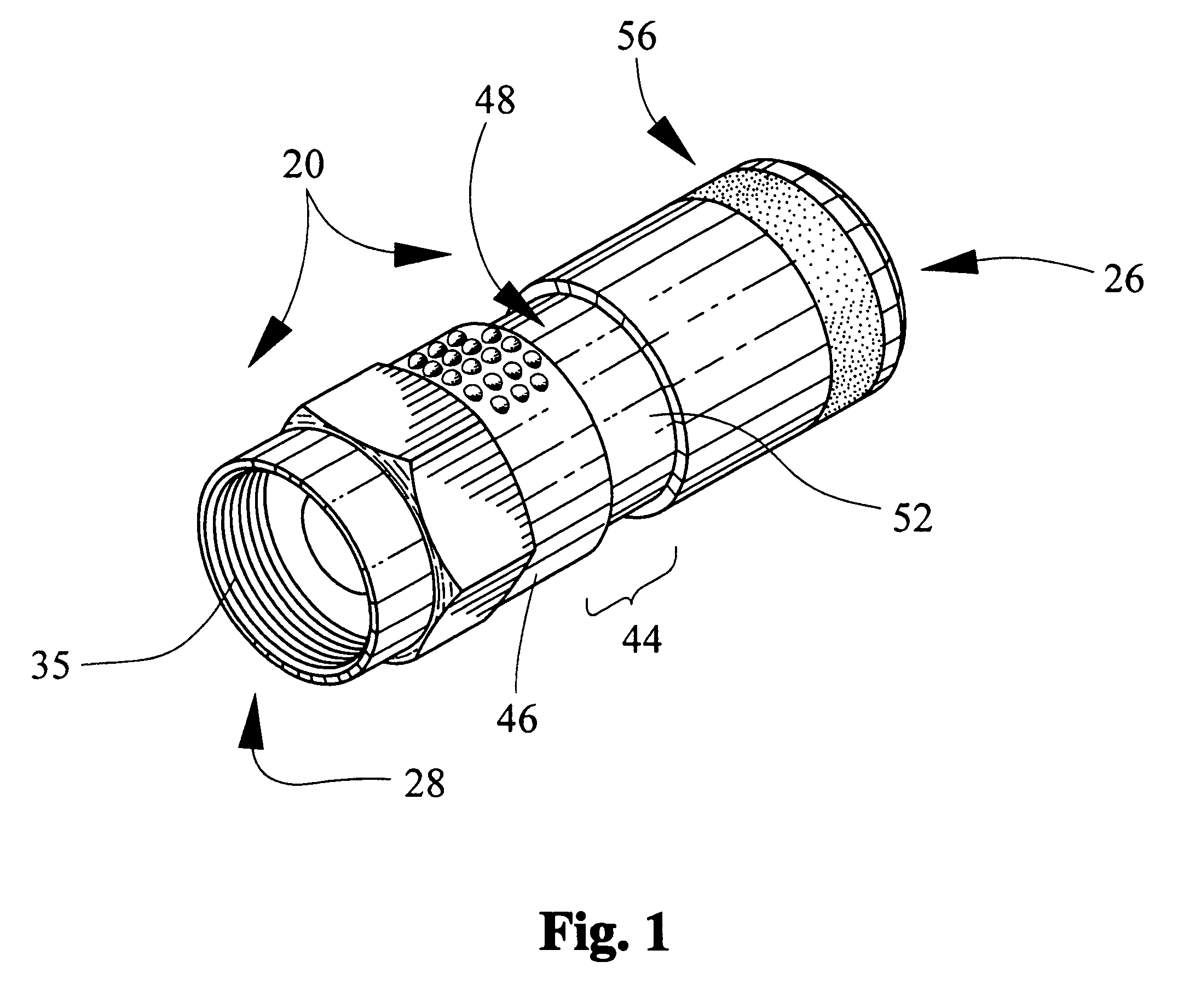

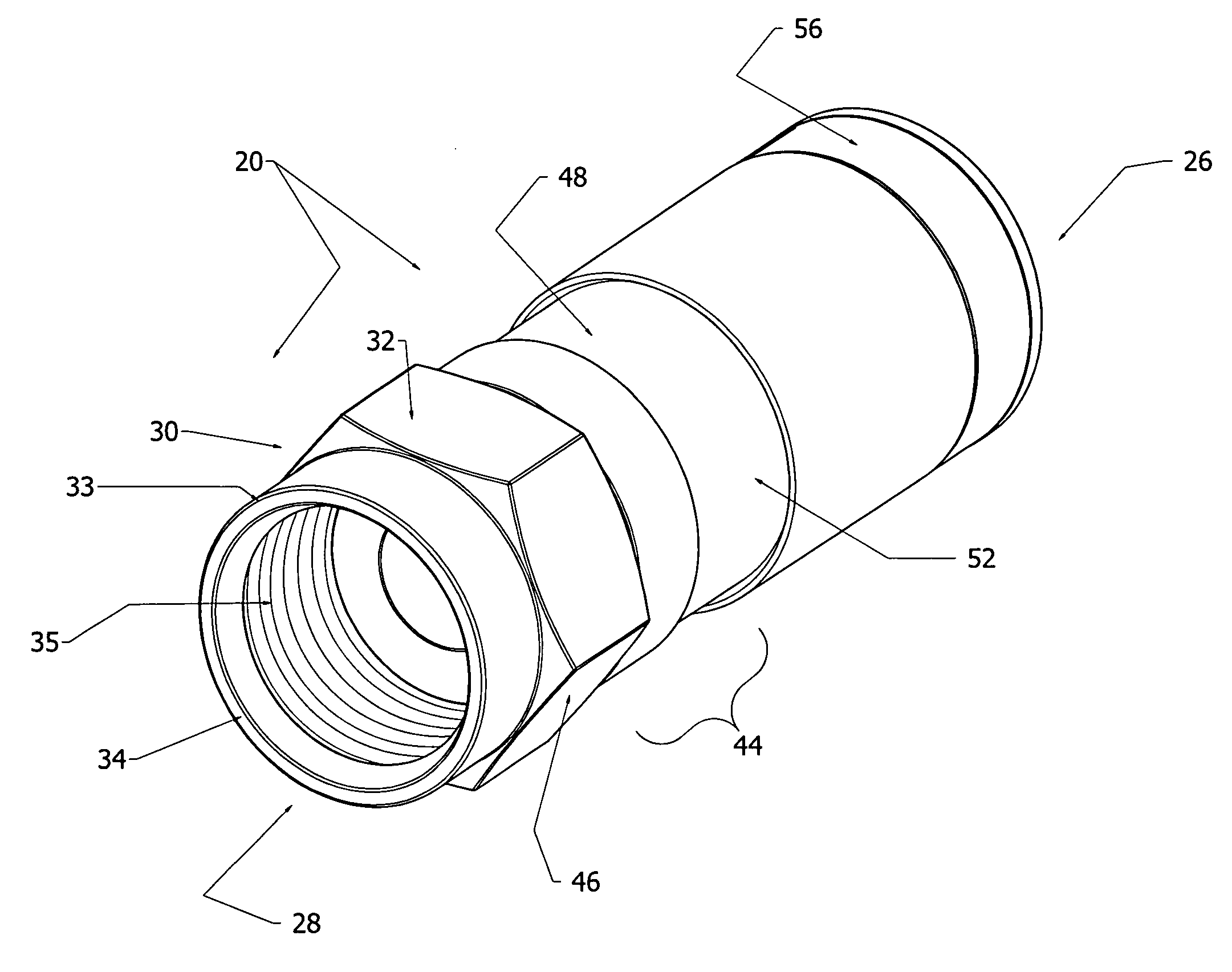

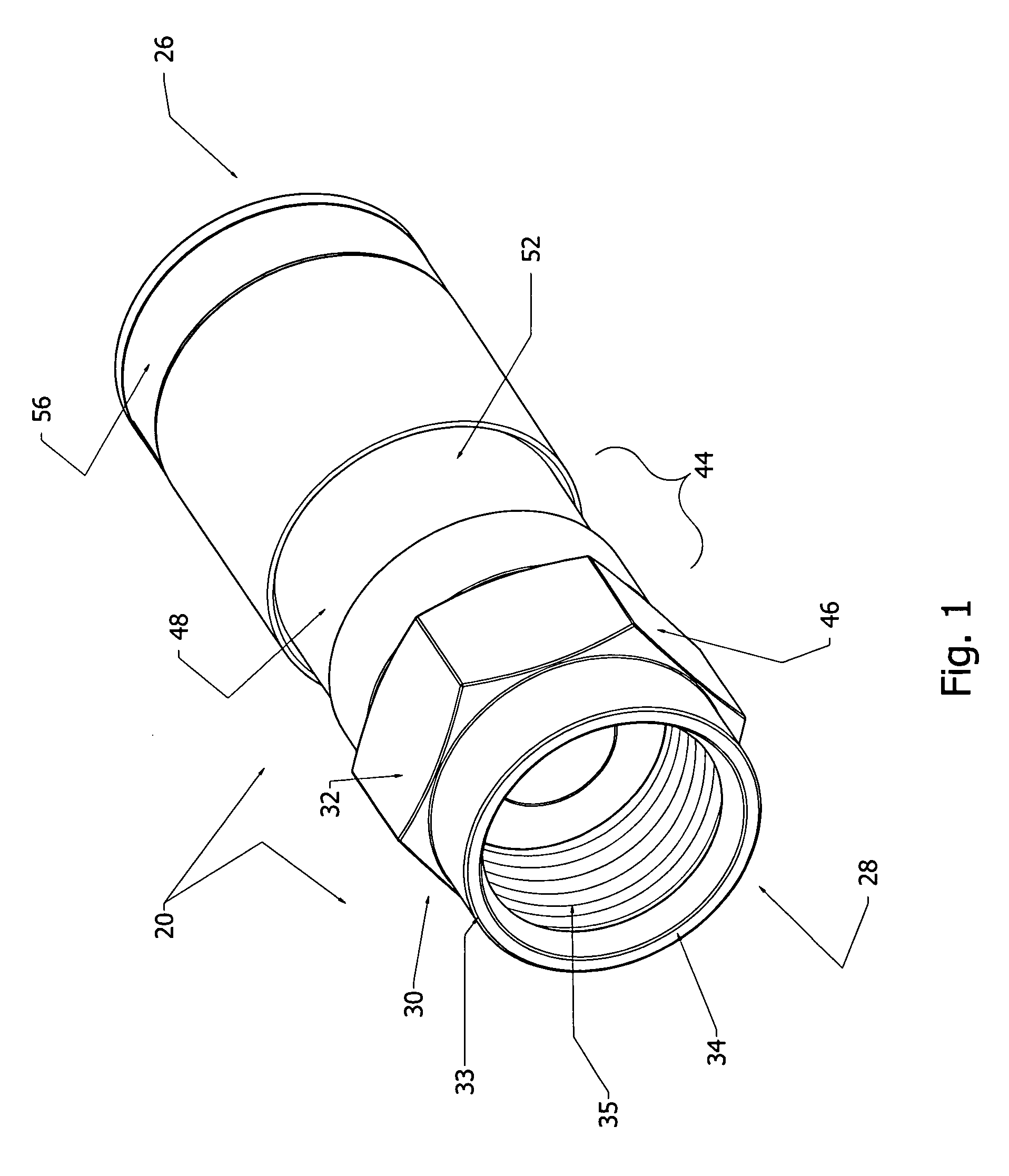

A jumper sleeve for connecting and disconnecting a male F connector to and from a female F connector includes a wrench portion and a grip portion. The wrench portion has a leading end, a trailing end, and a hollow main body located between the leading end and the trailing end. The main body of the wrench portion internally has a hexagonally shaped portion corresponding to a shaped outer surface of a rotatable connecting ring of the male F connector. The grip portion has a rear end and a front end connected to the trailing end of the wrench portion, and has a plurality of circumferentially spaced externally convex sections, each of which has a radially inward key formed near the rear end thereof. The jumper sleeve provides greater mechanical advantage to produce sufficient torsion force, enabling easy installation and removal of the male F connector.

Owner:PHOENIX COMM TECH INTIOAL

Jumper sleeve for connecting and disconnecting male F connector to and from female F connector

ActiveUS7837501B2Electrically conductive connectionsTwo pole connectionsEngineeringMechanical advantage

A jumper sleeve for connecting and disconnecting a male F connector to and from a female F connector includes a wrench portion and a grip portion. The wrench portion has a leading end, a trailing end, and a hollow main body located between the leading end and the trailing end. The main body of the wrench portion internally has a hexagonally shaped portion corresponding to a shaped outer surface of a rotatable connecting ring of the male F connector. The grip portion has a rear end and a front end connected to the trailing end of the wrench portion, and has a plurality of circumferentially spaced externally convex sections, each of which has a radially inward key formed near the rear end thereof. The jumper sleeve provides greater mechanical advantage to produce sufficient torsion force, enabling easy installation and removal of the male F connector.

