Ball valve with modified characteristics

a technology of characteristics and valves, applied in the field of control valves, can solve the problems of affecting the market acceptance of hvac, and further distorting the valve characteristics, so as to achieve the effect of eliminating the time-consuming operation of taking the valve apart and reassembling, and easy change of flow characteristics and flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

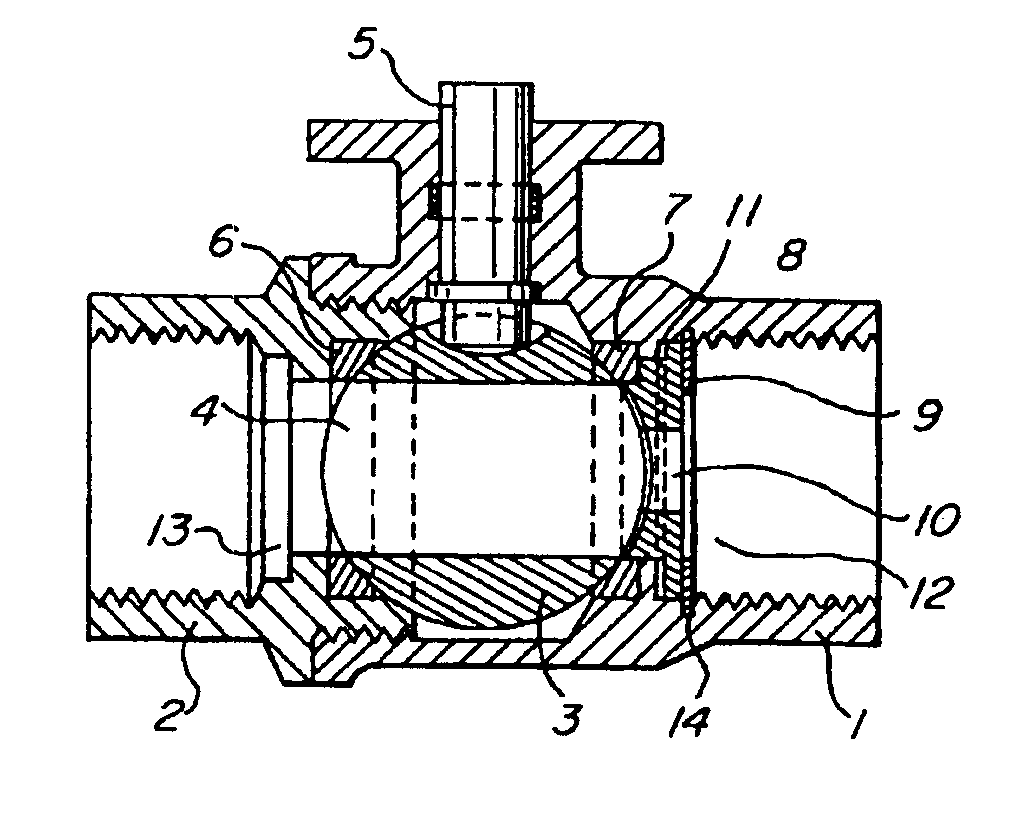

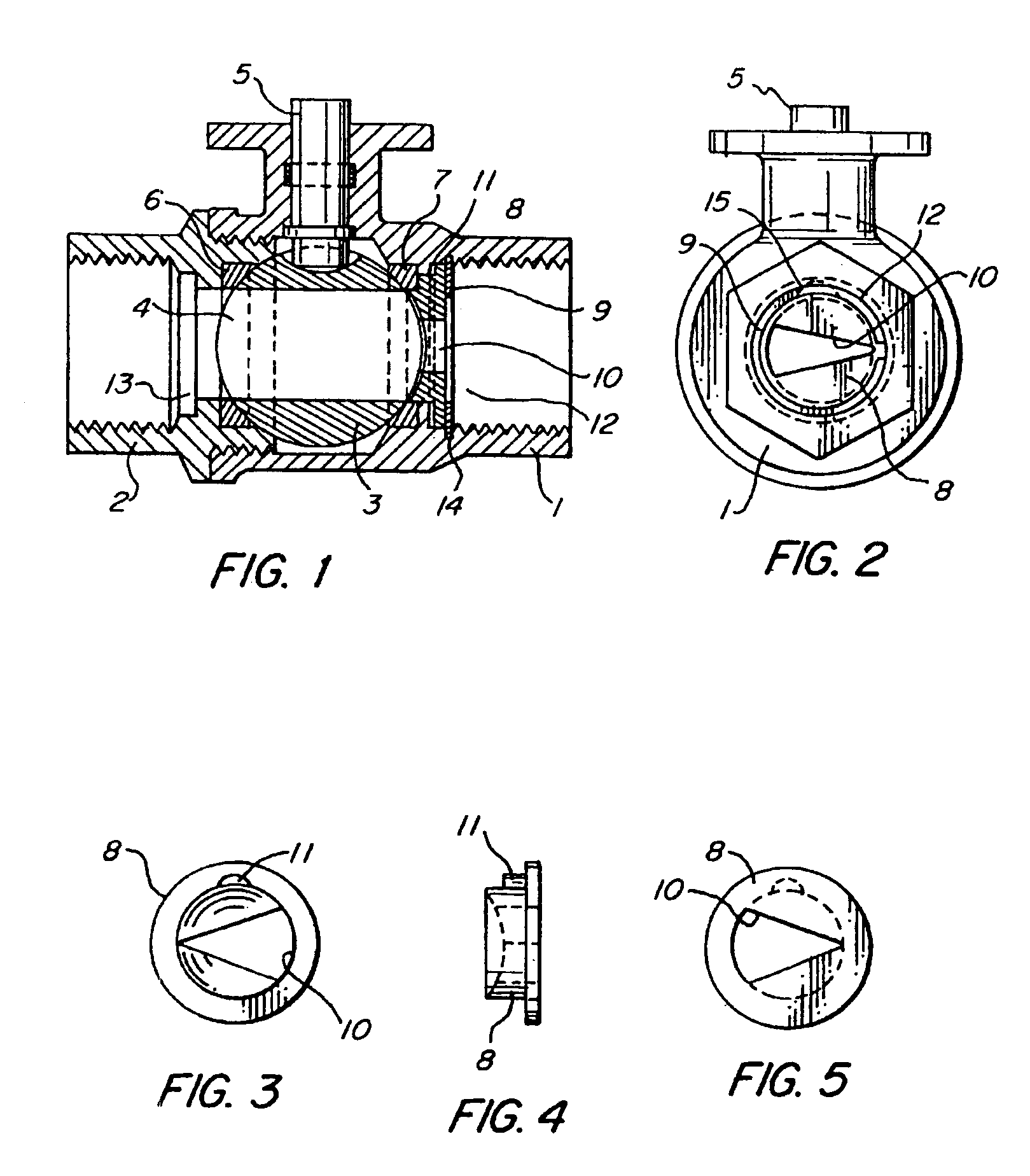

