Thermosensitive recording material

a recording material and thermosensitive technology, applied in thermography, duplicating/marking methods, printing, etc., can solve the problems of reducing the plasticizer resistance reducing the anti-sticking property of the thermosensitive recording material, and often performing the printing of low-torque printers. , to achieve the effect of stably providing and improving the anti-sticking property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

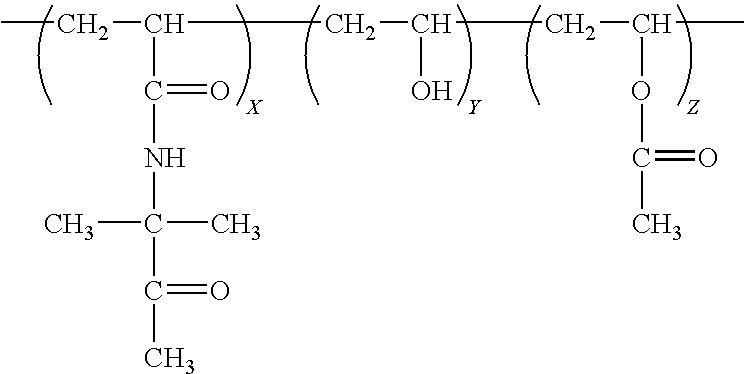

Method used

Image

Examples

example 1

1. Preparation of Undercoat Layer Coating Liquid

[0167]

[Liquid A (undercoat layer coating liquid)]Hollow plastic spherical particles (copolymer resin36 partsmainly formed of styrene-acrylic acid copolymer,product name: ROPAQUE HP-91, manufacturer:Rohm and Haas Company, solid content: 27.5%,number average particle diameter: 1 μm, void ratio:50%)Styrene-butadiene copolymer latex (product name:10 partsSMARTEX PA-9159, manufacturer: Nippon A & LInc., solid content: 47.5%)Water54 parts

2. Preparation of Thermosensitive Coloring Layer Coating Liquid

[0168]

[Liquid B (leuco dye dispersion liquid)]2-anilino-3-methyl-6-(di-n-butylamino)fluoran (leuco20 partsdye)10% itaconic acid-modified polyvinyl alcohol20 parts(modification ratio: 1 mol %)(product name: KL-318,manufacturer: Kuraray Co., Ltd., molecular weight:about 80,000) solutionWater60 parts

[0169]

[Liquid C (color developer dispersion liquid)]4-hydroxy-4′-isopropoxydiphenyl sulfone (color20 partsdeveloper)(product name: D-8, manufacturer: Ni...

example 2

[0184]A thermosensitive recording material of Example 2 was prepared in the same manner as in Example 1, provided that 20 parts of Oxidized Polyethylene Wax Emulsion 1 used in the protective layer coating liquid [Liquid F] was replaced with 20 parts of Oxidized Polyethylene Wax Emulsion 2 in Table 1.

example 3

[0185]A thermosensitive recording material of Example 3 was prepared in the same manner as in Example 1, provided that 20 parts of Oxidized Polyethylene Wax Emulsion 1 used in the protective layer coating liquid [Liquid F] was replaced with 20 parts of Oxidized Polyethylene Wax Emulsion 3 shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| number average particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com