Owner:PHOENIX COMM TECH INTIOAL

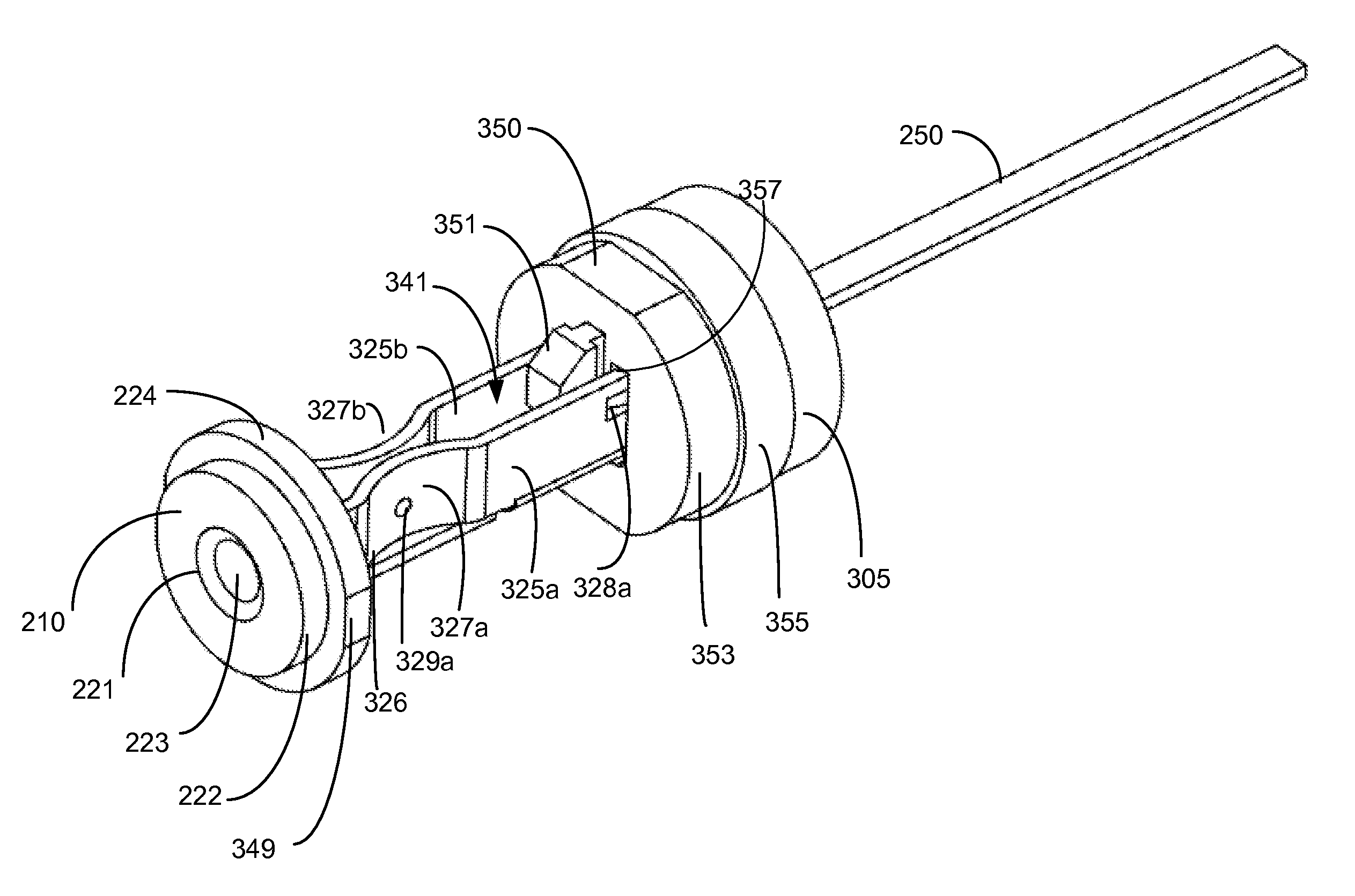

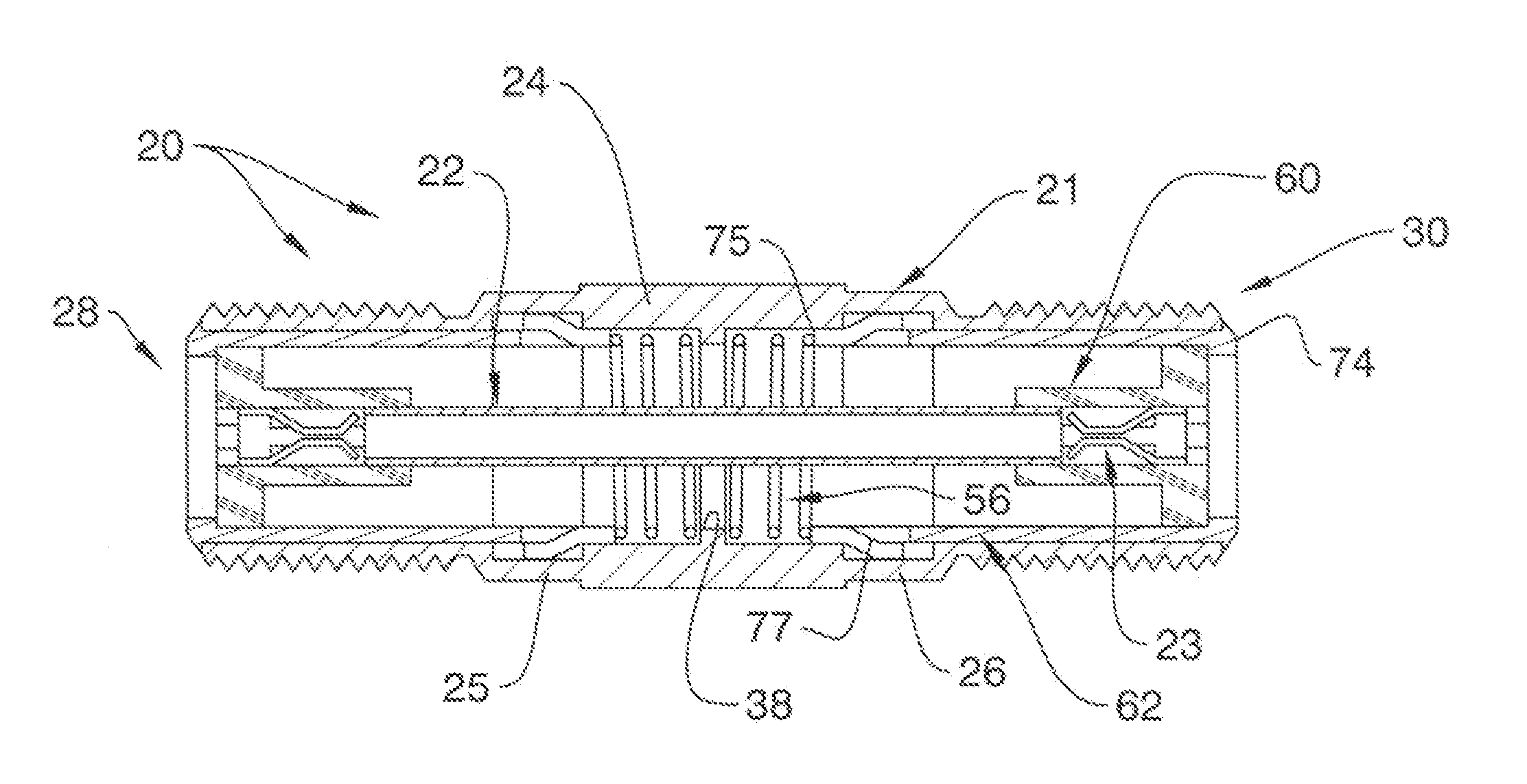

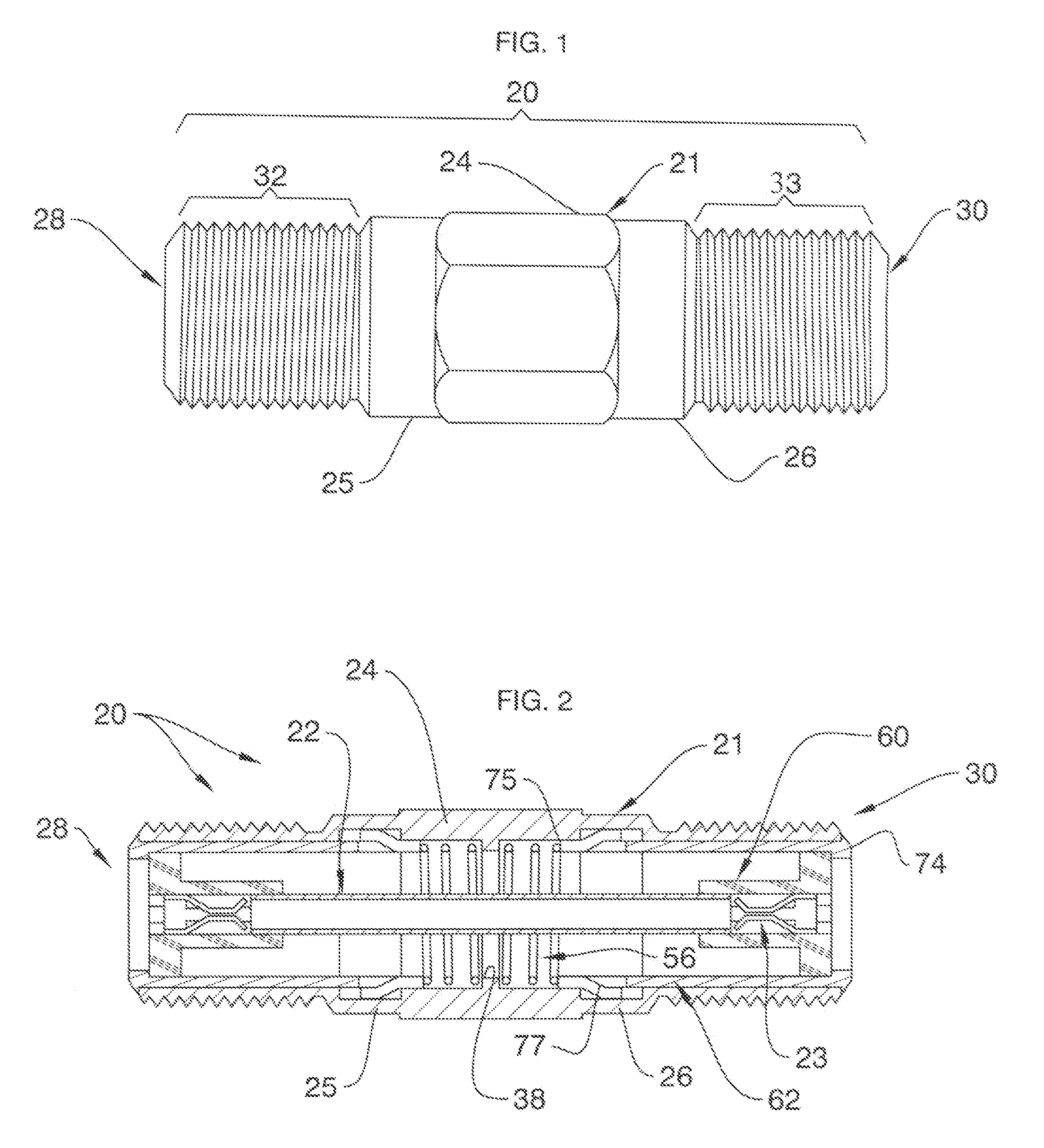

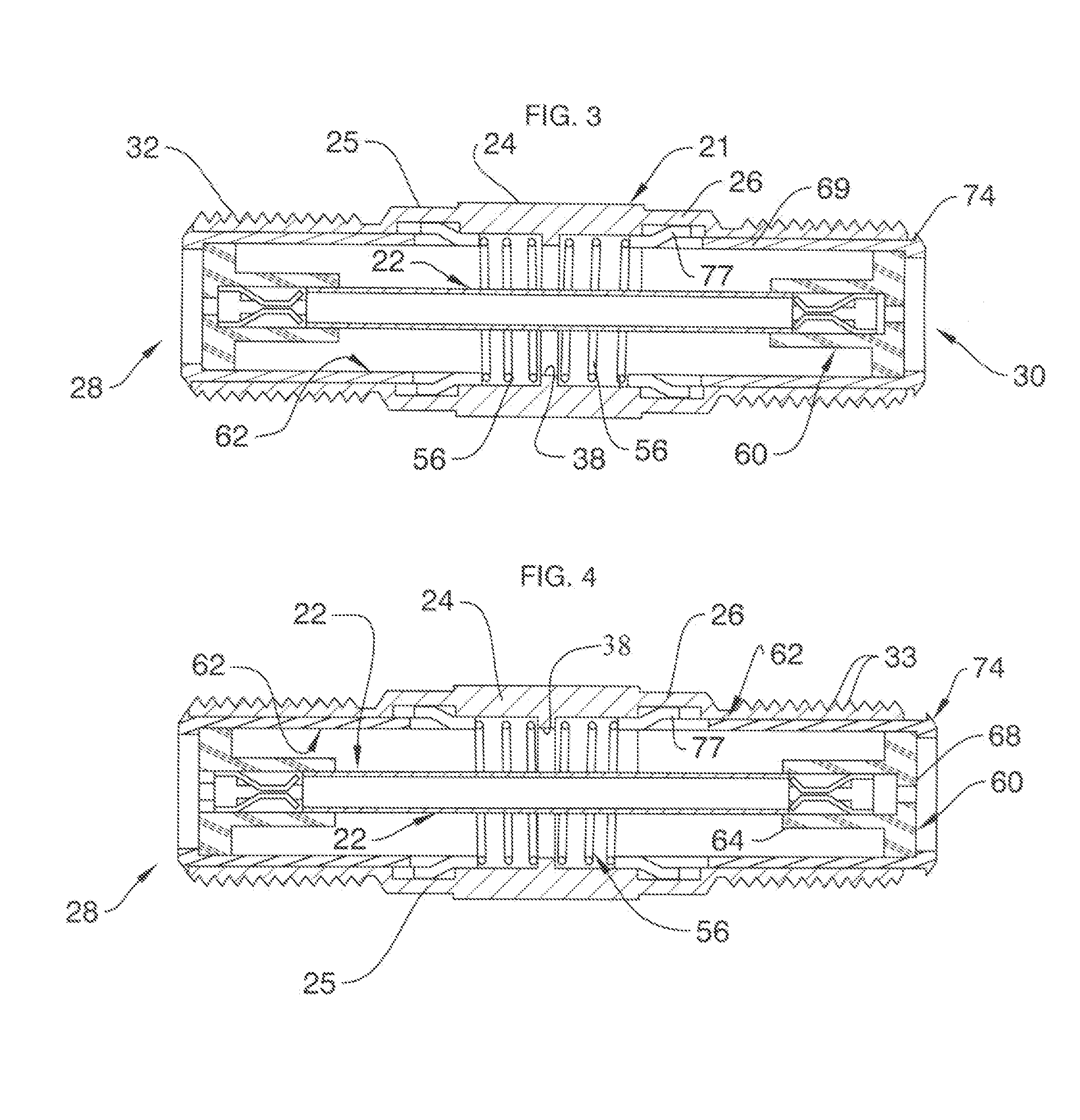

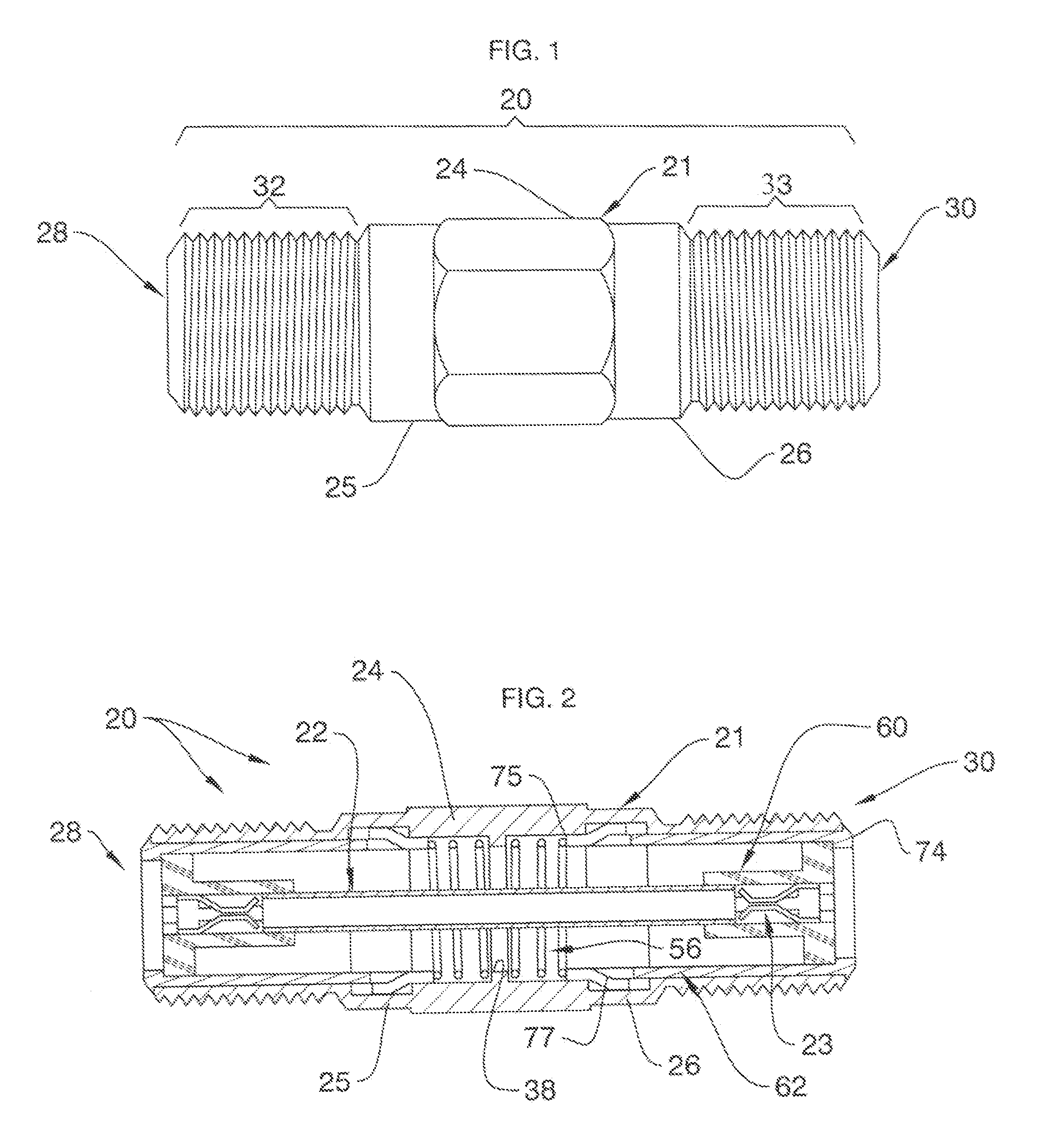

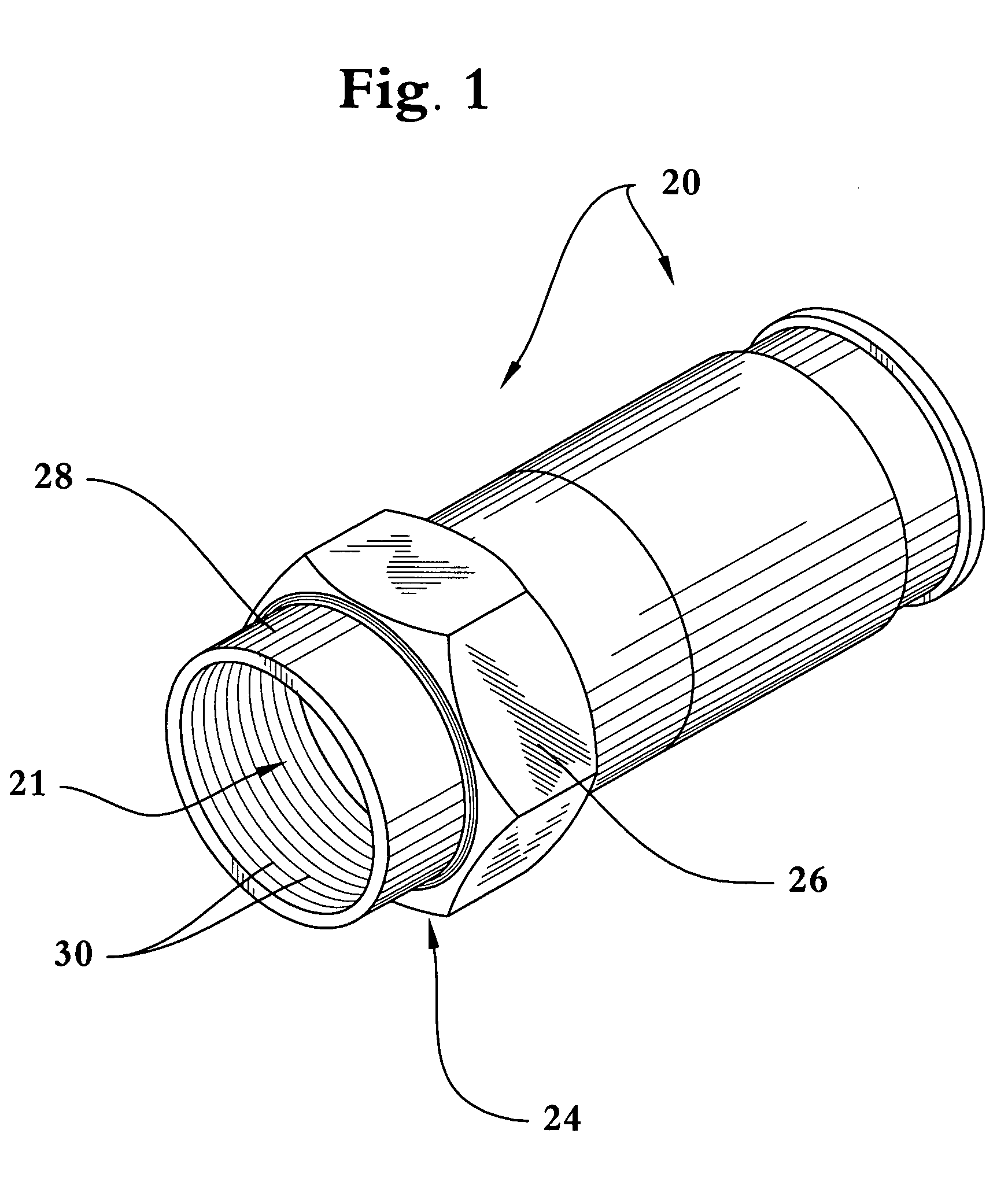

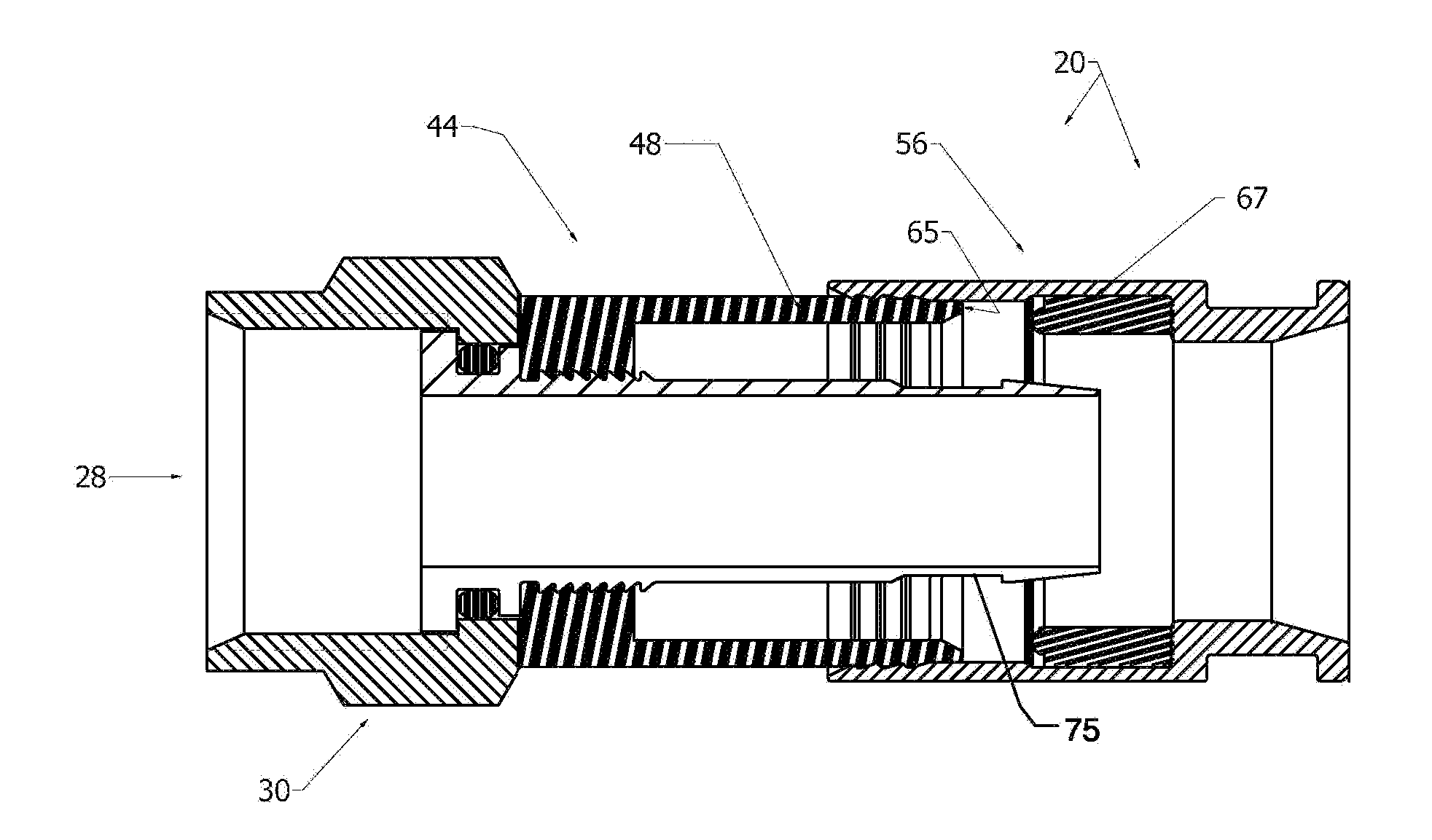

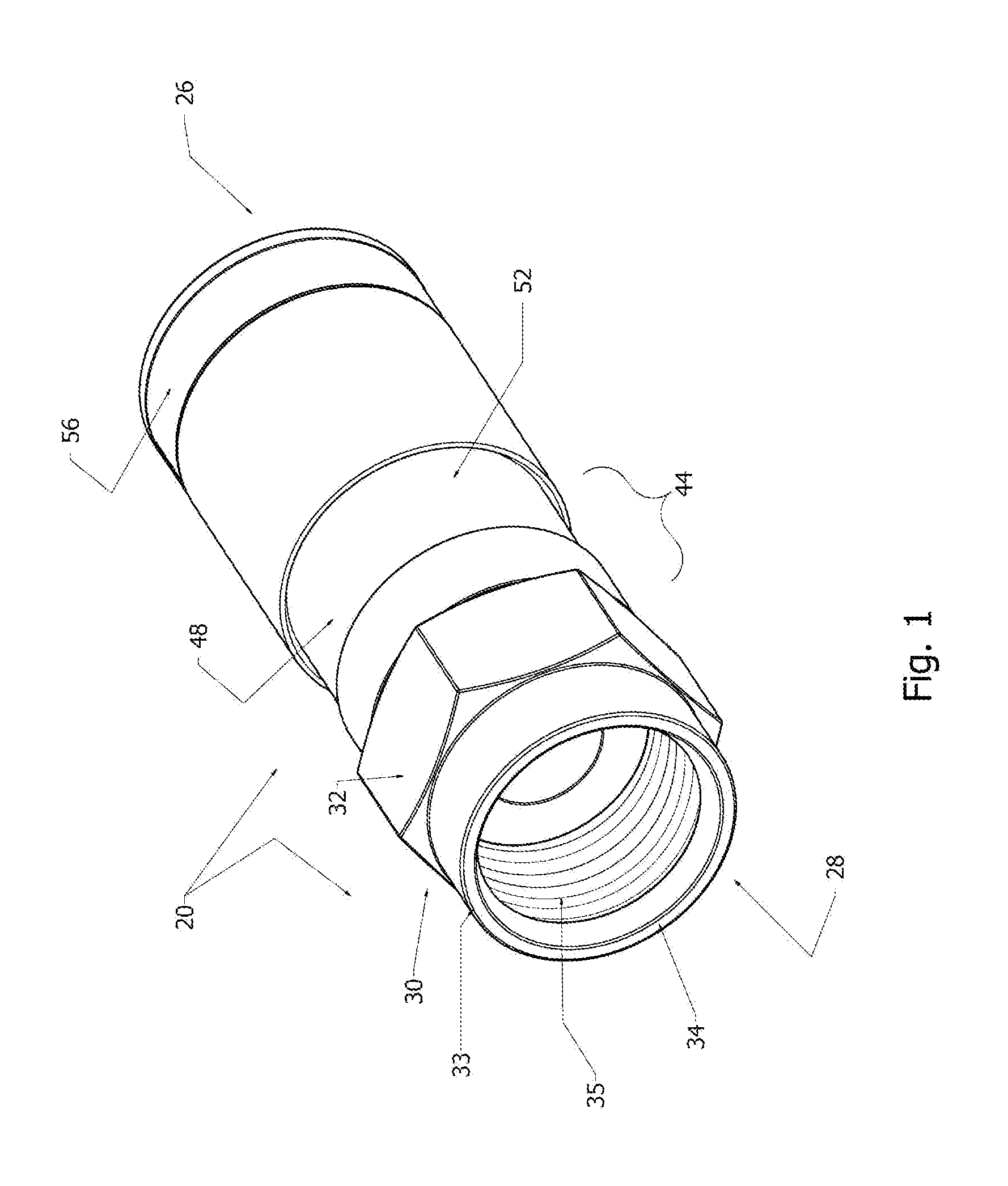

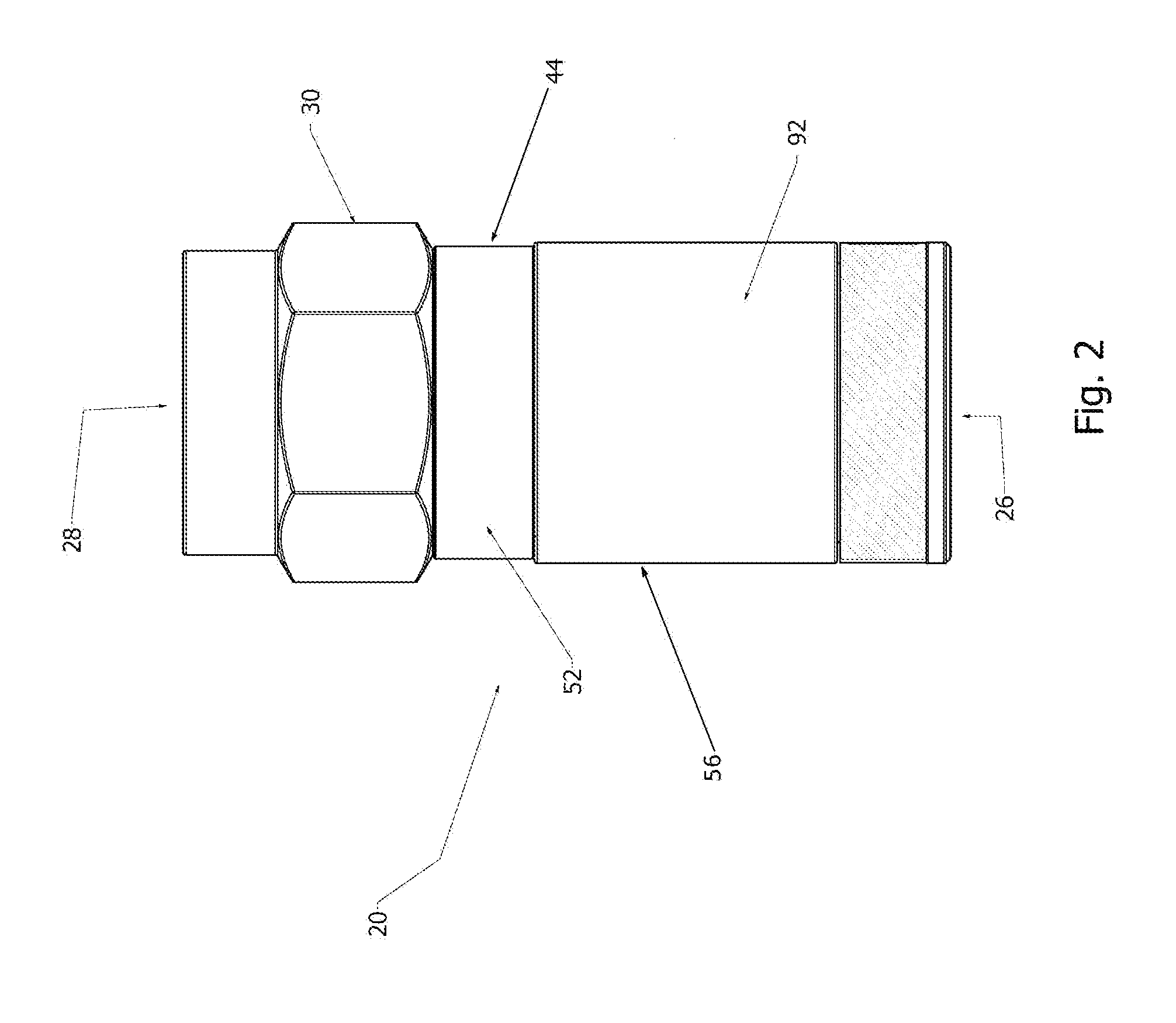

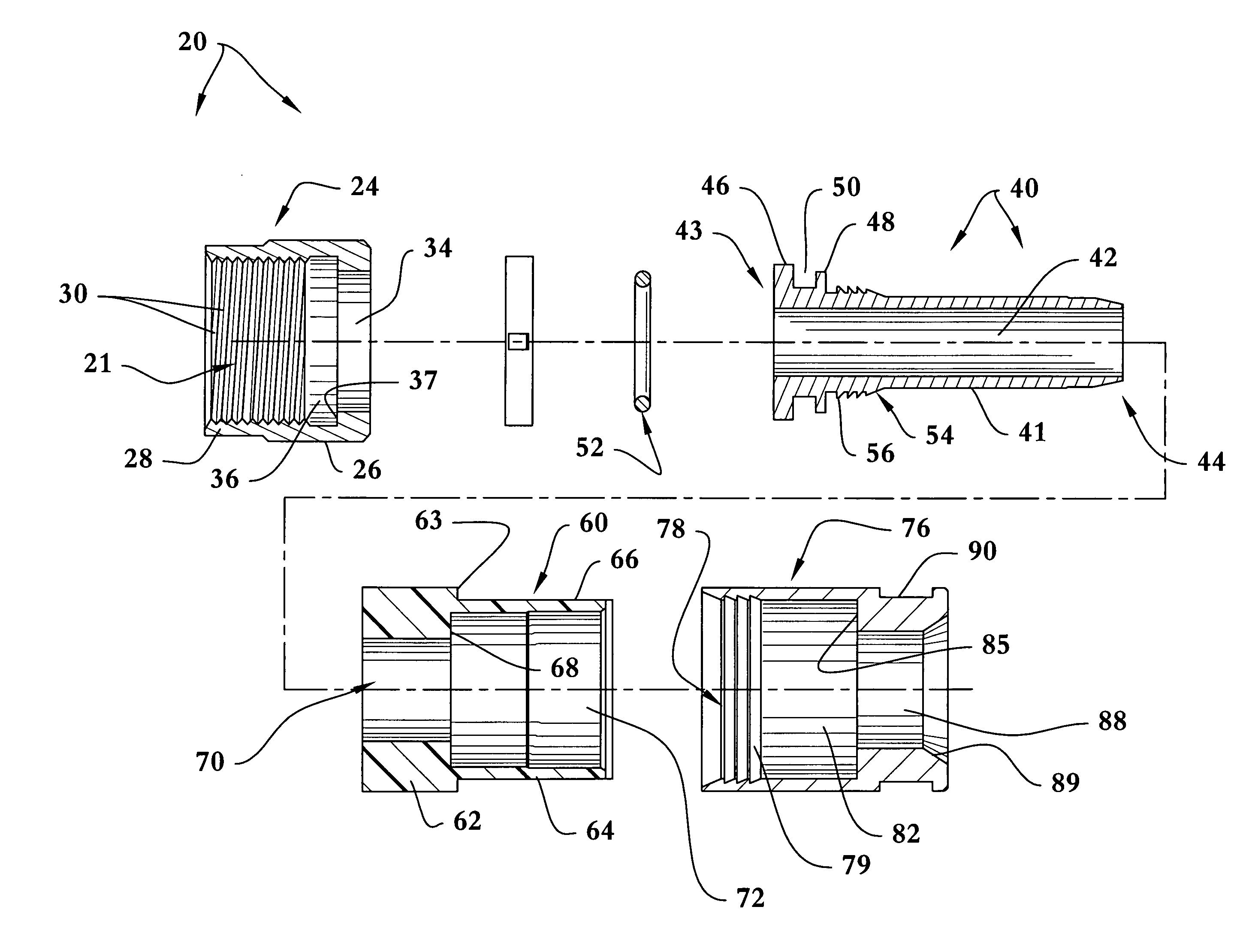

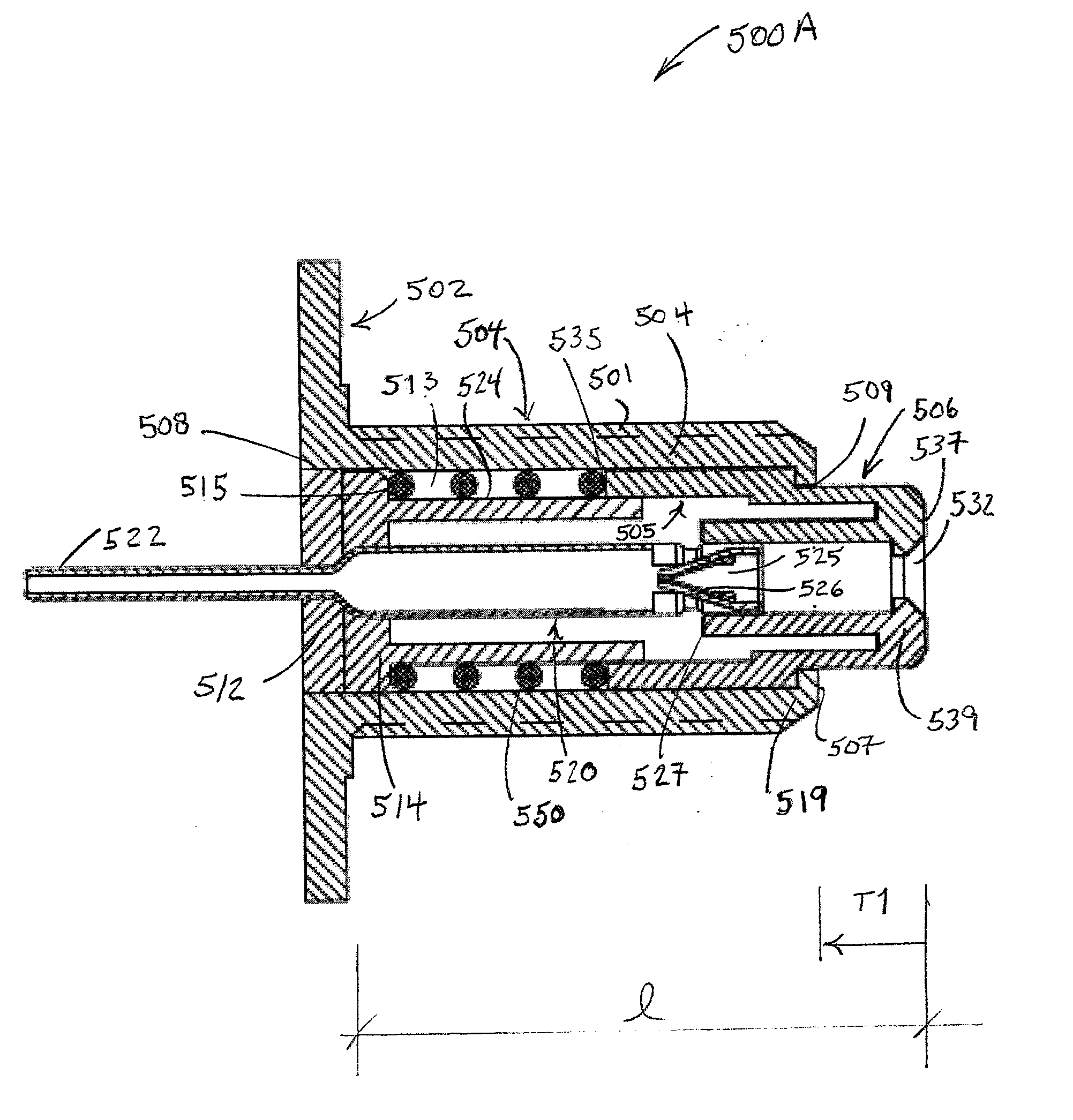

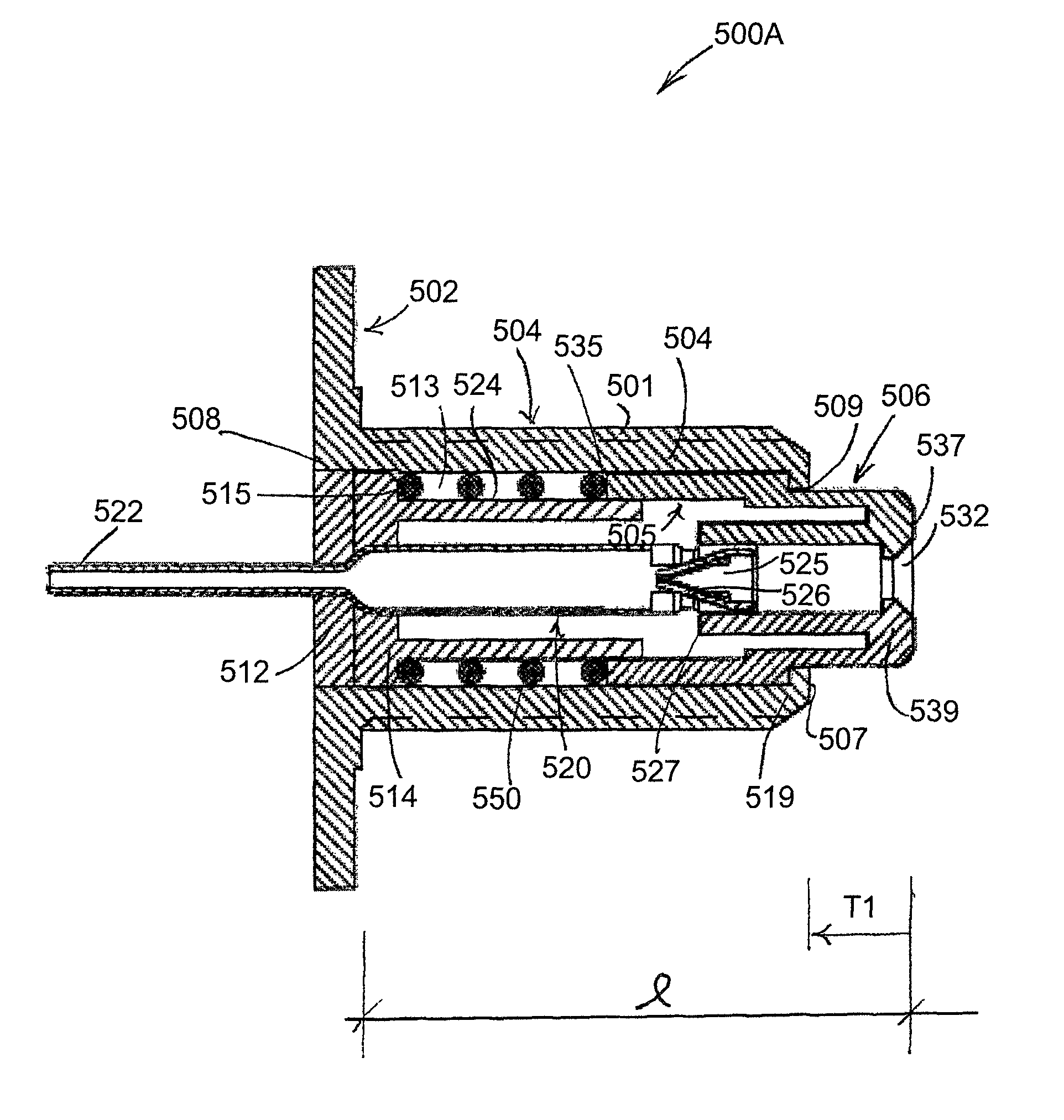

Coaxial Barrel Fittings and couplings with Ground Establishing Traveling Sleeves

ActiveUS20130102190A1Minimize resistance lossOvercome problemsElectrically conductive connectionsCoupling contact membersAxial displacementCoupling

