Upgrading crude oil using electrochemically-generated hydrogen

a technology of electrochemical hydrogen and crude oil, which is applied in the direction of hydrocarbon oil cracking process, hydrocracking, thermal non-catalytic cracking, etc., can solve the problems of crude oil or other heavy mineral oil use methods and apparatuses that are not suitable for crude oil or other heavy mineral oil, and achieve the elimination of hydrogen-generating and treating facilities, and the effect of reducing capital costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

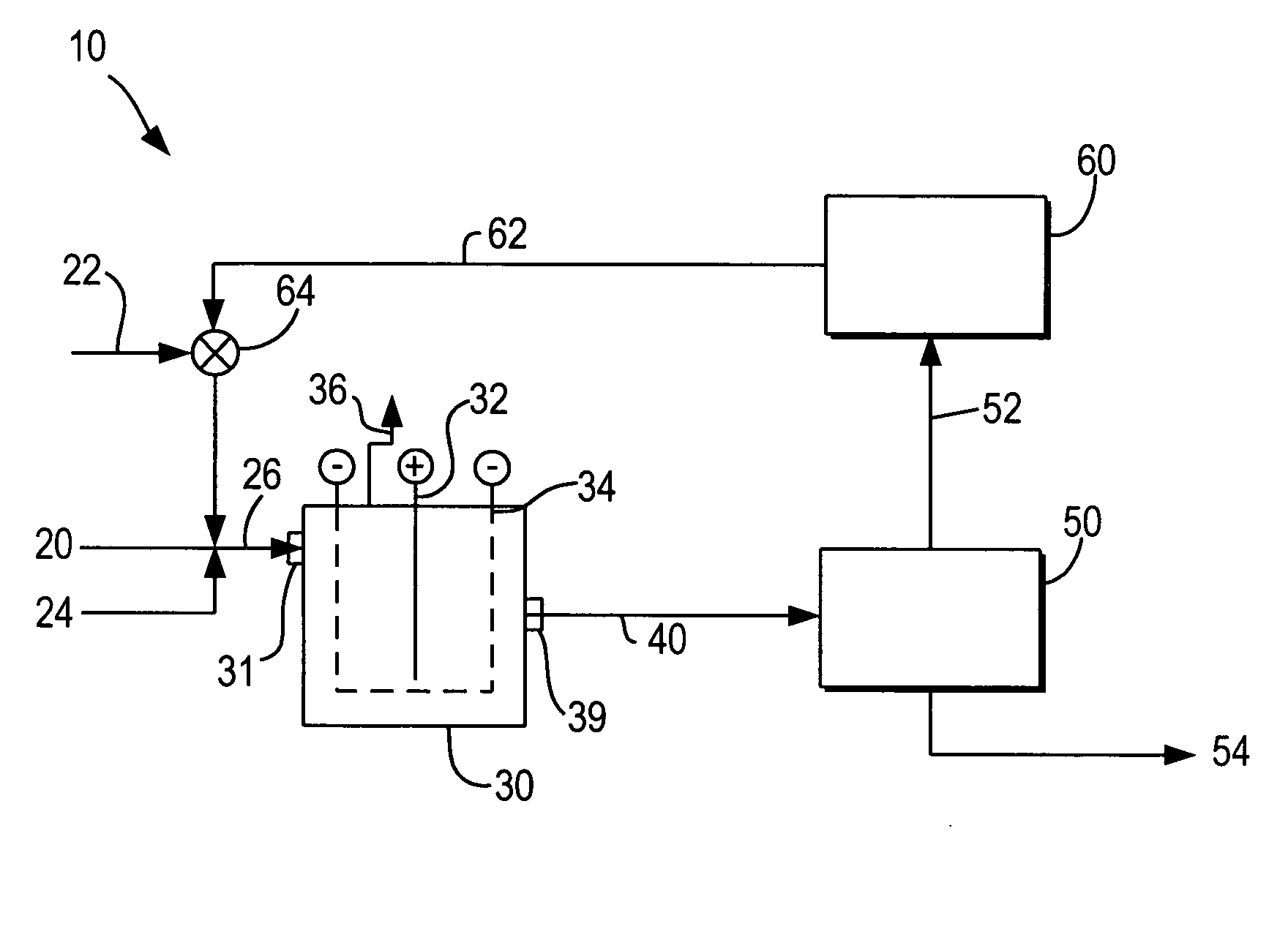