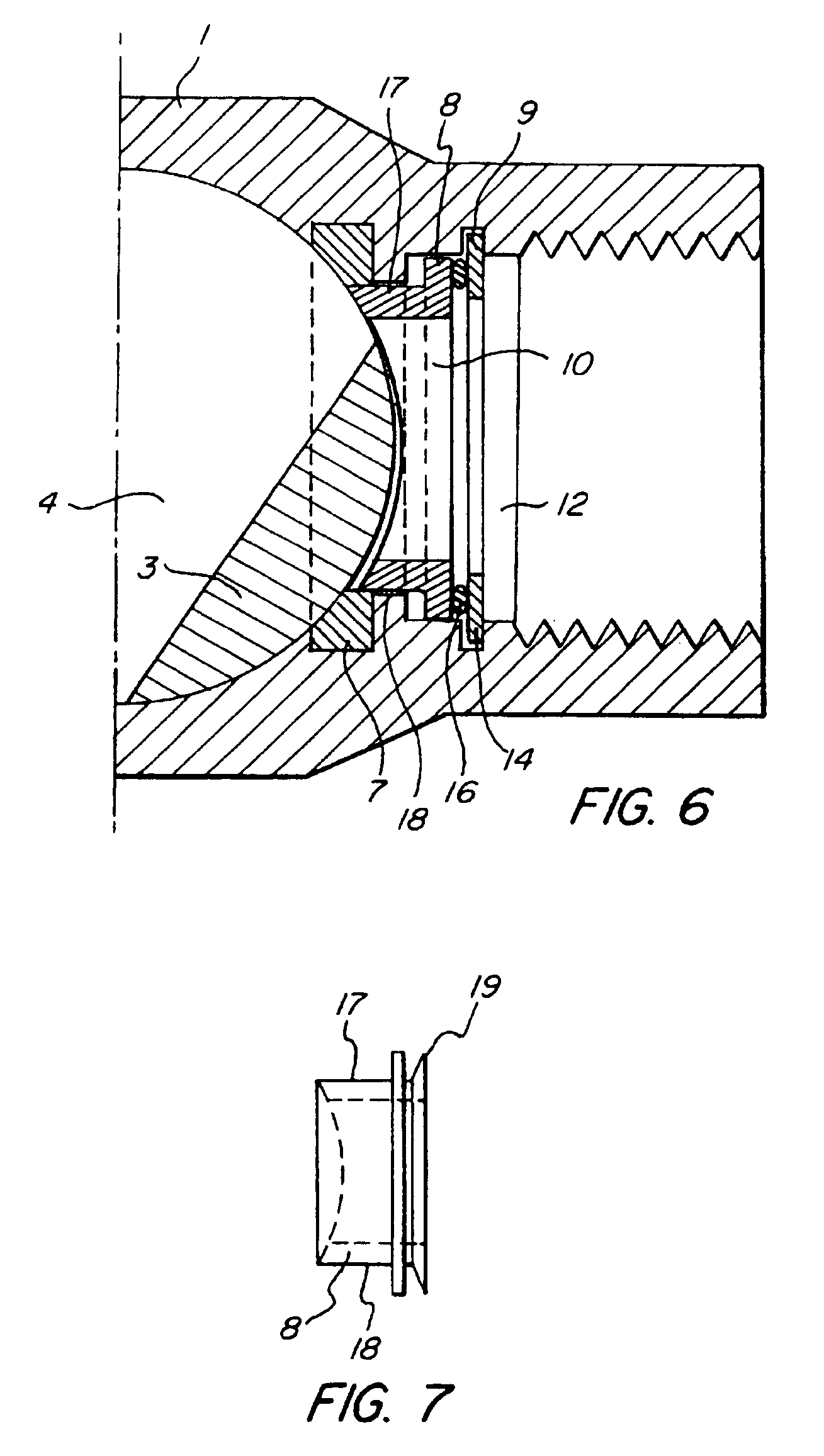

[0025]Referring to FIGS. 1-2 in detail, the present invention relates to a valve 100 having modified, and modifiable flow capacity and characteristics. As used herein, the term “front” refers to the “upstream” end of the valve 100, as that term would be understood by the skilled artisan, and the term “rear” refers to the “downstream” end of the valve 100.

[0026]Although this description is written in terms of valves used in conjunction with fluid flow, especially liquid (i.e., water) flow in HVAC systems, it will be recognized that it is equally applicable to valves in a variety of applications, where modification of flow capacity and / or flow characteristics without the need for disassembly and reassembly of the valve is desired. Additionally, although this specification is written in terms of ball valves, it should be recognized that the invention, and principles relating thereto, is equally applicable to plug valves.

[0027]Moreover, it will be recognized that some or all of the atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com