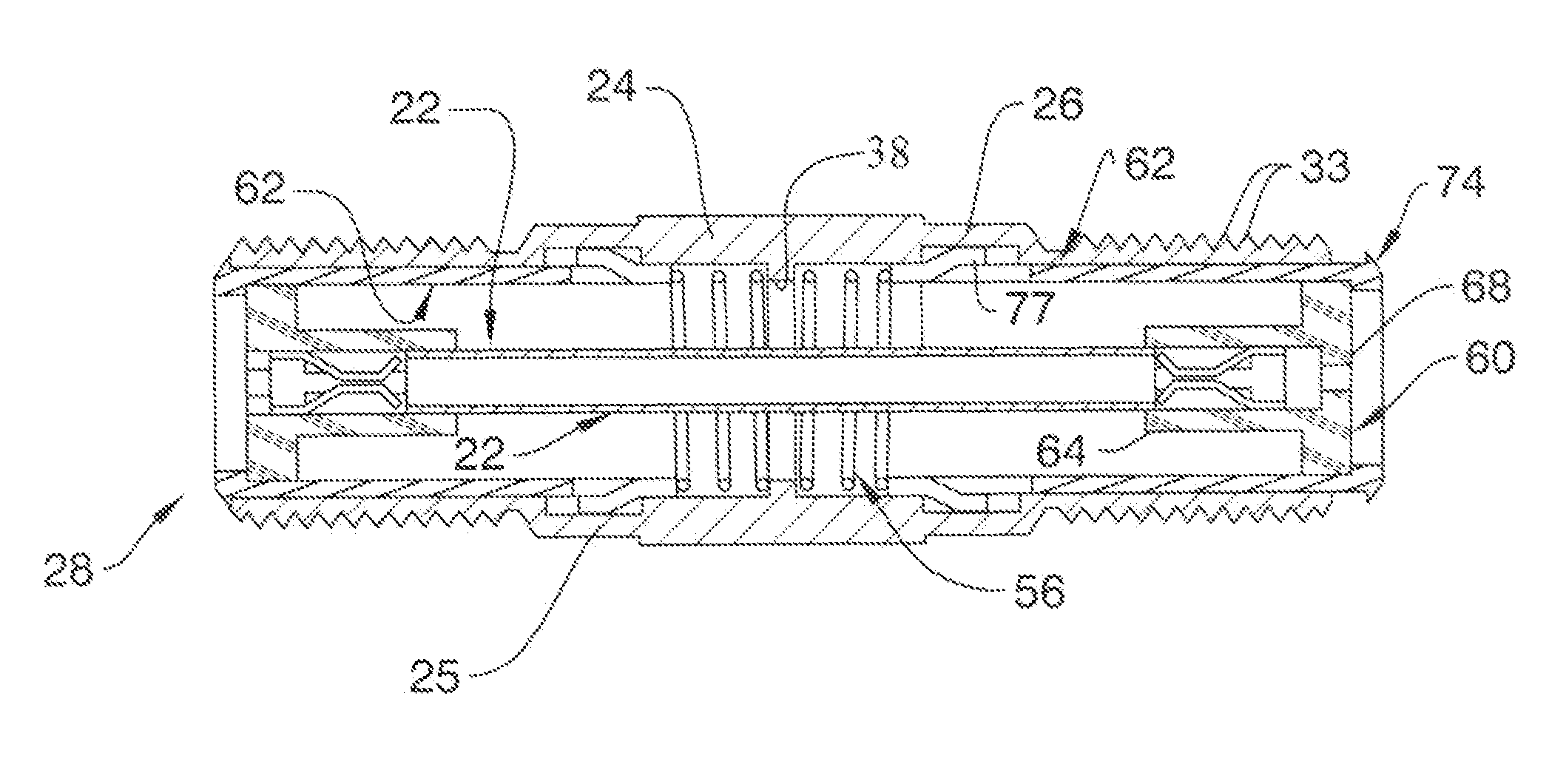

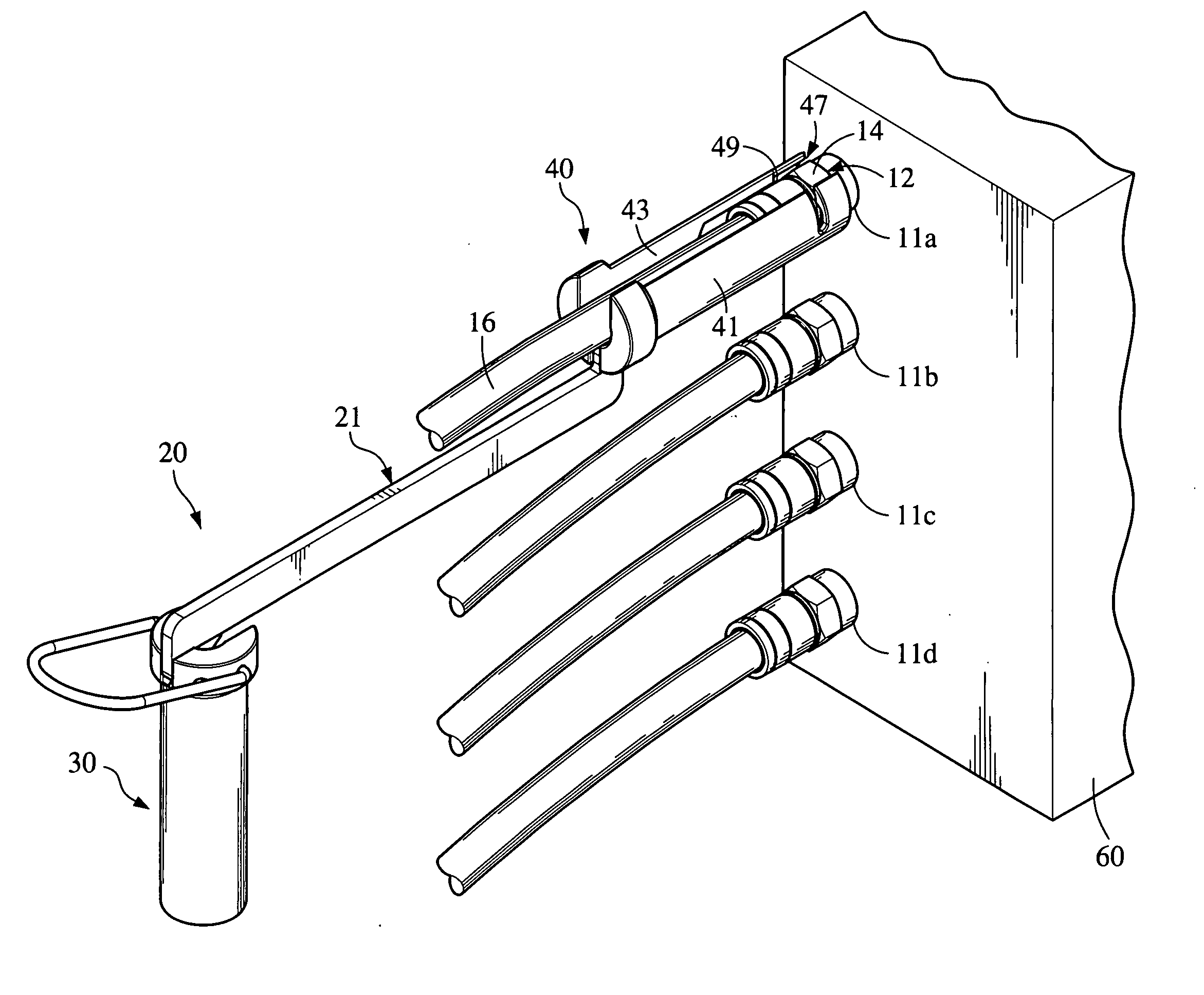

Barrel connectors, a right angled adaptor and a single ended fitting include at least one axially displaceable traveling sleeve for insuring electrical continuity with coaxial connector, nominally an F-connector. Each barrel connector described comprises a rigid, metallic hollow body housing an internal contact tube. At least one coiled spring is retained within the body. At least one elongated, tubular traveling sleeve is coaxially disposed within each body end and normally biased outwardly by the springs. The metallic traveling sleeves comprise an elongated shank that contacts the spring, and a head that seats against the connector body ends during installation. Catches or rings defined upon or mounted to travelling sleeve shanks are received within suitable grooves for anchoring the traveling sleeves while facilitating limited axial displacements. The traveling sleeves, and the contact tube therewithin, normally are biased outwardly so that even limited torquing of an F-connector will establish a ground path.

Owner:PERFECTVISION MFG

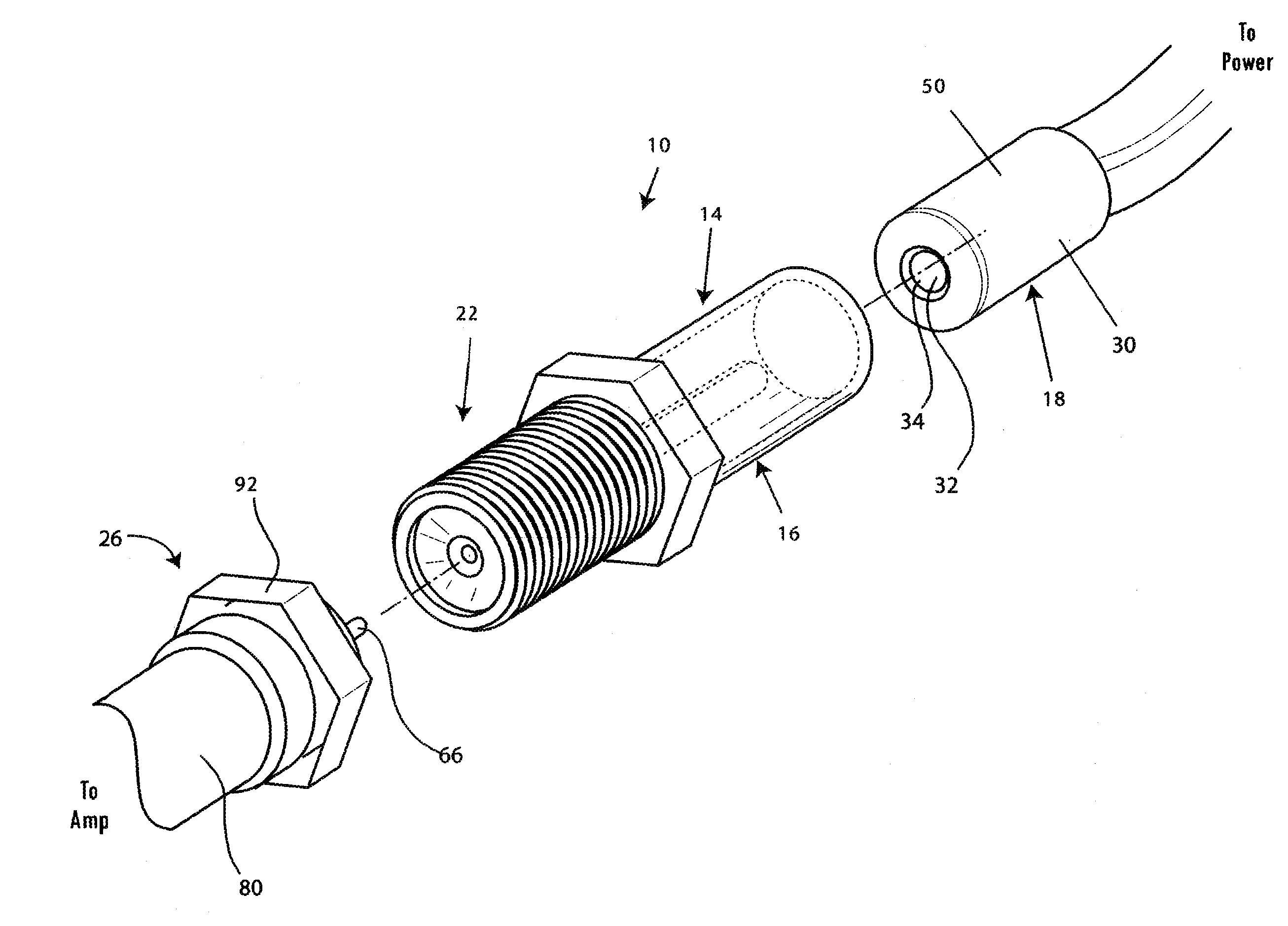

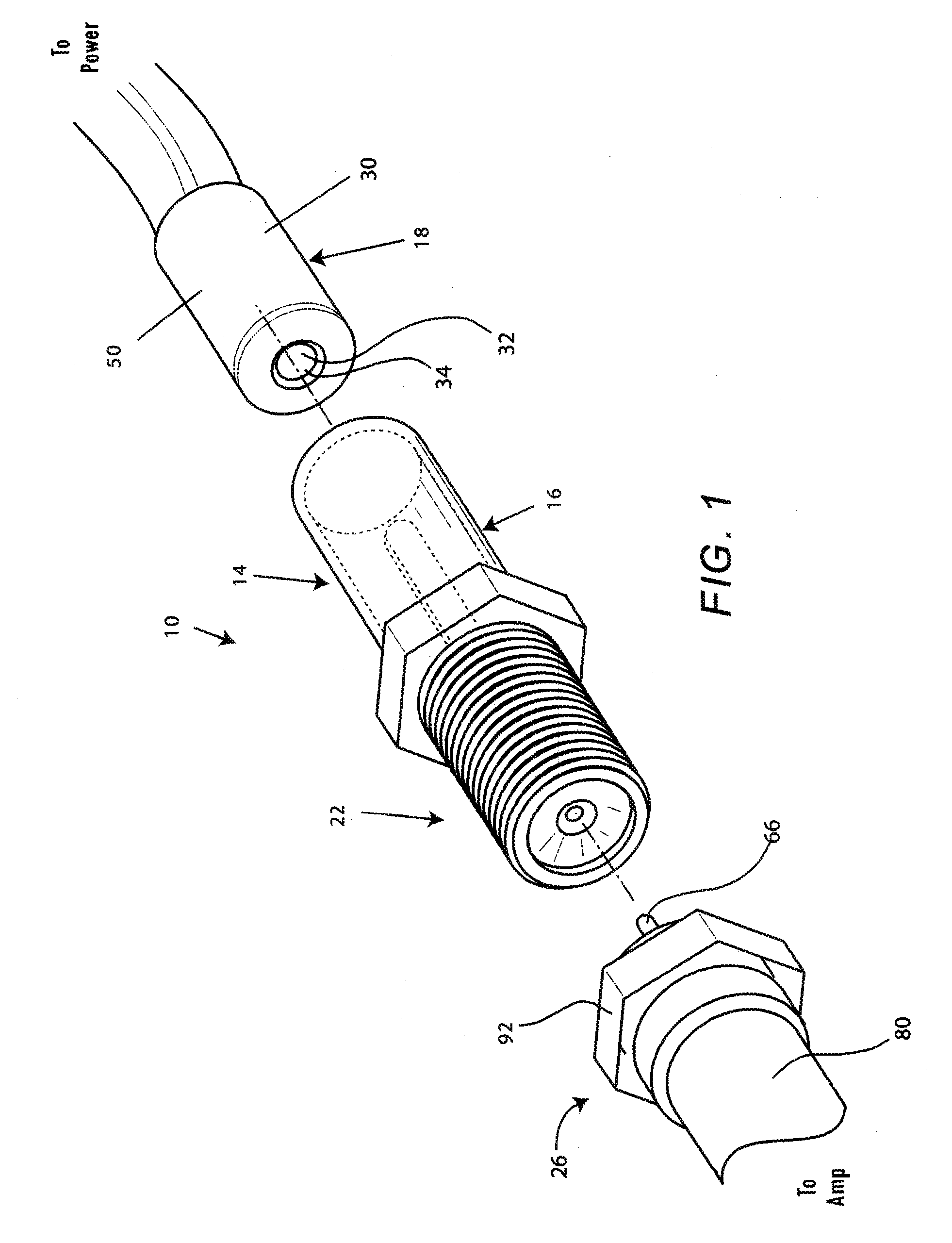

Coax-to-power adapter

A dc-to-coax adapter is provided for establishing an electrical coupling between a power source and a coaxial cable device. The adapter may include a power connector portion and an RF connector portion. In an exemplary embodiment the power connector portion comprises a dc jack adapted to establish an electrical coupling with a standard dc barrel plug connector and the RF connector portion comprises a female F connector adapted for establishing electrical coupling with a male F connector. The contacts of the power connector portion may be integrated with the contacts of the RF connector portion the adapter housing may provide a continuous ground connection.

Owner:CISCO TECH INC

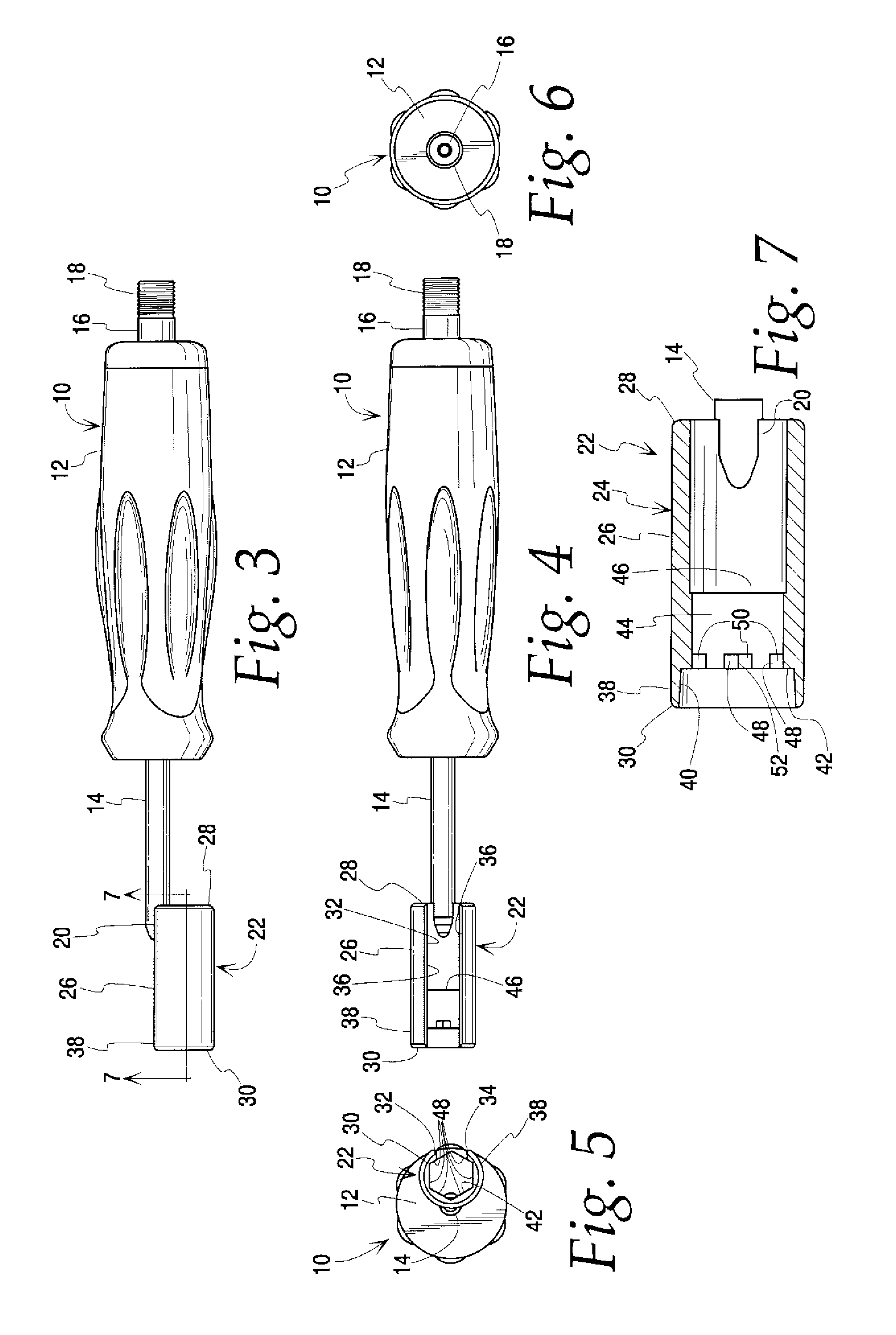

Tool for driving coaxial cable connectors

ActiveUS7181999B1Eliminate needTwo pole connectionsCoupling device engaging/disengagingEngineeringMechanical engineering

A driver tool for coaxial cable connectors is provided. The tool can drive both F-series coaxial cable connectors having a hex sleeve and BNC coaxial cable connectors having a bayonet sleeve. The driver tool has a socket which includes a first drive surface in the form of a plurality of flat segments formed on the socket and engageable in rotationally interlocking relation with the hex sleeve of an F connector. The socket also has a second drive surface in the form of a collar sized for frictional engagement in rotationally interlocking relation with the bayonet sleeve of a BNC connector. A longitudinal slot in the sleeve accommodates a coaxial cable. A handle and shaft connect to the socket.