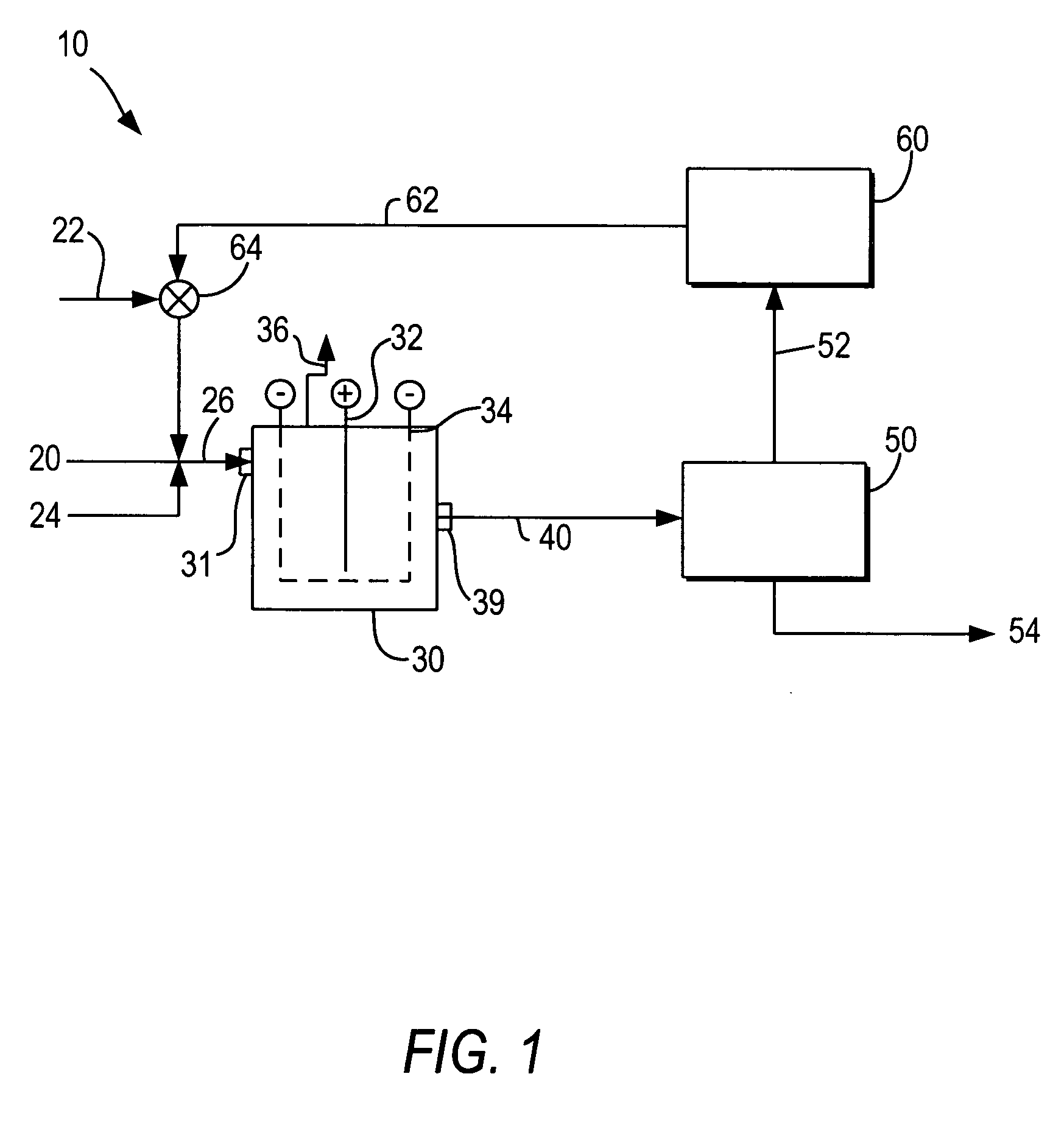

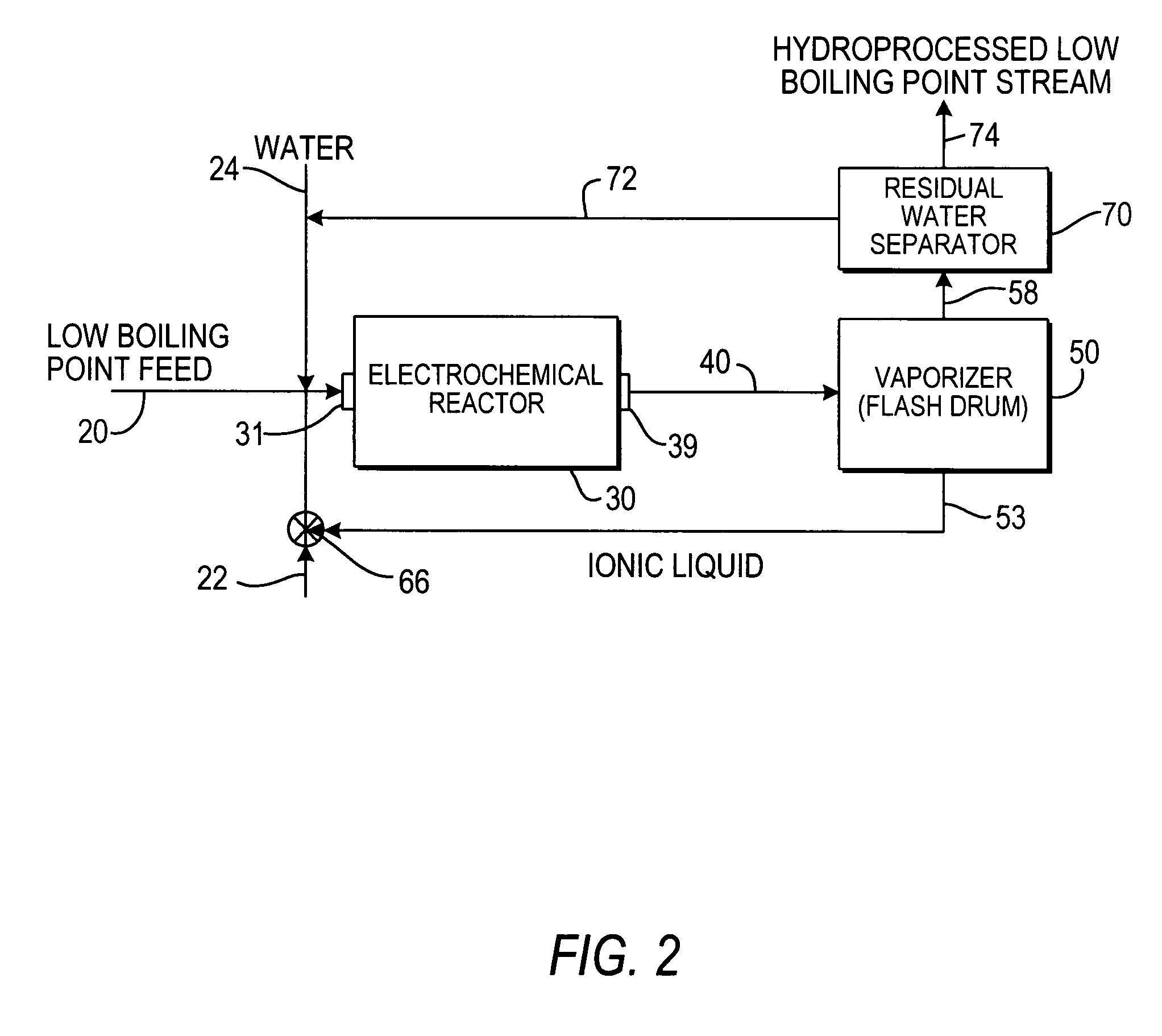

[0019]Referring now to the attached drawings, and specifically to FIG. 1, a suitable apparatus is schematically illustrated for practicing one embodiment of the method of the invention. In this embodiment of the complete system 10, a heavy oil petroleum feedstream 20, an ionic amphiphilic liquid 22 and liquid water feed 24 are preferably mixed to form feedstream 26 before entering inlet 31 of the electrochemical reaction vessel 30. Mixing of the feedstreams can be accomplished in any of various types of apparatus that are well known to those of ordinary skill in the art. The most efficient and economical mixing apparatus will be determined based upon the viscocity of the hydrocarbon feedstream as well as the volumetric flow rate to be delivered to the reactor 30.

[0020]Reactor 30 includes anode 32 and one or more cathodes 34 to which are applied a source of DC current (not shown). The cathodes are constructed of a porous material, as further described below. The design of the reactor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| operating temperature | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com