Owner:IDEAL IND INC

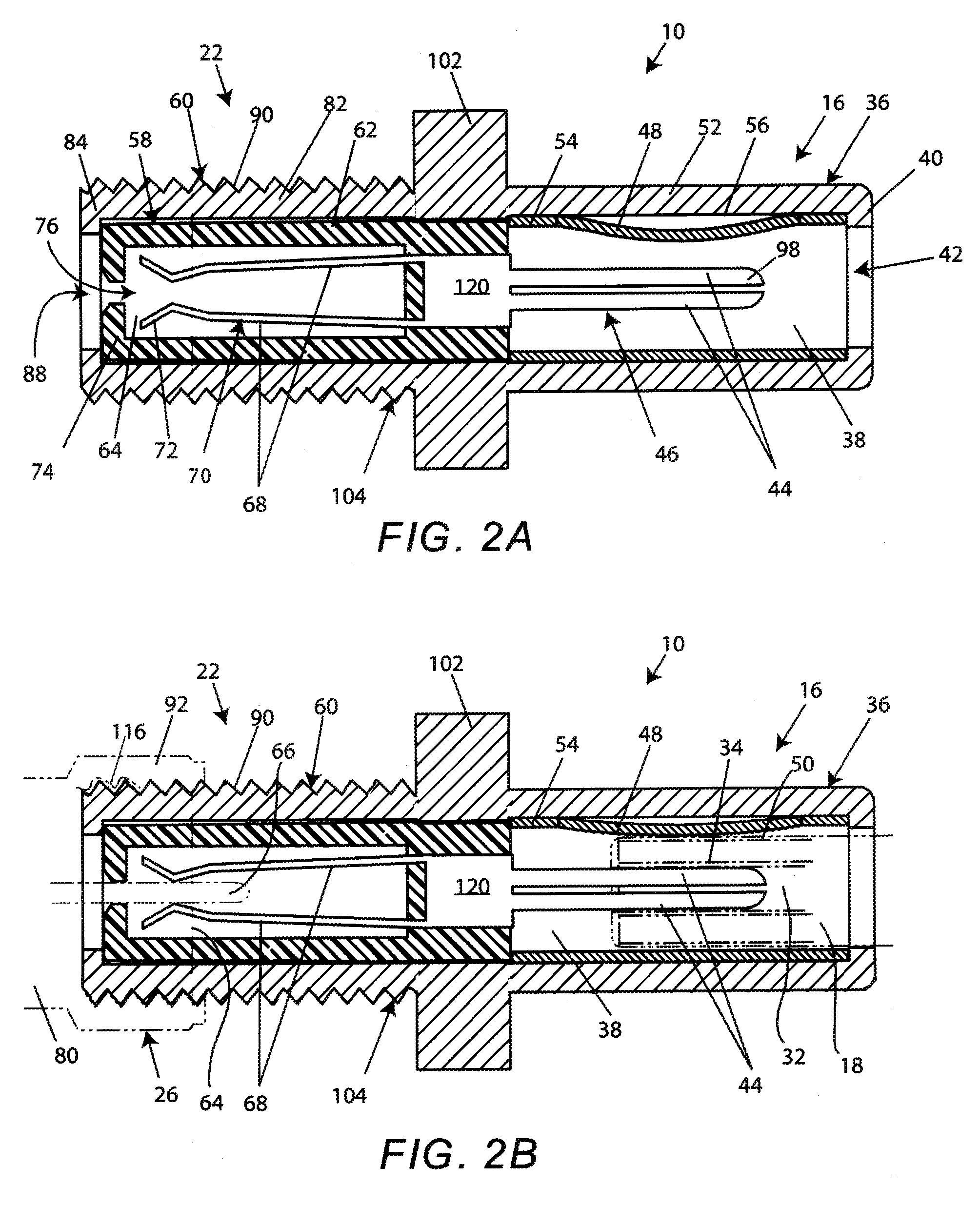

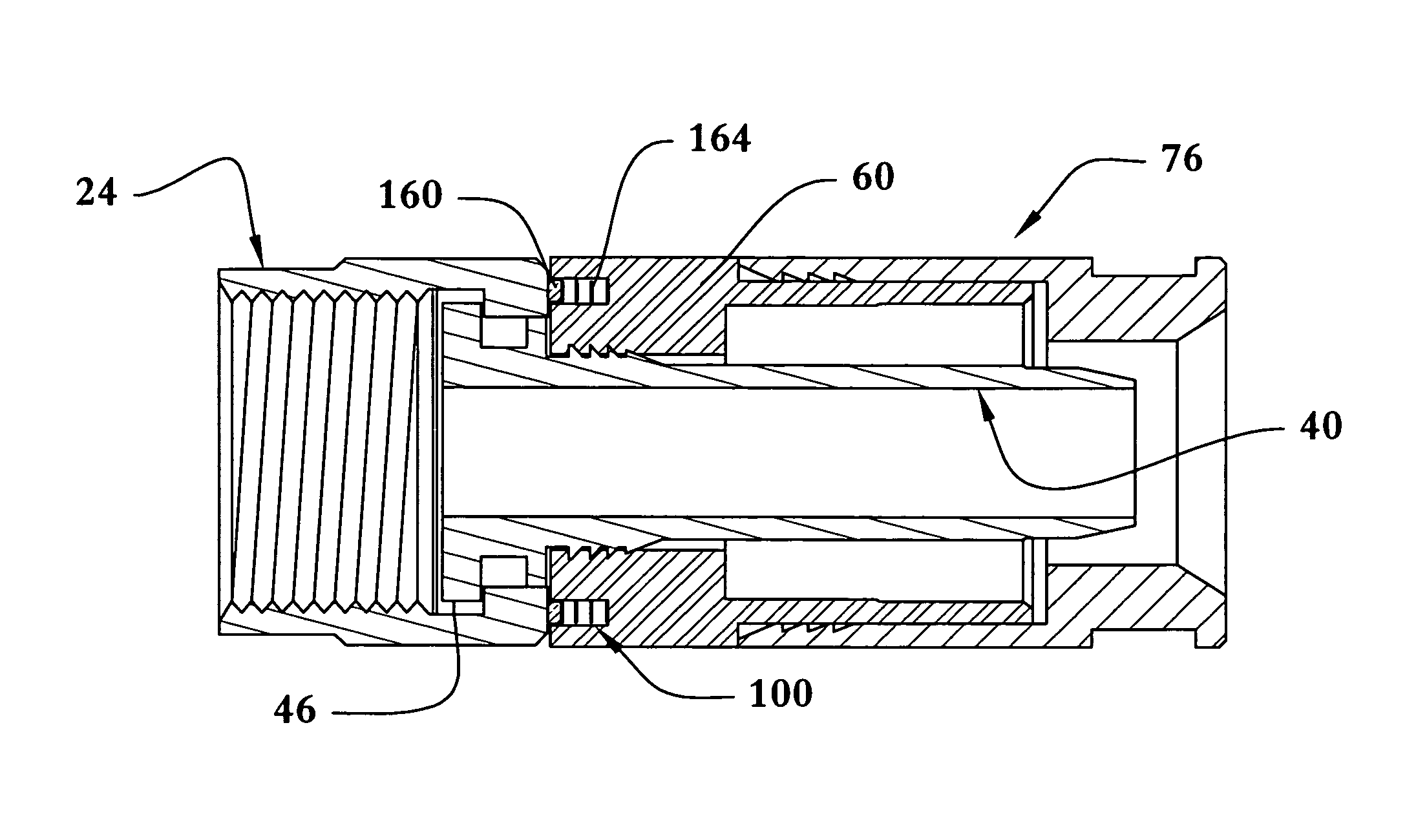

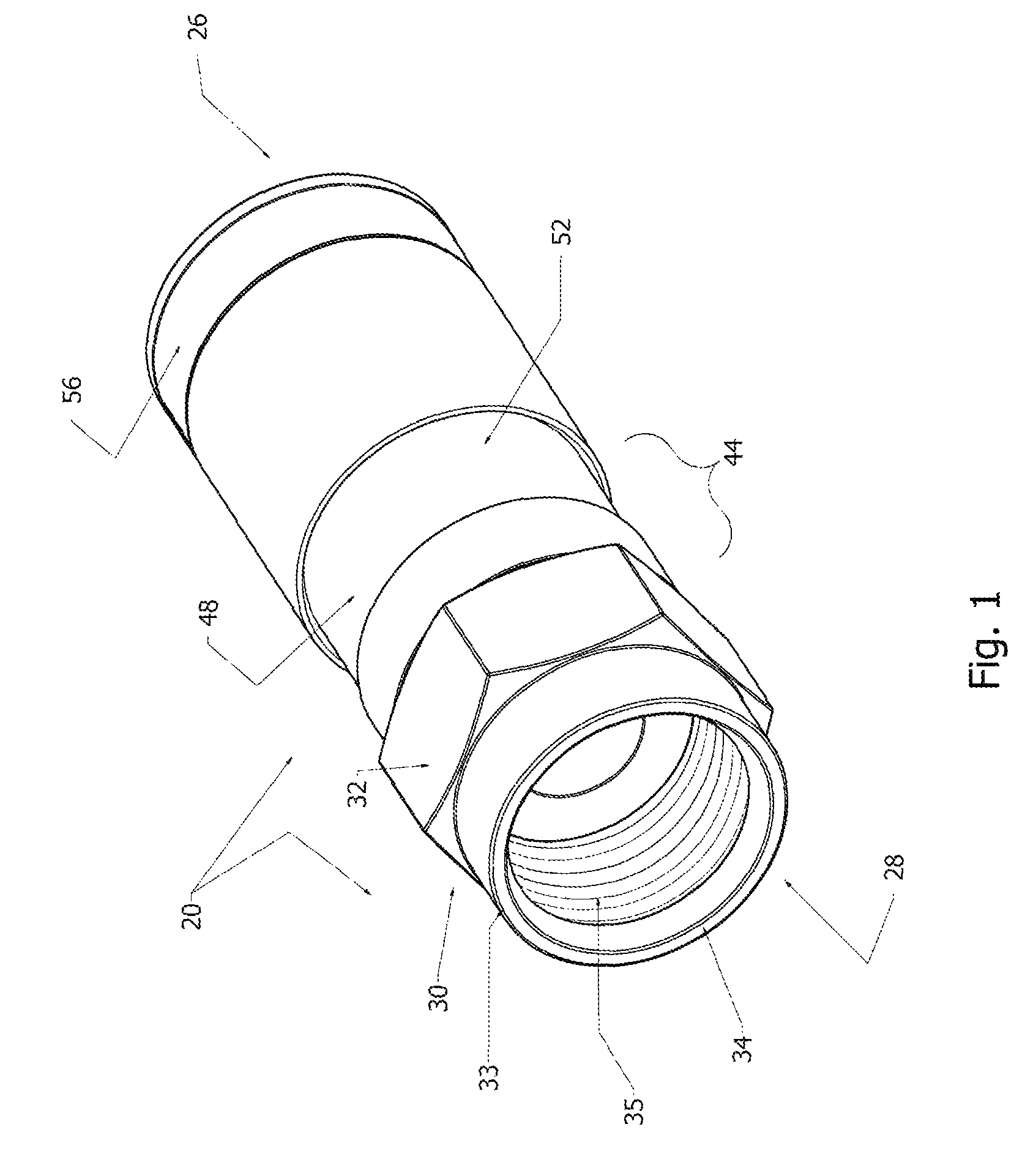

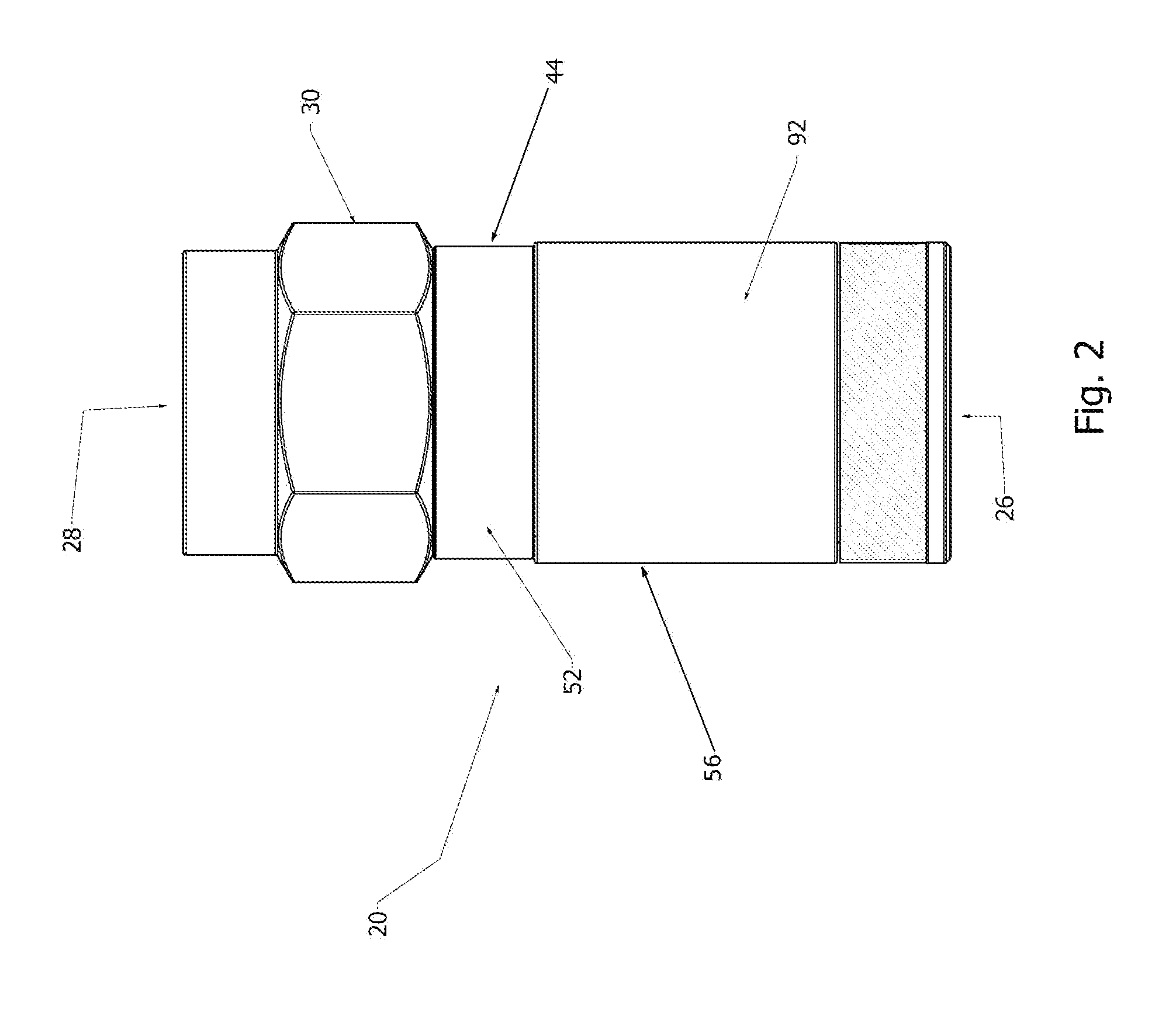

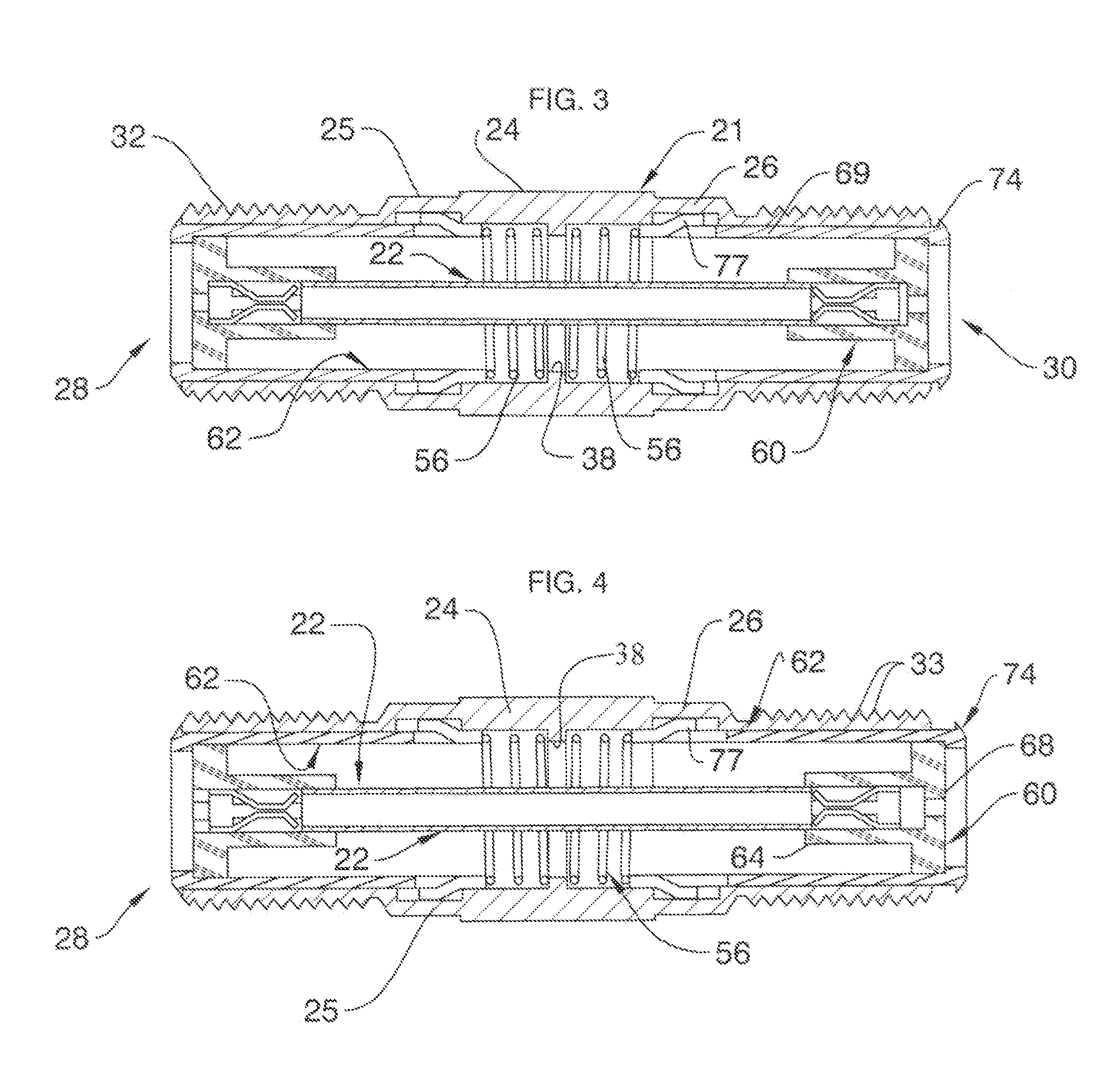

Compression type coaxial cable F-connectors with traveling seal and barbless post

InactiveUS20110065317A1The connection is tight and firmIncreased operating bandwidthOne pole connectionsElectrically conductive connectionsHigh bandwidthEngineering

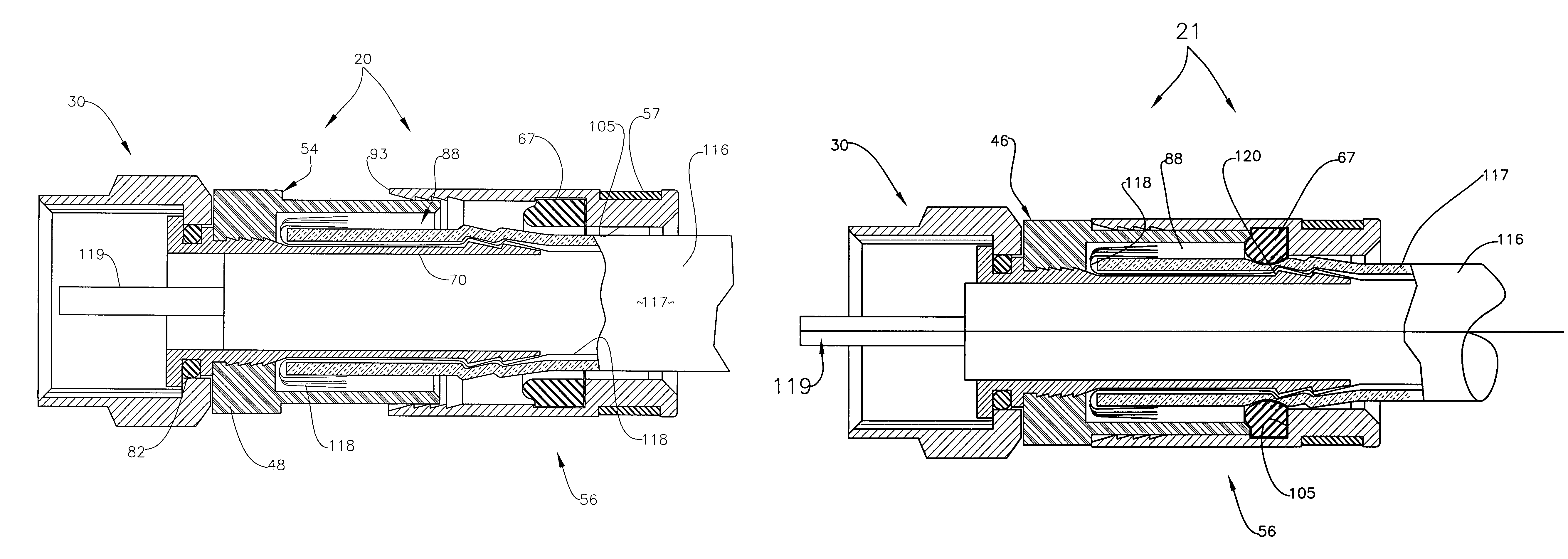

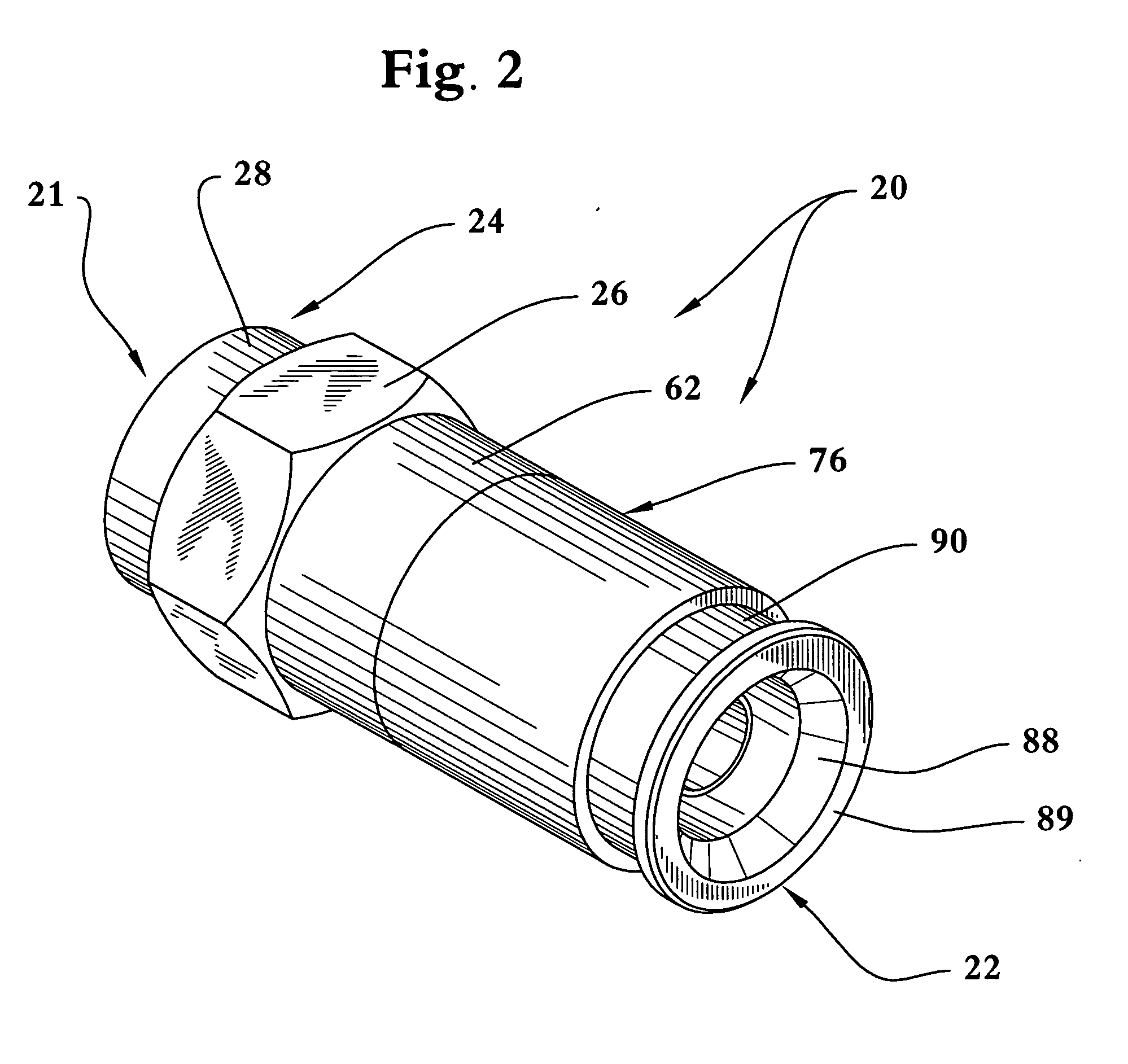

Axially compressible, self-sealing, high bandwidth F-connectors for conventional hand tools for interconnection with coaxial cable. An internal, dual segment sealing grommet activated by compression elongates and deforms to provide a travelling seal. Each connector has a rigid nut that is rotatably secured to a, tubular body. A rigid, conductive post has a barbless shank that coaxially extends through the connector and penetrates the coaxial cable within the connector. A tubular, metallic end cap is slidably fitted to a body shank, and is thereafter forcibly compressed lengthwise during installation. The end cap has a ring groove for seating the enhanced grommet. The end cap can irreversibly assume any position, being held by end cap teeth. The grommet travels and extrudes during compression to mate and intermingle with a portion of the cable braid that is looped back to form a prepared cable end.

Owner:PERFECTVISION MFG

Compression connector for coaxial cable and method of installation

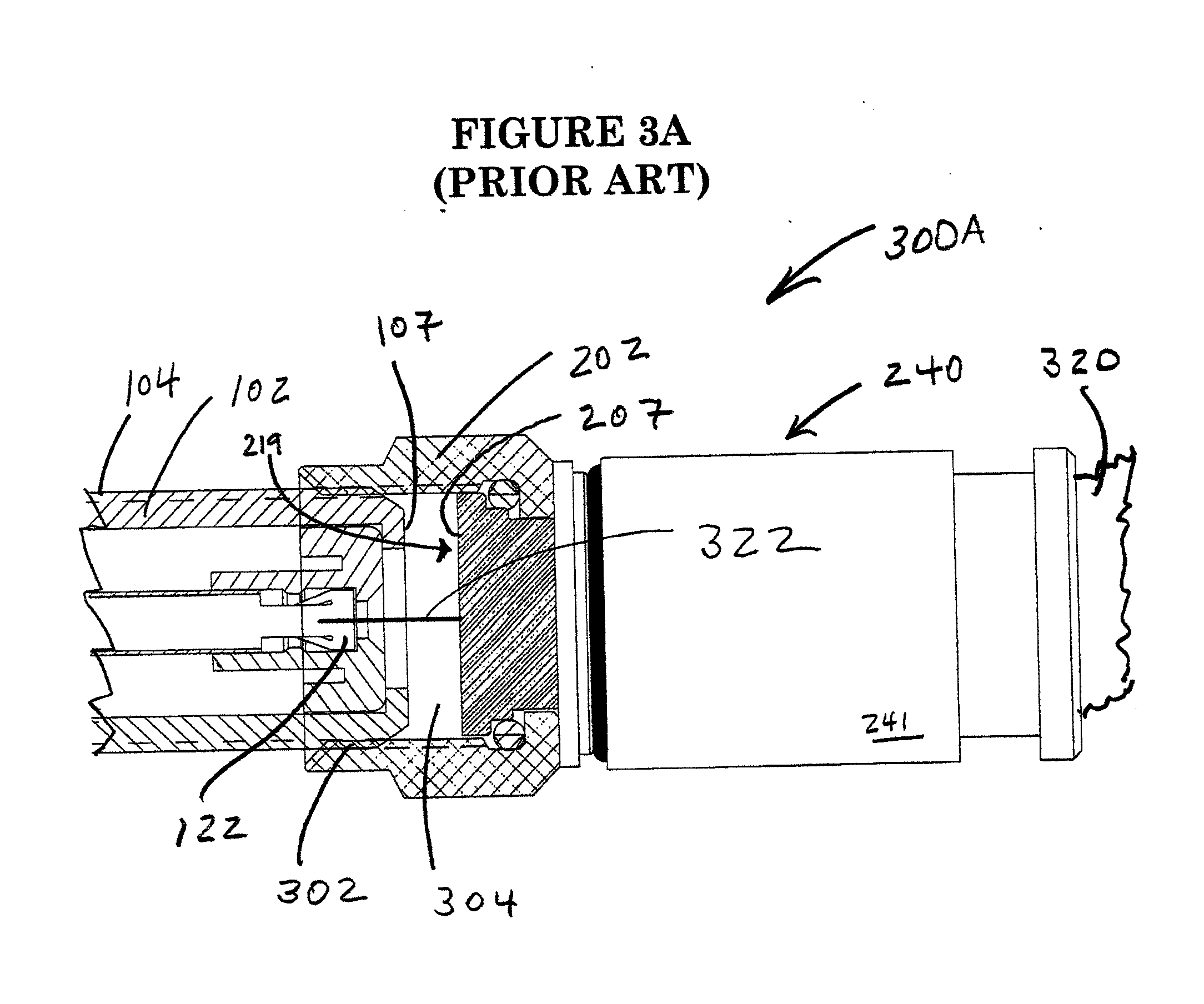

InactiveUS6887103B2Tight frictional engagementReduced cross sectionElectrically conductive connectionsAxial forceDielectric layer

An F connector for mounting to the prepared end of a coaxial cable by compression of portions of the connector into tight frictional engagement with the cable. The body and compression ring of the usual F connector are incorporated in a unitary, one-piece body having three axial sections. The first section surrounds and frictionally engages the outer surface of the post stem in the usual manner. The second section is spaced from the stem to provide an annular space for the shielding and outer dielectric layers of the cable, also in the usual manner. A third section of the body is joined to the second section by an area of reduced thickness. In a first disclosed embodiment, the body fractures at the area of reduced thickness in response to an axial force applied to the third section in the direction of the second section. The wall thickness of the third section tapers outwardly from the area of reduced thickness, whereby movement of the third section between the inner surface of the second section and the outer surface of the cable by the axial force subsequent to fracture applies a radially compressive force to the cable and provides the desired tight frictional engagement of the connector and cable. In a second embodiment, the third section includes two, axially spaced area of reduced thickness. The portions of the third section adjacent these reduced thickness areas are folded into the area between the second section and the cable as the axial force is applied, rather than being fractured.

Owner:PPC BROADBAND INC

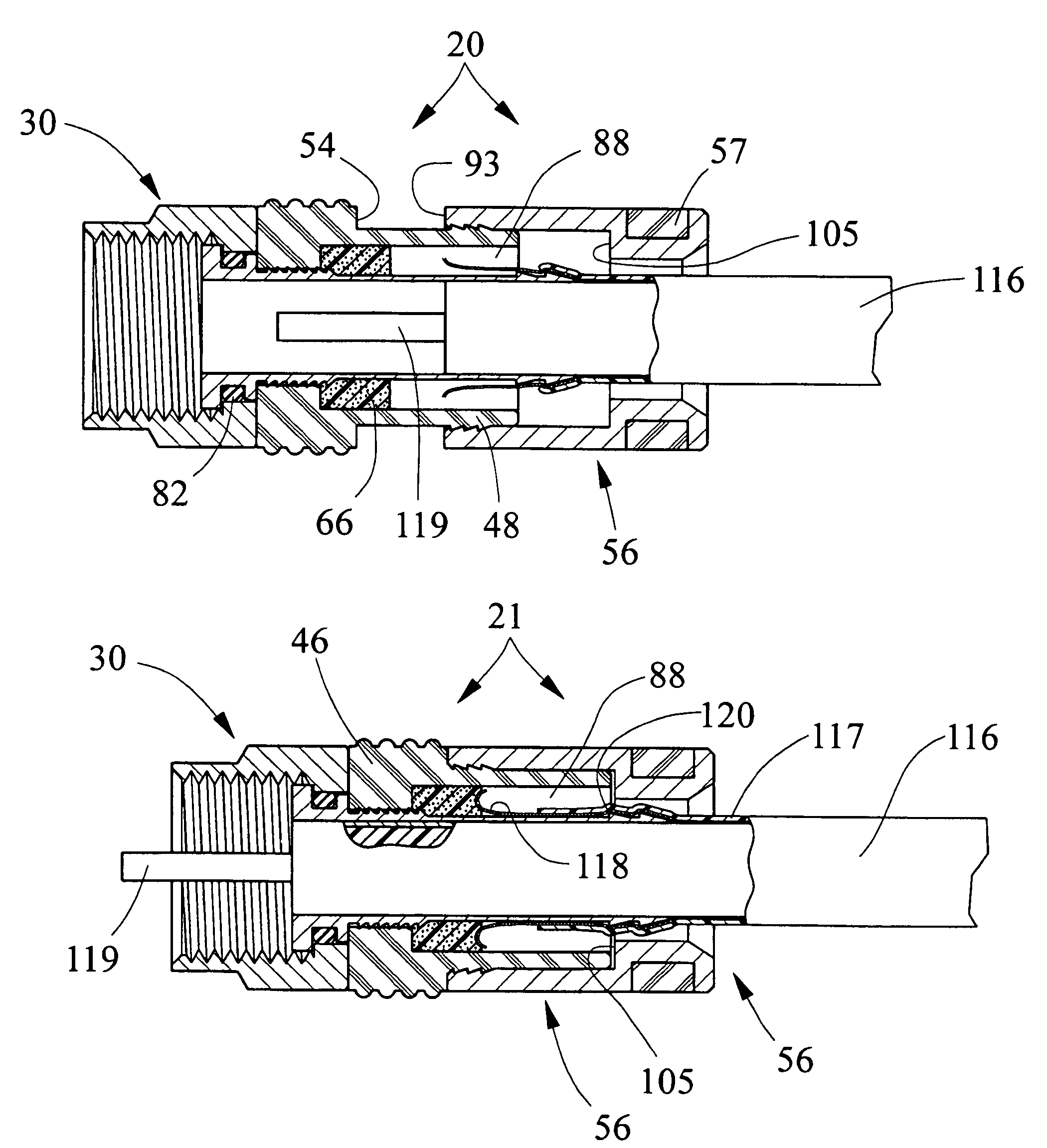

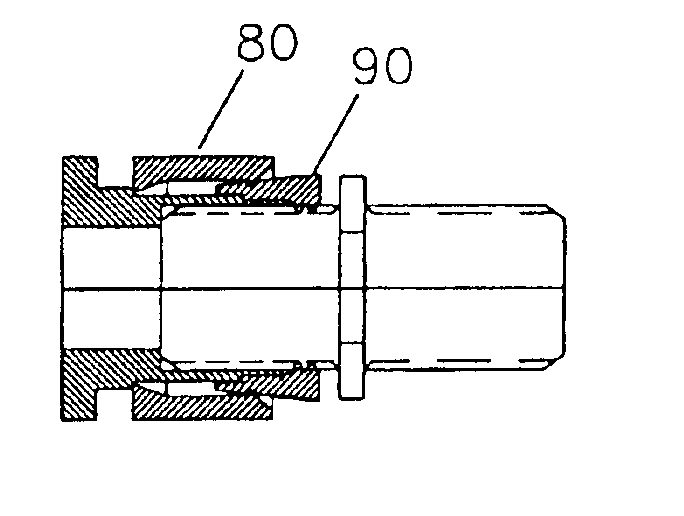

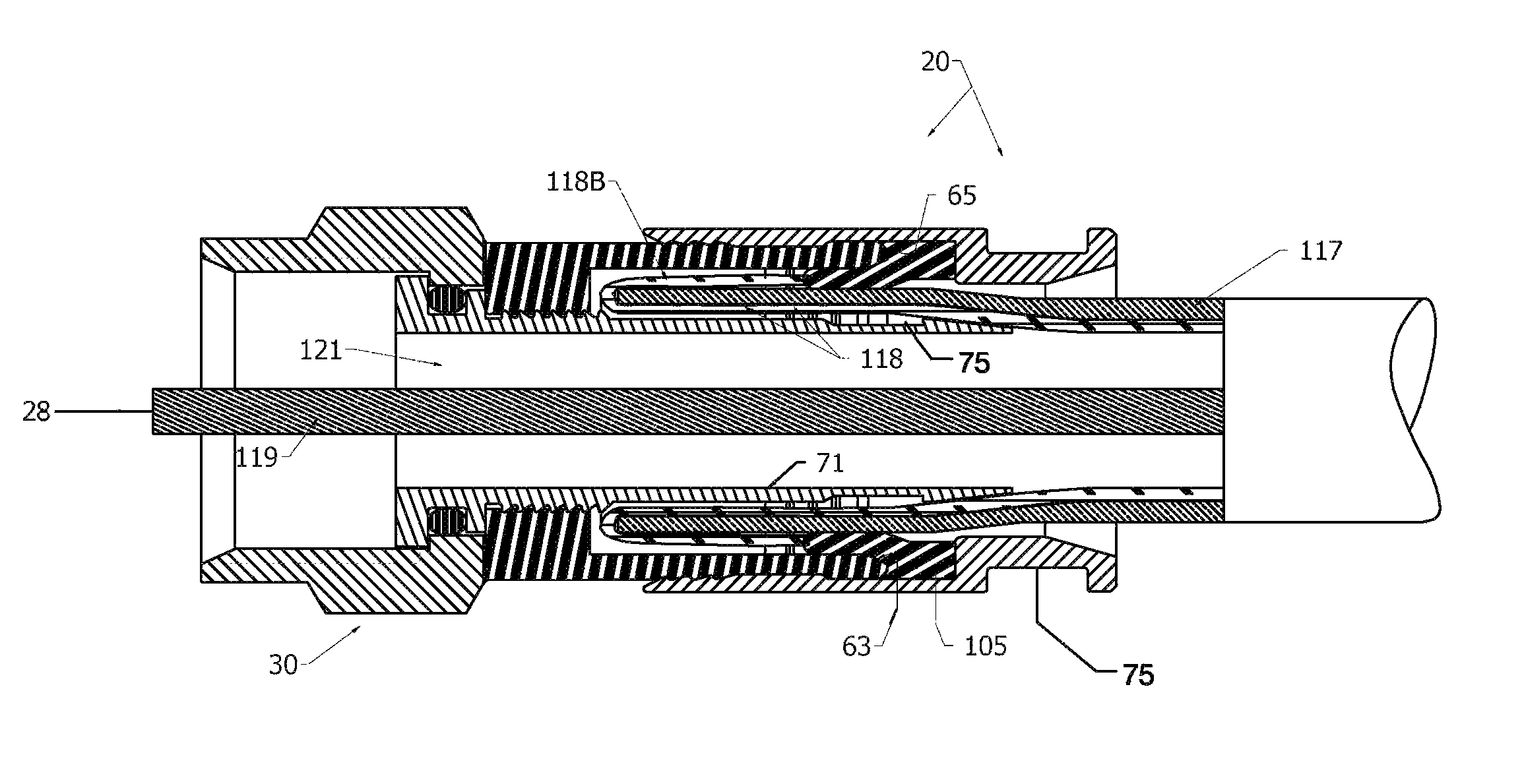

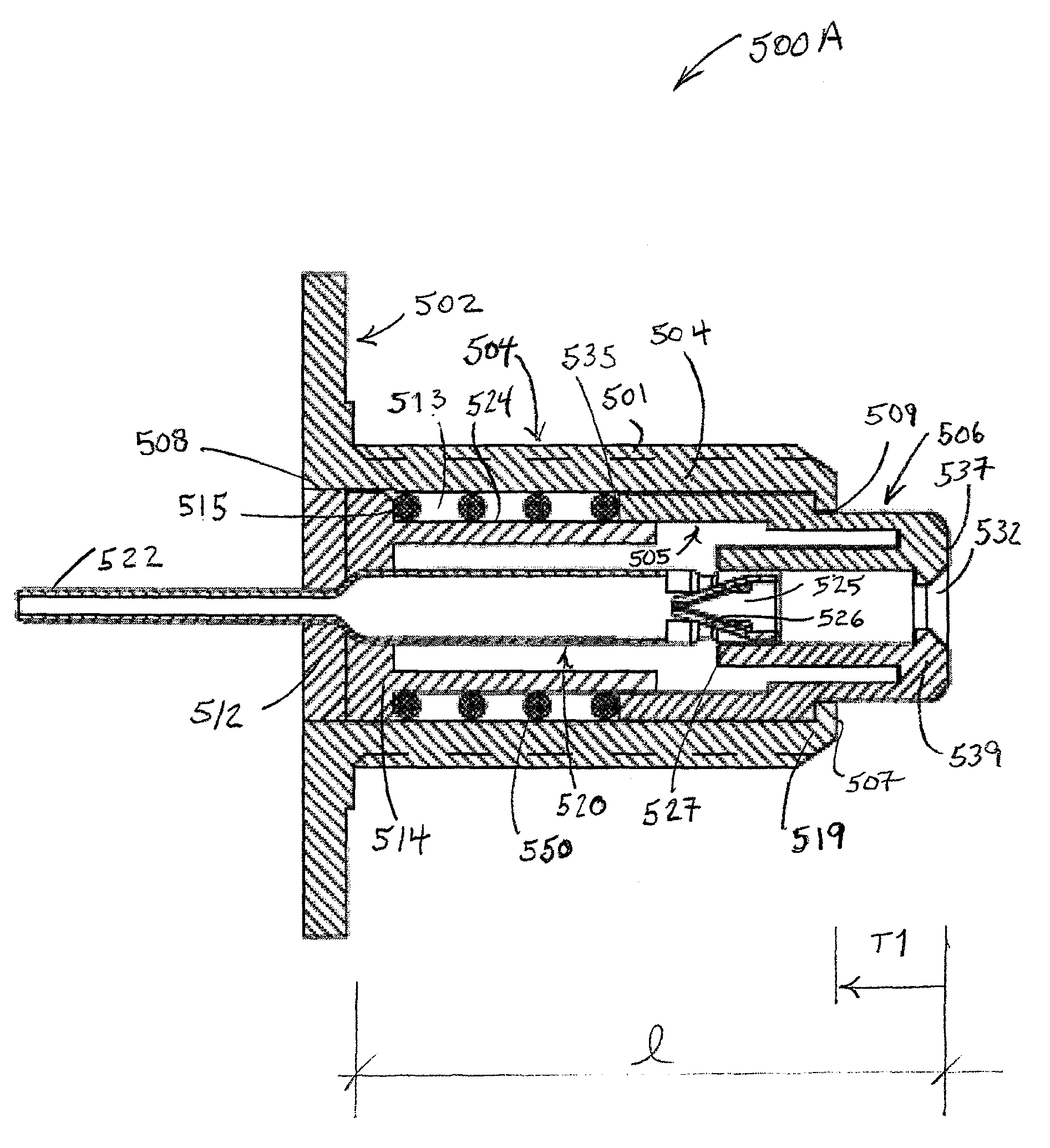

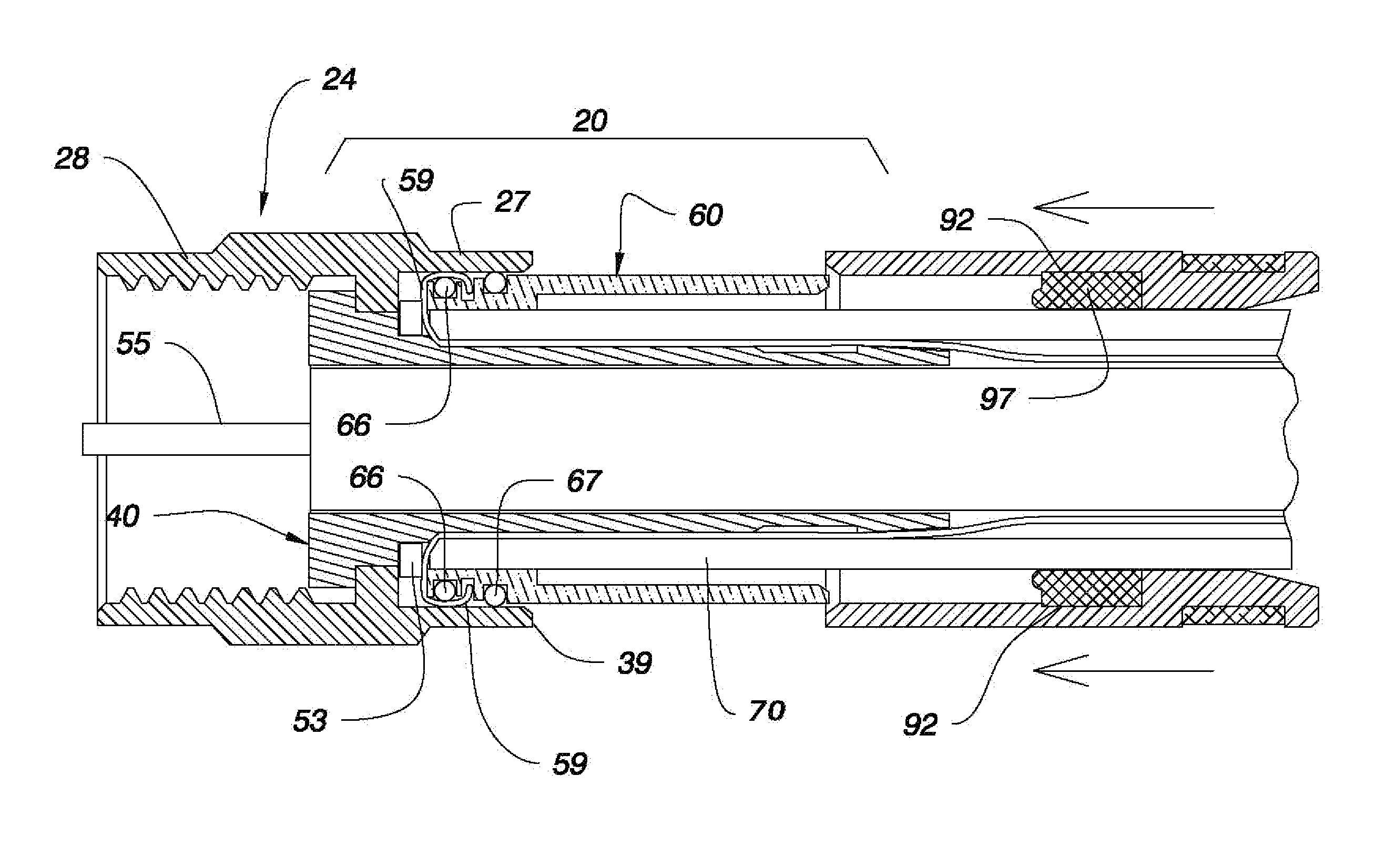

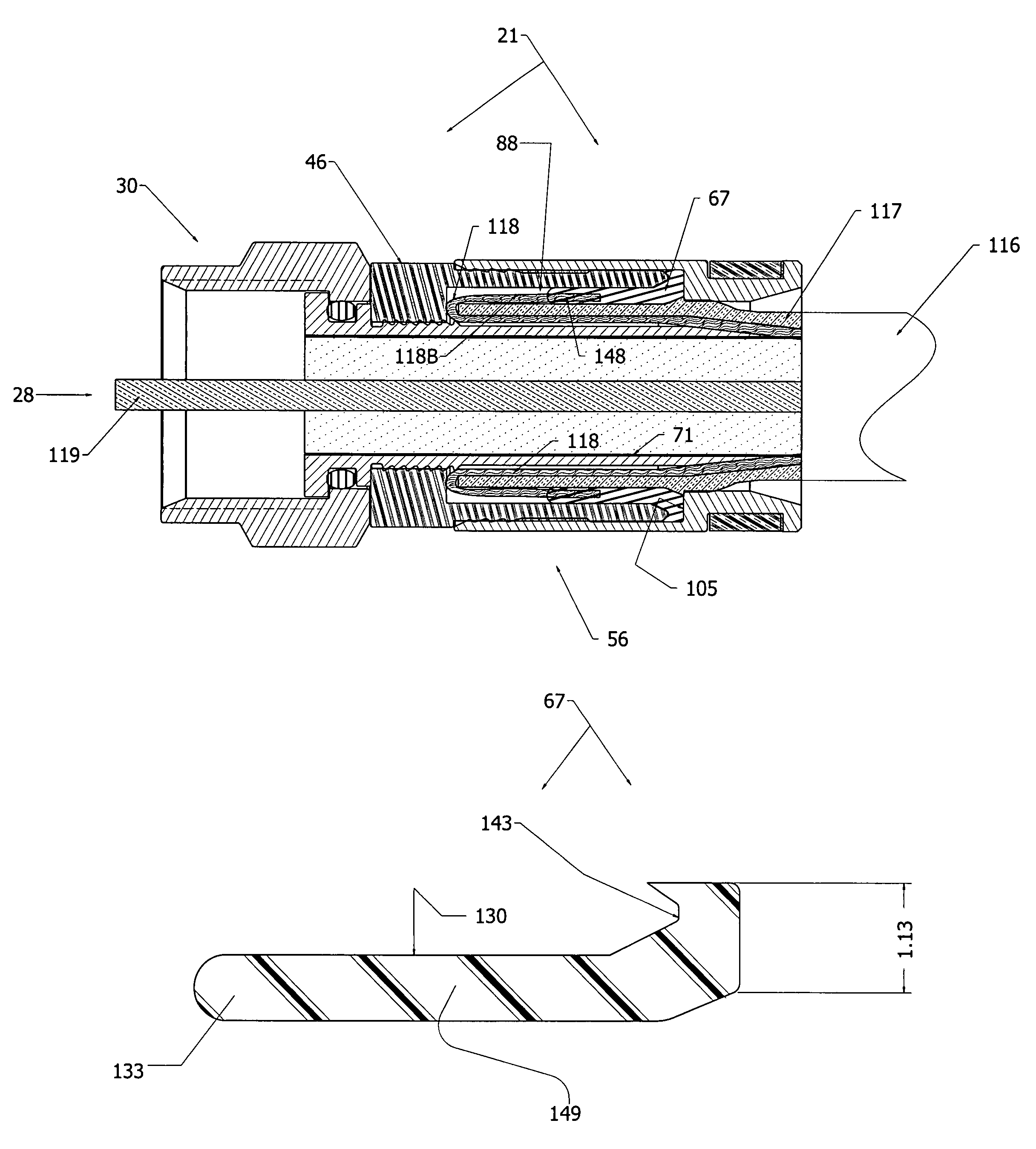

Enhanced coaxial connector continuity

ActiveUS8636541B2Reliable ground connectionEconomically manufacturedElectrically conductive connectionsMetal working apparatusInterconnectionEngineering

Axially compressible, F-connectors for conventional installation tools for interconnection with coaxial cable include adaptations for establishing electrical continuity despite inadequate nut tightening. Each connector has a rigid nut, a post penetrating the nut, a tubular body, and an end cap. The conductive post coaxially extends through the connector, linking the nut and body. A post end penetrates the coaxial cable. The connector may have a circumferential groove defined in the end cap mounting an annular D-ring which tensions contact between the post and nut. The connector may comprise a continuity coil seated within a post groove in spring-loaded contact with the nut and the post for promoting continuity. The connector may comprise a pressure spring and an O-ring seated within a post groove in spring-loaded contact with the nut for promoting continuity.

Owner:PERFECTVISION MFG

Compression type coaxial F-connector with traveling seal and grooved post

InactiveUS8834200B2The connection is tight and firmIncreased operating bandwidthOne pole connectionsElectrically conductive connectionsHigh bandwidthEngineering

Axially compressible, self-sealing, high bandwidth F-connectors for conventional hand tools for interconnection with coaxial cable. An internal, dual segment sealing grommet activated by compression elongates and deforms to provide a travelling seal. Each connector has a rigid nut that is rotatably secured to a, tubular body. A rigid, conductive post has a barbless shank with a groove that coaxially extends through the connector and penetrates the coaxial cable within the connector. A tubular, metallic end cap is slidably fitted to a body shank, and is thereafter forcibly compressed lengthwise during installation. The end cap has a ring groove for seating the enhanced grommet. The grommet travels and extrudes during compression to mate and intermingle with a portion of the cable braid that is looped back from a prepared cable end, and portions of the cable are urged towards the post groove for sealing.

Owner:PERFECTVISION MFG

Sealed compression type coaxial cable F-connectors

InactiveUS7841896B2Easy to useImprove sealingElectrically conductive connectionsCouplings bases/casesHigh bandwidthInterconnection

Owner:PERFECTVISION MFG

Coaxial barrel fittings and couplings with ground establishing traveling sleeves

ActiveUS8888527B2Overcome problemsElectrically conductive connectionsCoupling contact membersAxial displacementCoupling

Barrel connectors, a right angled adaptor and a single ended fitting include at least one axially displaceable traveling sleeve for insuring electrical continuity with coaxial connector, nominally an F-connector. Each barrel connector described comprises a rigid, metallic hollow body housing an internal contact tube. At least one coiled spring is retained within the body. At least one elongated, tubular traveling sleeve is coaxially disposed within each body end and normally biased outwardly by the springs. The metallic traveling sleeves comprise an elongated shank that contacts the spring, and a head that seats against the connector body ends during installation. Catches or rings defined upon or mounted to travelling sleeve shanks are received within suitable grooves for anchoring the traveling sleeves while facilitating limited axial displacements. The traveling sleeves, and the contact tube therewithin, normally are biased outwardly so that even limited torquing of an F-connector will establish a ground path.

Owner:PERFECTVISION MFG

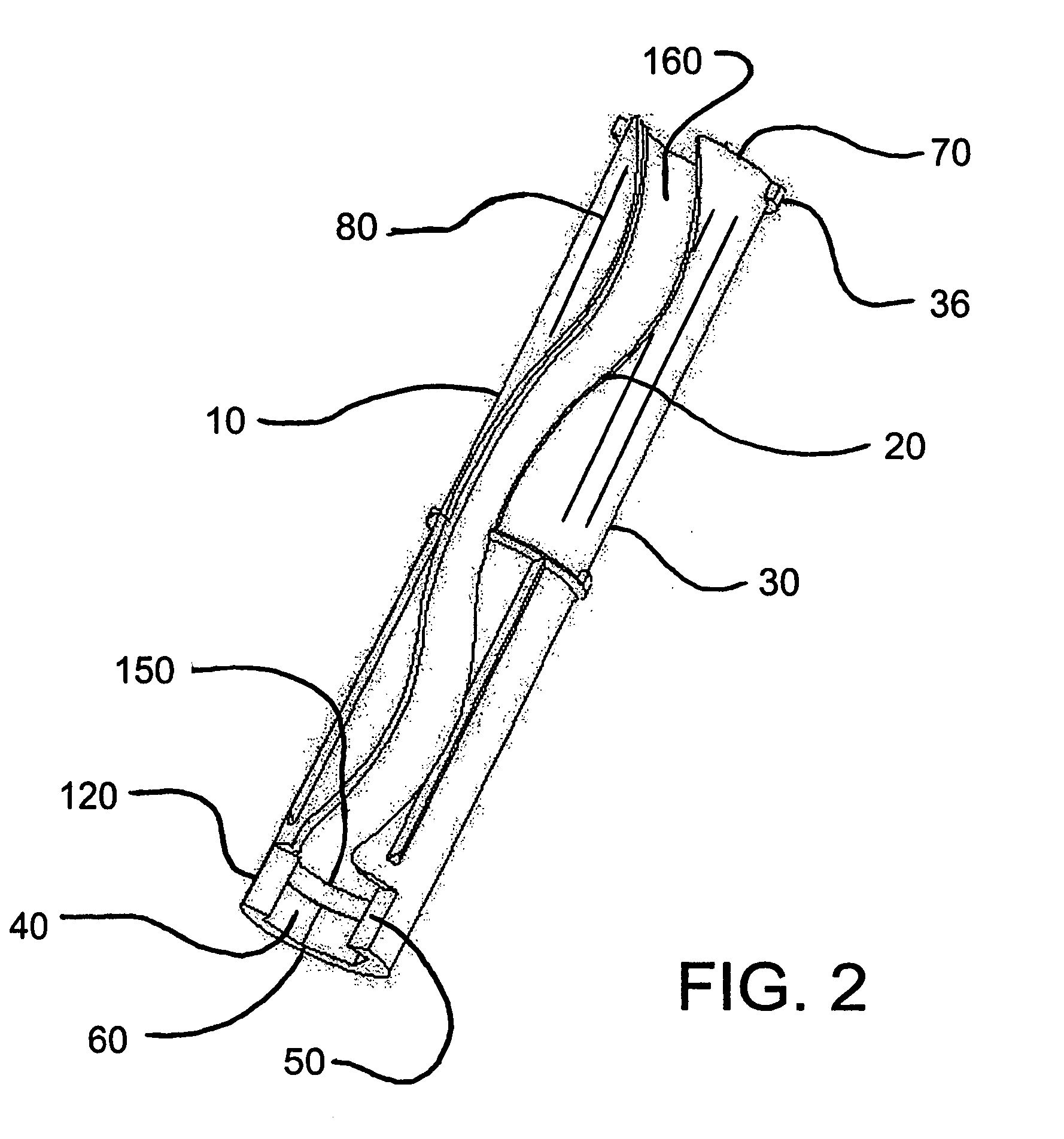

Cable wrench

InactiveUS6938522B1Prevent visibilityCoupling device engaging/disengagingCoupling device detailsVisibilityF connector

A Cable Wrench that guides, connects and disconnects an F-Connector male end attached to a coaxial cable, to an F-Connector female connection on a TV, VCR, computer or any other device that uses coaxial cable or a cable splitter. This invention prevents the coaxial cable from becoming disengaged, or from slipping out of the cable wrench by using a curved slot that runs the entire axial length of the tool. The wrench provides a large cut away section at the wrench end to allow better visibility while operating the tool and a section adjacent to and behind the wrench portion that is wider in order to allow use of the tool with crimped or large connectors.

Owner:STANNIK ROBERT THOMAS

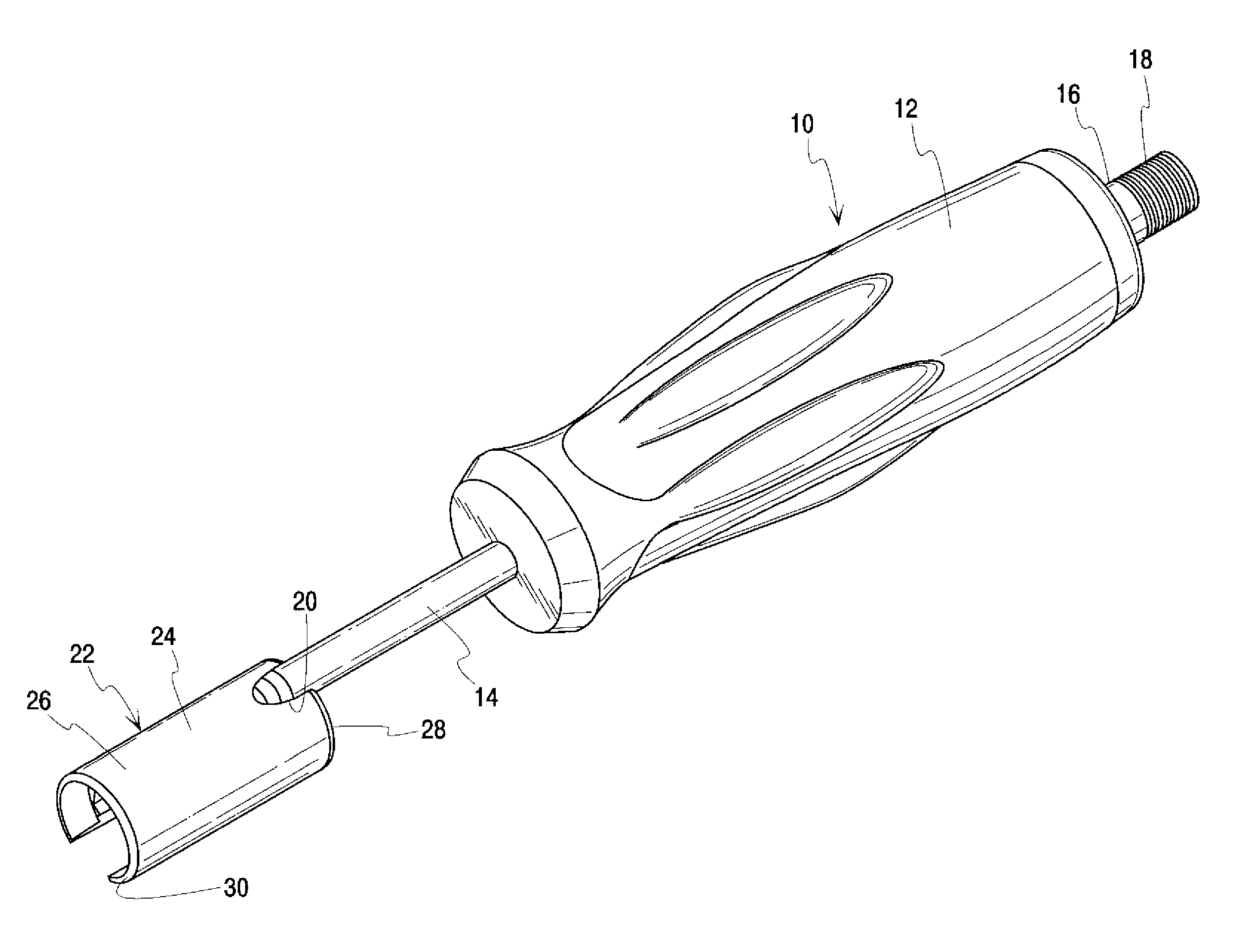

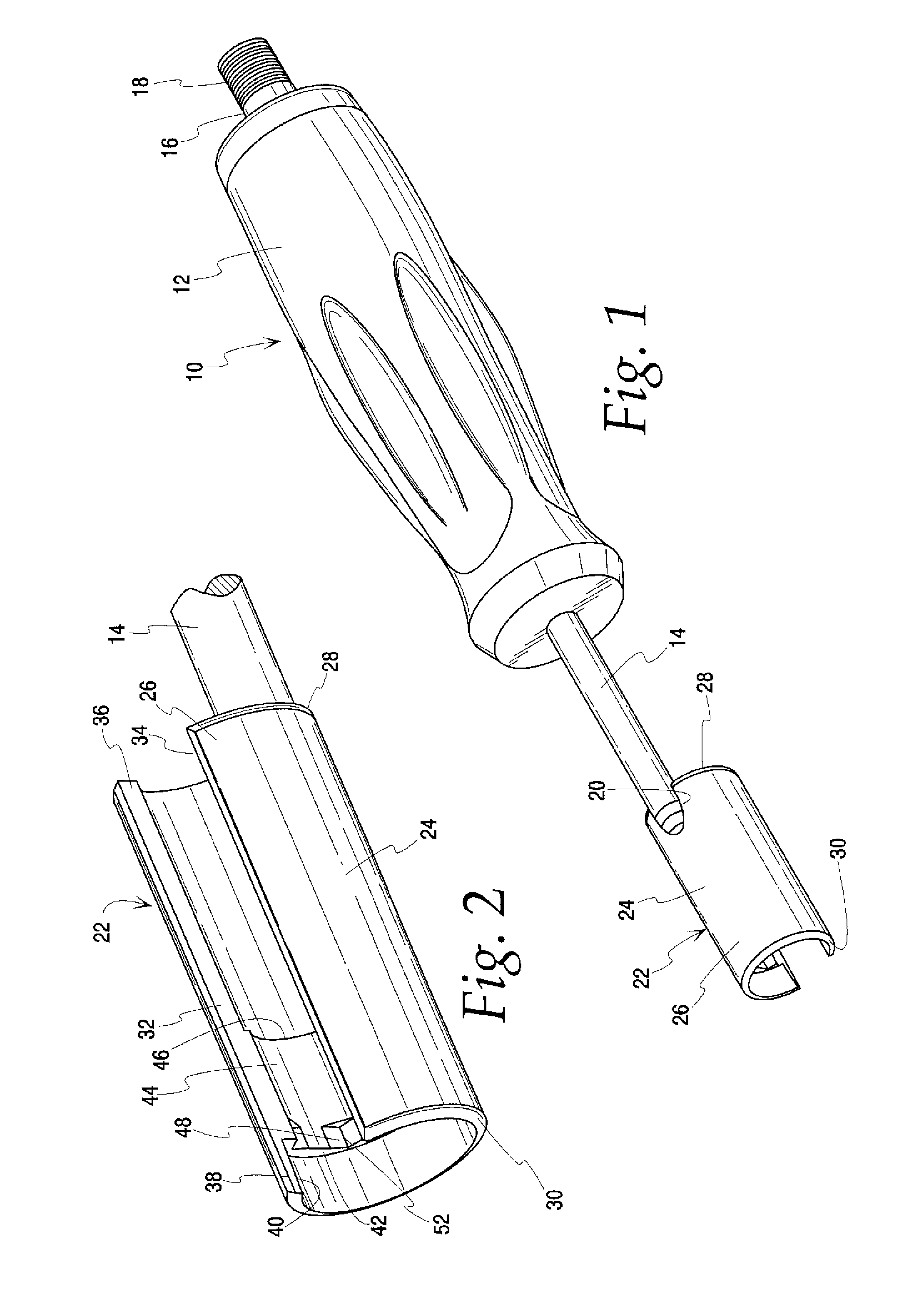

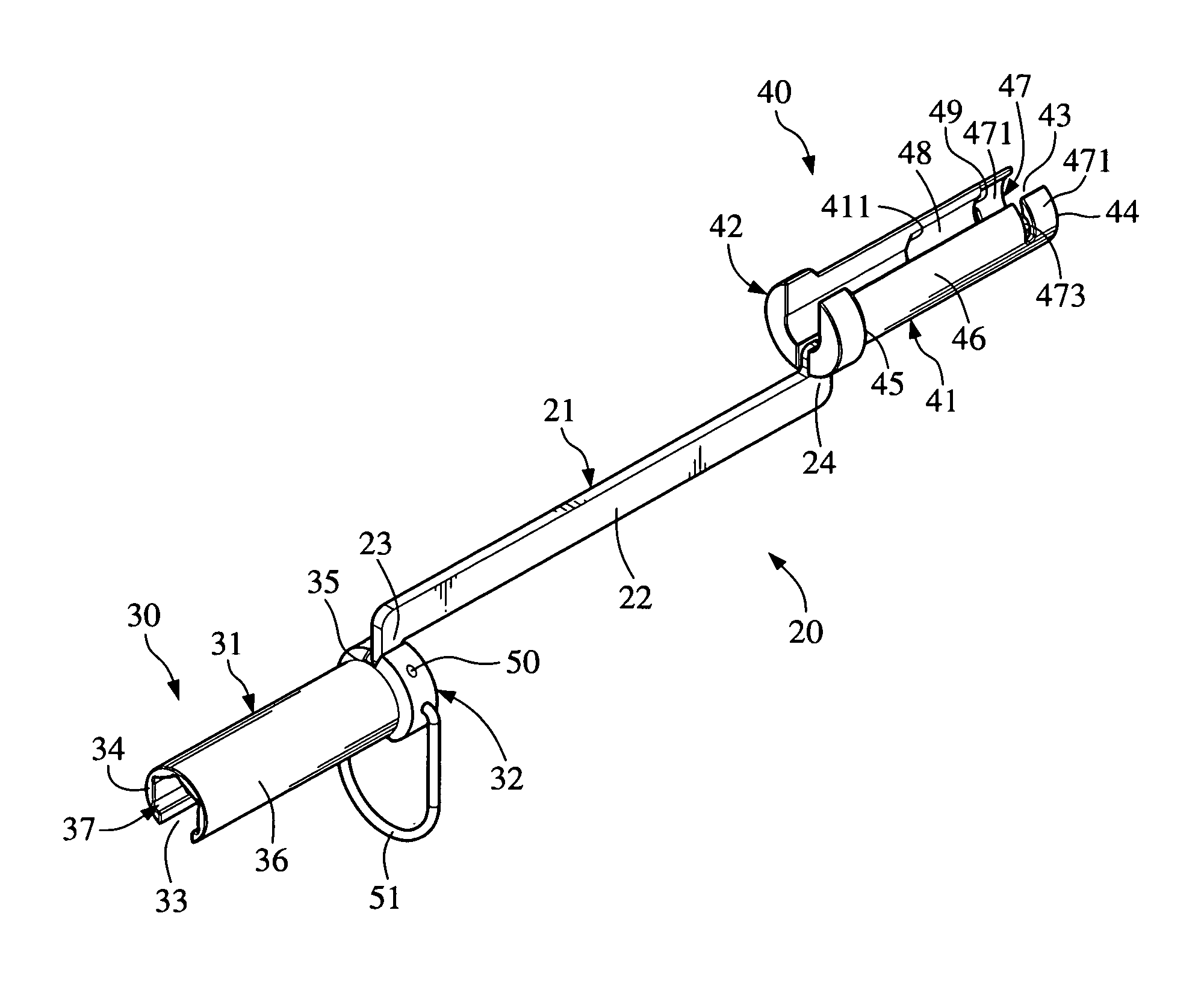

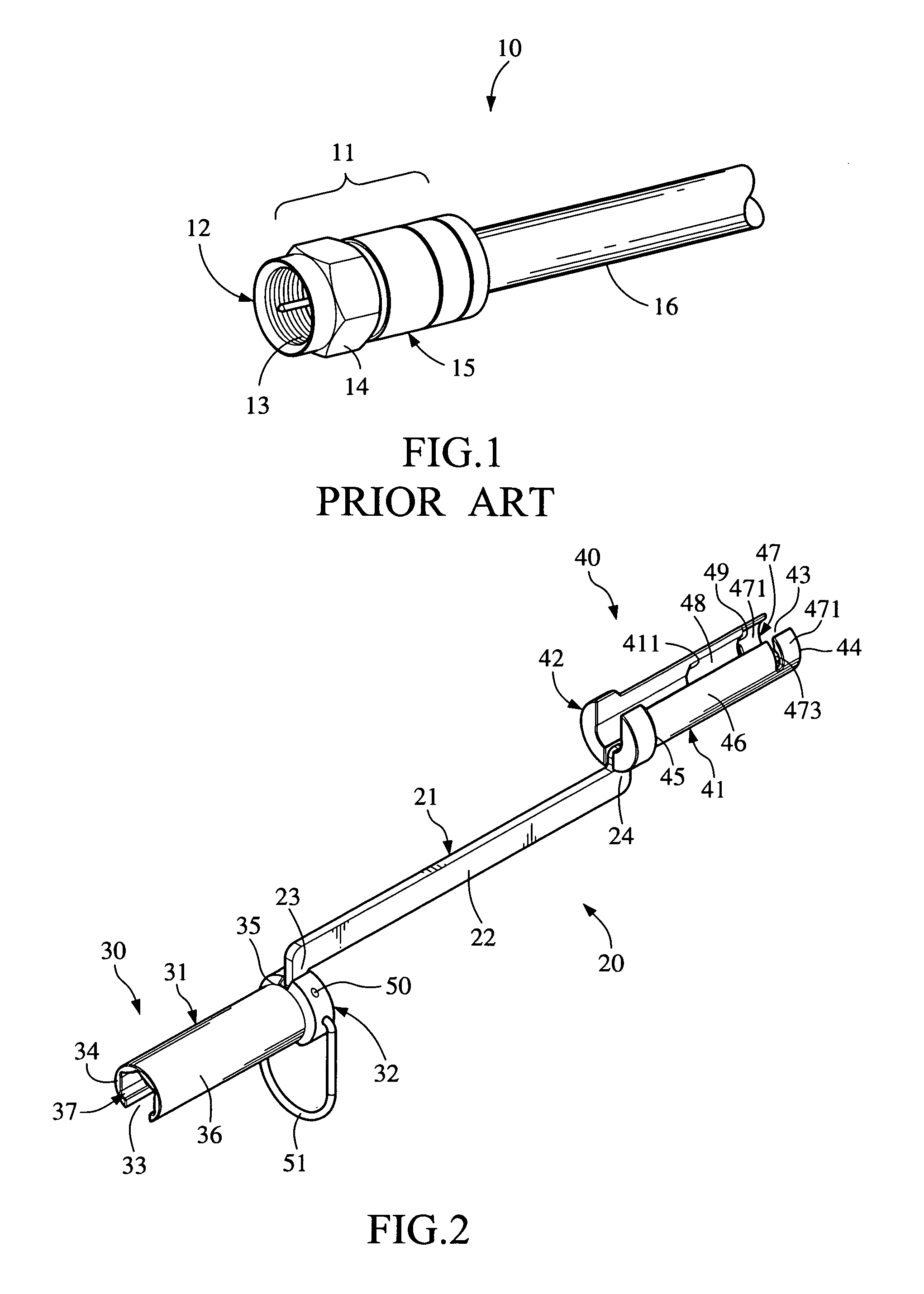

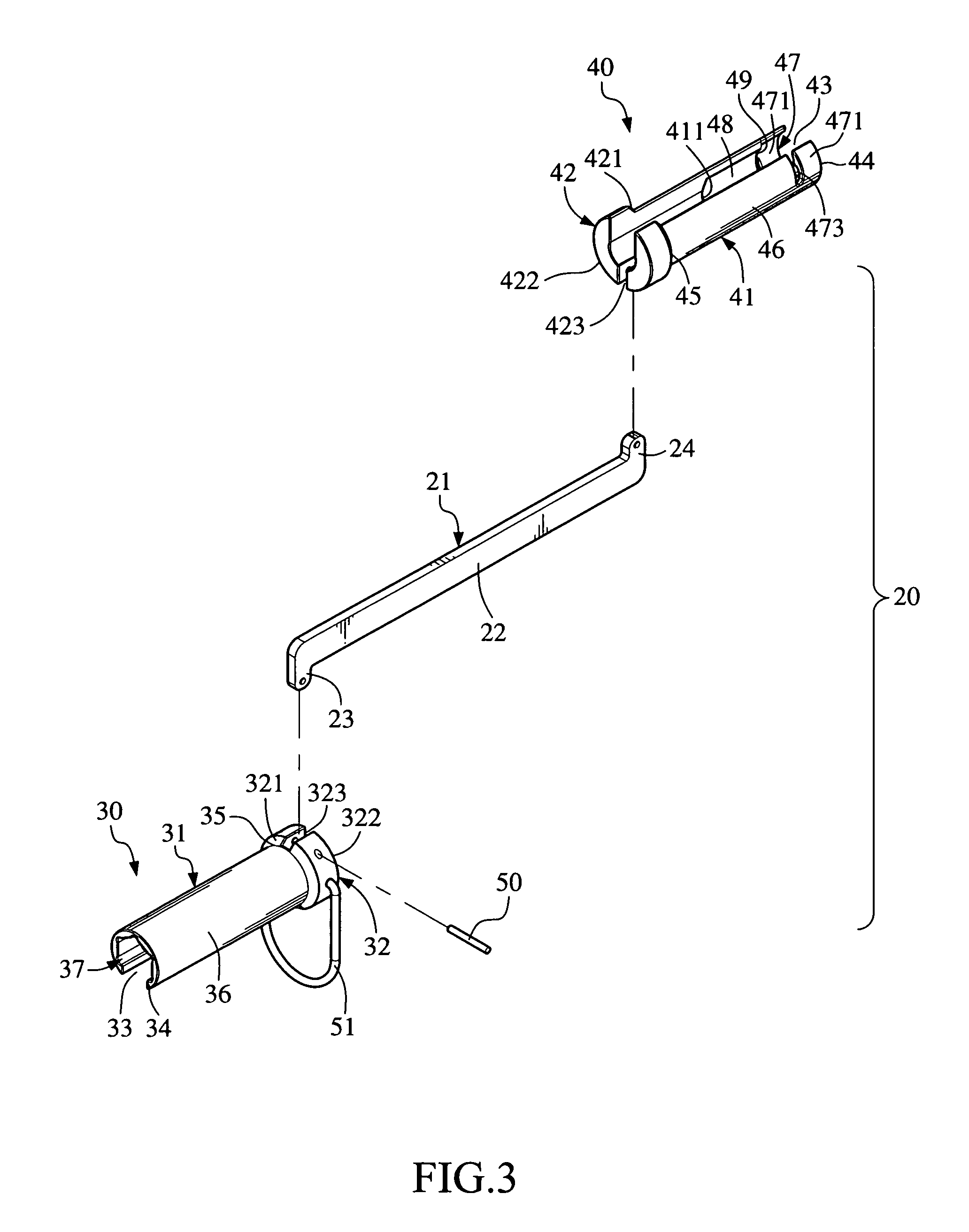

Tool for installing and removing male F-type coaxial cable connector

InactiveUS7975578B2Constant torqueSimply usedCoupling device engaging/disengagingTwo-part coupling devicesEngineeringElectric cables

A tool includes a first and a second socket wrench pivotally turnably connected to two ends of a link. Each of the first and second socket wrenches includes a wrench portion and a circular end portion having an axial slot extended through them. The wrench portion of the first socket wrench is internally formed of a hexagonally shaped portion for fitting around a hexagonally-shaped outer surface of a connecting ring of a male F connector to tighten or loosen the connecting ring to or from a female F connector, and the wrench portion of the second socket wrench is internally formed of a constant-torque shaped portion for fitting around the hexagonally-shaped outer surface of the connecting ring to prevent the tool from applying an excessive torque on the connecting ring when turning the same. The tool can be used without being hindered by bent or closely arranged cables.

Owner:PHOENIX COMM TECH INT

Enhanced coaxial connector continuity

ActiveUS20130164976A1Reliable and reliableEconomically manufacturedElectrically conductive connectionsMetal working apparatusInterconnectionEngineering

Axially compressible, F-connectors for conventional installation tools for interconnection with coaxial cable include adaptations for establishing electrical continuity despite inadequate nut tightening. Each connector has a rigid nut, a post penetrating the nut, a tubular body, and an end cap. The conductive post coaxially extends through the connector, linking the nut and body. A post end penetrates the coaxial cable. The connector may have a circumferential groove defined in the end cap mounting an annular D-ring which tensions contact between the post and nut. The connector may comprise a continuity coil seated within a post groove in spring-loaded contact with the nut and the post for promoting continuity. The connector may comprise a pressure spring and an O-ring seated within a post groove in spring-loaded contact with the nut for promoting continuity.

Owner:PERFECTVISION MFG

Tool for installing and removing male F-type coaxial cable connector

ActiveUS20100282030A1Easy to useConstant torqueCoupling device engaging/disengagingTwo-part coupling devicesEngineeringElectric cables

A tool includes a first and a second socket wrench pivotally turnably connected to two ends of a link. Each of the first and second socket wrenches includes a wrench portion and a circular end portion having an axial slot extended through them. The wrench portion of the first socket wrench is internally formed of a hexagonally shaped portion for fitting around a hexagonally-shaped outer surface of a connecting ring of a male F connector to tighten or loosen the connecting ring to or from a female F connector, and the wrench portion of the second socket wrench is internally formed of a constant-torque shaped portion for fitting around the hexagonally-shaped outer surface of the connecting ring to prevent the tool from applying an excessive torque on the connecting ring when turning the same. The tool can be used without being hindered by bent or closely arranged cables.

Owner:PHOENIX COMM TECH INT

Coaxial connector grounding inserts

ActiveUS8556654B2Reliable ground connectionEconomically manufacturedLine/current collector detailsClamped/spring connectionsInterconnectionEngineering

Axially compressible, F-connectors for conventional installation tools for interconnection with coaxial cable include grounding inserts for establishing electrical continuity despite inadequate nut tightening. The connector has a rigid nut, a post penetrating the nut, a tubular body, and an end cap. The conductive post coaxially extends through the connector, linking the nut and body. A post end penetrates the coaxial cable. Internal grounding inserts comprise a circular band coaxially engaging the post and portions on the band engaging the nut. Multiple radially spaced apart spring clips defined around the band grasp a flange portion of the post. The band is seated within a ring groove within the nut, making electrical contact. An alternative insert comprises a tubular band for contacting the post and an integral skirt abutting the nut's internal ring groove and contacting a portion of the socket to which the connector is coupled.

Owner:PERFECTVISION MFG

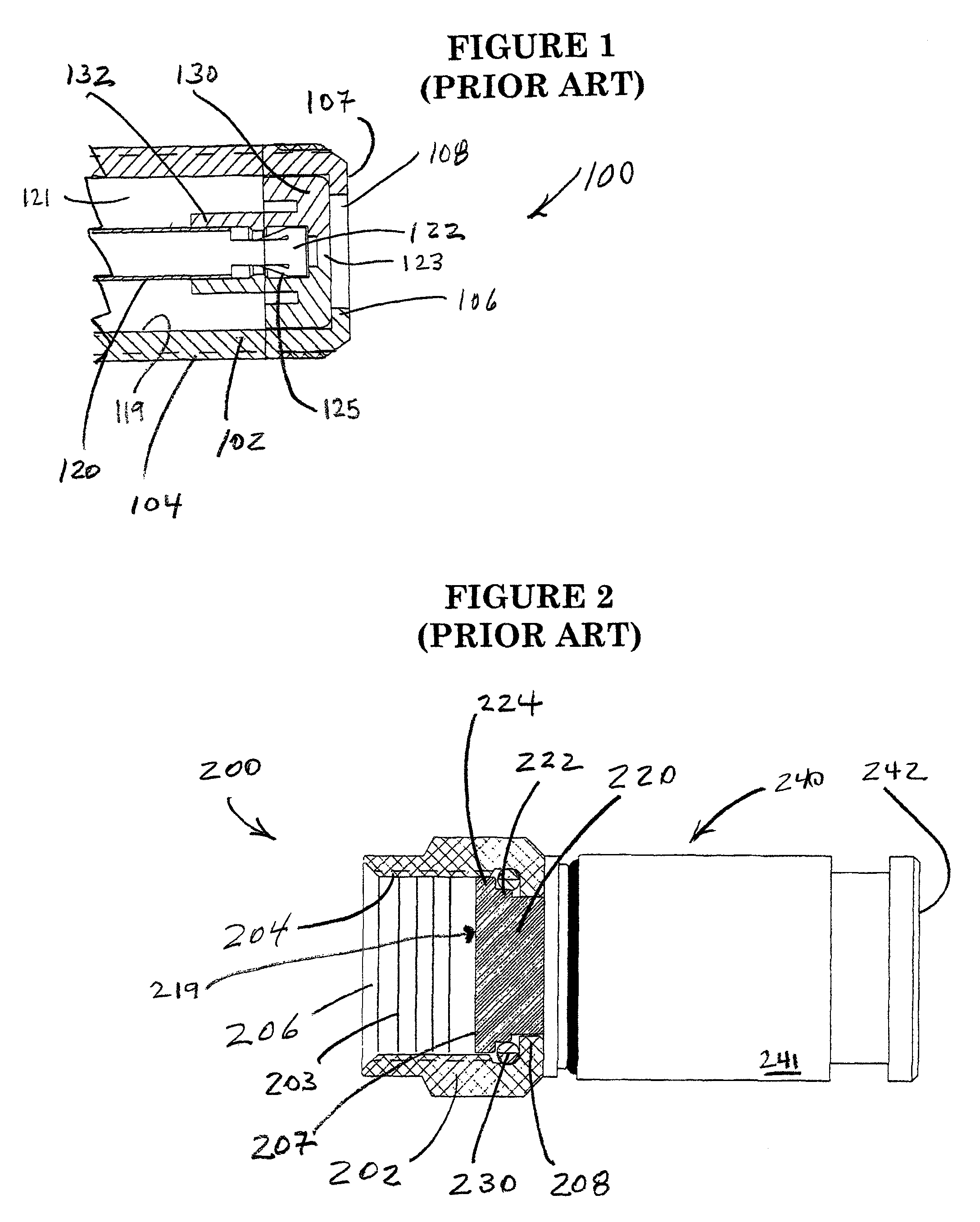

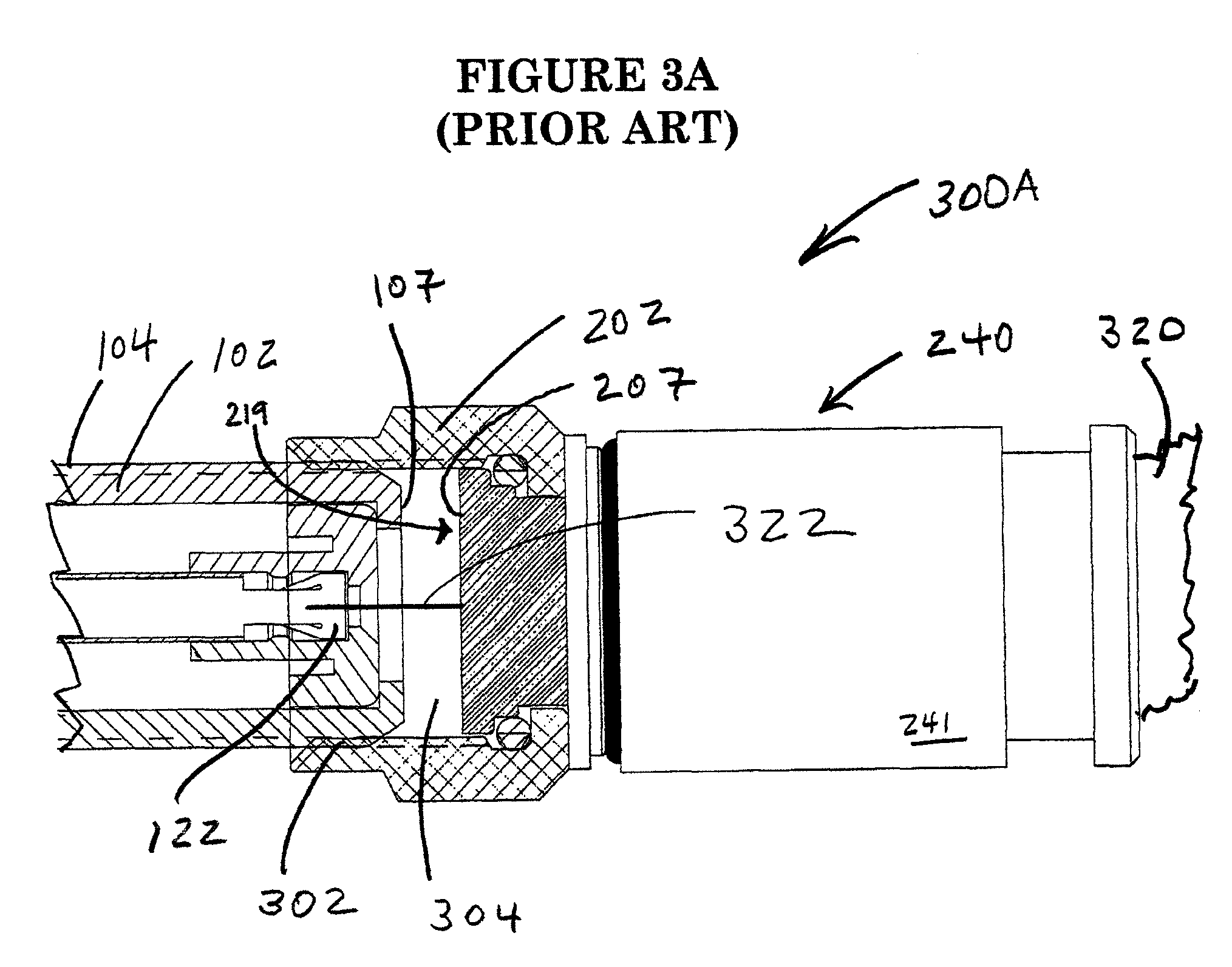

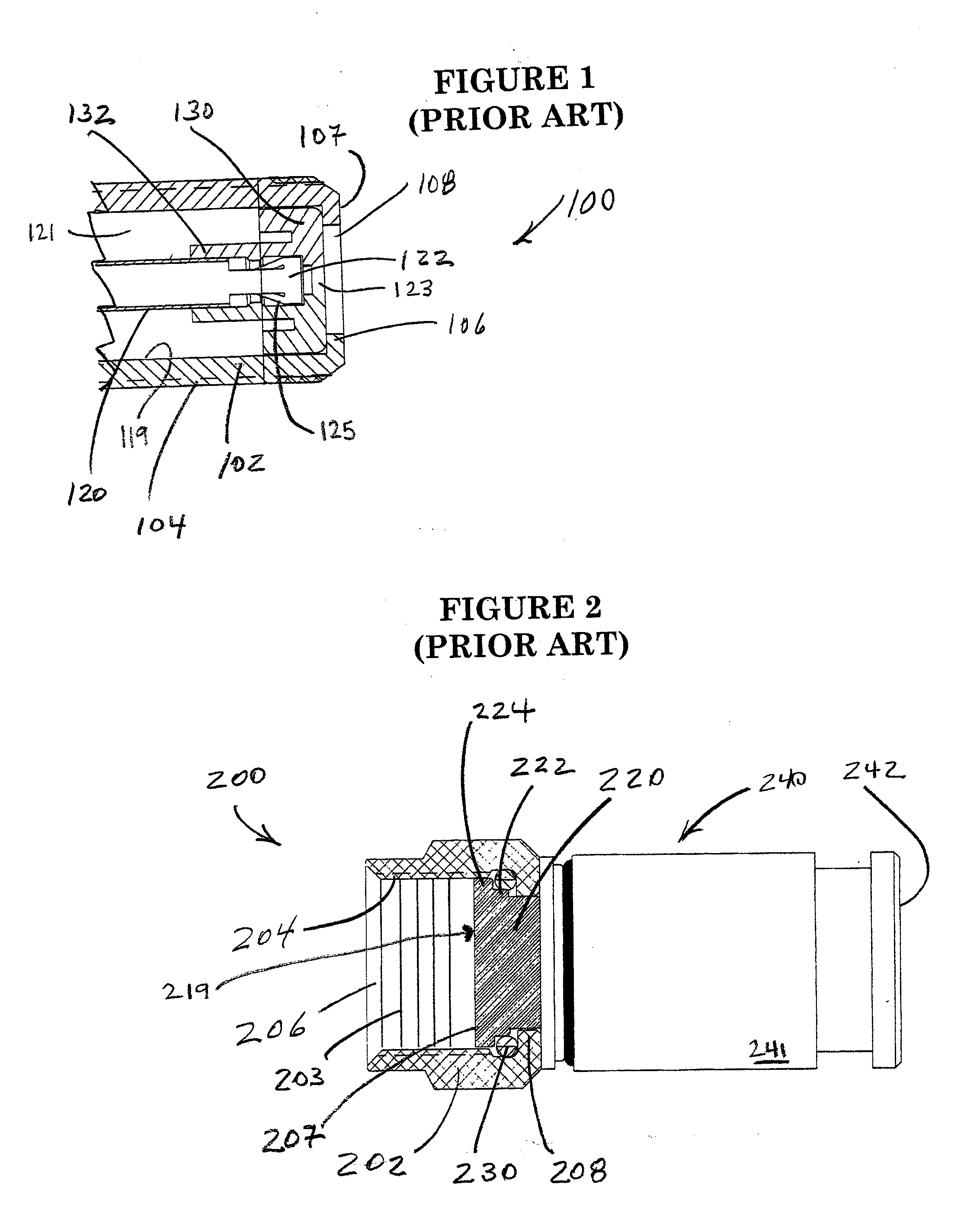

Moving part coaxial cable connectors

ActiveUS9136629B2Improve continuityImproves mated connector ground path continuityElectrically conductive connectionsCoupling device engaging/disengagingEngineeringF connector

A female F connector incorporates a nose protruding from an end of the connector and the nose is urged to protrude by a spring.

Owner:HOLLAND ELECTRONICS

Compression Type Coaxial F-Connector With Traveling Seal and Grooved Post

InactiveUS20130149884A1The connection is tight and firmIncreased operating bandwidthOne pole connectionsElectrically conductive connectionsHigh bandwidthEngineering

Axially compressible, self-sealing, high bandwidth F-connectors for conventional hand tools for interconnection with coaxial cable. An internal, dual segment sealing grommet activated by compression elongates and deforms to provide a travelling seal. Each connector has a rigid nut that is rotatably secured to a, tubular body. A rigid, conductive post has a barbless shank with a groove that coaxially extends through the connector and penetrates the coaxial cable within the connector. A tubular, metallic end cap is slidably fitted to a body shank, and is thereafter forcibly compressed lengthwise during installation. The end cap has a ring groove for seating the enhanced grommet. The grommet travels and extrudes during compression to mate and intermingle with a portion of the cable braid that is looped back from a prepared cable end, and portions of the cable are urged towards the post groove for sealing.

Owner:PERFECTVISION MFG

Coaxial connector grounding inserts

ActiveUS20130137299A1Reliable ground connectionEconomically manufacturedLine/current collector detailsClamped/spring connectionsInterconnectionEngineering

Axially compressible, F-connectors for conventional installation tools for interconnection with coaxial cable include grounding inserts for establishing electrical continuity despite inadequate nut tightening. The connector has a rigid nut, a post penetrating the nut, a tubular body, and an end cap. The conductive post coaxially extends through the connector, linking the nut and body. A post end penetrates the coaxial cable. Internal grounding inserts comprise a circular band coaxially engaging the post and portions on the band engaging the nut. Multiple radially spaced apart spring clips defined around the band grasp a flange portion of the post. The band is seated within a ring groove within the nut, making electrical contact. An alternative insert comprises a tubular band for contacting the post and an integral skirt abutting the nut's internal ring groove and contacting a portion of the socket to which the connector is coupled.

Owner:PERFECTVISION MFG

Moving part coaxial cable connectors

ActiveUS20140024234A1Improve continuityImproves mated connector ground path continuityContact member assembly/disassemblyCoupling device engaging/disengagingEngineeringF connector

A female F connector incorporates a nose protruding from an end of the connector and the nose is urged to protrude by a spring.

Owner:HOLLAND ELECTRONICS

Compression type coaxial cable F-connectors

InactiveUS20090176407A1Easy to useReliable functionElectrically conductive connectionsCoupling device detailsHigh bandwidthInterconnection

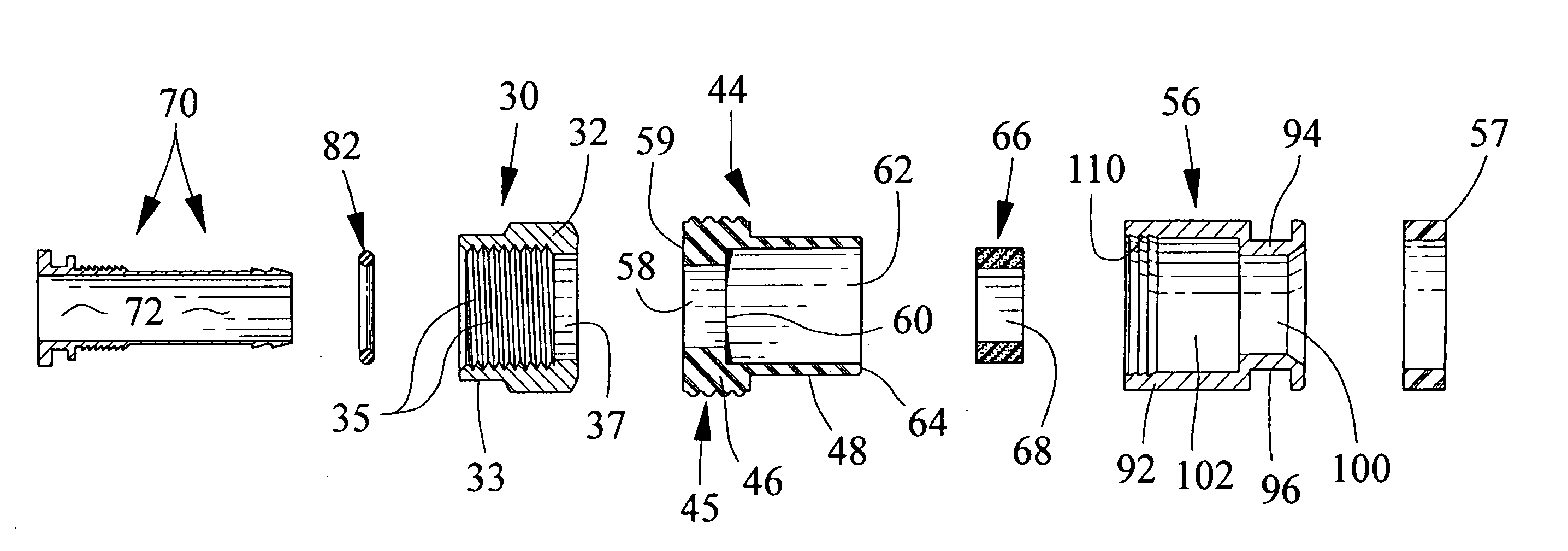

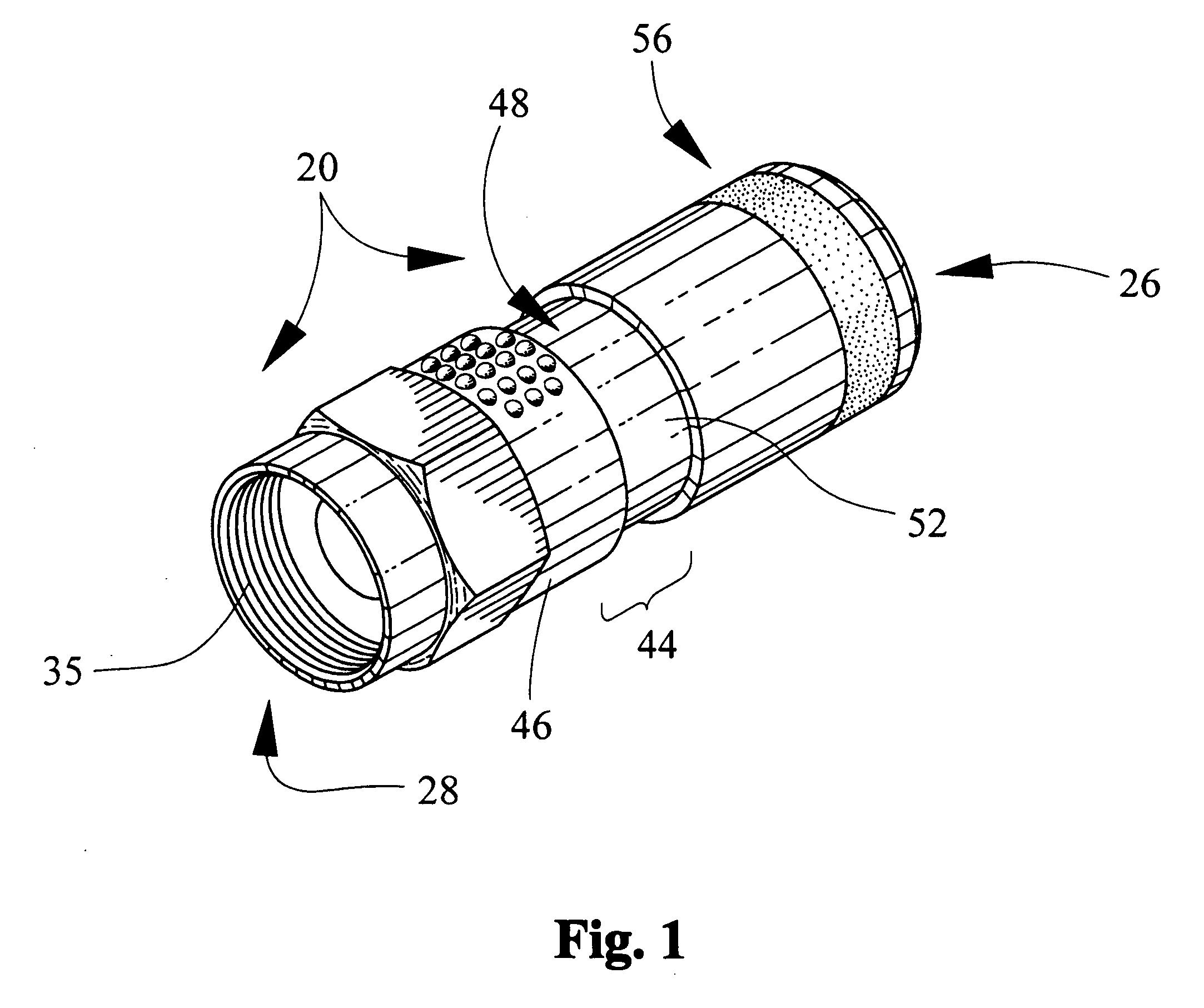

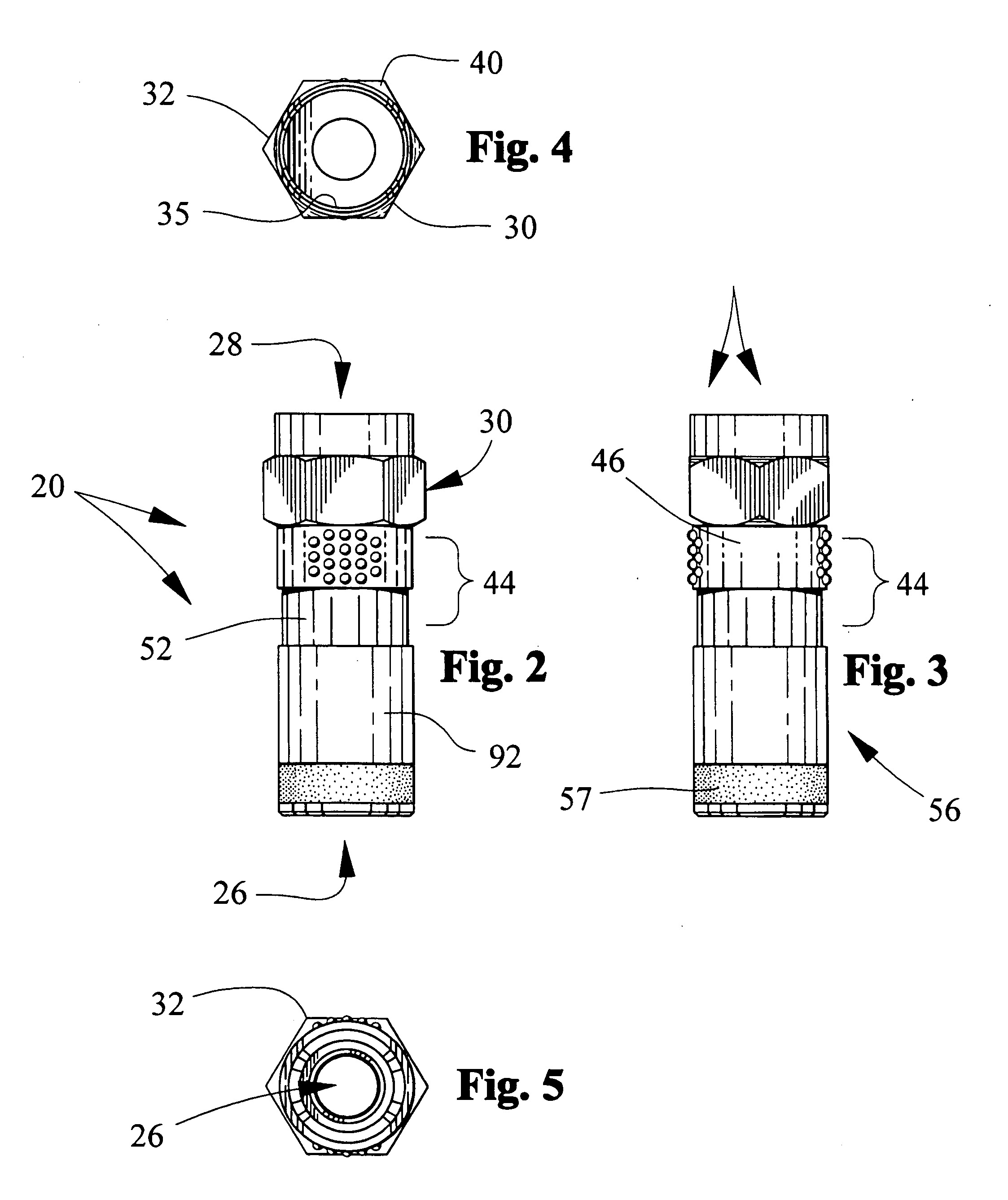

Axially compressible, high bandwidth F-connectors designed for conventional installation hand tools for interconnection with coaxial cable. Each connector has a rigid nut that is axially and rotatably secured to a molded plastic, tubular body. A rigid, conductive post coaxially extends through the connector, linking the nut and body. A post barbed end penetrates the cable within the connector. The body has a tubular shank with an obstruction-free surface and an integral stop ring. A tubular, metallic end cap is slidably fitted to the body shank, and thereafter forcibly compressed lengthwise, with travel limited by the stop ring. No detented structure is formed on the body, and the end cap can irreversibly assume any position, being held by end cap teeth. A tactile system comprising convex projections on the stop ring complemented by a resilient O-ring on the end cap helps installers determine correct placement through the sense of touch.

Owner:DS ENG

Enhanced continuity coaxial connectors with socketed nut

InactiveUS9166307B2Improve continuitySafely and properlyElectrically conductive connectionsEngineeringInterconnection

An axially compressible F-connector for conventional installation tools for interconnection with coaxial cable includes a rigid nut with a rear skirt forming a socket. A rigid, tubular post penetrates the nut and engages coaxial cable. An internal, slidable sleeve has a plug portion that is adapted to engage and seat within the socket. A tubular end cap completes the assembly. The tubular post coaxially extends through the connector, physically connecting the nut and coaxial cable it engages. However, grounding is insured by portions of the cable sheath that are sandwiched within the socket between the sleeve plug and the nut skirt by sealing O-rings affixed to the sleeve plug.

Owner:PERFECTVISION MFG

Moving part coaxial cable connector

ActiveUS9130288B2Improve continuityImproves mated connector ground path continuityElectrically conductive connectionsTwo pole connectionsEngineeringF connector

A female F connector incorporates a nose protruding from an end of the connector and the nose is urged to protrude by a spring.

Owner:HOLLAND ELECTRONICS

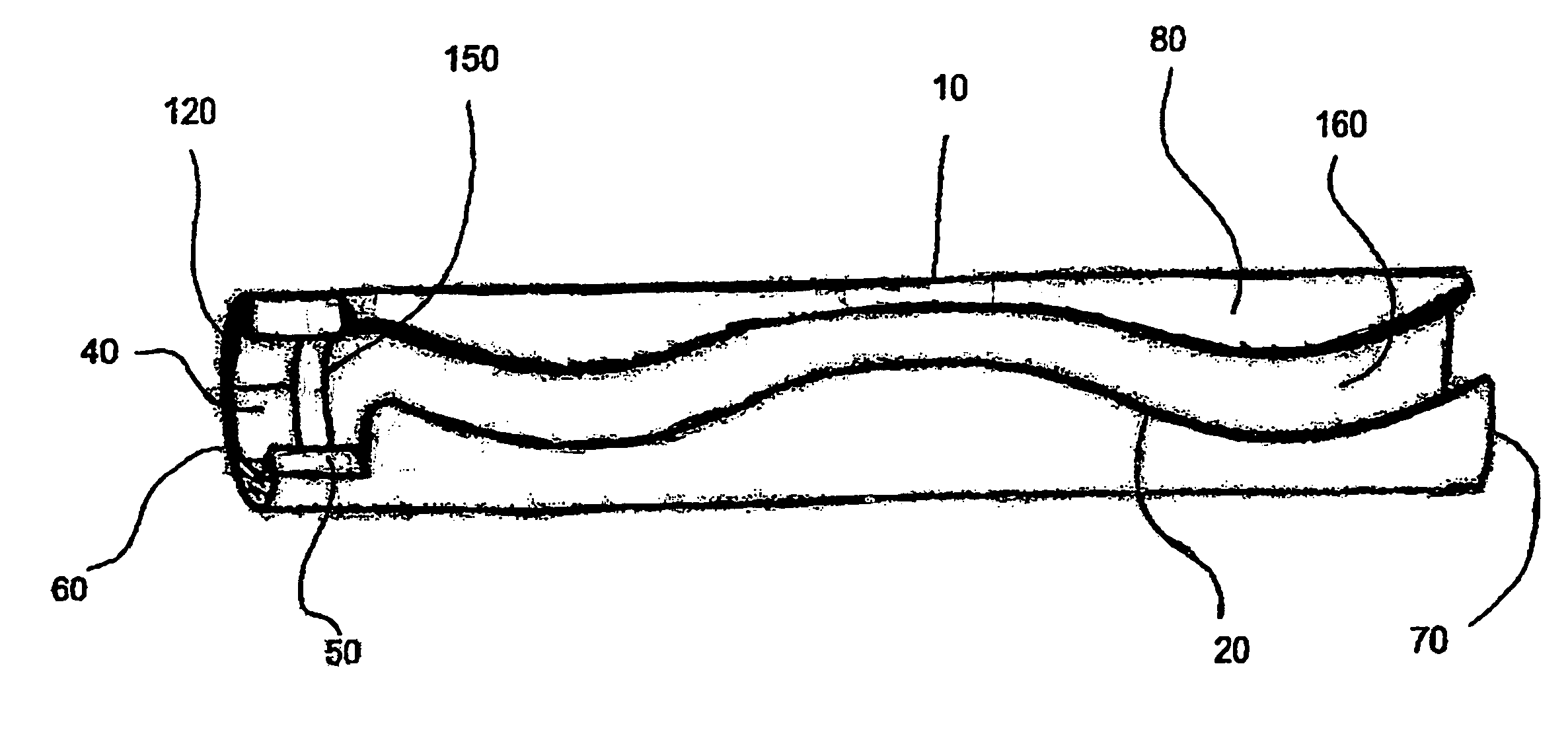

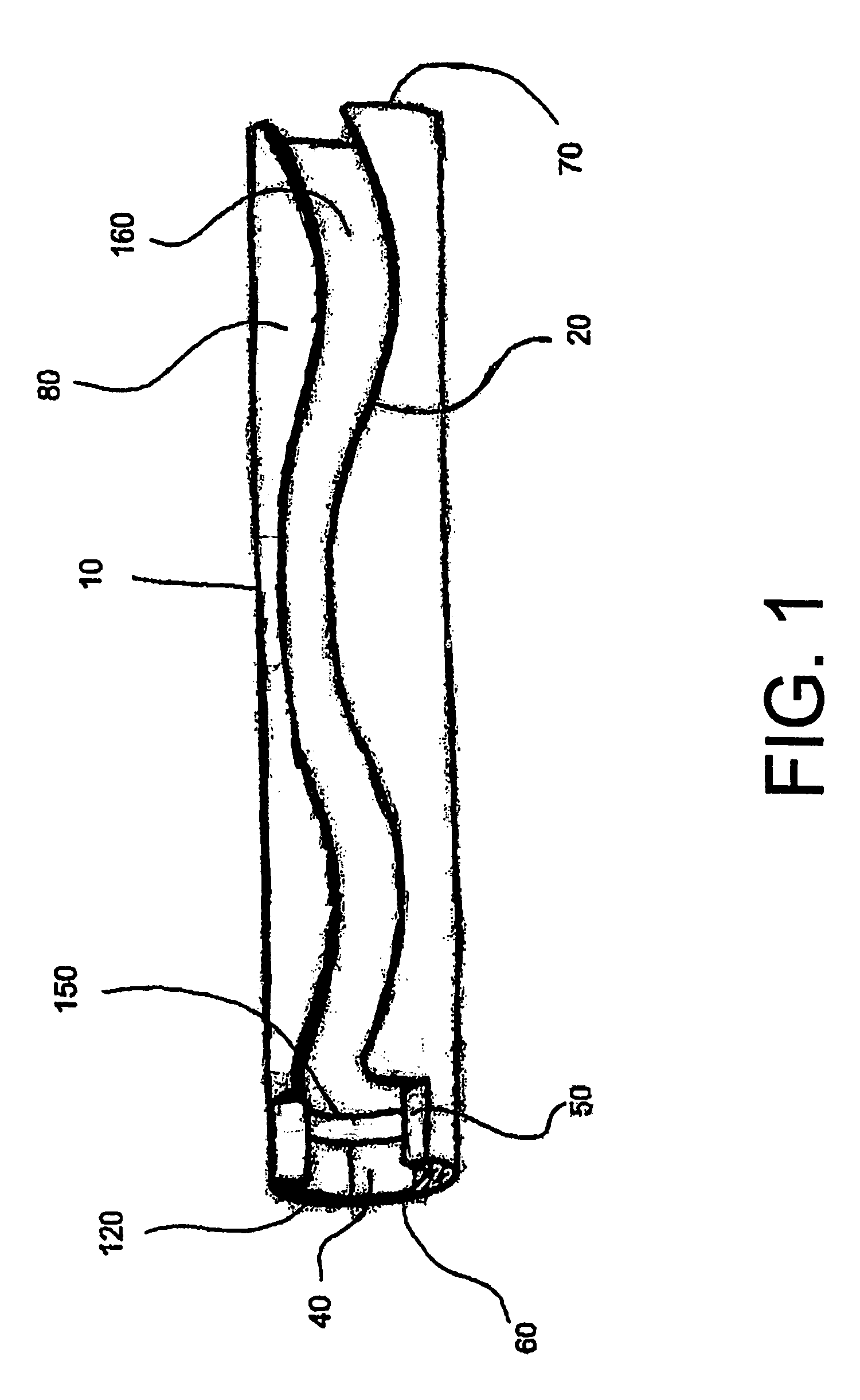

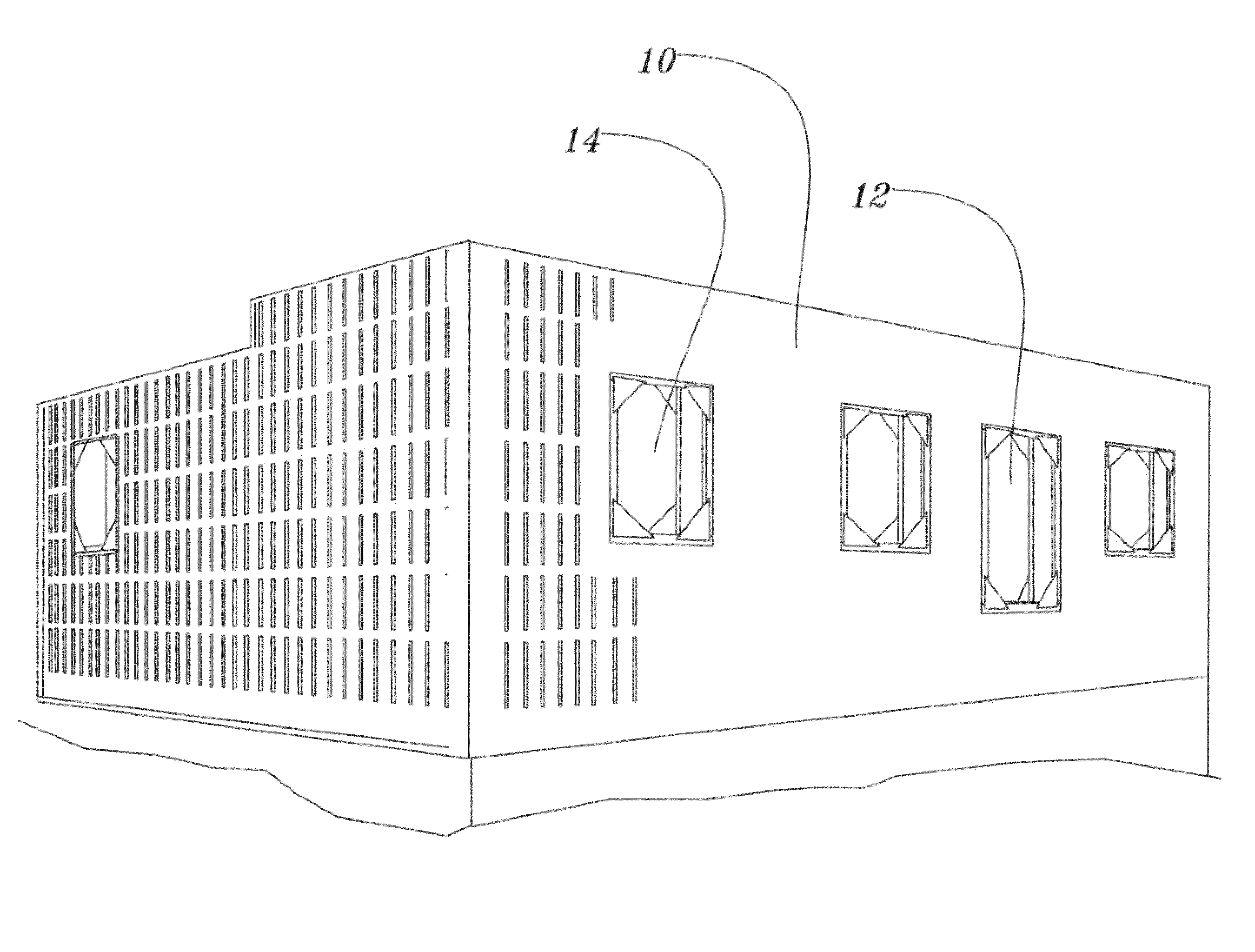

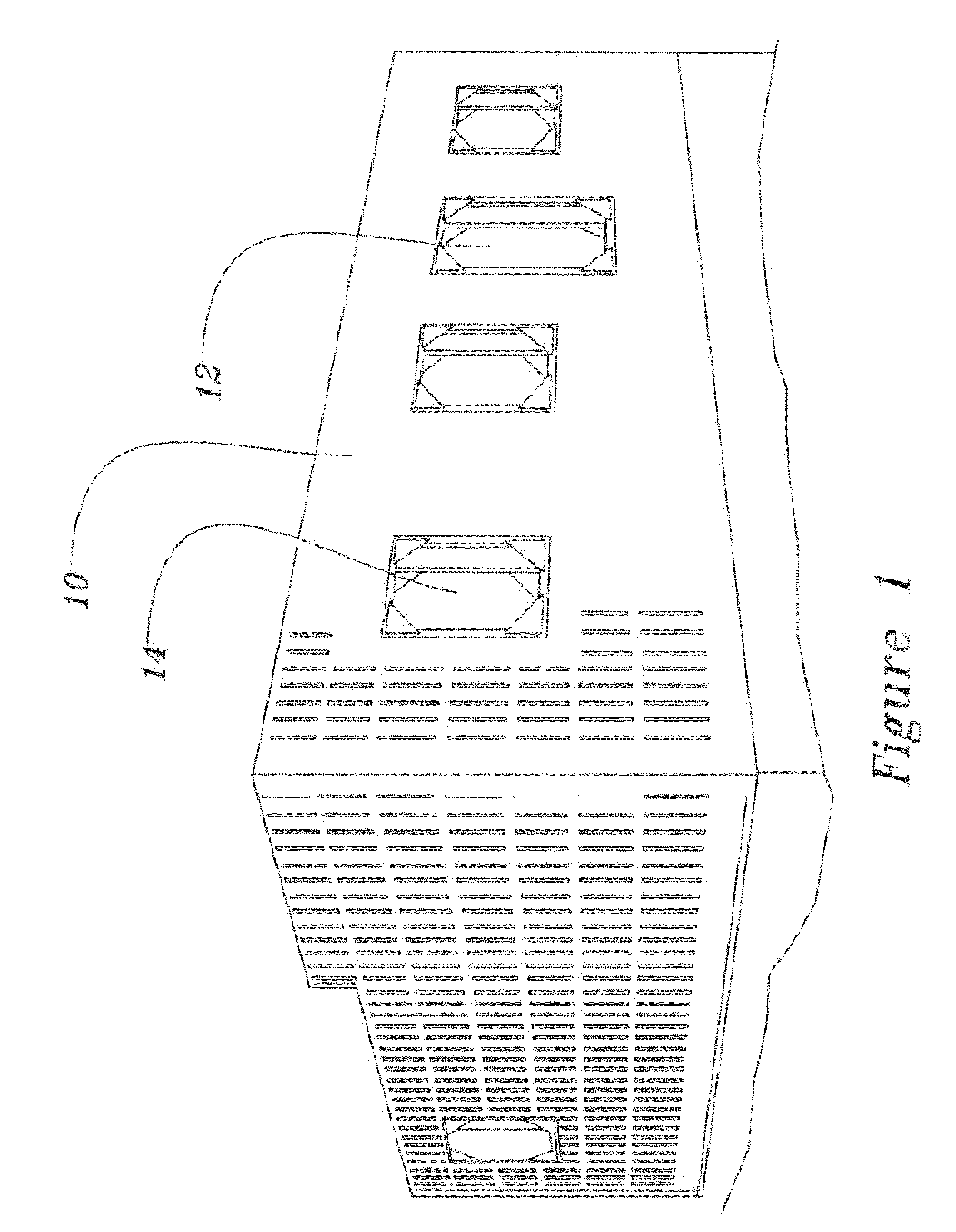

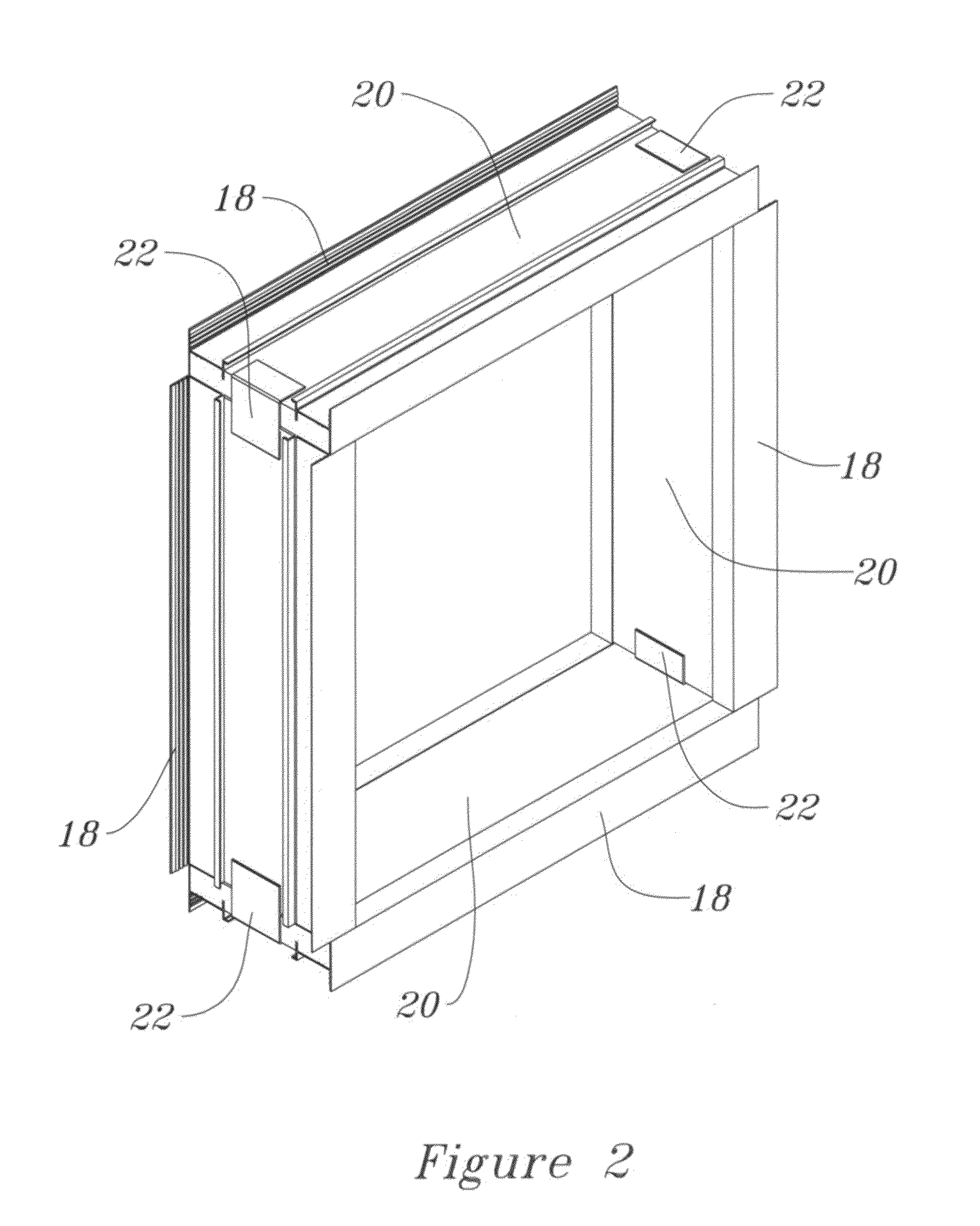

Buck system

The invention discloses an insulated buck system for an insulated concrete form ICF) structure having a plurality of extruded channels, a plurality of foam panels; and a plurality of F-connectors wherein the foam panels are inserted within the extruded channels. Pairs of the extruded channels containing foam in between (planks) are coupled to each other by the F-connectors. The structure of the insulated buck system provides and an insulated seal for the window or door installed within the insulated buck system. Additionally mounting plates for mounting items to the insulated buck system are described. A triangular bracing bracket is also disclosed. A kit of parts is described.

Owner:BRILL GEROW D MR

Compression type coaxial cable F-connectors with traveling seal and barbless post

InactiveUS8371874B2The connection is tight and firmIncreased operating bandwidthOne pole connectionsElectrically conductive connectionsHigh bandwidthEngineering

Axially compressible, self-sealing, high bandwidth F-connectors for conventional hand tools for interconnection with coaxial cable. An internal, dual segment sealing grommet activated by compression elongates and deforms to provide a travelling seal. Each connector has a rigid nut that is rotatably secured to a, tubular body. A rigid, conductive post has a barbless shank that coaxially extends through the connector and penetrates the coaxial cable within the connector. A tubular, metallic end cap is slidably fitted to a body shank, and is thereafter forcibly compressed lengthwise during installation. The end cap has a ring groove for seating the enhanced grommet. The end cap can irreversibly assume any position, being held by end cap teeth. The grommet travels and extrudes during compression to mate and intermingle with a portion of the cable braid that is looped back to form a prepared cable end.

Owner:PERFECTVISION MFG

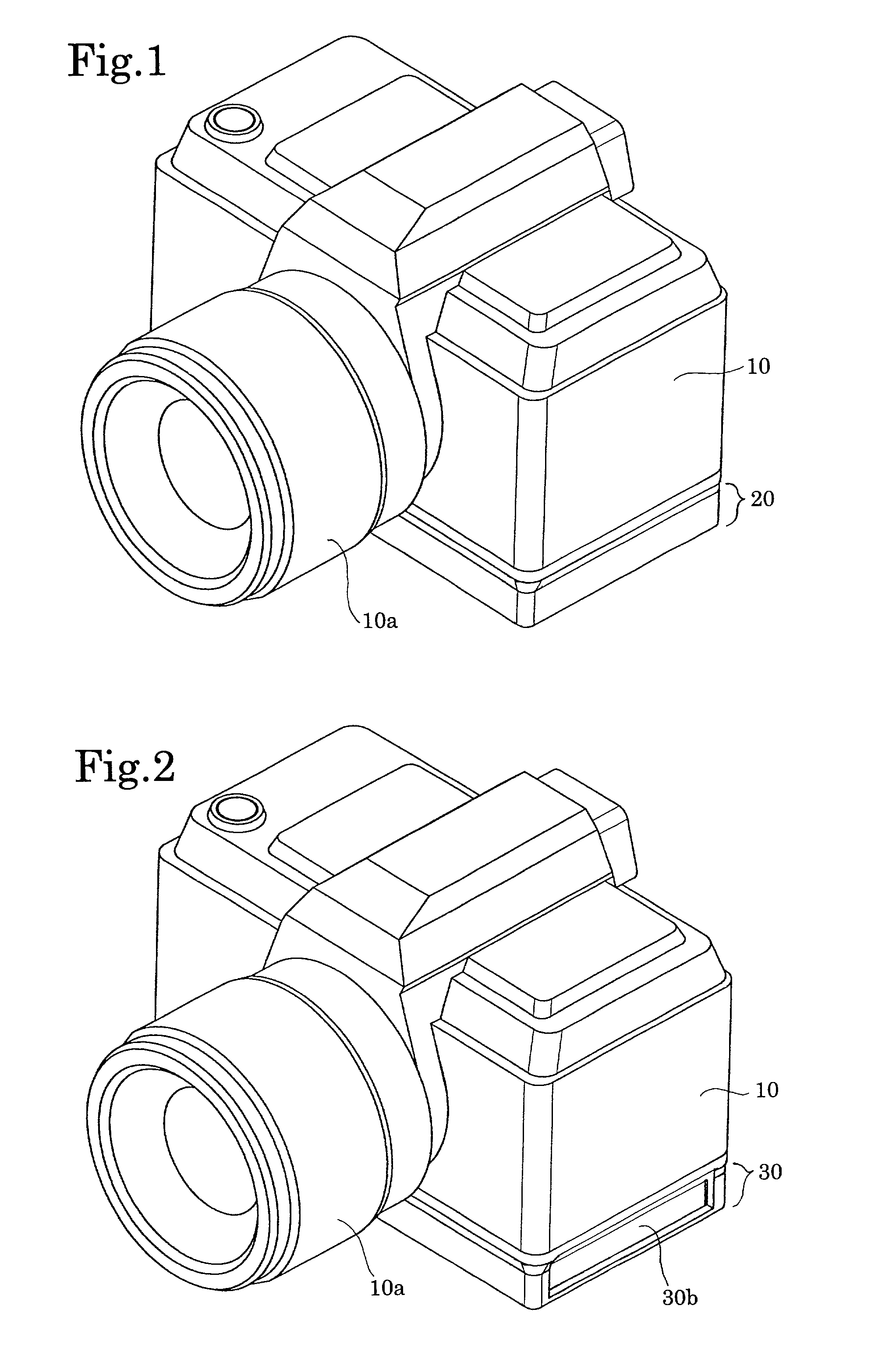

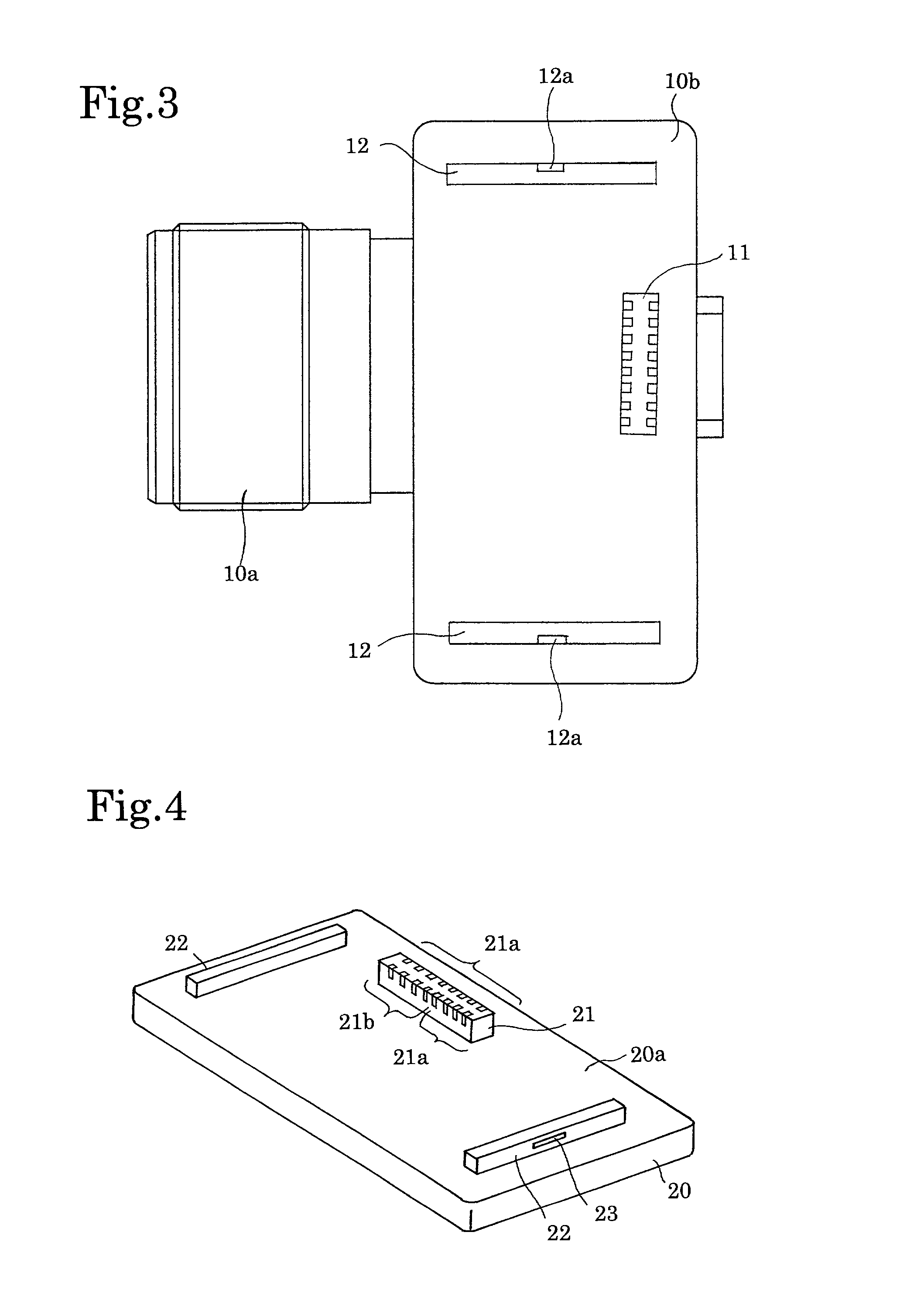

Auxiliary power supply unit and portable electronic system

InactiveUS6977688B2Avoid Voltage FluctuationsImprove battery efficiencyTelevision system detailsBatteries circuit arrangementsElectronic systemsEngineering

An auxiliary power supply unit which is mountable to a portable electronic device having a battery, includes at least one capacitor, and an I / F connector which is connectable to an I / F connector of the portable electronic device, the I / F connector of the portable electronic device including power terminals connected to the battery. The I / F connector of the auxiliary power supply unit includes power terminals connected to the at least one capacitor, wherein the at least one capacitor is connected in parallel to the battery when the auxiliary power supply unit is mounted to the portable electronic device via the power terminals of the I / F connectors.

Owner:RICOH IMAGING COMPANY

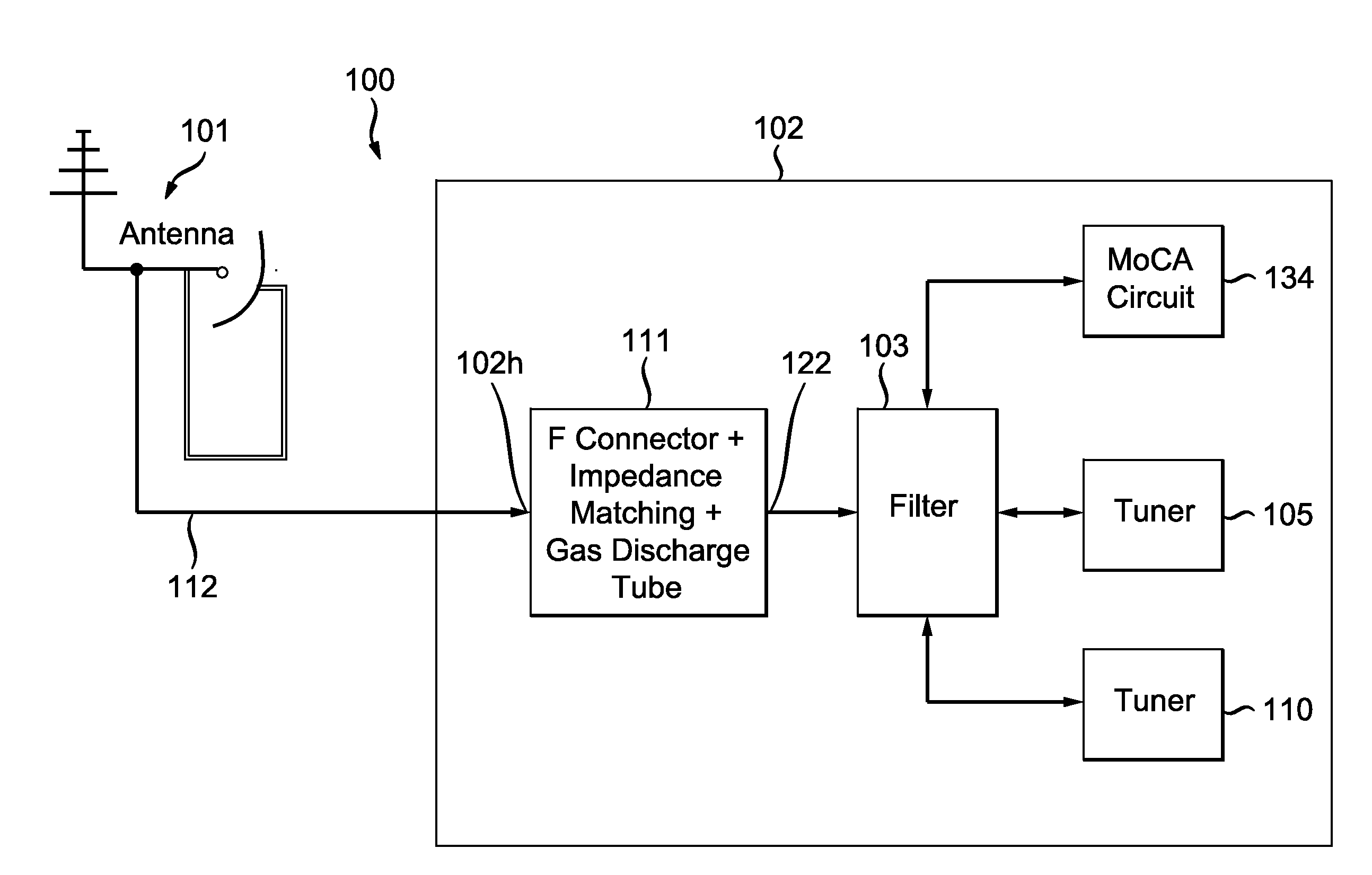

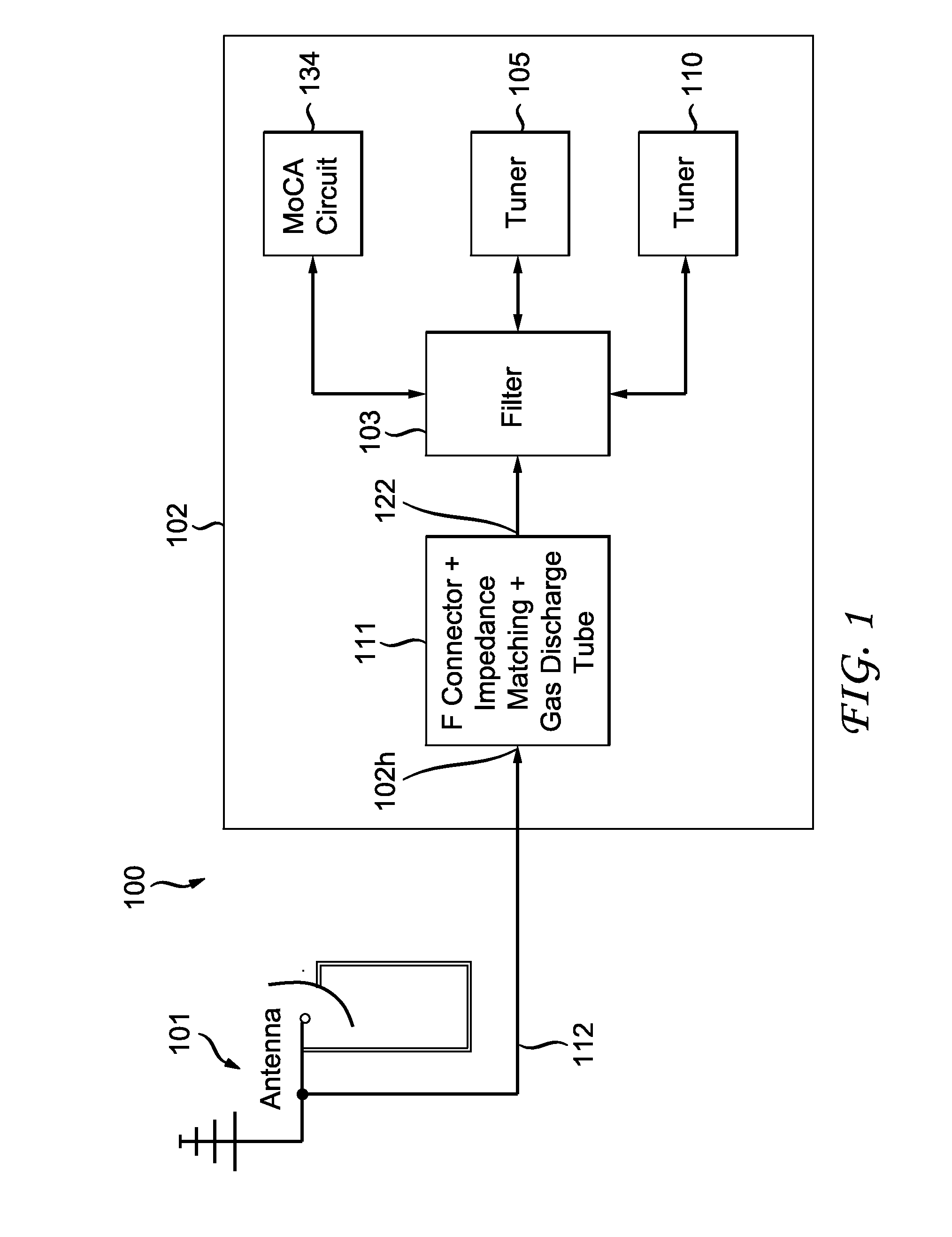

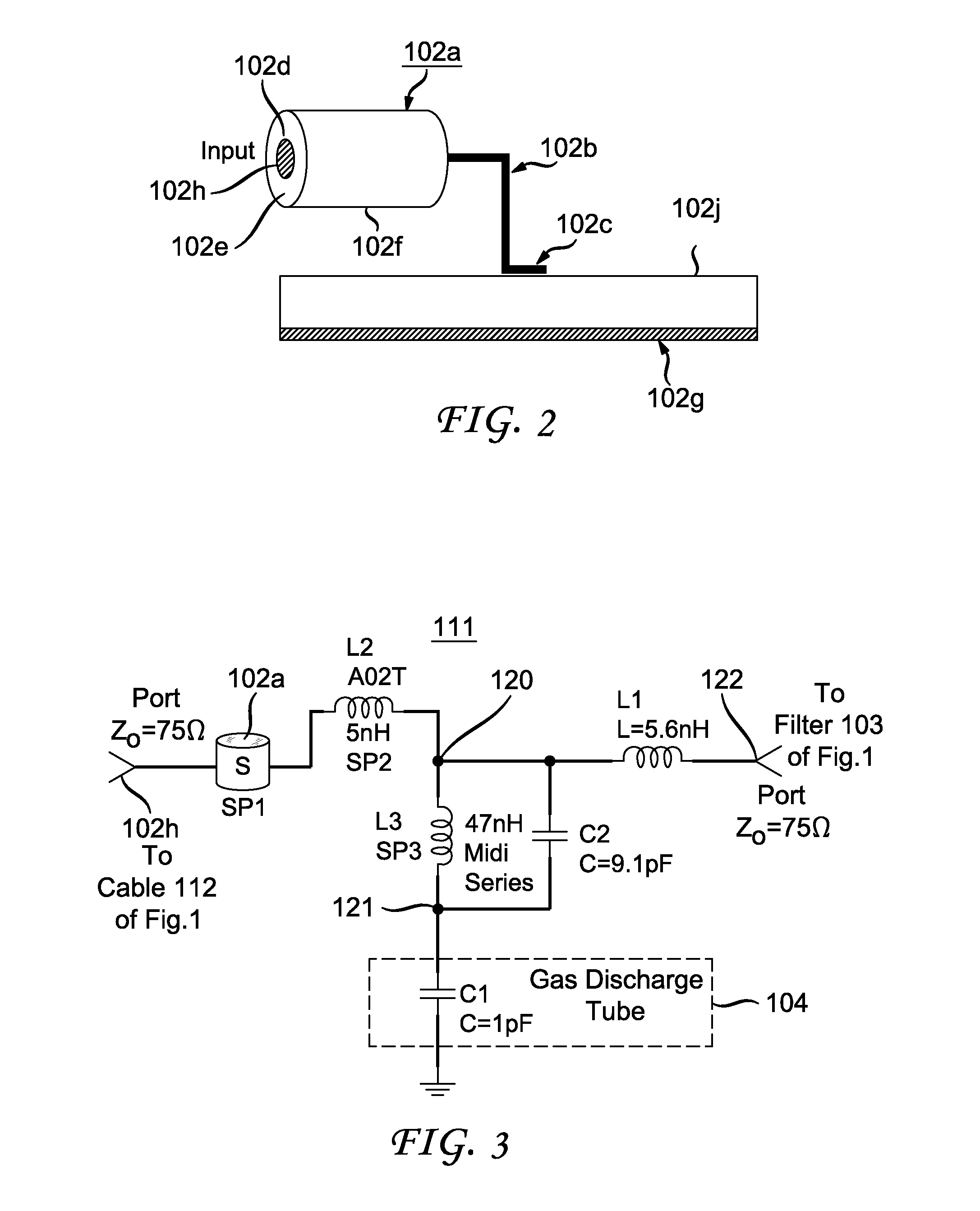

Surge protector for a transmission line connector

InactiveUS20150146336A1Improving return lossSuppress surge voltageHigh voltage circuit adaptationsEmergency protective arrangement detailsEngineeringImpedance matching

An F connector coupled to a transmission line applies a radio frequency (RF) signal to an RF input of a filter of a set-top box via an impedance matching network that includes a first inductor and a second inductor that are coupled in series. A capacitor and a third inductor are coupled in parallel between a discharge tube and a junction terminal that is interposed between the series coupled inductors for protecting electronic components such as the filter from a voltage surge developed in the transmission line.

Owner:THOMSON LICENSING SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com